Enhanced Pyroelectric Performance of Lead-Free Zn-Doped Na1/2Bi1/2TiO3-BaTiO3 Ceramics

Abstract

1. Introduction

2. Materials and Methods

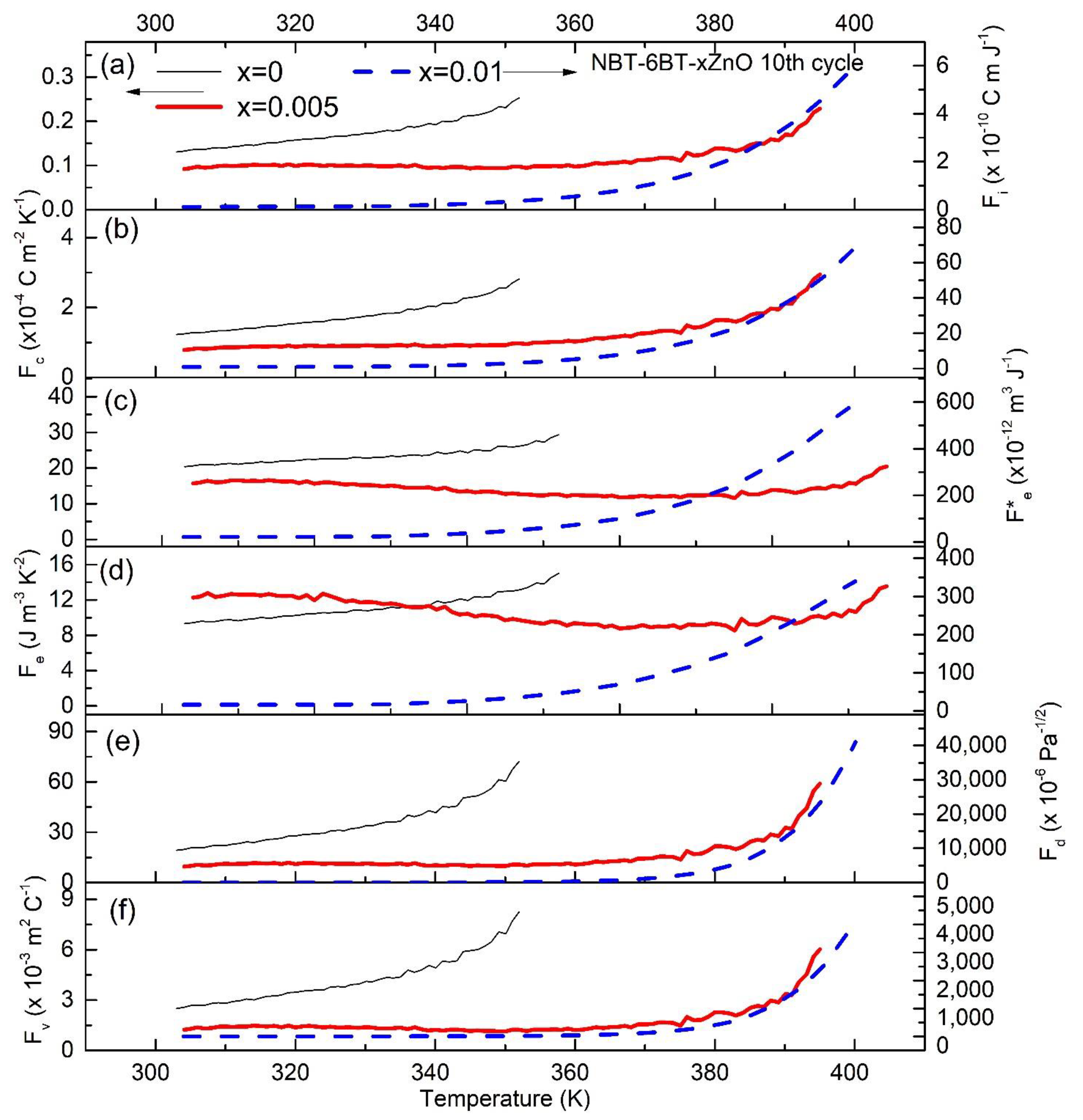

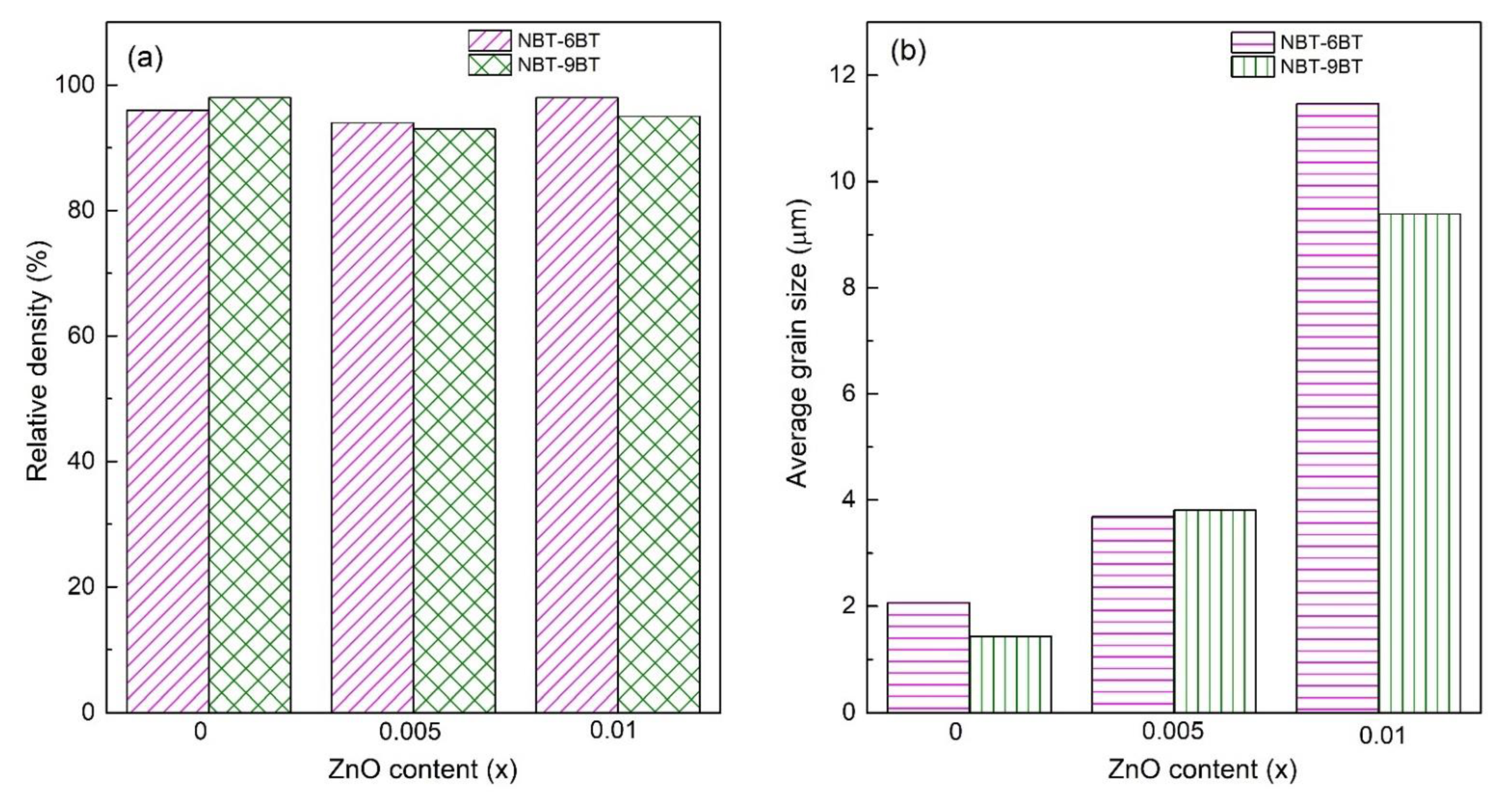

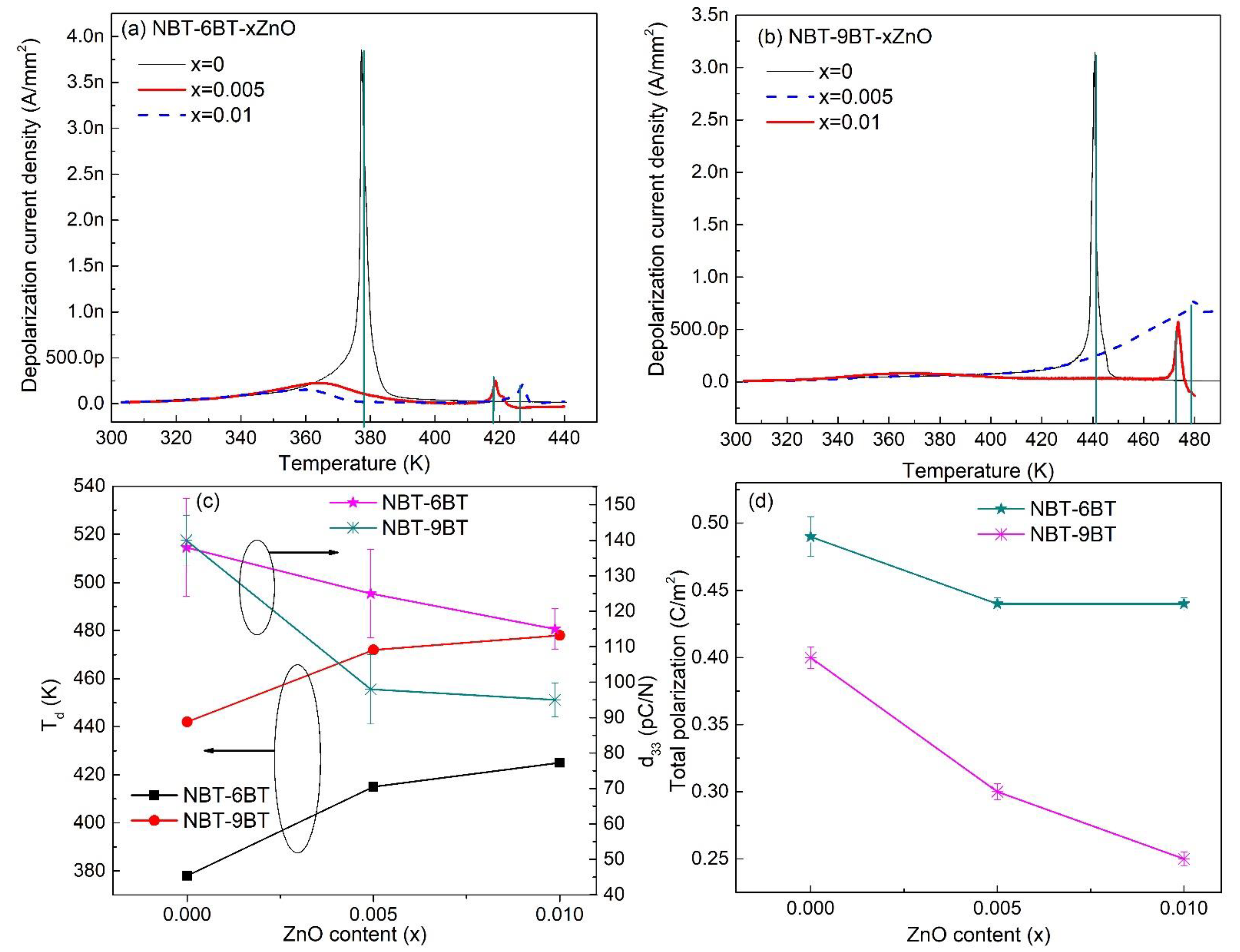

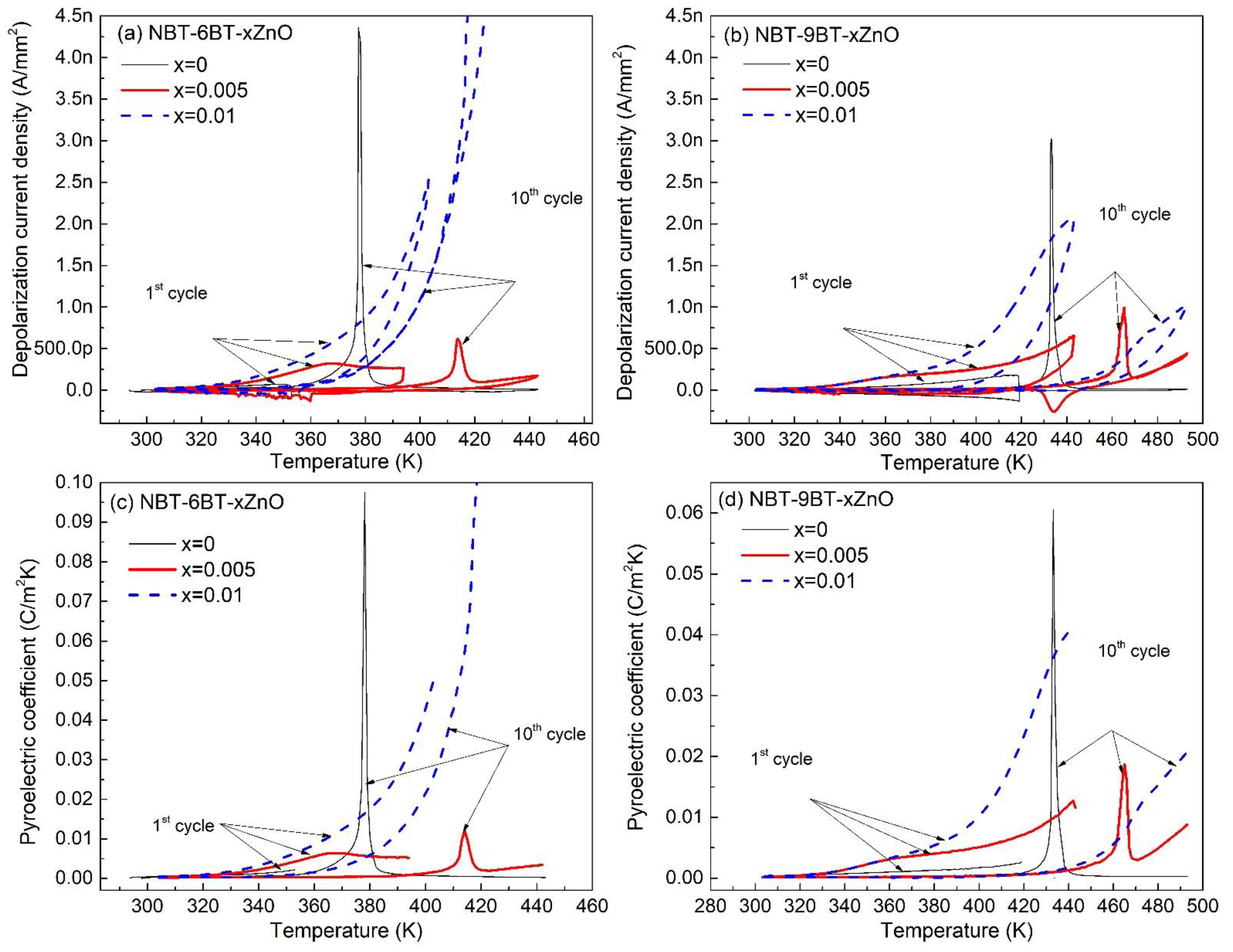

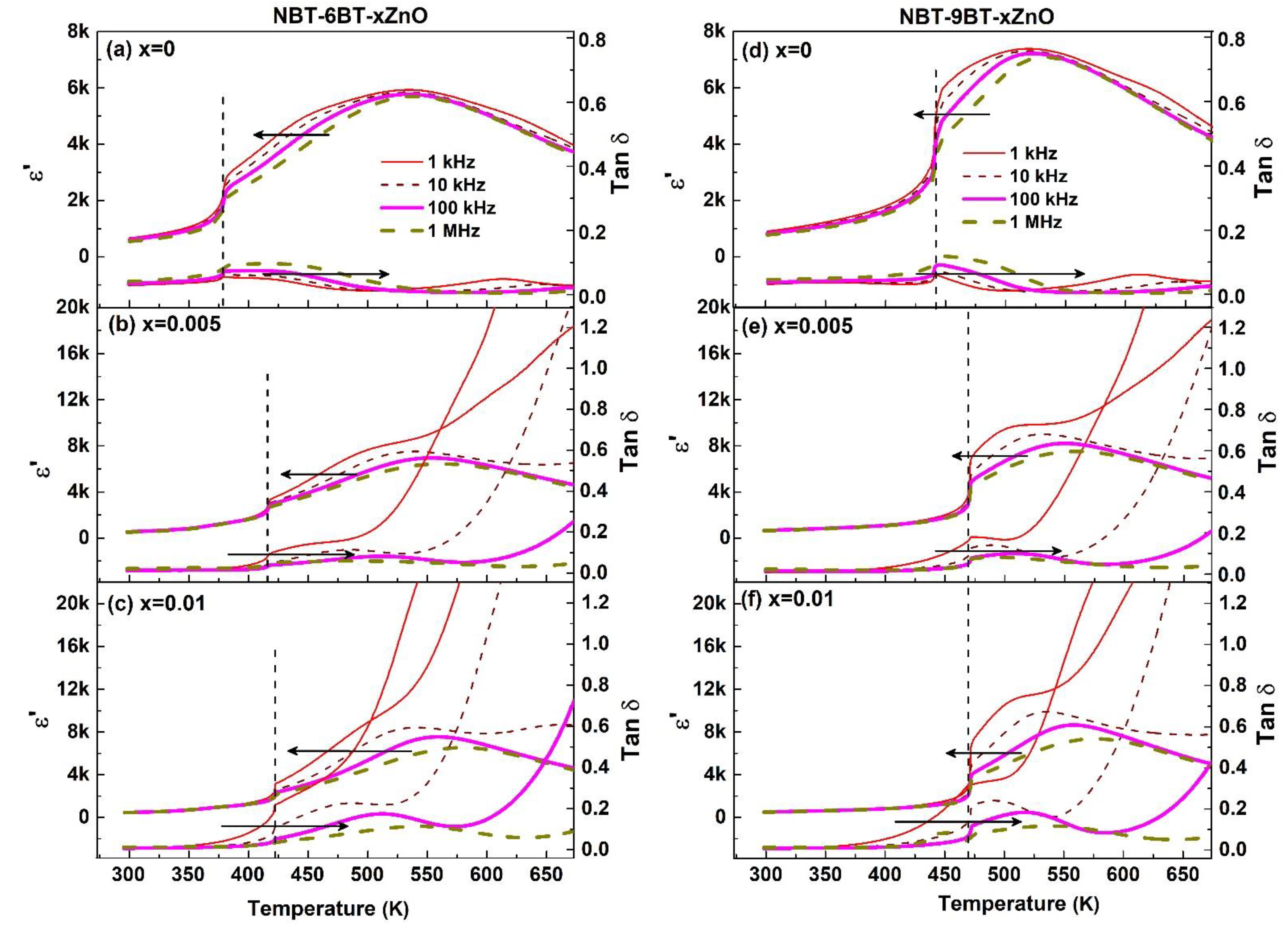

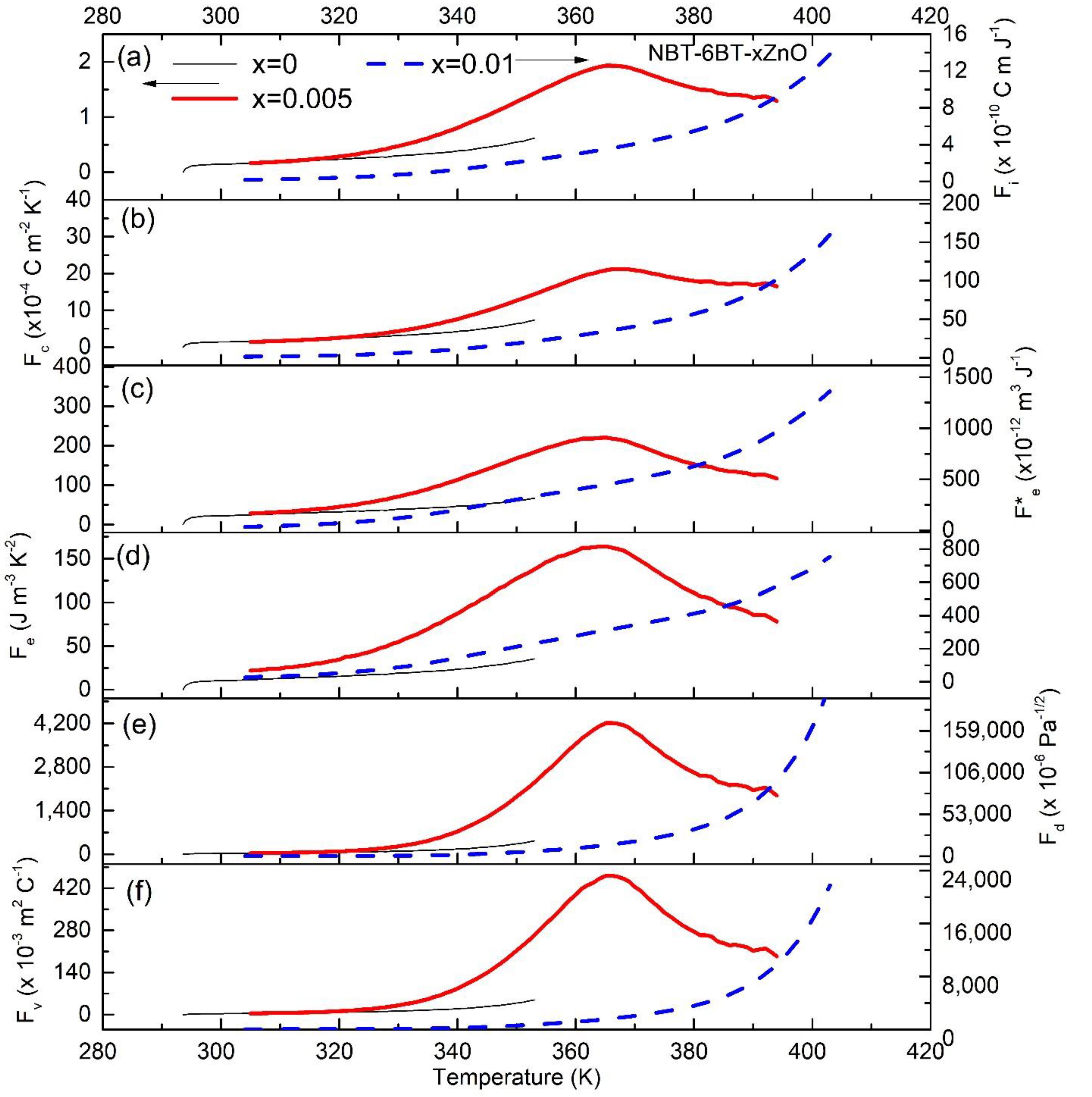

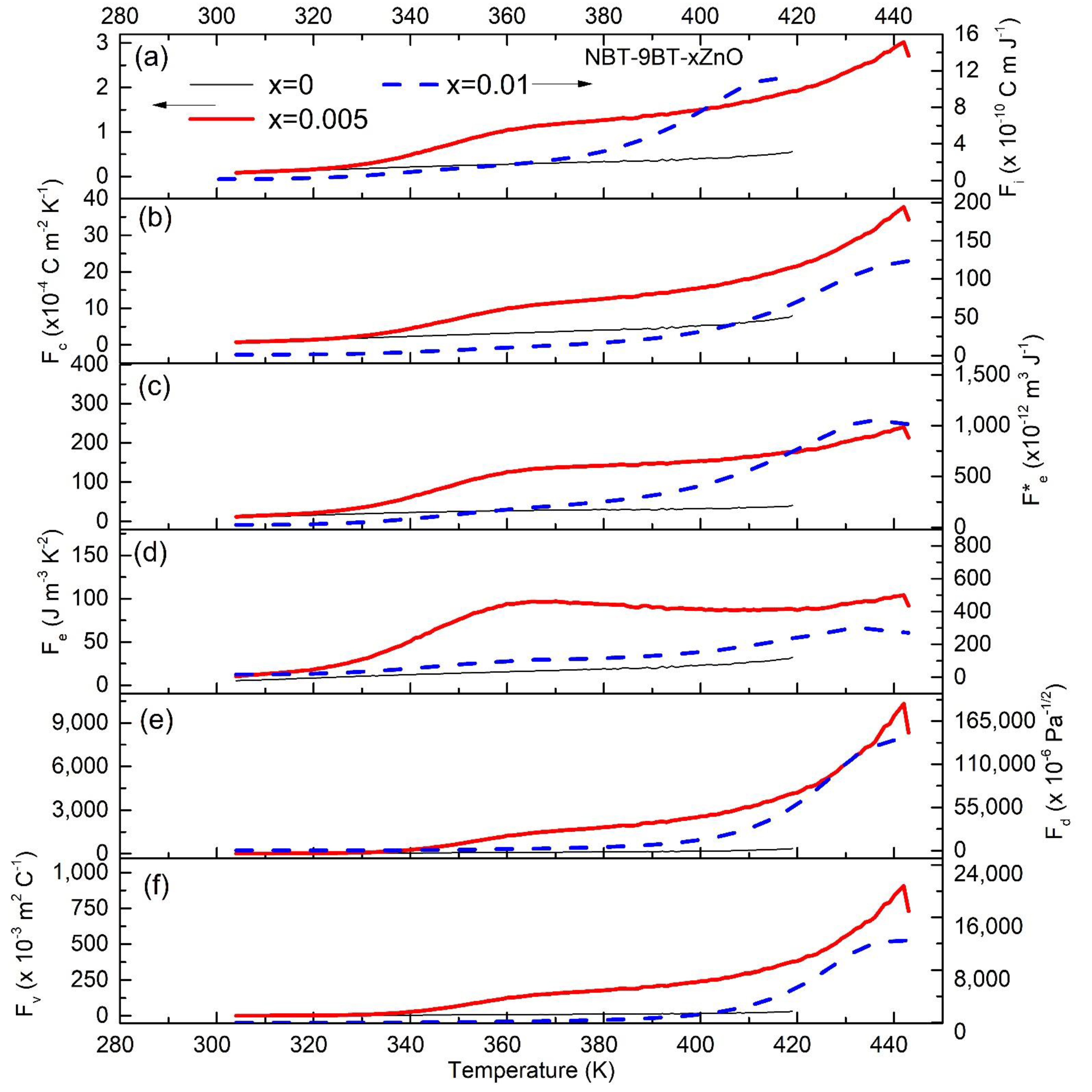

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Zhang, D.; Wu, H.; Bowen, C.R.; Yang, Y. Recent Advances in Pyroelectric Materials and Applications. Small 2021, 2103960. [Google Scholar] [CrossRef] [PubMed]

- He, H.; Lu, X.; Hanc, E.; Chen, C.; Zhang, H.; Lu, L. Advances in lead-free pyroelectric materials: A comprehensive review. J. Mater. Chem. C 2020, 8, 1494–1516. [Google Scholar] [CrossRef]

- Moisello, E.; Malcovati, P.; Bonizzoni, E. Thermal Sensors for Contactless Temperature Measurements, Occupancy Detection, and Automatic Operation of Appliances during the COVID-19 Pandemic: A Review. Micromachines 2021, 12, 148. [Google Scholar] [CrossRef]

- Bowen, C.R.; Kim, H.A.; Weaver, P.M.; Dunn, S. Piezoelectric and ferroelectric materials and structures for energy harvesting applications. Energy Environ. Sci. 2014, 7, 25–44. [Google Scholar] [CrossRef]

- Chamankar, N.; Khajavi, R.; Yousefi, A.A.; Rashidi, A.S.; Golestanifard, F. Comparing the piezo, pyro and dielectric properties of PZT particles synthesized by sol–gel and electrospinning methods. J. Mater. Sci. Mater. Electron. 2019, 30, 8721–8735. [Google Scholar] [CrossRef]

- Zhang, Y.; Xie, M.; Roscow, J.; Bao, Y.; Zhou, K.; Zhang, D.; Bowen, C.R. Enhanced pyroelectric and piezoelectric properties of PZT with aligned porosity for energy harvesting applications. J. Mater. Chem. A 2017, 5, 6569–6580. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Sharma, S.; Thakur, O.; Prakash, C.; Goel, T. Dielectric, piezoelectric and pyroelectric properties of PMN–PT (68:32) system. Ceram. Int. 2004, 30, 585–589. [Google Scholar] [CrossRef]

- Lau, S.T.; Cheng, C.H.; Choy, S.H.; Lin, D.; Kwok, K.; Chan, H.L.W. Lead-free ceramics for pyroelectric applications. J. Appl. Phys. 2008, 103, 104105. [Google Scholar] [CrossRef]

- Liu, Z.; Lu, T.; Dong, X.; Wang, G.; Liu, Y. Ferroelectric ceramics for pyroelectric detection applications: A review. IEEE Trans Ultrason. Ferroelectr. Freq. Control 2020, 68, 242–252. [Google Scholar] [CrossRef]

- Guo, F.; Yang, B.; Zhang, S.; Wu, F.; Liu, D.; Hu, P.; Sun, Y.; Wang, D.; Cao, W. Enhanced pyroelectric property in (1−x)(Bi0.5Na0.5)TiO3-xBa(Zr0.055Ti0.945)O3: Role of morphotropic phase boundary and ferroelectric-antiferroelectric phase transition. Appl. Phys. Lett. 2013, 103, 182906. [Google Scholar] [CrossRef]

- Li, J.F.; Wang, K.; Zhu, F.Y.; Cheng, L.Q.; Yao, F.Z. (K, Na) NbO3-Based Lead-Free Piezoceramics: Fundamental Aspects, Processing Technologies, and Remaining Challenges. J. Am. Ceram. Soc. 2013, 96, 3677–3696. [Google Scholar] [CrossRef]

- Xu, X.; Jiang, J.; Ahmad, H.; Yuan, G.; Yin, J.; Liu, Z. Improved ferroelectricity of (1−x)Na0.5Bi0.5TiO3–xBaTiO3 ceramics rapidly sintered at low temperature. Ceram. Int. 2014, 40, 11819–11824. [Google Scholar] [CrossRef]

- Swain, S.; Kar, S.K.; Kumar, P. Dielectric, optical, piezoelectric and ferroelectric studies of NBT–BT ceramics near MPB. Ceram. Int. 2015, 41, 10710–10717. [Google Scholar] [CrossRef]

- Martin, A.; Khansur, N.H.; Webber, K.G. Electric field-induced changes in the ferroelastic behavior of (Na1/2Bi1/2)TiO3-BaTiO3. J. Eur. Ceram. Soc. 2018, 38, 4623–4630. [Google Scholar] [CrossRef]

- Guennou, M.; Savinov, M.; Drahokoupil, J.; Luo, H.; Hlinka, J. Piezoelectric properties of tetragonal single-domain Mn-doped NBT-6 %BT single crystals. Appl. Phys. A 2014, 116, 225–228. [Google Scholar] [CrossRef]

- Lalitha, K.V.; Koruza, J.; Rödel, J. Propensity for spontaneous relaxor-ferroelectric transition in quenched (Na1/2Bi1/2)TiO3-BaTiO3 compositions. Appl. Phys. Lett. 2018, 113, 252902. [Google Scholar]

- Samantaray, K.S.; Amin, R.; Rini, E.G.; Bhaumik, I.; Mekki, A.; Harrabi, K.; Sen, S. Defect Dipole Induced Improved Electrocaloric Effect in Modified NBT-6BT Lead-Free Ceramics. arXiv 2021, arXiv:2110.04262. [Google Scholar]

- Turki, O.; Slimani, A.; Seveyrat, L.; Sassi, Z.; Khemakhem, H.; Lebrun, L. Enhancement of dielectric, piezoelectric, ferroelectric, and electrocaloric properties in slightly doped (Na0.5Bi0.5)0.94Ba0.06TiO3 ceramic by samarium. J. Appl. Phys. 2019, 125, 174103. [Google Scholar] [CrossRef]

- Uddin, S.; Zheng, G.P.; Iqbal, Y.; Ubic, R.; Yang, J. Unification of the negative electrocaloric effect in Bi1/2Na1/2TiO3-BaTiO3 solid solutions by Ba1/2Sr1/2TiO3 doping. J. Appl. Phys. 2013, 114, 213519. [Google Scholar] [CrossRef]

- Cao, W.; Li, W.; Xu, D.; Hou, Y.; Wang, W.; Fei, W. Enhanced electrocaloric effect in lead-free NBT-based ceramics. Ceram. Int. 2014, 40, 9273–9278. [Google Scholar] [CrossRef]

- Takenaka, T.; Maruyama, K.-I.; Sakata, K. (Bi1/2Na1/2)TiO3-BaTiO3 system for lead-free piezoelectric ceramics. Jpn. J. Appl. Phys. 1991, 30, 2236. [Google Scholar] [CrossRef]

- Martinez, F.L.; Hinojosa, J.; Domenech, G.; Fernandez-Luque, F.J.; Zapata, J.; Ruiz, R.; Pardo, L. Dielectric constant tunability at microwave frequencies and pyroelectric behavior of lead-free submicrometer-structured (Bi0.5Na0.5)1-xBaTiO3 ferroelectric ceramics. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2013, 60, 1595–1602. [Google Scholar] [CrossRef] [PubMed]

- Abe, J.; Kobune, M.; Nishimura, T.; Yazaw, T.; Nakai, Y. Effects of Manganese Addition on Pyroelectric Properties of (Bi0.5Na0.5TiO3)0.94(BaTiO3)0.06 Ceramics. Integr. Ferroelectr. 2006, 80, 87–95. [Google Scholar] [CrossRef]

- Balakt, A.; Shaw, C.; Zhang, Q. Large pyroelectric properties at reduced depolarization temperature in A-site nonstoichiometry composition of lead-free 0.94NaxBiyTiO3–0.06BazTiO3 ceramics. J. Mater. Sci. 2017, 52, 7382–7393. [Google Scholar] [CrossRef]

- Balakt, A.; Shaw, C.; Zhang, Q. The effects of Ba2+ content on depolarization temperature and pyroelectric properties of lead-free 0.94Na0.5Bi0.5TiO3–0.06Ba1+xTiO3 ceramics. J. Mater. Sci. Mater. Electron. 2016, 27, 12947–12954. [Google Scholar] [CrossRef][Green Version]

- Balakt, A.; Shaw, C.; Zhang, Q. Enhancement of pyroelectric properties of lead-free 0.94Na0.5Bi0.5TiO3-0.06BaTiO3 ceramics by La doping. J. Eur. Ceram. Soc. 2017, 37, 1459–1466. [Google Scholar] [CrossRef]

- Balakt, A.; Shaw, C.; Zhang, Q. The decrease of depolarization temperature and the improvement of pyroelectric properties by doping Ta in lead-free 0.94Na0.5Bi0.5TiO3-0.06BaTiO3 ceramics. Ceram. Int. 2017, 43, 3726–3733. [Google Scholar] [CrossRef]

- Balakt, A.; Shaw, C.; Zhang, Q. Giant pyroelectric properties in La and Ta co-doped lead-free 0.94Na0.5Bi0.5TiO3-0.06BaTiO3 ceramics. J. Alloys Compd. 2017, 709, 82–91. [Google Scholar] [CrossRef]

- Kodumudi Venkataraman, L.; Zhu, T.; Pinto Salazar, M.; Hofmann, K.; Iqbal Waidha, A.; Jaud, J.C.; Rödel, J. Thermal depolarization and electromechanical hardening in Zn2+-doped Na1/2Bi1/2TiO3-BaTiO3. J. Am. Ceram. Soc. 2021, 104, 2201–2212. [Google Scholar] [CrossRef]

- Saurabh, N.; Patel, S. Nonstoichiometric effect on electrocaloric, pyroelectric and energy storage properties of 0.94NaxBiyTiO3–0.06BaTiO3 bulk ceramics. J. Mater. Sci. Mater. Electron. 2021, 32, 26871–26893. [Google Scholar] [CrossRef]

- Li, L.; Wang, R.X.; Shen, M.; Zhang, H.; Gu, Z.B.; Zhang, S.T.; Wu, D. Phase/domain structure and enhanced thermal stable ferro-/pyroelectric properties of (1−x)0.94Na0.48Bi0.44TiO3-0.06BaTiO3: xZnO ceramics. J. Eur. Ceram. Soc. 2020, 40, 699–705. [Google Scholar]

- Bowen, C.; Taylor, J.; Le Boulbar, E.; Zabek, D.; Topolov, V. A modified figure of merit for pyroelectric energy harvesting. Mater. Lett. 2015, 138, 243–246. [Google Scholar] [CrossRef]

- Mangalam, R.V.K.; Agar, J.C.; Damodaran, A.R.; Karthik, J.; Martin, L.W.; Mangalam, V.K. Improved Pyroelectric Figures of Merit in Compositionally Graded PbZr1−xTixO3 Thin Films. ACS Appl. Mater. Interfaces 2013, 5, 13235–13241. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Roscow, J.; Xie, M.; Bowen, C. High piezoelectric sensitivity and hydrostatic figures of merit in unidirectional porous ferroelectric ceramics fabricated by freeze casting. J. Eur. Ceram. Soc. 2018, 38, 4203–4211. [Google Scholar] [CrossRef]

- Bowen, C.R.; Taylor, J.; LeBoulbar, E.; Zabek, D.; Chauhan, A.; Vaish, R. Pyroelectric materials and devices for energy harvesting applications. Energy Environ. Sci. 2014, 7, 3836–3856. [Google Scholar] [CrossRef]

- Sharma, M.; Singh, V.P.; Singh, S.; Azad, P.; Ilahi, B.; Madhar, N.A. Porous Ba0.85Ca0.15Zr0.1Ti0.9O3 Ceramics for Pyroelectric Applications. J. Electron. Mater. 2018, 47, 4882–4891. [Google Scholar] [CrossRef]

- Srikanth, K.; Singh, V.; Vaish, R. Enhanced pyroelectric figure of merits of porous BaSn0.05Ti0.95O3 ceramics. J. Eur. Ceram. Soc. 2017, 37, 3943–3950. [Google Scholar] [CrossRef]

- Li, L.; Zhu, M.; Zhou, K.; Wei, Q.; Zheng, M.; Hou, Y. Delayed thermal depolarization of Bi0.5Na0.5TiO3-BaTiO3 by doping acceptor Zn2+ with large ionic polarizability. J. Appl. Phys. 2017, 122, 204104. [Google Scholar] [CrossRef]

- Khatua, D.K.; Mishra, A.; Kumar, N.; Das Adhikary, G.; Shankar, U.; Majumdar, B.; Ranjan, R. A coupled microstructural-structural mechanism governing thermal depolarization delay in Na0.5Bi0.5TiO3-based piezoelectrics. Acta Mater. 2019, 179, 49–60. [Google Scholar] [CrossRef]

- Pintilie, L.; Iuga, A.; Stancu, V.; Botea, M. Estimation of the pyroelectric coefficient for ceramic Pb(Zr, Ti)O3 samples: Comparison of the results obtained by two easy to implement methods. Infrared Phys. Technol. 2020, 106, 103269. [Google Scholar] [CrossRef]

- Patel, S.; Chauhan, A.; Vaish, R. Large pyroelectric figure of merits for Sr-modified Ba0.85Ca0.15Zr0.1Ti0.9O3 ceramics. Solid State Sci. 2016, 52, 10–18. [Google Scholar] [CrossRef]

- Lewczuk-Jodłowiec, U.; Suchanicz, J.; Sitko, D.; Konieczny, K. Thermal properties of NBT-BT systems. Phase Transit. 2017, 90, 818–823. [Google Scholar] [CrossRef]

- Mahdi, R.; Al-Bahnam, N.; Abbo, A.; Hmood, J.; Majid, W.A. Optimization of sintering temperature for the enhancement of pyroelectric properties of lead-free 0.88(Na0.5Bi0.5)TiO3–0.084(K0.5Bi0.5)TiO3–0.036BaTiO3 piezoelectric ceramics. J. Alloys Compd. 2016, 688, 77–87. [Google Scholar] [CrossRef]

- Fang, B.; Wang, M.; Yuan, N.; Ding, J.; Zhao, X.; Xu, H.; Luo, H. Structural phase transition, optical and pyroelectric properties of lead-free single crystals. Chin. Sci. Bull. 2013, 58, 4064–4071. [Google Scholar] [CrossRef][Green Version]

- Zhang, J.; Dong, X.; Cao, F.; Guo, S.; Wang, G. Enhanced pyroelectric properties of Cax(Sr0.5Ba0.5)1−xNb2O6 lead-free ceramics. Appl. Phys. Lett. 2013, 102, 102908. [Google Scholar] [CrossRef]

- Srikanth, K.S.; Singh, V.P.; Vaish, R. Pyroelectric performance of porous Ba0.85Sr0.15TiO3 ceramics. Int. J. Appl. Ceram. Technol. 2017, 15, 140–147. [Google Scholar] [CrossRef]

| Compositions | p × 10−4 (C m−2 K−1) | Fi × 10−10 (C m J−1) | Fv × 10−3 (m2 C−1) | Fd × 10−6 (Pa−1/2) | Fc × 10−4 (C m−2K−1) | Ref. |

|---|---|---|---|---|---|---|

| at room temperature | ||||||

| NBT-6BT | 3.40 | 1.07 | 17.9 | 8.16 | 0.11 | Present work |

| NBT-6BT-0.005Zn | 2.18 | 1.41 | 28.20 | 21.8 | 0.16 | Present work |

| NBT-6BT-0.01Zn | 2.43 | 1.44 | 34.5 | 26.3 | 0.18 | Present work |

| NBT-9BT | 1.72 | 0.81 | 10 | 5.06 | 0.08 | Present work |

| NBT-9BT-0.005Zn | 1.71 | 0.83 | 13.6 | 11.3 | 0.09 | Present work |

| NBT-9BT-0.01Zn | 1.51 | 1.07 | 23 | 17.4 | 0.139 | Present work |

| NBT-6BT | 3.14 | 1.12 | 0.021 | 9.08 | 1.58 | [24,26,27,28] |

| NBT-6Ba1.02T | 3.54 | 1.244 | 0.95 | 8.3 | [25] | |

| N0.52B0.52T-6BT | 6.99 | 2.50 | 0.047 | 16.63 | 2.86 | [24] |

| NBT-6BT-0.002Ta | 7.14 | 2.55 | 0.033 | 1.29 | 2.42 | [27] |

| NBT-6BT-0.005La | 7.42 | 2.65 | 0.048 | 1.4 | 2.98 | [26] |

| 0.005La-NBT-6BT-0.002Ta | 12.92 | 4.61 | 0.078 | 2.76 | 2.57 | [28] |

| BNT-BKT-BT | 3.66 | 2.15 | 0.026 | 15.41 | [43] | |

| 0.95NBT-0.05BT- Mn-doped * | 8.34 | 1.11 | 0.016 | 8.64 | 0.29 | [44] |

| BNKBT | 3.25 | 1.95 | 0.026 | 13.43 | [8] | |

| KNLNTS | 1.90 | 0.93 | 0.007 | 11.51 | [8] | |

| Ca0.15(Sr0.5Ba0.5)0.85Nb2O6 | 3.61 | 1.71 | 0.02 | [45] | ||

| NBT-0.07BZT | 5.71 | 2.03 | 0.022 | 10.50 | [8] | |

| PZT | 4.14 | 1.42 | 0.008 | 9.01 | [8] | |

| BaSn0.05Ti0.95O3 | 5.57 | 3.55 | 0.018 | [37] | ||

| Ba0.85Sr0.15TiO3 | 7.2 | 3.14 | 0.009 | [46] | ||

| at around depolarization temperature | ||||||

| NBT-6BT (352 K) | 974 | 2.81 | 72.17 | 8.25 | 0.25 | Present work |

| NBT-6BT-0.005Zn (395 K) | 121 | 2.94 | 58.94 | 6.01 | 0.22 | Present work |

| NBT-6BT-0.01Zn(400 K) | 964 | 68.8 | 41126 | 4156 | 6.03 | Present work |

| NBT-9BT(420 K) | 605 | 2.75 | 41.7 | 3.79 | 0.19 | Present work |

| NBT-9BT-0.005Zn(442 K) | 187 | 4.05 | 116 | 10.25 | 0.32 | Present work |

| NBT-9BT-0.01Zn(442 K) | 108 | 5.77 | 312 | 27.36 | 0.52 | Present work |

| N0.50B0.49T-6BT(393 K) | 47.8 | 15.13 | 82.24 | 50.77 | 1.03 | [30] |

| N0.5B0.5T-6BT(383 K) | 87 | 28.19 | 90.52 | 66.44 | 1.46 | [30] |

| N0.5B0.51T-6BT(353 K) | 103 | 28.44 | 148.13 | 97.49 | 2.02 | [30] |

| N0.51B0.5T-6BT (353 K) | 105 | 34.37 | 223.75 | 120 | 2.41 | [30] |

| NBT-6BT (363 K) | 23.9 | 8.55 | 0.19 | 65.5 | [24,26,27,28] | |

| NBT-6BT (363 K) | 53.3 | 19.7 | 0.14 | 75.6 | [25] | |

| NBT-6Ba1.02T (358 K) | 741 | 260 | 1.64 | 915 | [25] | |

| N0.52B0.52T-0.06BT (355.7 K) | 75.33 | 26.92 | 0.39 | 138.72 | [24] | |

| NBT-6BT-0.002Ta (351.8 K) | 146.1 | 52.2 | 0.48 | 19.7 | [27] | |

| NBT-6BT-0.005La (346.5 K) | 86.1 | 30.8 | 0.52 | 15.8 | [26] | |

| 0.005La-NBT-6BT-0.002Ta (334.3 K) | 58.62 | 20.94 | 0.18 | 7.60 | [28] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patel, S.; Lalitha, K.V.; Saurabh, N. Enhanced Pyroelectric Performance of Lead-Free Zn-Doped Na1/2Bi1/2TiO3-BaTiO3 Ceramics. Materials 2022, 15, 87. https://doi.org/10.3390/ma15010087

Patel S, Lalitha KV, Saurabh N. Enhanced Pyroelectric Performance of Lead-Free Zn-Doped Na1/2Bi1/2TiO3-BaTiO3 Ceramics. Materials. 2022; 15(1):87. https://doi.org/10.3390/ma15010087

Chicago/Turabian StylePatel, Satyanarayan, Kodumudi Venkataraman Lalitha, and Nishchay Saurabh. 2022. "Enhanced Pyroelectric Performance of Lead-Free Zn-Doped Na1/2Bi1/2TiO3-BaTiO3 Ceramics" Materials 15, no. 1: 87. https://doi.org/10.3390/ma15010087

APA StylePatel, S., Lalitha, K. V., & Saurabh, N. (2022). Enhanced Pyroelectric Performance of Lead-Free Zn-Doped Na1/2Bi1/2TiO3-BaTiO3 Ceramics. Materials, 15(1), 87. https://doi.org/10.3390/ma15010087