Monitoring Dynamic Recrystallisation in Bioresorbable Alloy Mg-1Zn-0.2Ca by Means of an In Situ Acoustic Emission Technique

Abstract

:1. Introduction

- (1)

- (2)

- Sufficiently high strength and ductility, which are conventionally supposed to be better than 250 MPa and 15%, respectively [3]. High ductility is necessary to achieve the desired products’ shape during manufacturing, which traditionally involves metal forming operations. In addition, remaining ductile is a prime requirement for the final product as shape correction and adjustment may be needed during location-specific deployment.

- (3)

- The controllable (tuneable) rate of bio-corrosion (resorption), which is pivotal for the medical application of magnesium alloys as temporary structures. This rate should be neither too slow nor too fast and comply with the rate of tissue regeneration. Hence, it is commonly assumed to be not worse than 0.5 mm/year in vivo [3].

2. Materials and Methods

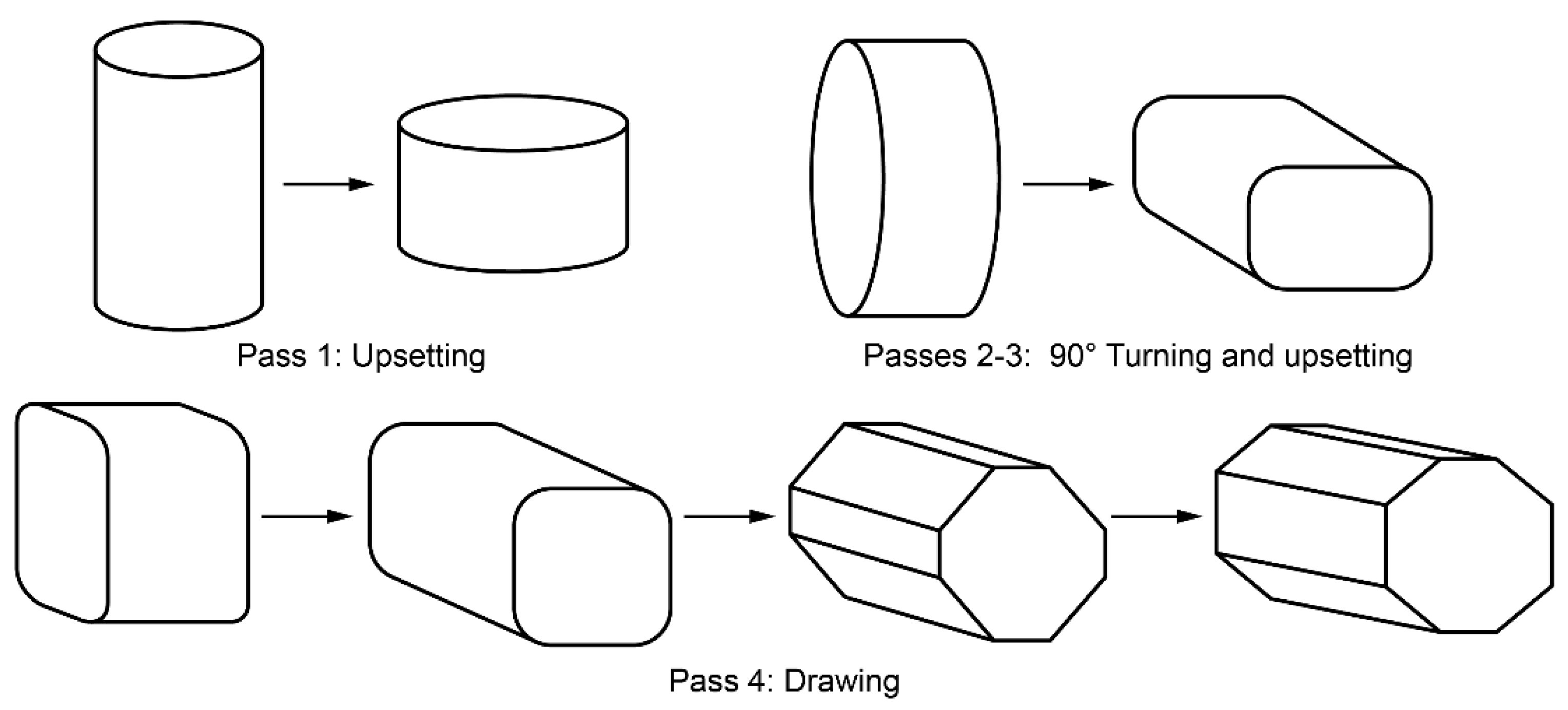

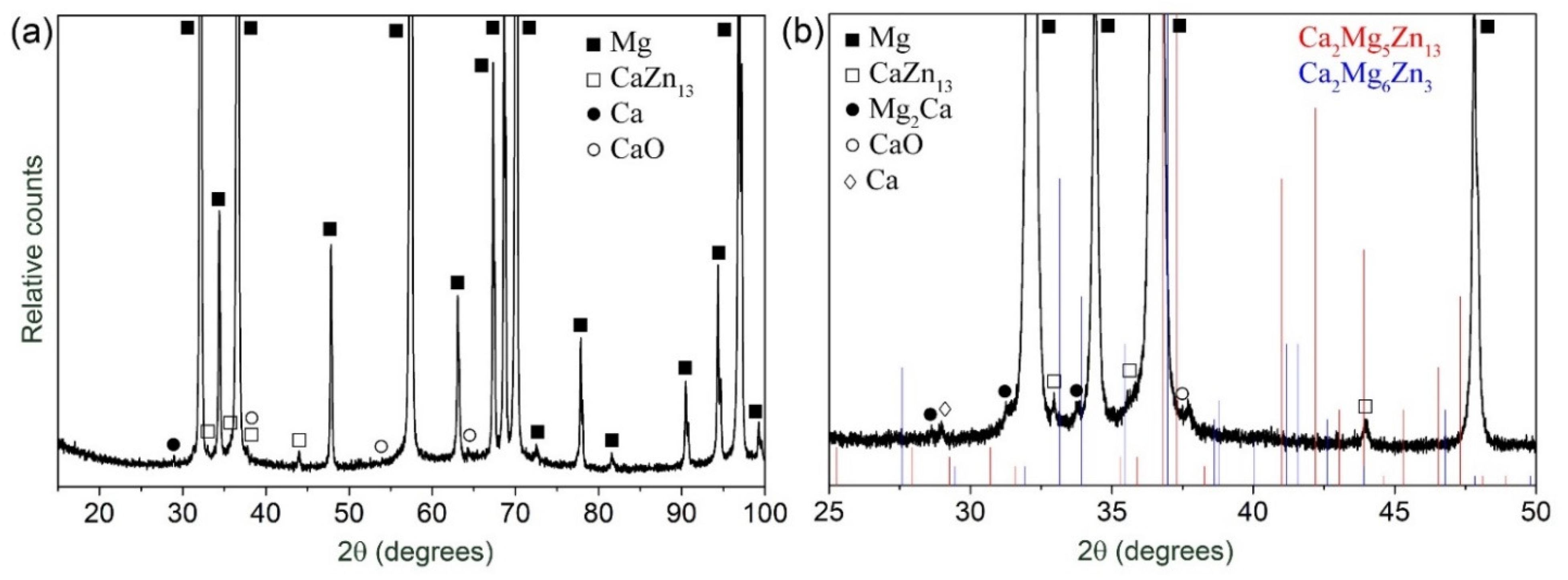

2.1. Alloy Processing

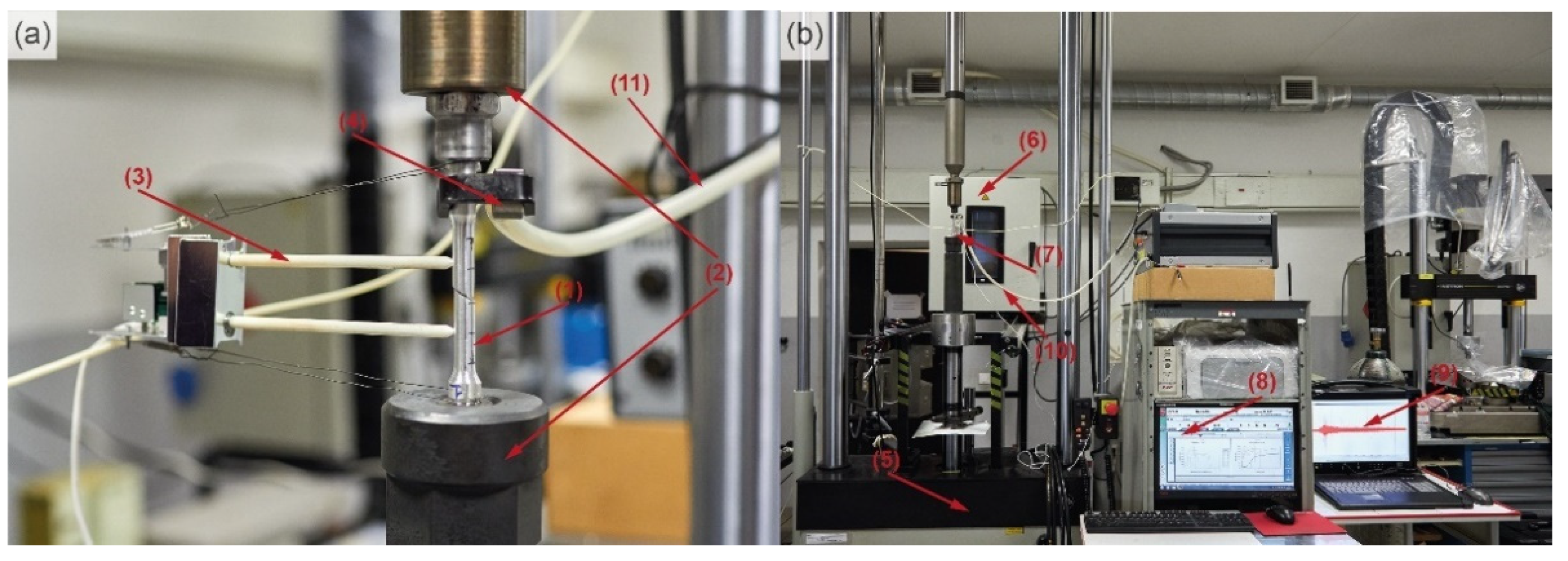

2.2. Mechanical Testing

2.3. Acoustic Emission Method

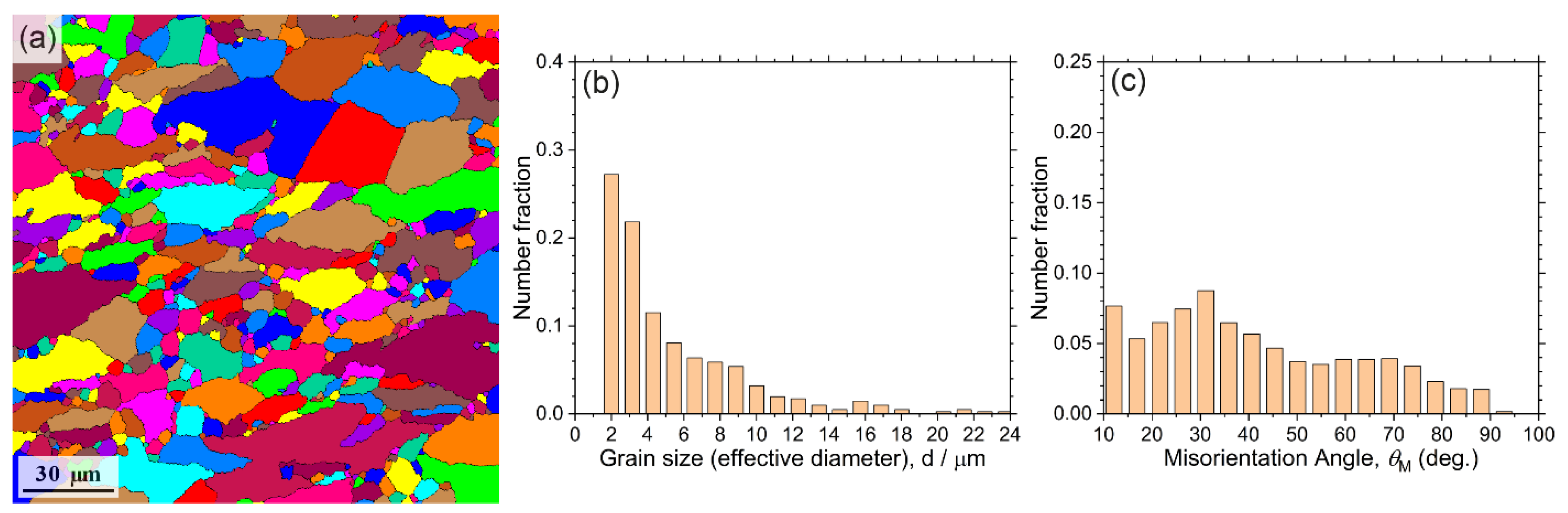

2.4. Microstructure Characterisation

3. Results

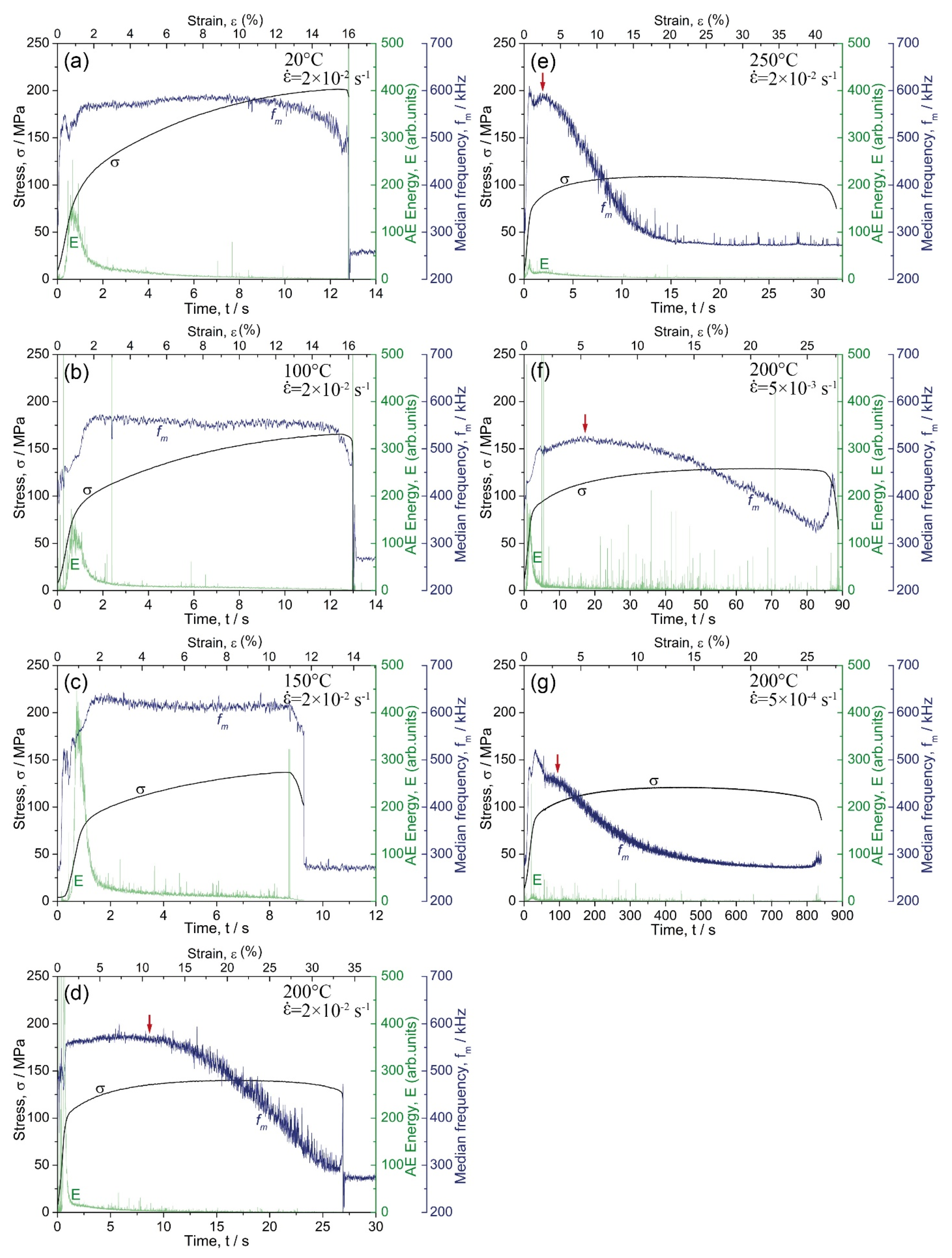

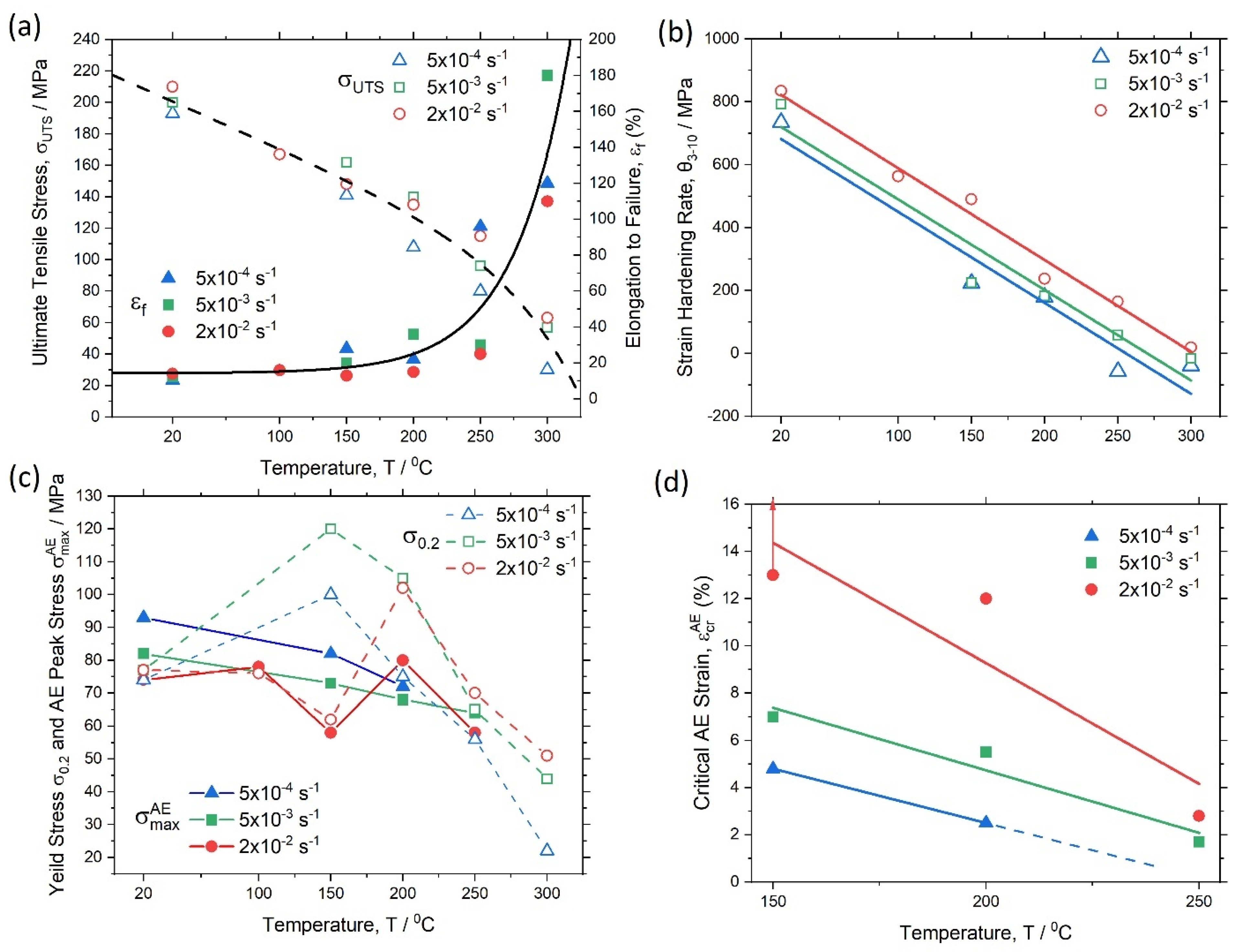

3.1. Mechanical Behaviour at Ambient and Elevated Temperatures

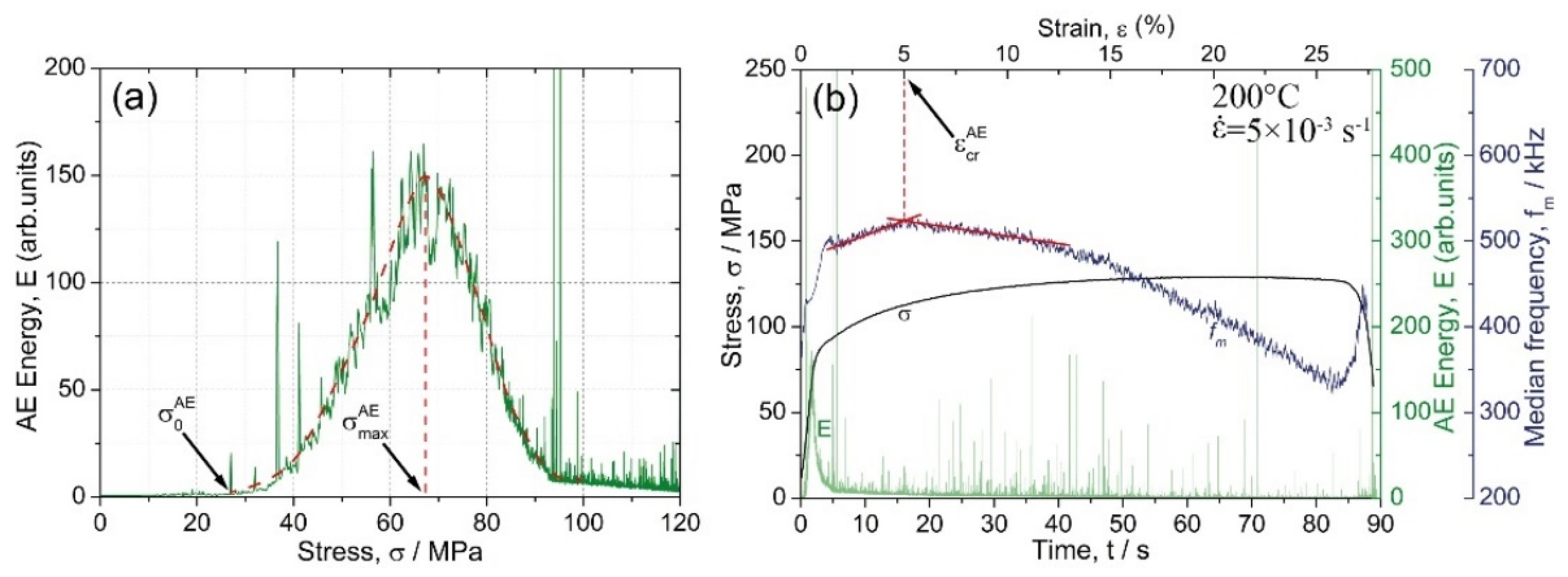

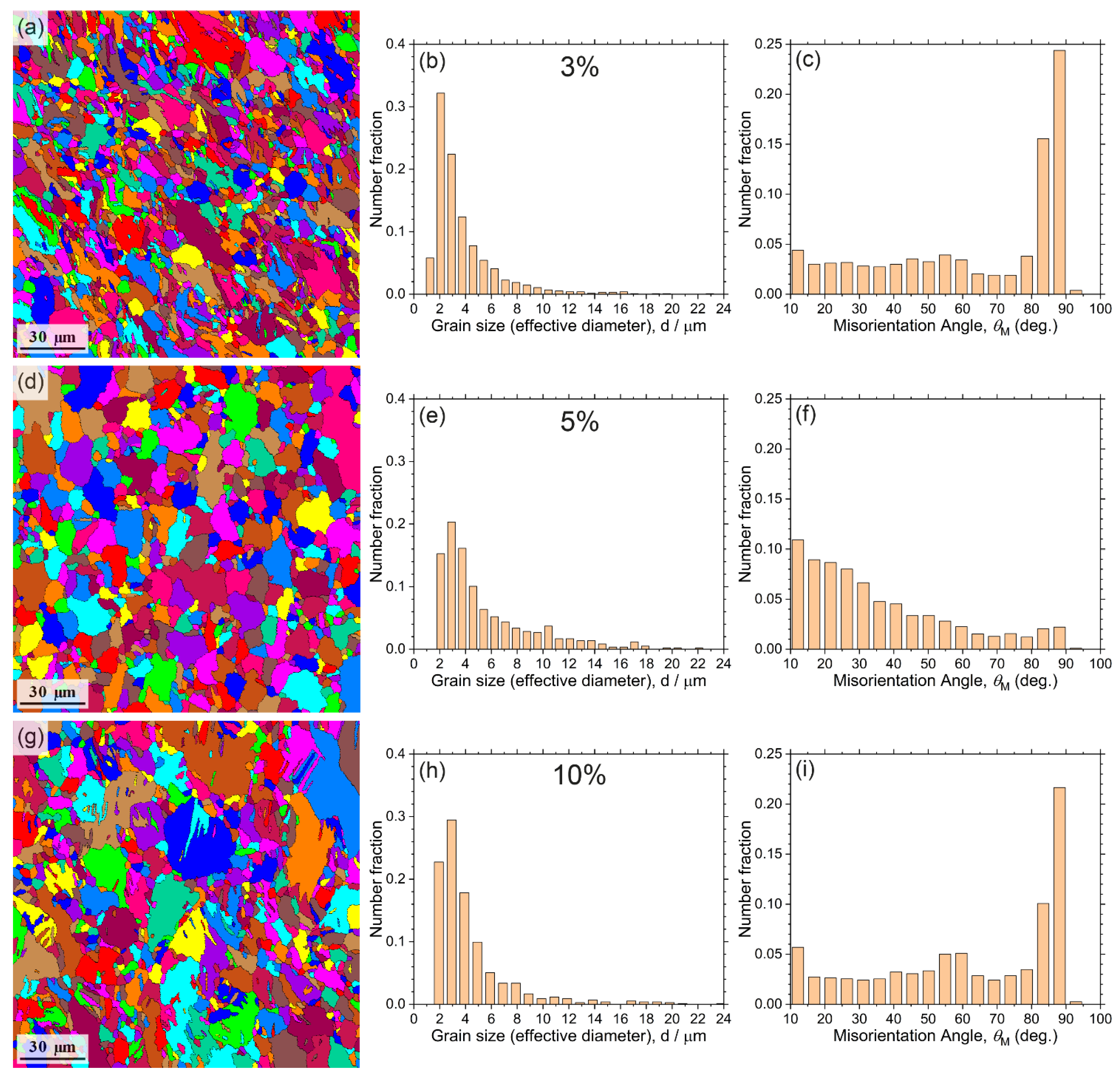

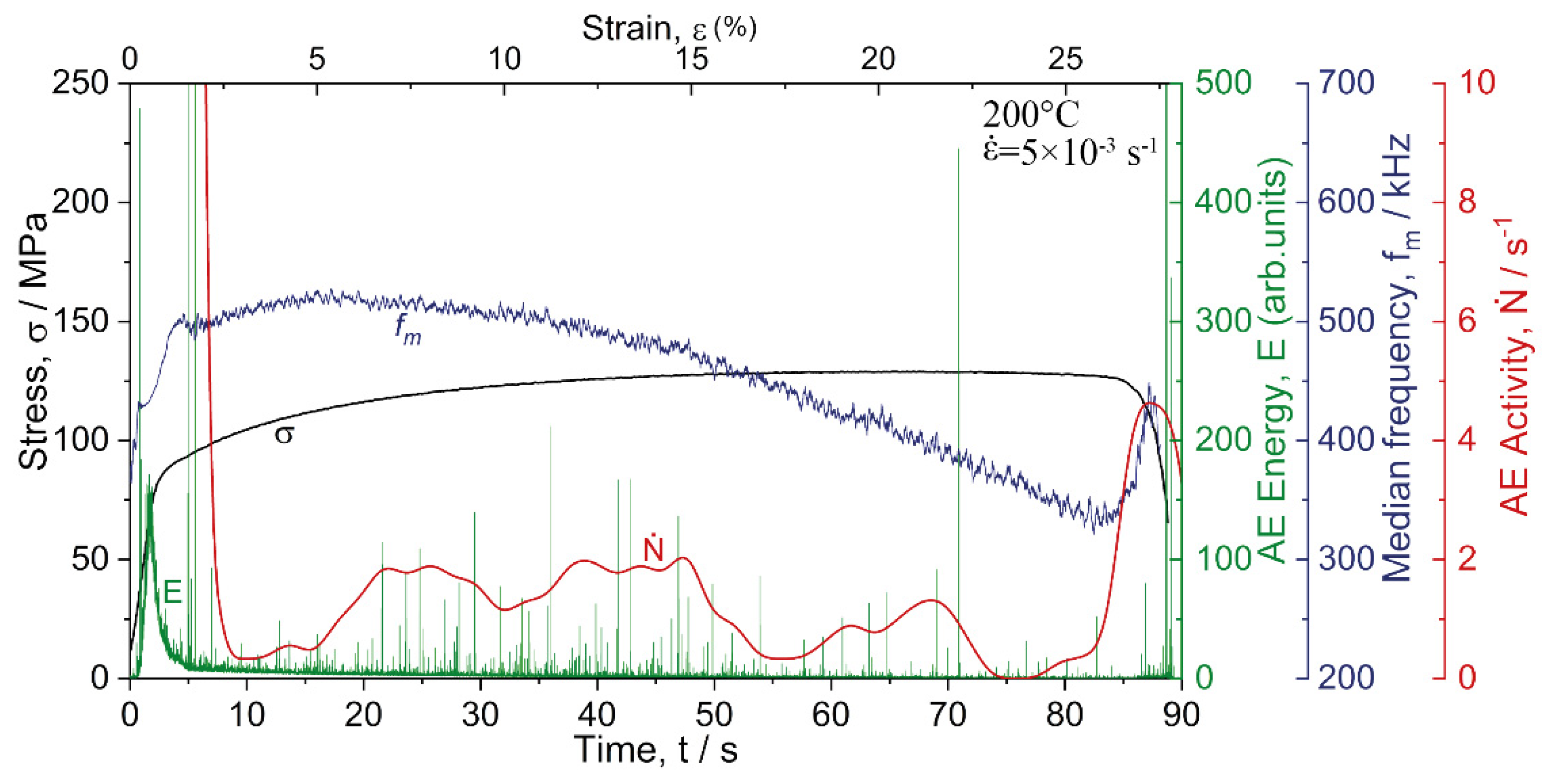

3.2. Acoustic Emission

4. Discussion

5. Conclusions

- The common trends towards decreasing strength and increasing ductility were observed with the increasing test temperature; the steepest change occurred at 250 °C.

- The advanced broadband AE technique was shown (for the first time to the best of our knowledge) to be well suited for reflecting the changes in the deformation behaviour associated with the dynamic recovery and recrystallisation occurring at elevated temperatures.

- The evolution of the AE spectral density with plastic strain at elevated temperatures exhibited a specific behaviour of the median frequency, which peaked at a certain strain where dynamic recovery and recrystallisation occurred. This characteristic, strongly non-monotonic behaviour of the AE spectrum, which contrasts to the steady strain dependence at low temperatures, serves as an indicator of the evolution of dynamic recrystallisation towards completeness. In the investigated range of strain rates, the effect of dynamic recrystallisation was observed at 150 °C and higher.

- The activity of mechanical twinning decreased with increasing temperature giving priority to dislocation slip. However, as recrystallisation proceeded and freshly nucleated grains grew, and the contribution of the twinning mode to the plastic flow regained and was visible even at elevated temperatures.

- The proposed methodology based on the modern AE method can be efficiently adapted and applied in both laboratory research and in industrial settings to find the optimised manufacturing conditions for nominally hard to deform magnesium alloys.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Atrens, A.; Song, G.-L.; Liu, M.; Shi, Z.; Cao, F.; Dargusch, M.S. Review of Recent Developments in the Field of Magnesium Corrosion. Adv. Eng. Mater. 2015, 17, 400–453. [Google Scholar] [CrossRef]

- Witte, F.; Hort, N.; Feyerabend, F.; Vogt, C. Magnesium (Mg) corrosion: A challenging concept for degradable implants. In Corrosion of Magnesium Alloys; Song, G.-L., Ed.; Woodhead Publishing: Sawston, UK, 2011; Chapter 10; pp. 403–425. [Google Scholar] [CrossRef]

- Erinc, M.; Sillekens, W.H.; Mannens, R.G.T.M.; Werkhoven, R.J. Applicability of existing magnesium alloys as biomedical implant materials. In Magnesium Technology; Nyberg, E.A., Agnew, S.R., Neelameggham, N.R., Pekguleryuz, M.O., Eds.; TMS (The Minerals and Materials Society): Warrendale, PA, USA, 2009; pp. 209–214. [Google Scholar]

- Chen, S.; Smith, C.E.; Xu, Z.; Sankar, J. Development of biodegradable Mg-Zn-Ca alloys for biomedical applications. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), Vancouver, BC, Canada, 12–18 November 2010; pp. 43–48. [Google Scholar]

- Riaz, U.; Shabib, I.; Haider, W. The current trends of Mg alloys in biomedical applications—A review. J. Biomed. Mater. Res. Part B Appl. Biomater. 2019, 107, 1970–1996. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Dou, J.; Yu, H.; Chen, C. Degradable magnesium-based alloys for biomedical applications: The role of critical alloying elements. J. Biomater. Appl. 2019, 33, 1348–1372. [Google Scholar] [CrossRef]

- Herber, V.; Okutan, B.; Antonoglou, G.; Sommer, N.G.; Payer, M. Bioresorbable Magnesium-Based Alloys as Novel Biomaterials in Oral Bone Regeneration: General Review and Clinical Perspectives. J. Clin. Med. 2021, 10, 1842. [Google Scholar] [CrossRef] [PubMed]

- Amani, S.; Faraji, G. Processing and Properties of Biodegradable Magnesium Microtubes for Using as Vascular Stents: A Brief Review. Met. Mater. Int. 2019, 25, 1341–1359. [Google Scholar] [CrossRef]

- Singh Raman, R.K.; Jafari, S.; Harandi, S.E. Corrosion fatigue fracture of magnesium alloys in bioimplant applications: A review. Eng. Fract. Mech. 2015, 137, 97–108. [Google Scholar] [CrossRef]

- Gunde, P.; Hänzi, A.C.; Sologubenko, A.S.; Uggowitzer, P.J. High-strength magnesium alloys for degradable implant applications. Mater. Sci. Eng. A 2011, 528, 1047–1054. [Google Scholar] [CrossRef]

- Hänzi, A.C.; Sologubenko, A.S.; Uggowitzer, P.J. Design strategy for new biodegradable Mg-Y-Zn alloys for medical applications. Int. J. Mater. Res. 2009, 100, 1127–1136. [Google Scholar] [CrossRef]

- Hofstetter, J.; Becker, M.; Martinelli, E.; Weinberg, A.M.; Mingler, B.; Kilian, H.; Pogatscher, S.; Uggowitzer, P.J.; Löffler, J.F. High-Strength Low-Alloy (HSLA) Mg–Zn–Ca Alloys with Excellent Biodegradation Performance. JOM 2014, 66, 566–572. [Google Scholar] [CrossRef]

- Hofstetter, J.; Martinelli, E.; Pogatscher, S.; Schmutz, P.; Povoden-Karadeniz, E.; Weinberg, A.M.; Uggowitzer, P.J.; Löffler, J.F. Influence of trace impurities on the in vitro and in vivo degradation of biodegradable Mg-5Zn-0.3Ca alloys. Acta Biomater. 2015, 23, 347–353. [Google Scholar] [CrossRef]

- Hofstetter, J.; Martinelli, E.; Weinberg, A.M.; Becker, M.; Mingler, B.; Uggowitzer, P.J.; Löffler, J.F. Assessing the degradation performance of ultrahigh-purity magnesium in vitro and in vivo. Corros. Sci. 2015, 91, 29–36. [Google Scholar] [CrossRef]

- Hofstetter, J.; Rüedi, S.; Baumgartner, I.; Kilian, H.; Mingler, B.; Povoden-Karadeniz, E.; Pogatscher, S.; Uggowitzer, P.J.; Löffler, J.F. Processing and microstructure–property relations of high-strength low-alloy (HSLA) Mg–Zn–Ca alloys. Acta Mater. 2015, 98, 423–432. [Google Scholar] [CrossRef]

- Gu, X.; Zheng, Y.; Cheng, Y.; Zhong, S.; Xi, T. In vitro corrosion and biocompatibility of binary magnesium alloys. Biomaterials 2009, 30, 484–498. [Google Scholar] [CrossRef] [PubMed]

- Hillis, J.E. The effects of heavy metal contamination on magnesium corrosion performance. SAE Trans. 1983, 92, 830362–830691. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Ralston, K.D.; Birbilis, N. Effect of grain size on corrosion: A review. Corrosion 2010, 66, 075005–075005-13. [Google Scholar] [CrossRef]

- Orlov, D.; Ralston, K.D.; Birbilis, N.; Estrin, Y. Enhanced corrosion resistance of Mg alloy ZK60 after processing by integrated extrusion and equal channel angular pressing. Acta Mater. 2011, 59, 6176–6186. [Google Scholar] [CrossRef]

- Vasilev, E.; Linderov, M.; Nugmanov, D.; Sitdikov, O.; Markushev, M.; Vinogradov, A. Fatigue Performance of Mg-Zn-Zr Alloy Processed by Hot Severe Plastic Deformation. Metals 2015, 5, 2316–2327. [Google Scholar] [CrossRef] [Green Version]

- Doležal, P.; Zapletal, J.; Fintová, S.; Trojanová, Z.; Greger, M.; Roupcová, P.; Podrábský, T. Influence of processing techniques on microstructure and mechanical properties of a biodegradable Mg-3Zn-2Ca Alloy. Materials 2016, 9, 880. [Google Scholar] [CrossRef] [Green Version]

- Galiyev, A.; Kaibyshev, R.; Gottstein, G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60. Acta Mater. 2001, 49, 1199–1207. [Google Scholar] [CrossRef]

- Nugmanov, D.; Sitdikov, O.; Markushev, M. Grain Refinement in the Magnesium Alloy ZK60 During Multi-Step Isothermal Forging. Mater. Sci. Forum 2015, 830–831, 7–10. [Google Scholar] [CrossRef]

- Al-Samman, T.; Gottstein, G. Dynamic recrystallization during high temperature deformation of magnesium. Mater. Sci. Eng. A 2008, 490, 411–420. [Google Scholar] [CrossRef]

- Avvari, M.; Narendranath, S.; Nayaka, H.S. A review on wrought magnesium alloys processed by equal channel angular pressing. Int. J. Mater. Prod. Technol. 2015, 51, 139–164. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, J. Microstructure and mechanical properties of AZ31 magnesium alloy processed by multi-directional forging at different temperatures. Mater. Sci. Eng. A 2016, 674, 52–58. [Google Scholar] [CrossRef]

- Ding, X.; Zhao, F.; Shuang, Y.; Ma, L.; Chu, Z.; Zhao, C. Characterization of hot deformation behavior of as-extruded AZ31 alloy through kinetic analysis and processing maps. J. Mater. Processing Technol. 2020, 276, 116325. [Google Scholar] [CrossRef]

- Zhang, K.; Zheng, J.-H.; Shao, Z.; Pruncu, C.; Turski, M.; Guerini, C.; Jiang, J. Experimental investigation of the viscoplastic behaviours and microstructure evolutions of AZ31B and Elektron 717 Mg-alloys. Mater. Des. 2019, 184, 108160. [Google Scholar] [CrossRef]

- Aliyari, S.; Fatemi, S.M.; Miresmaeili, S.M. Effects of solution treatment on high temperature deformation behavior of extruded Mg–0.35Y–2.17Nd–0.36Zr biomedical alloy. Trans. Nonferrous Met. Soc. China 2019, 29, 1842–1853, English Edition. [Google Scholar] [CrossRef]

- Kaviani, M.; Ebrahimi, G.R.; Ezatpour, H.R. Improving the mechanical properties and biocorrosion resistance of extruded Mg-Zn-Ca-Mn alloy through hot deformation. Mater. Chem. Phys. 2019, 234, 245–258. [Google Scholar] [CrossRef]

- Chaman-Ara, M.; Ebrahimi, G.R.; Ezatpour, H.R. Deformation behavior and processing maps of Mg-Zn-Y alloy containing I phase at elevated temperatures. Trans. Nonferrous Met. Soc. China 2018, 28, 629–641. [Google Scholar] [CrossRef]

- Nascimento, L.; Yi, S.; Bohlen, J.; Fuskova, L.; Letzig, D.; Kainer, K.U. High cycle fatigue behaviour of magnesium alloys. Procedia Eng. 2010, 2, 743–750. [Google Scholar] [CrossRef] [Green Version]

- Vinogradov, A.; Orlov, D.; Danyuk, A.; Estrin, Y. Effect of grain size on the mechanisms of plastic deformation in wrought Mg–Zn–Zr alloy revealed by acoustic emission measurements. Acta Mater. 2013, 61, 2044–2056. [Google Scholar] [CrossRef]

- Remy, L. Kinetics of f.c.c. deformation twinning and its relationship to stress-strain behaviour. Acta Metall. 1978, 26, 443–451. [Google Scholar] [CrossRef]

- Lou, X.Y.; Li, M.; Boger, R.K.; Agnew, S.R.; Wagoner, R.H. Hardening evolution of AZ31B Mg sheet. Int. J. Plast. 2007, 23, 44–86. [Google Scholar] [CrossRef]

- Yoo, M. Slip, twinning, and fracture in hexagonal close-packed metals. Met. Trans. A 1981, 12, 409–418. [Google Scholar] [CrossRef]

- Kocks, U.F.; Westlake, D.G. Importance of twinning for ductility of hcp polycrystals. Trans. Metall. Soc. AIME 1967, 239, 1107. [Google Scholar]

- Taylor, G.I. Plastic strain in metals. J. Inst. Met. 1938, 62, 307–324. [Google Scholar]

- Carpenter, S.R.; Heiple, C.R. Acoustic Emission Generated by Dislocation Mechanisms during the Deformation of Metals. In Fundamentals of Acoustic Emission; Ono, K., Ed.; Univeristy of California: Los Angeles, CA, USA, 1979; pp. 49–104. [Google Scholar]

- Eitzen, D.G.; Wadley, H.N.G. Acoustic-Emission—Establishing the Fundamentals. J. Res. Natl. Bur. Stand. 1984, 89, 75–100. [Google Scholar] [CrossRef]

- Wadley, H.N.G.; Mehrabian, R. Acoustic emission for materials processing: A review. Mater. Sci. Eng. 1984, 65, 245–263. [Google Scholar] [CrossRef]

- Zhang, B.P.; Wang, Y.; Geng, L. Research on Mg-Zn-Ca Alloy as Degradable Biomaterial, Biomaterials—Physics and Chemistry. In Biomaterials; Pignatello, R., Ed.; InTechOpen: London, UK, 2011. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y. Microstructure and Degradation Behaviour of Mg-Zn(-Ca) Alloys. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2014. [Google Scholar]

- Kulyasova, O.B.; Islamgaliev, R.K.; Zhao, Y.; Valiev, R.Z. Enhancement of the Mechanical Properties of an Mg-Zn-Ca Alloy Using High-Pressure Torsion. Adv. Eng. Mater. 2015, 17, 1738–1741. [Google Scholar] [CrossRef]

- Merson, D.; Brilevsky, A.; Myagkikh, P.; Tarkova, A.; Prokhorikhin, A.; Kretov, E.; Frolova, T.; Vinogradov, A. The Functional Properties of Mg–Zn–X Biodegradable Magnesium Alloys. Materials 2020, 13, 544. [Google Scholar] [CrossRef] [Green Version]

- Merson, D.; Brilevsky, A.; Myagkikh, P.; Markushev, M.; Vinogradov, A. Effect of deformation processing of the dilute Mg-1Zn-0.2Ca alloy on the mechanical properties and corrosion rate in a simulated body fluid. Lett. Mater. 2020, 10, 217–222. [Google Scholar] [CrossRef]

- Vinogradov, A.; Vasilev, E.; Kopylov, V.I.; Linderov, M.; Brilevesky, A.; Merson, D. High Performance Fine-Grained Biodegradable Mg-Zn-Ca Alloys Processed by Severe Plastic Deformation. Metals 2019, 9, 186. [Google Scholar] [CrossRef] [Green Version]

- Martynenko, N.S.; Anisimova, N.Y.; Rybalchenko, O.V.; Kiselevskiy, M.V.; Rybalchenko, G.; Straumal, B.; Temralieva, D.; Mansharipova, A.T.; Kabiyeva, A.O.; Gabdullin, M.T.; et al. Rationale for Processing of a Mg-Zn-Ca Alloy by Equal-Channel Angular Pressing for Use in Biodegradable Implants for Osteoreconstruction. Crystals 2021, 11, 1381. [Google Scholar] [CrossRef]

- Yang, L.; Liu, G.; Ma, L.; Zhang, E.; Zhou, X.; Thompson, G. Effect of iron content on the corrosion of pure magnesium: Critical factor for iron tolerance limit. Corros. Sci. 2018, 139, 421–429. [Google Scholar] [CrossRef]

- Liu, M.; Uggowitzer, P.J.; Nagasekhar, A.V.; Schmutz, P.; Easton, M.; Song, G.-L.; Atrens, A. Calculated phase diagrams and the corrosion of die-cast Mg–Al alloys. Corros. Sci. 2009, 51, 602–619. [Google Scholar] [CrossRef]

- Nugmanov, D.R.; Sitdikov, O.S.; Markushev, M.V. Microstructure evolution in MA14 magnesium alloy under multi-step isothermal forging. Lett. Mater. 2011, 1, 213–216. [Google Scholar] [CrossRef]

- Markushev, M.V.; Nugmanov, D.R.; Sitdikov, O.; Vinogradov, A. Structure, texture and strength of Mg-5.8Zn-0.65Zr alloy after hot-to-warm multi-step isothermal forging and isothermal rolling to large strains. Mater. Sci. Eng. A 2018, 709, 330–338. [Google Scholar] [CrossRef]

- Linderov, M.; Vasilev, E.; Merson, D.; Markushev, M.; Vinogradov, A. Corrosion Fatigue of Fine Grain Mg-Zn-Zr and Mg-Y-Zn Alloys. Metals 2018, 8, 20. [Google Scholar] [CrossRef] [Green Version]

- Lazarev, S.; Mozgovoi, A.; Vinogradov, A.; Lazarev, A.; Shvedov, A. Electromagnetic method of elastic wave excitation for calibration of acoustic emission sensors and apparatus. J. Acoust. Emiss. 2009, 27, 215–223. [Google Scholar]

- Vinogradov, A.; Nadtochiy, M.; Hashimoto, S.; Miura, S. Acoustic-Emission Spectrum and Its Orientation Dependence in Copper Single-Crystals. Mater. Trans. JIM 1995, 36, 496–503. [Google Scholar] [CrossRef] [Green Version]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Oh, J.C.; Ohkubo, T.; Mukai, T.; Hono, K. TEM and 3DAP characterization of an age-hardened Mg–Ca–Zn alloy. Scr. Mater. 2005, 53, 675–679. [Google Scholar] [CrossRef]

- Nie, J.F.; Muddle, B.C. Precipitation hardening of Mg-Ca(-Zn) alloys. Scr. Mater. 1997, 37, 1475–1481. [Google Scholar] [CrossRef]

- Heiple, C.R.; Carpenter, S.H. Acoustic Emission Produced by Deformation of Metals and Alloys—A review: Part I and II. J. Acoust. Emiss. 1987, 6, 177–237. [Google Scholar]

- Vinogradov, A.; Yasnikov, I.S.; Estrin, Y. Stochastic dislocation kinetics and fractal structures in deforming metals probed by acoustic emission and surface topography measurements. J. Appl. Phys. 2014, 115, 233506. [Google Scholar] [CrossRef]

- Vinogradov, A.; Lazarev, A. Continuous acoustic emission during intermittent plastic flow in α-brass. Scr. Mater. 2012, 66, 745–748. [Google Scholar] [CrossRef]

- McCrory, J.P.; Vinogradov, A.; Pearson, M.R.; Pullin, R.; Holford, K.M. Acoustic Emission Monitoring of Metals. In Acoustic Emission Testing: Basics for Research—Applications in Engineering; Grosse, C.U., Ohtsu, M., Aggelis, D.G., Shiotani, T., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 529–565. [Google Scholar] [CrossRef]

- Vinogradov, A.; Orlov, D.; Danyuk, A.; Estrin, Y. Deformation mechanisms underlying tension–compression asymmetry in magnesium alloy ZK60 revealed by acoustic emission monitoring. Mater. Sci. Eng. A 2015, 621, 243–251. [Google Scholar] [CrossRef]

- Vinogradov, A.; Heczko, M.; Mazánová, V.; Linderov, M.; Kruml, T. Kinetics of cyclically-induced mechanical twinning in γ-TiAl unveiled by a combination of acoustic emission, neutron diffraction and electron microscopy. Acta Mater. 2021, 212, 116921. [Google Scholar] [CrossRef]

- Vinogradov, A.; Lazarev, A.; Linderov, M.; Weidner, A.; Biermann, H. Kinetics of deformation processes in high-alloyed cast transformation-induced plasticity/twinning-induced plasticity steels determined by acoustic emission and scanning electron microscopy: Influence of austenite stability on deformation mechanisms. Acta Mater. 2013, 61, 2434–2449. [Google Scholar] [CrossRef]

- Linderov, M.; Segel, C.; Weidner, A.; Biermann, H.; Vinogradov, A. Deformation mechanisms in austenitic TRIP/TWIP steels at room and elevated temperature investigated by acoustic emission and scanning electron microscopy. Mater. Sci. Eng. A 2014, 597, 183–193. [Google Scholar] [CrossRef]

- Vinogradov, A.V.; Patlan, V.; Hashimoto, S. Spectral analysis of acoustic emission during cyclic deformation of copper single crystals. Philos. Mag. A 2001, 81, 1427–1446. [Google Scholar] [CrossRef]

- Agnew, S.R. Deformation mechanisms of magnesium alloys. In Advances in Wrought Magnesium Alloys: Fundamentals of Processing, Properties and Applications; Bettles, C., Barnett, M., Eds.; Woodhead Publishing: Sawston, UK, 2012; pp. 63–104. [Google Scholar] [CrossRef]

- Barnett, M.R.; Keshavarz, Z.; Beer, A.G.; Atwell, D. Influence of grain size on the compressive deformation of wrought Mg–3Al–1Zn. Acta Mater. 2004, 52, 5093–5103. [Google Scholar] [CrossRef]

- Kleiner, S.; Uggowitzer, P.J. Mechanical anisotropy of extruded Mg–6% Al–1% Zn alloy. Mater. Sci. Eng. A 2004, 379, 258–263. [Google Scholar] [CrossRef]

- Koike, J. Enhanced deformation mechanisms by anisotropic plasticity in polycrystalline Mg alloys at room temperature. Met. Mater. Trans. A 2005, 36, 1689–1696. [Google Scholar] [CrossRef]

- Chino, Y.; Mabuchi, M. Enhanced stretch formability of Mg–Al–Zn alloy sheets rolled at high temperature (723K). Scr. Mater. 2009, 60, 447–450. [Google Scholar] [CrossRef]

- Chapuis, A.; Driver, J.H. Temperature dependency of slip and twinning in plane strain compressed magnesium single crystals. Acta Mater. 2011, 59, 1986–1994. [Google Scholar] [CrossRef]

- Hutchinson, W.B.; Barnett, M.R. Effective values of critical resolved shear stress for slip in polycrystalline magnesium and other hcp metals. Scr. Mater. 2010, 63, 737–740. [Google Scholar] [CrossRef]

- Jain, A.; Agnew, S.R. Modeling the temperature dependent effect of twinning on the behavior of magnesium alloy AZ31B sheet. Mater. Sci. Eng. A 2007, 462, 29–36. [Google Scholar] [CrossRef]

- Chapuis, A.; Liu, Q. Investigating the temperature dependency of plastic deformation in a Mg-3Al-1Zn alloy. Mater. Sci. Eng. A 2018, 725, 108–118. [Google Scholar] [CrossRef]

- Zhang, H.K.; Xiao, H.; Fang, X.W.; Zhang, Q.; Logé, R.E.; Huang, K. A critical assessment of experimental investigation of dynamic recrystallization of metallic materials. Mater. Des. 2020, 193, 108873. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef] [Green Version]

- Vinogradov, A.; Vasilev, E.; Merson, D.; Estrin, Y. A Phenomenological Model of Twinning Kinetics. Adv. Eng. Mater. 2017, 19, 1600092. [Google Scholar] [CrossRef] [Green Version]

- Vinogradov, A.; Vasilev, E.; Seleznev, M.; Máthis, K.; Orlov, D.; Merson, D. On the limits of acoustic emission detectability for twinning. Mater. Lett. 2016, 183, 417–419. [Google Scholar] [CrossRef]

- Vinogradov, A.; Máthis, K. Acoustic Emission as a Tool for Exploring Deformation Mechanisms in Magnesium and Its Alloys In Situ. JOM 2016, 68, 3057–3062. [Google Scholar] [CrossRef]

| T, °C | , s−1 | |||||||

|---|---|---|---|---|---|---|---|---|

| 20 | 5 × 10−4 | 74 ± 2.5 | 193 ± 3 | 10.5 ± 0.5 | 734 ± 24 | 60 ± 4 | 93 ± 4 | |

| 5 × 10−3 | 77 ± 3 | 200 ± 3 | 12.5 ± 1 | 793 ± 29 | 23 ± 1 | 82 ± 3 | ||

| 2 × 10−2 | 77 ± 3 | 210 ± 3 | 14 ± 1 | 835 ± 32 | 38 ± 2 | 74 ± 3 | ||

| 100 | 2 × 10−2 | 76 | 167 | 16 | 563 | 38 | 78 | |

| 150 | 5 × 10−4 | 100 ± 4 | 141 ± 3 | 28 ± 2 | 222 ± 9 | 45 ± 2 | 82 ± 3 | 4.8 ± 0.2 |

| 5 × 10−3 | 120 ± 5 | 162 ± 5 | 20 ± 2 | 224 ± 11 | 45 ± 2 | 73 ± 3 | 7 ± 0.3 | |

| 2 × 10−2 | 62 ± 2.5 | 148 ± 3 | 13 ± 1 | 490 ± 18 | 30 ± 2 | 58 ± 2 | ||

| 200 | 5 × 10−4 | 75 ± 3 | 108 ± 3 | 22 ± 2 | 178 ± 9 | 26 ± 3 | 72 ± 3 | 2.5 ± 0.1 |

| 5 × 10−3 | 105 ± 4 | 140 ± 5 | 36 ± 5 | 182 ± 9 | 28 ± 3 | 68 ± 3 | 5.0 ± 0.2 | |

| 2 × 10−2 | 102 ± 4 | 135 ± 6 | 15 ± 1 | 237 ± 11 | 63 ± 4 | 80 ± 3 | 12 ± 0.4 | |

| 250 | 5 × 10−4 | 56 ± 2 | 80 ± 3 | 96 ± 12 | −58 ± 8 | - | - | - |

| 5 × 10−3 | 65 ± 3 | 96 ± 3 | 30 ± 2 | 58 ± 7 | 35 ± 2 | 64 ± 3 | 1.7 ± 0.1 | |

| 2 × 10−2 | 70 ± 3 | 115 ± 5 | 25 ± 2 | 165 ± 10 | 23 ± 2 | 58 ± 3 | 2.8 ± 0.1 | |

| 300 | 5 × 10−4 | 22 ± 2 | 30 ± 3 | 120 ± 30 | −39 ± 20 | - | - | - |

| 5 × 10−3 | 44 ± 3 | 57 ± 4 | 180 ± 35 | −16 ± 8 | - | - | - | |

| 2 × 10−2 | 51 ± 3 | 63 ± 4 | 110 ± 20 | 19 ± 8 | - | - | - |

| T, °C | Strain Rate, , s−1 | Strain (%) | ||

|---|---|---|---|---|

| 150 | 5 × 10−3 | 4.0 | 7.0 | 15 |

| 200 | 5 × 10−3 | 3.0 | 5.0 | 10 |

| 250 | 2 × 10−4 | 1.5 | 2.8 | 8.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Merson, D.; Linderov, M.; Brilevsky, A.; Danyuk, A.; Vinogradov, A. Monitoring Dynamic Recrystallisation in Bioresorbable Alloy Mg-1Zn-0.2Ca by Means of an In Situ Acoustic Emission Technique. Materials 2022, 15, 328. https://doi.org/10.3390/ma15010328

Merson D, Linderov M, Brilevsky A, Danyuk A, Vinogradov A. Monitoring Dynamic Recrystallisation in Bioresorbable Alloy Mg-1Zn-0.2Ca by Means of an In Situ Acoustic Emission Technique. Materials. 2022; 15(1):328. https://doi.org/10.3390/ma15010328

Chicago/Turabian StyleMerson, Dmitry, Mikhail Linderov, Alexander Brilevsky, Alexey Danyuk, and Alexei Vinogradov. 2022. "Monitoring Dynamic Recrystallisation in Bioresorbable Alloy Mg-1Zn-0.2Ca by Means of an In Situ Acoustic Emission Technique" Materials 15, no. 1: 328. https://doi.org/10.3390/ma15010328

APA StyleMerson, D., Linderov, M., Brilevsky, A., Danyuk, A., & Vinogradov, A. (2022). Monitoring Dynamic Recrystallisation in Bioresorbable Alloy Mg-1Zn-0.2Ca by Means of an In Situ Acoustic Emission Technique. Materials, 15(1), 328. https://doi.org/10.3390/ma15010328