The Art of Positronics in Contemporary Nanomaterials Science: A Case Study of Sub-Nanometer Scaled Glassy Arsenoselenides

Abstract

:1. Introduction

2. Materials and Methods

2.1. Nanocomposite Preparation and Microstructure Characterization

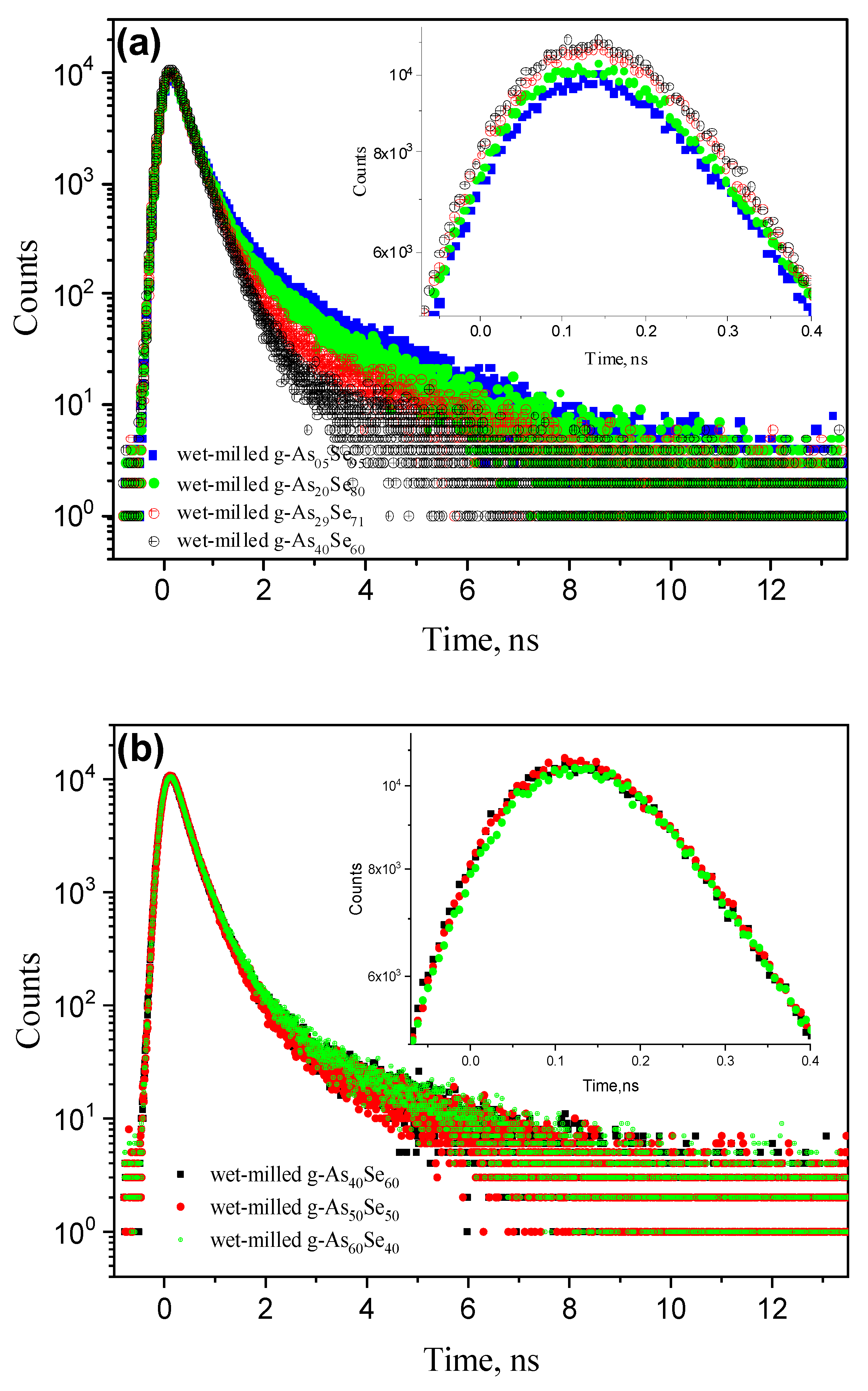

2.2. The PAL Spectra Recording and Preliminary Treatment

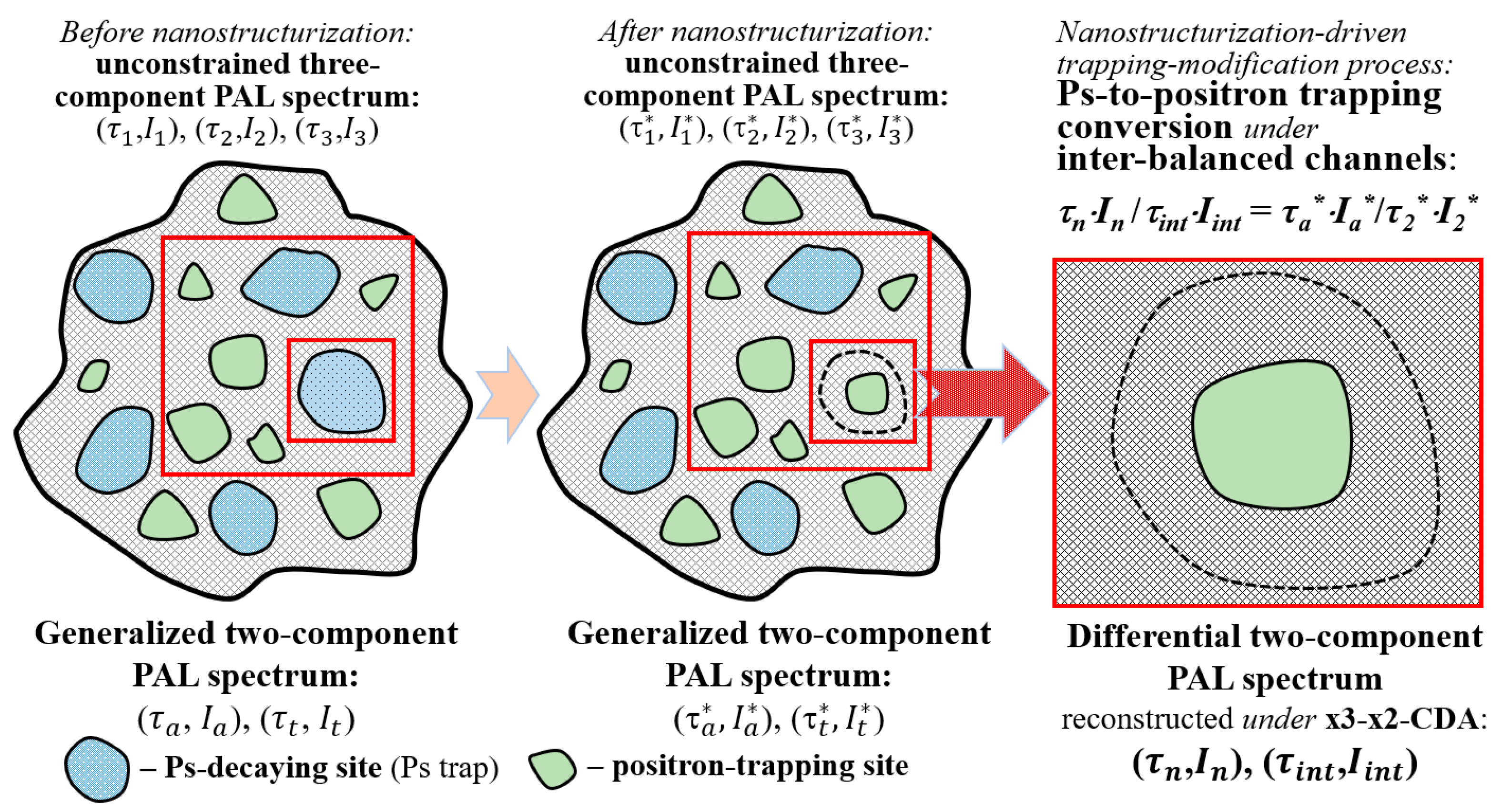

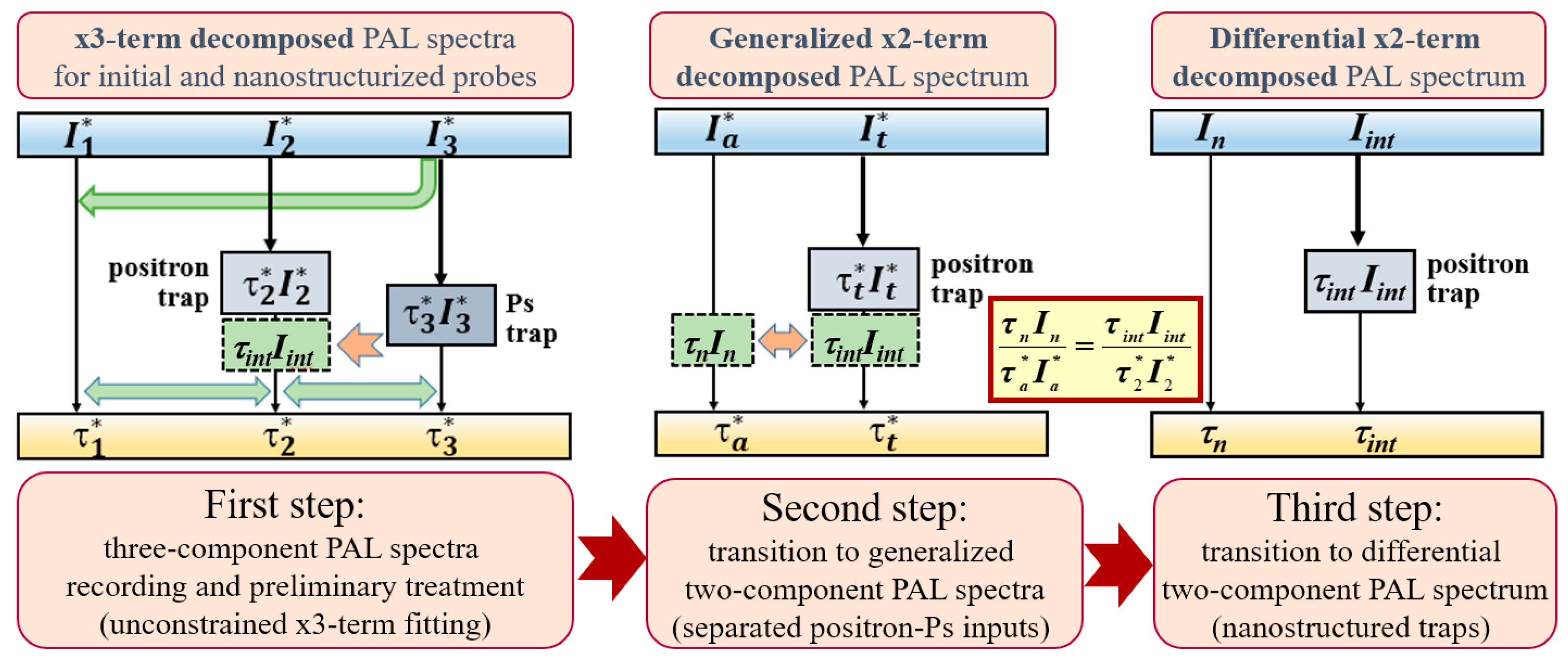

2.3. Algorithmization of the Multi-Channel PAL Spectra in Nanocomposites

2.3.1. Canonical Two-State STM Ignoring Ps-Decaying

2.3.2. Three-State Additive (Mixed Positron-Ps) STM

2.3.3. Two-State Ps-Positron Trapping-Conversion Model (TCM)

3. Results and Discussion

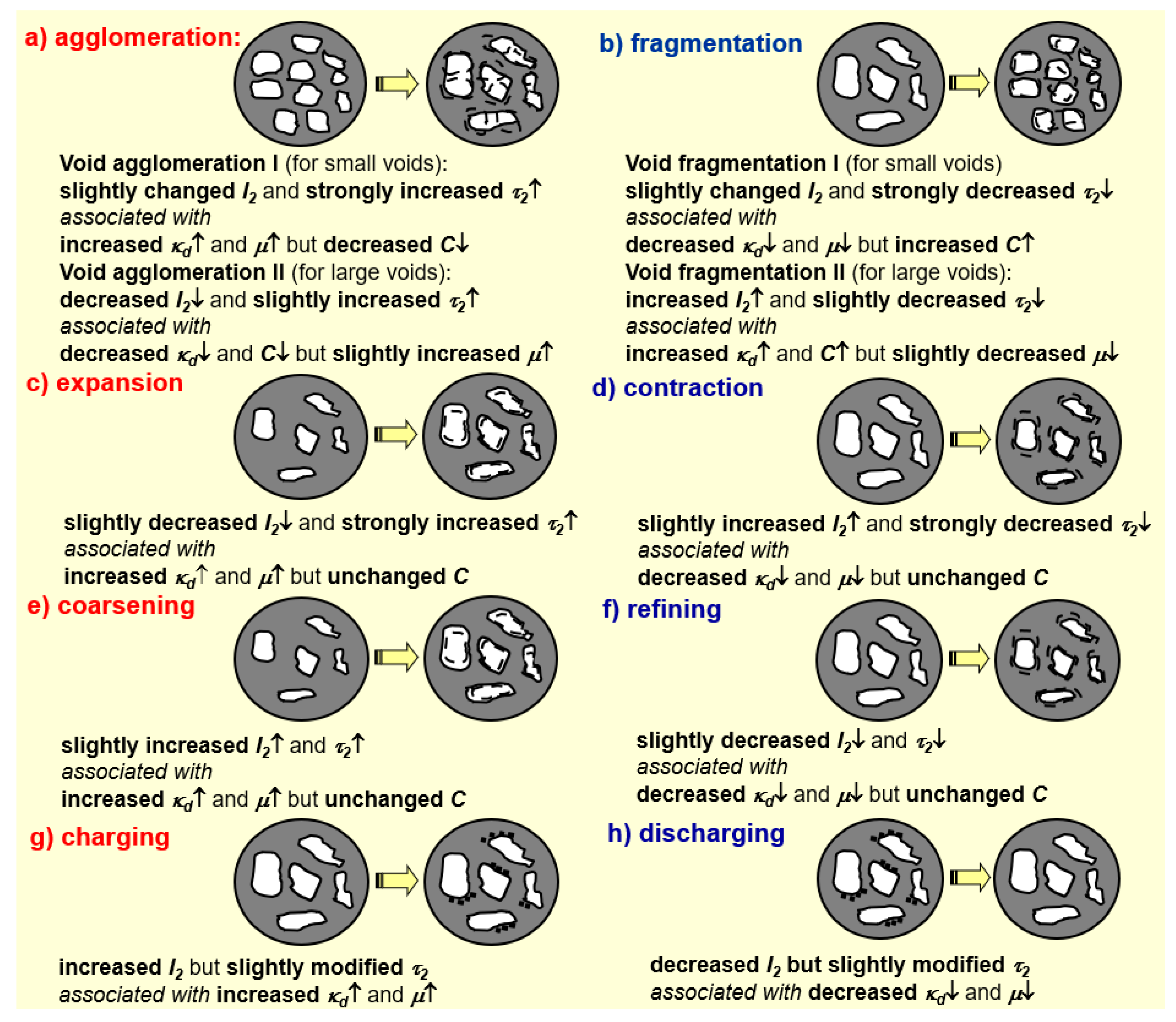

3.1. Volumetric Nanostructurization in g-AsxSe100−x under Modified Two-State STM

3.2. Volumetric Nanostructurization in Dry-Milled and Wet-Milled g-AsxSe100−x in Terms of Ps-to-Positron Trapping Conversion (x3-x2-CDA)

3.3. Positronics of Nanostructurization-Driven Volumetric Effects in g-AsxSe100−x

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Adam, J.-L.; Zhang, X. Chalcogenide Glasses: Preparation, Properties and Application; Woodhead Publishing Series in Electronic and Optical Mater: Philadelphia, PA, USA, 2013; pp. 1–717. [Google Scholar]

- Feltz, A. Amorphous Inorganic Materials and Glasses; VCH: Weinheim, Germany, 1993; pp. 1–446. [Google Scholar]

- Cui, S.; Chahal, R.; Shpotyuk, Y.; Boussard, C.; Lucas, J.; Charpentier, F.; Tariel, H.; Loreal, O.; Nazabal, V.; Sire, O.; et al. Selenide and telluride glasses for mid-infrared bio-sensing. Proc. SPIE 2014, 8938, 893805. [Google Scholar] [CrossRef]

- Dilda, P.J.; Hogg, P.J. Arsenical-based cancer drugs. Cancer Treat. Rev. 2007, 33, 542–564. [Google Scholar] [CrossRef] [PubMed]

- Ding, W.; Zhang, L.; Kim, S.; Tian, W.; Tong, Y.; Liu, J.; Ma, Y.; Chen, S. Arsenic sulfide as a potential anti-cancer drug. Molec. Med. Rep. 2015, 11, 968–974. [Google Scholar] [CrossRef] [Green Version]

- Tian, Y.; Wang, X.; Xi, R.; Pan, W.; Jiang, S.; Li, Z.; Zhao, Y.; Gao, G.; Liu, D. Enhanced antitumor activity of realgar mediated by milling it to nanosize. Intern. J. Nanomed. 2014, 9, 745–757. [Google Scholar] [CrossRef]

- Wu, J.-Z.; Ho, P.C. Evaluation of the in vitro activity and in vivo bioavailability of realgar nanoparticles prepared by cryo-grinding. Eur. J. Pharm. Sci. 2006, 29, 35–44. [Google Scholar] [CrossRef]

- Bujnakova, Z.; Balaz, P.; Makreski, P.; Jovanovski, G.; Caplovicova, M.; Caplovic, L.; Shpotyuk, O.; Ingram, A.; Lee, T.-C.; Cheng, J.-J.; et al. Arsenic sulfide nanoparticles prepared by milling: Properties, free-volume characterization, and anti-cancer effects. J. Mater. Sci. 2015, 50, 1973–1985. [Google Scholar] [CrossRef]

- Shpotyuk, O.; Bujňáková, Z.; Baláž, P.; Ingram, A.; Demchenko, P.; Kovalskiy, A.; Vlcek, M.; Shpotyuk, Y.; Cebulski, J.; Dziedzic, A. Nanostructurization effects in PVP-stabilized tetra-arsenic tetrasulfide As4S4 nanocomposites. Mater. Chem. Phys. 2017, 186, 251–260. [Google Scholar] [CrossRef]

- Baláž, P.; Achimovicova, M.; Baláž, M.; Billik, P.; Cherkezova-Zheleva, Z.; Manuel Criado, J.; Delogu, F.; Dutkova, E.; Gaffet, E.; Gotor, F.J.; et al. Hallmarks of mechanochemistry: From nanoparticles to technology. Chem. Soc. Rev. 2013, 42, 7571–7637. [Google Scholar] [CrossRef] [Green Version]

- Baláž, P.; Baláž, M.; Shpotyuk, O.; Demchenko, P.; Vlcek, M.; Shopska, M.; Briančin, J.; Bujňáková, Z.; Shpotyuk, Y.; Selepová, B.; et al. Properties of arsenic sulphide (β-As4S4) modified by mechanical activation. J. Mater. Sci. 2017, 52, 1747–1758. [Google Scholar] [CrossRef]

- Boldyreva, E. Mechanochemistry of inorganic and organic systems: What is similar, what is different? Chem. Soc. Rev. 2013, 42, 7719–7738. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, G.; Naskar, M.K.; Patra, A.; Chatterjee, M. Synthesis and characterization of PVP-encapsulated ZnS nanoparticles. Opt. Mater. 2006, 28, 1047–1053. [Google Scholar] [CrossRef]

- Saravanan, I.; Diwakar, S.; Mohankumar, R.; Pandurangan, A.; Jayavel, R. Synthesis, Structural and Optical Properties of PVP Encapsulated CdS Nanoparticles. Nanomater. Nanotechnol. 2011, 1, 42–48. [Google Scholar] [CrossRef]

- Shpotyuk, O.; Ingram, A.; Shpotyuk, Y.; Bujňáková, Z.; Baláž, P. PVP-stabilized arsenic sulfide As4S4 nanocomposites probed with positron annihilation lifetime spectroscopy. Polym. Eng. Sci. 2017, 57, 502–505. [Google Scholar] [CrossRef]

- West, R.N. Positron studies of condensed matter. Adv. Phys. 1973, 22, 263–383. [Google Scholar] [CrossRef]

- Saarinen, K.; Hautojarvi, P.; Corbel, C. Positron annihilation spectroscopy of defects in semiconductors. Semicond. Semimet. 1998, 51A, 210–285. [Google Scholar] [CrossRef]

- Krause-Rehberg, R.; Leipner, H. Positron Annihilation in Semiconductors: Defect Studies; Springer: Berlin/Heidelberg, Germany, 1999; pp. 1–350. [Google Scholar]

- Tuomisto, F.; Makkonen, I. Defect identification in semiconductors with positron annihilation: Experiment and theory. Rev. Mod. Phys. 2013, 85, 1583–1631. [Google Scholar] [CrossRef] [Green Version]

- Shpotyuk, M.; Ingram, A.; Shpotyuk, O. Characterization of radiation-induced effects in amorphous arsenic sulfides by positron annihilation lifetime spectroscopy. J. Mater. Res. 2015, 30, 1422–1429. [Google Scholar] [CrossRef]

- Shpotyuk, O.; Filipecki, J.; Ingram, A.; Golovchak, R.; Vakiv, M.; Klym, H.; Balitska, V.; Shpotyuk, M.; Kozdras, A. Positronics of subnanometer atomistic imperfections in solids as a high-informative structure characterization tool. Nanoscale Res. Lett. 2015, 10, 77. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shpotyuk, O.; Ingram, A.; Shpotyuk, Y. Free-volume characterization of nanostructurized substances by positron annihilation lifetime spectroscopy. Nucl. Instr. Meth. Phys. Res. 2018, 416, 102–109. [Google Scholar] [CrossRef]

- Shpotyuk, Y.; Cebulski, J.; Ingram, A.; Shpotyuk, O. Mathematical modelling of elementary trapping-reduction processes in positron annihilation lifetime spectroscopy: Methodology of Ps-to-positron trapping conversion. J. Phys. 2017, 936, 012049. [Google Scholar] [CrossRef]

- Jean, Y.C.; Mallon, P.E.; Schrader, D.M. Principles and Application of Positron and Positronium Chemistry; World Scientific: Singapore, 2003; pp. 1–406. [Google Scholar]

- Kansy, J. Microcomputer program for analysis of positron annihilation lifetime spectra. J. Nucl. Instr. Meth. Phys. Res. 1996, 374, 235–244. [Google Scholar] [CrossRef]

- Deng, Q.; Sundar, C.S.; Jean, Y.C. Pressure dependence of free-volume hole properties in an epoxy polymer. J. Phys. Chem. 1992, 96, 492–495. [Google Scholar] [CrossRef]

- Dlubek, G.; Saarinen, K.; Fretwell, H.M. Positron states in polyethylene and polytetrafluoroethylene: A positron lifetime and Doppler-broadening study. Nucl. Instr. Meth. Phys. Res. 1998, 142, 139–155. [Google Scholar] [CrossRef]

- Dlubek, G.; Clarke, A.P.; Fretwell, H.M.; Dugdale, S.B.; Alam, M.A. Positron lifetime studies of free volume4 hole size distribution in glassy polycarbonate and polysterene. Phys. Stat. Sol. 1996, 157, 351–364. [Google Scholar] [CrossRef]

- Pascual-Izarra, C.; Dong, A.W.; Pas, S.J.; Hill, A.J.; Boyd, B.J.; Drummond, C.J. Advanced fitting algorithms for analysing positron annihilation lifetime spectra. Nucl. Instr. Meth. Phys. Res. 2009, 603, 456–466. [Google Scholar] [CrossRef]

- Shpotyuk, O.; Filipecki, J. Radiation-induced defects in vitreous chalcogenide semiconductors studied by positron annihilation method. Mater. Sci. Eng. 2002, 91–92, 537–540. [Google Scholar] [CrossRef]

- Ghosh, S.; Nambissan, P.M.G.; Bhattacharya, R. Positron annihilation and Mössbauer spectroscopic studies of In3+ substitution effects in bulk and nanocrystalline MgMn0.1Fe1.9−xInxO4. Phys. Lett. 2004, 325, 301–308. [Google Scholar] [CrossRef]

- Castelli, F.; Consolatti, G.; Marlotti, G.T. Positronium confined in nanocavities: The role of electron exchange correlations. Nanomaterials 2021, 11, 2350. [Google Scholar] [CrossRef] [PubMed]

- Chakraverty, S.; Mitra, S.; Mandal, K.; Nambissan, P.M.G.; Chattopadhyay, S. Positron annihilation studies of some anomalous features of NiFe2O4 nanocrystals grown in SiO2. Phys. Rev. 2005, 71, 024115. [Google Scholar] [CrossRef]

- Mitra, S.; Mandal, K.; Sinha, S.; Nambissan, P.M.G.; Kumar, S. Size and temperature dependent cationic redistribution in NiFe2O4 (SiO2) nanocomposites: Positron annihilation and Mössbauer studies. J. Phys. 2006, 39, 4228–4235. [Google Scholar] [CrossRef]

- Shpotyuk, O.; Ingram, A.; Filipecki, J.; Bujňáková, Z.; Baláž, P. Positron annihilation lifetime study of atomic imperfections in nanostructurized solids: On the parameterized trapping in wet-milled arsenic sulphides As4S4. Phys. Stat. Sol. 2016, 253, 1054–1059. [Google Scholar] [CrossRef]

- Shpotyuk, O.; Ingram, A.; Shpotyuk, O. Photopolymerization shrinkage in dimethacrylate-based dental restorative composites probed by means of positron annihilation lifetime spectroscopy. Polymer 2020, 196, 122485. [Google Scholar] [CrossRef]

- Shpotyuk, O.; Ingram, A.; Shpotyuk, Y.; Filipecki, J.; Shpotyuk, O. Volumetric effects in the degradation of dimethacrylate-based polymer/filler nanocomposites: A positron annihilation study. Polym. Degrad. Stab. 2020, 176, 109150. [Google Scholar] [CrossRef]

- Bujňáková, Z.; Kello, M.; Kováč, J.; Tóthová, E.; Shpotyuk, O.; Baláž, P.; Mojžiš, J.; Andrejko, S. Preparation of As4S4/Fe3O4 nanosuspensions and in-vitro verification of their anticancer activity. Mater. Sci. Eng. 2020, 110, 110683. [Google Scholar] [CrossRef] [PubMed]

- Hautojarvi, P.; Pollanen, L.; Vehanen, A.; Yli-Kauppila, J. Vacancies and carbon impurities in α-irom: Neutron irradiation. J. Nucl. Mater. 1983, 14, 250–259. [Google Scholar] [CrossRef]

- Mascher, P.; Dannefaer, S.; Kerr, D. Positron trapping rates and their temperature dependencies in electron-irradiated silicon. Phys. Rev. 1989, 40, 11764–11771. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Kitai, A.H.; Mascher, P. Point defects and luminescence centers in zinc oxide and zinc oxide doped with manganese. J. Lumin. 1992, 54, 35–42. [Google Scholar] [CrossRef]

- Vijay, Y.K.; Wate, S.; Awasthi, D.K.; Das, D.; Ghughre, S. Ion induced effects in polymers. Indian J. Eng. Mater. Sci. 2000, 7, 375–377. [Google Scholar]

- Shantarovich, V.P.; Goldanskii, V.I. Positron annihilation in free volume elements of polymer structures. Hyperfine Interact. 1998, 116, 67–81. [Google Scholar] [CrossRef]

- Wan, Y.; Yang, H.; Zhao, D. “Host-Guest” Chemistry in the Synthesis of Ordered Nonsiliceous Mesoporous Materials. Accounts Chem. Res. 2006, 39, 423–432. [Google Scholar] [CrossRef]

- Hill, A.J.; Freeman, B.D.; Jaffe, M.; Merkel, T.C.; Pinnau, I. Tailoring nanospace. J. Molec. Struct. 2005, 739, 173–178. [Google Scholar] [CrossRef]

- Dlubek, G.; Taesler, C.; Pompe, G.; Piontek, J.; Petters, K.; Redmann, F.; Krause-Regberg, R. Interdiffusion in a particle matrix system of two miscible polymers: An investigation by positron annihilation lifetime spectroscopy and differential scanning calorimetry. J. Appl. Polym. Sci. 2002, 84, 654–664. [Google Scholar] [CrossRef]

- Shpotyuk, O.; Bujňáková, Z.; Baláž, P.; Ingram, A.; Shpotyuk, Y. Positron annihilation lifetime study of polyvinylpyrrolidone for nanoparticle-stabilizing pharmaceuticals. J. Pharm. Biomed. Anal. 2016, 117, 419–425. [Google Scholar] [CrossRef] [PubMed]

- Jensen, K.O.; Salmon, P.S.; Penfold, I.T.; Coleman, P.G. Microvoids in chalcogenide glasses studied by positron annihilation. J. Non-Cryst. Solids 1994, 170, 57–64. [Google Scholar] [CrossRef]

- Shpotyuk, O.; Filipecki, J. Free Volume in Vitreous Chalcogenide Semiconductors: Possibilities of Positron Annihilation Lifetime Study; WSP: Czestochowa, Poland, 2003; pp. 1–114. [Google Scholar]

- Hyla, M.; Filipecki, J.; Shpotyuk, O.; Popescu, M.; Balitska, V. Stoichiometric arsenic sulphoselenides as testing probes for positron trapping in chalcogenide glasses. J. Optoelectron. Adv. Mat. 2007, 9, 3177–3181. [Google Scholar]

- Shpotyuk, O.; Golovchak, R.; Ingram, A.; Boyko, V.; Shpotyuk, L. Comparative study of extended free-volume defects in As- and Ge-based glassy semiconductors: Theoretical prediction and experimental probing with PAL technique. Phys. Stat. Sol. 2013, 10, 117–120. [Google Scholar] [CrossRef]

- Shpotyuk, O.; Ingram, A.; Shpotyuk, M.; Filipecki, J. Prediction of free-volume-type correlations in glassy chalcogenides from positron lifetime measurements. Nucl. Instr. Meth. Phys. Res. 2014, 338, 66–71. [Google Scholar] [CrossRef]

- Shpotyuk, O.; Filipecki, J.; Shpotyuk, M.; Ingram, A. Free volume evolution in chalcogenide glasses as probed by PAL spectroscopy. Solid State Ion. 2014, 267, 38–43. [Google Scholar] [CrossRef]

- Ingram, A.; Golovchak, R.; Kostrzewa, M.; Wacke, S.; Shpotyuk, M.; Shpotyuk, O. Compositional dependences of average positron lifetime in binary As-S/Se glasses. Phys. B Condens. Matter 2012, 407, 652–655. [Google Scholar] [CrossRef]

- Hyla, M. Compositional anomalies in Se-rich As-Se glass-forming system as revealed from positron annihilation lifetime spectroscopy and ab initio cluster modeling. Comp. Mater. Sci. 2017, 135, 165–168. [Google Scholar] [CrossRef]

- Shpotyuk, O.; Hyla, M.; Boyko, V. Compositionally-dependent structural variations in glassy chalcogenides: The case of binary As-Se system. Comp. Mater. Sci. 2015, 110, 144–151. [Google Scholar] [CrossRef]

- Shpotyuk, Y.; Demchenko, P.; Bujňáková, Z.; Baláž, P.; Boussard-Pledel, C.; Bureau, B.; Shpotyuk, O. Effect of high-energy mechanical milling on the medium-range ordering in glassy As-Se. J. Am. Ceram. Soc. 2020, 103, 1631–1646. [Google Scholar] [CrossRef]

- Shpotyuk, Y.; Demchenko, P.; Shpotyuk, O.; Balitska, V.; Boussard-Pledel, C.; Bureau, B.; Lukáčová Bujňáková, Z.; Baláž, P. High-energy mechanical milling-driven reamorphization in glassy arsenic monoselenide g-AsSe: On the path tailoring special molecular-network glasses. Materials 2021, 14, 4478. [Google Scholar] [CrossRef] [PubMed]

- Shpotyuk, O.; Ingram, A.; Bujňáková, Z.; Baláž, P.; Shpotyuk, Y. Probing sub-atomistic free-volume imperfections in dry-milled nanoarsenicals with PAL spectroscopy. Nanoscale Res. Lett. 2016, 11, 10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shpotyuk, O.; Baláž, P.; Bujňáková, Z.; Ingram, A.; Demchenko, P.; Shpotyuk, Y. Mechanochemically driven amorphization of nanostructurized arsenicals, the case of β-As4S4. J. Mater. Sci. 2018, 53, 13464–13476. [Google Scholar] [CrossRef] [Green Version]

- Shpotyuk, O.; Ingram, A.; Baláž, P.; Bujňáková, Z.; Shpotyuk, Y.; Cebulski, J. Free volume studies on mechanochemically-milled β-As4S4 arsenical employing positron annihilation lifetime spectroscopy. Appl. Nanosci. 2019, 9, 647–656. [Google Scholar] [CrossRef]

- Palumbo, G.; Erb, U.; Aust, K.T. Triple line disclination effects on the mechanical behaviour of materials. Scr. Matallurgica Mater. 1990, 24, 2347–2350. [Google Scholar] [CrossRef]

- Palumbo, G.; Thorpe, S.J.; Aust, K.T. On the contribution of triple junctions to the structure and properties of nanocrystalline materials. Scr. Matallurgica Materialia. 1990, 24, 1347–1350. [Google Scholar] [CrossRef]

- Chattopadhyay, P.P.; Nambissan, P.M.G.; Pabi, S.K.; Manna, I. Polymorphic bcc to fcc transformation of nanocrystalline niobium studied by positron annihilation. Phys. Rev. 2001, 63, 054107. [Google Scholar] [CrossRef] [Green Version]

- Lavanya, K.; Senthil, V.; Rathi, V. Pelletization technology: A quick review. Int. J. Pharm. Sci. Res. 2011, 2, 1337–1355. [Google Scholar] [CrossRef]

- Hammannavar, P.B.; Lobo, B.; Nambissan, P.M.G. Positron annihilation studies of free volume changes accompanying the incorporation of lead nitrate in PVA-PVP polymeric blend. Rad. Phys. Chem. 2019, 158, 53–60. [Google Scholar] [CrossRef]

| Samples g-AsxSe100−x, x | χ = [FIT–1] | PAL Spectra Fitting Parameters | τav. | ||||

|---|---|---|---|---|---|---|---|

| τ1 | τ2 | τ3 | I2 | I3 | |||

| ns | ns | ns | a.u. | a.u. | ns | ||

| PVP pellets [47] | 0.20 | 0.196 | 0.472 | 1.867 | 0.256 | 0.119 | 0.466 |

| Unmilled, x = 5 | 0.04 | 0.217 | 0.377 | 2.000 | 0.300 | 0.011 | 0.285 |

| Dry-milled, x = 5 | 0.04 | 0.210 | 0.369 | 2.137 | 0.340 | 0.011 | 0.285 |

| Wet-milled, x = 5 | 0.03 | 0.212 | 0.495 | 1.764 | 0.303 | 0.112 | 0.472 |

| Unmilled, x = 10 | 0.03 | 0.216 | 0.380 | 2.232 | 0.290 | 0.012 | 0.288 |

| Dry-milled, x = 10 | 0.04 | 0.212 | 0.360 | 2.112 | 0.350 | 0.011 | 0.285 |

| Wet-milled, x = 10 | 0.07 | 0.202 | 0.438 | 1.708 | 0.348 | 0.101 | 0.436 |

| Unmilled, x = 20 | 0.03 | 0.213 | 0.368 | 2.103 | 0.340 | 0.015 | 0.294 |

| Dry-milled, x = 20 | 0.04 | 0.215 | 0.368 | 2.157 | 0.330 | 0.011 | 0.287 |

| Wet-milled, x = 20 | 0.07 | 0.211 | 0.454 | 1.706 | 0.303 | 0.086 | 0.413 |

| Unmilled, x = 29 | 0.03 | 0.212 | 0.365 | 2.117 | 0.370 | 0.012 | 0.291 |

| Dry-milled, x = 29 | 0.05 | 0.212 | 0.368 | 2.057 | 0.360 | 0.011 | 0.290 |

| Wet-milled, x = 29 | 0.19 | 0.206 | 0.390 | 1.747 | 0.342 | 0.042 | 0.334 |

| Unmilled, x = 40 | 0.01 | 0.193 | 0.358 | 2.091 | 0.620 | 0.007 | 0.309 |

| Dry-milled, x = 40 | 0.05 | 0.202 | 0.371 | 2.087 | 0.540 | 0.015 | 0.322 |

| Wet-milled, x = 40 | 0.07 | 0.212 | 0.428 | 1.891 | 0.400 | 0.052 | 0.386 |

| Unmilled, x = 45 | 0.04 | 0.185 | 0.352 | 1.964 | 0.670 | 0.008 | 0.311 |

| Dry-milled, x = 45 | 0.06 | 0.204 | 0.379 | 2.337 | 0.520 | 0.015 | 0.327 |

| Wet-milled, x = 45 | 0.08 | 0.201 | 0.405 | 1.855 | 0.500 | 0.047 | 0.382 |

| Unmilled, x = 50 | 0.06 | 0.205 | 0.370 | 2.106 | 0.540 | 0.015 | 0.323 |

| Dry-milled, x = 50 | 0.05 | 0.210 | 0.378 | 2.264 | 0.520 | 0.013 | 0.324 |

| Wet-milled, x = 50 | 0.08 | 0.207 | 0.411 | 1.833 | 0.440 | 0.049 | 0.381 |

| Unmilled, x = 55 | 0.07 | 0.207 | 0.370 | 2.183 | 0.510 | 0.014 | 0.318 |

| Dry-milled, x = 55 | 0.06 | 0.195 | 0.369 | 2.128 | 0.570 | 0.015 | 0.323 |

| Wet-milled, x = 55 | 0.08 | 0.202 | 0.419 | 1.845 | 0.460 | 0.065 | 0.409 |

| Unmilled, x = 60 | 0.05 | 0.194 | 0.359 | 2.108 | 0.580 | 0.015 | 0.318 |

| Dry-milled, x = 60 | 0.05 | 0.204 | 0.382 | 2.339 | 0.520 | 0.015 | 0.329 |

| Wet-milled, x = 60 | 0.06 | 0.216 | 0.442 | 1.903 | 0.400 | 0.059 | 0.406 |

| Unmilled, x = 65 | 0.06 | 0.207 | 0.367 | 2.098 | 0.520 | 0.015 | 0.319 |

| Dry-milled, x = 65 | 0.04 | 0.198 | 0.371 | 2.180 | 0.560 | 0.015 | 0.333 |

| Wet-milled, x = 65 | 0.07 | 0.202 | 0.403 | 1.914 | 0.470 | 0.049 | 0.380 |

| Samples g-AsxSe100−x, x | Positron Trapping Modes | Ps-Decay Modes | ||||||

|---|---|---|---|---|---|---|---|---|

| τavtr. | τb | κd | τ2 − τb | τ2/τb | ηd | R3 | fv | |

| ns | ns | ns−1 | ns | a.u. | a.u. | nm | % | |

| PVP pellets [47] | 0.276 | 0.236 | 0.87 | 0.24 | 1.99 | 0.17 | 0.276 | 1.88 |

| Unmilled, x = 5 | 0.276 | 0.249 | 0.59 | 0.13 | 1.52 | 0.13 | 0.288 | 0.20 |

| Dry-milled, x = 5 | 0.265 | 0.247 | 0.71 | 0.12 | 1.50 | 0.15 | 0.300 | 0.23 |

| Wet-milled, x = 5 | 0.309 | 0.263 | 0.92 | 0.23 | 1.88 | 0.20 | 0.271 | 1.60 |

| Unmilled, x = 10 | 0.264 | 0.247 | 0.59 | 0.13 | 1.54 | 0.13 | 0.307 | 0.26 |

| Dry-milled, x = 10 | 0.264 | 0.248 | 0.69 | 0.11 | 1.45 | 0.15 | 0.298 | 0.21 |

| Wet-milled, x = 10 | 0.293 | 0.255 | 1.03 | 0.18 | 1.72 | 0.21 | 0.259 | 1.32 |

| Unmilled, x = 20 | 0.267 | 0.249 | 0.68 | 0.12 | 1.48 | 0.15 | 0.297 | 0.29 |

| Dry-milled, x = 20 | 0.266 | 0.250 | 0.65 | 0.12 | 1.47 | 0.14 | 0.301 | 0.22 |

| Wet-milled, x = 20 | 0.292 | 0.257 | 0.84 | 0.20 | 1.77 | 0.18 | 0.259 | 1.13 |

| Unmilled, x = 29 | 0.269 | 0.251 | 0.74 | 0.11 | 1.45 | 0.16 | 0.298 | 0.24 |

| Dry-milled, x = 29 | 0.271 | 0.253 | 0.70 | 0.12 | 1.47 | 0.15 | 0.293 | 0.21 |

| Wet-milled, x = 29 | 0.272 | 0.248 | 0.82 | 0.14 | 1.58 | 0.17 | 0.263 | 0.57 |

| Unmilled, x = 40 | 0.296 | 0.271 | 1.49 | 0.09 | 1.32 | 0.29 | 0.296 | 0.15 |

| Dry-milled, x = 40 | 0.295 | 0.269 | 1.24 | 0.10 | 1.37 | 0.25 | 0.296 | 0.29 |

| Wet-milled, x = 40 | 0.303 | 0.269 | 1.00 | 0.16 | 1.58 | 0.21 | 0.277 | 0.83 |

| Unmilled, x = 45 | 0.298 | 0.272 | 1.73 | 0.08 | 1.30 | 0.32 | 0.270 | 0.11 |

| Dry-milled, x = 45 | 0.296 | 0.270 | 1.20 | 0.11 | 1.40 | 0.24 | 0.318 | 0.35 |

| Wet-milled, x = 45 | 0.308 | 0.273 | 1.31 | 0.14 | 1.54 | 0.26 | 0.274 | 0.72 |

| Unmilled, x = 50 | 0.295 | 0.271 | 1.19 | 0.10 | 1.36 | 0.24 | 0.298 | 0.29 |

| Dry-milled, x = 50 | 0.299 | 0.274 | 1.12 | 0.10 | 1.38 | 0.23 | 0.311 | 0.30 |

| Wet-milled, x = 50 | 0.301 | 0.268 | 1.10 | 0.14 | 1.53 | 0.23 | 0.272 | 0.74 |

| Unmilled, x = 55 | 0.291 | 0.268 | 1.10 | 0.10 | 1.38 | 0.23 | 0.304 | 0.30 |

| Dry-milled, x = 55 | 0.296 | 0.268 | 1.40 | 0.10 | 1.38 | 0.27 | 0.300 | 0.31 |

| Wet-milled, x = 55 | 0.309 | 0.271 | 1.26 | 0.15 | 1.25 | 0.26 | 0.273 | 0.99 |

| Unmilled, x = 60 | 0.291 | 0.266 | 1.40 | 0.09 | 1.35 | 0.27 | 0.298 | 0.30 |

| Dry-milled, x = 60 | 0.298 | 0.271 | 1.21 | 0.11 | 1.41 | 0.25 | 0.318 | 0.36 |

| Wet-milled, x = 60 | 0.312 | 0.276 | 1.01 | 0.17 | 1.61 | 0.22 | 0.278 | 0.97 |

| Unmilled, x = 65 | 0.291 | 0.269 | 1.11 | 0.10 | 1.37 | 0.23 | 0.296 | 0.30 |

| Dry-milled, x = 65 | 0.293 | 0.266 | 1.29 | 0.10 | 1.35 | 0.26 | 0.304 | 0.32 |

| Wet-milled, x = 65 | 0.301 | 0.268 | 1.22 | 0.14 | 1.22 | 0.25 | 0.279 | 0.80 |

| Samples g-AsxSe100-x, x | τB1–2 | κd1 | κd2 | κd1/κd2 |

|---|---|---|---|---|

| ns | ns−1 | ns−1 | a.u. | |

| Unmilled, x = 5 | 0.251 | 0.59 | 0.05 | 11.8 |

| Dry-milled, x = 5 | 0.249 | 0.70 | 0.05 | 14.0 |

| Wet-milled, x = 5 | 0.291 | 0.82 | 0.47 | 1.74 |

| Unmilled, x = 10 | 0.250 | 0.58 | 0.05 | 11.6 |

| Dry-milled, x = 10 | 0.251 | 0.68 | 0.05 | 13.6 |

| Wet-milled, x = 10 | 0.279 | 0.93 | 0.44 | 2.11 |

| Unmilled, x = 20 | 0.253 | 0.67 | 0.06 | 11.2 |

| Dry-milled, x = 20 | 0.252 | 0.64 | 0.06 | 10.7 |

| Wet-milled, x = 20 | 0.277 | 0.77 | 0.36 | 2.14 |

| Unmilled, x = 29 | 0.254 | 0.73 | 0.05 | 14.6 |

| Dry-milled, x = 29 | 0.256 | 0.70 | 0.05 | 14.0 |

| Wet-milled, x = 29 | 0.257 | 0.78 | 0.18 | 4.33 |

| Unmilled, x = 40 | 0.273 | 1.48 | 0.03 | 49.3 |

| Dry-milled, x = 40 | 0.273 | 1.22 | 0.07 | 17.4 |

| Wet-milled, x = 40 | 0.282 | 0.95 | 0.22 | 4.32 |

| Unmilled, x = 45 | 0.274 | 1.72 | 0.04 | 43.0 |

| Dry-milled, x = 45 | 0.273 | 1.18 | 0.07 | 16.9 |

| Wet-milled, x = 45 | 0.283 | 1.25 | 0.21 | 5.95 |

| Unmilled, x = 50 | 0.275 | 1.18 | 0.07 | 16.9 |

| Dry-milled, x = 50 | 0.277 | 1.10 | 0.06 | 18.3 |

| Wet-milled, x = 50 | 0.277 | 1.06 | 0.21 | 5.05 |

| Unmilled, x = 55 | 0.271 | 1.09 | 0.06 | 18.2 |

| Dry-milled, x = 55 | 0.272 | 1.38 | 0.07 | 19.7 |

| Wet-milled, x = 55 | 0.287 | 1.18 | 0.29 | 4.07 |

| Unmilled, x = 60 | 0.270 | 1.37 | 0.07 | 22.8 |

| Dry-milled, x = 60 | 0.274 | 1.19 | 0.07 | 17.0 |

| Wet-milled, x = 60 | 0.291 | 0.95 | 0.24 | 4.17 |

| Unmilled, x = 65 | 0.272 | 1.10 | 0.07 | 15.7 |

| Dry-milled, x = 65 | 0.259 | 1.32 | 0.07 | 18.9 |

| Wet-milled, x = 65 | 0.280 | 1.16 | 0.22 | 5.27 |

| Positron Annihilation Channel | Bulk g-As-Se (Unmilled, Unpelletized) | Cgp g-As-Se (Unmilled, Pelletized) | Fgp g-As-Se (Dry-Milled, Pelletized) | Fgp g-As-Se/PVP (Wet-Milled, Pelletized) |

|---|---|---|---|---|

| {DFB} state | {DFB}g-As-Se–int | {DFB}g-As-Se–int | {DFB}g-As-Se–int | {DFB}g-As-Se–int |

| Positron {e+}-traps | {e+}g-As-Se–int | {e+}g-As-Se–int | {e+}g-As-Se–int | {e+}g-As-Se–int |

| - | {e+}g-As-Se–IF-1 | {e+}g-As-Se–IF-2 | {e+}g-As-Se/PVP–IF-3 | |

| Positronium {Ps}-traps | {Ps}g-As-Se–int-1 | {Ps}g-As-Se–int-2 | {Ps}g-As-Se–int-2 | {Ps}g-As-Se–int-2 |

| - | {Ps}g-As-Se–FVE-1 | {Ps}g-As-Se–FVE-2 | {Ps}g-As-Se/PVP–FVE-3 |

| Sample | I Component | II Component | Positron Trapping Modes | ||||||

|---|---|---|---|---|---|---|---|---|---|

| τn | In | τint | Iint | τavNP | τbNP | κdNP | τint − τbNP | τint/τbNP | |

| ns | a.u. | ns | a.u. | ns | ns | ns−1 | ns | a.u. | |

| x = 5 | 0.210 | 0.573 | 0.357 | 0.310 | 0.261 | 0.245 | 0.69 ≅ 0.7 | 0.11 | 1.46 |

| x = 10 | 0.218 | 0.574 | 0.364 | 0.272 | 0.265 | 0.250 | 0.60 ≅ 0.6 | 0.11 | 1.46 |

| x = 20 | 0.216 | 0.561 | 0.357 | 0.201 | 0.264 | 0.249 | 0.63 ≅ 0.6 | 0.11 | 1.43 |

| x = 33 | 0.212 | 0.475 | 0.362 | 0.304 | 0.270 | 0.253 | 0.77 ≅ 0.8 | 0.11 | 1.44 |

| x = 40 | 0.194 | 0.334 | 0.352 | 0.472 | 0.287 | 0.263 | 1.35 ≅ 1.4 | 0.09 | 1.34 |

| x = 45 | 0.205 | 0.320 | 0.369 | 0.376 | 0.294 | 0.270 | 1.17 ≅ 1.2 | 0.10 | 1.37 |

| x = 50 | 0.211 | 0.351 | 0.368 | 0.403 | 0.295 | 0.274 | 1.08 ≅ 1.1 | 0.10 | 1.35 |

| x = 55 | 0.193 | 0.331 | 0.358 | 0.464 | 0.289 | 0.264 | 1.39 ≅ 1.4 | 0.09 | 1.35 |

| x = 60 | 0.201 | 0.359 | 0.367 | 0.418 | 0.291 | 0.266 | 1.21 ≅ 1.2 | 0.10 | 1.38 |

| x = 65 | 0.193 | 0.315 | 0.353 | 0.433 | 0.286 | 0.261 | 1.37 ≅ 1.4 | 0.09 | 1.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shpotyuk, O.; Ingram, A.; Boussard-Pledel, C.; Bureau, B.; Lukáčová Bujňáková, Z.; Baláž, P.; Mahlovanyi, B.; Shpotyuk, Y. The Art of Positronics in Contemporary Nanomaterials Science: A Case Study of Sub-Nanometer Scaled Glassy Arsenoselenides. Materials 2022, 15, 302. https://doi.org/10.3390/ma15010302

Shpotyuk O, Ingram A, Boussard-Pledel C, Bureau B, Lukáčová Bujňáková Z, Baláž P, Mahlovanyi B, Shpotyuk Y. The Art of Positronics in Contemporary Nanomaterials Science: A Case Study of Sub-Nanometer Scaled Glassy Arsenoselenides. Materials. 2022; 15(1):302. https://doi.org/10.3390/ma15010302

Chicago/Turabian StyleShpotyuk, Oleh, Adam Ingram, Catherine Boussard-Pledel, Bruno Bureau, Zdenka Lukáčová Bujňáková, Peter Baláž, Bohdan Mahlovanyi, and Yaroslav Shpotyuk. 2022. "The Art of Positronics in Contemporary Nanomaterials Science: A Case Study of Sub-Nanometer Scaled Glassy Arsenoselenides" Materials 15, no. 1: 302. https://doi.org/10.3390/ma15010302

APA StyleShpotyuk, O., Ingram, A., Boussard-Pledel, C., Bureau, B., Lukáčová Bujňáková, Z., Baláž, P., Mahlovanyi, B., & Shpotyuk, Y. (2022). The Art of Positronics in Contemporary Nanomaterials Science: A Case Study of Sub-Nanometer Scaled Glassy Arsenoselenides. Materials, 15(1), 302. https://doi.org/10.3390/ma15010302