Interlaboratory Comparison as a Source of Information for the Product Evaluation Process. Case Study of Ceramic Tiles Adhesives

Abstract

:1. Introduction

2. Materials and Methods

2.1. Short History of Interlaboratory Comparisons Organized by Ceprocim

2.2. Ceramic Tile Adhesives (CTAs)

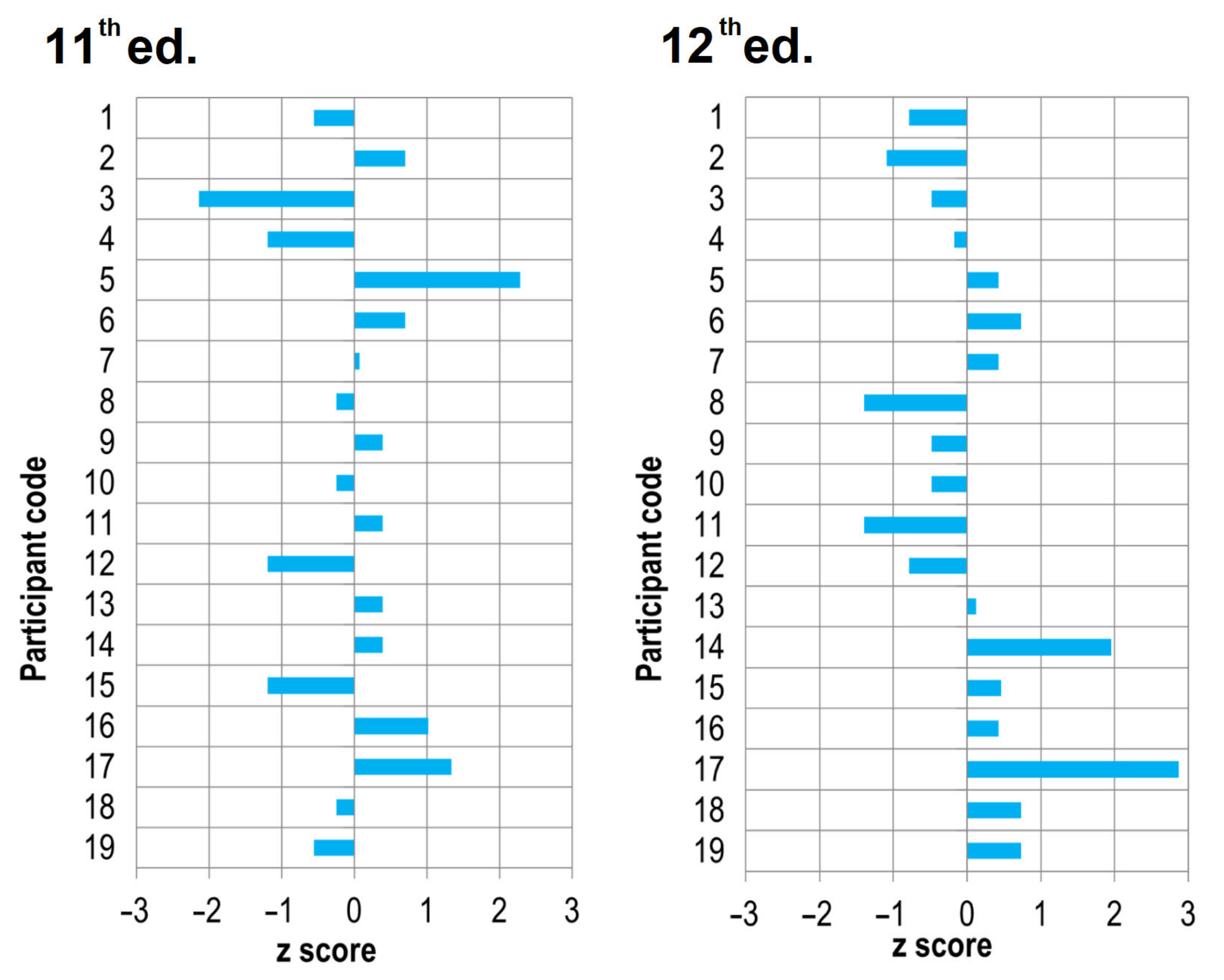

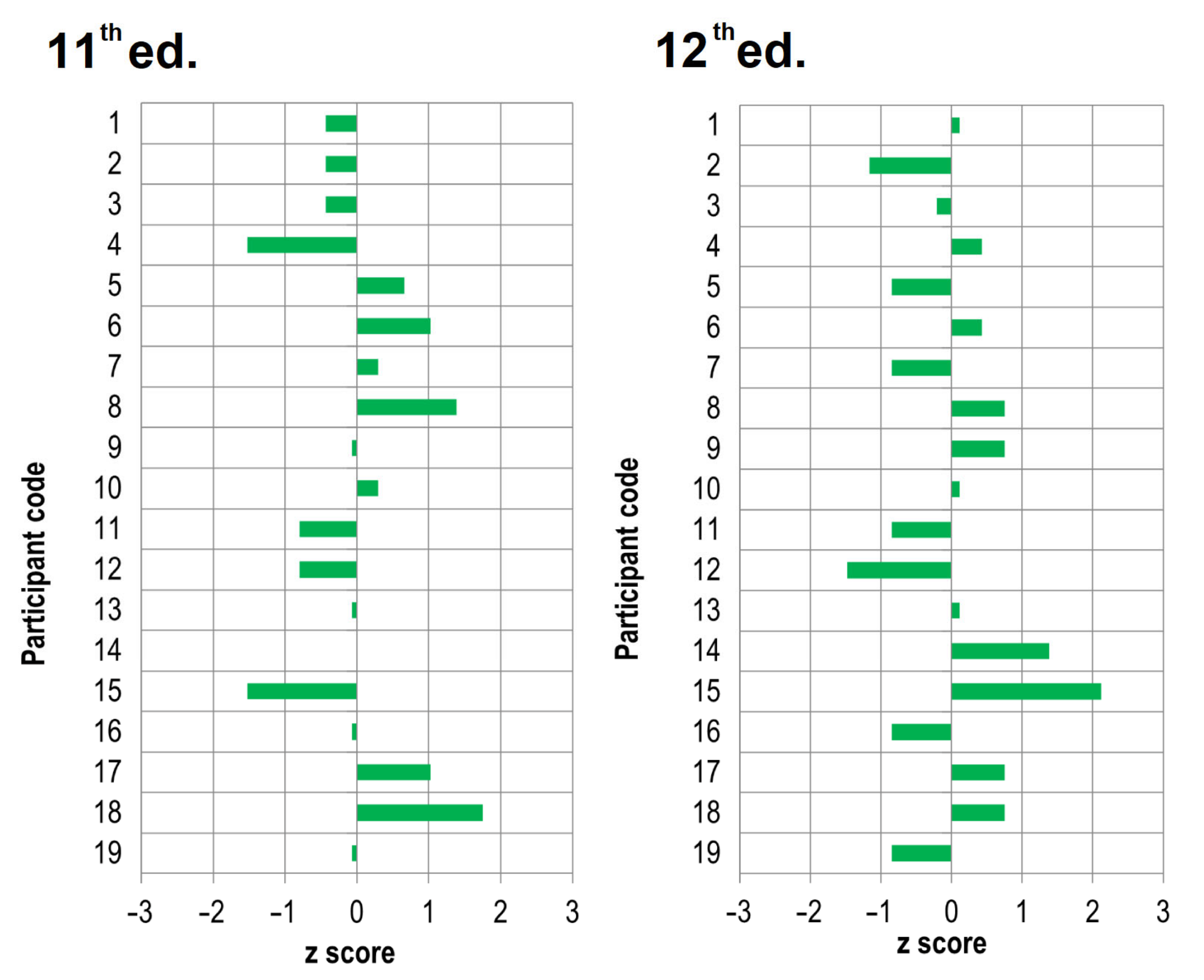

2.3. Evaluation of the Results Using the z-Score

- σpt—standard deviation for proficiency assessment,

- p—the number of participant laboratories that carried on the test on concrete slab.

- xi—the value obtained by each participant for each test,

- xpt—the assigned value on total participants for each test.

- satisfactory, when |z| ≤ 2;

- questionable, when 2 < |z| < 3;

- unsatisfactory, when |z| ≥ 3.

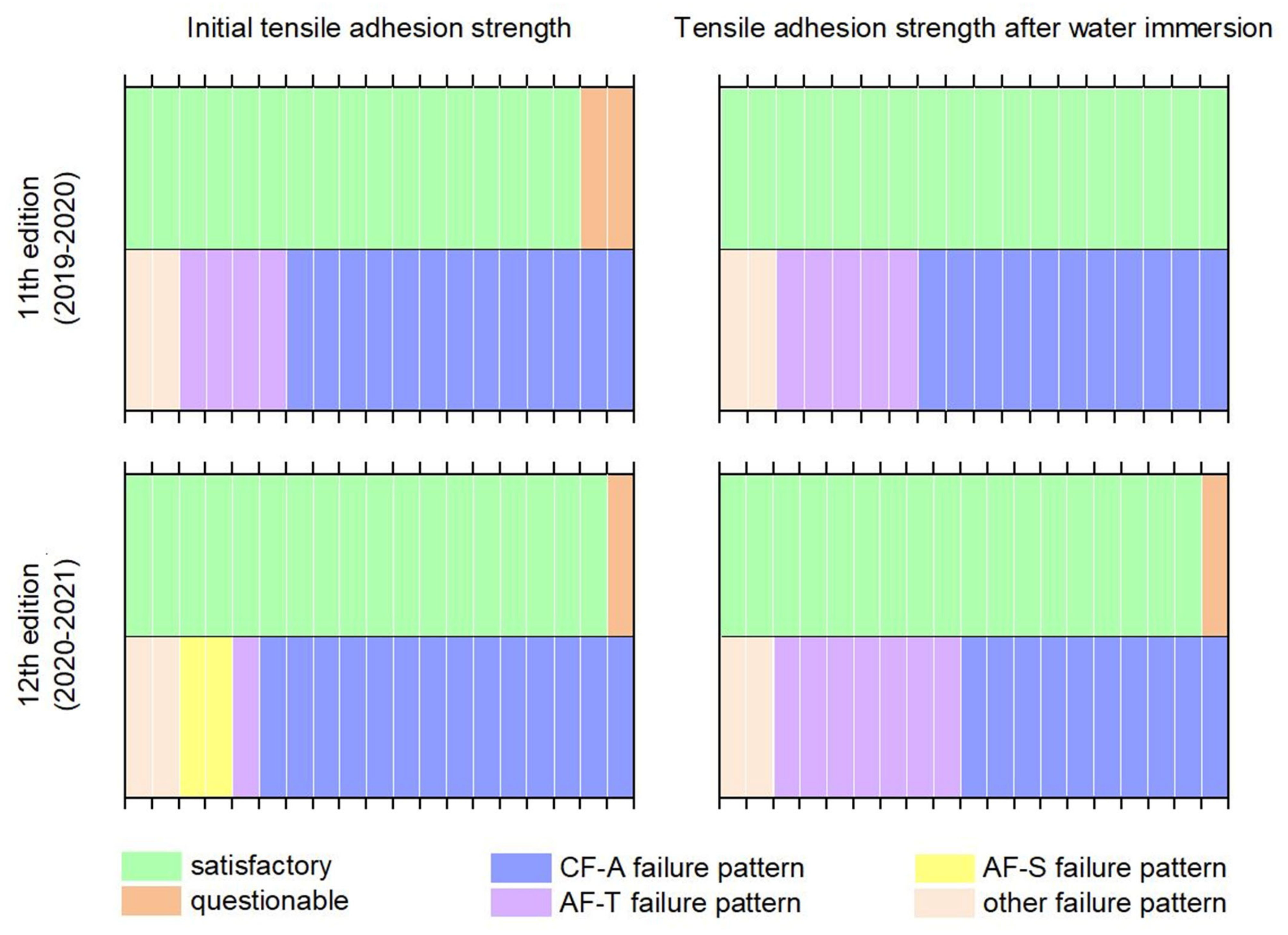

3. Results

4. Discussion

4.1. ILC Results in the Light of ISO 13528 Guidelines

4.2. Factors Influencing the Measurement of Tensile Adhesion Strength

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Regulation (EU). No. 305/2011 of the European Parliament and of the Council. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32011R0305 (accessed on 16 October 2021).

- Zio, E. The future of risk assessment. Reliab. Eng. Syst. Saf. 2018, 177, 176–190. [Google Scholar] [CrossRef] [Green Version]

- Iqbal, S.; Choudhry, R.M.; Holschemacher, K.; Ali, A.; Tamošaitienė, J. Risk management in construction projects. Technol. Econ. Dev. Econ. 2015, 21, 65–78. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Turskis, Z.; Tamošaitiene, J. Risk assessment of construction projects. J. Civil. Eng. Manag. 2010, 16, 33–46. [Google Scholar] [CrossRef] [Green Version]

- Szymański, P. Risk management in construction projects. Procedia Eng. 2017, 208, 174–182. [Google Scholar] [CrossRef]

- Hinrichs, W. The impact of measurement uncertainty on the producer’s and user’s risks, on classification and conformity assessment: An example based on tests on some construction products. Accredit. Qual. Assur. 2010, 15, 289–296. [Google Scholar] [CrossRef]

- Szewczak, E. Ryzyko związane z niepewnością wyników badań i oceną zgodności wyrobów budowlanych. Mater. Bud. 2011, 470(10), 73–75. [Google Scholar]

- Szewczak, E.; Piekarczuk, A. Performance evaluation of the construction products as a research challenge. Small error–big difference in assessment? Bull. Polish Acad. Sci. Tech. Sci. 2016, 64, 675–686. [Google Scholar] [CrossRef] [Green Version]

- Szewczak, E.; Bondarzewski, A. Is the assessment of interlaboratory comparison results for a small number of tests and limited number of participants reliable and rational? Accredit. Qual. Assur. 2016, 21, 91–100. [Google Scholar] [CrossRef] [Green Version]

- Nowicka, E.; Szewczak, E. Indoor Sound Pressure Level from Service Equipment in Buildings: Influence of Testing Methods on Measurement Results. Arch. Acoust. 2021, 46, 547–559. [Google Scholar]

- Łukasik, M.; Michałowski, B.; Michalak, J. Assessment of the Constancy of Performance of Cementitious Adhesives for Ceramic Tiles: Analysis of the Test Results Commissioned by Polish Market Surveillance Authorities. Appl. Sci. 2020, 10, 6561. [Google Scholar] [CrossRef]

- Kulesza, M.; Łukasik, M.; Michalowski, B.; Michalak, J. Risk related to the assessment and verification of the constancy of performance of construction products. Analysis of the results of the tests of cementitious adhesives for ceramic tiles commissioned by Polish construction supervision authorities in 2016–2020. Cement Wapno Beton 2020, 25, 444–456. [Google Scholar]

- Rossi, G.B.; Crenna, F. A probabilistic approach to measurement-based decisions. Measurement 2006, 39, 101–119. [Google Scholar] [CrossRef]

- Magnusson, B.; Näykki, T.; Hovind, H.; Krysell, M. Handbook for Calculation of Measurement Uncertainty in Environmental Laboratories; Nordic Innovation: Oslo, Norway, 2017; Available online: www.nordtest.info (accessed on 14 October 2021).

- Theodorsson, E. Total error vs. measurement uncertainty: Revolution or evolution? Clin. Chem. Lab. Med. 2016, 54, 235–239. [Google Scholar]

- Kallner, A. Is the combination of trueness and precision in one expression meaningful? On the use of total error and uncertainty in clinical chemistry. Clin. Chem. Lab. Med. 2016, 54, 1291–1297. [Google Scholar] [CrossRef]

- Farrance, I.; Badrick, T.; Frenkel, R. Uncertainty in measurement and total error: Different roads to the same quality destination? Clin. Chem. Lab. Med. 2018, 56, 2010–2014. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO/IEC Guide 99:2007 International Vocabulary of Metrology—Basic and General Concepts and Associated Terms (VIM); International Organization for Standardization (ISO): Geneva, Switzerland, 2009. [Google Scholar]

- International Organization of Legal Metrology (OIML). G 1-106 Evaluation of measurement Data—The Role of Measurement Uncertainty in Conformity Assessment; International Organization of Legal Metrology (OIML): Paris, France, 2017. [Google Scholar]

- Szewczak, E.; Winkler-Skalna, A.; Czarnecki, L. Sustainable Test Methods for Construction Materials and Elements. Materials 2020, 13, 606. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kacker, R.N. Measurement uncertainty and its connection with true value in the GUM versus JCGM documents. Measurement 2018, 127, 525–532. [Google Scholar] [CrossRef]

- Forbes, A.B. Measurement uncertainty and optimized conformance assessment. Measurement 2006, 39, 808–814. [Google Scholar] [CrossRef]

- Williams, A. Principles of the EURACHEM/CITAC guide “Use of uncertainty information in compliance assessment”. Accredit. Qual. Assur. 2008, 13, 633–638. [Google Scholar] [CrossRef] [Green Version]

- Pendrill, L.R. Using measurement uncertainty in decision-making and conformity assessment. Metrologia 2014, 51, S206. [Google Scholar] [CrossRef] [Green Version]

- Loftus, P.; Giudice, S. Relevance of methods and standards for the assessment of measurement system performance in a High-Value Manufacturing Industry. Metrologia 2014, 51, S219. [Google Scholar] [CrossRef]

- Desimoni, E.; Brunetti, B. Uncertainty of measurement and conformity assessment: A review. Anal. Bioanal. Chem. 2011, 400, 1729–1741. [Google Scholar] [CrossRef]

- Miller, W.G. The role of proficiency testing in achieving standardization and harmonization between laboratories. Clin. Biochem. 2009, 42, 232–235. [Google Scholar] [CrossRef] [PubMed]

- Koch, M.; Magnusson, B. Use of characteristic functions derived from proficiency testing data to evaluate measurement uncertainties. Accredit. Qual. Assur. 2012, 17, 399–403. [Google Scholar] [CrossRef]

- Côté, I.; Robouch, P.; Robouch, B.; Bisson, D.; Gamache, P.; LeBlanc, A.; Dumas, P.; Pedneault, M. Determination of the standard deviation for proficiency assessment from past participant’s performances. Accredit. Qual. Assur. 2012, 17, 389–393. [Google Scholar] [CrossRef] [Green Version]

- Coarna, M.; Guslicov, G.; Stancu, C.; Vlad, C. Interlaboratory test on adhesives for ceramic tiles in the last 5 years. In Proceedings of the 4th International Proficiency Testing Conference, Brasov, Romania, 18–20 September 2013; pp. 17–20. [Google Scholar]

- De Medeiros Albano, F.; Ten Caten, C.S. Proficiency tests for laboratories: A systematic review. Accredit. Qual. Assur. 2014, 19, 245–257. [Google Scholar] [CrossRef]

- De Medeiros Albano, F.; Ten Caten, C.S. Analysis of the relationships between proficiency testing, validation of methods and estimation of measurement uncertainty: A qualitative study with experts. Accredit. Qual. Assur. 2016, 21, 161–166. [Google Scholar] [CrossRef]

- Huang, H. A new method for estimating consensus values in interlaboratory comparisons. Metrologia 2018, 55, 106. [Google Scholar] [CrossRef]

- Stancu, C. The 10th edition of interlaboratory tests for adhesives for ceramic tiles—An anniversary edition. In Proceedings of the 7th International Proficiency Testing Conference, Oradea, Romania, 10–13 September 2019; p. 99. [Google Scholar]

- Morales, C.; Giraldo, R. Reference versus consensus values in proficiency testing of clinical chemistry: A statistical comparison based on laboratories results in Colombia. Accredit. Qual. Assur. 2020, 25, 99–105. [Google Scholar] [CrossRef]

- Kotyczka-Moranska, M.; Mastalerz, M.; Plis, A.; Sciazko, M. Inter-laboratory proficiency testing of the measurement of gypsum parameters with small numbers of participants. Accredit. Qual. Assur. 2020, 25, 373–381. [Google Scholar] [CrossRef]

- Skrzypczak, I.; Leśniak, A.; Ochab, P.; Górka, M.; Kokoszka, W.; Sikora, A. Interlaboratory Comparative Tests in Ready-Mixed Concrete Quality Assessment. Materials 2021, 14, 3475. [Google Scholar] [CrossRef] [PubMed]

- European Committee for Standardization (CEN). EN 12004:2007+A1:2012 Adhesives for Tiles—Requirements, Evaluation of Conformity, Classification, and Designation; European Committee for Standardization (CEN): Brussels, Belgium, 2012. [Google Scholar]

- European Committee for Standardization (CEN). EN ISO/IEC 17043:2010 Conformity Assessment—General Requirements for Proficiency Testing; European Committee for Standardization (CEN): Brussels, Belgium, 2010. [Google Scholar]

- Stancu, C. The importance of laboratories participation in interlaboratory comparison. Case study: Interlaboratory tests on adhesives for ceramic tiles. In Proceedings of the 13th Conferinţā de Ştiinţa şi Ingineria Materialelor Oxidice, Alba Julia, Romania, 1–3 October 2021. [Google Scholar]

- European Committee for Standardization (CEN). EN ISO/IEC 17025:2018-02 General Requirements for the Competence of Testing and Calibration Laboratories; European Committee for Standardization (CEN): Brussels, Belgium, 2018. [Google Scholar]

- Michalak, J. Ceramic Tile Adhesives from the Producer’s Perspective: A Literature Review. Ceramics 2021, 4, 378–390. [Google Scholar] [CrossRef]

- Baraldi, L. World production and consumption of ceramic tiles. Ceram. World Rev. 2021, 31, 26–41. [Google Scholar]

- European Commission. Summary of references of harmonised standards published in the Official Journal—Regulation (EU) No305/2011 of the European Parliament and of the Council of 9 March 2011 laying down harmonised conditions for the marketing of construction products and repealing Council Directive 89/106/EEC.; European Commission (EU): Brussels, Belgium, 2019; Available online: https://ec.europa.eu/docsroom/documents/38863 (accessed on 23 October 2021).

- European Committee for Standardization (CEN). EN 12004-1:2017 Adhesives for Ceramic Tiles—Part 1: Requirements, Assessment and Verification of Constancy of Performance, Classification and Marking; European Committee for Standardization (CEN): Brussels, Belgium, 2017. [Google Scholar]

- International Organization for Standardization (ISO). ISO 13007-1:2004 Ceramic Tiles—Grouts and Adhesive—Part. 1: Terms, Definitions and Specifications for Adhesives; International Organization for Standardization (ISO): Geneva, Switzerland, 2004. [Google Scholar]

- International Organization for Standardization (ISO). ISO 13007-1:2014 Ceramic Tiles—Grouts and Adhesives—Part 1: Terms, Definitions and Specifications for Adhesives; International Organization for Standardization (ISO): Geneva, Switzerland, 2014. [Google Scholar]

- International Organization for Standardization (ISO). ISO 13528:2015 Statistical Methods for use in Proficiency Testing by Interlaboratory Comparison; International Organization for Standardization (ISO): Geneva, Switzerland, 2015. [Google Scholar]

- Felixberger, J.K. Polymer-Modified Thin-Bed Tile Adhesive; Institut De Promocio Ceramica: Castelló, Spain, 2008. [Google Scholar]

- European Committee for Standardization (CEN). EN 1323:2007 Adhesives for Tiles—Concrete Slabs for Tests; European Committee for Standardization (CEN): Brussels, Belgium, 2007. [Google Scholar]

- Nosal, K.; Niziurska, M.; Wieczorek, M. Wpływ zanieczyszczeń zawartych w wodzie przeznaczonej do sezonowania zapraw klejowych do płytek na ich przyczepność. Prace Inst. Ceram. Mater. Bud. 2015, 8, 61–70. [Google Scholar]

- Niziurska, M. Znaczenie właściwości płytek ceramicznych w zapewnieniu trwałości okładzin mocowanych zaprawami cementowymi. Prace Inst. Ceram. Mater. Bud. 2013, 6, 17–26. [Google Scholar]

| Participant Code | Initial Tensile Adhesion Strength | Tensile Adhesion Strength after Water Immersion | ||

|---|---|---|---|---|

| [N/mm2] | Dominant Failure Pattern | [N/mm2] | Dominant Failure Pattern | |

| 1 | 1.5 | AF-T | 0.7 | AF-T |

| 2 | 1.9 | 70% CF-A/30% AF-T | 0.7 | 50% CF-A/50% AF-T |

| 3 | 1.0 | CF-A | 0.7 | CF-A |

| 4 | 1.3 | AF-T | 0.4 | AF-T |

| 5 | 2.4 | CF-A | 1.0 | CF-A |

| 6 | 1.9 | CF-A | 1.1 | AF-T |

| 7 | 1.7 | CF-A | 0.9 | CF-A |

| 8 | 1.6 | CF-A | 1.2 | CF-A |

| 9 | 1.8 | CF-A | 0.8 | CF-A |

| 10 | 1.6 | CF-A | 0.9 | CF-A |

| 11 | 1.8 | AF-T | 0.6 | AF-T |

| 12 | 1.3 | CF-A | 0.6 | CF-A |

| 13 | 1.8 | CF-A | 0.8 | CF-A |

| 14 | 1.8 | CF-A | ||

| 15 | 1.3 | CF-A | 0.4 | CF-A |

| 16 | 2.0 | 70% CF-A/30% AF-T | 0.8 | 40% CF-A/60% AF-T |

| 17 | 2.1 | CF-A | 1.1 | CF-A |

| 18 | 1.6 | AF-T | 1.3 | AF-T |

| 19 | 1.5 | CF-A | 0.8 | CF-A |

| Participant Code | Initial Tensile Adhesion Strength | Tensile Adhesion Strength after Water Immersion | ||

|---|---|---|---|---|

| [N/mm2] | Dominant Failure Pattern | [N/mm2] | Dominant Failure Patten | |

| 1 | 1.5 | CF-A | 0.9 | AF-T |

| 2 | 1.4 | 50% CF-A/50% AF-T | 0.5 | 5% CF-A/95% AF-T |

| 3 | 1.6 | CF-A | 0.8 | CF-A |

| 4 | 1.7 | CF-A | 1.0 | CF-A |

| 5 | 1.9 | CF-A | 0.6 | AF-T |

| 6 | 2.0 | CF-A | 1.0 | AF-T |

| 7 | 1.9 | CF-A | 0.6 | CF-A |

| 8 | 1.3 | CF-A | 1.1 | CF-A |

| 9 | 1.6 | CF-A | 1.1 | CF-A |

| 10 | 1.6 | CF-A | 0.9 | AF-T |

| 11 | 1.3 | AF-S | 0.6 | AF-T |

| 12 | 1.5 | AF-T | 0.4 | AF-T |

| 13 | 1.8 | CF-A | 0.9 | CF-A |

| 14 | 2.4 | AF-S | 1.3 | AF-T |

| 15 | 1.9 | CF-A | 1.5 | CF-A |

| 16 | 1.9 | 50% CF-A/50% AF-T | 0.6 | 20% CF-A/80% AF-T |

| 17 | 2.7 | CF-A | 1.1 | CF-A |

| 18 | 2.0 | CF-A | 1.1 | CF-A |

| 19 | 2.0 | CF-A | 0.6 | CF-A |

| ILC Edition | No. of Laboratories | Initial Tensile Adhesion Strength [N/mm2] | Tensile Adhesion Strength after Water Immersion [N/mm2] | ||

|---|---|---|---|---|---|

| Lowest Value | Highest Value | Lowest Value | Highest Value | ||

| The same laboratories participating in both ILC editions | |||||

| 11th (2019–2020) | 19 | 1.0 | 2.4 | 0.4 | 1.3 |

| 12th (2020–2021) | 19 * | 1.3 | 2.4 | 0.4 | 1.5 |

| All participating laboratories | |||||

| 11th (2019–2020) | 29 | 0.3 | 2.6 | 0.4 | 1.9 |

| 12th (2020–2021) | 27 | 1.3 | 2.7 | 0.4 | 2.0 |

| Parameter | Initial Tensile Adhesion Strength | Tensile Adhesion Strength after Water Immersion | ||

|---|---|---|---|---|

| 11th ed. | 12th ed. * | 11th ed. | 12th ed. | |

| x* [N/mm2] | 1.7 | 1.8 | 0.8 | 0.9 |

| s* [N/mm2] | 0.3 | 0.3 | 0.2 | 0.3 |

| xpt [N/mm2] | 1.7 | 1.8 | 0.8 | 0.9 |

| σpt [N/mm2] | 0.3 | 0.3 | 0.3 | 0.3 |

| u(xpt) | 0.1 | 0.1 | 0.1 | 0.1 |

| V | 18.9 | 18.6 | 33.5 | 36.2 |

| Predominant Failure Pattern | Initial Adhesion | Adhesion after Water Immersion | ||

|---|---|---|---|---|

| 11th ed. | 12th ed. * | 11th ed. | 12th ed. | |

| AF-S | 0 | 2 | 0 | 0 |

| AF-T | 4 | 1 | 5 | 7 |

| CF-A | 13 | 14 | 11 | 10 |

| Other | 2 | 2 | 2 | 2 |

| Total | 19 | 19 | 18 | 19 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stancu, C.; Michalak, J. Interlaboratory Comparison as a Source of Information for the Product Evaluation Process. Case Study of Ceramic Tiles Adhesives. Materials 2022, 15, 253. https://doi.org/10.3390/ma15010253

Stancu C, Michalak J. Interlaboratory Comparison as a Source of Information for the Product Evaluation Process. Case Study of Ceramic Tiles Adhesives. Materials. 2022; 15(1):253. https://doi.org/10.3390/ma15010253

Chicago/Turabian StyleStancu, Cristina, and Jacek Michalak. 2022. "Interlaboratory Comparison as a Source of Information for the Product Evaluation Process. Case Study of Ceramic Tiles Adhesives" Materials 15, no. 1: 253. https://doi.org/10.3390/ma15010253

APA StyleStancu, C., & Michalak, J. (2022). Interlaboratory Comparison as a Source of Information for the Product Evaluation Process. Case Study of Ceramic Tiles Adhesives. Materials, 15(1), 253. https://doi.org/10.3390/ma15010253