Microwave-Assisted Hydrothermal Synthesis of Zinc-Aluminum Spinel ZnAl2O4

Abstract

1. Introduction

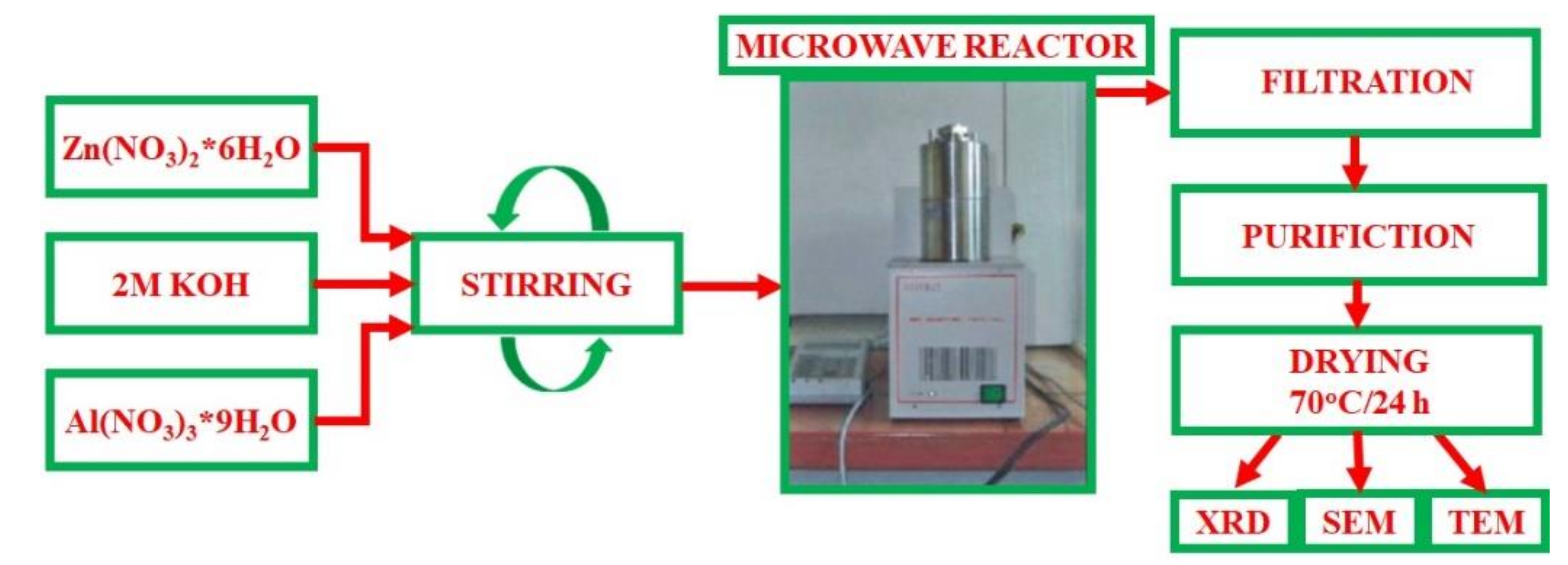

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

X-ray Tomography of Ceramic Preforms

4. Conclusions

- High density;

- Phase homogeneity;

- Nanometric grain size.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bosi, F.; Biagioni, C.; Pasero, M. Nomenclature and classification of the spinel supergroup. Eur. J. Mineral. 2019, 31, 183–192. [Google Scholar] [CrossRef]

- O’Neill, H.S.C.; Navrotsky, A. Simple spinels: Crystallographic parameters, cation radii, lattice energies, and cation distribution. Am. Mineral. 1983, 68, 181–194. [Google Scholar]

- Hill, R.J.; Craig, J.R.; Gibbs, G.V. Systematics of the Spinel Structure Type. Phys. Chem. Miner. 1979, 4, 317. [Google Scholar] [CrossRef]

- Sommer, S.; Drath Bøjesen, E.; Lock, N.; Kasai, H.; Skibsted, J.; Nishibori, E.; Iversen, B.B. Probing the validity of the spinel inversion model: A combined SPXRD, PDF, EXAFS and NMR study of ZnAl2O4. Dalton Trans. 2020, 49, 13449. [Google Scholar] [CrossRef]

- Seko, A.; Oba, F.; Tanaka, I. Classification of spinel structures based on first-principles cluster expansion analysis. Phys. Rev. B 2010, 81, 054114. [Google Scholar] [CrossRef]

- Da Silva, A.A.; de Souza Goncalves, A.; Davolos, M.R. Characterization of nanosized ZnAl2O4 spinel synthesized by the sol–gel method. J. Sol-Gel Sci. Technol. 2009, 49, 101–105. [Google Scholar] [CrossRef]

- Sharma, R.K.; Ghosen, R. Synthesis and characterization of nanocrystalline zinc aluminate spinel powder by sol–gel method. Ceram. Int. 2014, 40, 3209–3214. [Google Scholar] [CrossRef]

- Davar, F.; Salavati-Niasari, M. Synthesis and characterization of spinel-type zinc aluminate nanoparticles by a modified sol–gel method using new precursor. J. Alloys Compd. 2011, 509, 2487–2492. [Google Scholar] [CrossRef]

- Zulfakar, M.S.; Abdullah, H.; Jalal, W.N.W.; Zainuddin, Z.; Shaari, S. Study of Nanocrystalline ZnAl2O4 and ZnFe2O4 with SiO2 on Structural and Optical Properties Synthesized by Sol-Gel Method. Adv. Mater. Res. 2015, 1119, 96–100. [Google Scholar] [CrossRef]

- Valenzuela, M.A.; Bosch, E.; Aguilar-Rios, G.; Montoya, A.; Schifter, I. Comparison Between Sol-Gel, Coprecipitation and Wet Mixing Synthesis of ZnAl2O4. J. Sol-Gel Sci. Technol. 1997, 8, 107–110. [Google Scholar] [CrossRef]

- Wei, X.; Chen, D. Synthesis and characterization of nanosized zinc aluminate spinel by sol–gel technique. Mater. Lett. 2006, 60, 823–827. [Google Scholar] [CrossRef]

- Belyaev, A.V.; Lelet, M.I.; Kirillova, N.I.; Khamaletdinova, N.M.; Boldin, M.S.; Murashov, A.A.; Balabanov, S.S. Sol-gel synthesis and characterization of ZnAl2O4 powders for transparent ceramics. Ceram. Int. 2019, 45, 4835–4839. [Google Scholar] [CrossRef]

- Confalonieri, G.; Rotiroti, N.; Bernasconi, A.; Dapiaggi, M. Structural Study of Nano-Sized Gahnite (ZnAl2O4): From the Average to the Local Scale. Nanomaterials 2020, 10, 824. [Google Scholar] [CrossRef]

- Mathur, S.; Veith, M.; Haas, M.; Shen, H.; Lecerf, N.; Huch, V.; Hufner, S.; Haberkorn, R.; Beck, H.P.; Jilavi, M. Single-Source Sol–Gel Synthesis of Nanocrystalline ZnAl2O4: Structural and Optical Properties. J. Am. Ceram. Soc. 2001, 84, 1921–1928. [Google Scholar] [CrossRef]

- De Macedo, H.P.; de Araújo Medeiros, R.L.B.; de Medeiros, A.L.; de Oliveira, A.A.S.; de Figueredo, G.P.; de Freitas Melo, M.A.; de Araújo Melo, D.M. Characterization of ZnAl2O4 Spinel Obtained by Hydrothermal and Microwave Assisted Combustion Method: A Comparative Study. Mater. Res. 2017, 20 (Suppl. S2), 29–33. [Google Scholar] [CrossRef]

- Miron, I.; Enache, C.; Vasile, M.; Grozescu, I. Optical properties of ZnAl2O4 nanomaterials obtained by the hydrothermal method. Phys. Scr. 2012, T149, 014064. [Google Scholar] [CrossRef]

- Sibera, D.; Strachowski, T.; Lojkowski, W.; Narkiewicz, U.; Chudoba, T.; Jędrzejewski, R.; Majcher, A.; Presz, A. Nano-ZnAl2O4—Hydrothermal MW Assisted Synthesis In A Stop-Flow Reactor And Characterization. Maint. Probl. 2010, 4, 91–102. [Google Scholar]

- Zawadzki, M. Synthesis of nanosized and microporous zinc aluminate spinel by microwave assisted hydrothermal method (microwave–hydrothermal synthesis of ZnAl2O4). Solid State Sci. 2006, 8, 14–18. [Google Scholar] [CrossRef]

- Chen, X.Y.; Ma, C.; Zhang, Z.J.; Wang, B.N. Ultrafine gahnite (ZnAl2O4) nanocrystals: Hydrothermal synthesis and photoluminescent properties. Mater. Sci. Eng. B 2008, 151, 224–230. [Google Scholar] [CrossRef]

- Chen, Z.; Shi, E.; Zheng, Y.; Li, W.; Wu, N.; Zhong, W. Synthesis of mono-dispersed ZnAl2O4 powders under hydrothermal conditions. Mater. Lett. 2002, 56, 601–605. [Google Scholar] [CrossRef]

- Battistona, S.; Rigoa, C.; da Cruz Severoa, E.; Mazuttia, M.A.; Kuhna, R.C.; Gündelb, A.; Foletto, E.L. Synthesis of Zinc Aluminate (ZnAl2O4) Spinel and its Application as Photocatalyst. Mater. Res. 2014, 17, 734–738. [Google Scholar] [CrossRef]

- Marconato Stringhini, F.; Foletto, E.L.; Sallet, D.; Assumpção Bertuol, D.; Chiavone-Filho, O.; Oller do Nascimento, C.A. Synthesis of porous zinc aluminate spinel (ZnAl2O4) by metal-chitosan complexation method. J. Alloys Compd. 2014, 588, 305–309. [Google Scholar] [CrossRef]

- Farhadi, S.; Panahandehjoo, S. Spinel-type zinc aluminate (ZnAl2O4) nanoparticles prepared by the co-precipitation method: A novel, green and recyclable heterogeneous catalyst for the acetylation of amines, alcohols and phenols under solvent-free conditions. Appl. Catal. A Gen. 2010, 382, 293–302. [Google Scholar] [CrossRef]

- Foletto, E.L.; Battiston, S.; Simoes, J.M.; Moro Bassaco, M.; Severo Fagundes Pereira, L.; Marlon de Moraes Flores, E.; Irineu Muller, E. Synthesis of ZnAl2O4 nanoparticles by different routes and the effect of its pore size on the photocatalytic process. Microporous Mesoporous Mater. 2012, 163, 29–33. [Google Scholar] [CrossRef]

- Ge, D.-L.; Fan, Y.-J.; Qi, C.-L.; Sun, Z.-X. Facile synthesis of highly thermostable mesoporous ZnAl2O4 with adjustable pore size. J. Mater. Chem. A 2013, 1, 1651. [Google Scholar] [CrossRef]

- Ananda, G.T.; Kennedya, L.J.; Vijayac, J.J.; Kaviyarasana, K.; Sukumar, M. Structural, optical and magnetic characterization of Zn1−xNixAl2O4 (0 ≤ x ≤ 5) spinel nanostructures synthesized by microwave combustion technique. Ceram. Int. 2015, 41, 603–615. [Google Scholar] [CrossRef]

- Mirbagheri, S.A.; Masoudpanah, S.M.; Alamolhod, S. Structural and optical properties of ZnAl2O4 powders synthesized by solution combustion method: Effects of mixture of fuels. Optik 2020, 204, 164170. [Google Scholar] [CrossRef]

- Mohanty, P.; Mohapatro, S.; Mahapatra, R.; Mishra, D.K. Low cost synthesis route of spinel ZnAl2O4. Mater. Today Proc. 2021, 35, 130–132. [Google Scholar] [CrossRef]

- Ianos, R.; Lazau, R.; Lazau, I.; Pacurariu, C. Chemical oxidation of residual carbon from ZnAl2O4 powders prepared by combustion synthesis. J. Eur. Ceram. Soc. 2012, 32, 1605–1611. [Google Scholar] [CrossRef]

- Han, M.; Wang, Z.; Xu, Y.; Wu, R.; Jiao, S.; Chen, Y.; Feng, S. Physical properties of MgAl2O4, CoAl2O4, NiAl2O4, CuAl2O4, and ZnAl2O4 spinels synthesized by a solution combustion method. Mater. Chem. Phys. 2018, 215, 251–258. [Google Scholar] [CrossRef]

- Sirikajorn, T.; Mekasuwandumrong, O.; Praserthdam, P.; Goodwin, J.G., Jr.; Panpranot, J. Effect of Support Crystallite Size on Catalytic Activity and Deactivation of Nanocrystalline ZnAl2O4-Supported Pd Catalysts in Liquid-Phase Hydrogenation. Catal. Lett. 2008, 126, 313–318. [Google Scholar] [CrossRef]

- Song, X.; Zheng, S.; Zhang, J.; Li, W.; Chen, Q.; Cao, B. Synthesis of monodispersed ZnAl2O4 nanoparticles and their tribology properties as lubricant additives. Mater. Res. Bull. 2012, 47, 4305–4310. [Google Scholar] [CrossRef]

- Zawadzki, M. Pd and ZnAl2O4 nanoparticles prepared by microwave-solvothermal method as catalyst precursors. J. Alloys Compd. 2007, 439, 312–320. [Google Scholar] [CrossRef]

- Ghorbani-Choghamarani, A.; Mohammadi, M.; Shiri, L.; Taherinia, Z. Synthesis and characterization of spinel FeAl2O4 (hercynite) magnetic nanoparticles and their application in multicomponent reactions. Res. Chem. Intermed. 2019, 45, 5705–5723. [Google Scholar] [CrossRef]

- Enhessari, M. FeAl2O4 Nanopowders; Structural Analysis and Band Gap Energy. High Temp. Mater. Proc. 2017, 36, 789–793. [Google Scholar] [CrossRef]

- Azam, M.; Nairan, A.; Riaz, S.; Naseem, S. FeAl2O4 thin films prepared by sol-gel—structural and magnetic properties. Mater. Today Proc. 2015, 2, 5150–5154. [Google Scholar] [CrossRef]

- Jastrzębska, I.; Szczerba, J.; Błachowski, A.; Stoch, P. Structure and microstructure evolution of hercynite spinel (Fe2+Al2O4) after annealing treatment. Eur. J. Mineral. 2017, 29, 63–72. [Google Scholar] [CrossRef]

- Daghetta, M.A.A.; Dapiaggi, M.; Pellegrino, L.; Pastore, B.; Pagliari, L.; Mazzocchia, C.V. Synthesis of Hercynite at very Mild Condition. Chem. Eng. Trans. 2015, 43, 1741–1746. [Google Scholar] [CrossRef]

- Nestola, F.; Periotto, B.; Anzolini, C.; Andreozzi, G.B.; Woodland, A.B.; Lenaz, D.; Alvaro, M.; Princivalle, F. Equation of state of hercynite, FeAl2O4, and high-pressure systematics of Mg-Fe-Cr-Al spinels. Mineral. Mag. 2015, 79, 285–294. [Google Scholar] [CrossRef]

- Castillo Rodriguez, G.A.; Garcıa Guillen, G.; Mendivil Palma, M.I.; Das Roy, T.K.; Guzman Hernandez, A.M. Synthesis and Characterization of Hercynite Nanoparticles by Pulsed Laser Ablation in Liquid Technique. Int. J. Appl. Ceram. Technol. 2014, 12, E34–E43. [Google Scholar] [CrossRef]

- Hou, Q.; Meng, F.; Sun, J. Electrical and optical properties of Al-doped ZnO and ZnAl2O4 films prepared by atomic layer deposition. Nanoscale Res. Lett. 2013, 8, 144. [Google Scholar] [CrossRef]

- Kim, B.-N.; Hiraga, K.; Jeong, A.; Hu, C.; Suzuki, T.S.; Yun, J.-D.; Sakka, Y. Transparent ZnAl2O4 ceramics fabricated by spark plasma sintering. J. Ceram. Soc. Jpn. 2014, 122, 784–787. [Google Scholar] [CrossRef]

- Guo, Y.; Lu, Y.; Liu, C.; Wang, J.; Han, J.; Ruan, J. Effect of ZnAl2O4 crystallization on ion-exchange properties in aluminosilicate glass. J. Alloys Compd. 2021, 851, 156891. [Google Scholar] [CrossRef]

- Salih, E.Y.; Mohd Sabri, M.F.; Sulaiman, K.; Hussein, M.Z.; Said, S.M.; Usop, R.; Mohd Salleh, M.F.; Bashir Ali Bashir, M. Thermal, structural, textural and optical properties of ZnO/ZnAl2O4 mixed metal oxide-based Zn/Al layered double hydroxide. Mater. Res. Express 2018, 5, 116202. [Google Scholar] [CrossRef]

- Iaiche, S.; Djelloul, A. ZnO/ZnAl2O4 Nanocomposite Films Studied by X-ray Diffraction, FTIR, and X-ray Photoelectron Spectroscopy. J. Spectrosc. 2015, 2015, 836859. [Google Scholar] [CrossRef]

- Salih, E.Y.; Mohd Sabri, M.F.; Hussein, M.Z.; Sulaiman, K.; Mohd Said, S.; Saifullah, B.; Bashir Ali Bashir, M. Structural, optical and electrical properties of ZnO/ZnAl2O4 nanocomposites prepared via thermal reduction approach. J. Mater. Sci. 2018, 53, 581–590. [Google Scholar] [CrossRef]

- Chandramohan, R.; Dhanasekaran, V.; Arumugam, R.; Sundaram, K.; Thirumalai, J.; Mahalingam, T. Physical Properties Evaluation Of Annealed ZnAl2O4 Alloy Thin Films. Dig. J. Nanomater. Biostructures 2012, 7, 1315–1325. [Google Scholar]

- Kumar, K.; Ramamoorthy, K.; Koinkar, P.M.; Chandramohan, R.; Sankaranarayan, K. A novel in situ synthesis and growth of ZnAl2O4 thin films. J. Cryst. Growth 2006, 289, 405–407. [Google Scholar] [CrossRef]

- Somraksa, W.; Suwanboon, S.; Amornpitoksuk, P.; Randorn, C. Physical and Photocatalytic Properties of CeO2/ZnO/ZnAl2O4 Ternary Nanocomposite Prepared by Co-precipitation Method. Mater. Res. 2020, 23, e20190627. [Google Scholar] [CrossRef]

- Iaiche, S.; Boukaous, C.; Alamarguy, D.; Djelloul, A.; Hamana, D. Effect of Solution Concentration on ZnO/ZnAl2O4 Nanocomposite Thin Films Formation Deposited by Ultrasonic Spray Pyrolysis on Glass and Si(111) Substrates. J. Nano Res. 2020, 63, 10–30. [Google Scholar] [CrossRef]

- Gorghinian, A.; Mottana, A.; Rossi, A.; Oltean, F.M.; Esposito, A.; Marcelli, A. Investigating the colour of spinel: 1. Red gem-quality spinels (“balas”) from Ratnapura (Sri Lanka). Rend. Lincei 2013, 24, 127–140. [Google Scholar] [CrossRef]

- Phyo, M.M.; Bieler, E.; Franz, L.; Balmer, W.; Krzemnicki, M.S. Spinel from Mogok, Myanmar—A Detailed Inclusion Study by Raman Microspectroscopy and Scanning Electron Microscopy. J. Gemmol. 2019, 36, 418–435. [Google Scholar] [CrossRef]

- Huong, L.T.-T.; Häger, T.; Hofmeister, W.; Hauzenberger, C.; Schwarz, D.; Van Long, P.; Wehrmeister, U.; Khoi, N.N.; Nhung, N.T. Gemstones from Vietnam: An Update. Gems Gemol. 2012, 48, 158–176. [Google Scholar] [CrossRef][Green Version]

- Kruzslicz, A.B.; Nasdala, L.; Wildner, M.; Škoda, R.; Redhammer, G.J.; Hauzenberger, C.; Wanthanachaisaeng, B. Black Spinel—A Gem Material from Bo Phloi, Thailand. J. Gemmol. 2020, 37, 66–79. [Google Scholar] [CrossRef]

- Htoo, K.M.; Khin, T.; Htoon, S. Study on Physical Properties and Chemical Composition of Some Myanmar Gems. J. Myanmar Acad. Arts Sci. 2004, 2, 173–178. [Google Scholar]

- Azer, C.; Ramadan, A.R.; Ghaly, G.; Ragai, J. Preparation and Characterization of Cobalt Aluminate Spinels CoAl2O4 Doped with Magnesium Oxide. Adsorpt. Sci. Technol. 2012, 30, 399–407. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, C.; Liu, Y.; Shi, Q.; Wang, W.; Zha, Y. Green and red photoluminescence from ZnAl2O4:Mn phosphors prepared by sol―gel method. J. Lumin. 2012, 132, 1529–1531. [Google Scholar] [CrossRef]

- Bakhmetyev, V.V.; Lebedev, L.A.; Malygin, V.V.; Podsypanina, N.S.; Sychov, M.M.; Belyaev, V.V. Effect of Composition and Synthesis Route on Structure and Luminescence of NaBaPO4:Eu2+ and ZnAl2O4:Eu3+. JJAP Conf. Proc. 2016, 4, 011104. [Google Scholar] [CrossRef]

- Tshabalala, K.G.; Nagpure, I.M.; Swart, H.C.; Ntwaeaborwa, O.M.; Cho, S.H.; Park, J.-K. Enhanced green emission from UV down-converting Ce3+–Tb3+ co-activated ZnAl2O4 phosphor. J. Vac. Sci. Technol. B 2012, 30, 031401. [Google Scholar] [CrossRef]

- Kumar, M.; Natarajan, V.; Godbole, S.V. Synthesis, characterization, photoluminescence and thermally stimulated luminescence investigations of orange red-emitting Sm3+-doped ZnAl2O4 phosphor. Bull. Mater. Sci. 2014, 37, 1205–1214. [Google Scholar] [CrossRef]

- Kumaria, P.; Dwivedi, Y.; Bahadur, A. Analysis of bright red-orange emitting Mn2+:ZnAl2O4 spinel nanophosphor. Optik 2018, 154, 126–132. [Google Scholar] [CrossRef]

- Strek, W.; Deren, P.; Bednarkiewicz, A.; Zawadzki, M.; Wrzyszcz, J. Emission properties of nanostructured Eu3+ doped zinc aluminate spinels. J. Alloys Compd. 2000, 300–301, 456–458. [Google Scholar] [CrossRef]

- Belyaev, A.; Basyrova, L.; Sysoev, V.; Lelet, M.; Balabanov, S.; Kalganov, V.; Mikhailovski, V.; Baranov, M.; Stepanidenko, E.; Vitkin, V.; et al. Microstructure, doping and optical properties of Co2+:ZnAl2O4 transparent ceramics for saturable absorbers: Effect of the ZnF2 sintering additive. J. Alloys Compd. 2020, 829, 154514. [Google Scholar] [CrossRef]

- Kumar, M.; Mohapatra, M. A case study of energy transfermechanism from uraniumto europium in ZnAl2O4 spinel host by photoluminescence spectroscopy. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2016, 159, 42–47. [Google Scholar] [CrossRef]

- Sumathi, S.; Kavipriya, A. Structural, optical and photocatalytic activity of cerium doped zinc aluminate. Solid State Sci. 2017, 65, 52e60. [Google Scholar] [CrossRef]

- Luchechko, A.; Zhydachevskyy, Y.; Ubizskii, S.; Kravets, O.; Popov, A.I.; Rogulis, U.; Elsts, E.; Bulur, E.; Suchocki, A. Afterglow, TL and OSL Properties of Mn2+-doped ZnGa2O4 Phosphor. Sci. Rep. 2019, 9, 9544. [Google Scholar] [CrossRef]

- Mykhailovych, V.; Kanak, A.; Cojocaru, Ş.; Chitoiu-Arsene, E.-D.; Palamaru, M.N.; Iordan, A.-R.; Korovyanko, O.; Diaconu, A.; Ciobanu, V.G.; Caruntu, G.; et al. Structural, Optical, and Catalytic Properties of MgCr2O4 Spinel-Type Nanostructures Synthesized by Sol–Gel Auto-Combustion Method. Catalysts 2021, 11, 1476. [Google Scholar] [CrossRef]

- Zhai, B.-G.; Huang, Y.-M. Green Afterglow of Undoped SrAl2O4. Nanomaterials 2021, 11, 2331. [Google Scholar] [CrossRef]

- Web Site of Ertec Poland. Available online: www.ertec.pl (accessed on 20 July 2019).

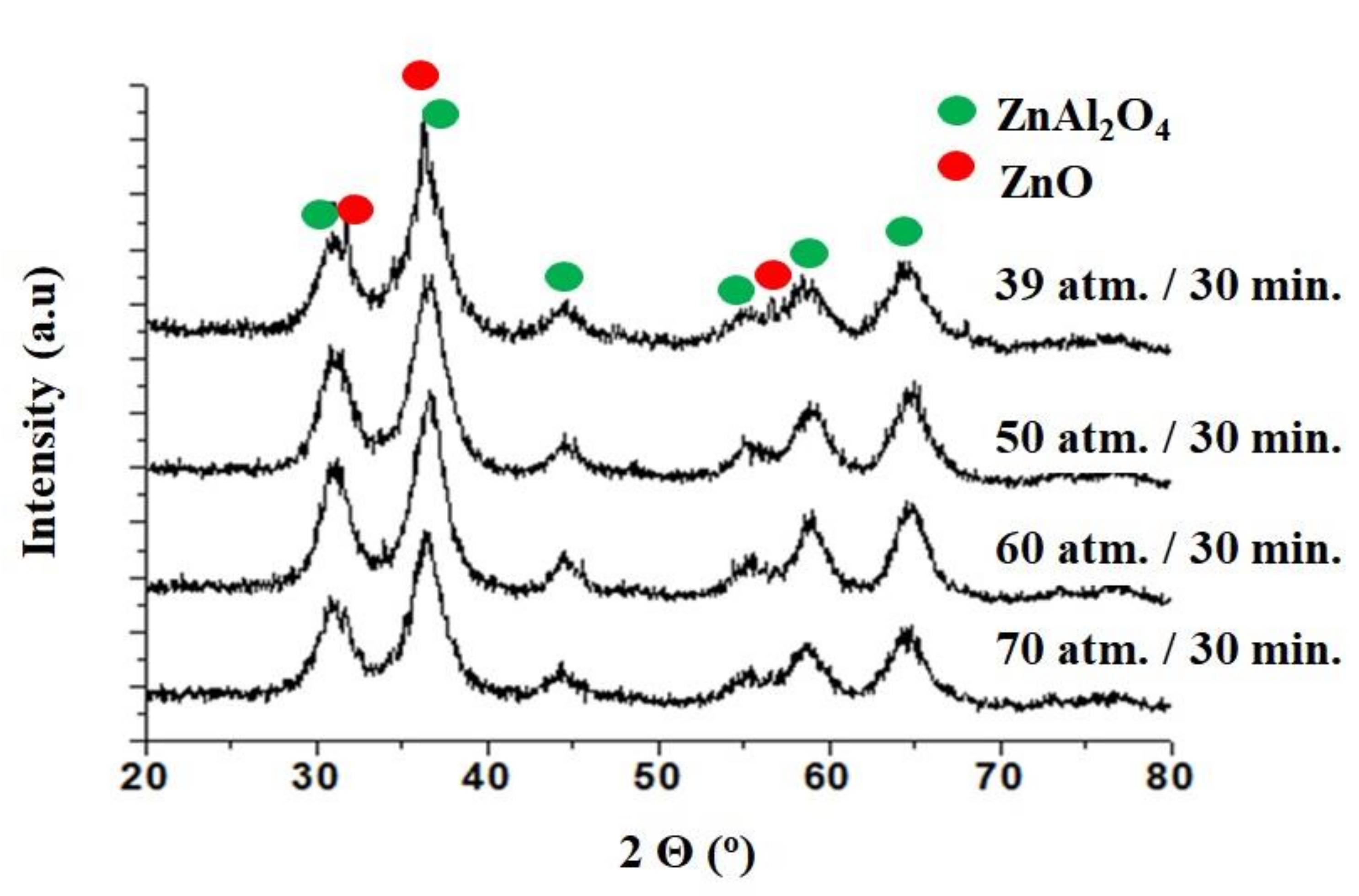

| Time (min) | 15 | 30 | 60 |

| Pressure (atm) | 39 | 39 | 39 |

| Density (g/cm3) | 3.72 | 3.53 | 3.68 |

| BET (m2/g) | 260 | 266 | 262 |

| Grain size (nm) | 6–7 | 6–7 | 6–7 |

| Phases | ZnAl2O4 + ZnO | ZnAl2O4 + ZnO | ZnAl2O4 + ZnO |

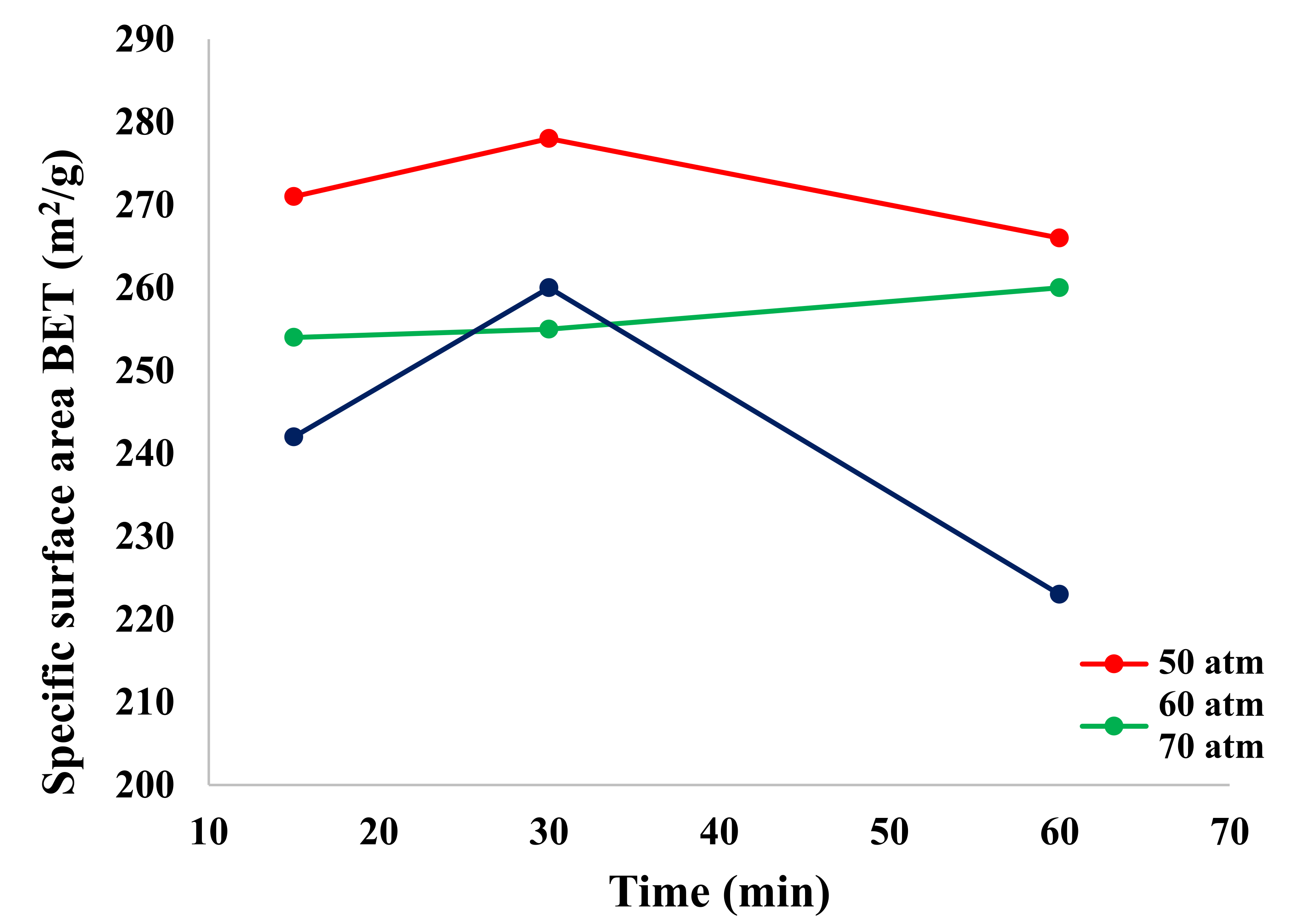

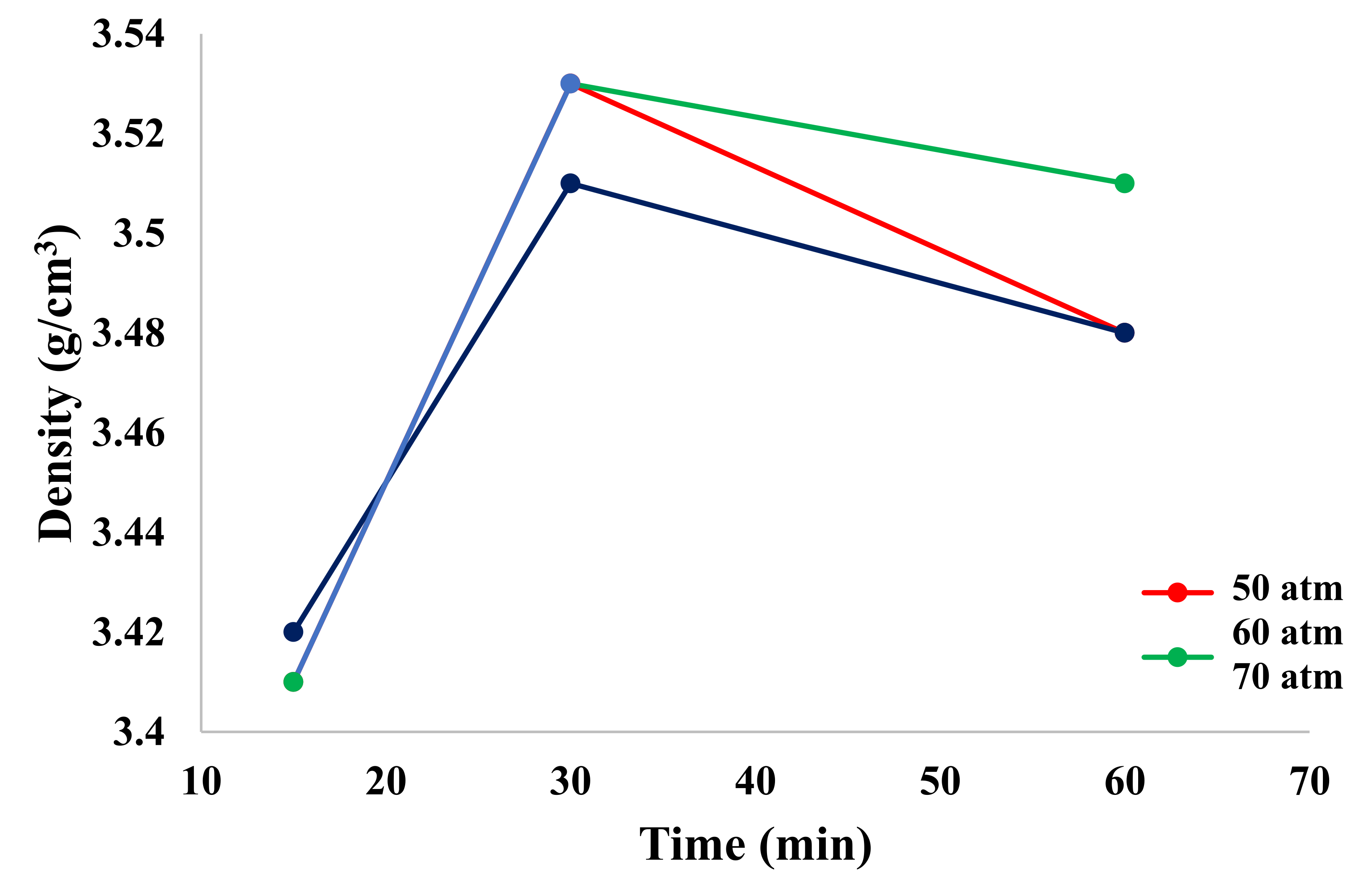

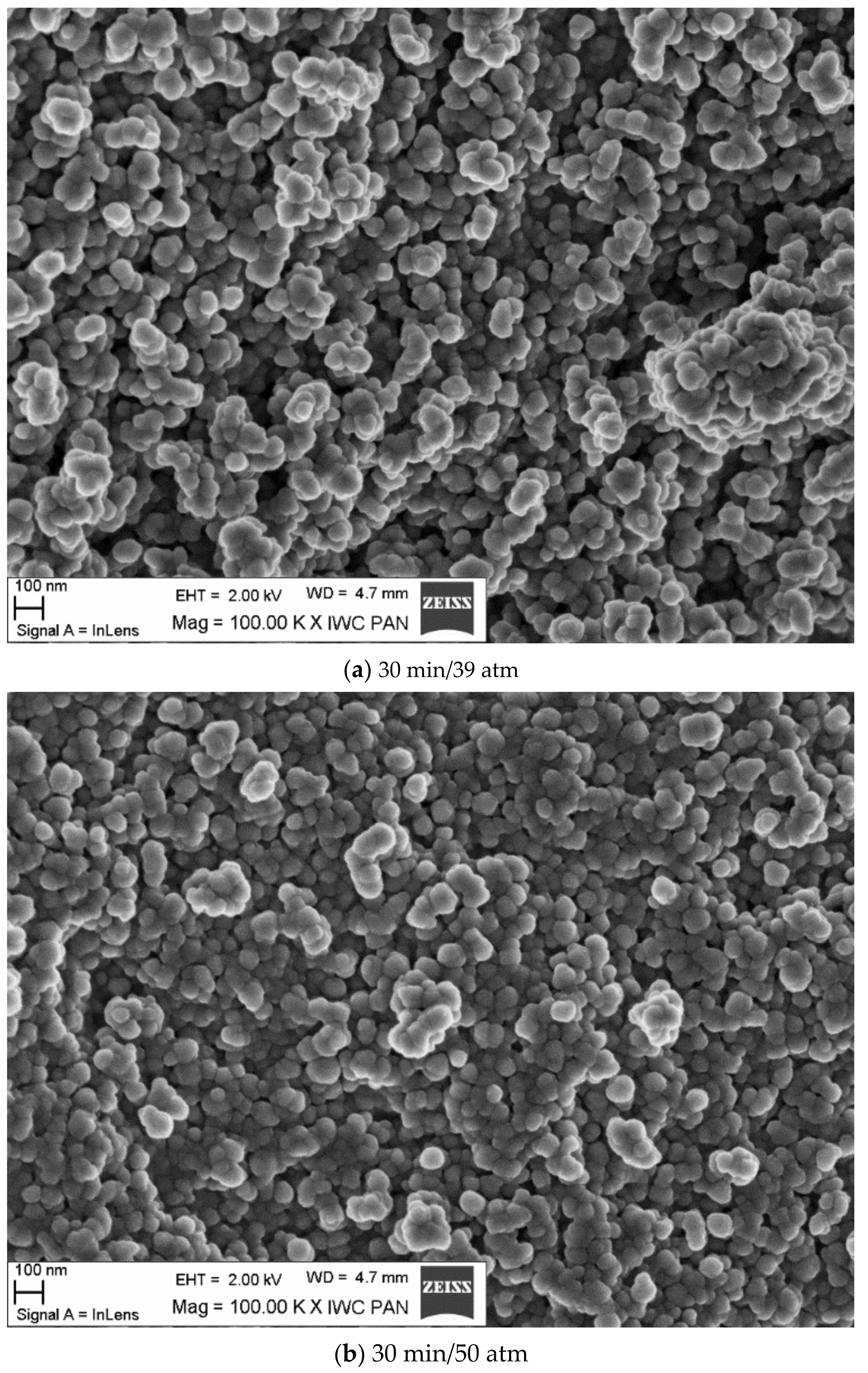

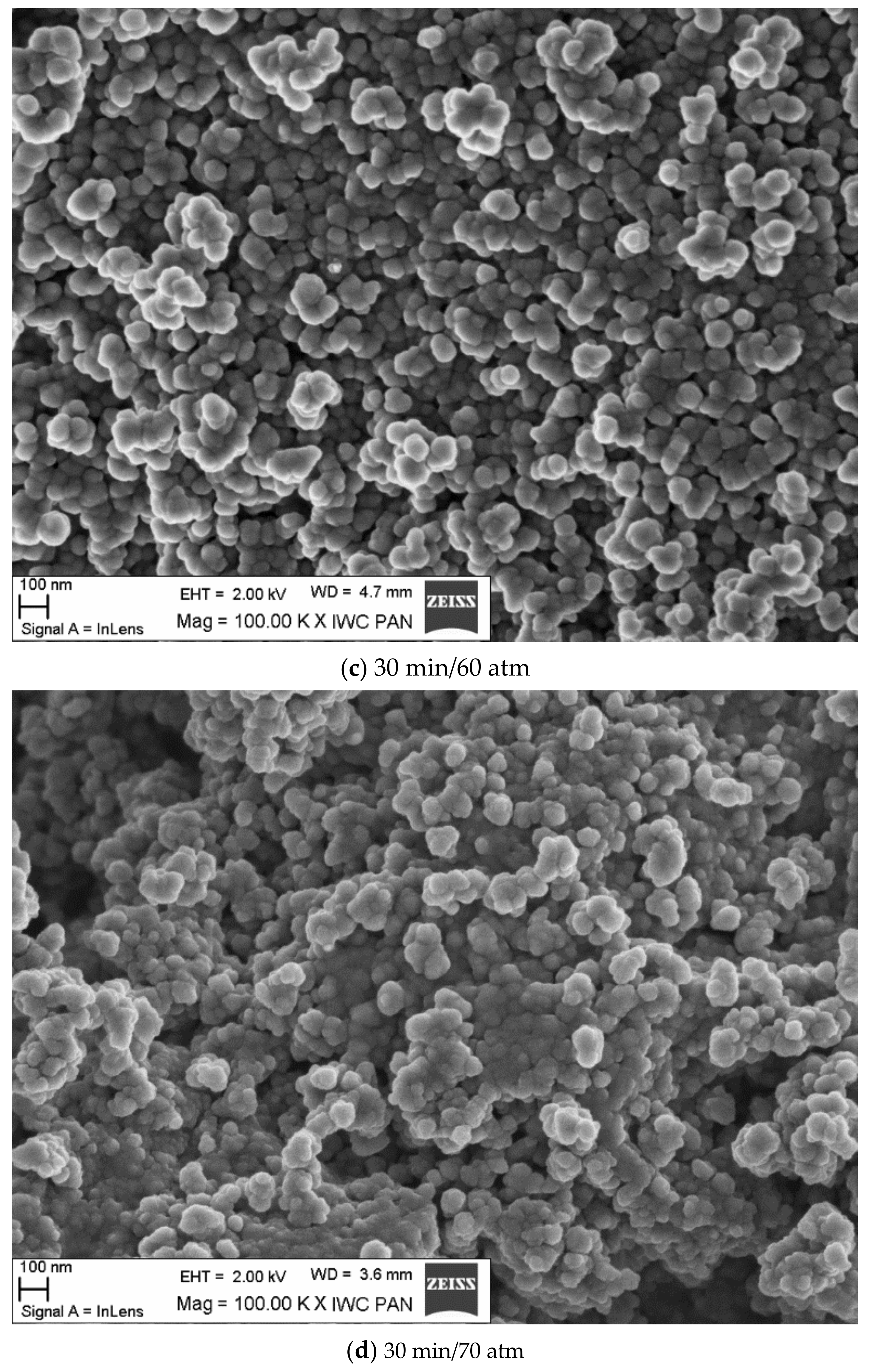

| Sample | Density (g/cm3) | BET (m2/g) | Grain Size (nm) | Phases |

|---|---|---|---|---|

| 15 min/50 atm | 3.41 | 271 | 7 | ZnAl2O4 |

| 15 min/60 atm | 3.41 | 254 | 7 | ZnAl2O4 |

| 15 min/70 atm | 3.42 | 242 | 7 | ZnAl2O4 |

| 30 min/50 atm | 3.53 | 278 | 6 | ZnAl2O4 |

| 30 min/60 atm | 3.53 | 255 | 8 | ZnAl2O4 |

| 30 min/70 atm | 3.51 | 260 | 6 | ZnAl2O4 |

| 60 min/50 atm | 3.48 | 266 | 6 | ZnAl2O4 |

| 60 min/60 atm | 3.51 | 260 | 6 | ZnAl2O4 |

| 60 min/70 atm | 3.48 | 223 | 7 | ZnAl2O4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Strachowski, T.; Grzanka, E.; Mizeracki, J.; Chlanda, A.; Baran, M.; Małek, M.; Niedziałek, M. Microwave-Assisted Hydrothermal Synthesis of Zinc-Aluminum Spinel ZnAl2O4. Materials 2022, 15, 245. https://doi.org/10.3390/ma15010245

Strachowski T, Grzanka E, Mizeracki J, Chlanda A, Baran M, Małek M, Niedziałek M. Microwave-Assisted Hydrothermal Synthesis of Zinc-Aluminum Spinel ZnAl2O4. Materials. 2022; 15(1):245. https://doi.org/10.3390/ma15010245

Chicago/Turabian StyleStrachowski, Tomasz, Ewa Grzanka, Jan Mizeracki, Adrian Chlanda, Magdalena Baran, Marcin Małek, and Marlena Niedziałek. 2022. "Microwave-Assisted Hydrothermal Synthesis of Zinc-Aluminum Spinel ZnAl2O4" Materials 15, no. 1: 245. https://doi.org/10.3390/ma15010245

APA StyleStrachowski, T., Grzanka, E., Mizeracki, J., Chlanda, A., Baran, M., Małek, M., & Niedziałek, M. (2022). Microwave-Assisted Hydrothermal Synthesis of Zinc-Aluminum Spinel ZnAl2O4. Materials, 15(1), 245. https://doi.org/10.3390/ma15010245