Microstructure, Texture and Mechanical Properties in Aluminum Produced by Friction-Assisted Lateral Extrusion

Abstract

1. Introduction

2. Materials and Methods

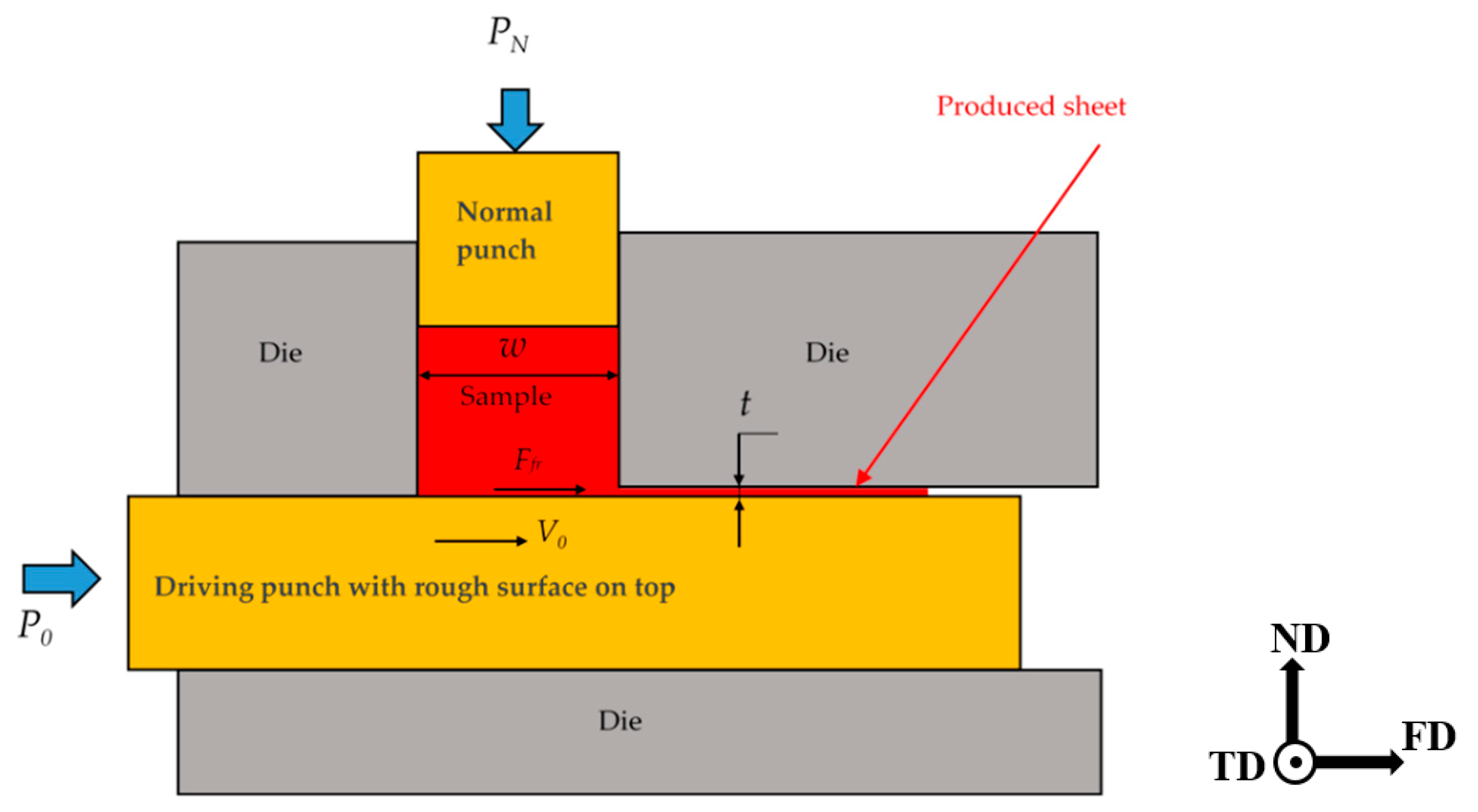

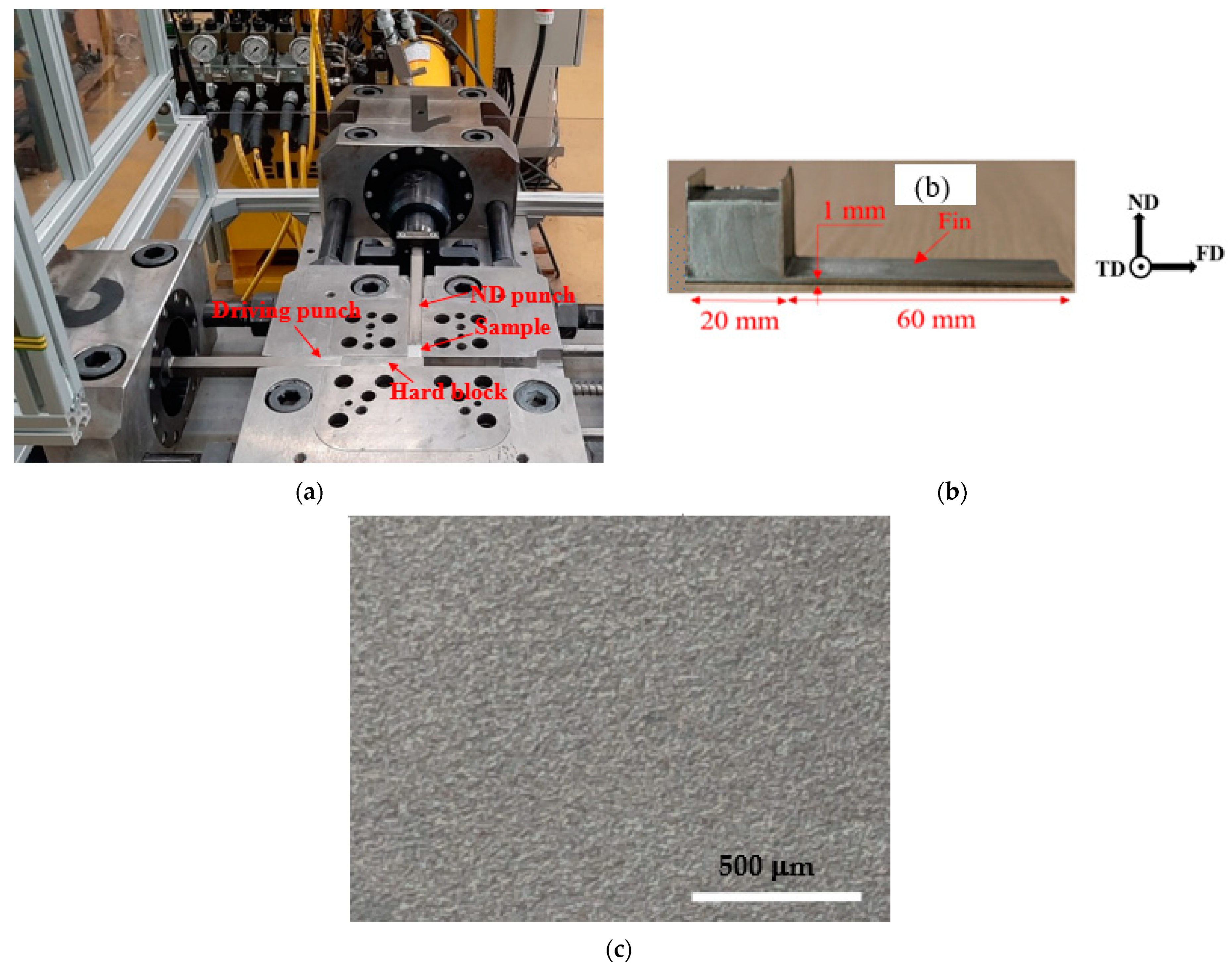

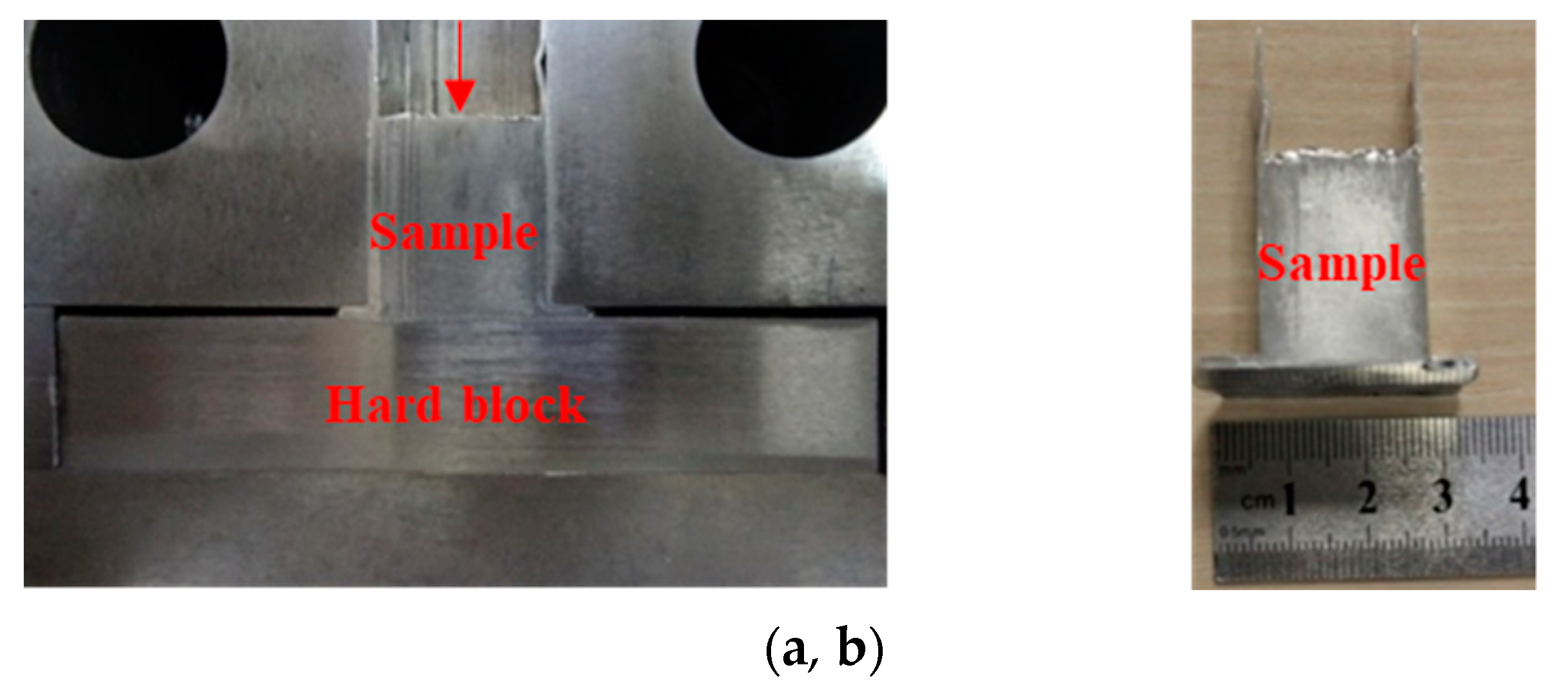

2.1. The FALEP Process

2.2. Experimental Conditions

3. Experimental Results

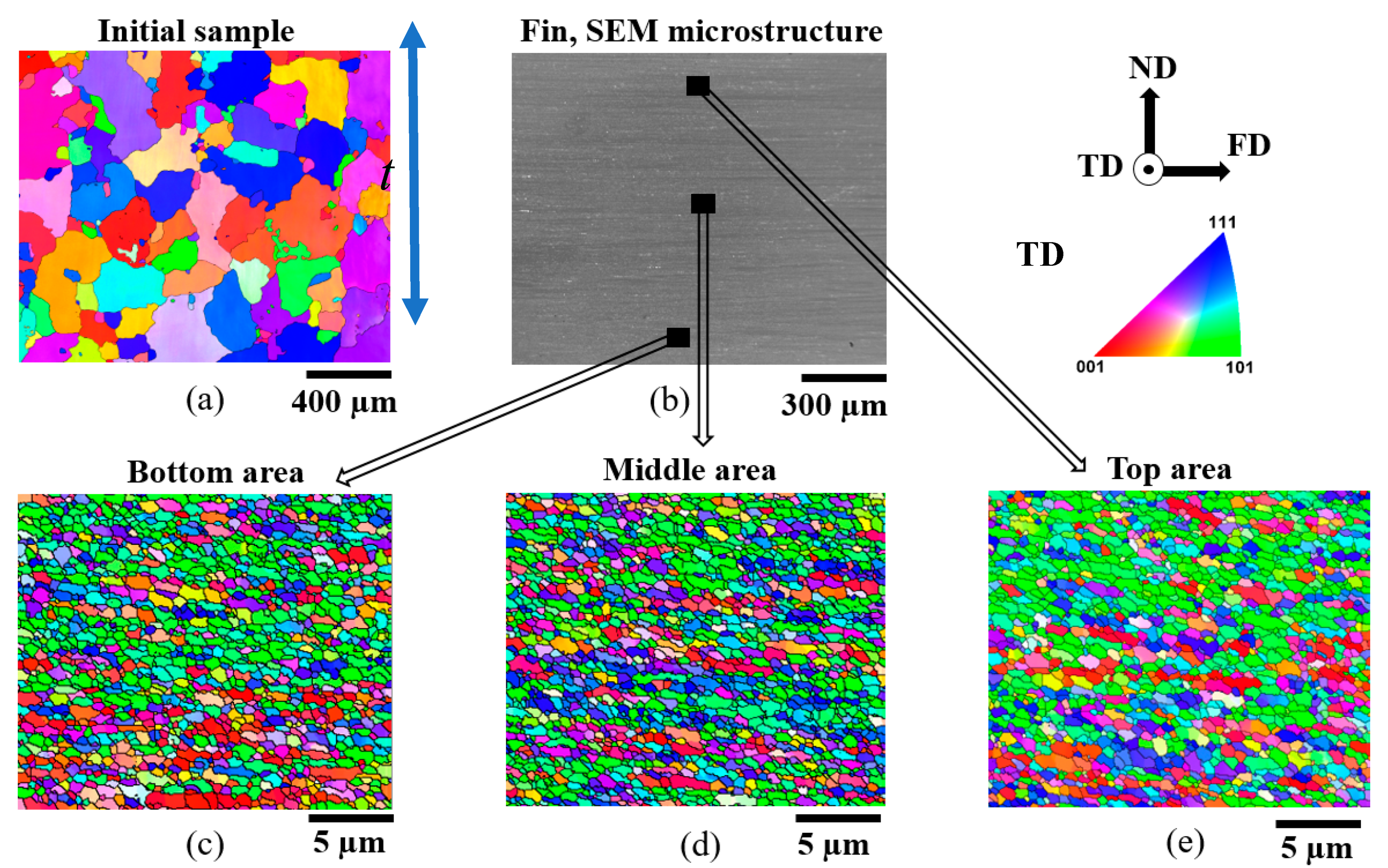

3.1. Microstructure Evolution

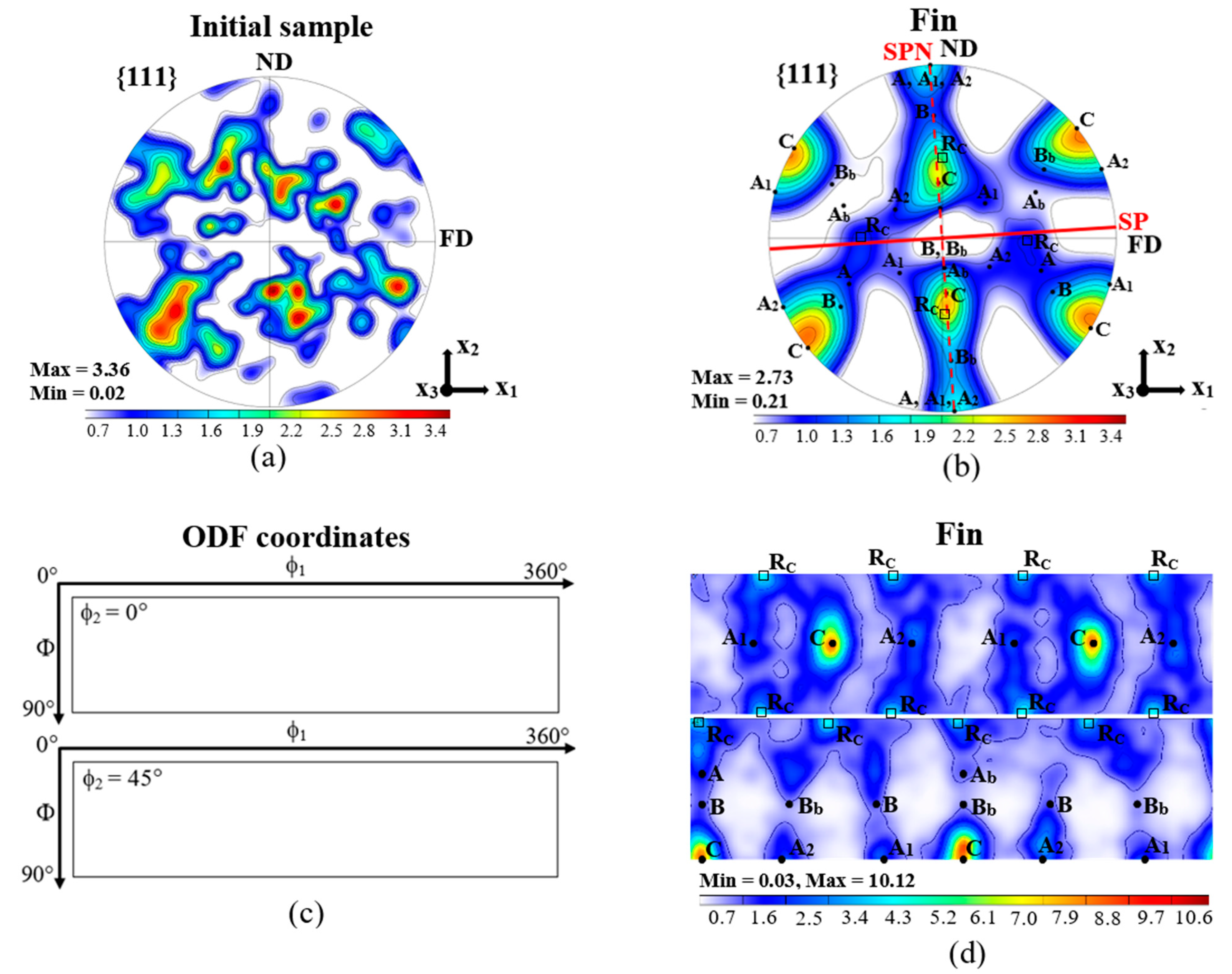

3.2. Crystallographic Texture

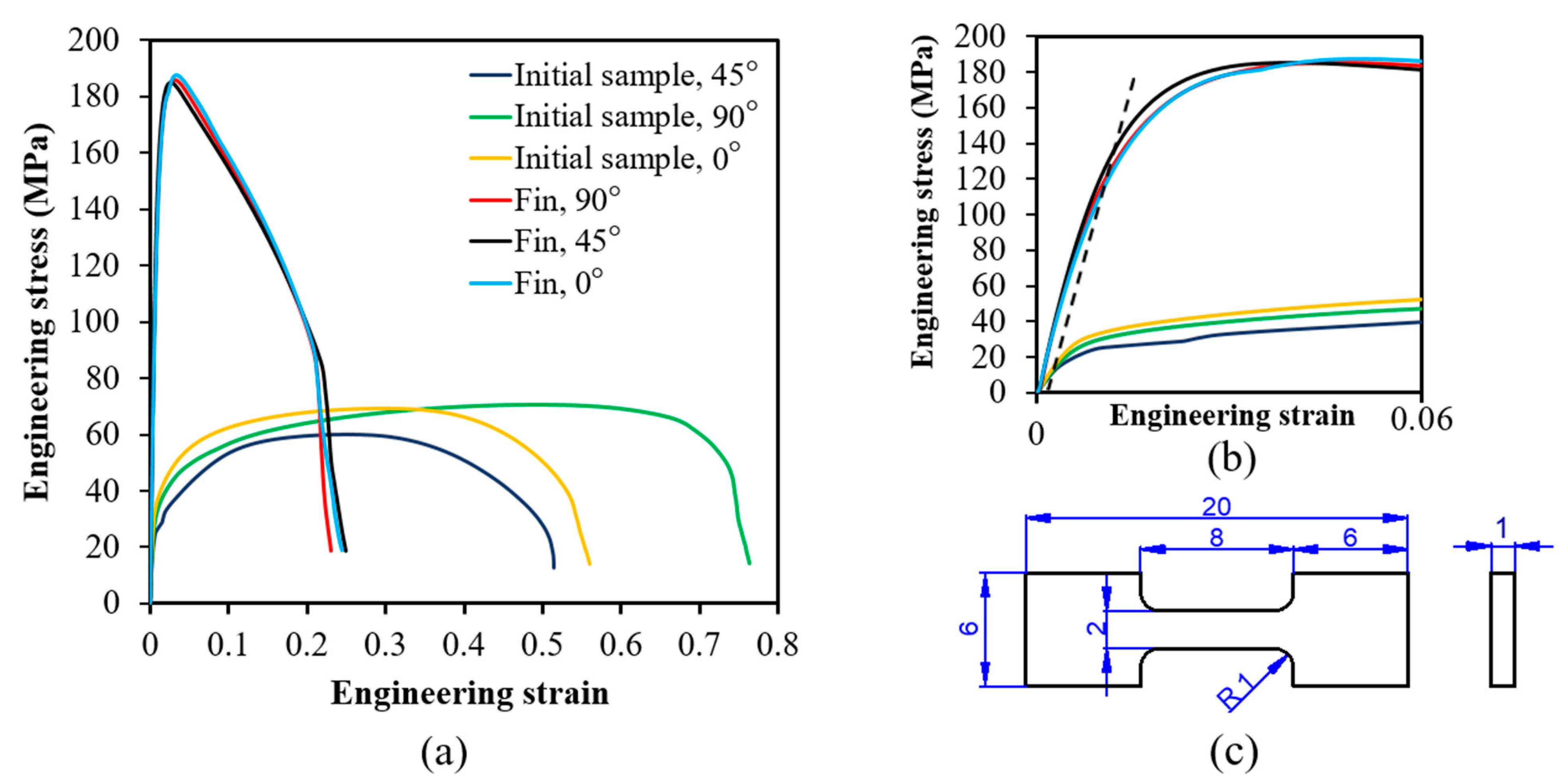

3.3. Mechanical Properties

3.4. Lankford Parameter

4. Discussion

4.1. FALEP Characteristics

4.2. Mechanical Behaviour of Al-1050

4.3. Crystallographic Texture

4.4. Lankford Parameter

5. Conclusions

- FALEP produced sheet materials with very high and homogeneous strains, which led to significant grain refinement in Al-1050 by reducing the grain size more than 160 times; to 600 nm, in a single step;

- FALEP produced simple shear texture in Al-1050 with the shear plane parallel to the plane of the produced fin;

- FALEP significantly increased the material strength: the yield strength of Al-1050 increased by about 10 times and the ultimate strength increased about three times;

- FALEP produced exceptional high average R-value for aluminum (1.28), with moderate anisotropy ( = −0.31).

- Polycrystal simulations confirmed the obtained R-values and explained their experimental distribution, as well.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zehetbauer, M.J.; Zhu, Y. Producing Bulk Ultrafine-Grained Materials by Severe Plastic Deformation: Ten Years Later. JOM 2016, 68, 1216–1226. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel ultra-high straining process for bulk materials—development of the accumulative roll-bonding (ARB) process. Acta Mater. 1999, 47, 579–583. [Google Scholar] [CrossRef]

- Cui, Q.; Ohori, K. Grain refinement of high purity aluminium by asymmetric rolling. Mater. Sci. Technol. 2000, 16, 1095–1101. [Google Scholar] [CrossRef]

- Saito, Y.; Utsunomiya, H.; Suzuki, H.; Sakai, T. Improvement in the r-value of aluminum strip by a continuous shear deformation process. Scr. Mater. 2000, 42, 1139–1144. [Google Scholar] [CrossRef]

- Huang, J.; Zhu, Y.; Jiang, H.; Lowe, T. Microstructures and dislocation configurations in nanostructured Cu processed by repetitive corrugation and straightening. Acta Mater. 2001, 49, 1497–1505. [Google Scholar] [CrossRef]

- Nam, C.; Han, J.; Chung, Y.; Shin, M. Effect of precipitates on microstructural evolution of 7050 Al alloy sheet during equal channel angular rolling. Mater. Sci. Eng. A 2003, 347, 253–257. [Google Scholar] [CrossRef]

- Beygelzimer, Y.; Toth, L.S.; Fundenberger, J.-J. Procédé de Formation d’un Objet plat Métallique à Grains Ultrafins. WO2017017341, 2 February 2017. [Google Scholar]

- Vu, V.Q.; Beygelzimer, Y.; Kulagin, R.; Toth, L.S. The New Plastic Flow Machining Process for Producing Thin Sheets. Adv. Mater. Sci. Eng. 2018, 2018, 1–8. [Google Scholar] [CrossRef]

- Vu, V.Q.; Beygelzimer, Y.; Toth, L.S.; Fundenberger, J.-J.; Kulagin, R.; Chen, C. The plastic flow machining: A new SPD process for producing metal sheets with gradient structures. Mater. Charact. 2018, 138, 208–214. [Google Scholar] [CrossRef]

- Vu, V.Q.; Beygelzimer, Y.; Kulagin, R.; Toth, L.S. Mechanical Modelling of the Plastic Flow Machining Process. Materials 2018, 11, 1218. [Google Scholar] [CrossRef] [PubMed]

- Vu, V.Q.; Toth, L.S.; Beygelzimer, Y.; Kulagin, R.; Kobaissy, A.H. Modeling of Crystallographic Texture in Plastic Flow Machining. Adv. Eng. Mater. 2020, 22, 1900661. [Google Scholar] [CrossRef]

- Nakamura, T.; Tanaka, S.; Hiraiwa, M.; Imaizumi, H.; Tomizawa, Y.; Osakada, K. Friction—Assisted Extrusion of Thin Strips of Aluminium Composite Material from Powder Metals. CIRP Ann. 1992, 41, 281–284. [Google Scholar] [CrossRef]

- Nakamura, T.; Hiraiwa, M.; Imaizumi, H.; Tomizawa, Y. Development of Friction-Assisted Extrusion Process for Producing Thin Metal Strips. JSME Int. J. Ser. C Dyn. Control. Robot. Des. Manuf. 1995, 38, 143–148. [Google Scholar] [CrossRef]

- Horita, Z.; Tang, Y.; Masuda, T.; Takizawa, Y. Severe Plastic Deformation under High Pressure: Upsizing Sample Dimensions. Mater. Trans. 2020, 61, 1177–1190. [Google Scholar] [CrossRef]

- Xu, C.; Schroeder, S.; Berbon, P.B.; Langdon, T.G. Principles of ECAP–Conform as a continuous process for achieving grain refinement: Application to an aluminum alloy. Acta Mater. 2010, 58, 1379–1386. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Tsuji, N.; Saito, Y.; Lee, S.-H.; Minamino, Y. ARB (Accumulative Roll-Bonding) and other new Techniques to Produce Bulk Ultrafine Grained Materials. Adv. Eng. Mater. 2003, 5, 338–344. [Google Scholar] [CrossRef]

- Hasani, A.; Tóth, L.S.; Beausir, B.; Beausir, B. Principles of Nonequal Channel Angular Pressing. J. Eng. Mater. Technol. 2010, 132, 031001. [Google Scholar] [CrossRef]

- Tóth, L.S.; Lapovok, R.; Hasani, A.; Gu, C. Non-equal channel angular pressing of aluminum alloy. Scr. Mater. 2009, 61, 1121–1124. [Google Scholar] [CrossRef]

- Pippan, R.; Scheriau, S.; Taylor, A.; Hafok, M.; Hohenwarter, A.; Bachmaier, A. Saturation of Fragmentation During Severe Plastic Deformation. Annu. Rev. Mater. Res. 2010, 40, 319–343. [Google Scholar] [CrossRef]

- Chen, C.; Beygelzimer, Y.; Tóth, L.S.; Fundenberger, J.-J. Microstructure and strain in protrusions formed during severe plastic deformation of aluminum. Mater. Lett. 2015, 159, 253–256. [Google Scholar] [CrossRef]

- Tóth, L.; Neale, K.; Jonas, J. Stress response and persistence characteristics of the ideal orientations of shear textures. Acta Met. 1989, 37, 2197–2210. [Google Scholar] [CrossRef]

- Akramov, S.; Lee, M.G.; Kim, I.S.; Sung, D.Y.; Park, B.H.; Kim, I. R-Value and Texture Change of AA 1050 Al Alloy Sheet by Equal Channel Angular Pressing. Mater. Sci. Forum 2005, 495-497, 803–808. [Google Scholar] [CrossRef]

- Sakai, T.; Hamada, S.; Saito, Y. Improvement of the r-value in 5052 aluminum alloy sheets having through-thickness shear texture by 2-pass single-roll drive unidirectional shear rolling. Scr. Mater. 2001, 44, 2569–2573. [Google Scholar] [CrossRef]

- Lapovok, R.; McKenzie, P.W.J.; Thomson, P.F.; Semiatin, S.L. Processing and properties of ultrafine-grain aluminum alloy 5005 sheet. J. Mater. Sci. 2007, 42, 1649–1659. [Google Scholar] [CrossRef]

- Toth, L.S.; Gu, C. Ultrafine-grain metals by severe plastic deformation. Mater. Charact. 2014, 92, 1–14. [Google Scholar] [CrossRef]

- Arzaghi, M.; Fundenberger, J.; Toth, L.; Arruffat, R.; Faure, L.; Beausir, B.; Sauvage, X. Microstructure, texture and mechanical properties of aluminum processed by high-pressure tube twisting. Acta Mater. 2012, 60, 4393–4408. [Google Scholar] [CrossRef]

- Salamati, M.; Tamimi, S.; Moturu, S.; Sivaswamy, G.; Qarni, M.J.; Rosochowski, A. Microstructure and mechanical properties of Al-1050 during incremental ECAP. IOP Conf. Ser. Mater. Sci. Eng. 2017, 194, 12009. [Google Scholar] [CrossRef]

- Yu, C.; Kao, P.; Chang, C. Transition of tensile deformation behaviors in ultrafine-grained aluminum. Acta Mater. 2005, 53, 4019–4028. [Google Scholar] [CrossRef]

- Kim, Y.S.; Kang, S.H.; Shin, D.H. Effect of Rolling Direction on the Microstructure and Mechanical Properties of Accumulative Roll Bonding (ARB) Processed Commercially Pure 1050 Aluminum Alloy. Mater. Sci. Forum 2006, 503, 681–686. [Google Scholar] [CrossRef]

- Jiang, J.; Ding, Y.; Zuo, F.; Shan, A. Mechanical properties and microstructures of ultrafine-grained pure aluminum by asymmetric rolling. Scr. Mater. 2009, 60, 905–908. [Google Scholar] [CrossRef]

- Tóth, L.S.; Jonas, J.J. Analytic Prediction of Texture and Length Changes During Free-End Torsion. Textures Microstruct. 1989, 10, 195–209. [Google Scholar] [CrossRef]

- Tóth, L.; Jonas, J. Modelling the texture changes produced by dynamic recrystallization. Scr. Met. et Mater. 1992, 27, 359–363. [Google Scholar] [CrossRef]

- Utsunomiya, H.; Ueno, T.; Sakai, T. Improvement in the r-value of aluminum sheets by differential-friction rolling. Scr. Mater. 2007, 57, 1109–1112. [Google Scholar] [CrossRef]

- Lee, J.-H.; Kim, G.-H.; Nam, S.K.; Kim, I.; Lee, D.N. Calculation of plastic strain ratio of AA1050 Al alloy sheet processed by heavy asymmetric rolling–annealing followed by light rolling–annealing. Comput. Mater. Sci. 2015, 100, 45–51. [Google Scholar] [CrossRef]

- Beausir, J.-J. Fundenberger, Analysis Tools for Electron and X-ray Diffraction, ATEX Software; Université de Lorraine: Metz, France, 2017; Available online: www.atex-software.eu.

- Arzaghi, M.; Beausir, B.; Tóth, L. Contribution of non-octahedral slip to texture evolution of fcc polycrystals in simple shear. Acta Mater. 2009, 57, 2440–2453. [Google Scholar] [CrossRef]

| Initial Material State | After FALEP | |||||||

|---|---|---|---|---|---|---|---|---|

| Angle | YS (MPa) | UTS (MPa) | Unif. Elong. (%) | Total Elong. (%) | YS (MPa) | UTS (MPa) | Unif. Elong. (%) | Total Elong. (%) |

| 0° | 13 | 70 | 32 | 55 | 113 | 187 | 5.2 | 21 |

| 45° | 10 | 60 | 26 | 52 | 135 | 185 | 3 | 22 |

| 90° | 11 | 71 | 52 | 74 | 119 | 186 | 5 | 21 |

| R0 | R45 | R90 | Ref. | |||

|---|---|---|---|---|---|---|

| FALEP, Al-1050 | 1.04 | 1.43 | 1.21 | 1.28 | −0.31 | This work |

| Sheet ECAP, Al-1050 | 0.64 | 1.45 | 0.81 | 1.01 | −0.47 | [24] |

| Conshearing, Al-1050 | 0.94 | - | - | - | - | [5] |

| Asymmetric Rolling, Al-5052 | 0.9 | 1.1 | 0.8 | 1.00 | −0.14 | [25] |

| Sheet-ECAP, AA5005 | 0.83 | 1.23 | 0.98 | 1.07 | −0.65 | [26] |

| Initial Material State | After SPD Processing | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| YS (MPa) | UTS (MPa) | Unif. Elong. (%) | Total Elong. (%) | Grain Size (µm) | SPD Process | YS (MPa) | UTS (MPa) | Unif. Elong. (%) | Total Elong. (%) | Grain Size (µm) | Ref. |

| 10–13 | 60–71 | 26–52 | 51–76 | 100 | 1 FALEP pass | 113–135 | 185–187 | 3–5.2 | 21–22 | 0.66 | This paper |

| 25–28 | 65–70 | 30–32 | 55–57 | 100 | 1 PFM pass | 125–135 | 170–175 | 5–6 | 18–25 | 0.8–1.8 | [10] |

| 55 | 345 | 20 | - | 24 | HPTT | 346 | 405 | 2 | 2 | 0.5 | [28] |

| - | 76 | 35 | 55 | - | 4 Increm. ECAP | - | 177 | 1.5 | 15 | - | [29] |

| - | - | - | - | 330 | 8 ECAP passes | - | 140–175 | 3–3.5 | 10–15 | 0.59 | [30] |

| 90 | 110 | - | 15 | - | 7 ARB passes | 120 | 150 | - | 9 | 0.7 | [31] |

| - | 100 | 4 | 17 | - | 60% ASR | - | 176 | 2 | 6.5 | - | [32] |

| R0 | R45 | R90 | |||

|---|---|---|---|---|---|

| Measured | 1.04 | 1.43 | 1.21 | 1.28 | −0.31 |

| Simulated | 0.95 | 1.26 | 0.98 | 1.11 | −0.30 |

| <111> // ND fiber | 5.7 | 5.7 | 5.7 | 5.70 | 0.00 |

| <110> // SD fiber | 1.11 | 5.67 | 0.95 | 3.35 | −4.64 |

| A/Ab component | 0.2 | 9.3 | 0.95 | 4.94 | −8.73 |

| B/Bb component | 6.47 | 2.3 | 1.14 | 3.05 | 1.51 |

| C component | 7.9 | 3.6 | 1.4 | 4.13 | 1.05 |

| A1/A2 component | 1.83 | 1.29 | 1.48 | 1.47 | 0.37 |

| RC (45° rotated cube) | 0.15 | 2.68 | 0.15 | 1.42 | −2.53 |

| Random texture | 1.00 | 1.00 | 1.00 | 1.00 | 0.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vu, V.Q.; Toth, L.S.; Beygelzimer, Y.; Zhao, Y. Microstructure, Texture and Mechanical Properties in Aluminum Produced by Friction-Assisted Lateral Extrusion. Materials 2021, 14, 2465. https://doi.org/10.3390/ma14092465

Vu VQ, Toth LS, Beygelzimer Y, Zhao Y. Microstructure, Texture and Mechanical Properties in Aluminum Produced by Friction-Assisted Lateral Extrusion. Materials. 2021; 14(9):2465. https://doi.org/10.3390/ma14092465

Chicago/Turabian StyleVu, Viet Q., Laszlo S. Toth, Yan Beygelzimer, and Yajun Zhao. 2021. "Microstructure, Texture and Mechanical Properties in Aluminum Produced by Friction-Assisted Lateral Extrusion" Materials 14, no. 9: 2465. https://doi.org/10.3390/ma14092465

APA StyleVu, V. Q., Toth, L. S., Beygelzimer, Y., & Zhao, Y. (2021). Microstructure, Texture and Mechanical Properties in Aluminum Produced by Friction-Assisted Lateral Extrusion. Materials, 14(9), 2465. https://doi.org/10.3390/ma14092465