1. Introduction

In recent times, the usage of miniature products and their applications has significantly increased. This has led to an increase in the demand to create complex geometries with precise dimensions and high quality. These devices are comprehensively studied, which allows for constructive applications for chemical and biological investigation [

1]. Generally, microchannels/slits are made of glass and polymer materials [

2]. The microchannel chips that are made from polymeric materials have many limitations, viz. low solidity after exposure to a heated atmosphere, meager chemical resistance and optical properties, and low porousness to moisture [

3,

4]. Therefore, quantifiable fabrication methods have been examined for quartz-glass-based microchannels [

5]. The patterns created in glass and ceramics are difficult to create due to the brittleness of quartz glass. This led to glass and ceramics being replaced by polydimethylsiloxane (PDMS) in many applications [

6]. Quartz glass may be an immaculate shape of silica with a SiO

2 content of more than 99.9% and it has been used widely in lenses, computers, resonators, windows, smartphones, GPS equipment, communication (3C) engineering, and electronic industries for high-quality tuned circuits. Quartz is widely used in micro device testing, metrology components, jewelry, gemstones, frequency control, mirror substrates, piezoelectric applications for converting electrical to mechanical energy (and vice versa), and medical incision devices [

6,

7,

8,

9]. Owing to its higher hardness, brittleness, and higher melting point, machining quartz is difficult [

10] and thus quartz was used as the workpiece material for the study.

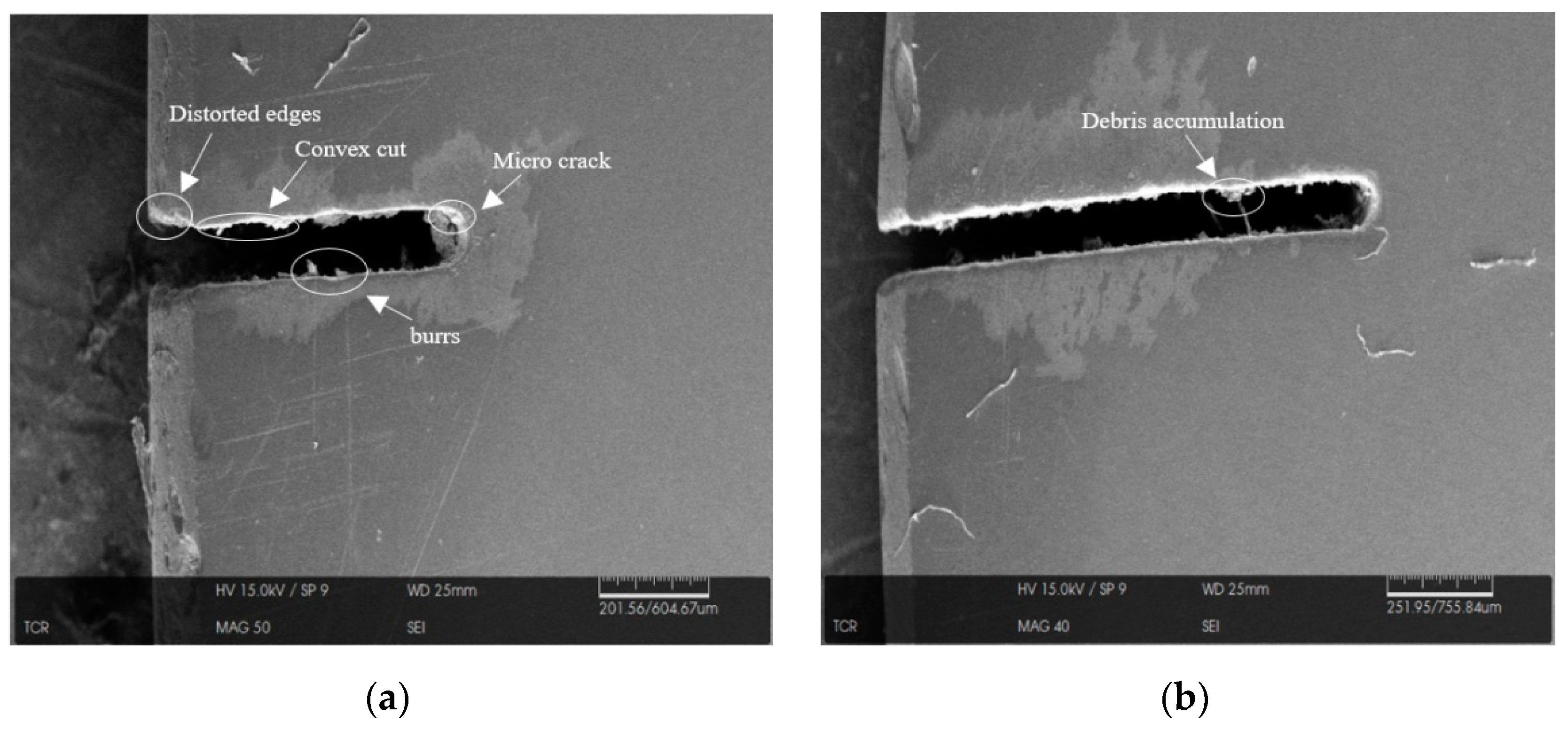

The literature reveals that microslits on quartz material can be fabricated using various unconventional machining processes. Overcut and rough surfaces were observed with ultrashort laser pulse processes [

11]. When using a Nd:YAG laser, damage and thermal cracks on the the inner machine surface were observed [

12,

13]. When an abrasive slurry jet was applied to machine the quartz, a large wavy pattern was observed and the material removal rate decreased [

14]. Microedge cracks and burrs were noticed when a laser-assisted dry microgrinding process was applied [

15]. Burrs can be reduced using laser-assisted dry microgrinding machining processes but the heat affected zone (HAZ) across the surface is a challenge [

16]. When powder-mixed rotary ultrasonic motion was applied to quartz, the material removal rate increased but the chances of crack propagation limits its use [

17]. Rounded cracks were formed and the machined surface melted when using the electrochemical spark trepanning process [

18]. A high aspect ratio was obtained using the ultra-short laser-machining processes; however, the surface roughness and surface quality were poor [

19]. Furthermore, these processes had a high setup and machining cost. Other developed and broadly acknowledged machining processes, such as electrochemical machining (ECM) and wire electrical discharge machining (W-EDM), are only able to machine electrically conducting materials [

20,

21,

22]. To overcome the previously stated key impediments, there emerges a need to create an advanced hybrid machining process that can machine different electrically nonconducting materials and make strides in the quality and nature of the machining performance [

23,

24].

TW-ECDM is an eminent micromachining approach with enormous potential for machining (slicing/cutting) two-dimensional and complicated profiles of a wide variety of hard, thermal-shock-resistant, indispensable, brittle, and electrically insulating materials, such as glass, zirconia, alumina, and composites. It is also known as the traveling wire electrochemical spark machining (TW-ECSM) process. A TW-ECDM process is a hybrid approach of the ECM and W-EDM processes that offers a 5 to 50 times higher material removal rate than W-EDM and ECM, and it diminishes the tool wear rate [

25]. The TW-ECDM process is steadier than W-EDM and gives a better surface finish when contrasted with ECM. In the TW-ECDM process, both the electric discharge erosion and electrochemical dissolution (ESD) impacts are utilized for the evacuation of the material [

26]. This helps to machine the workpiece and electrochemical dissolution gives a better and smoother surface finish.

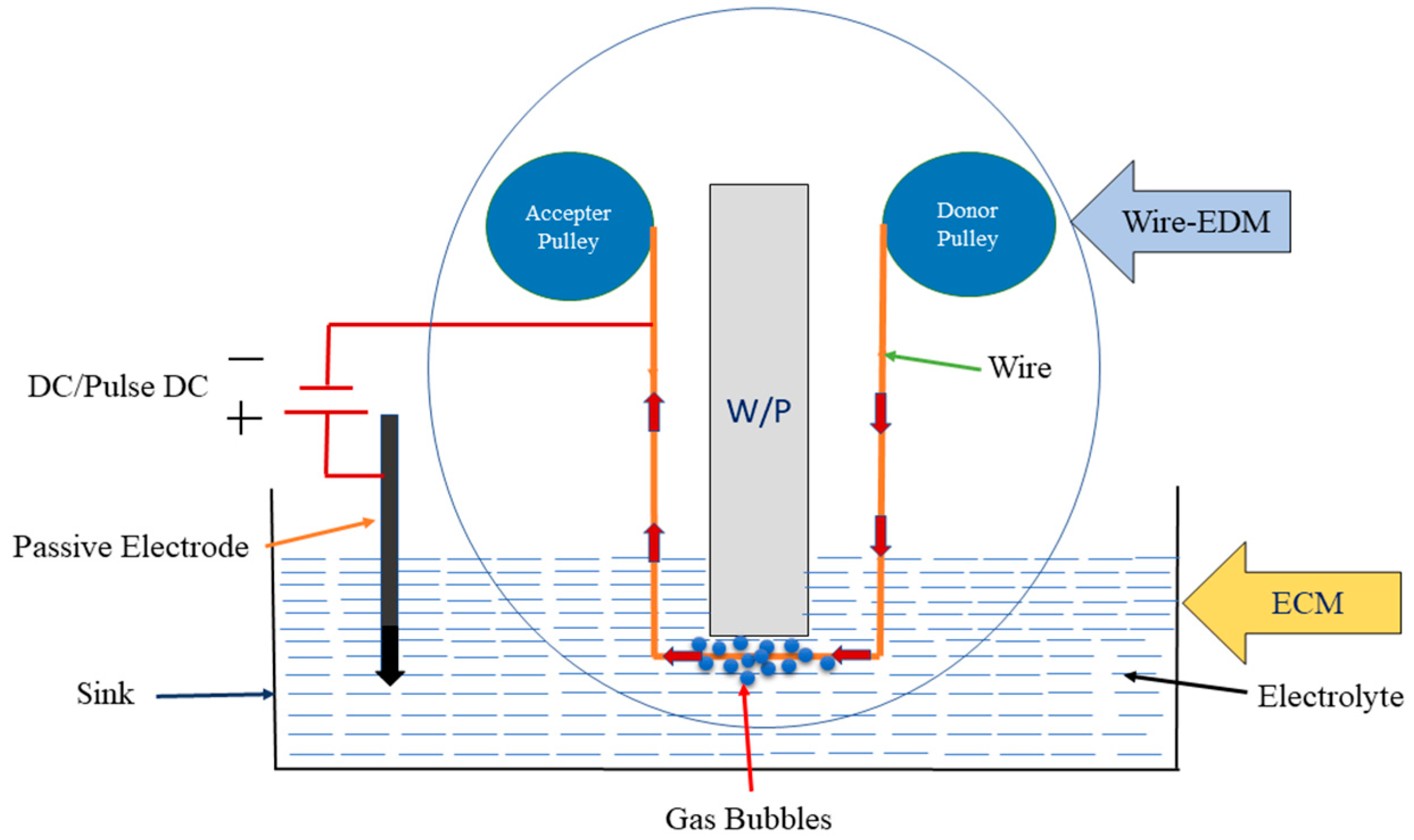

Figure 1 schematically demonstrates the TW-ECDM process. In this procedure, two terminals (electrodes) are utilized, which are plunged into the electrolyte. The electrolyte could be either alkaline or acidic. A traveling (circulating) wire is used as a cathode, which is used to cut or slice the workpiece and the auxiliary (assistant or passive) cathode is utilized as an anode. A circulating wire is kept away (0.1–0.5 mm) from the workpiece and the passive electrode is kept around 30–80 mm away from the machining zone to preserve the current density. With an increase in DC power, electrolysis is observed, and further increasing the voltage results in gas bubble generation, which is responsible for generating the spark [

27]. It was observed that gas bubble formation increases with the applied voltage that was responsible for generating the spark. By further increasing the voltage, the bubbles begin to break down and provide a steady gas film around the wire. If the potential difference is high enough for a given pair of electrodes, sparking is observed, where this spark causes a streamline of high-energy electrons that are transferred with exceptionally high speed toward the workpiece. This burst of electrons produces compressive shock waves on the surface of the workpiece, which results in removing the material via melting, vaporization, and thermal erosion [

28,

29,

30].

Many researchers have studied various aspects of the TW-ECDM process.

Table 1 represents the various wires (tool electrodes) and their sizes, workpiece materials, and key findings regarding the TW-ECDM process till now. The use of a pulse DC supply reduced the surface roughness as compared to simple DC, and therefore, pulse a DC supply was selected for the present study [

31]. The machining performance was improved by keeping a minimum distance between the wire and the workpiece [

32]. Thermal cracks, the HAZ, and a high kerf width were found for a higher voltage, which reduced the precision and quality of machined slits, and therefore, it needs to be minimized. The electric field through the tool electrode (wire) and electrolyte was found to be responsible for producing the spark. A titrated flow for the electrolyte in the TW-ECDM process was proposed to improve the gas film formation, quality of the machined slits, and reduce the waste of the electrolyte [

33]. It flushed the burrs from the cutting area and produced a stable gas film; as a result, a long and straight slit with a minimum kerf width was observed. The use of controlled electrolyte flow enhanced the machining efficiency and quality at a lesser cost. The addition of SiC particles with the titrated electrolytic flow was explored and, as a result, the surface texture improved by 80% and the mean slit breadth reduced from 200 to 185 μm [

34].

The combined effects of the sparking mechanism, electrolysis, and abrasive cutting on the surface roughness, slit expansion, and MRR were reported. It was noticed that the reciprocating mechanism in TW-ECDM helped to machine the irregular cross-section [

36]. Furthermore, by adding abrasive particles into the electrolyte, the slit expansion was reduced because the abrasive particles disturbed the accumulated gas bubbles that formed an isolating film around the wire. To minimize the slit expansion, the duty factor should be low and the power frequency should be high. Therefore, during the present study, to reduce the slit expansion/kerf width, a low duty factor and a high power frequency were selected.

During machining, when the wire is in contact with the electrolyte, a high electric field intensity occurs at that spot; as a result, wire breakage occurs. Another reason for frequent wire breakage is the breakdown of the gas film [

28]. Discharge current flows in KOH for less time as compared to NaOH. Furthermore, the impulsive force is lower, and therefore, the slit expansion is reduced [

36]; as such, in the present study, a KOH electrolyte was used. Recent studies of the W-EDM process showed that the use of a coated wire in W-EDM gives better machining performance and improves the strength, conductivity, flushability, cutting speed, cooling, and sparking abilities [

47]. A coated wire runs smoothly without rupturing in comparison to a conventional wire, and consequently, a zinc-coated brass wire was chosen because of its cooling, flushability, and cutting speed abilities [

48].

All the prior detailed research regarding this topic is restricted to the fabrication of microslits on quartz and it is clear that a need still exists for an electrolyte and a wire that can efficiently machine microslits. During the electrolysis process, bubbles form and stick on the surface of the wire (tool electrode) after a less active surface area of wire becomes available, which reduces the efficiency of the electrolysis process. Furthermore, bombarding electrons raise the temperature of the workpiece for a short time, and due to the quenching phenomenon, the temperature of the workpiece decreases; thus, better electrolysis is required for stable machining. Moreover, for stable and efficient machining performance, it is required to reduce the wire breakage, improve the gas film formation, eliminating the debris (fine size) from the machining area, and provide a uniform electrolysis process. For this reason, a stable and efficient machining process, along with a better electrolysis process, are crucial determinants of the quartz machining quality and merit further analysis. The MHD approach can be a potential solution as it improves the electrolysis process and flushes debris from the machining area. To produce stable machining operations, the wire breakage phenomenon needs to be minimized, and thus, a zinc-coated brass wire was used to reduce the wire breakage during the process. Therefore, in the present work, an experiment was undertaken to fabricate microslits on quartz material with the integration of MHD-assisted TW-ECDM and a zinc-coated brass wire approach. The applied voltage, percentage of electrolyte concentration, and wire speed were selected as the input process parameters, and the material removal rate (MRR), length of cut (LOC), and surface roughness (Ra) were selected as the quality characteristics. The subsequent section illustrates the materials and methods that were used to conduct the investigation.

2. Experimental Methodology

As discussed in the introduction section, owing to the higher hardness, nonconductivity, and higher melting point, the processing of quartz is difficult, and thus, quartz with the size of 75 × 25 × 2 mm was used as the workpiece material for this study [

33]; some major properties of quartz material are given in

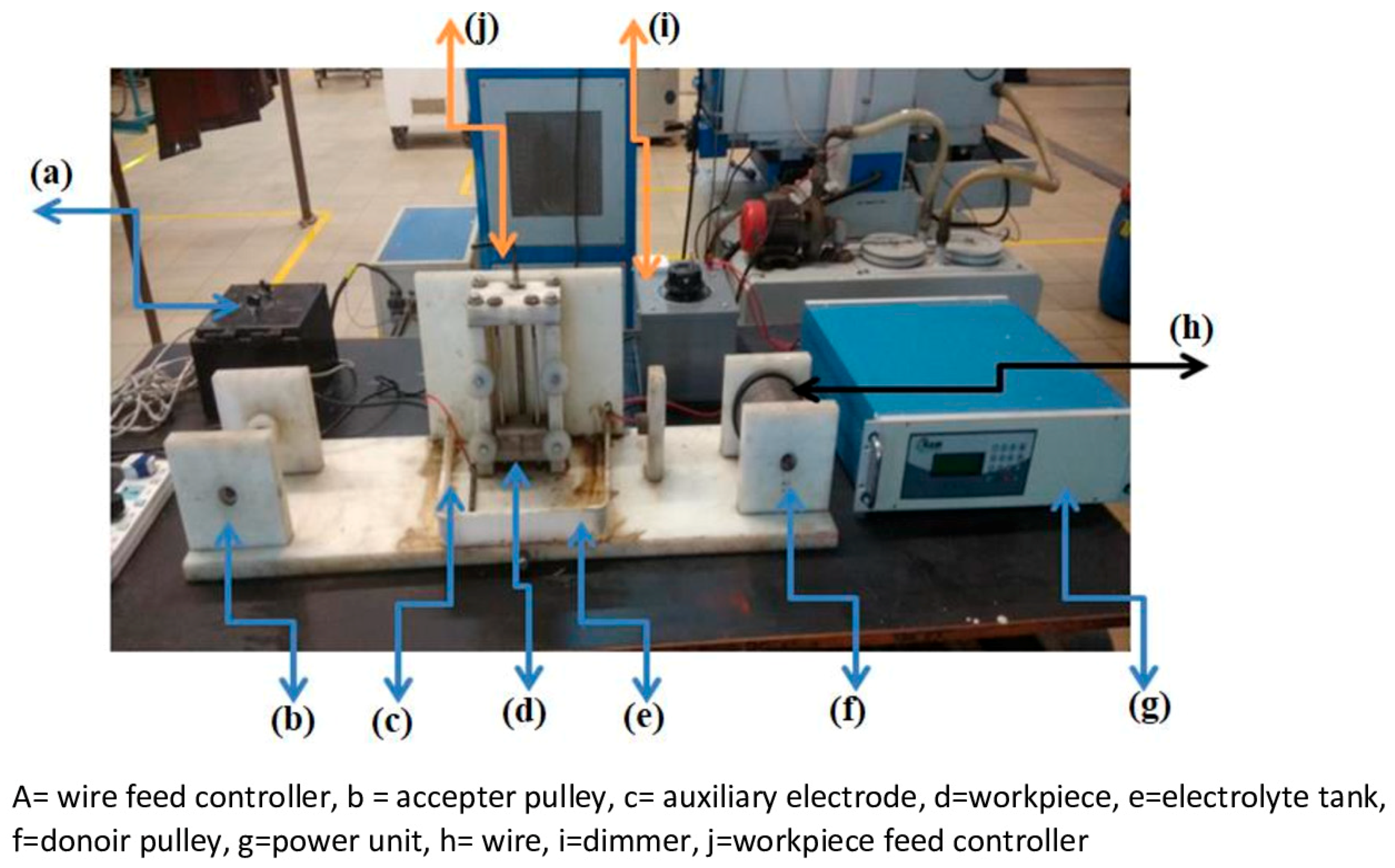

Table 2. The TW-ECDM setup was designed and developed and the major units of the setup are as follows: passive (auxiliary) and the active (wire) electrodes, machining chamber, pulse DC power supply, wire feed controller, tank (contained the electrolyte), workpiece clamping, and the feed mechanism as shown in

Figure 2.

A polymer-based material was utilized for the setup fabrication due to its exceptional scratch- and chemical-resistant nature. The size of the electrolyte tank was 120 × 100 × 40 mm. The passive (auxiliary) electrode was made of a 20 mm diameter graphite rod that was 80 mm in length. In the proposed study, a pulse mode DC power supply with a maximum voltage of 220 V and a current of 6 A was deployed. The positive and negative ends were connected to the anode and cathode, respectively. For guiding the wire, the pulley was made of Teflon material to maintain proper tension. A NaOH electrolyte was selected over KOH for better performance [

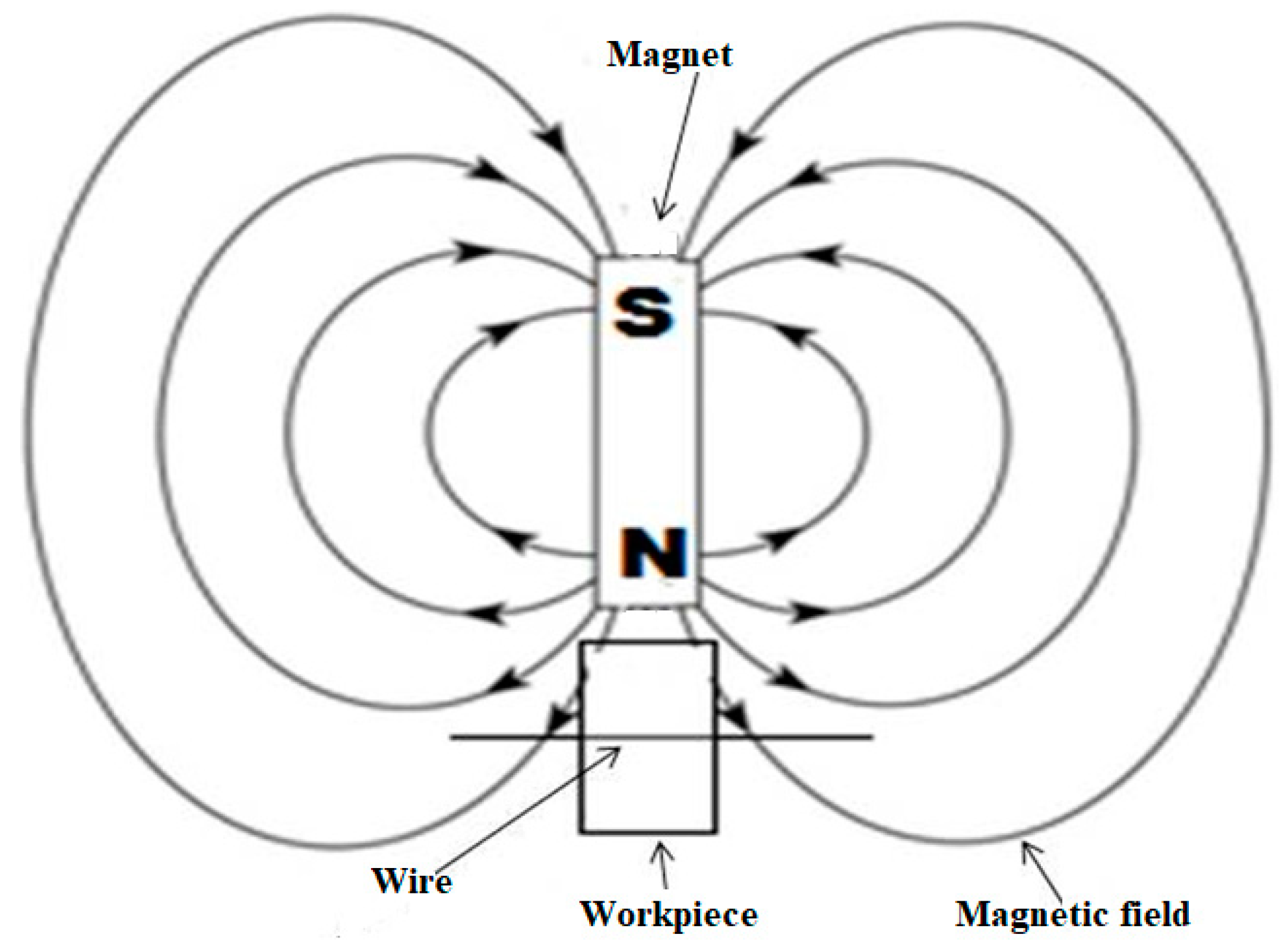

36]. In the present work, a neodymium permanent magnet (disc type) was used to produce magnetic fields and the properties of the magnet are presented in

Table 3. The workpiece and magnet were kept at a right angle to each other to obtain a better magnetic effect, as depicted in

Figure 3.

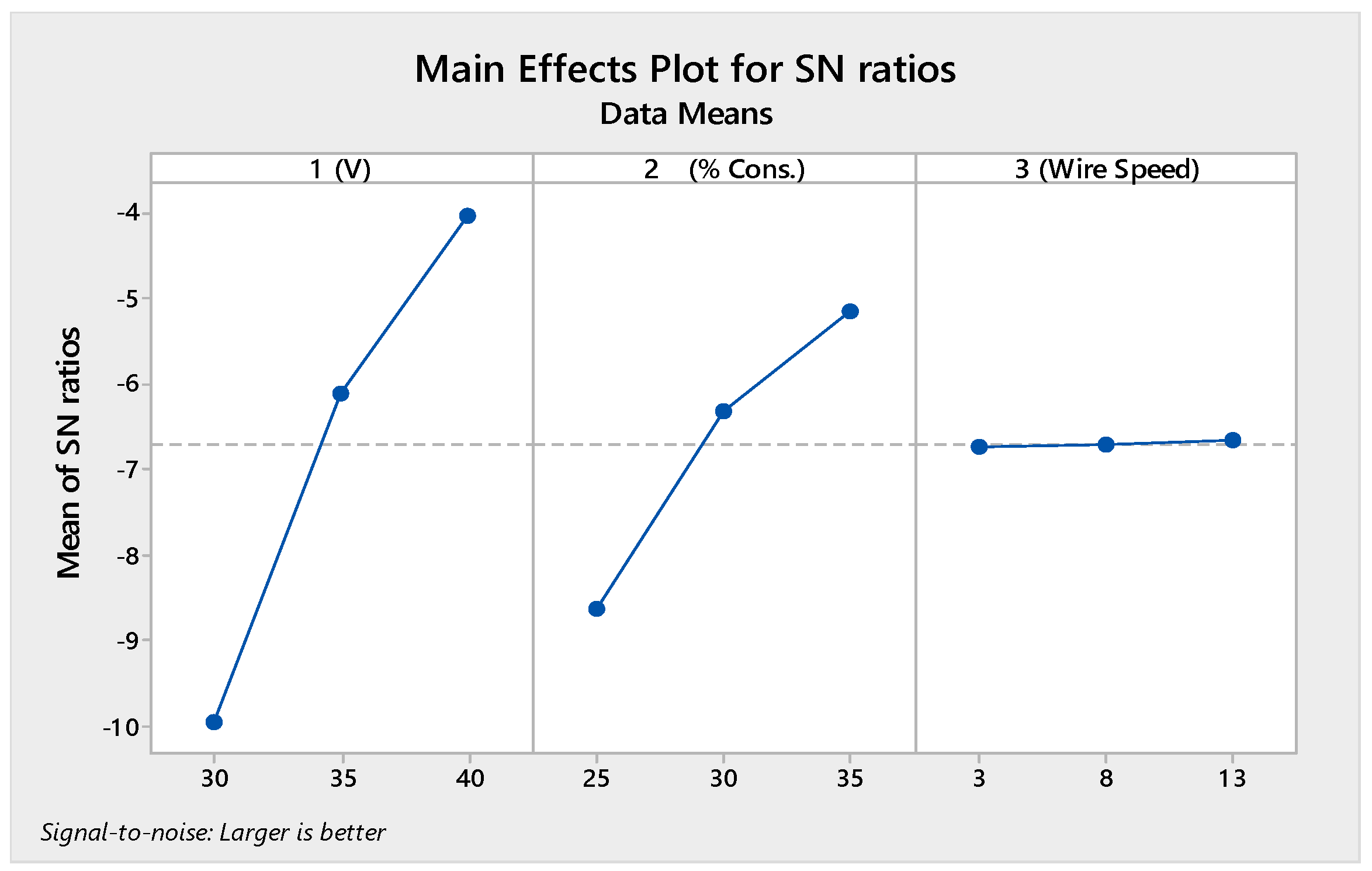

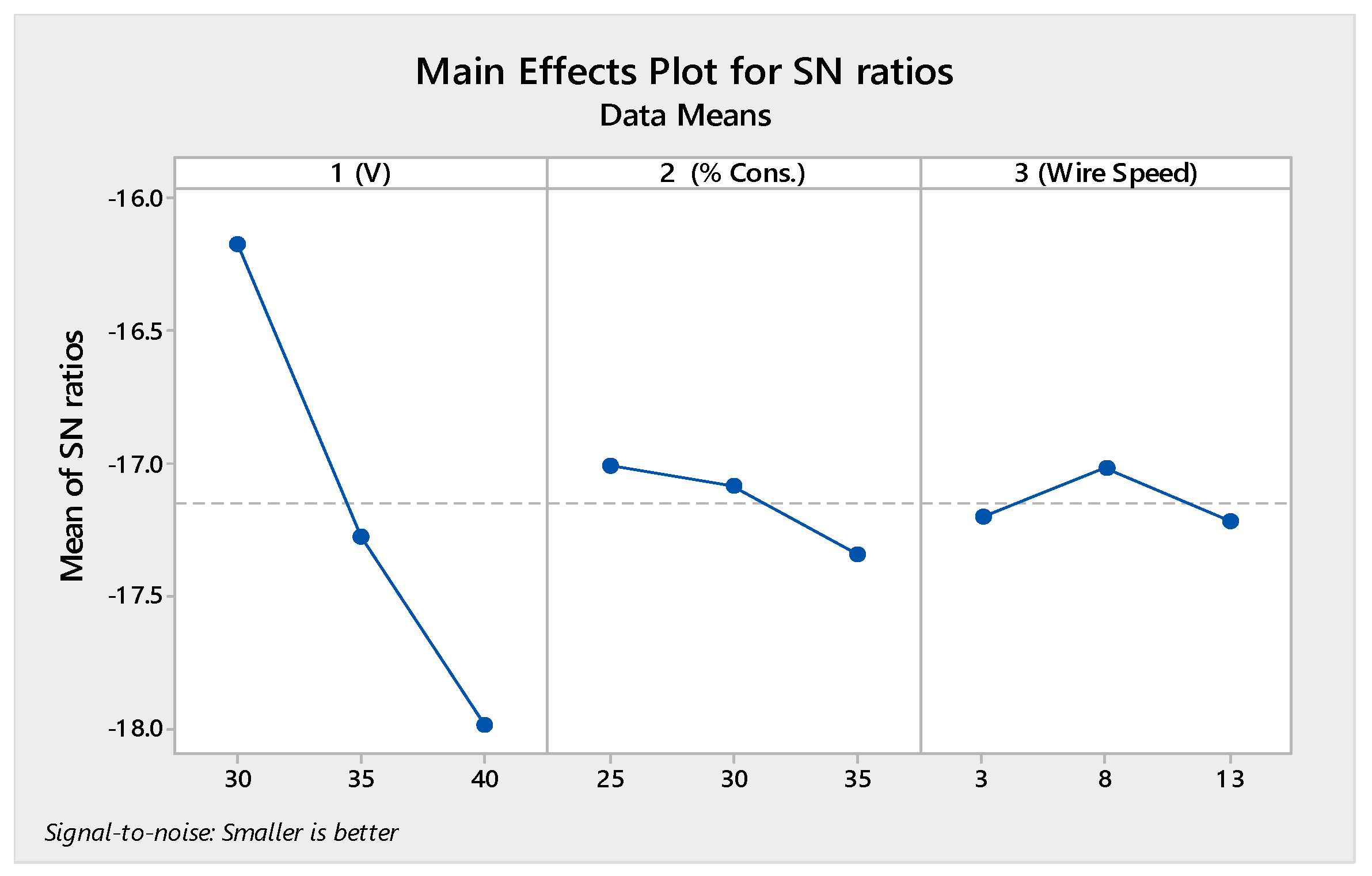

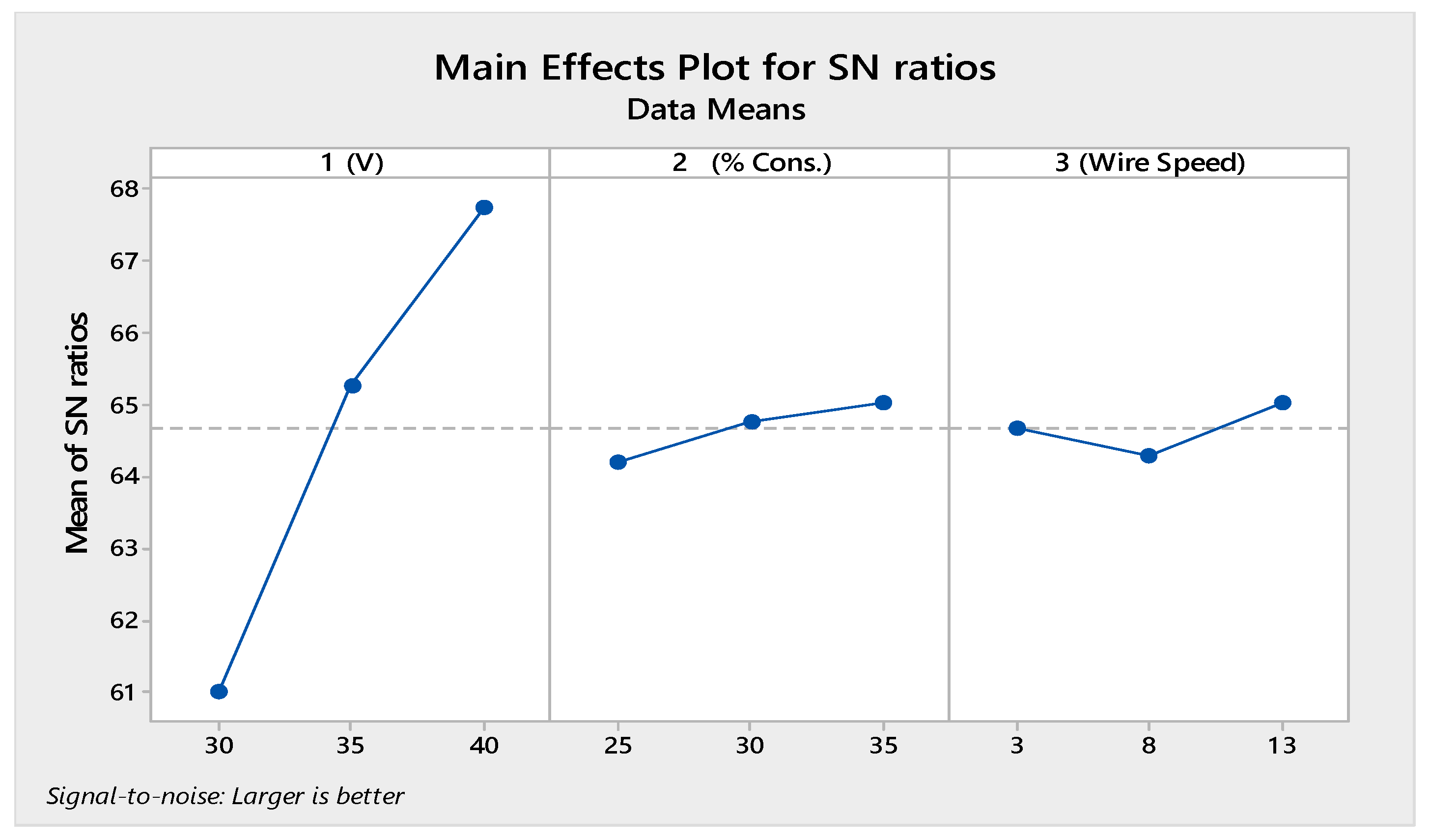

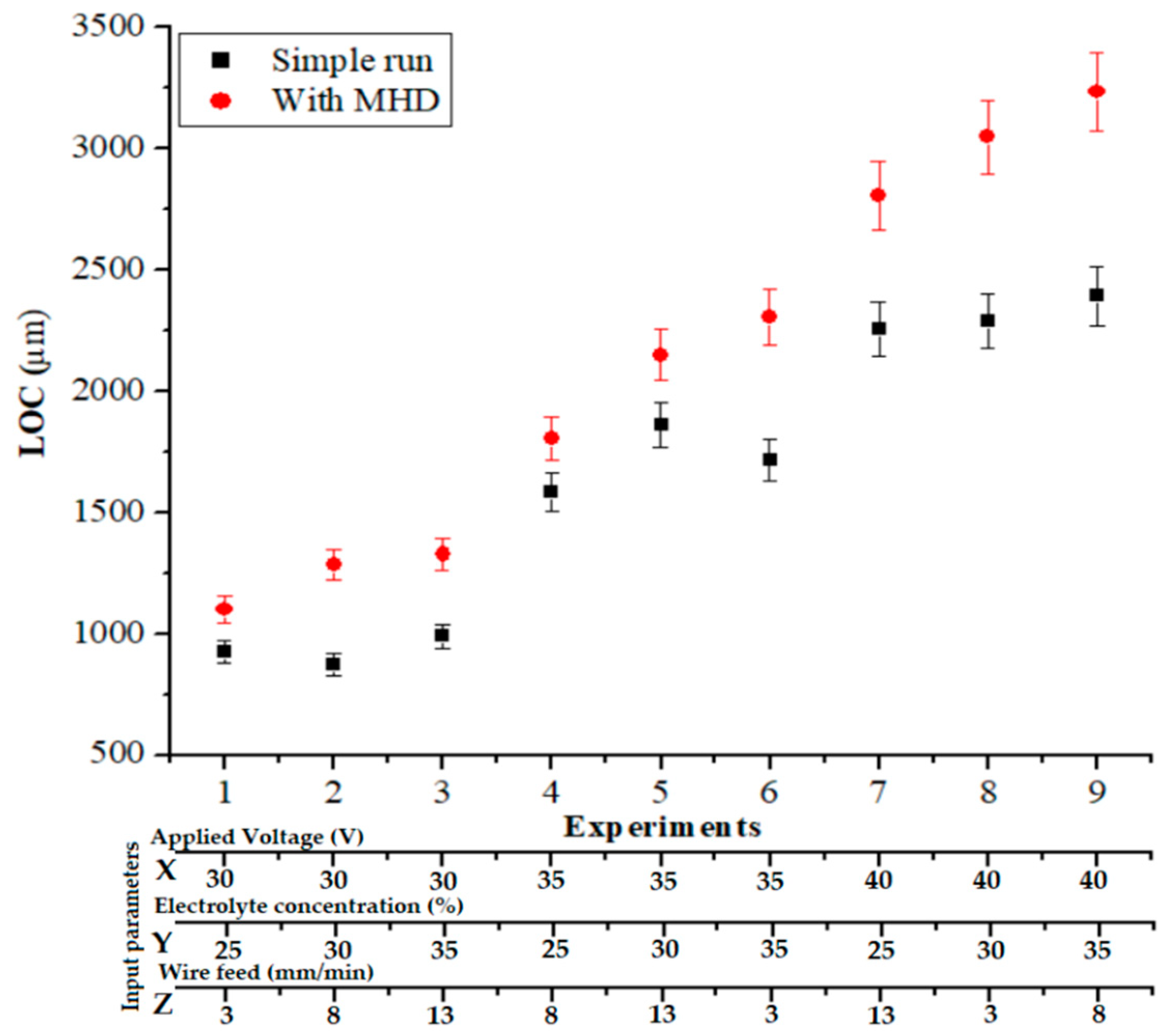

For the analysis of the experimental results, MINITAB-17 software (Gandhinagar, Gujarat, India) was used to evaluate the performance of the process. An L9 orthogonal array (OA) was used to consider the variable parameters of voltage, electrolyte concentration, and wire feed (speed). Three response parameters, namely, the material removal rate (MRR), length of cut (LOC), and surface roughness (Ra) were considered.

Initial Trials

The conditions for the initial trials are summarized in

Table 4.

Based on the initial trials, the available literature, and experimental restrictions, the range of input process parameters was selected to be wire speed: 0–15 m/min, electrolyte concentration: 25 to 35 (g/L), and voltage: 30–40 V. During the experiment, three levels of each input process parameter were selected, which are shown in

Table 5. In addition to the Taguchi method, analysis of variance (ANOVA) was used to measure the impact of each input process parameter on the MRR, LOC, and R

a. It also indicated the relative contribution of each input process parameter on the response. In the Taguchi design, the signal and noise represent the desired mean value and the undesirable (i.e., standard deviation) value of the output characteristics, respectively. In the present study, the interactions between the input machining parameters were neglected.

MRR was calculated using Equation (1):

where

Wb and

Wa represent the weight of the workpiece before and after the experiment (mg/min), respectively, and

t is the total machining time (min), where each experiment was designed for 10 min of machining time.

A METTLER TOLEDO model was used to measure the weight of the workpiece. To measure the LOC, a scanning electron microscope was used. A surface roughness tester (model no-ISR-S400) was used to measure

Ra. Equations (2)–(4) show the improvement ratio calculations of

MRR,

LOC, and

Ra, respectively:

where

MRRwmf is the material removal rate with a magnetic field (MHD) and

MRRwomf is the material removal rate without a magnetic field (MHD);

where

Rawmf is the surface roughness with a magnetic field (MHD) and

Rawomf is the surface roughness without a magnetic field (MHD);

where

LOCwmf is the length of cut with a magnetic field (MHD) and

LOCwomf is the length of cut without a magnetic field (MHD).