Fatigue Modeling and Numerical Analysis of Re-Filling Probe Hole of Friction Stir Spot Welded Joints in Aluminum Alloys

Abstract

1. Introduction

2. Materials and Methods

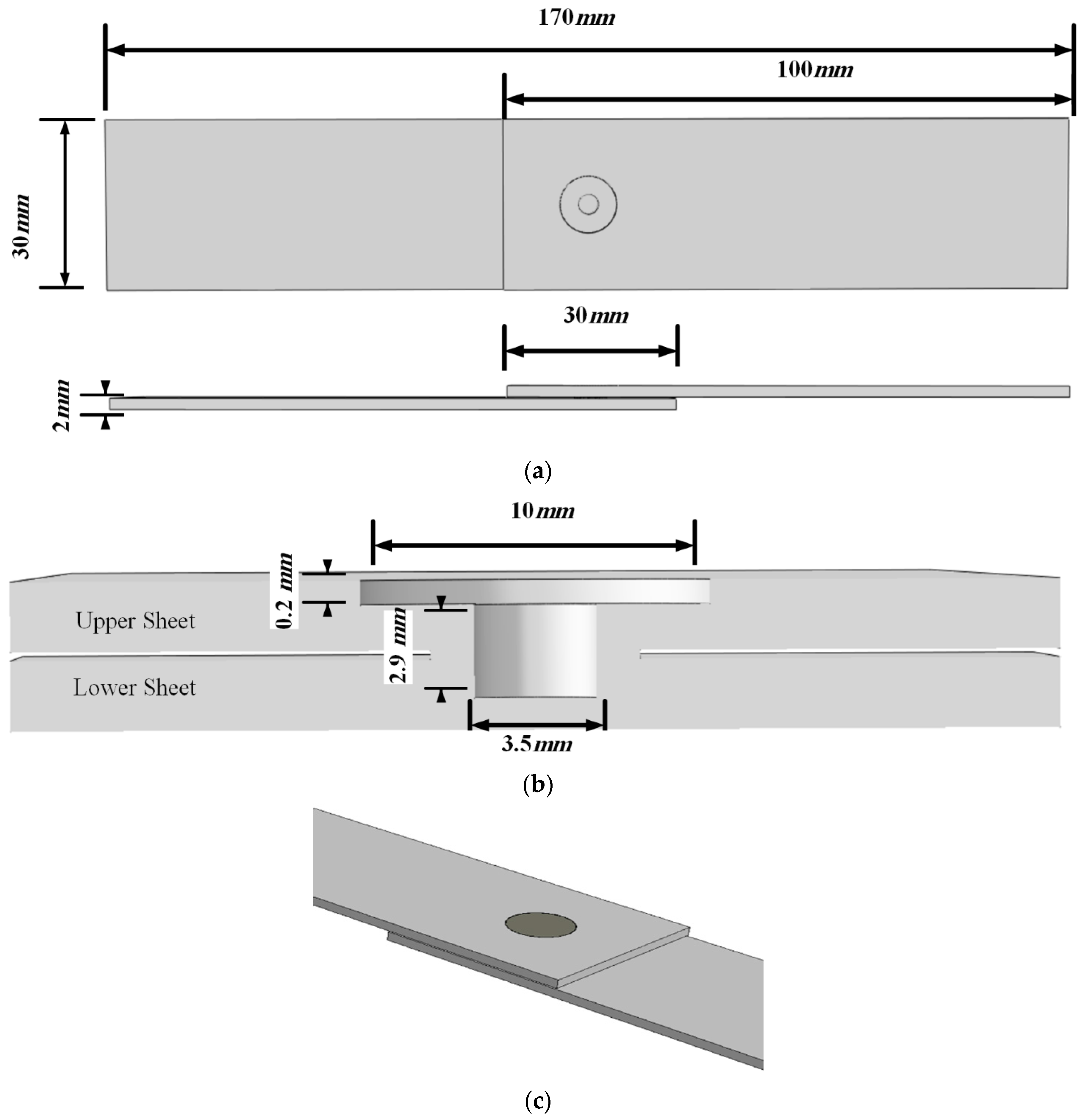

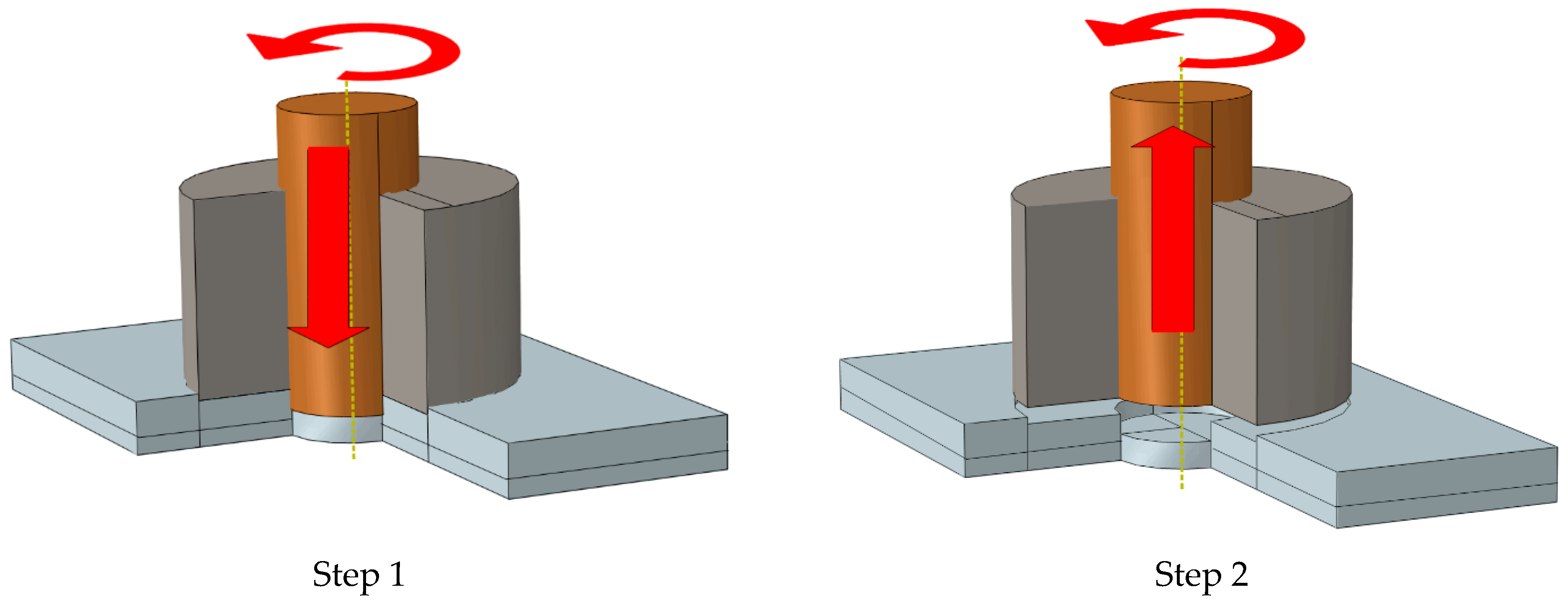

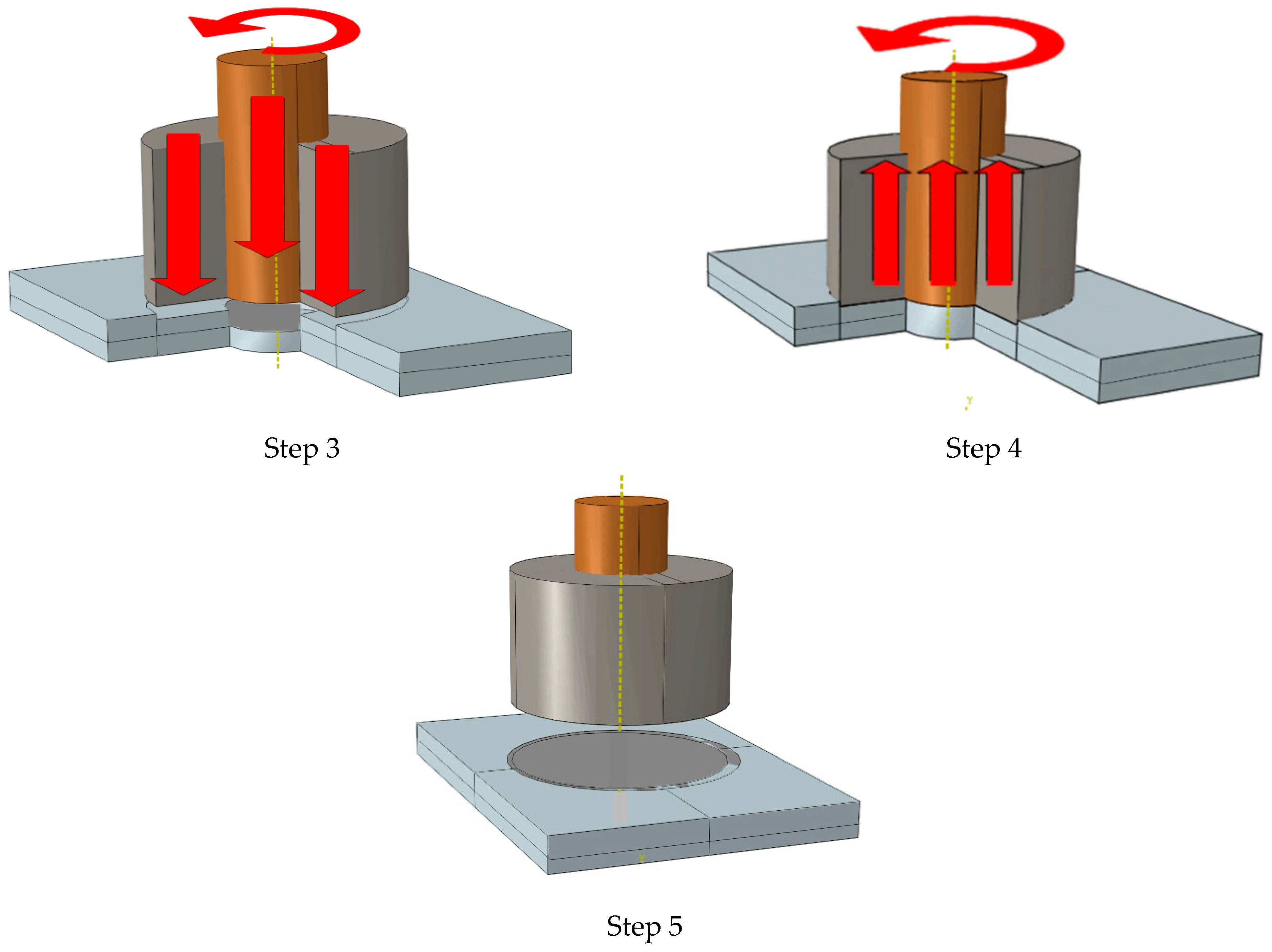

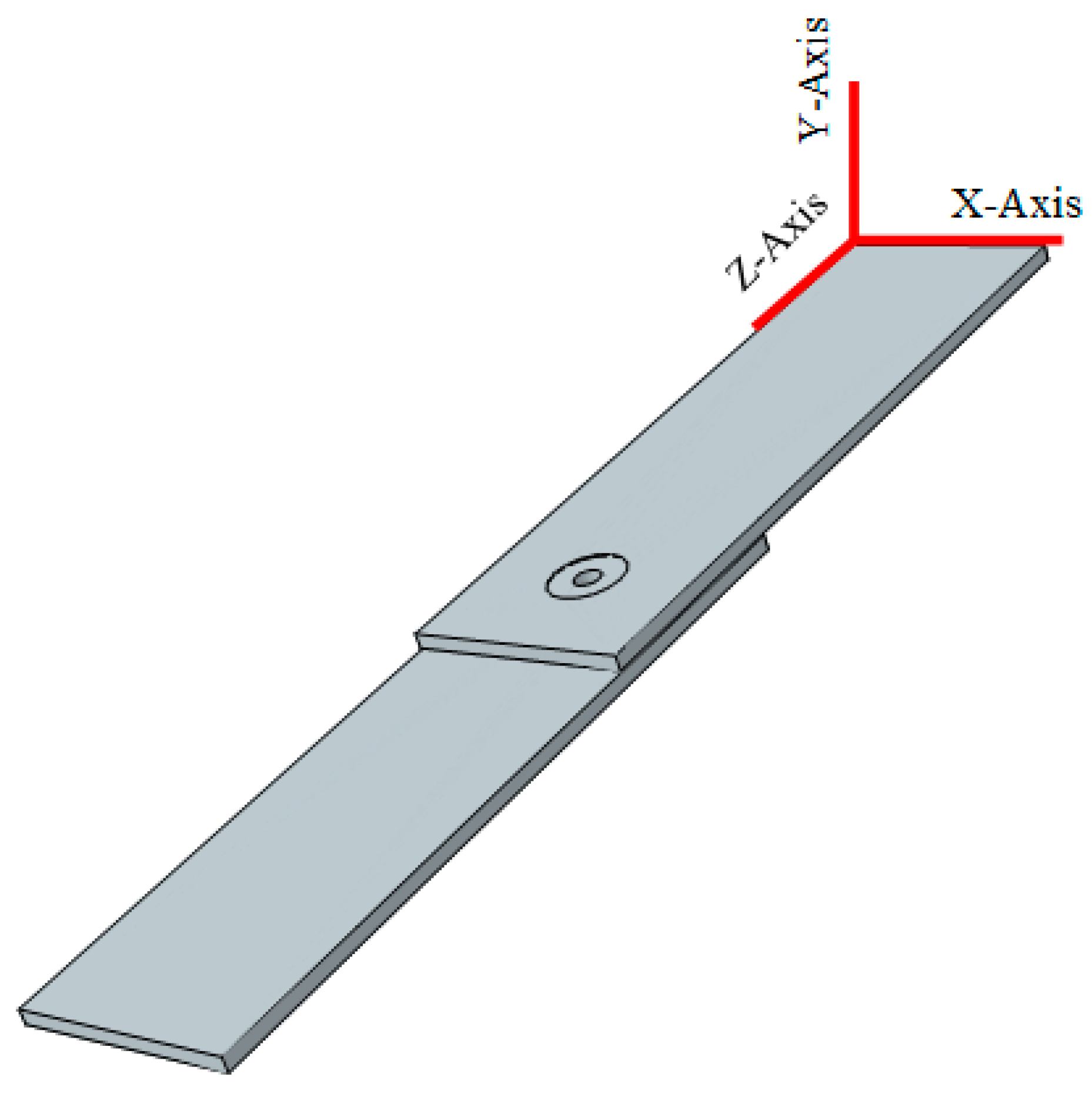

2.1. Materials and Design

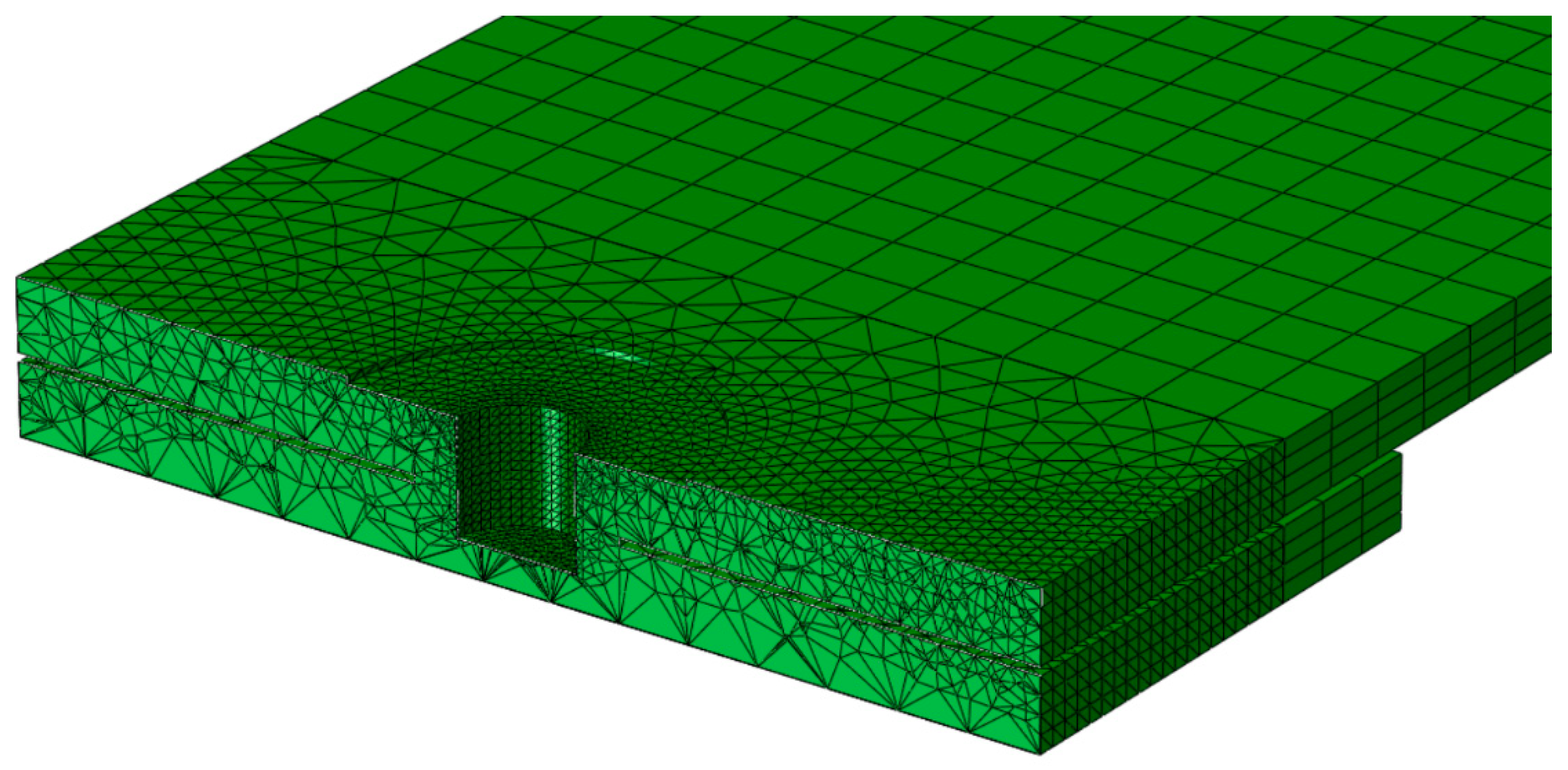

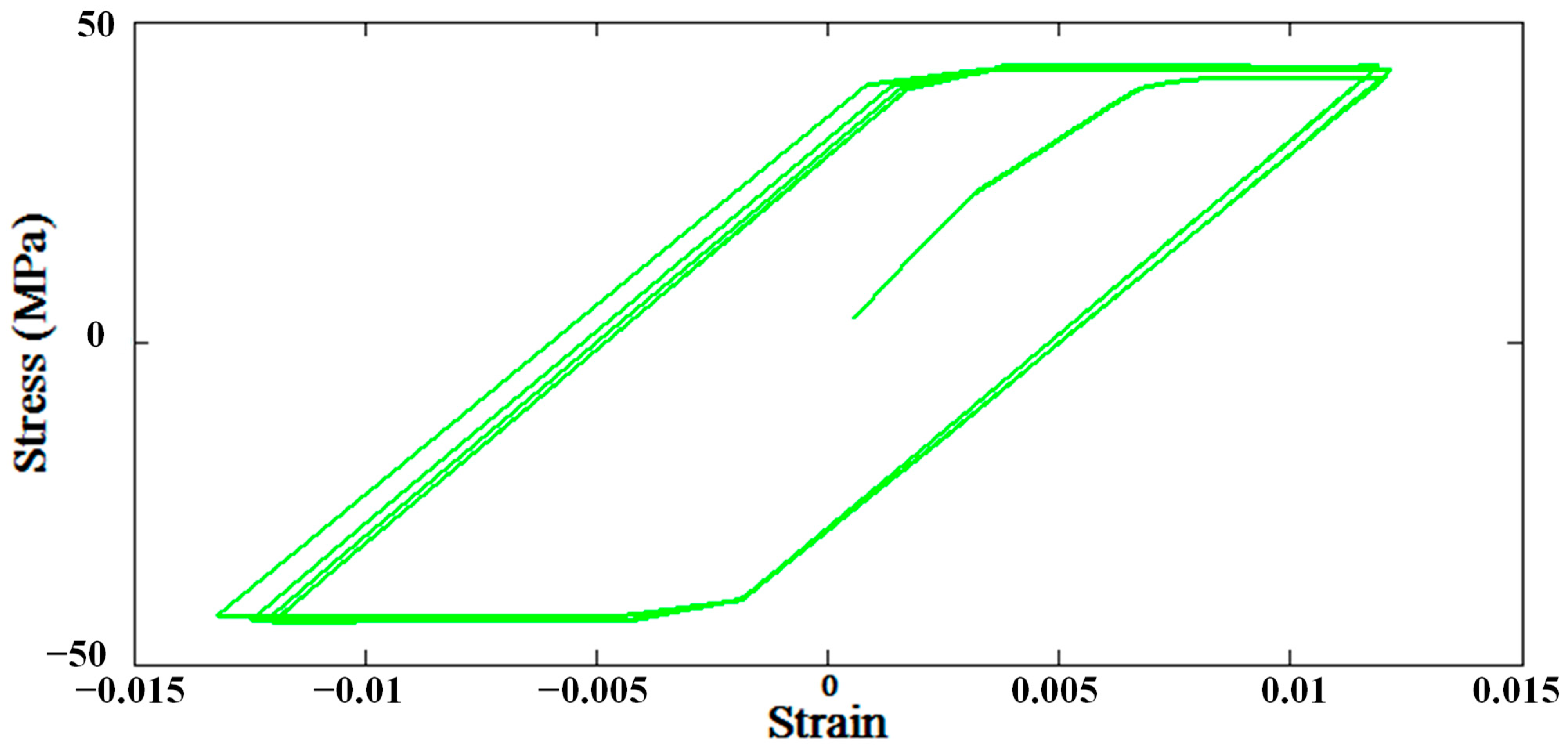

2.2. Numerical Modeling

2.3. Fatigue Life Prediction

3. Results

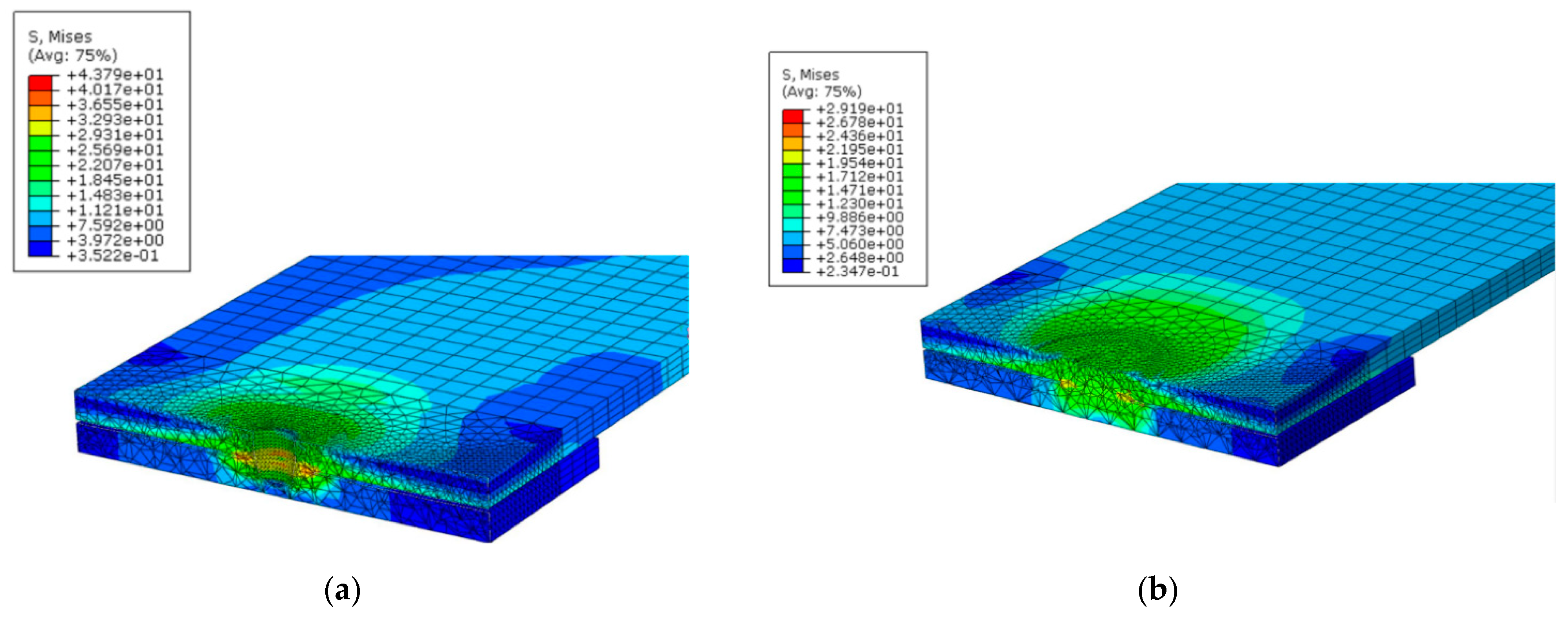

3.1. Tensile Strength

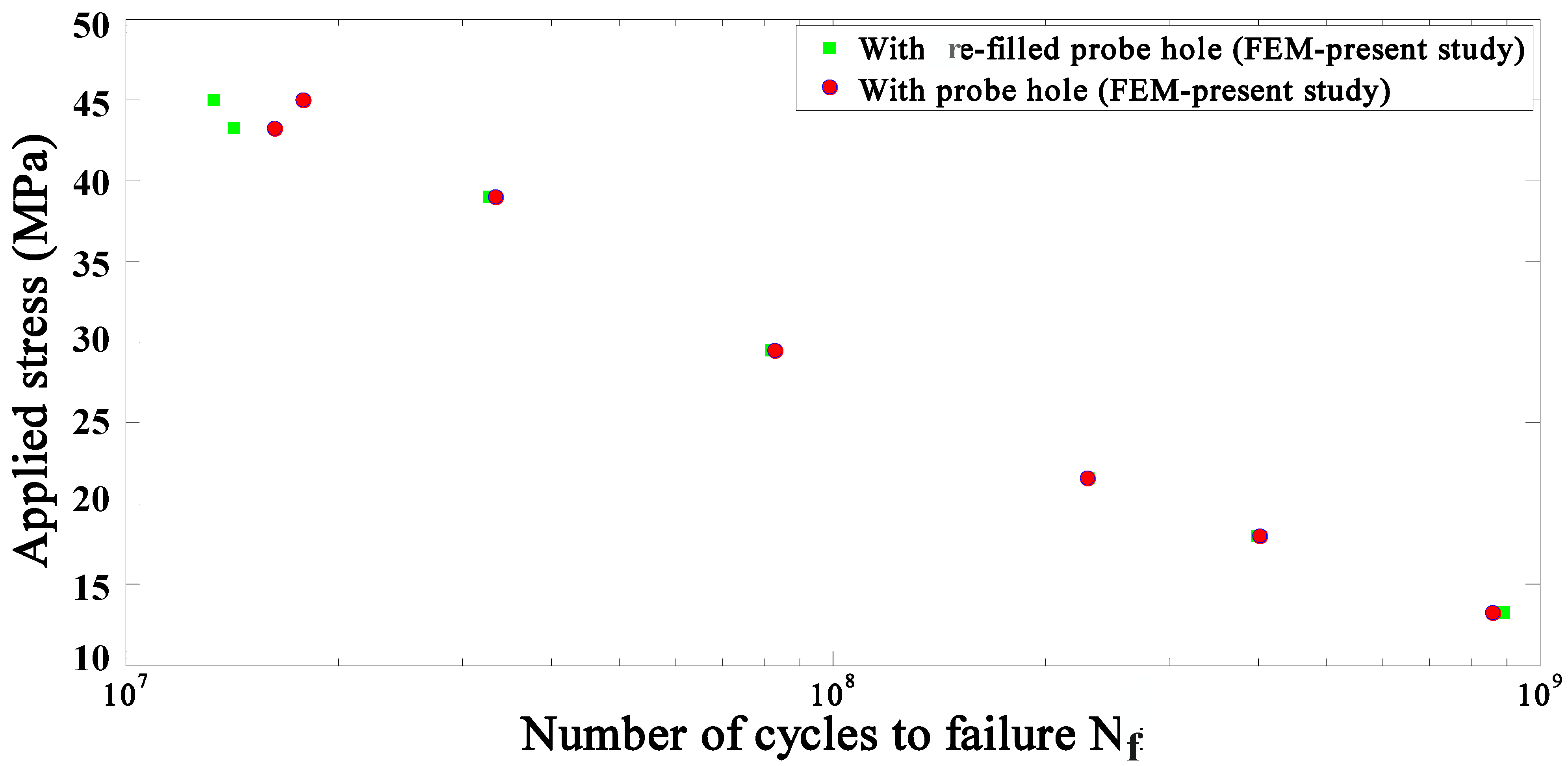

3.2. Fatigue Prediction

4. Conclusions

- The tensile strength of the FSSW joint is improved by re-filling the probe hole because of the effective cross-sectional area. In fact, the fracture path is increased, and therefore stress in the fracture path decreases.

- Fatigue strengths of joints with both probe hole and re-filling probe hole are almost the same at low applied load levels.

- At high applied load levels, the joint with a probe hole has higher fatigue strength than the joint with a re-filled probe hole.

- Using a strain-based approach, by calculating the strain from volume averaging of the strains of the elements near the welding zone (a cylindrical-shaped volume), is a reliable approach to determine the fatigue life.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, X.W.; Fu, T.; Li, W.Y. Friction Stir Spot Welding: A Review on Joint Macro- and Microstructure, Property, and Process Modelling. Adv. Mater. Sci. Eng. 2014, 2014, 697170. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, Y.; Zhao, H.; Wang, X. Interface Behavior and Impact Properties of Dissimilar Al/Steel Keyhole-Free FSSW Joints. Metals 2019, 9, 691. [Google Scholar] [CrossRef]

- Hassanifard, S.; Mohammadpour, M.; Rashid, H.A. A novel method for improving fatigue life of friction stir spot welded joints using localized plasticity. Mater. Des. 2014, 53, 962–971. [Google Scholar] [CrossRef]

- Bagheri, B.; Abbasi, M.; Givi, M. Effects of Vibration on Microstructure and Thermal Properties of Friction Stir Spot Welded (FSSW) Aluminum Alloy (Al5083). Int. J. Precis. Eng. Manuf. 2019, 20, 1219–1227. [Google Scholar] [CrossRef]

- Niroumand-Jadidi, A.; Kashani-Bozorg, S.F. Microstructure and property assessment of dissimilar joints of 6061-T6 Al/dual-phase steel fabricated by friction stir spot welding. Weld. World 2018, 62, 751–765. [Google Scholar] [CrossRef]

- Ogawa, Y.; Akebono, H.; Tanaka, K.; Sugeta, A. Effect of welding time on fatigue properties of friction stir spot welds of Al to carbon fibre-reinforced plastic. Sci. Technol. Weld. Join. 2018, 24, 235–242. [Google Scholar] [CrossRef]

- Uematsu, Y.; Tokaji, K.; Tozaki, Y.; Nakashima, Y.; Shimizu, T. Fatigue behaviour of dissimilar friction stir spot welds between A6061-T6 and low carbon steel sheets welded by a scroll grooved tool without probe. Fatigue Fract. Eng. Mater. Struct. 2011, 34, 581–591. [Google Scholar] [CrossRef]

- Lin, P.-C.; Lin, S.-H.; Pan, J.; Pan, T.; Nicholson, J.M.; Garman, M.A. Microstructures and Failure Mechanisms of Spot Friction Welds in Lap-Shear Specimens of Aluminum 6111-T4 Sheets. SAE Tech. Pap. Ser. 2004, 113, 602–609. [Google Scholar] [CrossRef]

- Tozaki, Y.; Uematsu, Y.; Tokaji, K. Effect of tool geometry on microstructure and static strength in friction stir spot welded aluminium alloys. Int. J. Mach. Tools Manuf. 2007, 47, 2230–2236. [Google Scholar] [CrossRef]

- Hassanifard, S.; Ahmadi, S.R.; Pour, M.M. Weld arrangement effects on the fatigue behavior of multi friction stir spot welded joints. Mater. Des. 2013, 44, 291–302. [Google Scholar] [CrossRef]

- Ebrahimpour, A.; Mostafapour, A.; Samadian, K. Finite element and experimental investigation on the effects of temperature, strain and strain rate on microstructure and mechanical properties of FSSWed TRIP steel joints. Mater. Res. Express 2018, 6, 016559. [Google Scholar] [CrossRef]

- Uematsu, Y.; Tokaji, K.; Tozaki, Y.; Kurita, T.; Murata, S. Effect of re-filling probe hole on tensile failure and fatigue behaviour of friction stir spot welded joints in Al–Mg–Si alloy. Int. J. Fatigue 2008, 30, 1956–1966. [Google Scholar] [CrossRef]

- Kwee, I.; De Waele, W.; Faes, K. Weldability of high-strength aluminium alloy EN AW-7475-T761 sheets for aerospace applications, using refill friction stir spot welding. Weld. World 2019, 63, 1001–1011. [Google Scholar] [CrossRef]

- Kubit, A.; Drabczyk, M.; Trzepiecinski, T.; Bochnowski, W.; Kaščák, Ľ.; Slota, J. Fatigue Life Assessment of Refill Friction Stir Spot Welded Alclad 7075-T6 Aluminium Alloy Joints. Metals 2020, 10, 633. [Google Scholar] [CrossRef]

- Deng, L.; Li, S.; Ke, L.; Liu, J.; Kang, J. Microstructure and Fracture Behavior of Refill Friction Stir Spot Welded Joints of AA2024 Using a Novel Refill Technique. Metals 2019, 9, 286. [Google Scholar] [CrossRef]

- Branco, R.; Costa, J.; Berto, F.; Antunes, F. Fatigue life assessment of notched round bars under multiaxial loading based on the total strain energy density approach. Theor. Appl. Fract. Mech. 2018, 97, 340–348. [Google Scholar] [CrossRef]

- Nogueira, F.; Cunha, J.; Mateus, A.; Malça, C.; Costa, J.; Branco, R. Cyclic plastic behaviour of 7075 aluminium alloy. Procedia Struct. Integr. 2020, 25, 438–444. [Google Scholar] [CrossRef]

- Xin, H.; Correia, J.A.; Veljkovic, M.; Berto, F.; Manuel, L. Residual stress effects on fatigue life prediction using hardness measurements for butt-welded joints made of high strength steels. Int. J. Fatigue 2021, 147, 106175. [Google Scholar] [CrossRef]

- Foti, P.; Berto, F. Fatigue assessment of high strength welded joints through the strain energy density method. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 2694–2702. [Google Scholar] [CrossRef]

- Sandnes, L.; Grong, Ø.; Welo, T.; Berto, F. Fatigue properties of AA6060-T6 butt welds made by hybrid metal extrusion & bonding. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 2349–2358. [Google Scholar] [CrossRef]

- Macek, W.; Branco, R.; Szala, M.; Marciniak, Z.; Ulewicz, R.; Sczygiol, N.; Kardasz, P. Profile and Areal Surface Parameters for Fatigue Fracture Characterisation. Materials 2020, 13, 3691. [Google Scholar] [CrossRef]

- Panin, S.; Vlasov, I.; Maksimov, P.; Moiseenko, D.; Maruschak, P.; Yakovlev, A.; Schmauder, S.; Berto, F. Increasing Fatigue Life of 09Mn2Si Steel by Helical Rolling: Theoretical–Experimental Study on Governing Role of Grain Boundaries. Materials 2020, 13, 4531. [Google Scholar] [CrossRef] [PubMed]

- Song, W.; Liu, X.; Berto, F.; Razavi, S.M.J. Low-Cycle Fatigue Behavior of 10CrNi3MoV High Strength Steel and Its Undermatched Welds. Materials 2018, 11, 661. [Google Scholar] [CrossRef] [PubMed]

- Yousefi, A.; Jolaiy, S.; Hedayati, R.; Serjouei, A.; Bodaghi, M. Fatigue Life Improvement of Cracked Aluminum 6061-T6 Plates Repaired by Composite Patches. Materials 2021, 14, 1421. [Google Scholar] [CrossRef]

- Singh, A.; Das, S.; Craciun, E.-M. Effect of Thermomechanical Loading on an Edge Crack of Finite Length in an Infinite Orthotropic Strip. Mech. Compos. Mater. 2019, 55, 285–296. [Google Scholar] [CrossRef]

- Araque, O.; Arzola, N. Weld Magnification Factor Approach in Cruciform Joints Considering Post Welding Cooling Medium and Weld Size. Materials 2018, 11, 81. [Google Scholar] [CrossRef]

- Yousefi, A.; Mashhadi, M.M.; Safarabadi, M. Numerical analysis of cracked aluminum plate repaired with multi-scale reinforcement composite patches. J. Compos. Mater. 2020, 54, 4341–4357. [Google Scholar] [CrossRef]

- Khenyab, A.Y.; Ajaj, H.F.; Helal, R.A. Effect of Underground Corrosion on the Buckling of Al Alloy 6061-T4 Columns under Increasing Load. Al-Nahrain J. Eng. Sci. 2018, 21, 417–427. [Google Scholar] [CrossRef]

- Akram, S.; Jaffery, S.H.I.; Khan, M.; Fahad, M.; Mubashar, A.; Ali, L. Numerical and experimental investigation of Johnson–Cook material models for aluminum (Al 6061-T6) alloy using orthogonal machining approach. Adv. Mech. Eng. 2018, 10. [Google Scholar] [CrossRef]

- Shen, Z.; Ding, Y.; Chen, J.; Fu, L.; Liu, X.C.; Chen, H.; Guo, W.; Gerlich, A.P. Microstructure, static and fatigue properties of refill friction stir spot welded 7075-T6 aluminium alloy using a modified tool. Sci. Technol. Weld. Join. 2019, 24, 587–600. [Google Scholar] [CrossRef]

- Piccini, J.M.; Svoboda, H.G. Tool geometry optimization in friction stir spot welding of Al-steel joints. J. Manuf. Process. 2017, 26, 142–154. [Google Scholar] [CrossRef]

- Abaqus, V. 6.14 Documentation; Dassault Systemes Simulia Corporation: Johnston, RI, USA, 2014; Volume 651, p. 6.2. [Google Scholar]

- Fatemi, A.; Plaseied, A.; Khosrovaneh, A.; Tanner, D. Application of bi-linear log–log S–N model to strain-controlled fatigue data of aluminum alloys and its effect on life predictions. Int. J. Fatigue 2005, 27, 1040–1050. [Google Scholar] [CrossRef]

- Abood, A.N.; Saleh, A.H.; Abdullah, Z.W. Effect of Heat Treatment on Strain Life of Aluminum Alloy AA 6061. J. Mater. Sci. Res. 2013, 2, 51. [Google Scholar] [CrossRef]

- Badarinarayan, H.; Shi, Y.; Li, X.; Okamoto, K. Effect of tool geometry on hook formation and static strength of friction stir spot welded aluminum 5754-O sheets. Int. J. Mach. Tools Manuf. 2009, 49, 814–823. [Google Scholar] [CrossRef]

| A (MPa) | B (MPa) | C0 | n | m0 |

|---|---|---|---|---|

| 250 | 79.7 | 0.00249 | 0.499 | 1.499 |

| Plane | Z = 0 | Y = 0 | X = 0 | Z = 2L | |

|---|---|---|---|---|---|

| Simulation | |||||

| Static | , | ||||

| Fatigue | , | ||||

| Materials Constant | Aluminum 6061-T4 |

|---|---|

| (mm/mm) | 0.15 |

| Fatigue ductility exponent, c | −0.520 |

| Fatigue strength coefficient, (MPa) | 332 |

| Fatigue strength exponent, b | −0.120 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yousefi, A.; Serjouei, A.; Hedayati, R.; Bodaghi, M. Fatigue Modeling and Numerical Analysis of Re-Filling Probe Hole of Friction Stir Spot Welded Joints in Aluminum Alloys. Materials 2021, 14, 2171. https://doi.org/10.3390/ma14092171

Yousefi A, Serjouei A, Hedayati R, Bodaghi M. Fatigue Modeling and Numerical Analysis of Re-Filling Probe Hole of Friction Stir Spot Welded Joints in Aluminum Alloys. Materials. 2021; 14(9):2171. https://doi.org/10.3390/ma14092171

Chicago/Turabian StyleYousefi, Armin, Ahmad Serjouei, Reza Hedayati, and Mahdi Bodaghi. 2021. "Fatigue Modeling and Numerical Analysis of Re-Filling Probe Hole of Friction Stir Spot Welded Joints in Aluminum Alloys" Materials 14, no. 9: 2171. https://doi.org/10.3390/ma14092171

APA StyleYousefi, A., Serjouei, A., Hedayati, R., & Bodaghi, M. (2021). Fatigue Modeling and Numerical Analysis of Re-Filling Probe Hole of Friction Stir Spot Welded Joints in Aluminum Alloys. Materials, 14(9), 2171. https://doi.org/10.3390/ma14092171