Properties Evaluation of the Welded Joints Made by Disk Laser

Abstract

1. Introduction

1.1. Weldability of Progressive Steel Sheets for the Automotive Industry

1.2. The Aim of the Current Investigation

2. Materials and Methods

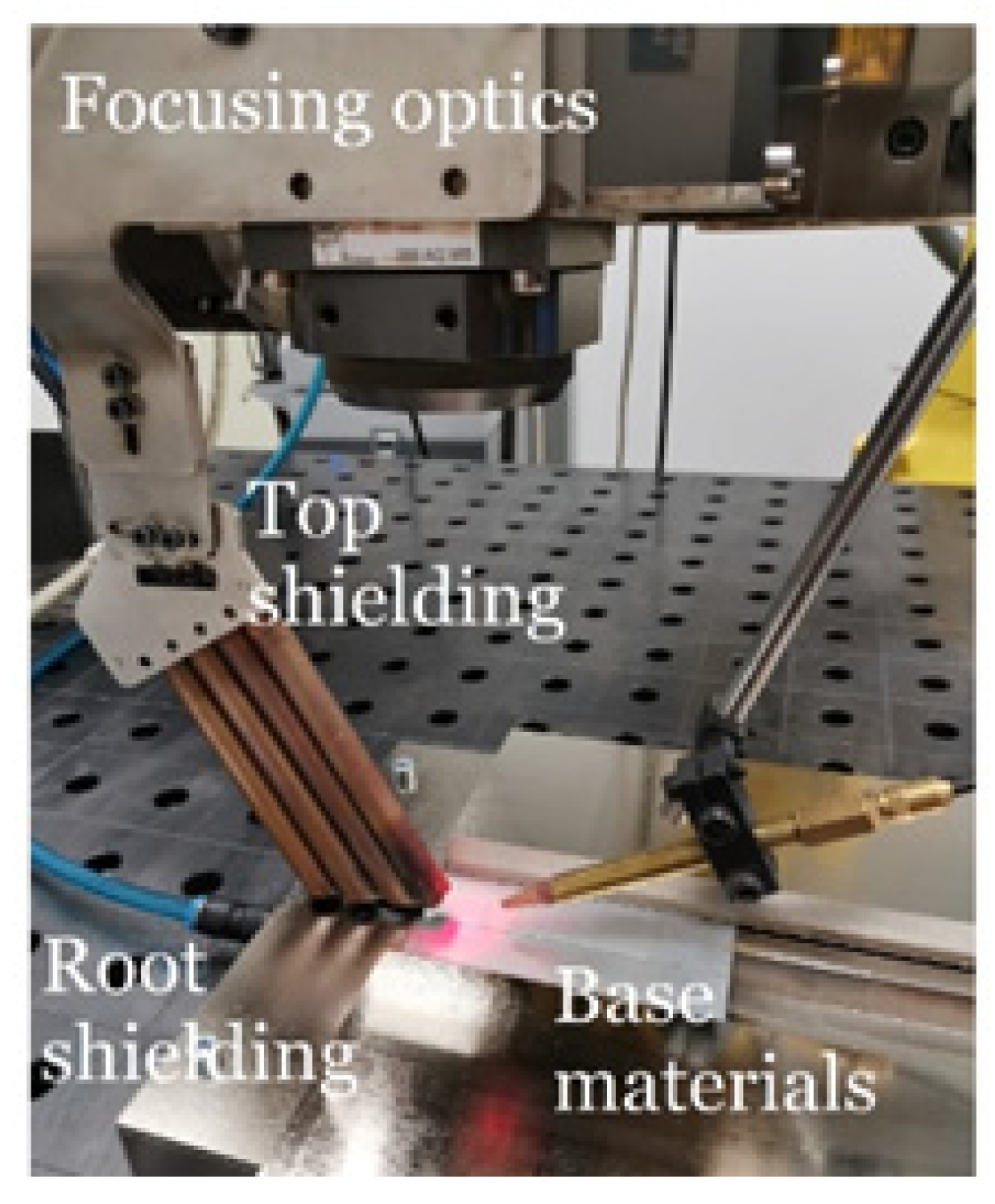

Disk Laser Welding

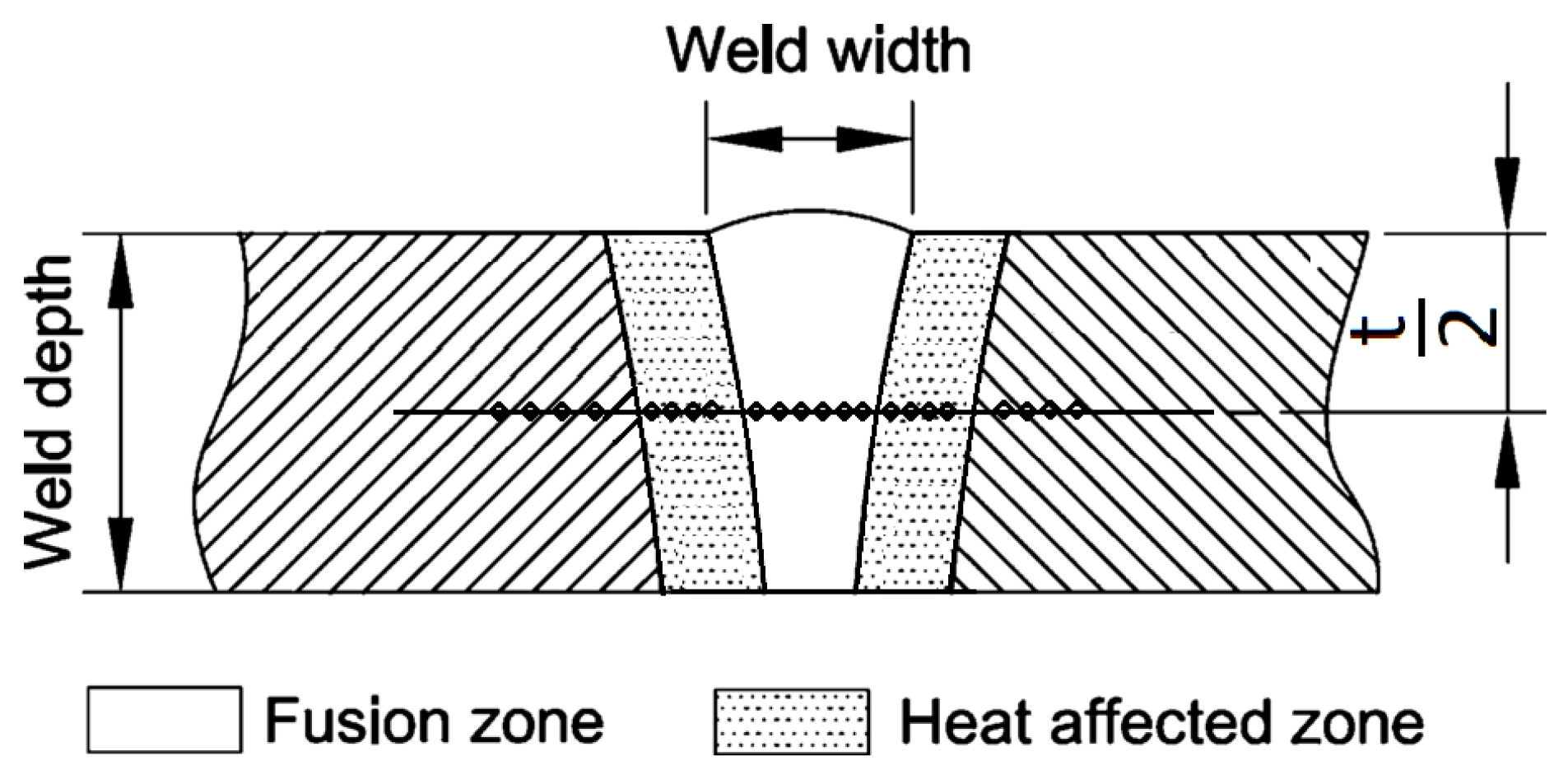

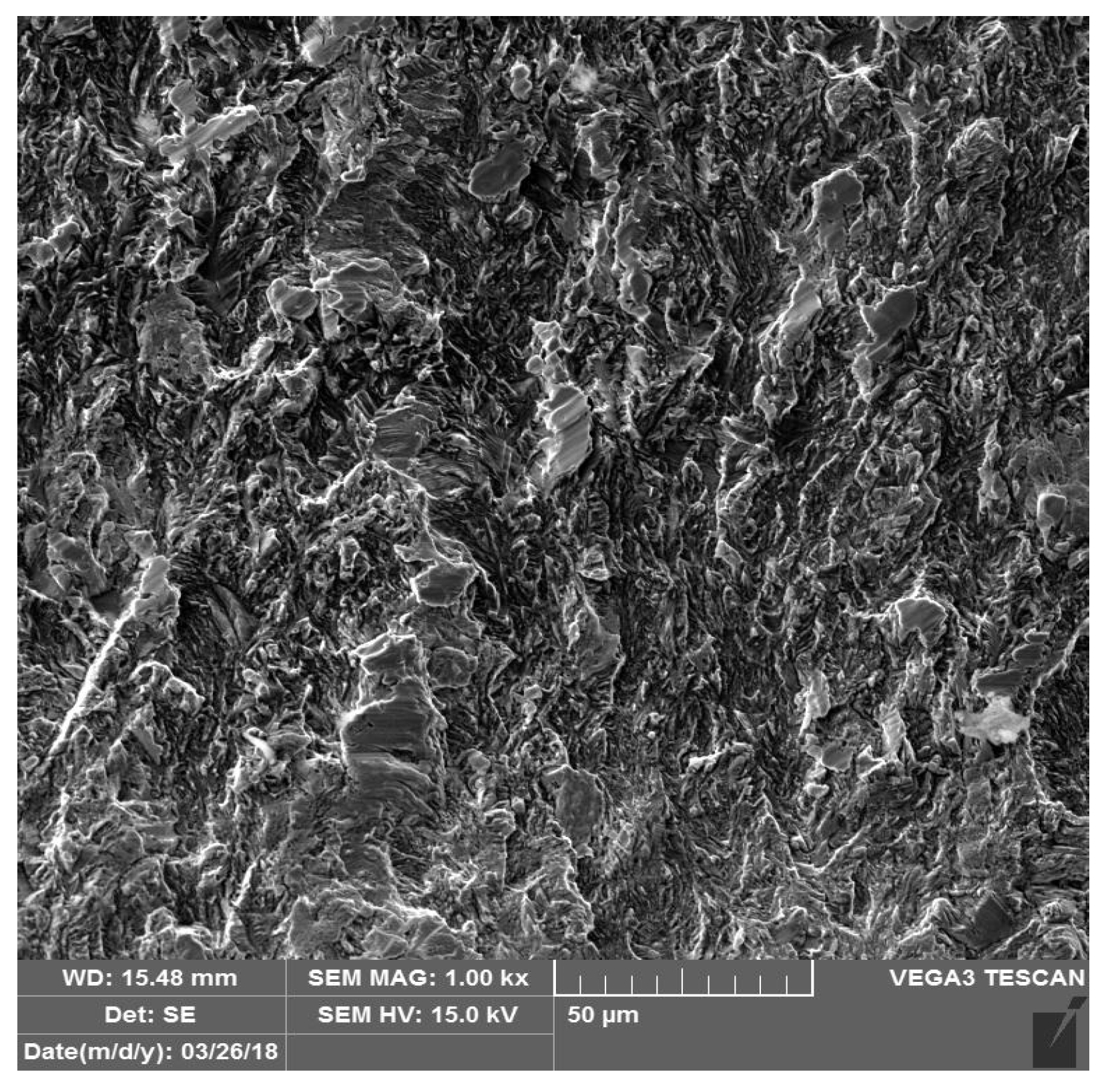

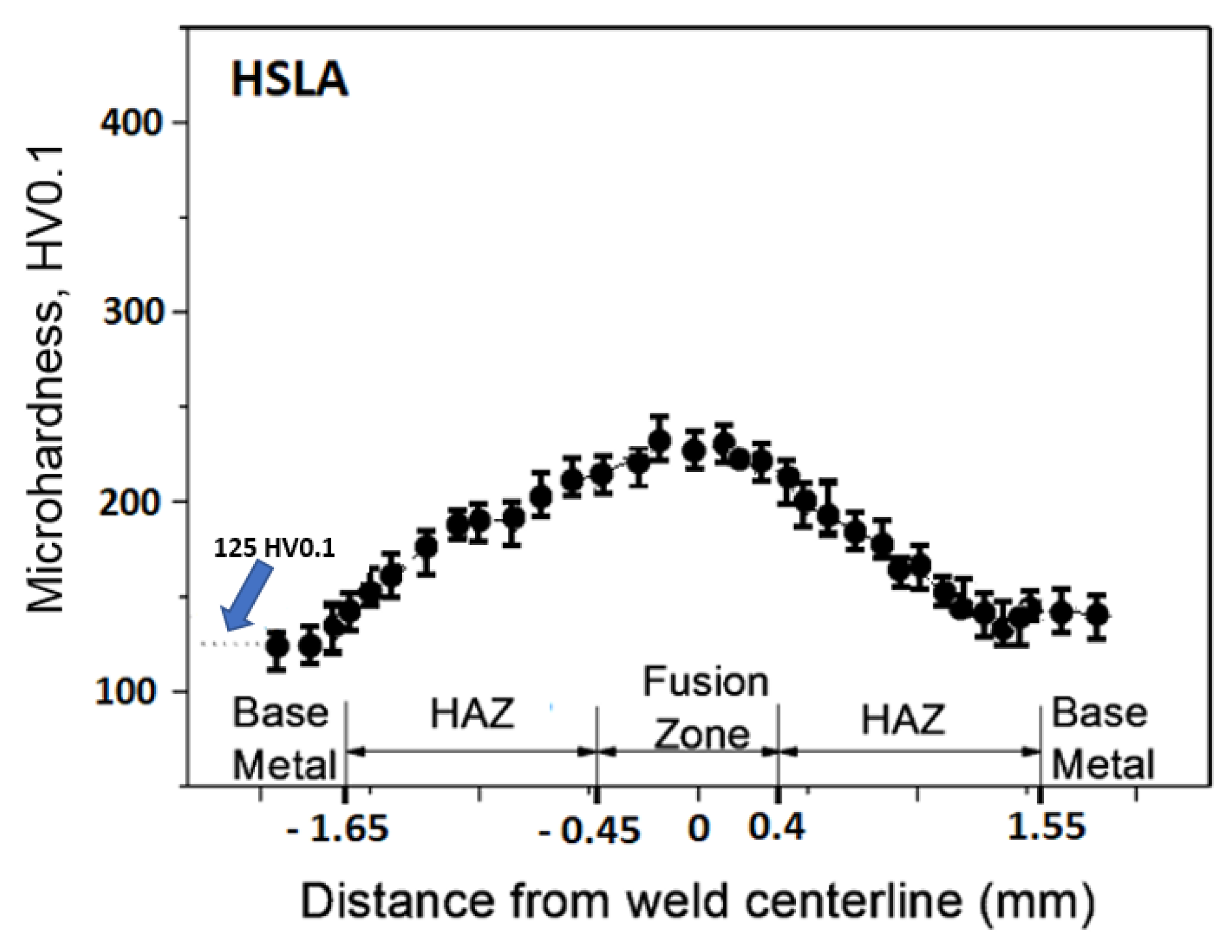

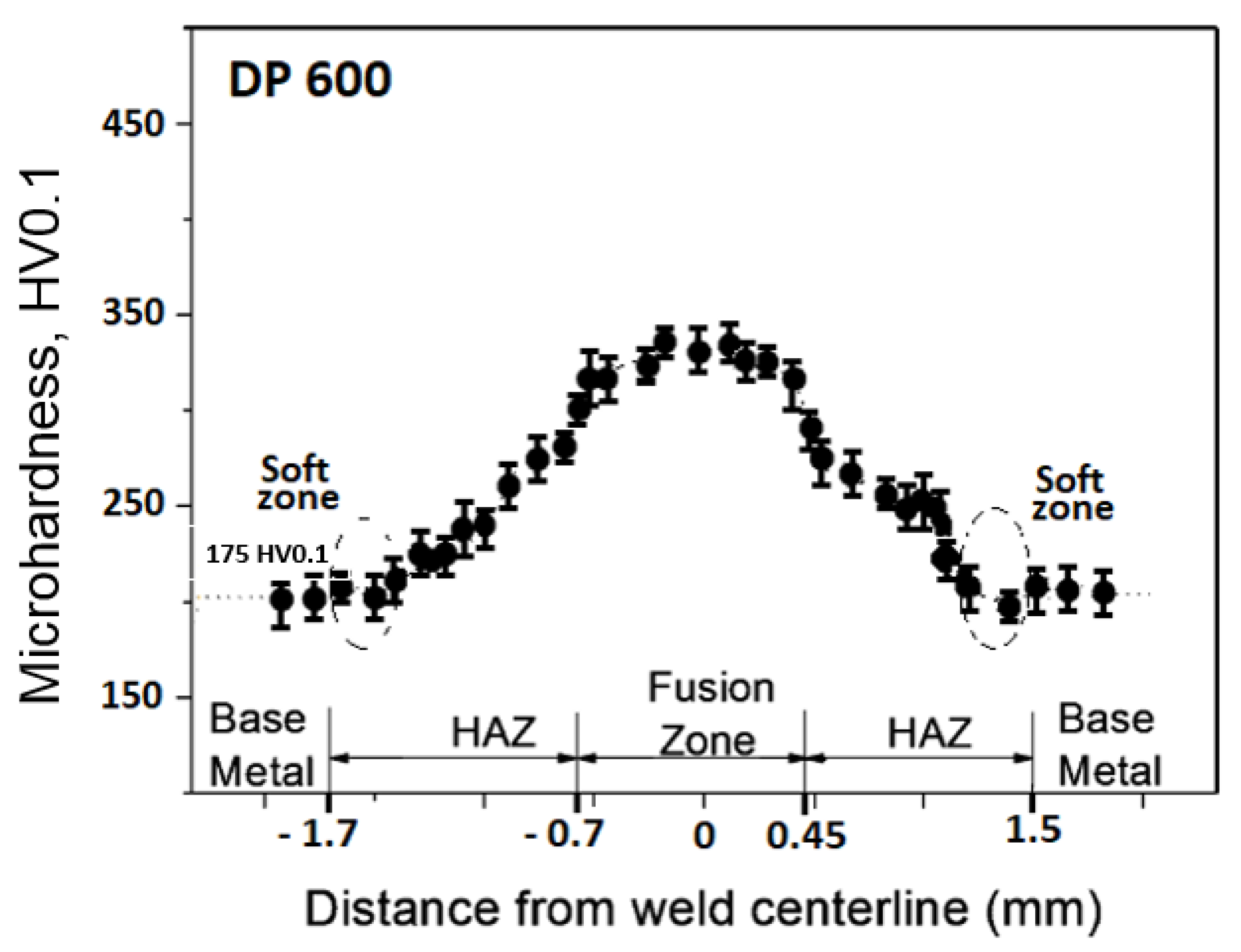

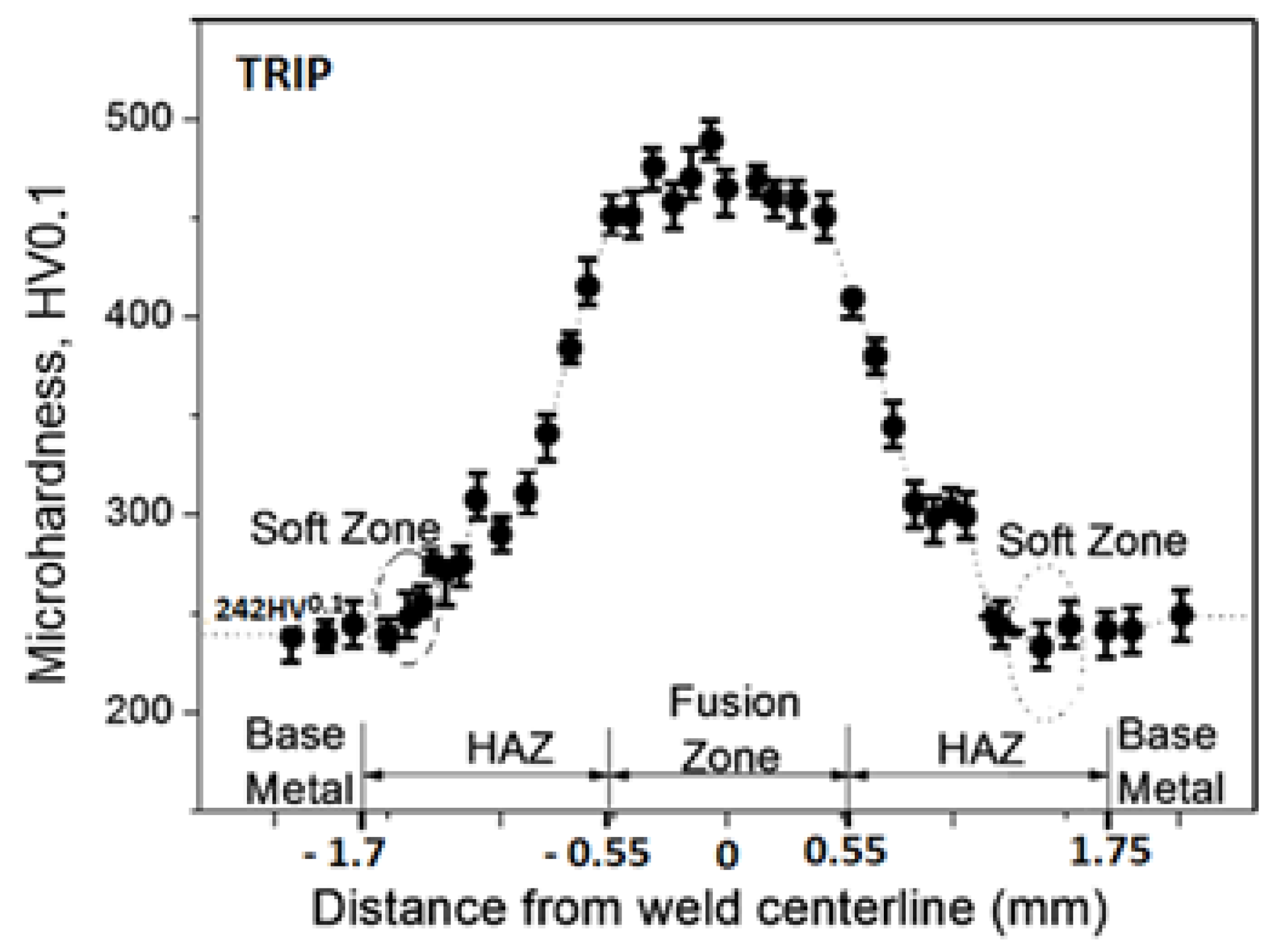

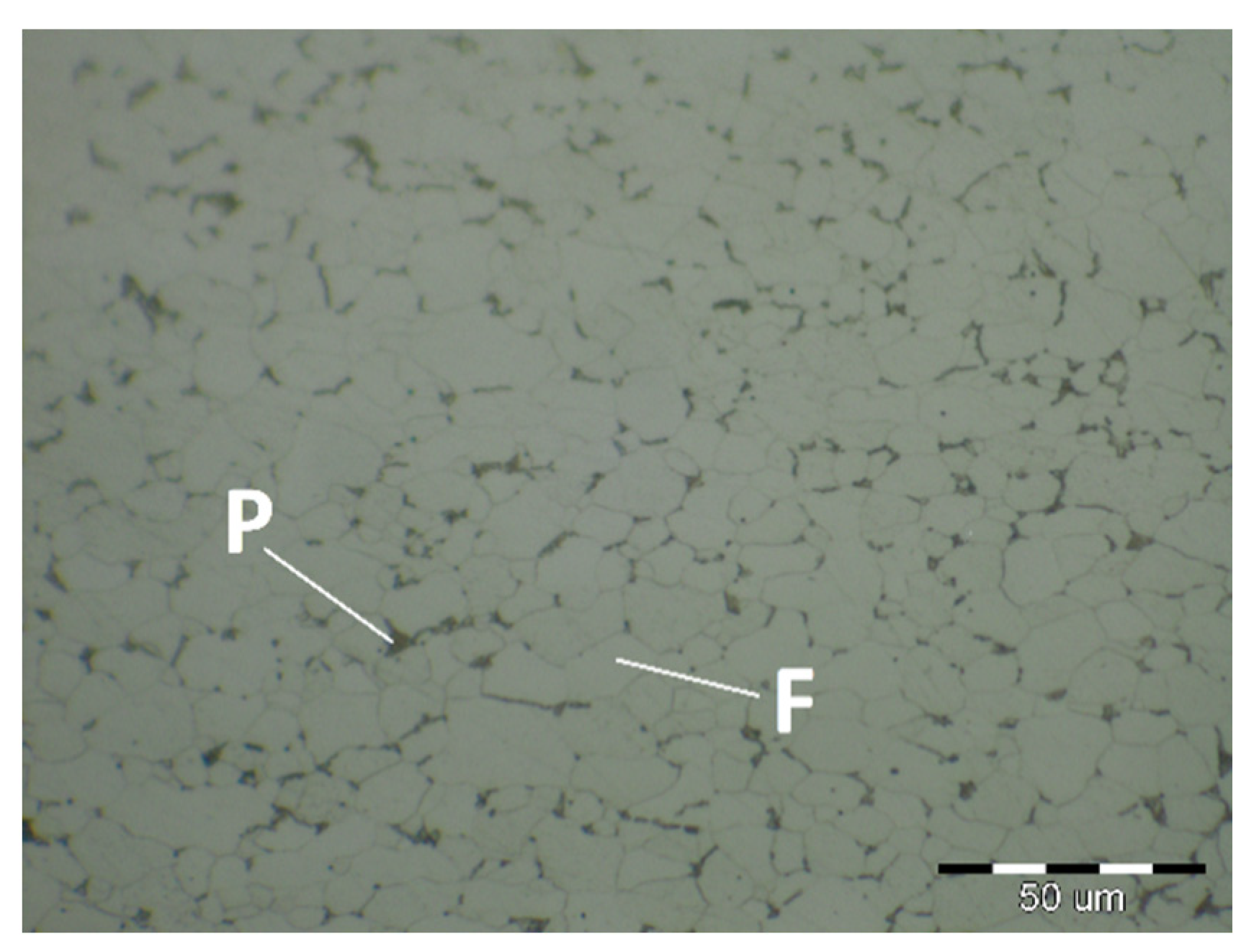

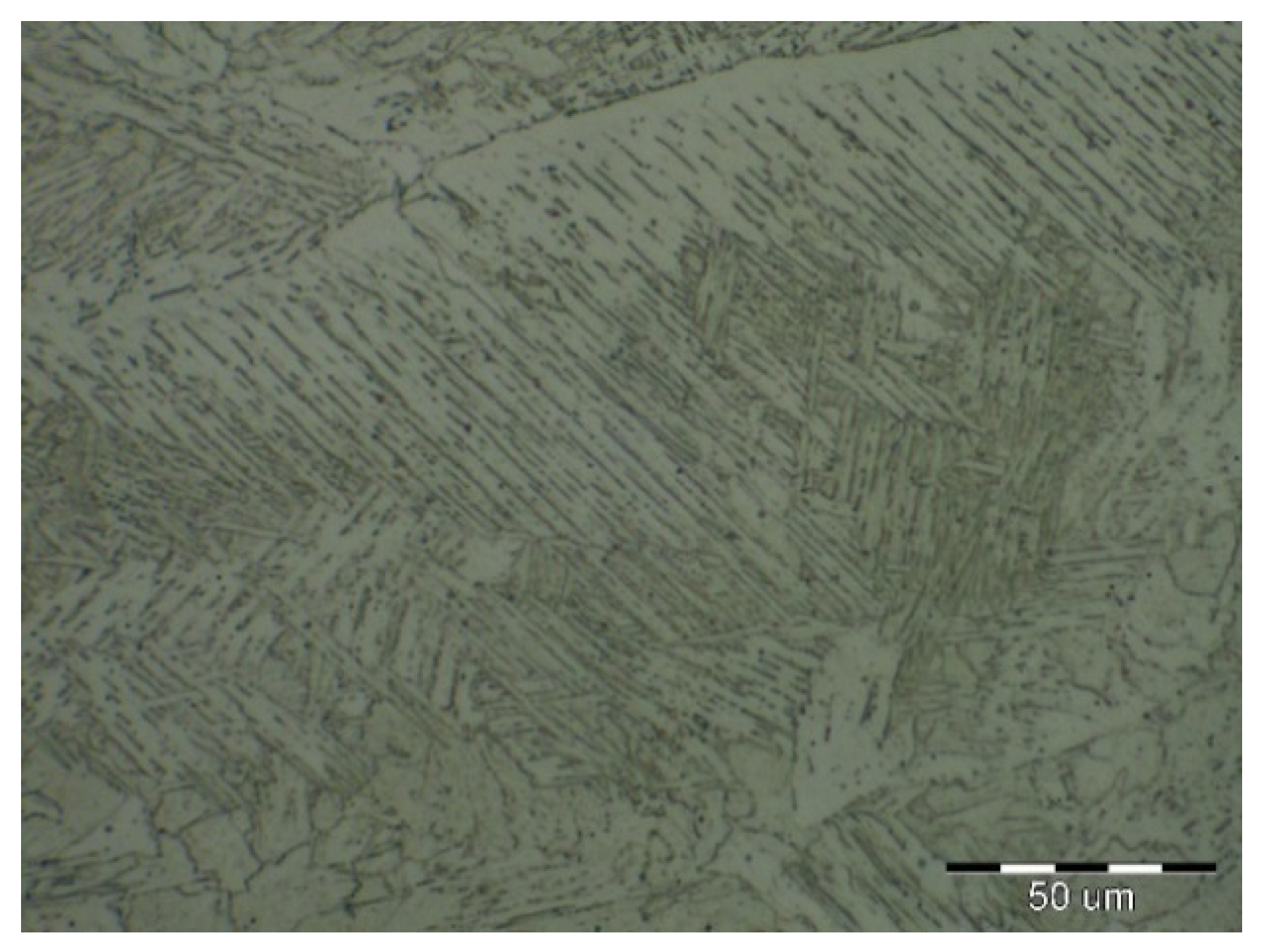

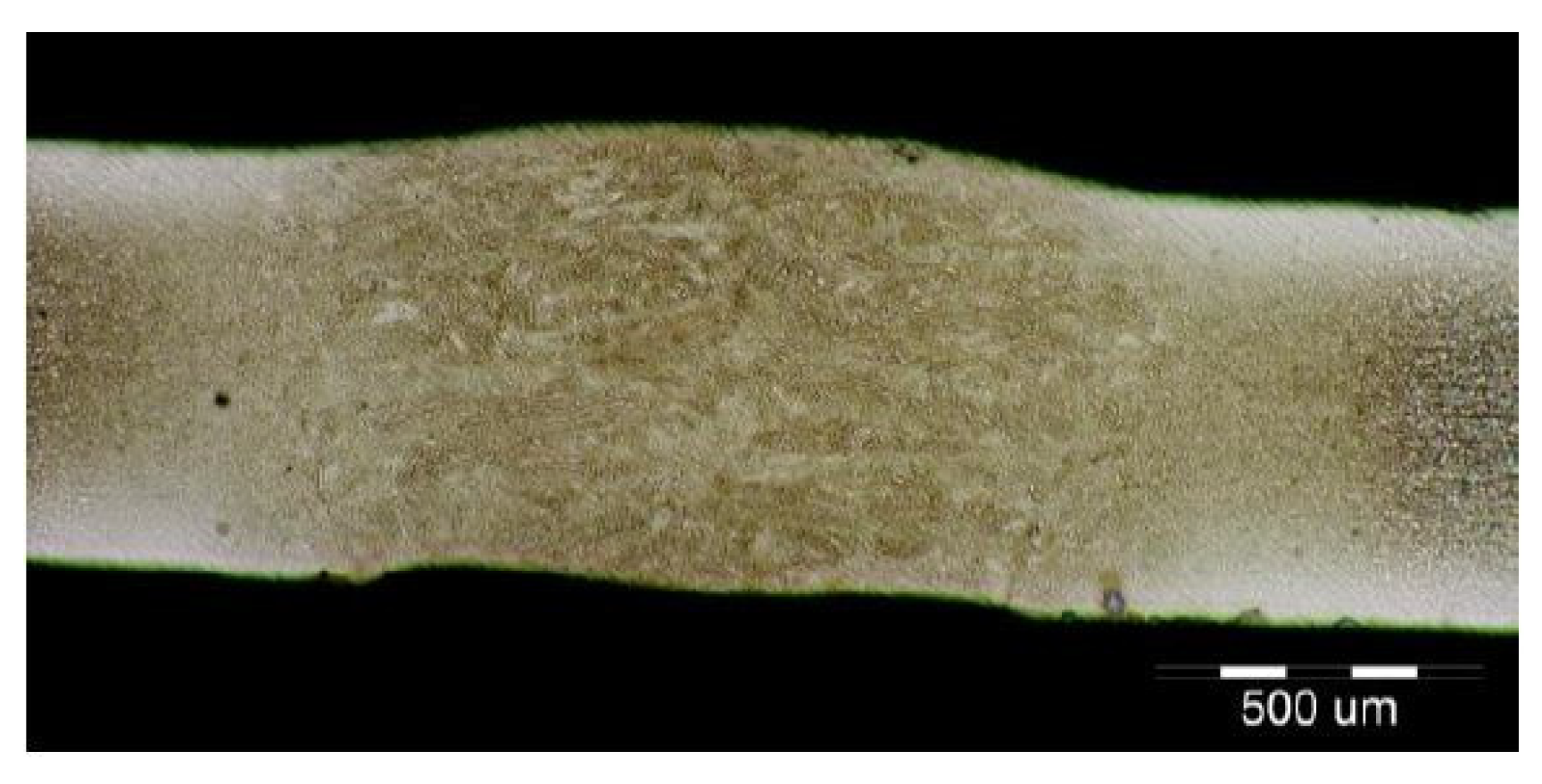

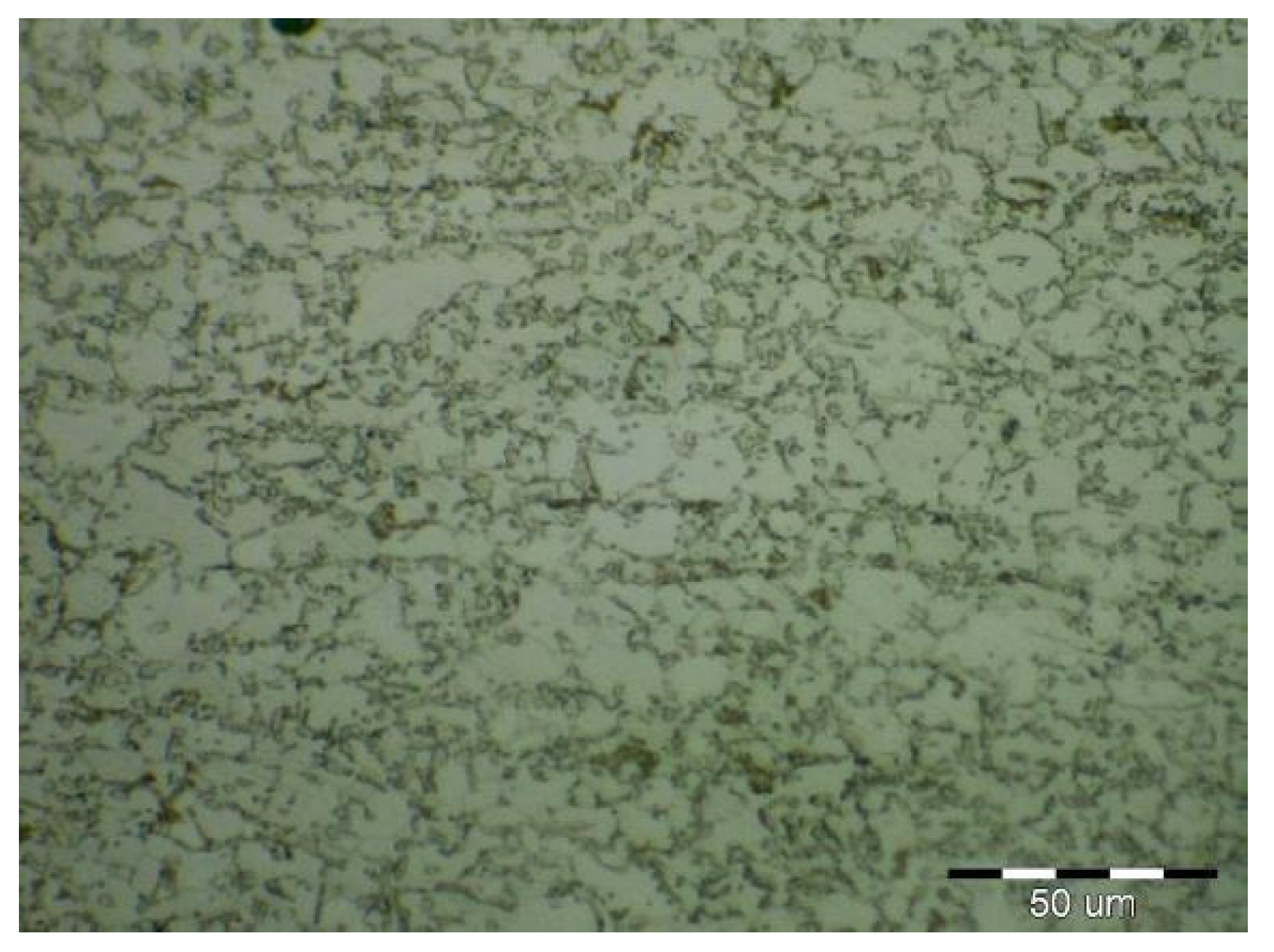

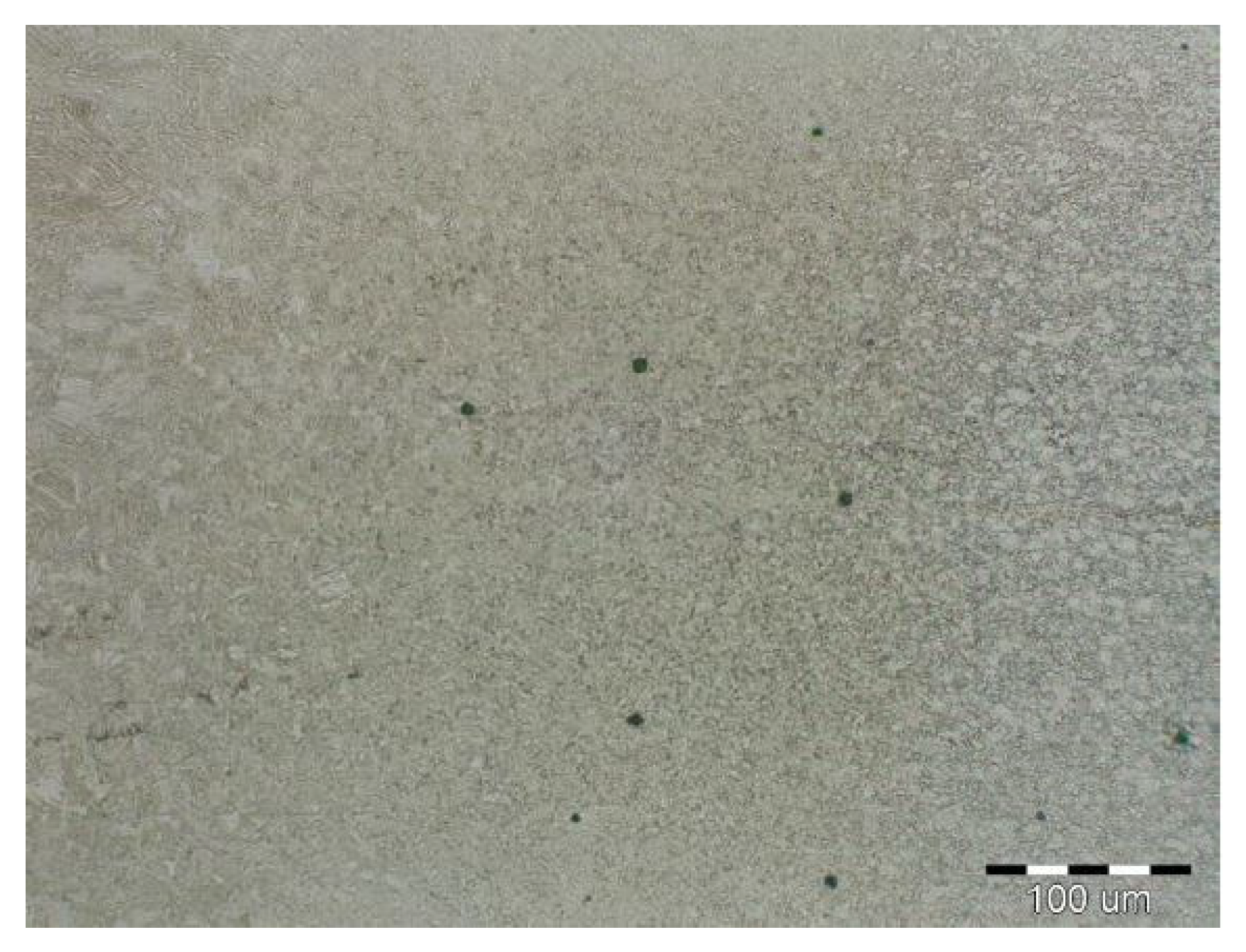

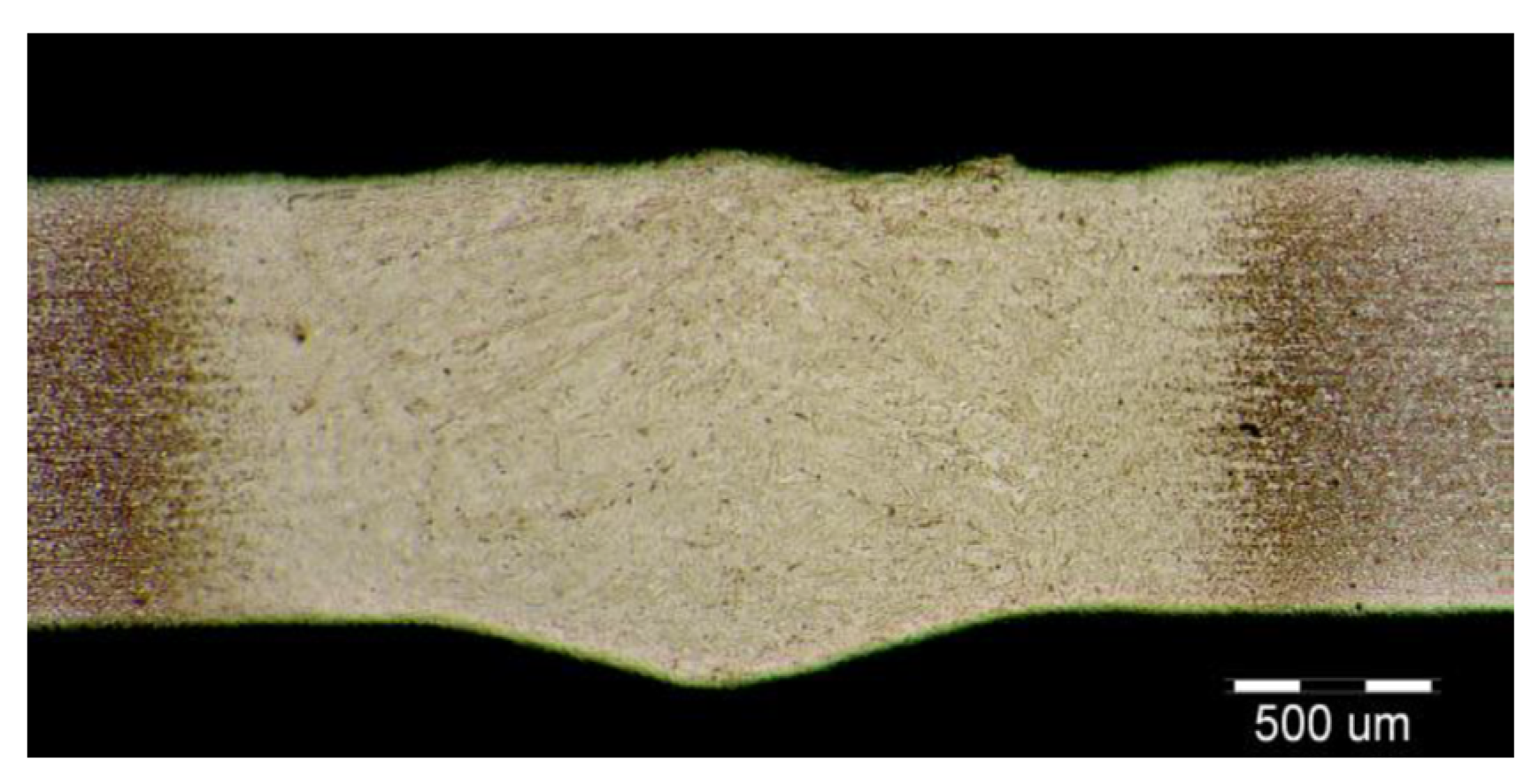

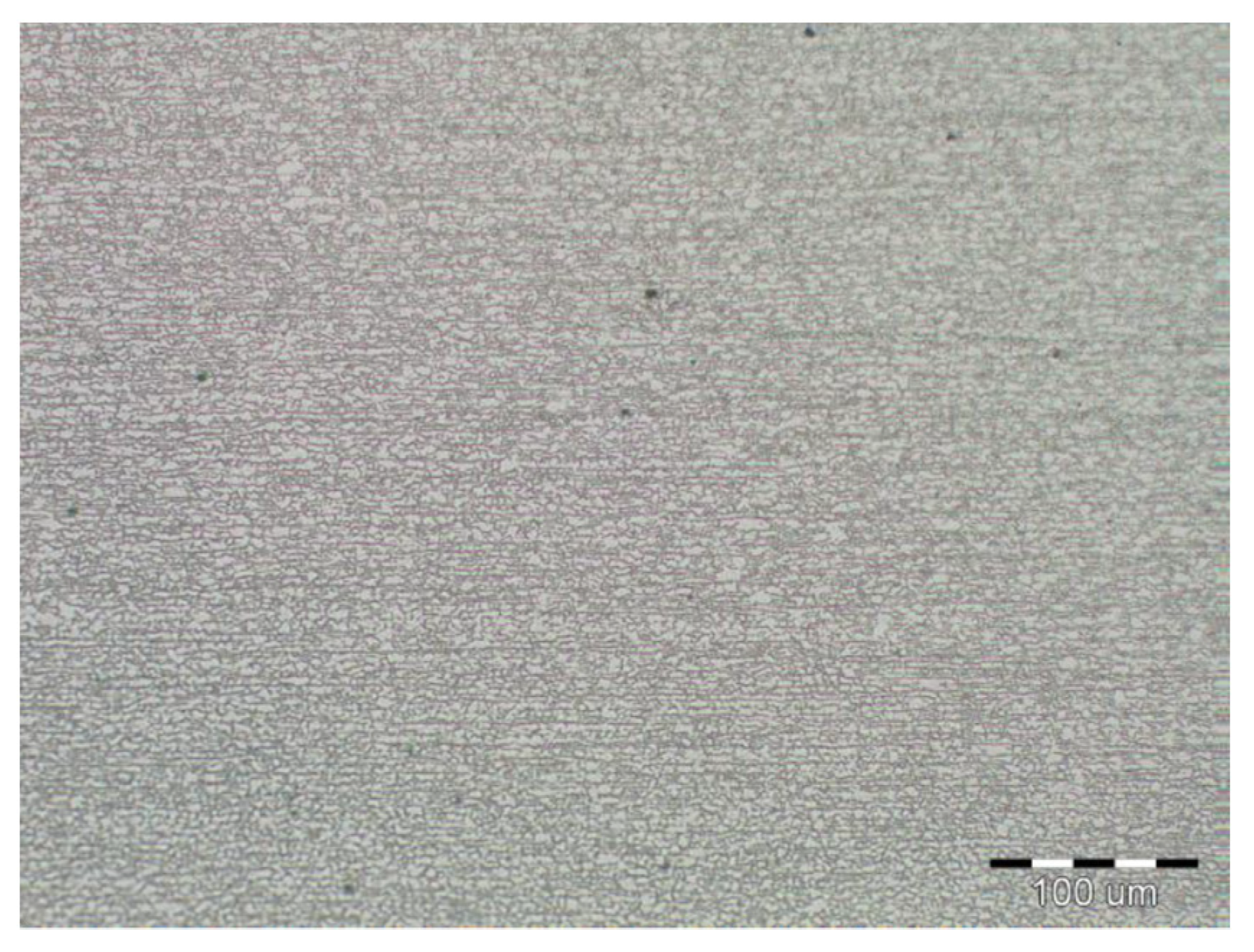

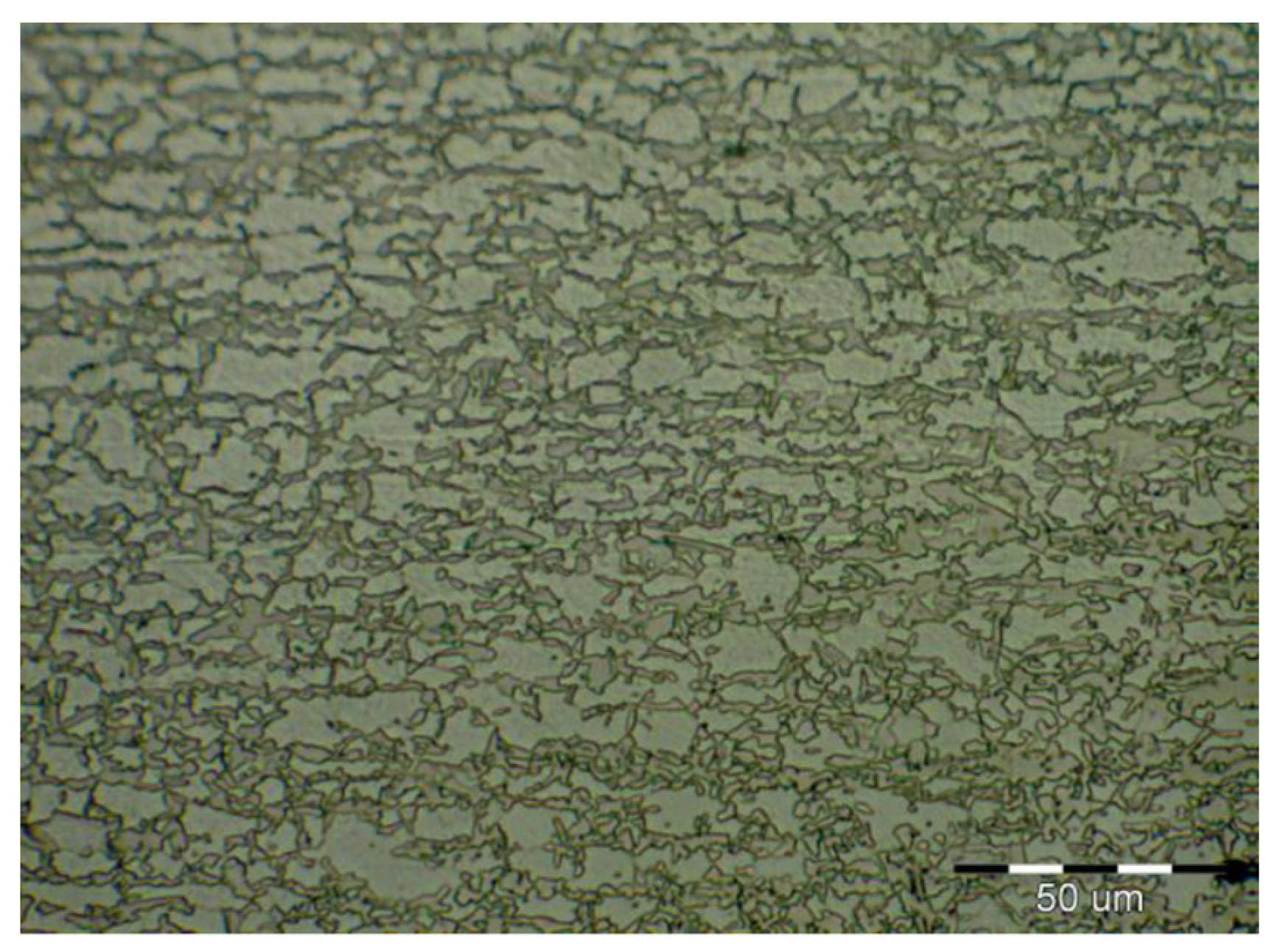

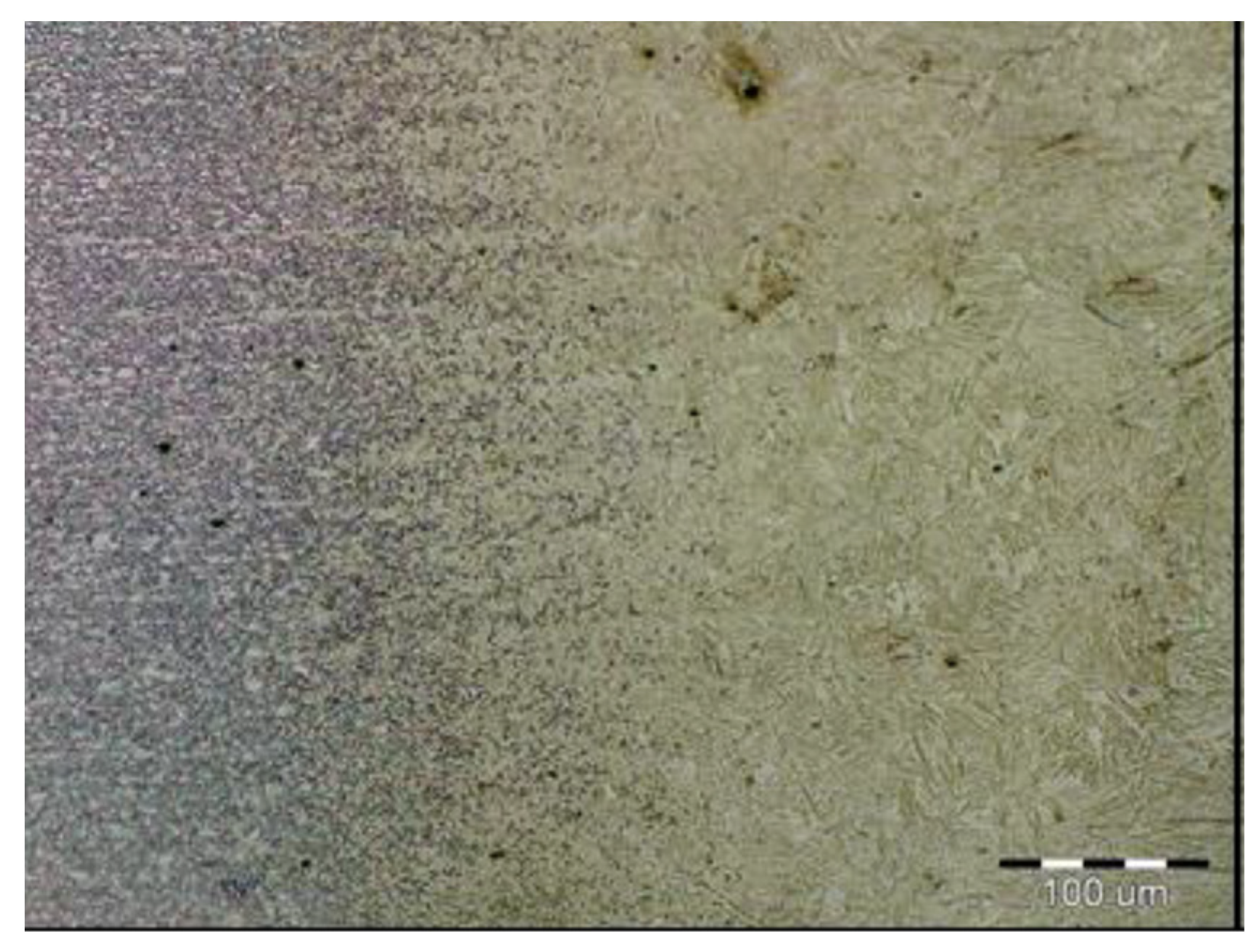

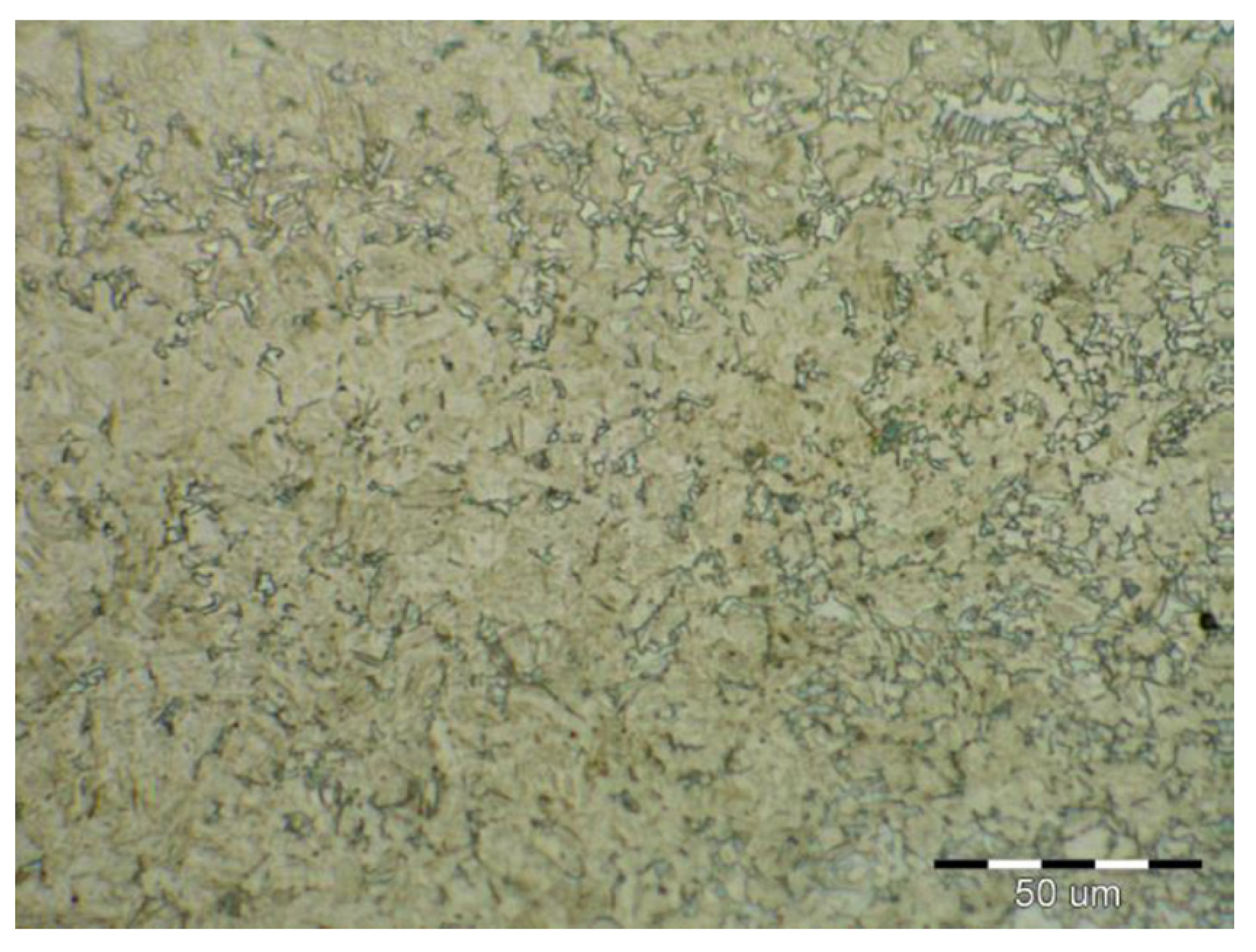

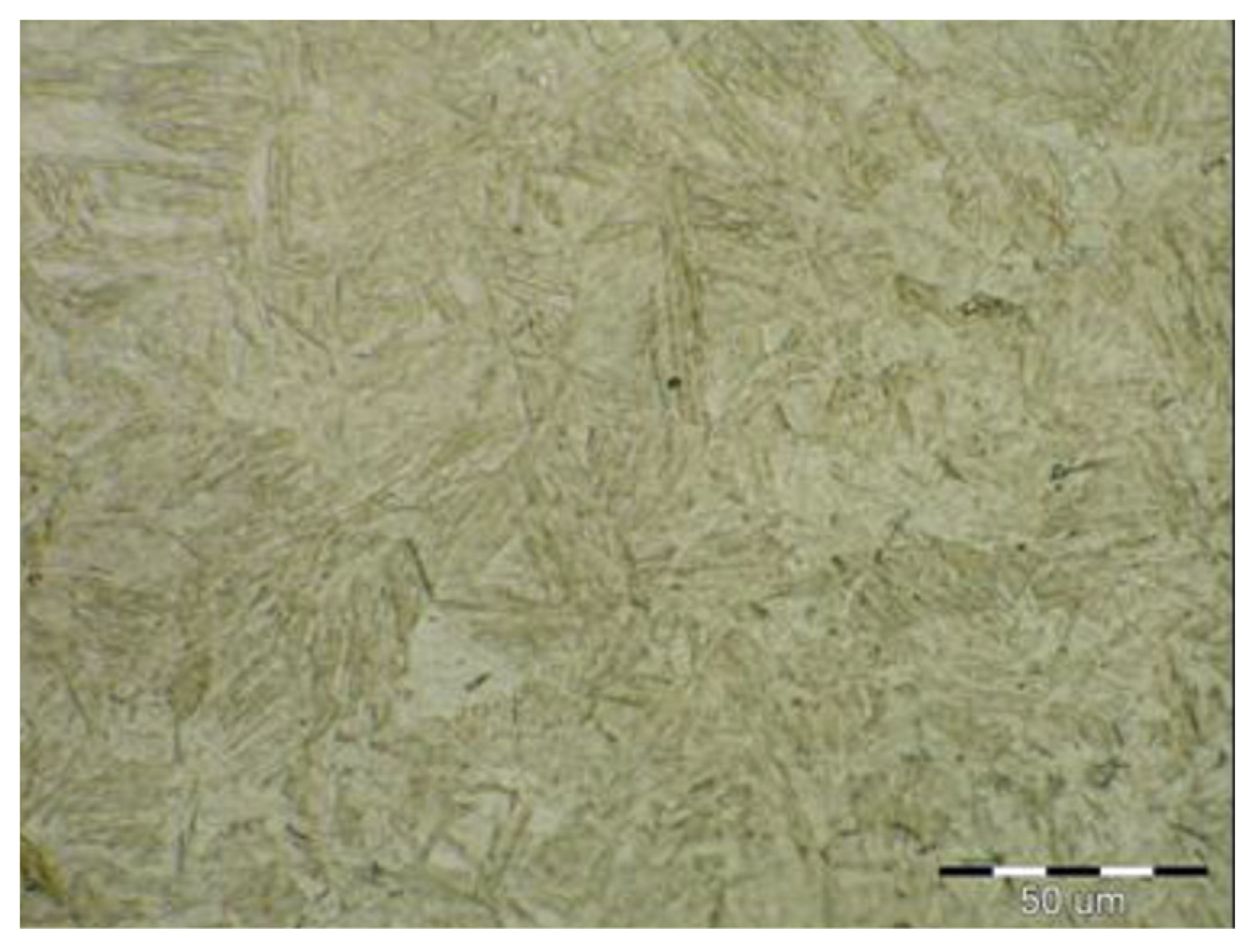

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Viňáš, J. Quality evaluation of laser welded sheets for cars body. In Proceedings of the Mat/tech—Automotive Industry; Faculty of Mechanical Engineering, Technical University of Košice: Košice, Slovakia, 2005; pp. 119–124. [Google Scholar]

- Yin, H.-X.; Zhao, A.-M.; Zhao, Z.-Z.; Li, X.; Li, S.-J.; Hu, H.-J.; Xia, W.-G. Influence of original microstructure on the transformation behavior and mechanical properties of ultra-high-strength TRIP-aided steel. Int. J. Miner. Metall. Mater. 2015. [Google Scholar] [CrossRef]

- Wang, W.-Q.; Dong, S.-C.; Jiang, F.; Cao, M. Effects of Ar and He on Microstructures and Properties of Laser Welded 800MPa TRIP Steel. MATEC Web Conf. 2018. [Google Scholar] [CrossRef][Green Version]

- Viňáš, J.; Ábel, M. Analysis of laser welds on automotive steel sheets. Mater. Sci. Forum 2015, 818, 239–242. [Google Scholar] [CrossRef]

- Xia, M.; Tian, Z.; Zhao, L.; Zhou, Y.N. Metallurgical and mechanical properties of fusion zones of TRIP steels in laser welding. ISIJ Int. 2008. [Google Scholar] [CrossRef]

- Grajcar, A.; Różański, M.; Stano, S.; Kowalski, A. Microstructure characterization of laser-welded Nb-microalloyed silicon-aluminum TRIP steel. J. Mater. Eng. Perform. 2014. [Google Scholar] [CrossRef]

- Viňáš, J.; Kaseak, L.; Greš, M. Optimization of resistance spot welding parameters for microalloyed steel sheets. Open Eng. 2016. [Google Scholar] [CrossRef]

- Sahul, M.; Turňa, M.; Šugárová, J.; Sahul, M. Influence of Laser Welding Aluminium Alloy on Mechanical Properties of Welded Joints. Manuf. Technol. 2013, 13, 526–530. [Google Scholar] [CrossRef]

- Vontorová, J.; Mohyla, P.; Ševčíková, X. Influence of CMT and MIG soldering on zinc layer thickness. In Proceedings of the METAL 2012 Conference Proceedings, 21st International Conference on Metallurgy and Materials, Brno, Czech Republic, 23–25 May 2012. [Google Scholar]

- Gould, J.E.; Khurana, S.P.; Li, T. Predictions of microstructures when welding automotive advanced high-strength steels. Weld. J. (Miami Fla) 2006, 85, 111. [Google Scholar]

- Sreenivasan, N.; Xia, M.; Lawson, S.; Zhou, Y. Effect of laser welding on formability of DP980 steel. J. Eng. Mater. Technol. Trans. ASME 2008. [Google Scholar] [CrossRef]

- Lima, S.F.; Gonzales, D.; Liu, S. Microstructure and Mechanical Behavior of Induction-Assisted Laser Welded AHS Steels. Weld. J. (Miami Fla) 2017, 96, 376–388. [Google Scholar]

- Ferreira, C.C.D.A.; Braga, V.; De Siqueira, R.H.M.; De Carvalho, S.M.; De Lima, M.S.F. Laser beam welding of DP980 dual phase steel at high temperatures. Opt. Laser Technol. 2020. [Google Scholar] [CrossRef]

- Worldautosteel Advanced High Strength Steel (Ahss) Application Guidelines. 2009. Available online: http://www.Worldautosteel.Org/Projects/Ahssguidelines/Ahss-Application-Guidelines-Version-4.Aspx (accessed on 15 April 2021).

- Xia, M.; Biro, E.; Tian, Z.; Zhou, Y.N. Effects of heat input and martensite on HAZ softening in laser welding of dual phase steels. ISIJ Int. 2008. [Google Scholar] [CrossRef]

- Biro, E.; McDermid, J.R.; Embury, J.D.; Zhou, Y. Softening kinetics in the subcritical heat-affected zone of dual-phase steel welds. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2010. [Google Scholar] [CrossRef]

- Xu, W.; Westerbaan, D.; Nayak, S.S.; Chen, D.L.; Goodwin, F.; Biro, E.; Zhou, Y. Microstructure and fatigue performance of single and multiple linear fiber laser welded DP980 dual-phase steel. Mater. Sci. Eng. A 2012. [Google Scholar] [CrossRef]

- Xu, W.; Westerbaan, D.; Nayak, S.S.; Chen, D.L.; Goodwin, F.; Zhou, Y. Tensile and fatigue properties of fiber laser welded high strength low alloy and DP980 dual-phase steel joints. Mater. Des. 2013. [Google Scholar] [CrossRef]

- Farabi, N.; Chen, D.L.; Zhou, Y. Microstructure and mechanical properties of laser welded dissimilar DP600/DP980 dual-phase steel joints. J. Alloys Compd. 2011. [Google Scholar] [CrossRef]

- Farabi, N.; Chen, D.L.; Li, J.; Zhou, Y.; Dong, S.J. Microstructure and mechanical properties of laser welded DP600 steel joints. Mater. Sci. Eng. A 2010. [Google Scholar] [CrossRef]

- Anand, D.; Chen, D.L.; Bhole, S.D.; Andreychuk, P.; Boudreau, G. Fatigue behavior of tailor (laser)-welded blanks for automotive applications. Mater. Sci. Eng. A 2006. [Google Scholar] [CrossRef]

- Panda, S.K.; Sreenivasan, N.; Kuntz, M.L.; Zhou, Y. Numerical simulations and experimental results of tensile test behavior of laser butt welded DP9B0 steels. J. Eng. Mater. Technol. Trans. ASME 2008. [Google Scholar] [CrossRef]

- Bandyopadhyay, K.; Panda, S.K.; Saha, P. Optimization of Fiber Laser Welding of DP980 Steels Using RSM to Improve Weld Properties for Formability. J. Mater. Eng. Perform. 2016. [Google Scholar] [CrossRef]

- Parkes, D.; Xu, W.; Westerbaan, D.; Nayak, S.S.; Zhou, Y.; Goodwin, F.; Bhole, S.; Chen, D.L. Microstructure and fatigue properties of fiber laser welded dissimilar joints between high strength low alloy and dual-phase steels. Mater. Des. 2013. [Google Scholar] [CrossRef]

- Canning, J. Fibre lasers and related technologies. Opt. Lasers Eng. 2006. [Google Scholar] [CrossRef]

- Assunção, E.; Quintino, L.; Miranda, R. Comparative study of laser welding in tailor blanks for the automotive industry. Int. J. Adv. Manuf. Technol. 2010. [Google Scholar] [CrossRef]

- Rooks, B. Tailor-welded blanks bring multiple benefits to car design. Assem. Autom. 2001. [Google Scholar] [CrossRef]

- Duley, W.W. Laser Welding; John Wiley & Sons: New York, NY, USA, 1999; ISBN 978-0471246794. [Google Scholar]

- Sharma, R.S.; Molian, P. Yb:YAG laser welding of TRIP780 steel with dual phase and mild steels for use in tailor welded blanks. Mater. Des. 2009. [Google Scholar] [CrossRef]

- Kinoshita, K.; Mizutani, M.; Kawahito, Y.; Katayama, S. Phenomena Elucidation in High-Power Fiber Laser Welding of Stainless Steel. Yosetsu Gakkai Ronbunshu Q. J. Jpn. Weld. Soc. 2007. [Google Scholar] [CrossRef]

- Chan, C.L.; Mazumder, J. One-dimensional steady-state model for damage by vaporization and liquid expulsion due to laser-material interaction. J. Appl. Phys. 1987. [Google Scholar] [CrossRef]

- Mazumder, J. Overview of melt dynamics in laser processing. Opt. Eng. 1991. [Google Scholar] [CrossRef]

- Dawes, C.T. Laser Welding, 1st ed.; Woodhead Publishing: Cambridge, UK, 1992; ISBN 9781855730342. [Google Scholar]

- Ono, M.; Yoshitake, A.; Omura, M. Laser weldability of high-strength steel sheets in fabrication of tailor welded blanks. Weld. Int. 2004. [Google Scholar] [CrossRef]

- Gumenyuk, A.; Rethmeier, M. Developments in hybrid laser-arc welding technology. In Handbook of Laser Welding Technologies; Woodhead Publishing: Sawston, UK, 2013; ISBN 9780857098771. [Google Scholar]

- Dowden, J. The Theory of Laser Materials Processing: Heat and Mass Transfer in Modern Technology; Springer: Berlin/Heidelberg, Germany, 2009; ISBN 1402093403. [Google Scholar]

- Kroos, J.; Gratzke, U.; Simon, G. Towards a self-consistent model of the keyhole in penetration laser beam welding. J. Phys. D Appl. Phys. 1993. [Google Scholar] [CrossRef]

- Cui, Q.L.; Parkes, D.; Westerbaan, D.; Nayak, S.S.; Zhou, Y.; Liu, D.; Goodwin, F.; Bhole, S.; Chen, D.L. Effect of coating on fiber laser welded joints of DP980 steels. Mater. Des. 2016. [Google Scholar] [CrossRef]

- Khedkar, P.; Motagi, R.; Mahajan, P.; Makwana, G. A Review on Advance High Strength Steels. Int. J. Curr. Eng. Technol. 2016, 240–243. Available online: https://inpressco.com/wp-content/uploads/2016/10/Paper53240-243.pdf (accessed on 15 April 2021).

- Baluch, N.; Udin, Z.M.; Abdullah, C.S. Advanced High Strength Steel in Auto Industry: An Overview. Eng. Technol. Appl. Sci. Res. 2014. [Google Scholar] [CrossRef]

- Bhattacharya, D. Microalloyed steels for the automotive industry. Tecnol. Metal. Mater. Min. 2014. [Google Scholar] [CrossRef]

- Dan, W.J.; Li, S.H.; Zhang, W.G.; Lin, Z.Q. The effect of strain-induced martensitic transformation on mechanical properties of TRIP steel. Mater. Des. 2008. [Google Scholar] [CrossRef]

- Gonçalves, T.S.; de Faria, G.L.; de Siqueira, R.H.M.; de Lima, M.S.F. Weldability and mechanical behavior of laser-welded TRIP 750 steel sheets. Int. J. Adv. Manuf. Technol. 2020. [Google Scholar] [CrossRef]

- Yang, Y.S.; Lee, S.H. Study on the joining strength of laser spot welding for automotive applications. J. Mater. Process. Technol. 1999. [Google Scholar] [CrossRef]

- Stano, S. New solid-state lasers and their application in welding as generators of laser radiation. Weld. Int. 2007. [Google Scholar] [CrossRef]

- Lisiecki, A. Diode laser welding of high yield steel. In Laser Technology 2012: Applications of Lasers; International Society for Optics and Photonics: Bellingham, WA, USA, 2013. [Google Scholar]

- Cretteur, L.; Koruk, A.I.; Tosal-Martínez, L. Improvement of weldability of TRIP steels by use of in-situ pre- and post-heat treatments. Steel Res. 2002. [Google Scholar] [CrossRef]

- Aslanlar, S. The effect of nucleus size on mechanical properties in electrical resistance spot welding of sheets used in automotive industry. Mater. Des. 2006. [Google Scholar] [CrossRef]

- Burgmann, P.; Clymer, K.; Cobb, S.; Davis, J.; Liu, M.; Miller, M.; O’Loughlin, A.; Smith, M.; Findley, K.O.; Liu, S. Weldability, processing, microstructure and mechanical behavior relationships in advanced high-strength steel. Iron Steel Technol. 2010, 7, 76–85. [Google Scholar]

- Senkara, J. Contemporary car body steels for automotive industry and technological guidelines of their pressure welding. Weld. Int. 2013. [Google Scholar] [CrossRef]

- Agarwal, G.; Kumar, A.; Richardson, I.M.; Hermans, M.J.M. Evaluation of solidification cracking susceptibility during laser welding in advanced high strength automotive steels. Mater. Des. 2019. [Google Scholar] [CrossRef]

- Rappaz, M.; Dantzig, J.A. Solidification, 1st ed.; EPFL Press: Lausanne, Switzerland, 2009; ISBN 9780849382383. [Google Scholar]

- Wang, N.; Mokadem, S.; Rappaz, M.; Kurz, W. Solidification cracking of superalloy single- and bi-crystals. Acta Mater. 2004. [Google Scholar] [CrossRef]

- Glicksman, M.E. Principles of Solidification: An Introduction to Modern Casting and Crystal Growth Concepts; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011; ISBN 9781441973436. [Google Scholar]

- Zhao, H.; White, D.R.; Debroy, T. Current issues and problems in laser welding of automotive aluminum alloys. Int. Mater. Rev. 1999. [Google Scholar] [CrossRef]

- Coniglio, N.; Cross, C.E. Mechanisms for solidification crack initiation and growth in aluminum welding. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2009. [Google Scholar] [CrossRef]

- Wei, H.; He, Q.; Chen, J.-S.; Wang, H.-P.; Carlson, B.E. Coupled thermal-mechanical-contact analysis of hot cracking in laser welded lap joints. J. Laser Appl. 2017. [Google Scholar] [CrossRef]

- Wȩglowski, M.S.; Kwieciński, K.; Krasnowski, K.; Jachym, R. Characteristics of Nd:YAG laser welded joints of dual phase steel. Arch. Civ. Mech. Eng. 2009. [Google Scholar] [CrossRef]

- Grajcar, A.; Rózański, M.; Stano, S.; Kowalski, A.; Grzegorczyk, B. Effect of heat input on microstructure and hardness distribution of laser welded Si-Al TRIP-type steel. Adv. Mater. Sci. Eng. 2014. [Google Scholar] [CrossRef]

- Traint, S.; Pichler, A.; Sierlinger, R.; Pauli, H.; Werner, E.A. Low-alloyed TRIP-steels with optimized strength, forming and welding properties. Steel Res. Int. 2006. [Google Scholar] [CrossRef]

- Amirthalingam, M.; Hermans, M.J.M.; Zhao, L.; Richardson, I.M. Quantitative analysis of microstructural constituents in welded transformation-induced-plasticity steels. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2010. [Google Scholar] [CrossRef][Green Version]

- Amirthalingam, M.; Hermans, M.; Richardson, I. Microstructural development during welding of siliconand aluminum-based transformation-induced plasticity steels-inclusion and elemental partitioning analysis. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2009. [Google Scholar] [CrossRef]

- Grajcar, A.; Radwański, K.; Krztoń, H. Microstructural analysis of a thermomechanically processed Si-Al TRIP steel characterized by EBSD and X-ray techniques. In Solid State Phenomena; Trans Tech Publications Ltd.: Bäch, Switzerland, 2013. [Google Scholar]

- Sondel, M.; Koukal, J.; Schwarz, D.; Mohyla, P. Secondary hardening of T24 steel weld joints performed at incorrect interpass temperature and low temperature heat treatment. In Advances in Materials Technology for Fossil Power Plants, Proceedings of the 8th International Conference, Hong Kong, China, 20–24 June 2016; Springer: Berlin/Heidelberg, Germany, 2016; ISBN-13: 978-3319124742. [Google Scholar]

- Sugimoto, K.I.; Nagasaka, A.; Kobayashi, M.; Hashimoto, S.I. Effects of Retained Austenite Parameters on Warm Stretch-flangeability in TRIP-aided Dual-phase Sheet Steels. ISIJ Int. 1999. [Google Scholar] [CrossRef]

- Mukherjee, M.; Mohanty, O.N.; Hashimoto, S.I.; Hojo, T.; Sugimoto, K.I. Acoustic emission technique to study the effect of strain rate on the deformation behaviour of TRIP aided steels with different matrix microstructures. ISIJ Int. 2006. [Google Scholar] [CrossRef]

- Brandt, M.L.; Olson, G.B. Bainitic stabilization of austenite in low alloy sheet steels. Iron Steelmak. 1993, 20, 55–60. [Google Scholar]

- Takahashi, M.; Bhadeshia, H.K.D.H. Model for the microstructure of some advanced bainitic steels. Mater. Trans. JIM 1991. [Google Scholar] [CrossRef]

- Timokhina, I.B.; Hodgson, P.D.; Pereloma, E.V. Effect of microstructure on the stability of retained austenite in transformation-induced-plasticity steels. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2004. [Google Scholar] [CrossRef]

- Jacques, P.J.; Delannay, F.; Ladrière, J. On the influence of interactions between phases on the mechanical stability of retained austenite in transformation-induced plasticity multiphase steels. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2001. [Google Scholar] [CrossRef]

- BUNSHAH ED RF Measurement of Mechanical Properties (Techniques of Metals Research, v 5, Parts 1, 2); Interscience Publisher: Geneva, Switzerland; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1971; p. 474.

- Mealy, N.E.; Bayés, M. ASM Handbook. Mechanial Testing and Evaluation; ASM International: Materials Park, OH, USA, 2005; ISBN 0-87170-389-0. [Google Scholar]

- Bleck, W.; Larour, P.; Bäumer, A. High strain rate tensile testing of modern car body steels. Mater. Forum 2005, 29, 21–28. [Google Scholar]

- Yurioka, N.; Kasuya, T. A chart method to determine necessary preheat in steel welding. Weld. World Soudage Monde 1995. [Google Scholar] [CrossRef]

- Yurioka, N. Prediction of Weld Metal Strength—IIW Doc. IX-2058-03; Nippon Steel Corporation, Technical Development Bureau 20-1: Chiba, Japan, 2003; 32p. [Google Scholar]

- Babu, S.S.; Elmer, J.W.; David, S.A.; Quintana, M.A. In situ observations of non-equilibrium austenite formation during weld solidification of an Fe-C-Al-Mn low-alloy steel. Proc. R. Soc. A Math. Phys. Eng. Sci. 2002. [Google Scholar] [CrossRef]

- Vuherer, T.; Maruschak, P.; Samardžić, I. Behaviour of coarse grain heat affected zone (HAZ) during cycle loading. Metalurgija 2012, 51, 301–304. Available online: https://hrcak.srce.hr/80847 (accessed on 15 April 2021).

- Mohyla, P.; Foldynová, K. Effect of post-welding heat treatment on mechanical properties of joints of steel P92 formed by submerged arc welding. Metal Sci. Heat Treat. 2014. [Google Scholar] [CrossRef]

| A-HSLA | C | Mn | Si | P | S | Al | Cu | Cr |

| 0.005 | 0.409 | 0.128 | 0.037 | <0.002 | 0.034 | 0.015 | 0.031 | |

| Mo | Ni | V | Ti | Nb | Co | W | Fe | |

| 0.008 | 0.006 | 0.006 | 0.033 | 0.035 | 0.021 | 0.038 | Res. | |

| B-DP600 | C | Mn | Si | P | S | Al | Cu | Cr |

| 0.111 | 1.963 | 0.279 | 0.026 | <0.002 | 0.031 | 0.019 | 0.206 | |

| Mo | Ni | V | Ti | Nb | Co | W | Fe | |

| <0.002 | <0.002 | 0.012 | <0.002 | 0.020 | 0.017 | 0.005 | Res. | |

| C-TRIP | C | Mn | Si | P | S | Al | Cu | Cr |

| 0.087 | 1.487 | 0.184 | 0.024 | <0.002 | 2.245 | 0.021 | 0.041 | |

| Mo | Ni | V | Ti | Nb | Co | W | Fe | |

| 0.022 | <0.002 | 0.011 | 0.007 | 0.023 | 0.022 | <0.002 | Res. |

| Steel | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation A5 (%) |

|---|---|---|---|

| A-HSLA | 240–330 | 340–450 | 32 |

| B-DP600 | 300–470 | 580–670 | 26 |

| C-TRIP | 480 | min. 700 | 25 |

| Welding Parameters: | |

|---|---|

| Laser power | 1200 W |

| Laser mode | Multi-Mode |

| Shielding gas | High Purity: Ar 4.8—Argon 99.998% |

| Flow rate Ar | 20 L/min |

| Welding speed | 2.4 m/min |

| Laser beam focusing | On the surface of the sheet f = 0 mm |

| Wavelength | λ = 1.03 μm |

| Methods of evaluation of welded joints: | Standard: |

| The visual testing of fusion welds in metallic materials. | ISO 17637 |

| Tensile tests of a welded joint in the transverse direction. | EN ISO 4136, |

| Microhardness testing on transverse sections of welded joints of metallic materials. | EN ISO 9015-2 |

| Macroscopic and microscopic examination of welds by Olympus BXFM light microscope. | EN ISO 17639 |

| For etching and macro and microstructures visualization the nital (2% HNO3 solution) was used | - |

| Sample | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Failure Location |

|---|---|---|---|

| A-HSLA | 319 ± 4 | 422 ± 4 | Base material |

| B-DP600 | 372 ± 3 | 620 ± 5 | Base material |

| C-TRIP | 448 ± 4 | 764 ± 4 | Base material |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Viňáš, J.; Brezinová, J.; Sailer, H.; Brezina, J.; Sahul, M.; Maruschak, P.; Prentkovskis, O. Properties Evaluation of the Welded Joints Made by Disk Laser. Materials 2021, 14, 2002. https://doi.org/10.3390/ma14082002

Viňáš J, Brezinová J, Sailer H, Brezina J, Sahul M, Maruschak P, Prentkovskis O. Properties Evaluation of the Welded Joints Made by Disk Laser. Materials. 2021; 14(8):2002. https://doi.org/10.3390/ma14082002

Chicago/Turabian StyleViňáš, Ján, Janette Brezinová, Henrich Sailer, Jakub Brezina, Miroslav Sahul, Pavlo Maruschak, and Olegas Prentkovskis. 2021. "Properties Evaluation of the Welded Joints Made by Disk Laser" Materials 14, no. 8: 2002. https://doi.org/10.3390/ma14082002

APA StyleViňáš, J., Brezinová, J., Sailer, H., Brezina, J., Sahul, M., Maruschak, P., & Prentkovskis, O. (2021). Properties Evaluation of the Welded Joints Made by Disk Laser. Materials, 14(8), 2002. https://doi.org/10.3390/ma14082002