Influence of Temperature on the Mechanical Performance of Unidirectional Carbon Fiber Reinforced Polymer Straps

Abstract

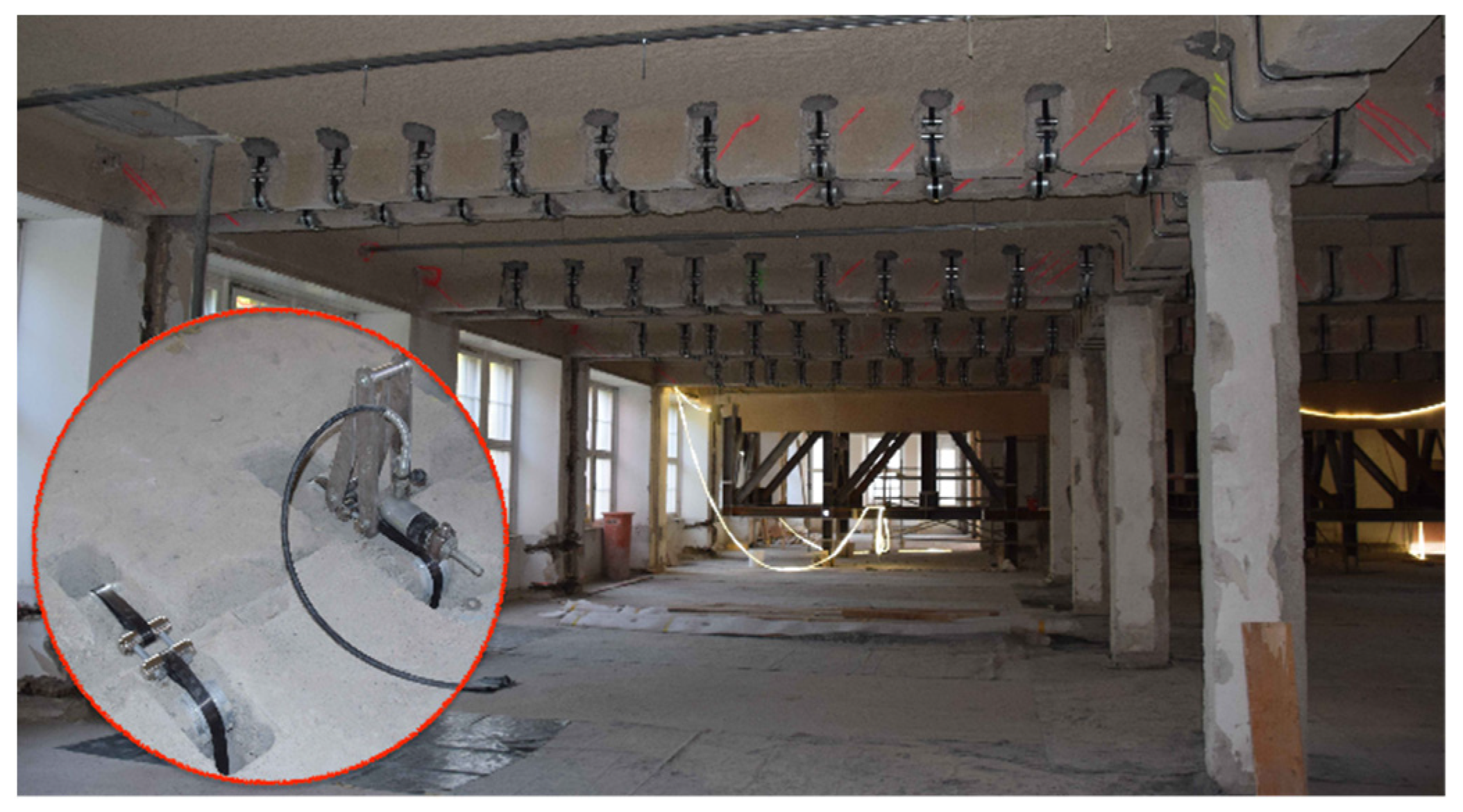

1. Introduction

2. Material Characterization and Manufacture

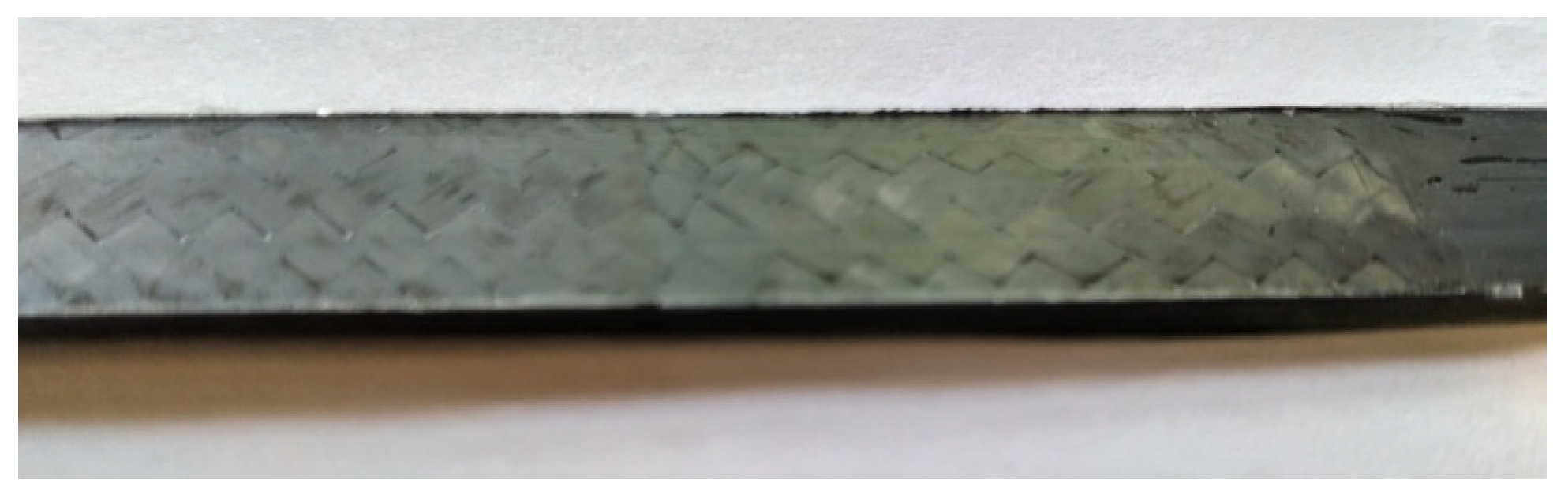

2.1. Materials

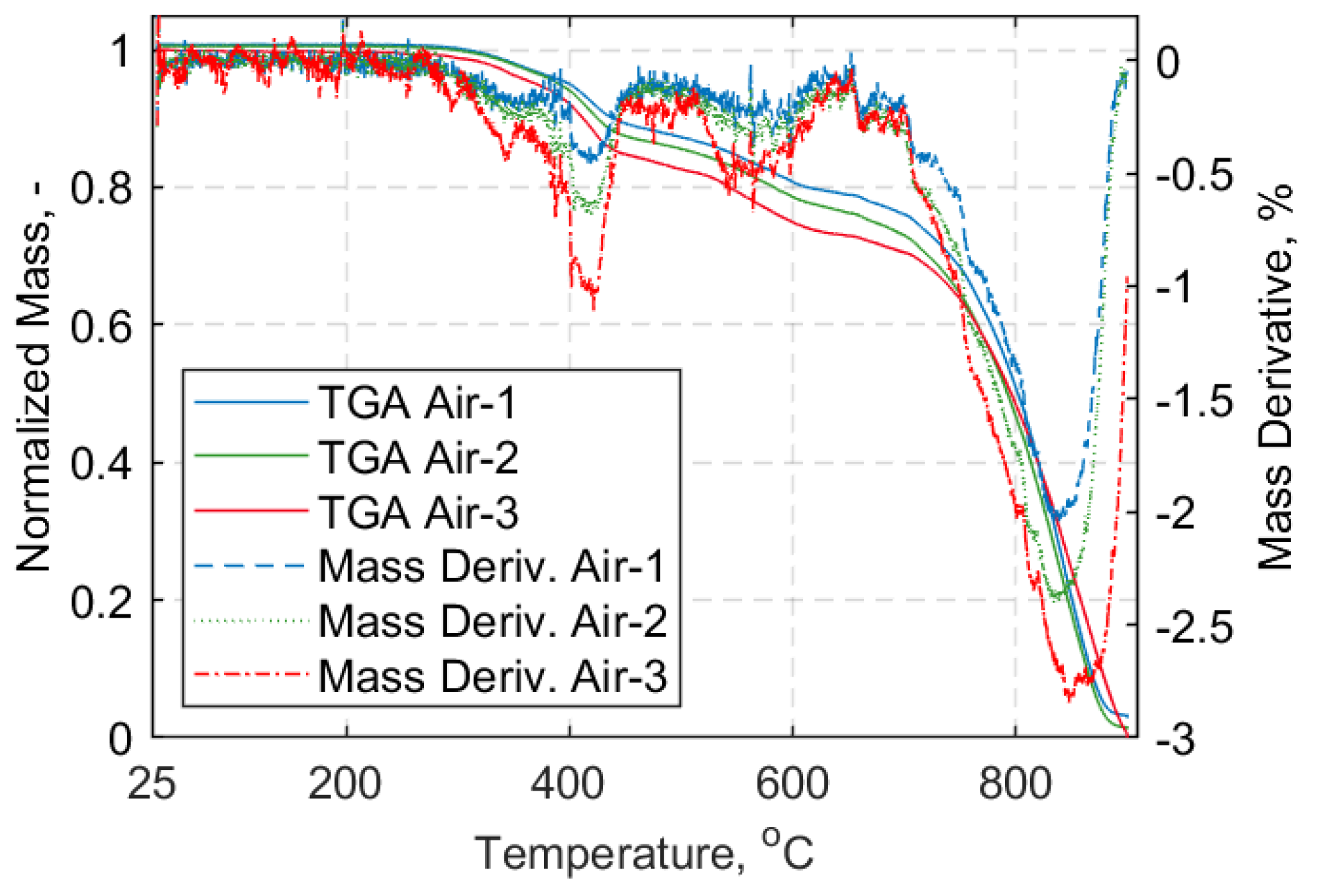

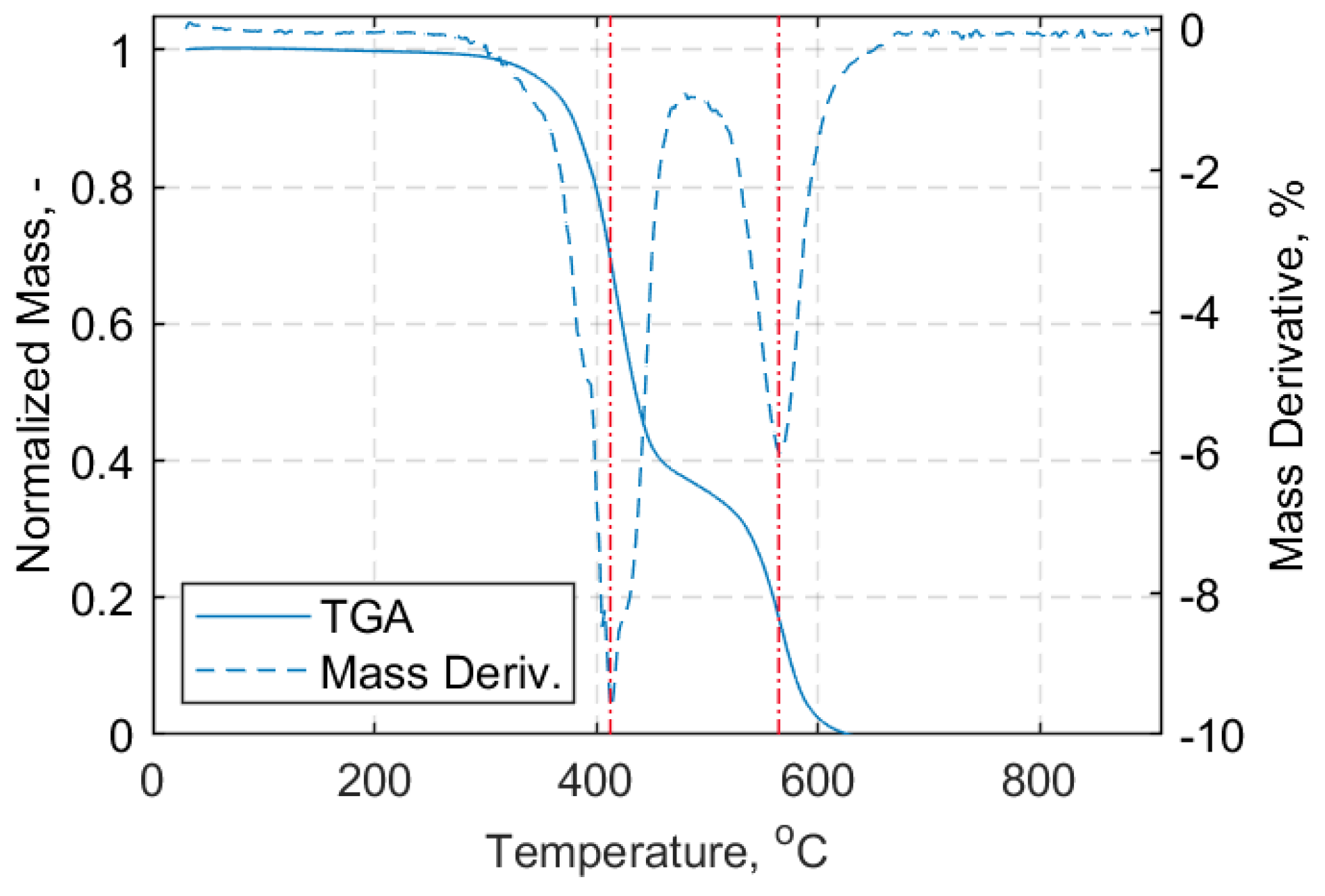

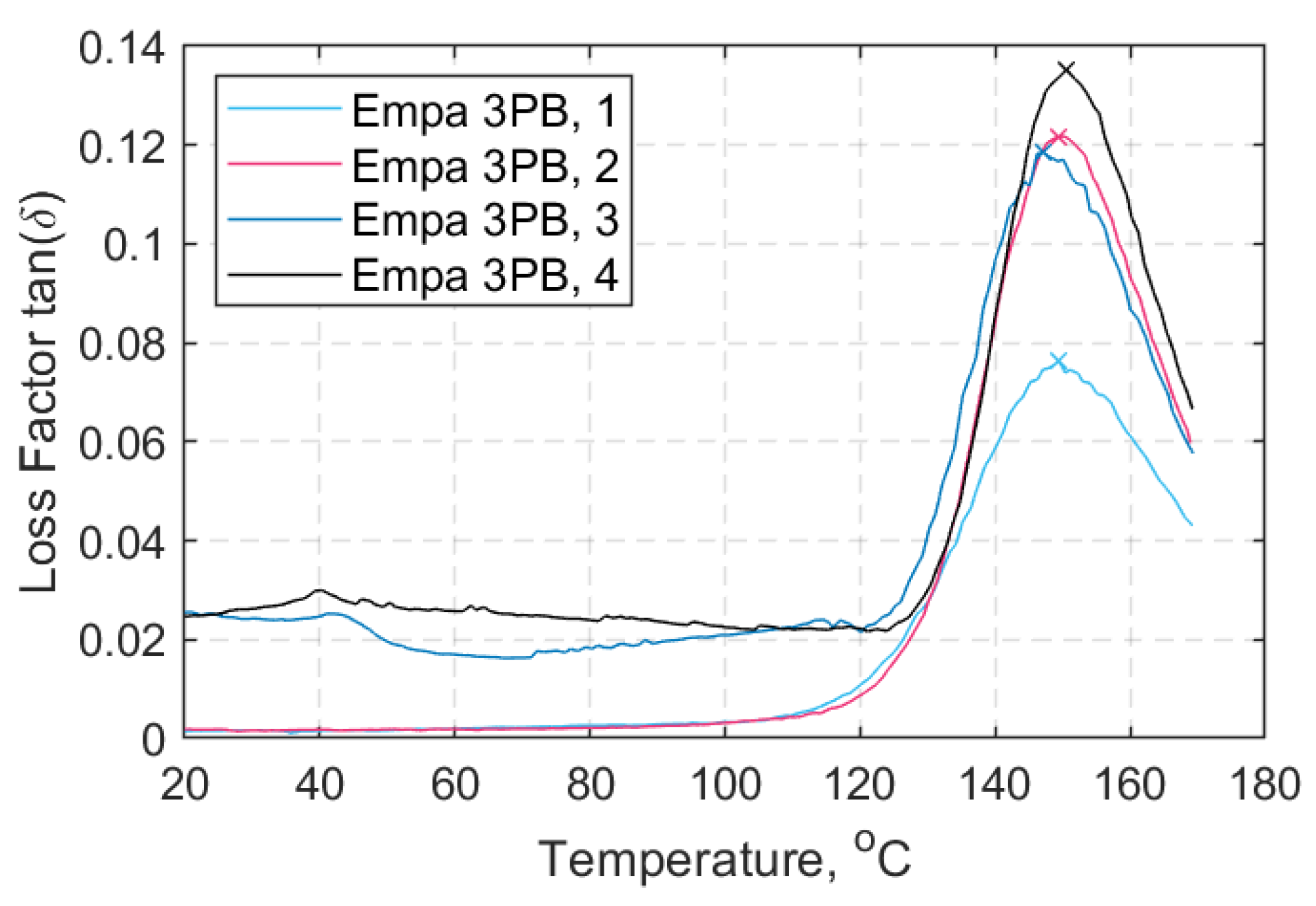

2.2. Characterization

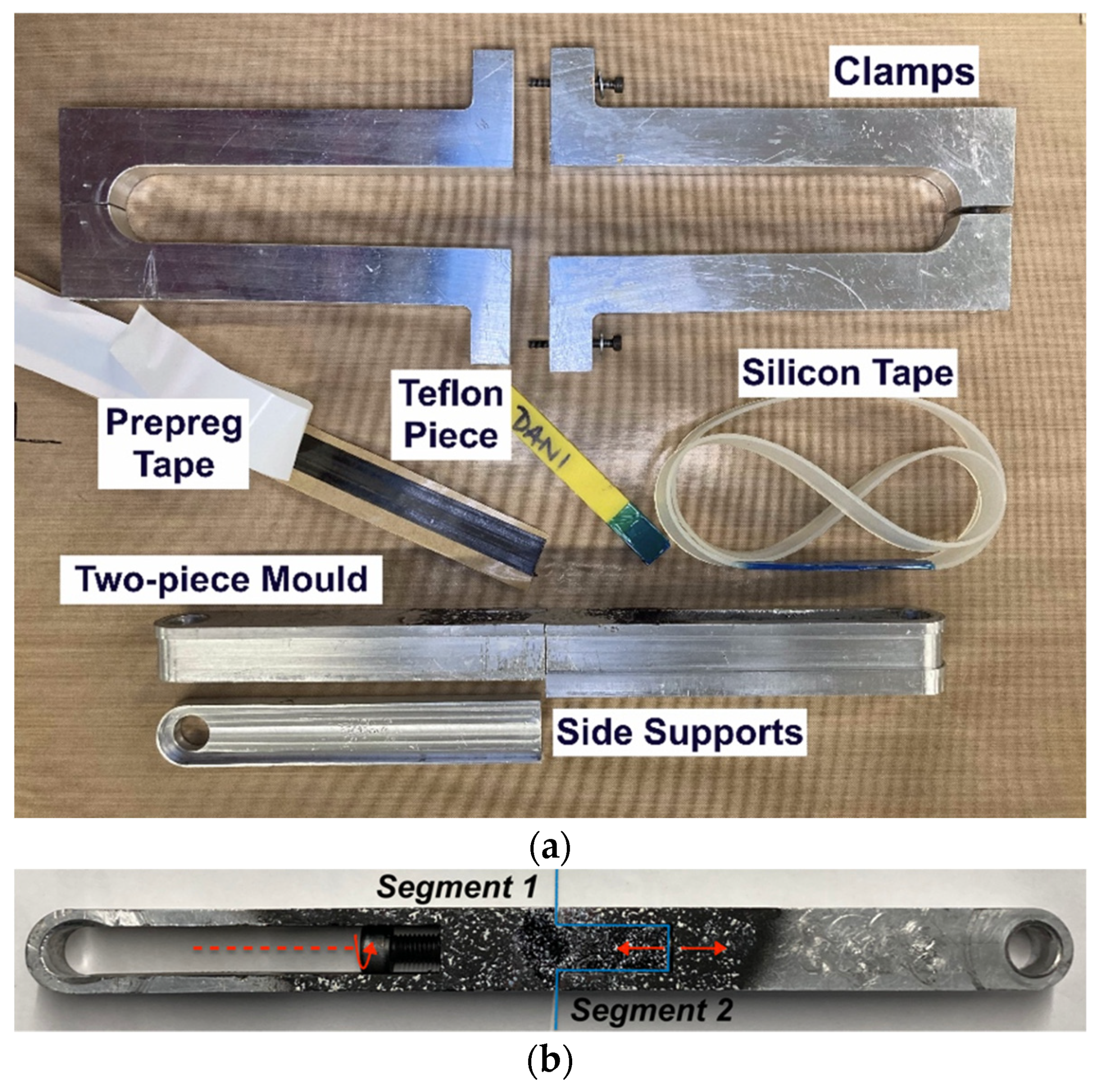

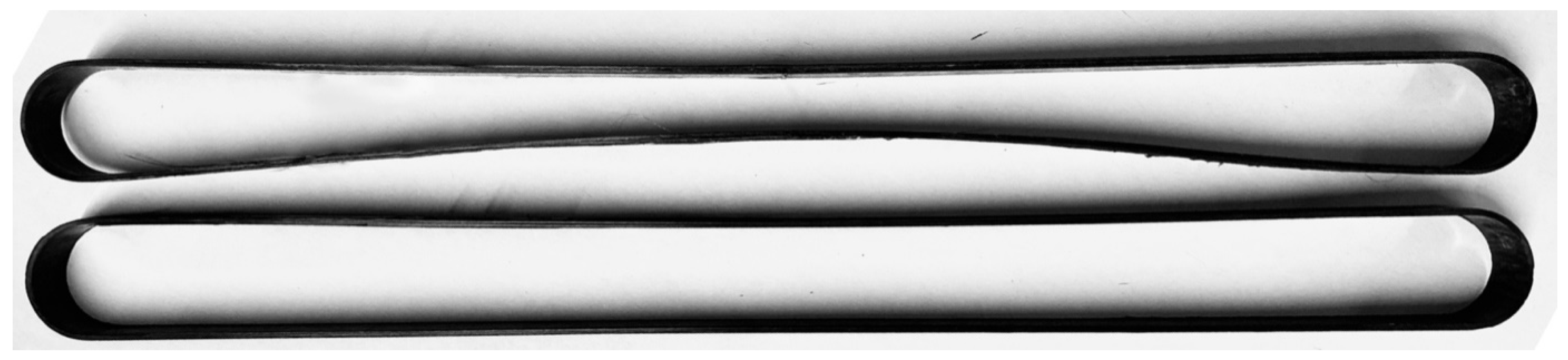

2.3. Manufacture

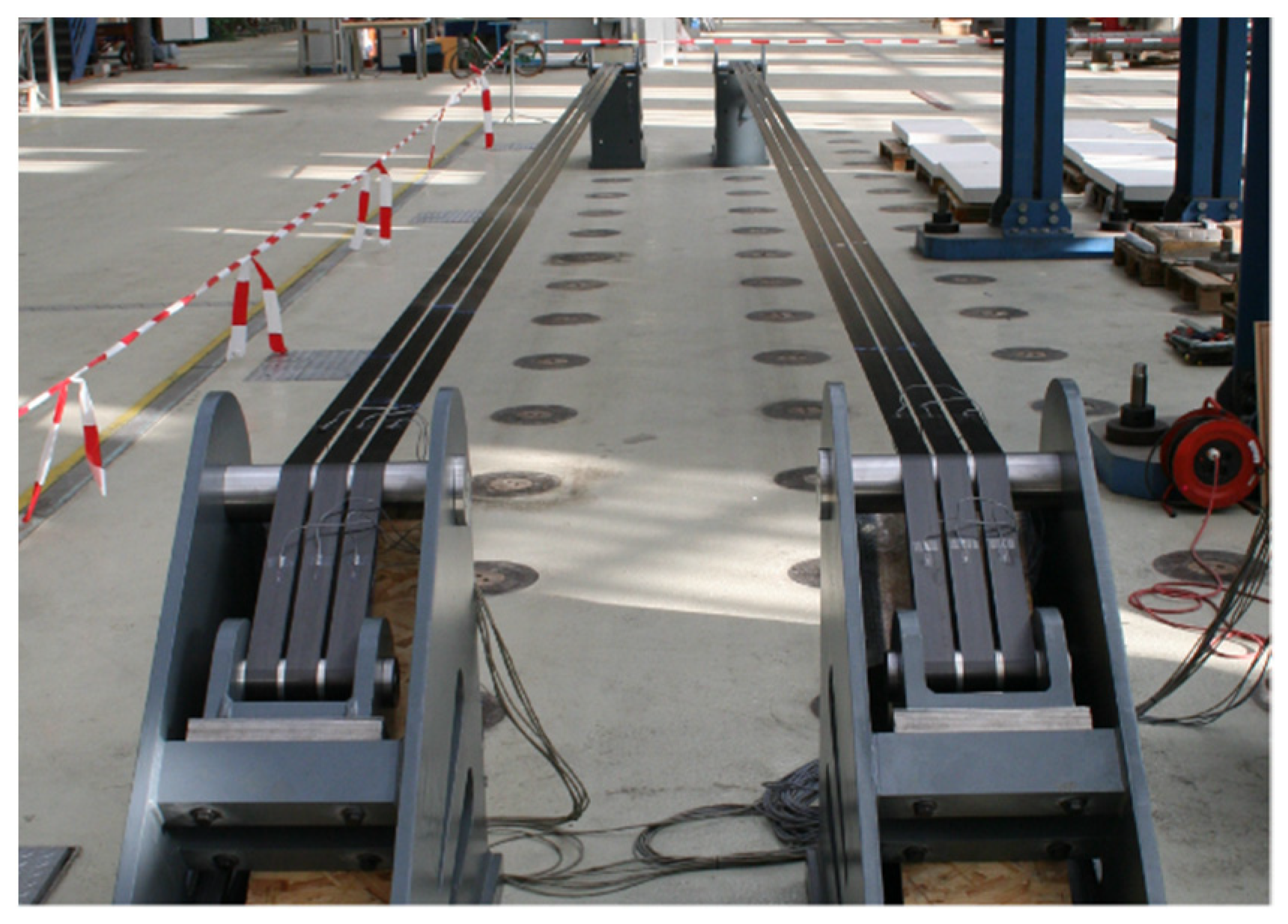

3. Preload Estimation & Experimental Set-Up

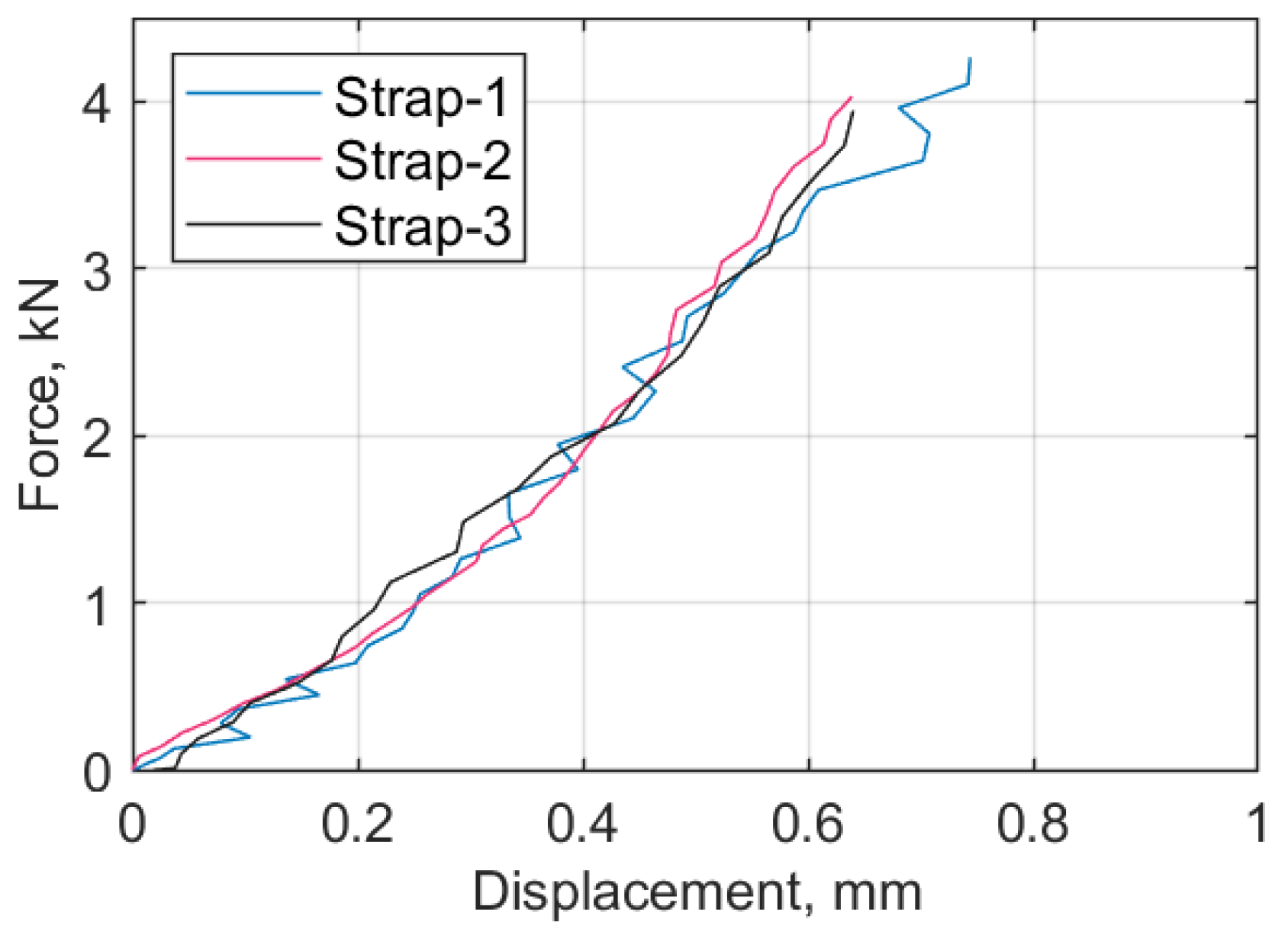

3.1. Preload Experimental Estimation

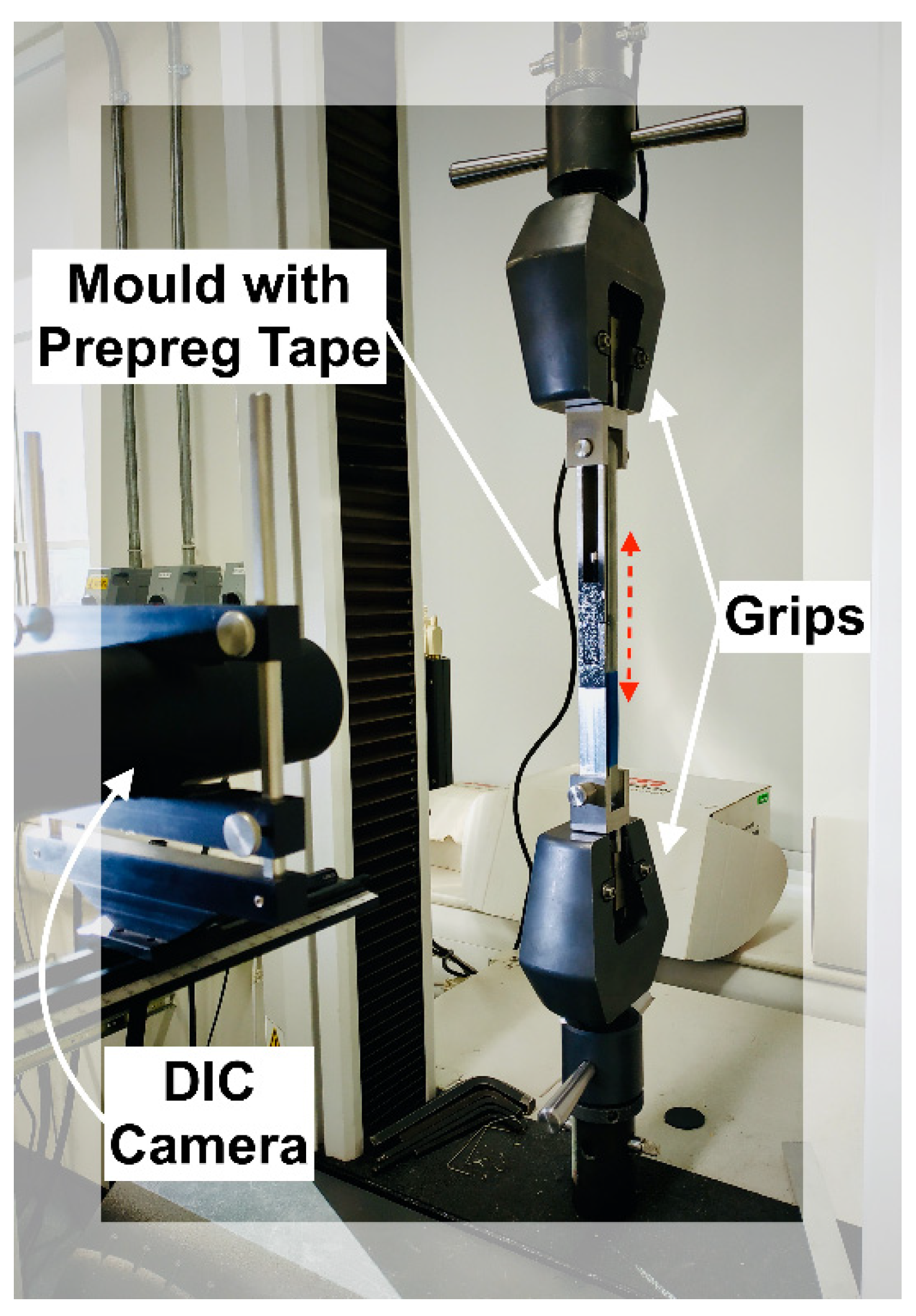

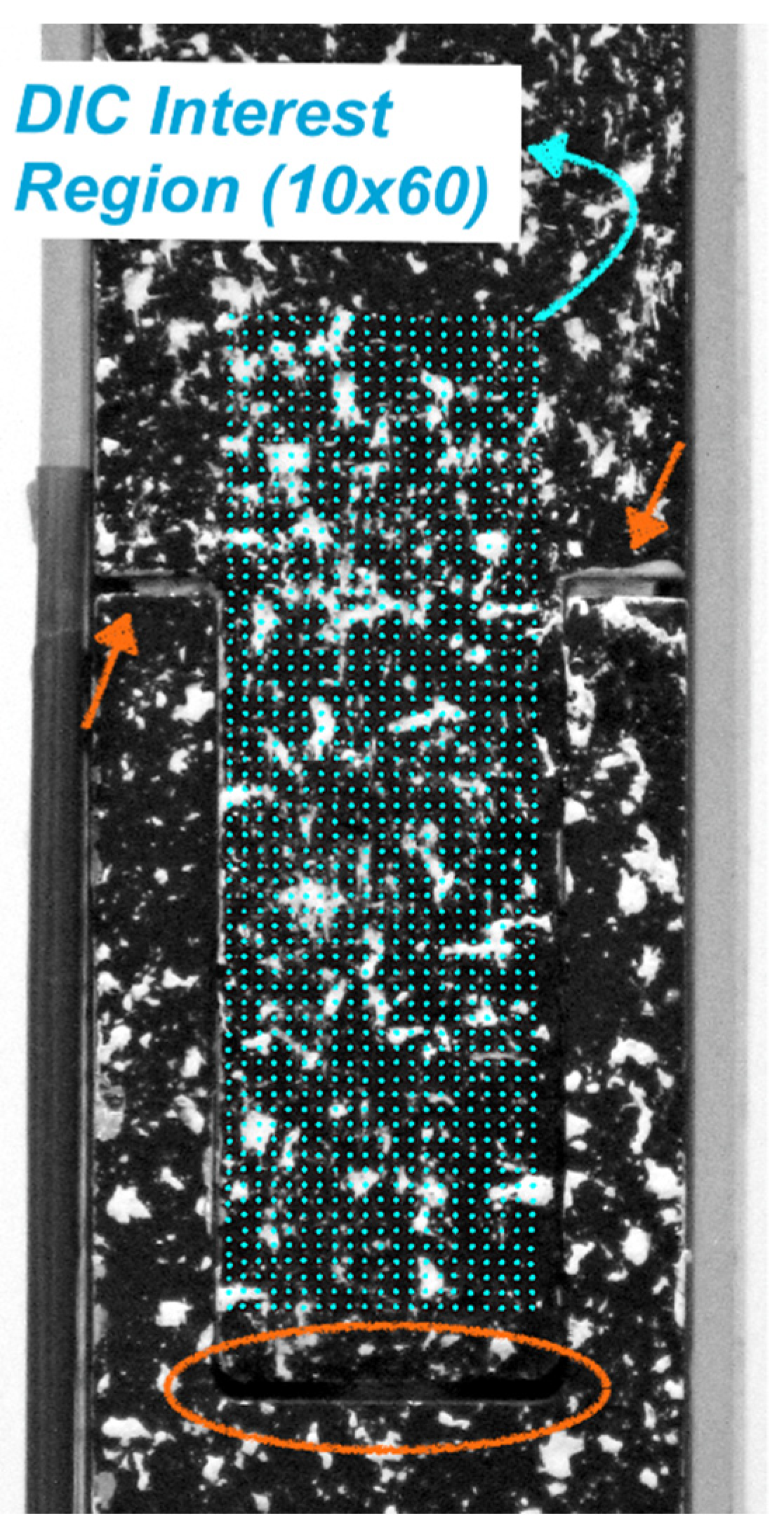

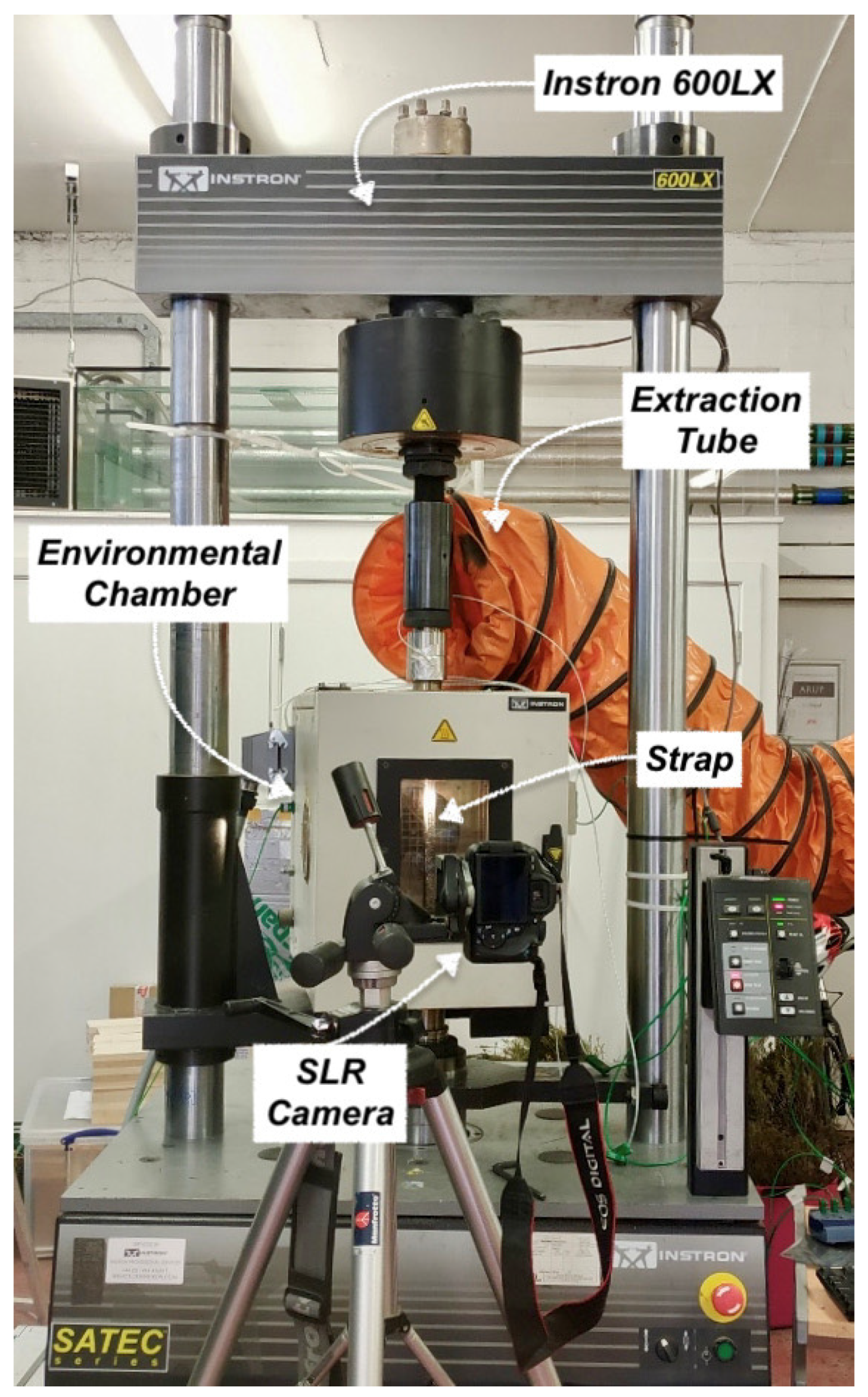

3.2. Test Set-Up

4. Results

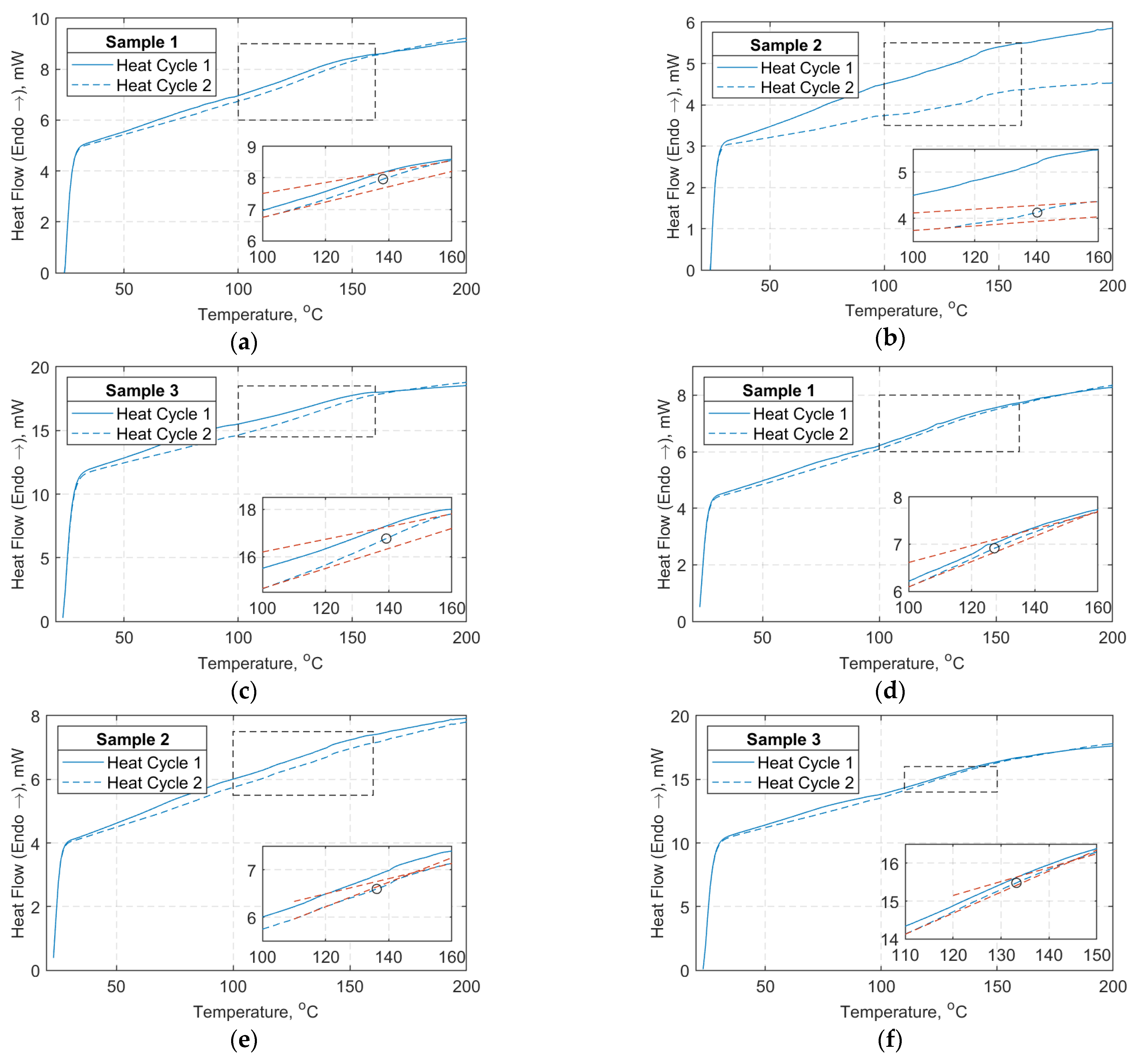

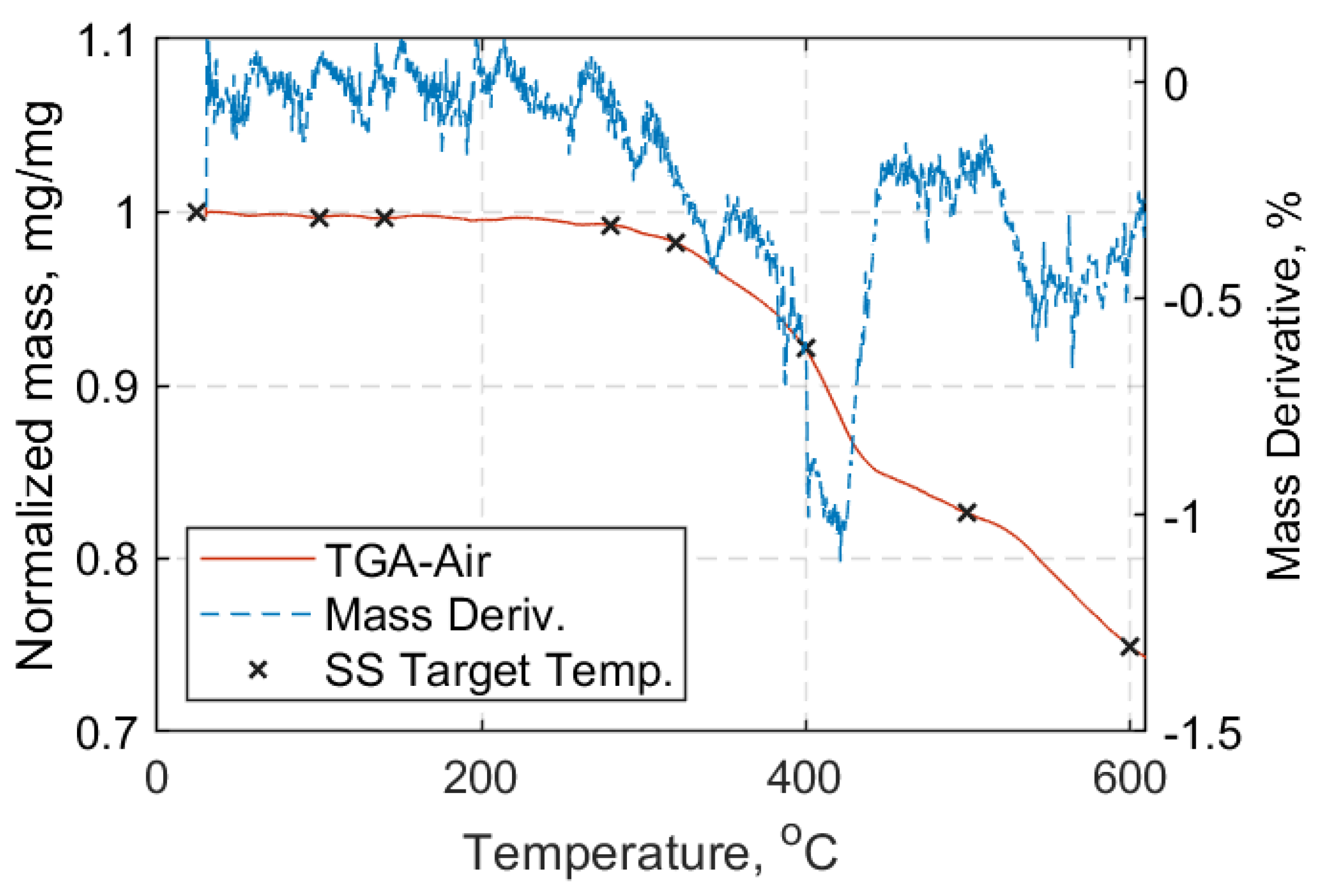

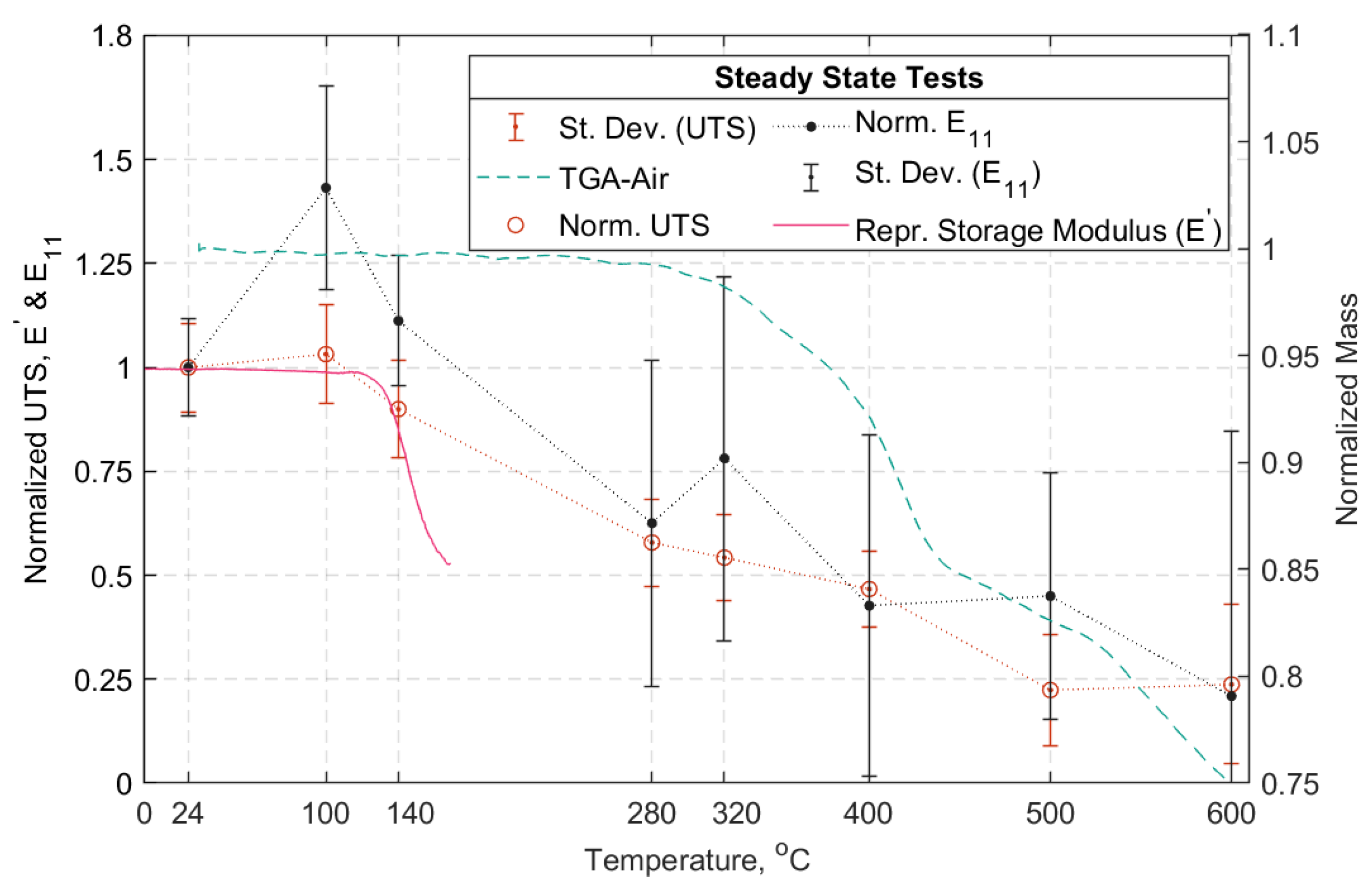

4.1. Material Characterization

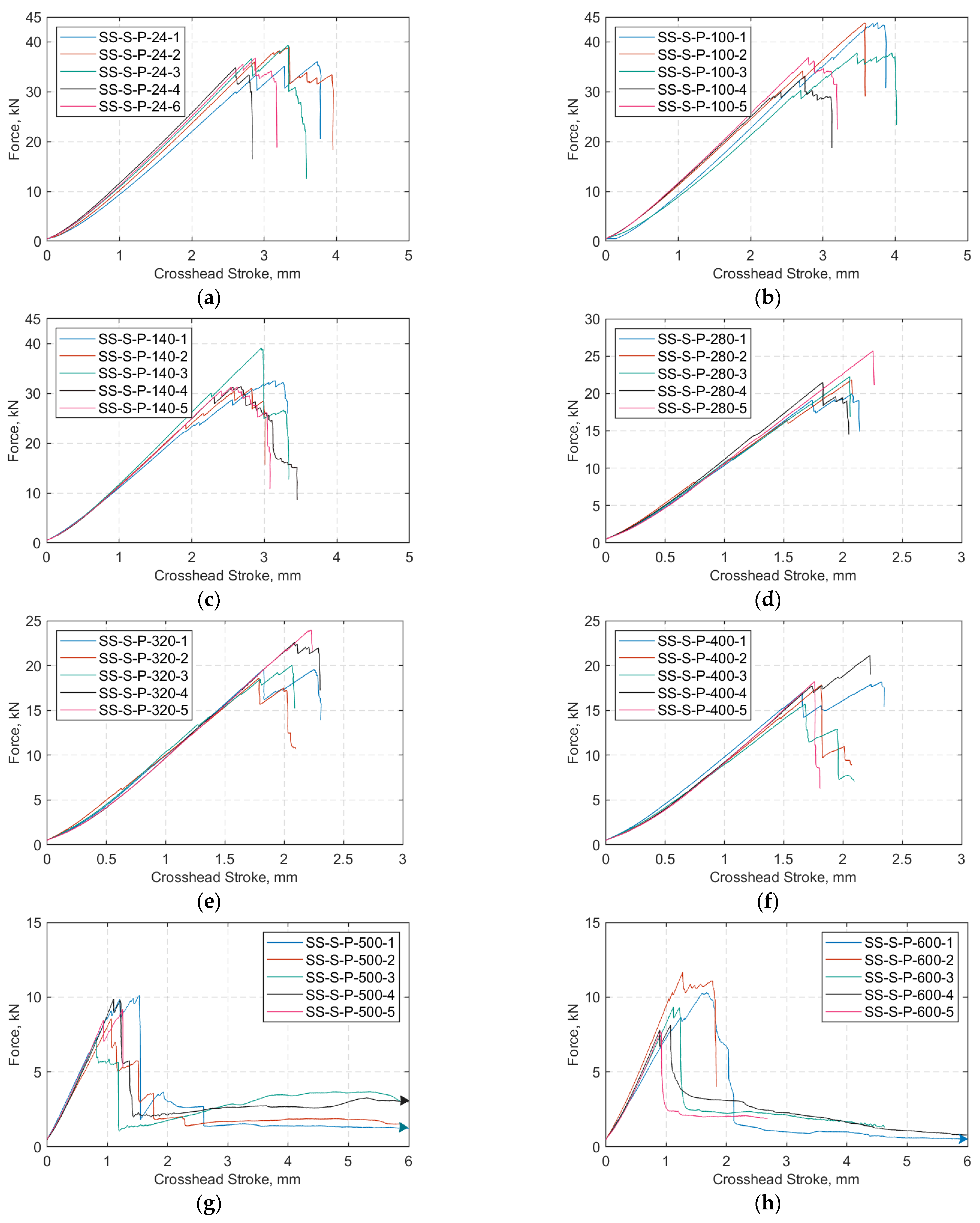

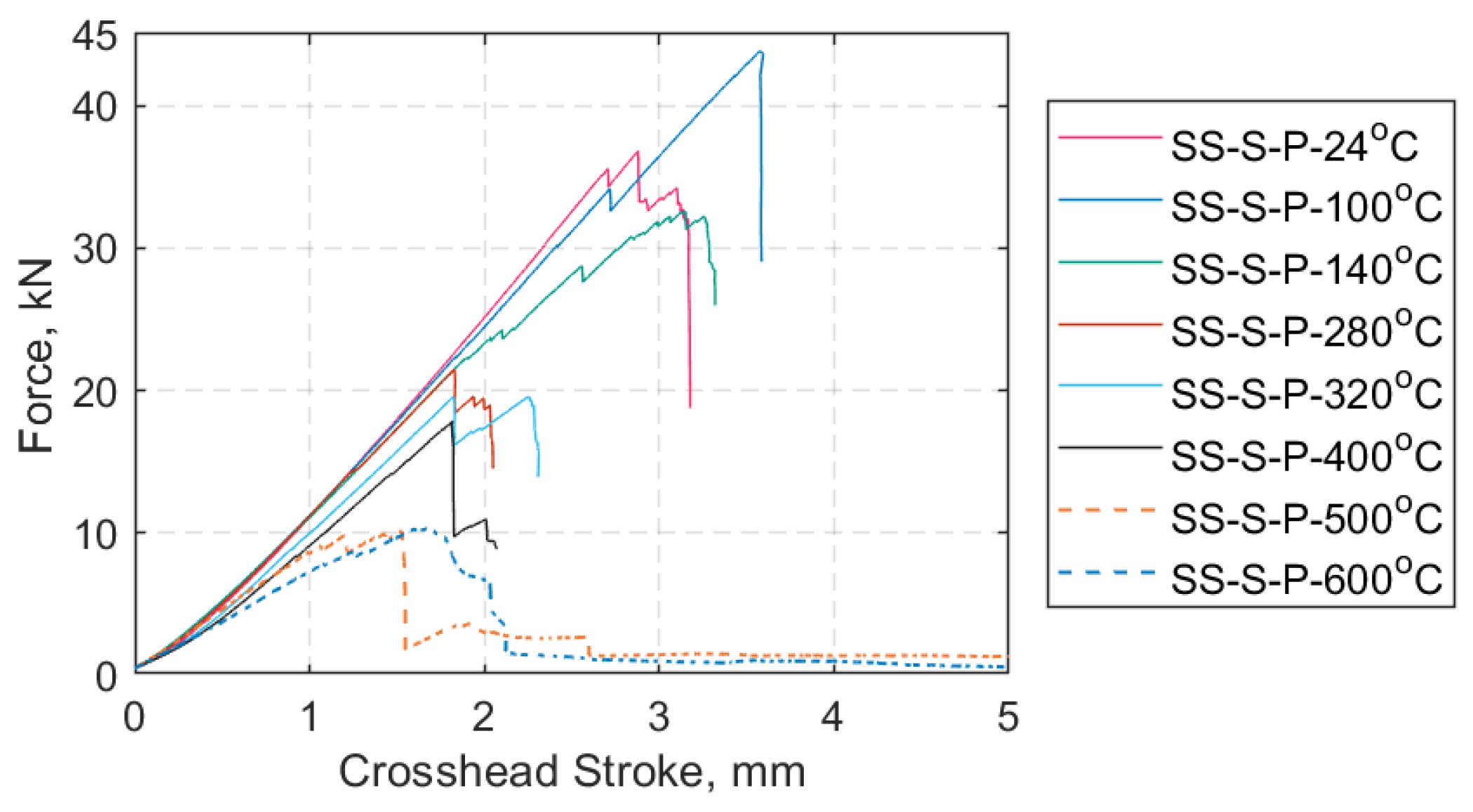

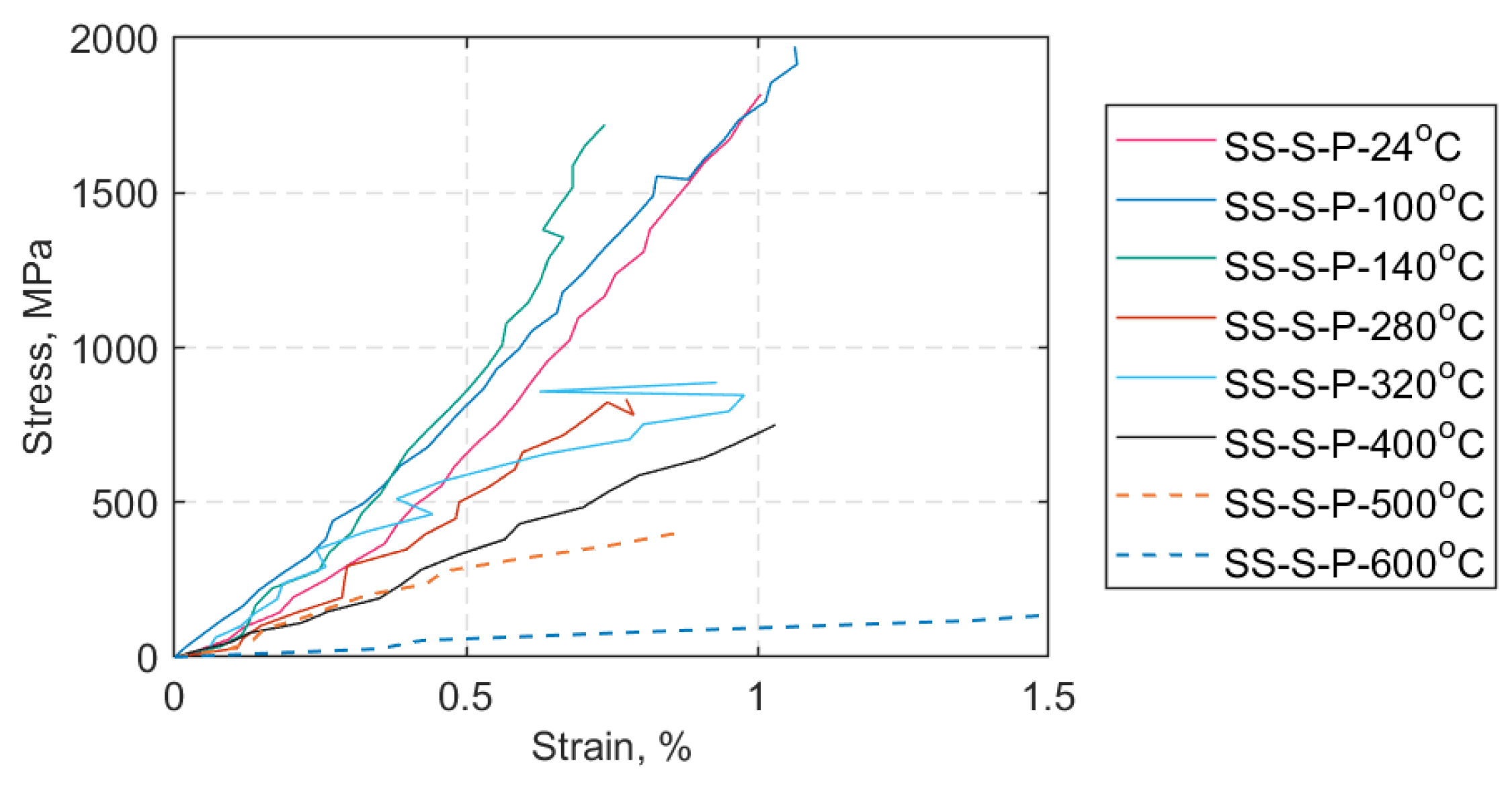

4.2. Steady State Thermal (SS) Results

- SS-Steady State;

- S-Standard Strap Models;

- P-Prestressed; and

- 24 °C, 100 °C, 140 °C, …, 600 °C for each temperature case.

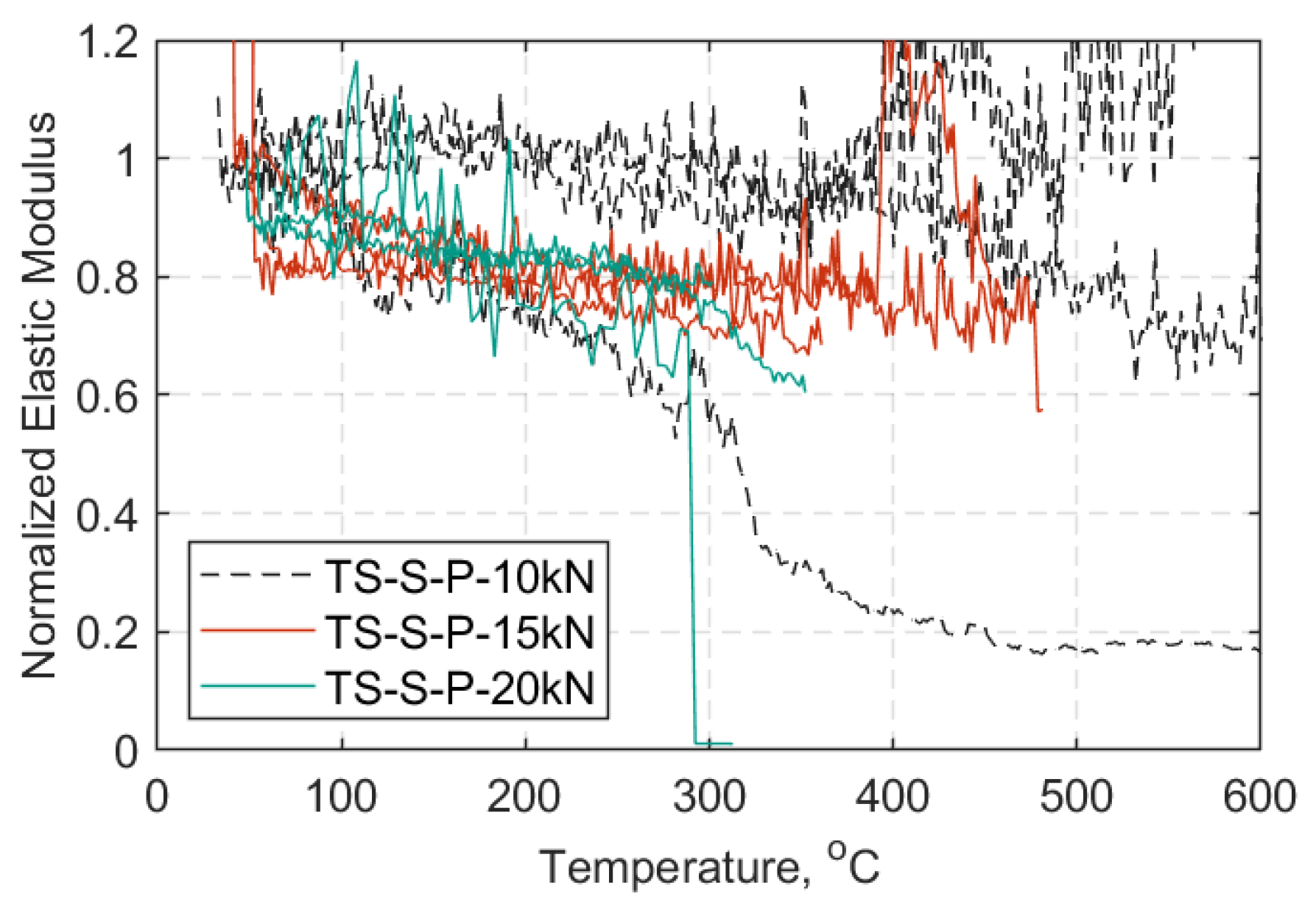

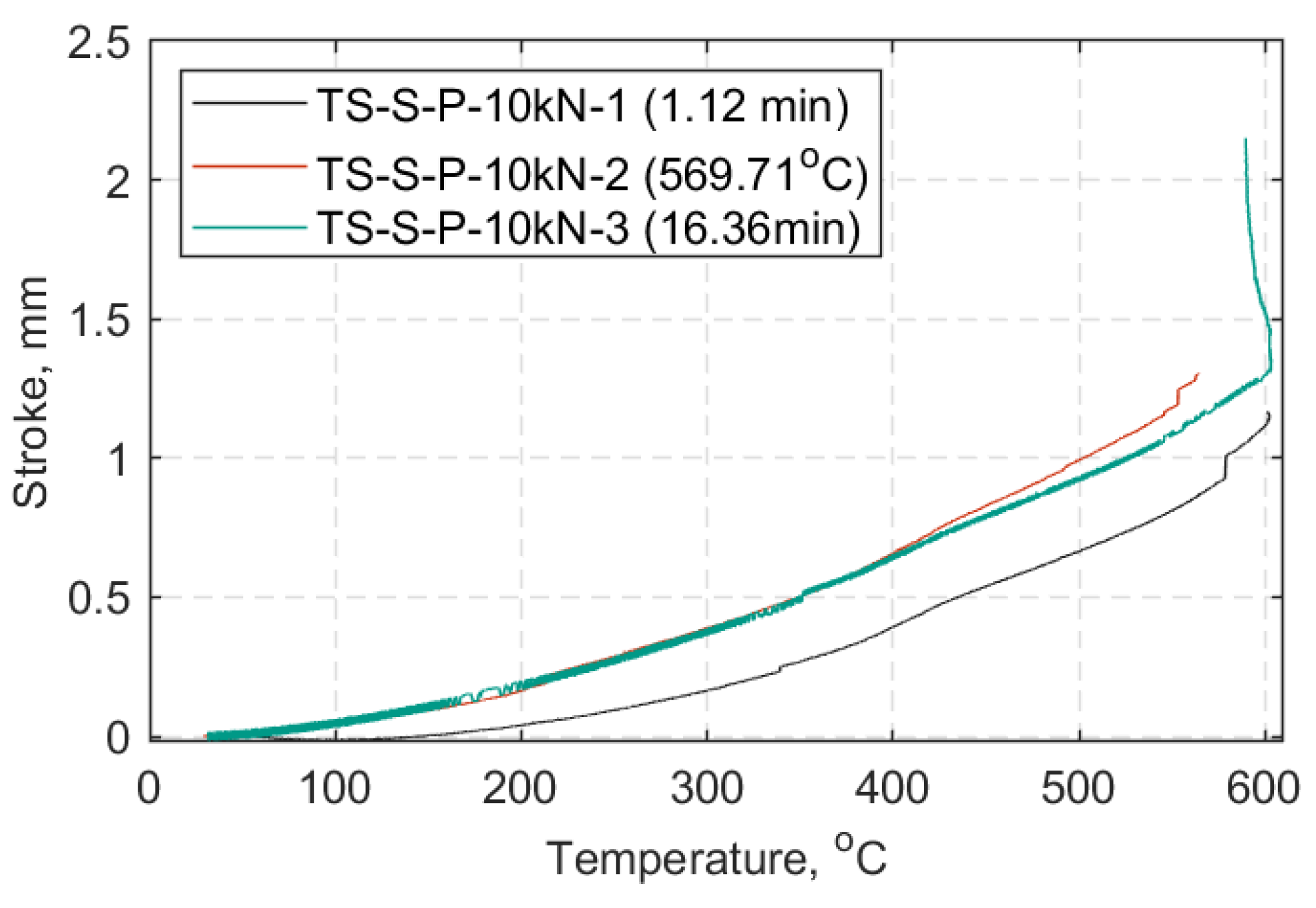

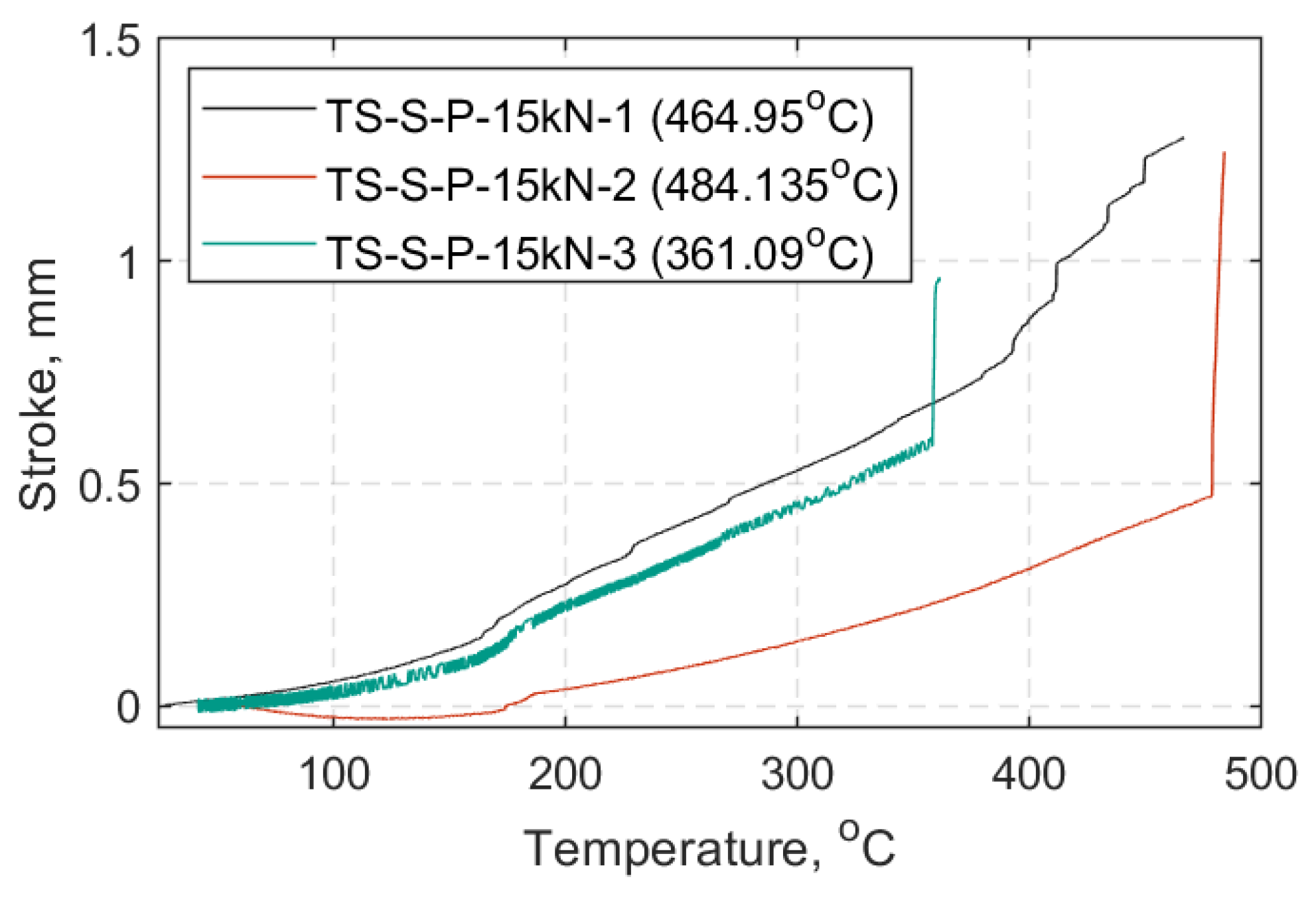

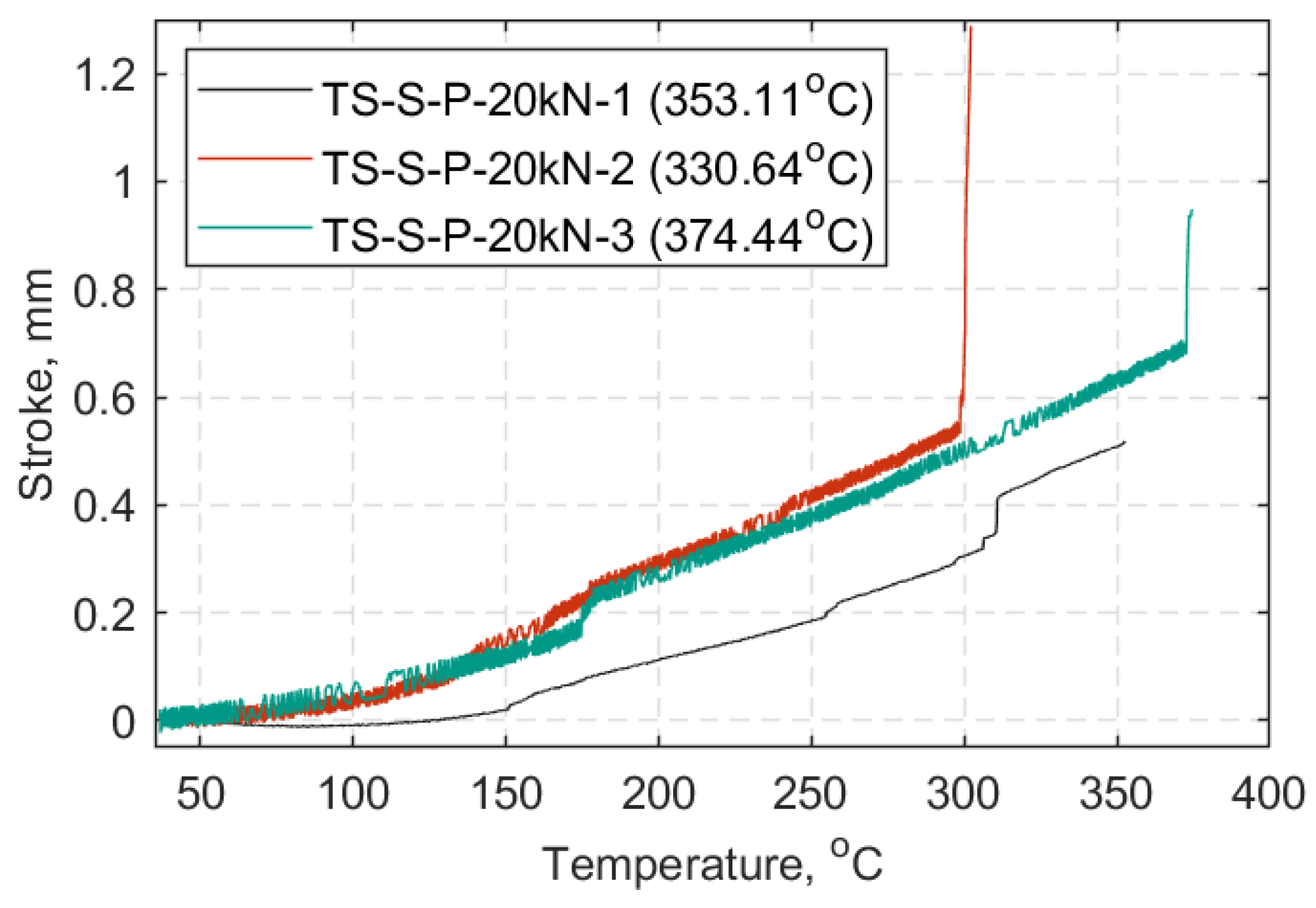

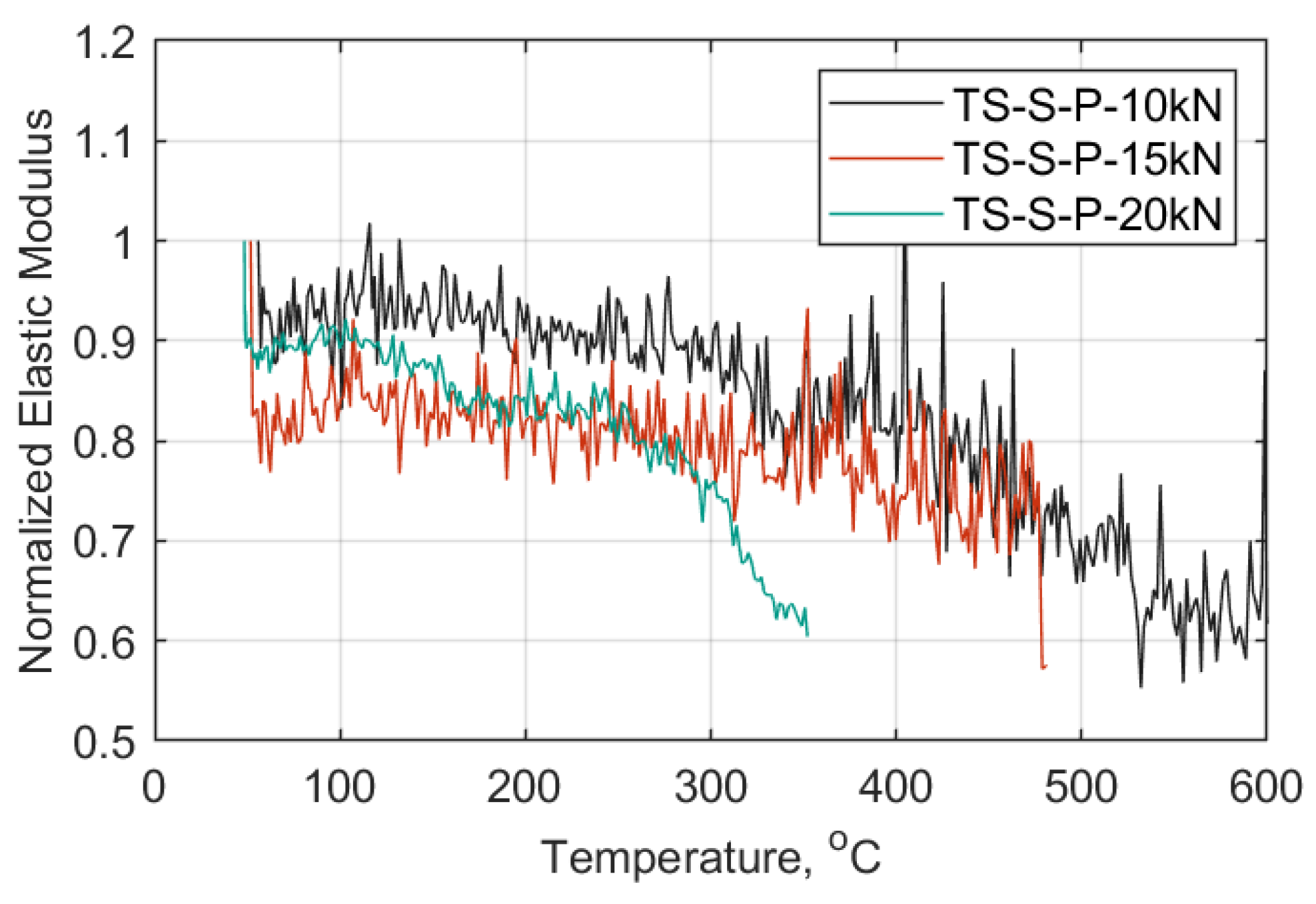

4.3. Transient State Thermal (TS) Results

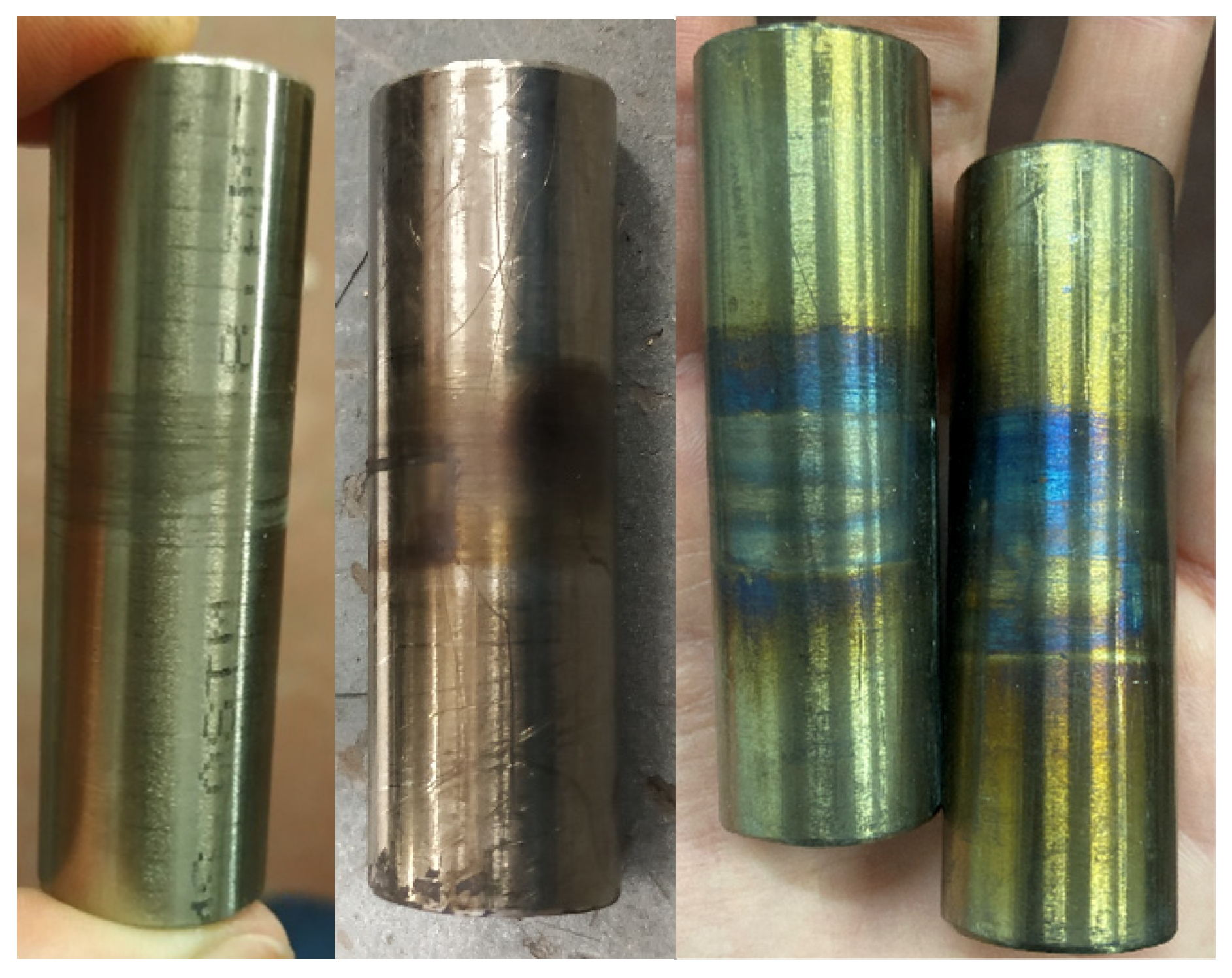

4.4. Failure Modes

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Before Burn-Off | After Burn-Off | ||||

|---|---|---|---|---|---|

| Sample | Empty Crucible (gr) | Composite Only Weight (gr) | Crucible + Composite (gr) | Crucible + Composite (gr) | Composite Only (gr) |

| 1 | 36.4974 | 0.7488 | 37.2462 | 37.0346 | 0.5372 |

| 2 | 31.2341 | 0.8254 | 32.0595 | 31.8110 | 0.5769 |

| 3 | 30.9408 | 0.8591 | 31.7999 | 31.5610 | 0.6202 |

| 4 | 32.5407 | 0.6603 | 33.2010 | 33.0336 | 0.4929 |

| 5 | 38.7678 | 0.8456 | 39.6134 | 39.3808 | 0.6130 |

Appendix B

| Temp. | Property | 1 | 2 | 3 | 4 | 5 | Average | St. Dev. |

|---|---|---|---|---|---|---|---|---|

| 24 °C | UTS (MPa) | 1894.61 | 1803.63 | 1934.70 | 1575.41 | 1629.63 | 1767.60 | 159.16 |

| Fmax (kN) | 36.10 | 39.05 | 39.33 | 34.87 | 36.80 | 37.23 | 1.92 | |

| E11 (GPa) | 138.34 | 156.46 | 115.72 | 155.91 | 146.52 | 142.59 | 16.77 | |

| 100 °C | UTS (MPa) | 1932.46 | 2017.30 | 1706.77 | 1479.77 | 1742.57 | 1775.78 | 209.98 |

| Fmax (kN) | 43.90 | 43.79 | 37.83 | 33.16 | 36.89 | 39.11 | 4.66 | |

| E11 (GPa) | N/A | 152.87 | 203.02 | 188.25 | 272.66 | 204.20 | 50.26 | |

| 140 °C | UTS (MPa) | 1625.08 | 1428.75 | 1837.35 | 1425.86 | 1424.88 | 1548.39 | 183.00 |

| Fmax (kN) | 32.58 | 31.09 | 39.12 | 31.45 | 31.31 | 33.11 | 3.41 | |

| E11 (GPa) | 156.08 | 187.50 | 163.73 | 127.02 | 252.02 | 158.58 | 24.94 | |

| 280 °C | UTS (MPa) | 903.16 | 952.96 | 1020.58 | 936.10 | 1166.90 | 995.94 | 104.73 |

| Fmax (kN) | 19.94 | 21.78 | 22.22 | 21.47 | 25.69 | 22.22 | 2.12 | |

| E11 (GPa) | 92.79 | 88.25 | 145.26 | 56.46 | 63.05 | 89.16 | 35.04 | |

| 320 °C | UTS (MPa) | 895.80 | 797.21 | 922.96 | 1010.05 | 1041.57 | 933.52 | 97.01 |

| Fmax (kN) | 19.56 | 18.58 | 20.02 | 22.59 | 23.98 | 20.95 | 2.25 | |

| E11 (GPa) | 173.01 | 60.59 | 130.99 | 130.05 | 62.34 | 111.40 | 48.77 | |

| 400 °C | UTS (MPa) | 790.28 | 828.89 | 703.78 | 907.66 | 786.15 | 803.35 | 74.01 |

| Fmax (kN) | 18.14 | 17.80 | 15.69 | 21.13 | 18.18 | 18.19 | 1.94 | |

| E11 (GPa) | 77.90 | 80.07 | N/A | 25.96 | 59.64 | 60.89 | 25.03 | |

| 500 °C | UTS (MPa) | 454.52 | 368.94 | 315.66 | 410.51 | 377.38 | 385.40 | 51.49 |

| Fmax (kN) | 10.10 | 8.55 | 7.29 | 9.87 | 9.19 | 9.00 | 1.13 | |

| E11 (GPa) | 80.30 | 64.09 | 33.18 | 79.32 | 64.09 | 64.20 | 19.04 | |

| 600 °C | UTS (MPa) | 448.07 | 516.80 | 410.88 | 341.38 | 326.66 | 408.76 | 78.27 |

| Fmax (kN) | 10.31 | 11.65 | 9.34 | 8.11 | 7.73 | 9.42 | 1.61 | |

| E11 (GPa) | N/A | N/A | 11.68 | 28.26 | 49.59 | 29.84 | 19.01 |

References

- Morgan, P. 23-The Use of Carbon Fibers. In Carbon Fibers and Their Composites, 1st ed.; CRC Press: Boca Raton, FL, USA, 2005; pp. 951–1042. [Google Scholar]

- Gao, J.; Zhao, B. Application of CFRP Suspenders for through and Half-through Arch Bridges. In Proceedings of the 2015 4th International Conference on Sustainable Energy and Environmental Engineering, Shenzhen, China, 20–21 December 2015. [Google Scholar]

- Hollaway, L.C. The evolution of and the way forward for advanced polymer composites in the civil infrastructure. Constr. Build. Mater. 2003, 17, 365–378. [Google Scholar] [CrossRef]

- CarboLink AG. Undermülistrasse 25; CarboLink AG: Fehraltorf, Switzerland, 2000. [Google Scholar]

- Talreja, R.; Singh, C.V. Damage in composite materials. In Damage and Failure of Composite Materials; Cambridge University Press: Cambridge, UK, 2012; pp. 36–56. [Google Scholar]

- Mansfield, E.H. Load Transfer from a Pin to a Wound Fibre Composite Strip; Procurement Executive, Ministry of Defence; Aeronautical Research Council Reports and Memoranda: Great Britain, UK, 1977; pp. 1–35. [Google Scholar]

- Martin, R.H. Delamination Failure in a Unidirectional Curved Composite Laminate; Analytical Services and Materials, Inc.: Hampton, VA, USA, 1990. [Google Scholar]

- Schürmann, H. Konstruieren mit Faser-Kunststoff-Verbunden; Springer Berlin Heidelberg: Berlin, Germany, 2007; pp. 485–511. [Google Scholar]

- Wang, L.; Zhang, J.; Xu, J.; Han, Q. Anchorage systems of CFRP cables in cable structures—A review. Constr. Build. Mater. 2018, 160, 82–99. [Google Scholar] [CrossRef]

- Conen, H. Deformation und Versagen von GFK-strangschlaufen. Kunstoffe 1966, 9, 629–681. [Google Scholar]

- Winistörfer, A.U. Development of Non-Laminated Advanced Composite Straps for Civil Engineering Applications. Ph.D Thesis, University of Warwick, Coventry, UK, 1999. [Google Scholar]

- Winistörfer, A.; Meier, U. CARBOSTRAP–An advanced composite tendon system. In FRPRCS-5: Fibre-Reinforced Plastics for Reinforced Concrete Structures; The Authors and Thomas Telford Limited: London, UK, 2001; pp. 231–238. [Google Scholar]

- Lees, J.M.; Winistörfer, A.U.; Meier, U. External Prestressed Carbon Fiber-Reinforced Polymer Straps for Shear Enhancement of Concrete. J. Compos. Constr. 2002, 6, 249–256. [Google Scholar] [CrossRef]

- Meier, U.; Brönnimann, R.; Widmann, R.; Winistörfer, P. Bowstring-arch bridge made of CFRP, GFRP and glulam. In Proceedings of the Asia-Pacific Conference on FRP in Structures (APFIS 2009), Seoul, Korea, 9–11 December 2009. [Google Scholar]

- Schlaich, M.; Bleicher, A. Spannbandbrücke mit Kohlenstofffaser-Lamellen. Bautechnik 2007, 84, 311–319. [Google Scholar] [CrossRef]

- Meier, U.O.; Winistörfer, A.U.; Haspel, L. World’s first large bridge fully relying on carbon fiber rein-forced polymer hangers. In Proceedings of the SAMPE Europe Conference, Amsterdam, The Netherlands, 30 September–1 October 2020. [Google Scholar]

- Ortega, L.R.C.; López, J.R. New stress ribbon footbridge over Jucar river. In Proceedings of the International Conference on Research in Construction: Structural Milestones of Architecture and Engineering, Madrid, Spain, 17–18 November 2011; pp. 219–225. [Google Scholar]

- Liu, Y.; Zwingmann, B.; Schlaich, M. Carbon Fiber Reinforced Polymer for Cable Structures—A Review. Polymers 2015, 7, 2078–2099. [Google Scholar] [CrossRef]

- ACCIONA. Business as Unusual, Spain. Available online: https://mediacdn.acciona.com/media/1004093/iplusdplusi_en.pdf (accessed on 8 April 2021).

- Baschnagel, F.; Rohr, V.; Terrasi, G.P. Fretting Fatigue Behaviour of Pin-Loaded Thermoset Carbon-Fibre-Reinforced Polymer (CFRP) Straps. Polymers 2016, 8, 124. [Google Scholar] [CrossRef] [PubMed]

- Baschnagel, F.; Härdi, R.; Triantafyllidis, Z.; Meier, U.; Terrasi, G. Fatigue and Durability of Laminated Carbon Fibre Reinforced Polymer Straps for Bridge Suspenders. Polymers 2018, 10, 169. [Google Scholar] [CrossRef] [PubMed]

- Kragh, E.; Narasimhan, H.; Jensen, J.L. Fire Protection of Bridge Cables. Struct. Eng. Int. 2020, 30, 530–533. [Google Scholar] [CrossRef]

- Fontanari, V.; Benedetti, M.; Monelli, B.D.; Degasperi, F. Fire behavior of steel wire ropes: Experimental investigation and numerical analysis. Eng. Struct. 2015, 84, 340–349. [Google Scholar] [CrossRef]

- Kotsovinos, P.; Judge, R.; Walker, G.; Woodburn, P. Fire Performance of Structural Cables: Current Understanding, Knowledge Gaps, and Proposed Research Agenda. J. Struct. Eng. 2020, 146, 03120002. [Google Scholar] [CrossRef]

- Buchanan, A.H.; Abu, A.K. Structural Design for Fire Safety; John Wiley & Sons, Ltd.: Chichester, UK, 2016. [Google Scholar]

- Mahieux, C.A. Effect of Temperature on Polymer Matrix Composites. In Environmental Degradation of Industrial Composites; Elsevier: Amsterdam, The Netherlands, 2006; pp. 17–83. [Google Scholar]

- Bai, Y.; Keller, T. Thermomechanical Properties of FRP Composites. In High Temperature Performance of Polymer Composites; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2013; pp. 79–98. [Google Scholar]

- Feih, S.; Mouritz, A.P. Tensile properties of carbon fibres and carbon fibre–polymer composites in fire. Compos. Part A Appl. Sci. Manuf. 2012, 43, 765–772. [Google Scholar] [CrossRef]

- Yu, B.; Kodur, V. Effect of temperature on strength and stiffness properties of near-surface mounted FRP reinforcement. Compos. Part B Eng. 2014, 58, 510–517. [Google Scholar] [CrossRef]

- Terrasi, G.; McIntyre, E.; Bisby, L.; Lämmlein, T.; Lura, P. Transient Thermal Tensile Behaviour of Novel Pitch-Based Ultra-High Modulus CFRP Tendons. Polymers 2016, 8, 446. [Google Scholar] [CrossRef] [PubMed]

- Zhou, F.; Zhang, J.; Song, S.; Yang, D.; Wang, C. Effect of Temperature on Material Properties of Carbon Fiber Reinforced Polymer (CFRP) Tendons: Experiments and Model Assessment. Materials 2019, 12, 1025. [Google Scholar] [CrossRef] [PubMed]

- Titanium Grade 5, Narrowboat Way, Hurst Business Park, Brierley Hill, West Midlands, DY5 1UF UK. Available online: https://www.alloywire.com/products/titanium-grade-5-6al4v/ (accessed on 8 April 2021).

- IMS60 E13 24K 830tex. TohoTenax Teijin, Wuppertahl, Germany. Available online: http://www.ezentrumbilder.de/rg/pdf/td_en_IMS60_en.pdf (accessed on 8 April 2021).

- Huntsman Advanced Materials GmbH: Basel, Switzerland.

- Standard Test Methods for Constituent Content of Composite Materials; ASTM D3171-15; ASTM International: West Conshohocken, PA, USA, 2015.

- ISO, 6721–11:2019. Plastics—Determination of Dynamic Mechanical Properties—Part 11: Glass Transition Temperature; International Organization for Standardization: Geneva, Switzerland, 2019. [Google Scholar]

- Stratford, T.J.; Bisby, L.A. Effect of Warm Temperatures on Externally Bonded FRP Strengthening. J. Compos. Constr. 2012, 16, 235–244. [Google Scholar] [CrossRef]

- Standard Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential Scanning Calorimetry; ASTM D3418-15; ASTM International: West Conshohocken, PA, USA, 2015.

- Gorjup, D.; Slavic, J.; Boltezar, M. Ladisk/Pydic: First Release; Zenodo: Geneva, Switzerland, 2017. [Google Scholar]

- ISO. Plastics–Determination of Tensile Properties. Part 5: Test Conditions for Unidirectional Fibre-Reinforced Plastic Composites; International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

- Wang, Y.C.; Kodur, V. Variation of strength and stiffness of fibre reinforced polymer reinforcing bars with temperature. Cem. Concr. Compos. 2005, 27, 864–874. [Google Scholar] [CrossRef]

- Park, S.-J.; Heo, G.-Y. Precursors and Manufacturing of Carbon Fibers. In Carbon Fibers; Springer: Dordrecht, The Netherlands, 2014; pp. 31–66. [Google Scholar]

- Gibson, A.G.; Wu, Y.S.; Evans, J.T.; Mouritz, A.P. Laminate Theory Analysis of Composites under Load in Fire. J. Compos. Mater. 2005, 40, 639–658. [Google Scholar] [CrossRef]

- Koyanagi, J.; Nakada, M.; Miyano, Y. Tensile strength at elevated temperature and its applicability as an accelerated testing methodology for unidirectional composites. Mech. Time Depend. Mater. 2011, 16, 19–30. [Google Scholar] [CrossRef]

| Titanium Ti-6Al-4V (Grade 5), Solution Treated Alloy (STA) | Density (g/cm3): 4.43 Tensile Strength—Yield (MPa): 1790 Young’s Modulus (GPa): 114 |

| IMS60 E13 24K 830tex | Density (g/cm3): 1.79 Tensile Strength (MPa): 5600 Young’s Modulus (GPa): 290 |

| Epoxy Resin XB 3515/Aradur® 5021 | Density (g/cm3): 1.17 Tensile Strength (MPa): 60 ± 1.43Young’s Modulus (GPa): 2.62 ± 0.033 |

| Sample | Density (g/cm3) | Vf (%) | Vm (%) | Vv (%) |

|---|---|---|---|---|

| 1 | 1.4559 | 58.353 | 35.165 | 6.482 |

| 2 | 1.4420 | 56.304 | 37.105 | 6.591 |

| 3 | 1.4858 | 59.922 | 35.313 | 4.765 |

| 4 | 1.5520 | 64.723 | 33.630 | 1.648 |

| 5 | 1.4154 | 57.322 | 33.276 | 9.402 |

| Average | 1.4702 | 59.325 | 34.898 | 5.778 |

| St. Deviation | ±0.0468 | ±2.952 | ±1.368 | ±2.545 |

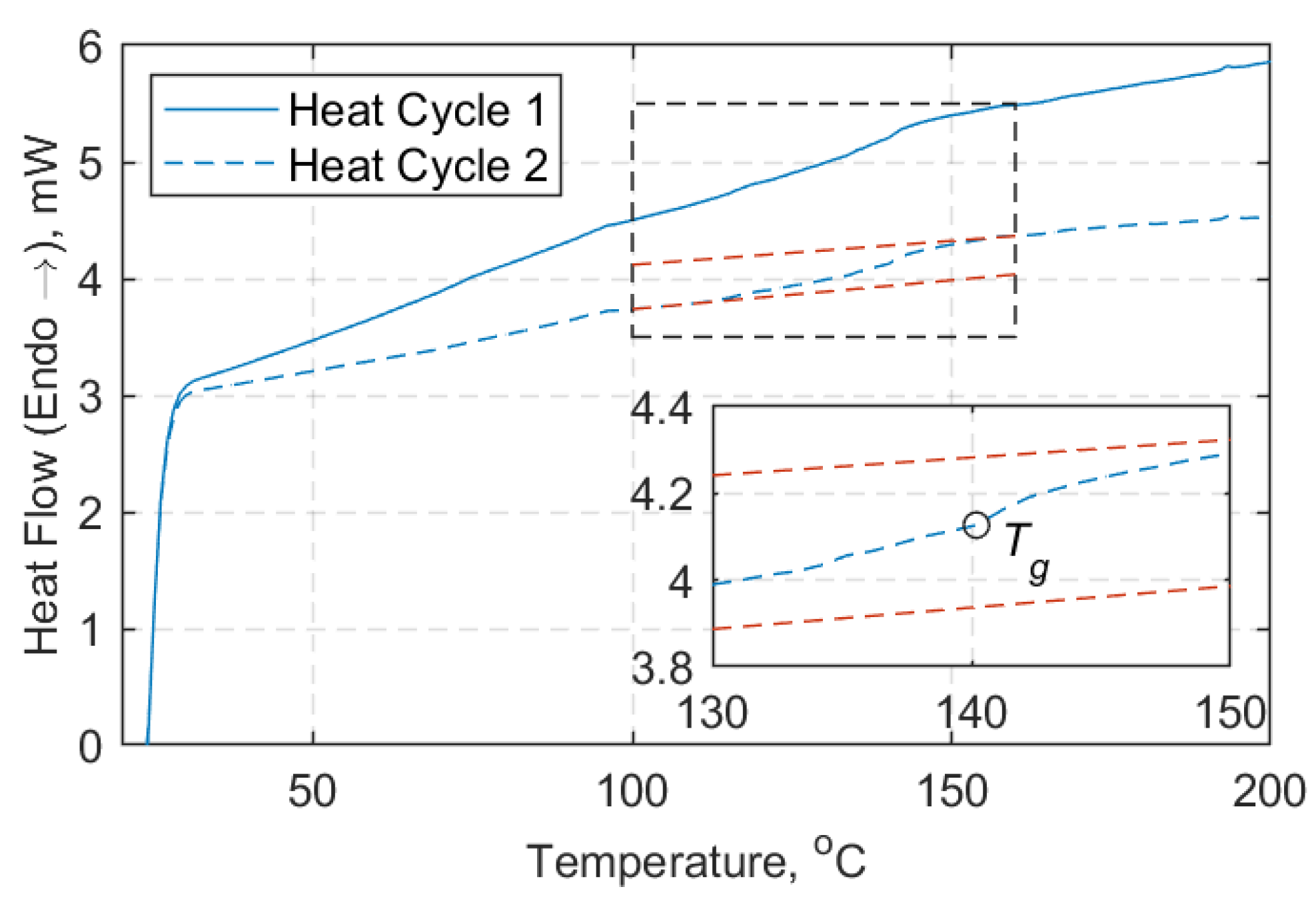

| DSC Samples | |||

| Sample | Weight, mg | Extracted Sample Location | Tg, Heat Cycle 2 (°C) |

| 1 | 19.964 | Middle | 138.19 |

| 17.348 | Curvature | 127.19 | |

| 2 | 12.870 | Middle | 140.19 |

| 15.938 | Curvature | 136.21 | |

| 3 | 38.790 | Middle | 139.22 |

| 38.830 | Curvature | 133.21 | |

| Average | 135.70 | ||

| St. Deviation | ±4.850 | ||

| DMTA Samples | |||

| Sample | Initial Shape State | Tg, Peak tanδ Value (°C) | |

| 3PB-1 | Sagging-like | 149.50 | |

| 3PB-2 | Sagging-like | 149.40 | |

| 3PB-3 | Hogging-like | 147.20 | |

| 3PB-4 | Hogging-like | 150.60 | |

| Average | 149.18 | ||

| St. Deviation | ±1.425 | ||

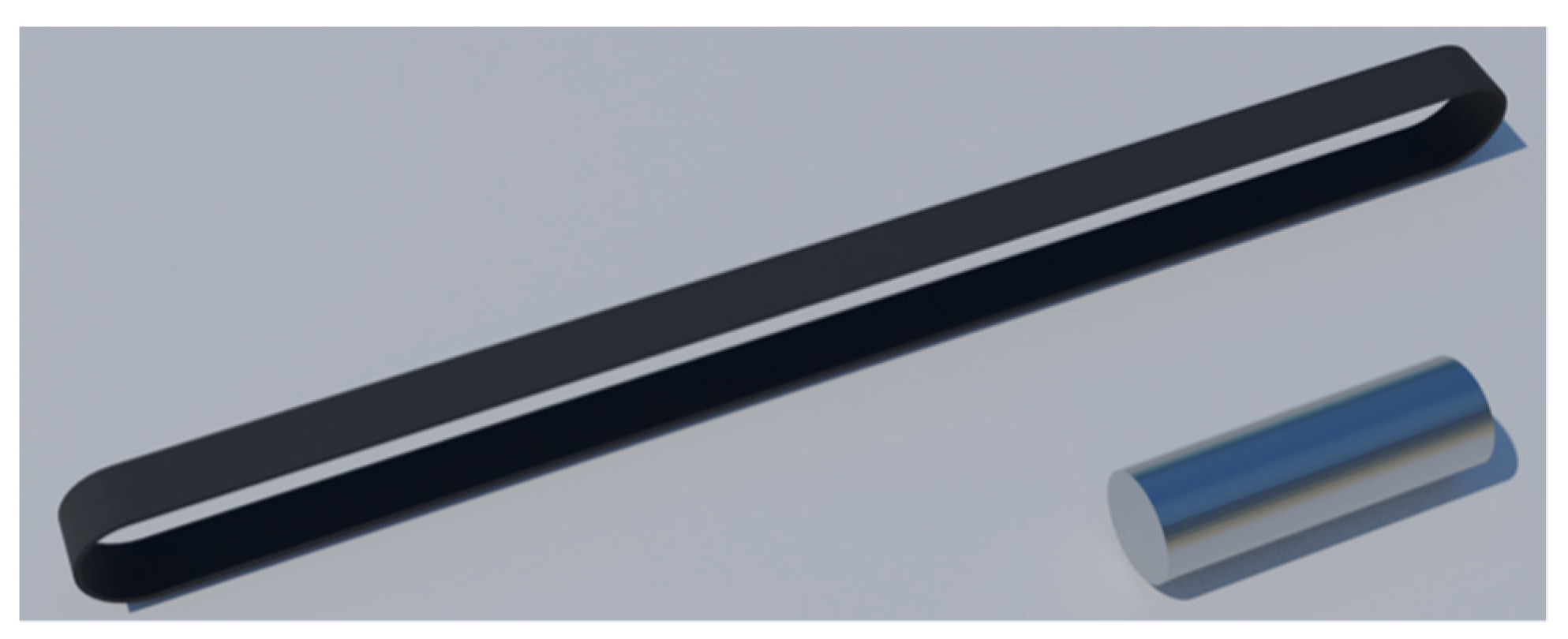

| Titanium Pin | |

| Length (mm) | 62 |

| Diameter (mm) | 20 ± 0.1 |

| CFRP Strap | |

| Shaft Length (mm) Radius of Curvature (mm) | 250 10 |

| Width (mm) | 12 |

| Thickness (mm) | 1 |

| DIC Values | Caliper Values | ||

|---|---|---|---|

| Sample | δmax, mm | Left/Right Gap, mm | Middle Gap, mm |

| Strap-1 | 0.744 | 0.92/0.94 | 0.95/0.95 |

| Strap-2 | 0.639 | 0.86/0.95 | 0.91/0.91 |

| Strap-3 | 0.640 | 0.82/0.86 | 0.93/0.92 |

| Average | 0.674 | 0.892 | 0.928 |

| St. Dev. | ±0.060 | ±0.052 | ±0.018 |

| 24 °C | 100 °C | 140 °C | 280 °C | 320 °C | 400 °C | 500 °C | 600 °C | ||

|---|---|---|---|---|---|---|---|---|---|

| Fmax (kN) | Average | 37.23 | 39.11 | 33.11 | 22.22 | 20.95 | 18.19 | 9.00 | 9.42 |

| St. Dev. | ±1.92 | ±4.66 | ±3.41 | ±2.12 | ±2.25 | ±1.94 | ±1.13 | ±1.61 | |

| UTS (MPa) | Average | 1767.60 | 1775.78 | 1548.39 | 995.94 | 933.52 | 803.35 | 385.40 | 408.76 |

| St. Dev. | ±159.16 | ±209.98 | ±183.00 | ±104.73 | ±97.01 | ±74.01 | ±51.49 | ±78.27 | |

| E11 (GPa) | Average | 142.59 | 204.20 | 158.58 | 89.16 | 111.40 | 60.89 | 64.20 | 29.84 |

| St. Dev. | ±16.77 | ±50.26 | ±24.94 | ±35.04 | ±48.77 | ±25.03 | ±19.04 | ±19.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stankovic, D.; Bisby, L.A.; Terrasi, G.P. Influence of Temperature on the Mechanical Performance of Unidirectional Carbon Fiber Reinforced Polymer Straps. Materials 2021, 14, 1903. https://doi.org/10.3390/ma14081903

Stankovic D, Bisby LA, Terrasi GP. Influence of Temperature on the Mechanical Performance of Unidirectional Carbon Fiber Reinforced Polymer Straps. Materials. 2021; 14(8):1903. https://doi.org/10.3390/ma14081903

Chicago/Turabian StyleStankovic, Danijela, Luke A. Bisby, and Giovanni P. Terrasi. 2021. "Influence of Temperature on the Mechanical Performance of Unidirectional Carbon Fiber Reinforced Polymer Straps" Materials 14, no. 8: 1903. https://doi.org/10.3390/ma14081903

APA StyleStankovic, D., Bisby, L. A., & Terrasi, G. P. (2021). Influence of Temperature on the Mechanical Performance of Unidirectional Carbon Fiber Reinforced Polymer Straps. Materials, 14(8), 1903. https://doi.org/10.3390/ma14081903