Selective Laser Melting of Maraging Steel Using Synchronized Three-Spot Scanning Strategies

Abstract

1. Introduction

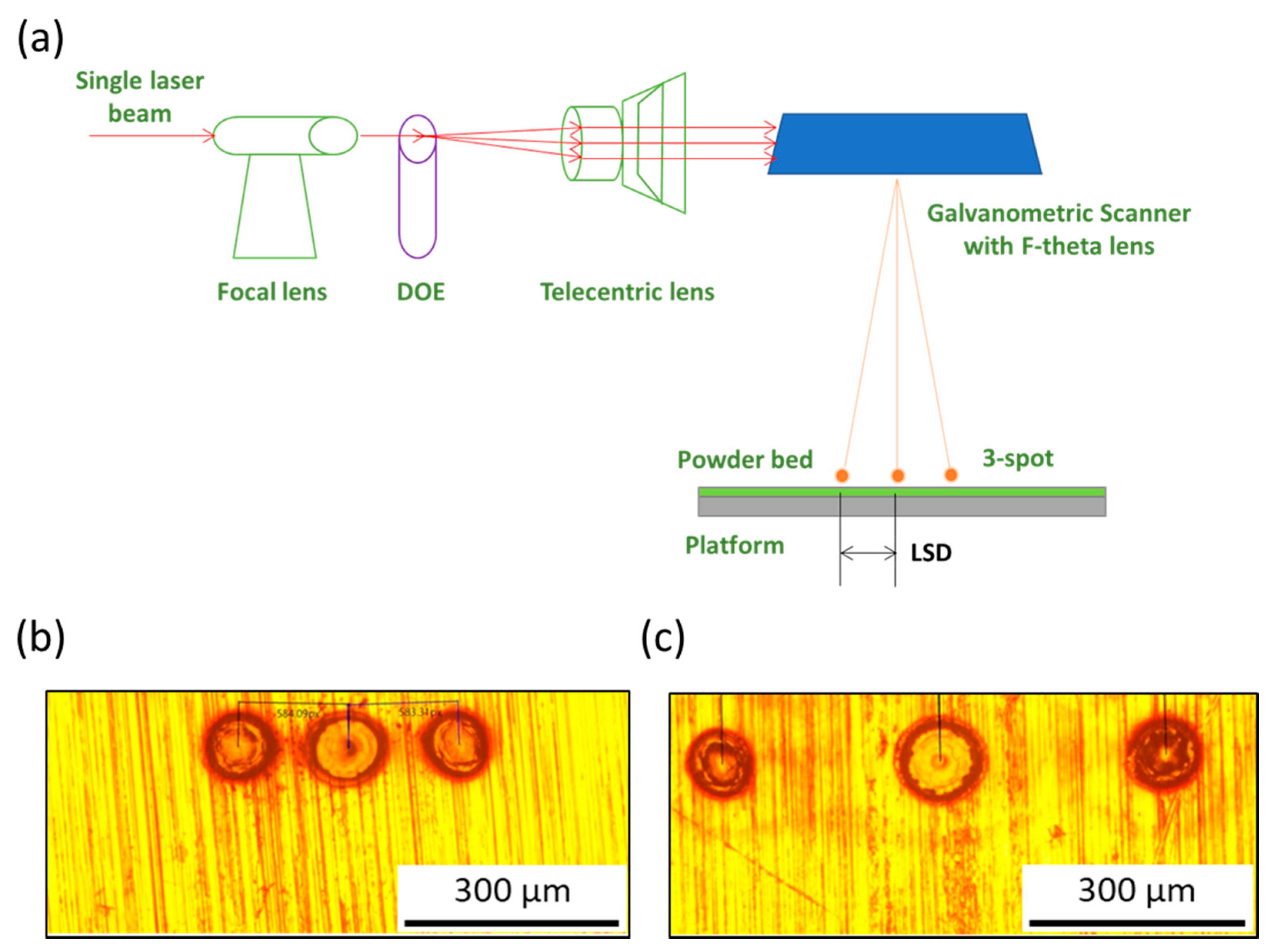

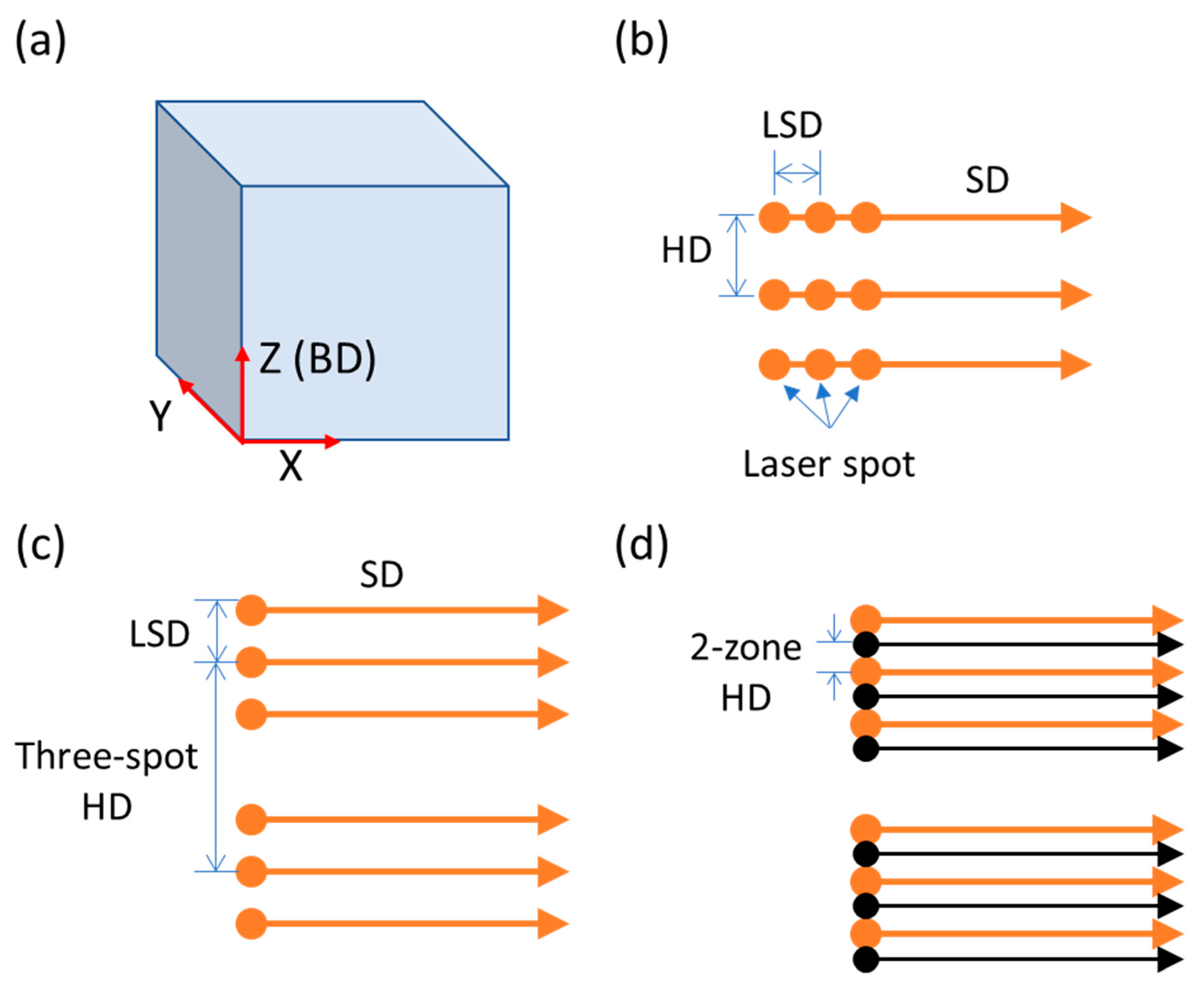

2. Experiment

3. Results and Discussion

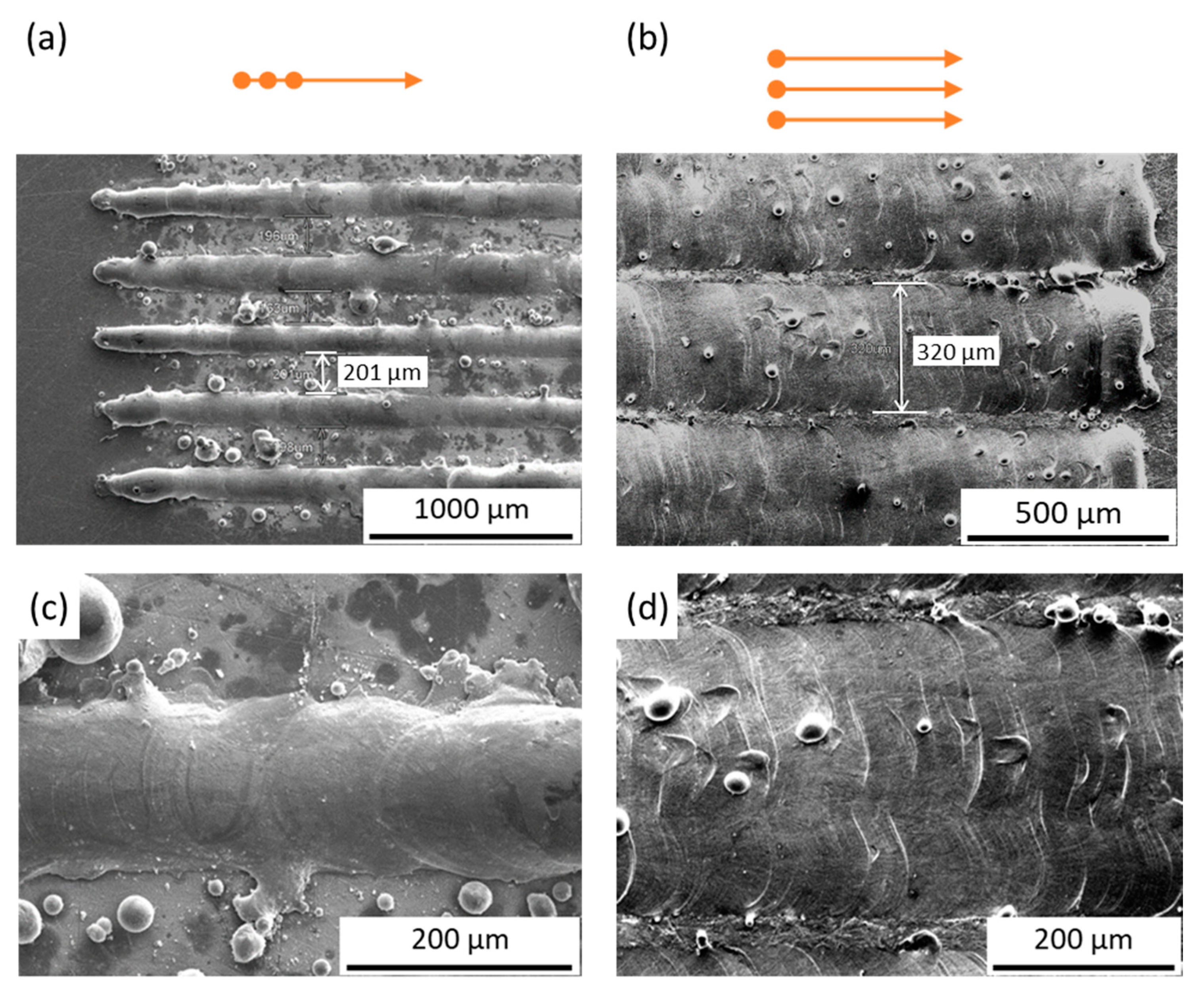

3.1. Single-Layer Process

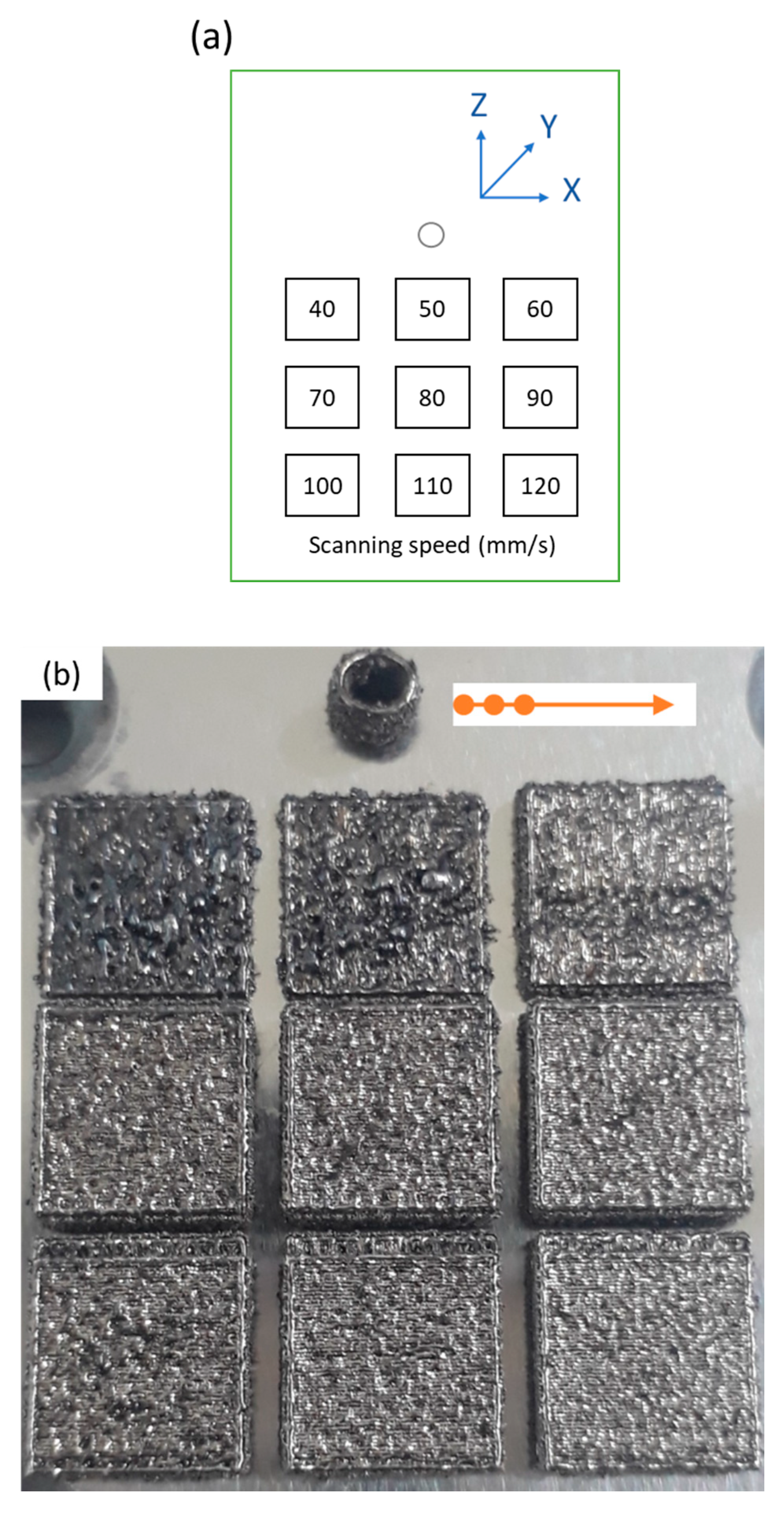

3.2. Cubic Parts

3.3. Microstructure Analysis

4. Conclusions

- The average surface roughness Ra produced by the two scanning methods is similar, i.e., around 8.3~9.3 µm, mainly because of the different re-melting effects: (1) SiL: the second and third laser spot followed by the first spot scanning path; (2) SL: the second path of the three-spot scanned in the same direction again using the offset from the first scanning path.

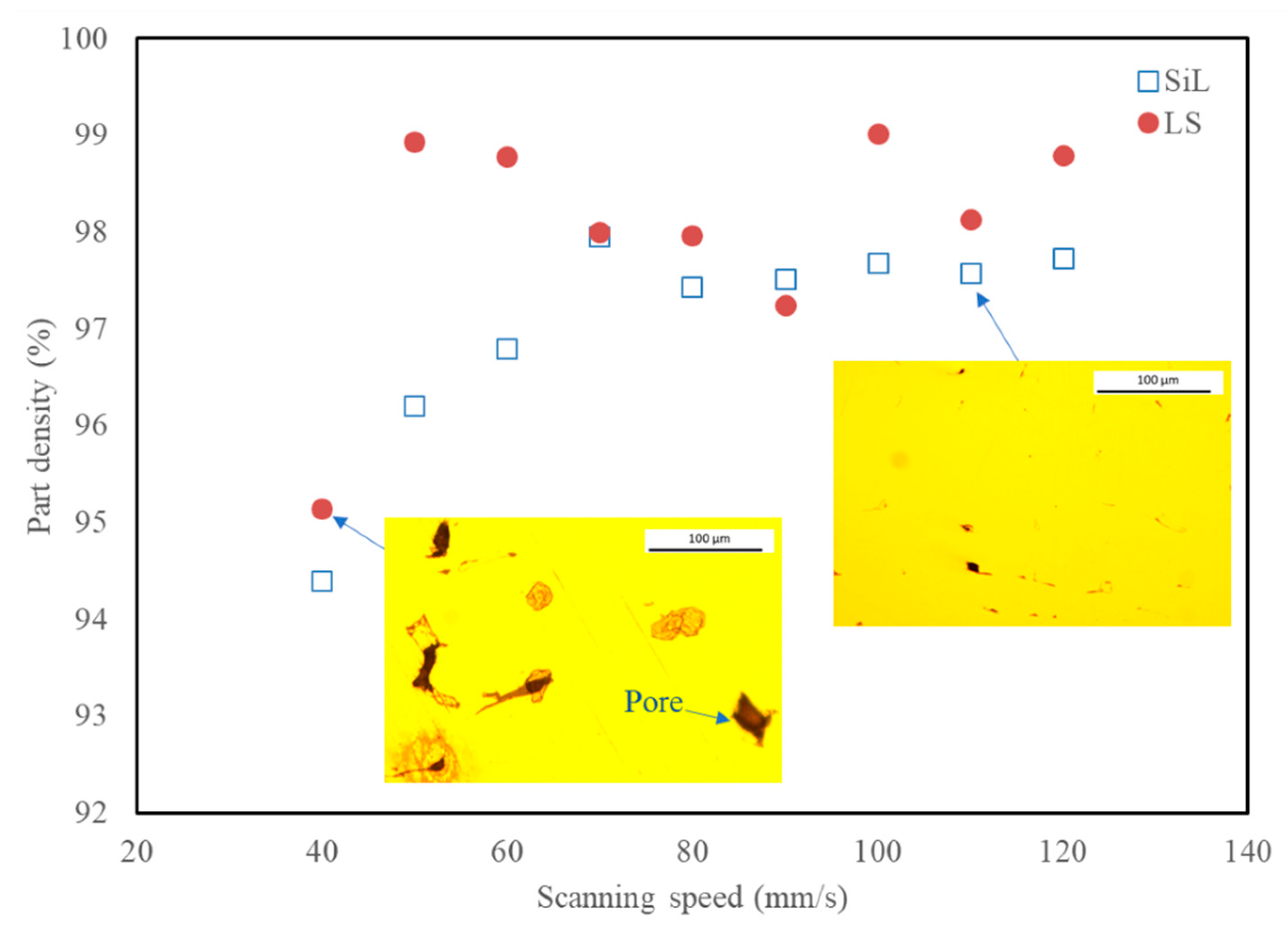

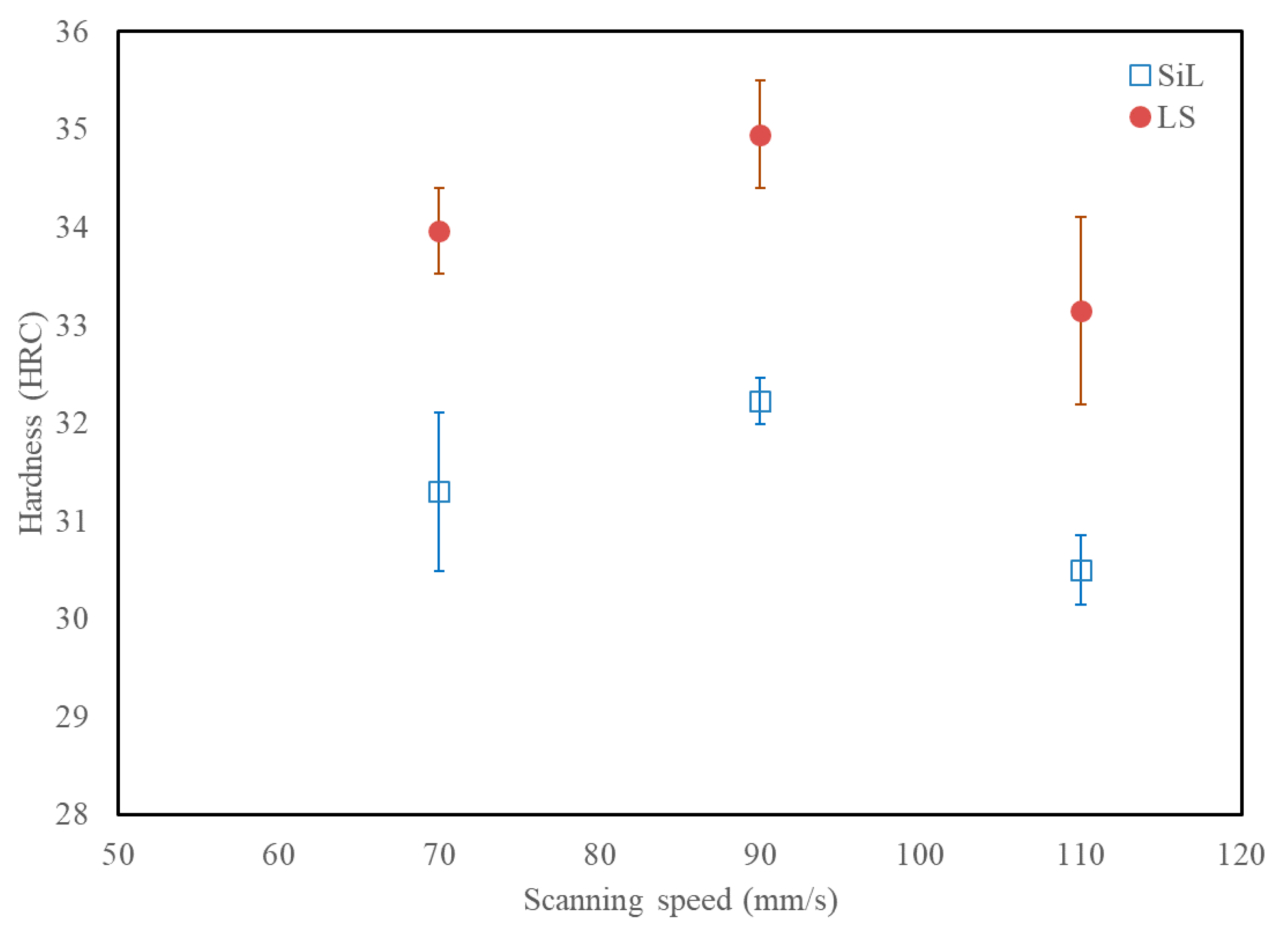

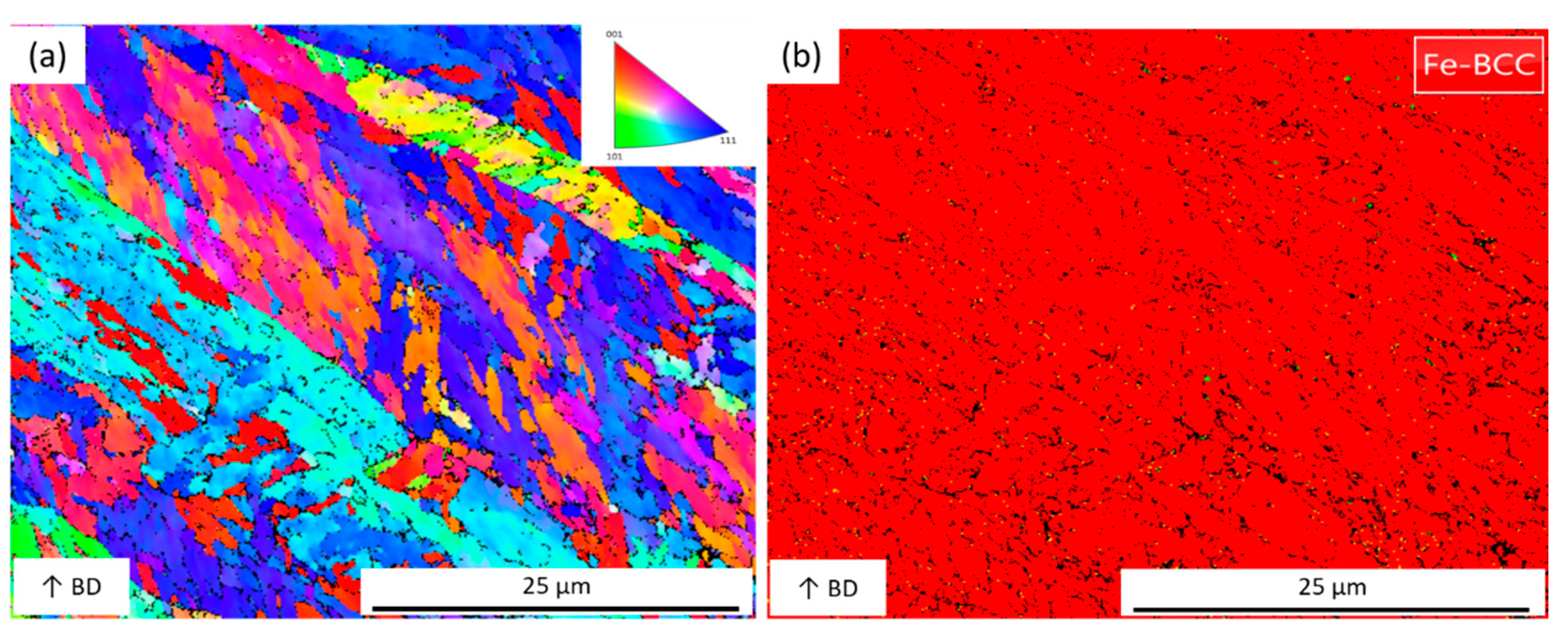

- The relative density and surface hardness produced by the LS scanning strategy is higher than the SiL because the SL can produce fewer pores and finer microstructures inside the specimen. The maximum relative density and average surface hardness by the LS scanning are about 99.02% and 34.0 HRC.

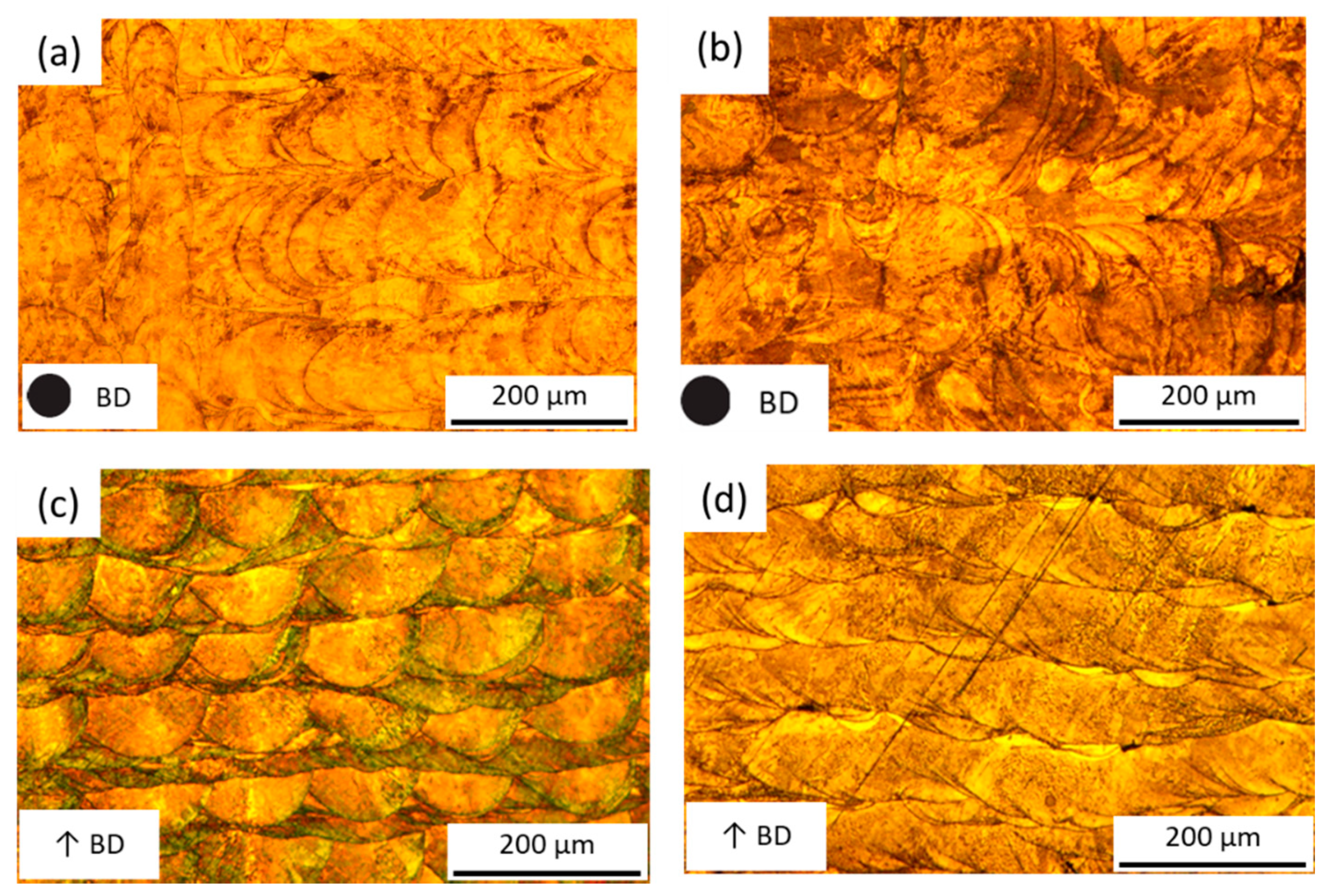

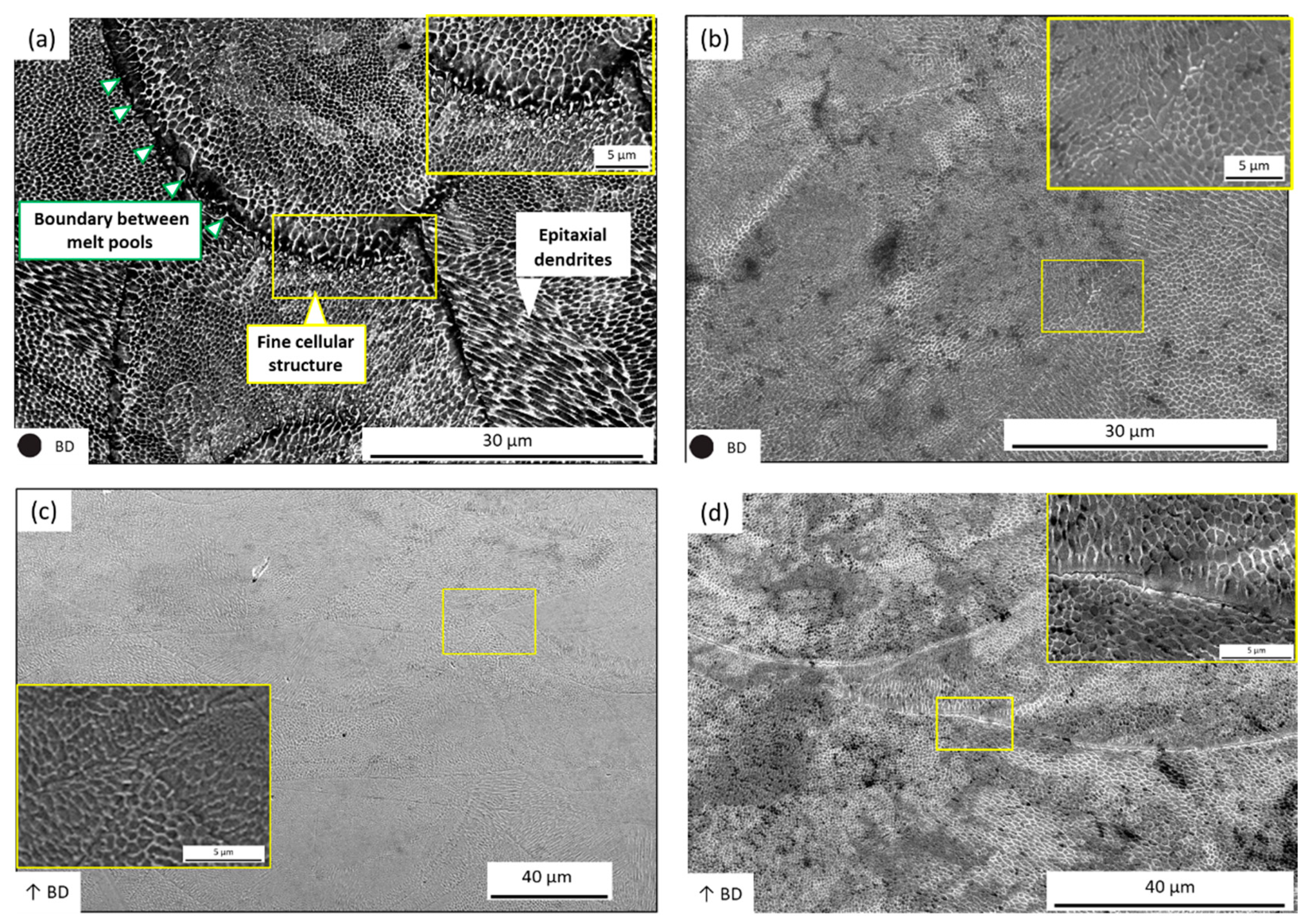

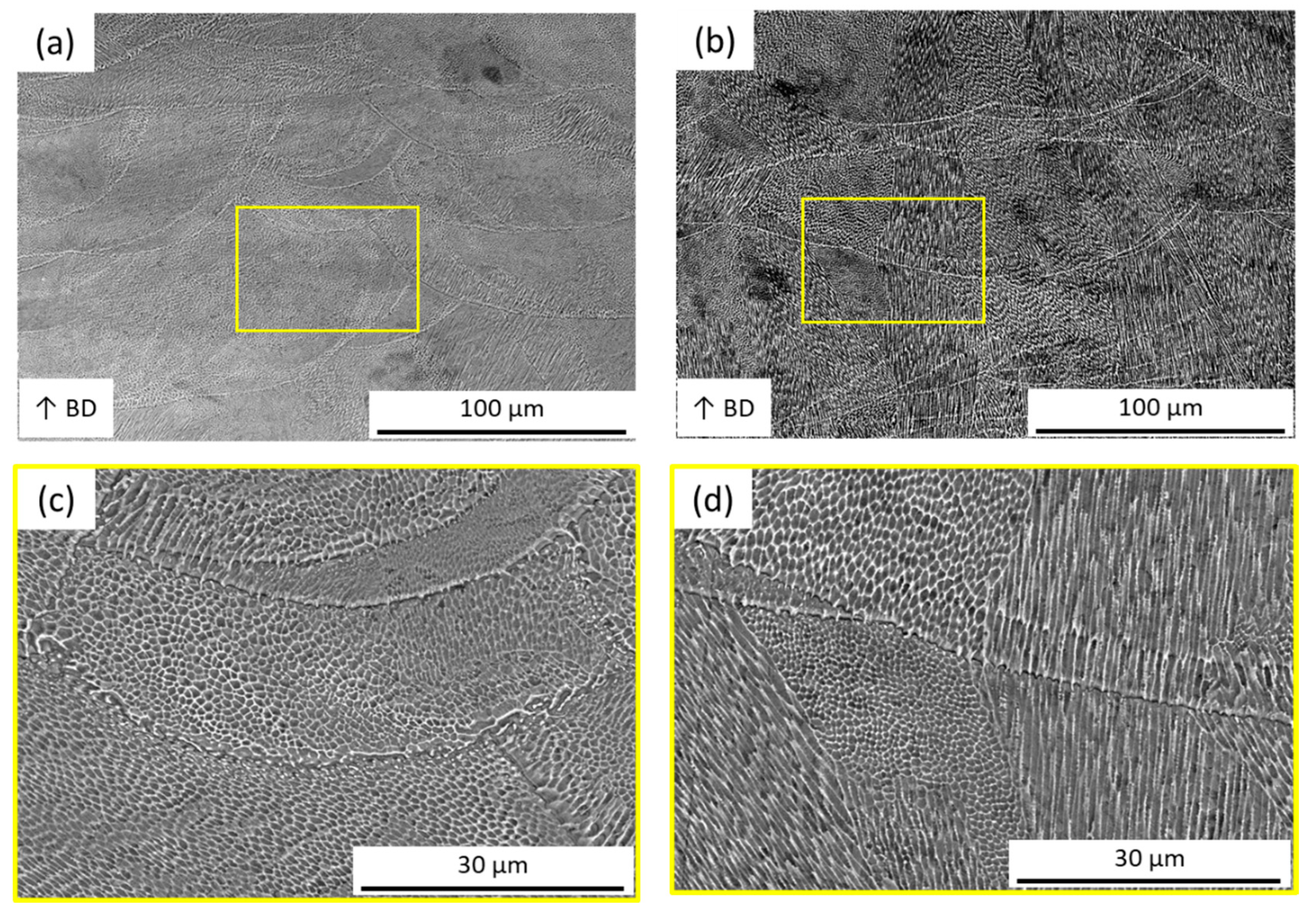

- The morphology of the molten pools generated by the two scanning methods is different, i.e., the molten pool of LS and SiL samples show long semi-elliptical and hemispherical shapes, respectively. The LS scanning strategy resulted in wide and flat molten pools with fine cellular and dendrites microstructures.

- At present, the split efficiency of the three spots after DOE is similar. In the future, the new DOE design can change the splitting efficiency. For example, the second point is the main beam, and the first and third spots are the pre- and post-heating beam (power is smaller than the main beam). It is expected that the microstructure characteristics by SiL scanning strategy can be further improved.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sing, S.L.; Yeong, W.Y. Laser powder bed fusion for metal additive manufacturing: Perspectives on recent developments. Virtual Phys. Prototyp. 2020, 15, 359–370. [Google Scholar] [CrossRef]

- Childs, T.; Hauser, C.; Badrossamay, M. Mapping and modelling single scan track formation in direct metal selective laser melting. J. CIRP Ann. 2004, 53, 191–194. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Gusarov, A.; Yadroitsava, I.; Smurov, I. Single track formation in selective laser melting of metal powders. J. Mater. Process. Technol. 2010, 210, 1624–1631. [Google Scholar] [CrossRef]

- Zaeh, M.F.; Branner, G. Investigations on residual stresses and deformations in selective laser melting. Prod. Eng. 2009, 4, 35–45. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Deckers, J.; Yasa, E.; Wauthle, R. Assessing and comparing influencing factors of residual stresses in selective laser melting using a novel analysis method. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 980–991. [Google Scholar] [CrossRef]

- Cheng, B.; Shrestha, S.; Chou, K. Stress and deformation evaluations of scanning strategy effect in selective laser melting. Addit. Manuf. 2016, 12, 240–251. [Google Scholar]

- Matsumoto, M.; Shiomi, M.; Osakada, K.; Abe, F. Finite element analysis of single layer forming on metallic powder bed in rapid prototyping by selective laser processing. Int. J. Mach. Tools Manuf. 2002, 42, 61–67. [Google Scholar] [CrossRef]

- Kruth, J.P.; Froyen, L.; van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Pruncu, C.I.; Hopper, C.; Hooper, P.A.; Tan, Z.; Zhu, H.; Lin, J.; Jiang, J. Study of the effects of hot forging on the additively manufactured stainless steel preforms. J. Manuf. Process. 2020, 57, 668–676. [Google Scholar] [CrossRef]

- Wilkes, J.; Hagedorn, Y.-C.; Meiners, W.; Wissenbach, K. Additive manufacturing of ZrO2-Al2O3 ceramic components by selective laser melting. Rapid Prototyp. J. 2013, 19. [Google Scholar] [CrossRef]

- Heeling, T.; Wegener, K. The effect of multi-beam strategies on selective laser melting of stainless steel 316L. Addit. Manuf. 2018, 22, 334–342. [Google Scholar] [CrossRef]

- Tsai, C.-Y.; Cheng, C.-W.; Lee, A.-C.; Tsai, M.-C. Synchronized multi-spot scanning strategies for the laser powder bed fusion process. Addit. Manuf. 2019, 27, 1–7. [Google Scholar] [CrossRef]

- Zhang, W.; Hou, W.; Deike, L.; Arnold, C.B. Using a dual-laser system to create periodic coalescence in laser powder bed fusion. Acta Mater. 2020, 201, 14–22. [Google Scholar] [CrossRef]

- Cheng, C.-W.; Liou, Y.-W.; Lee, A.-C.; Tsai, M.-C. Single track of selective laser melting process: Modeling and experimental comparison. J. Laser Micro Nanoeng. 2019, 14, 138–141. [Google Scholar]

- Takata, N.; Nishida, R.; Suzki, A.; Kobashi, M.; Kato, M. Crystallographic features of microstructure in maraging steel fabricated by selective laser melting. Metals 2018, 8, 440. [Google Scholar] [CrossRef]

- Montero-Sistiaga, M.; Pourbabak, S.; Humbeeck, J.; Schryvers, D.; Vanmeensel, K. Microstructure and mechanical properties of Hastelloy X produced by HP-SLM (high power selective laser melting). Mater. Des. 2019, 165, 107598. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, C.-W.; Jhang Jian, W.-Y.; Makala, B.P.R. Selective Laser Melting of Maraging Steel Using Synchronized Three-Spot Scanning Strategies. Materials 2021, 14, 1905. https://doi.org/10.3390/ma14081905

Cheng C-W, Jhang Jian W-Y, Makala BPR. Selective Laser Melting of Maraging Steel Using Synchronized Three-Spot Scanning Strategies. Materials. 2021; 14(8):1905. https://doi.org/10.3390/ma14081905

Chicago/Turabian StyleCheng, Chung-Wei, Wei-You Jhang Jian, and Bhargav Prasad Reddy Makala. 2021. "Selective Laser Melting of Maraging Steel Using Synchronized Three-Spot Scanning Strategies" Materials 14, no. 8: 1905. https://doi.org/10.3390/ma14081905

APA StyleCheng, C.-W., Jhang Jian, W.-Y., & Makala, B. P. R. (2021). Selective Laser Melting of Maraging Steel Using Synchronized Three-Spot Scanning Strategies. Materials, 14(8), 1905. https://doi.org/10.3390/ma14081905