Evaluating Energy Generation Capacity of PVDF Sensors: Effects of Sensor Geometry and Loading

Abstract

1. Introduction

2. Related Works

3. Materials and Method

3.1. Piezoelectric Sensor Design and Construction

3.2. Sensor Geometry

3.3. Applied Loading and Frequency

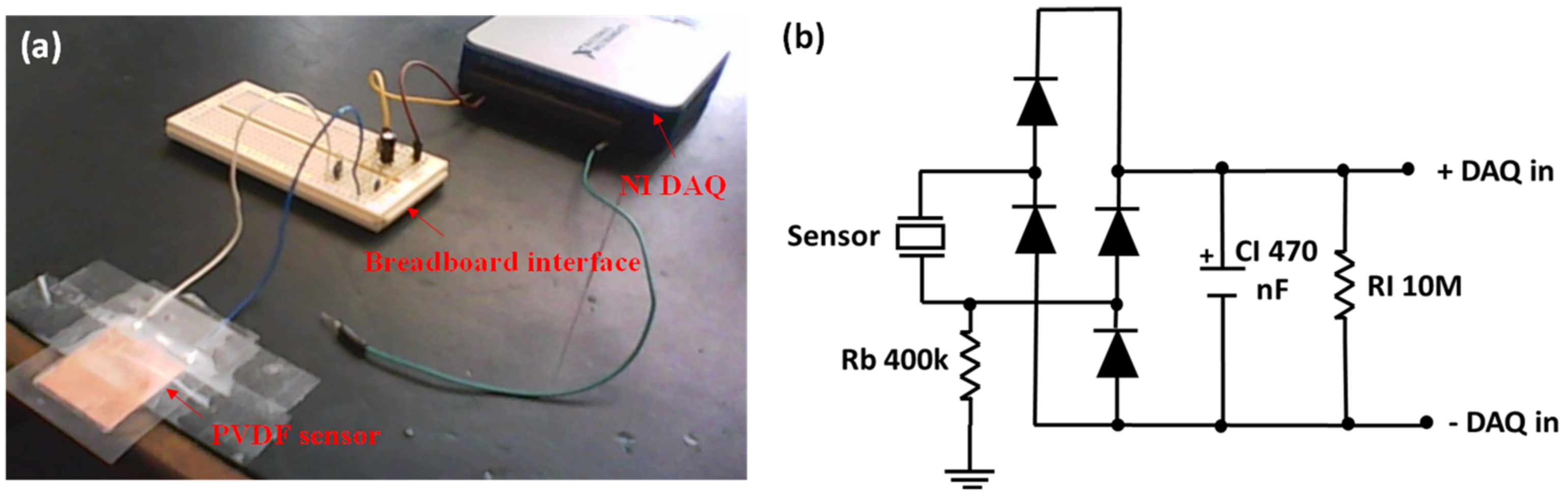

3.4. Experiments and Energy Harvesting Circuits

4. Results and Discussion

4.1. Capacitance

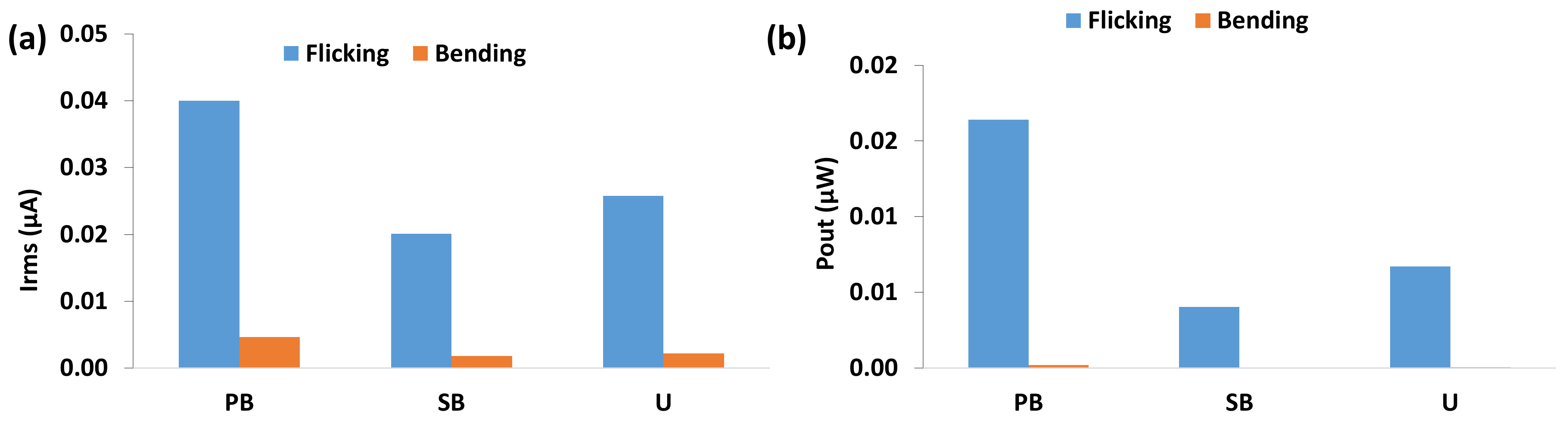

4.2. Effect of Sensor Type

4.3. Effect of PVDF Thickness

4.4. Effect of Aspect Ratio

4.5. Effect of Surface Area

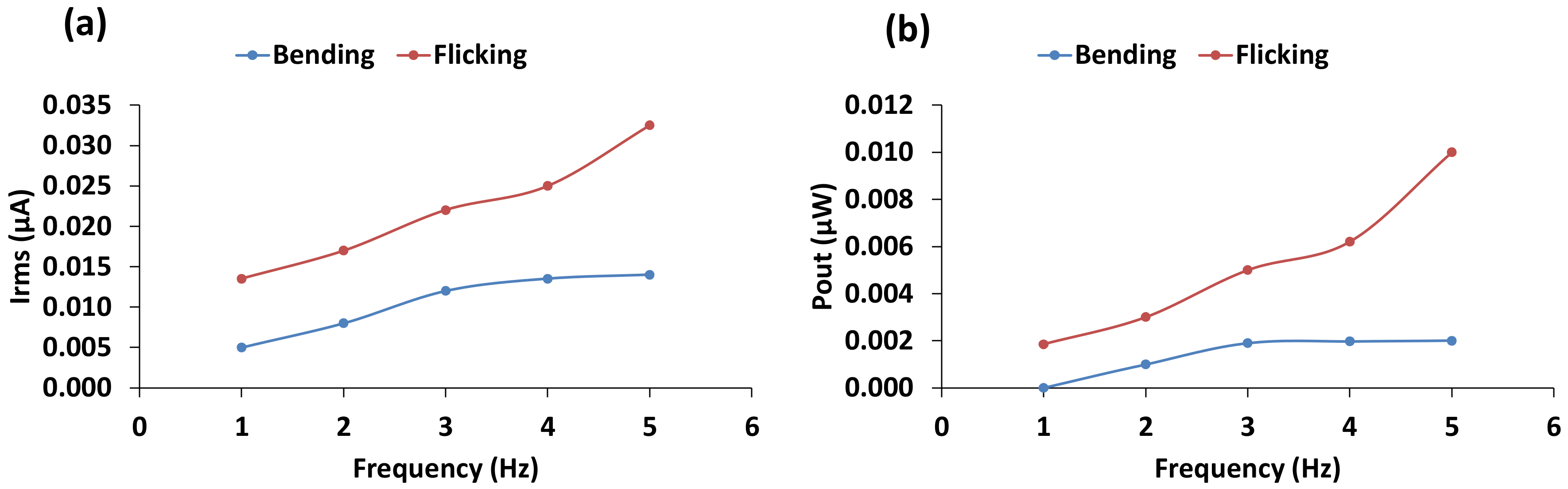

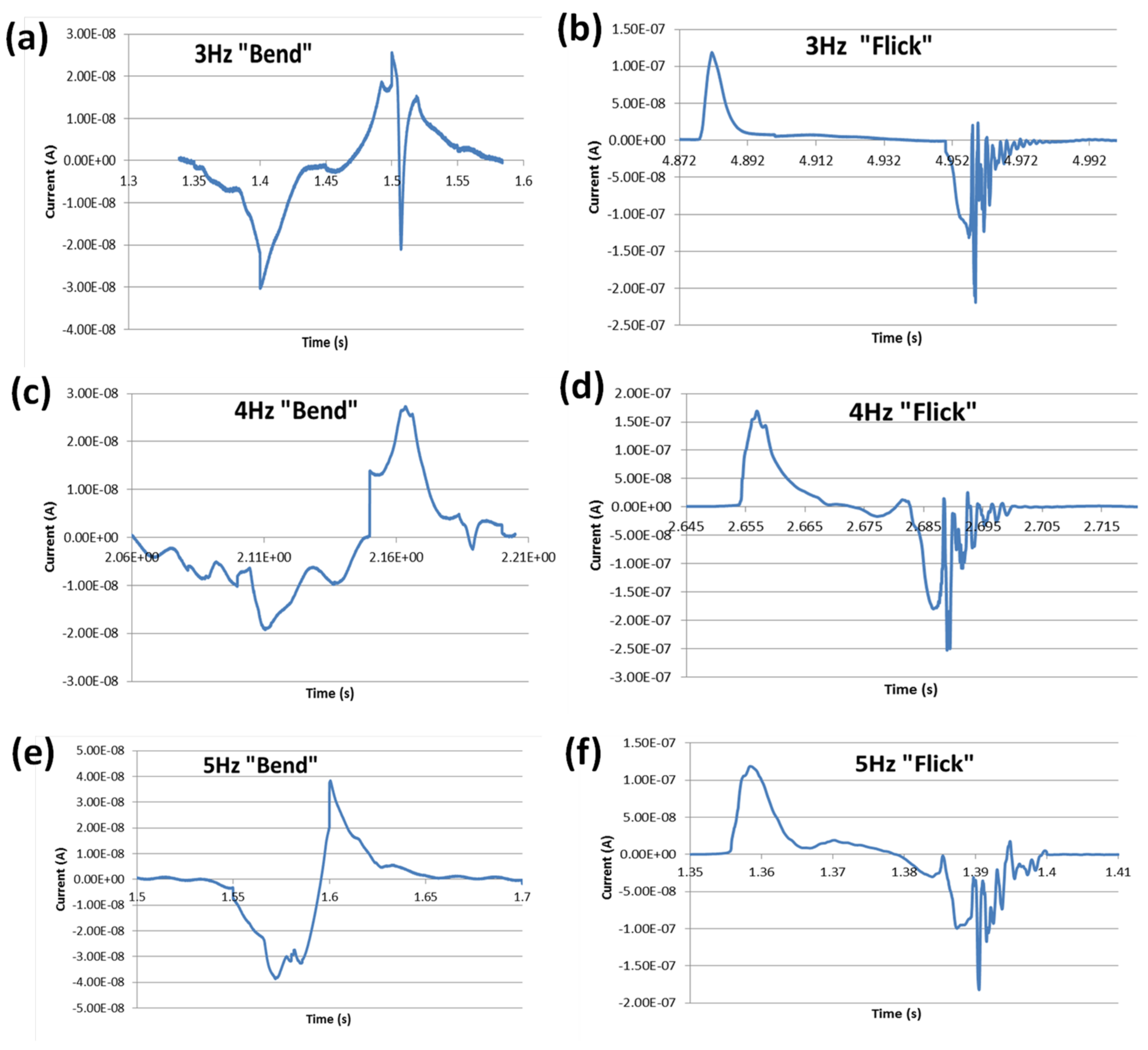

4.6. Effect of Loading Frequency

4.7. Effect of Mechanical Strain

4.8. Analysis of Energy Harvesting Circuit Efficiency

5. Conclusions and Outlook

- Among the three sensor configurations, parallel bimorph sensor was shown to be the best energy harvester in that it generated the highest amount of electrical power. Practically measured capacitance values for PVDF sensors with large thicknesses were found to be close to the theoretical values [23].

- Given the range of PVDF thickness studied, power output seems to decrease with increasing PVDF thickness. Such trend could be because the stiffness of the PVDF dielectric might have dominated power generation, and the sensor thickness passed the optimum value after which the power output decreased.

- Power output increased consistently with the increase of sensor surface area. Flicking movement showed greater power output than bending for all surface areas as well as far greater increase in power output with surface area. As for the effect of geometry, power output increased initially with increasing aspect ratio, reaching the maximum value at an aspect ratio of around 2:1, and then decreasing for higher aspect ratios.

- Mean current and power output showed a significant increase with the increase in loading frequency for flicking. However, for bending, modest increases were noticed initially (3 Hz and 4 Hz) with the output dropping for higher frequency (5 Hz).

- Power output also followed an increasing trend with the increase of mechanical strain up to a certain value of strain. In addition, an increase in loading frequency resulted in an increase in power generation, however, it did not increase linearly as “wave-cutting” decreased the potential for charge generation at higher frequencies.

- A simple energy harvesting circuit was found to successfully convert the AC signal generated by the sensor into DC signal, but at the cost of a significant loss in power output.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chiu, Y.-Y.; Lin, W.-Y.; Wang, H.-Y.; Huang, S.-B.; Wu, M.-H. Development of a piezoelectric polyvinylidene fluoride (PVDF) polymer-based sensor patch for simultaneous heartbeat and respiration monitoring. Sens. Actuators A 2013, 189, 328–334. [Google Scholar] [CrossRef]

- Hackworth, R.; Moreira, J.R.; Maxwell, R.; Kotha, R.; Ayon, A. Piezoelectric charging for smart fabric applications. In Proceedings of the Symposium on Design, Test, Integration and Packaging of MEMS/MOEMS (DTIP), Aix-en-Provence, France, 11–13 May 2011. [Google Scholar]

- Caliò, R.; Rongala, U.B.; Camboni, D.; Milazzo, M.; Stefanini, C.; de Petris, G.; Oddo, C.M. Piezoelectric energy harvesting solutions. Sensors 2014, 14, 4755–4790. [Google Scholar] [CrossRef] [PubMed]

- Pallapa, M.; Aly Saad Aly, M.; Aly, S.; Chen, A.; Wong, L.; Wong, K.W.; Abdel-Rahman, E.; Tze, J.; Yeow, W. Modeling and simulation of a piezoelectric micro-power generator. In Proceedings of the COMSOL Conference, Boston, MA, USA, 7 October 2010. [Google Scholar]

- Ottman, G.K.; Hofmann, H.F.; Bhatt, A.C.; Lesieutre, G.A. Adaptive piezoelectric energy harvesting circuit for wireless remote power supply. IEEE Trans. Power Electron. 2002, 17, 669–676. [Google Scholar] [CrossRef]

- Starner, T. Human-powered wearable computing. IBM Syst. J. 1996, 35, 618–629. [Google Scholar] [CrossRef]

- Won, S.S.; Seo, H.; Kawahara, M.; Glinsek, S.; Lee, J.; Kim, Y.; Jeong, C.K.; Kingon, A.I.; Kim, S.-H. Flexible vibrational energy harvesting devices using strain-engineered perovskite piezoelectric thin films. Nano Energy 2019, 55, 182–192. [Google Scholar] [CrossRef]

- Yeo, H.G.; Jung, J.; Sim, M.; Jang, J.E.; Choi, H. Integrated piezoelectric AlN thin film with SU-8/PDMS supporting layer for flexible sensor array. Sensors 2020, 20, 315. [Google Scholar] [CrossRef] [PubMed]

- Song, H.J.; Choi, Y.-T.; Wereley, N.M.; Purekar, A. Comparison of monolithic and composite piezoelectric material-based energy harvesting devices. J. Intell. Mater. Syst. Struct. 2014, 25, 1825–1837. [Google Scholar] [CrossRef]

- Jones, G.; Assink, R.; Dargaville, T.; Chaplya, P.; Clough, R.; Elliott, J.; Martin, J.; Mowery, D.; Celina, M. Characterization, Performance and Optimization of PVDF as a Piezoelectric Film for Advanced Space Mirror Concepts; Technical Report No. 876343; Sandia National Laboratories: Livermore, CA, USA, 2005.

- Paradiso, J.A.; Starner, T. Energy scavenging for mobile and wireless electronics. IEEE Pervasive Comput. 2005, 4, 18–27. [Google Scholar] [CrossRef]

- Ng, T.; Liao, W.-H. Sensitivity analysis and energy harvesting for a self-powered piezoelectric sensor. J. Intell. Mater. Syst. Struct. 2005, 16, 785–797. [Google Scholar] [CrossRef]

- Ozeri, S.; Shmilovitz, D. Static force measurement by piezoelectric sensors. In Proceedings of the IEEE International Symposium on Circuits and Systems, Island of Kos, Greece, 21–24 May 2006. [Google Scholar]

- Guizzetti, M.; Ferrari, V.; Marioli, D.; Zawada, T. Thickness optimization of a piezoelectric converter for energy harvesting. In Proceedings of the COMSOL Conference, Boston, MA, USA, 8–10 October 2009. [Google Scholar]

- Granstrom, J.; Feenstra, J.; Sodano, H.A.; Farinholt, K. Energy harvesting from a backpack instrumented with piezoelectric shoulder straps. Smart Mater. Struct. 2007, 16, 1810–1820. [Google Scholar] [CrossRef]

- Waqar, S.; McCarthy, J.M.; Deivasigamani, A.; Wang, C.H.; Wang, L.; Coman, F.; John, S. Dual field finite element simulations of piezo-patches on fabrics: A parametric study. In Proceedings of the 4th International Conference on Smart Materials and Nanotechnology in Engineering, Gold Coast, Australia, 10–12 July 2013; p. 87931K. [Google Scholar]

- Kasyap, V.S.A.; Lim, J.; Ngo, K.; Kurdila, A.; Nishida, T.; Sheplak, M.; Cattafesta, L. Energy Reclamation from a Vibrating Piezoceramic Composite Beam. Available online: https://www.img.ufl.edu/publication/1604/energy-reclamation-vibrating-piezoceramic-composite-beam (accessed on 26 May 2020).

- Arnau, A.; Soares, D. Fundamentals of piezoelectricity. In Piezoelectric Transducers and Applications; Vives, A.A., Ed.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 1–38. ISBN 978-3-540-77508-9. [Google Scholar]

- Kashiwao, T.; Izadgoshasb, I.; Lim, Y.Y.; Deguchi, M. Optimization of rectifier circuits for a vibration energy harvesting system using a macro-fiber composite piezoelectric element. Microelectron. J. 2016, 54, 109–115. [Google Scholar] [CrossRef]

- Songsukthawan, P.; Jettanasen, C. Generation and storage of electrical energy from piezoelectric materials. In Proceedings of the IEEE 3rd International Future Energy Electronics Conference and ECCE Asia (IFEEC 2017-ECCE Asia), Kaohsiung, Taiwan, 3–7 June 2017; pp. 2256–2259. [Google Scholar]

- Chen, D.; Chen, K.; Brown, K.; Hang, A.; Zhang, J.X.J. Liquid-phase tuning of porous PVDF-TrFE film on flexible substrate for energy harvesting. Appl. Phys. Lett. 2017, 110, 153902. [Google Scholar] [CrossRef]

- Elahi, H.; Israr, A.; Swati, R.; Khan, H.; Tamoor, A. Stability of piezoelectric material for suspension applications. In Proceedings of the 5th International Conference on Aerospace Science and Engineering, Islamabad, Pakistan, 14–16 November 2017. [Google Scholar]

- Park, S.; Kim, Y.; Jung, H.; Park, J.-Y.; Lee, N.; Seo, Y. Energy harvesting efficiency of piezoelectric polymer film with graphene and metal electrodes. Sci. Rep. 2017, 7, 17290. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.; Worthington, E.; Njuguna, J. Analyses of power output of piezoelectric energy-harvesting devices directly connected to a load resistor using a coupled piezoelectric-circuit finite element method. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2009, 56, 1309–1317. [Google Scholar] [CrossRef] [PubMed]

- Erturk, A.; Inman, D.J. Piezoelectric Energy Harvesting: Erturk/Piezoelectric Energy Harvesting; John Wiley and Sons, Ltd.: Chichester, UK, 2011; ISBN 978-1-119-99115-1. [Google Scholar]

- Bernard, F.; Gimeno, L.; Viala, B.; Cugat, O. The effect of temperature and strain on power conversion efficiency of PVDF-based thermal energy harvesters. Proceedings 2017, 1, 576. [Google Scholar] [CrossRef]

| Sensor Type | Thickness, t (mm) | Aspect Ratio, L/W | Surface Area, A (mm2) |

|---|---|---|---|

| PB | 0.0254 | 1 | 100 |

| PB | 0.0254 | 1 | 400 |

| PB | 0.0254 | 1 | 625 |

| PB | 0.0254 | 25:12 | 300 |

| PB | 0.0254 | 4:3 | 300 |

| PB | 0.0254 | 3 | 300 |

| PB | 0.254 | 1 | 225 |

| PB | 0.508 | 1 | 225 |

| PB | 0.0254 | 1 | 225 |

| U | 0.0254 | 1 | 225 |

| SB | 0.0254 | 1 | 225 |

| Sensor Type | Thickness t (mm) | Aspect Ratio L/W | Surface Area, A (mm2) | Calculated Capacitance (nF) | Measured Capacitance (nF) | Measured Capacitance per Unit Area (pF/mm2) |

|---|---|---|---|---|---|---|

| PB | 0.0254 | 1:1 | 100 | 0.6 | 0.06 | 0.6 |

| PB | 0.0254 | 1:1 | 225 | 1.4 | 0.1 | 0.44 |

| PB | 0.0254 | 1:1 | 400 | 2.5 | 0.3 | 0.75 |

| PB | 0.0254 | 1:1 | 625 | 3.9 | 0.34 | 0.54 |

| PB | 0.0254 | 25:12 | 300 | 1.9 | 0.25 | 0.83 |

| PB | 0.0254 | 4:3 | 300 | 1.9 | 0.34 | 1.13 |

| PB | 0.0254 | 3:1 | 300 | 1.9 | 0.23 | 0.77 |

| PB | 0.254 | 1:1 | 225 | 0.14 | 0.12 | 0.53 |

| PB | 0.508 | 1:1 | 225 | 0.071 | 0.09 | 0.4 |

| U | 0.0254 | 1:1 | 225 | 0.71 | 0.16 | 0.71 |

| SB | 0.0254 | 1:1 | 225 | 0.36 | 0.1 | 0.44 |

| Loading Frequency (Hz) | Time Constant (τ) | |

|---|---|---|

| Bending | Flicking | |

| 3 | 0.0157866 | 0.00376225 |

| 4 | 0.01664428 | 0.0044029 |

| 5 | 0.00989307 | 0.00300784 |

| Strain | Rectifier | Capacitor (nF) | * Ipp (nA) | Irms or $ Idc (nA) | Pout (nW) | Charging Time (s) |

|---|---|---|---|---|---|---|

| 0.0123 | No | - | 135 | 34.0 | 11.0 | - |

| 0.0216 | No | - | 294 | 49.4 | 24.5 | - |

| 0.0123 | FW | - | 116 | 35.6 | 12.8 | - |

| 0.0216 | FW | - | 140 | 47.6 | 22.7 | - |

| 0.0123 | FW | 470 | 2.88 | 26.5 | 7.01 | 9.92 |

| 0.0216 | FW | 470 | 4.64 | 34.7 | 12.0 | 7.34 |

| 0.0123 | FW | 1000 | 1.42 | 20.3 | 4.12 | 13.91 |

| 0.0216 | FW | 1000 | 1.93 | 33.3 | 11.1 | 11.42 |

| Vpeak | Vrms | Grounding | Sensor |

|---|---|---|---|

| 2.37 mV | 2.16 mV | Through Body | Yes |

| 75.8 mV | 53.1 mV | Direct | Yes |

| 3.66 mV | 3.01 mV | Ungrounded | Yes |

| 4.94 mV | 4.12 mV | Through Body | No |

| 88.7 mV | 61.3 mV | Direct | No |

| 10.1 mV | 6.96 mV | Ungrounded | No |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uddin, M.; Alford, S.; Aziz, S.M. Evaluating Energy Generation Capacity of PVDF Sensors: Effects of Sensor Geometry and Loading. Materials 2021, 14, 1895. https://doi.org/10.3390/ma14081895

Uddin M, Alford S, Aziz SM. Evaluating Energy Generation Capacity of PVDF Sensors: Effects of Sensor Geometry and Loading. Materials. 2021; 14(8):1895. https://doi.org/10.3390/ma14081895

Chicago/Turabian StyleUddin, Mohammad, Shane Alford, and Syed Mahfuzul Aziz. 2021. "Evaluating Energy Generation Capacity of PVDF Sensors: Effects of Sensor Geometry and Loading" Materials 14, no. 8: 1895. https://doi.org/10.3390/ma14081895

APA StyleUddin, M., Alford, S., & Aziz, S. M. (2021). Evaluating Energy Generation Capacity of PVDF Sensors: Effects of Sensor Geometry and Loading. Materials, 14(8), 1895. https://doi.org/10.3390/ma14081895