Analytical Modelling of Temperature Distribution in SLM Process with Consideration of Scan Strategy Difference between Layers

Abstract

1. Introduction

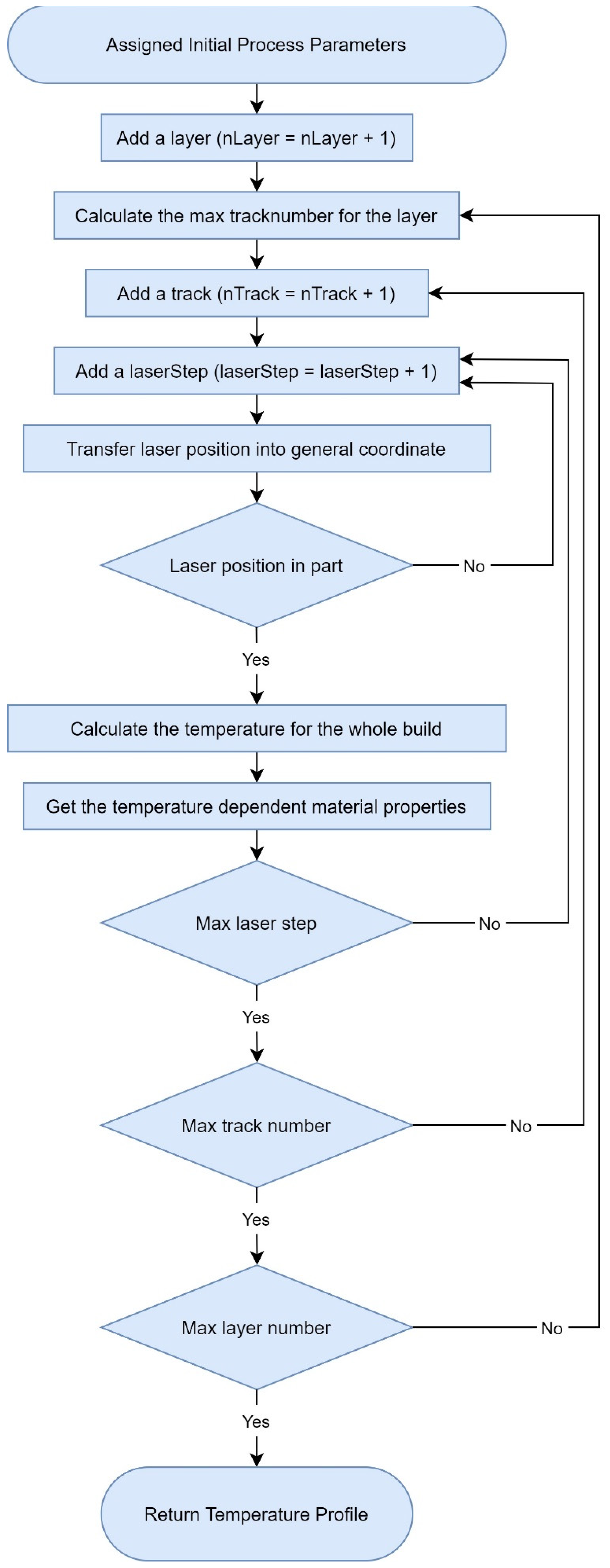

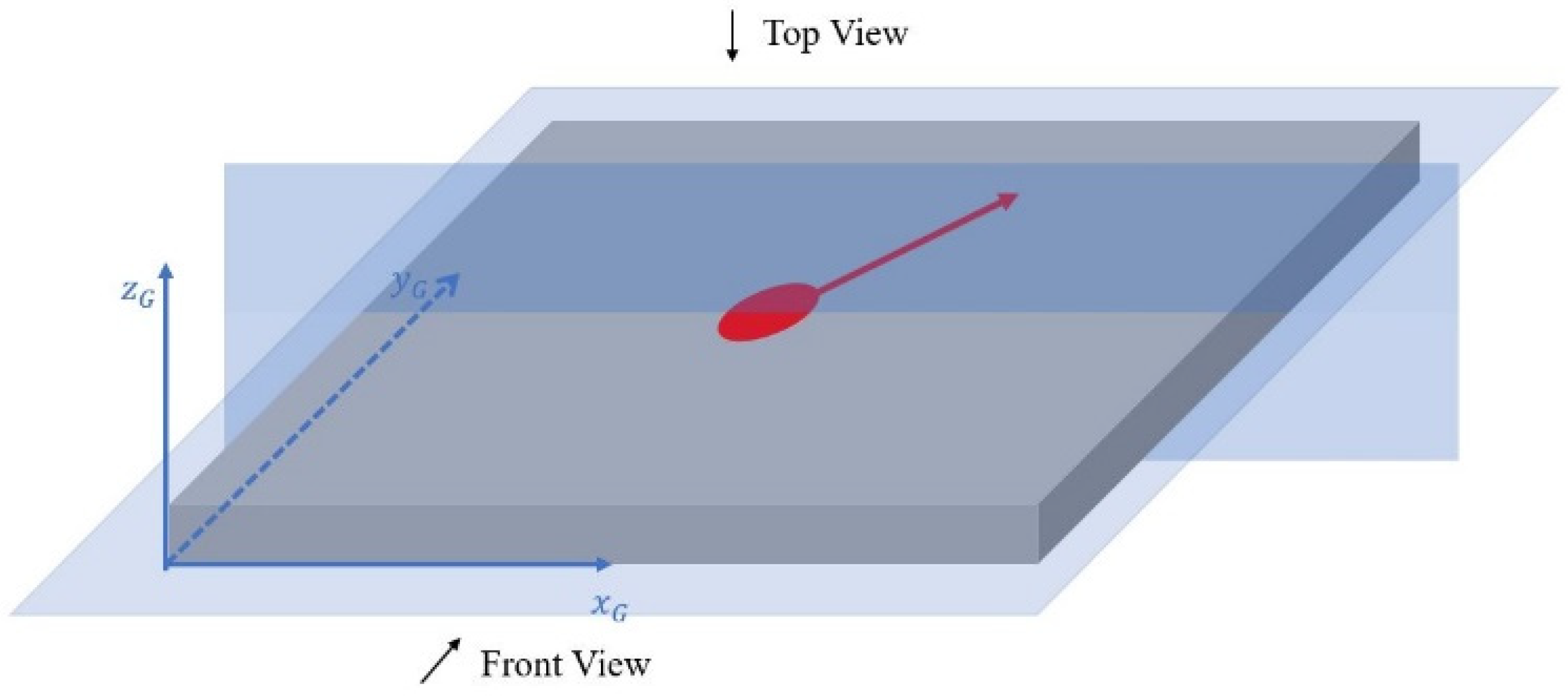

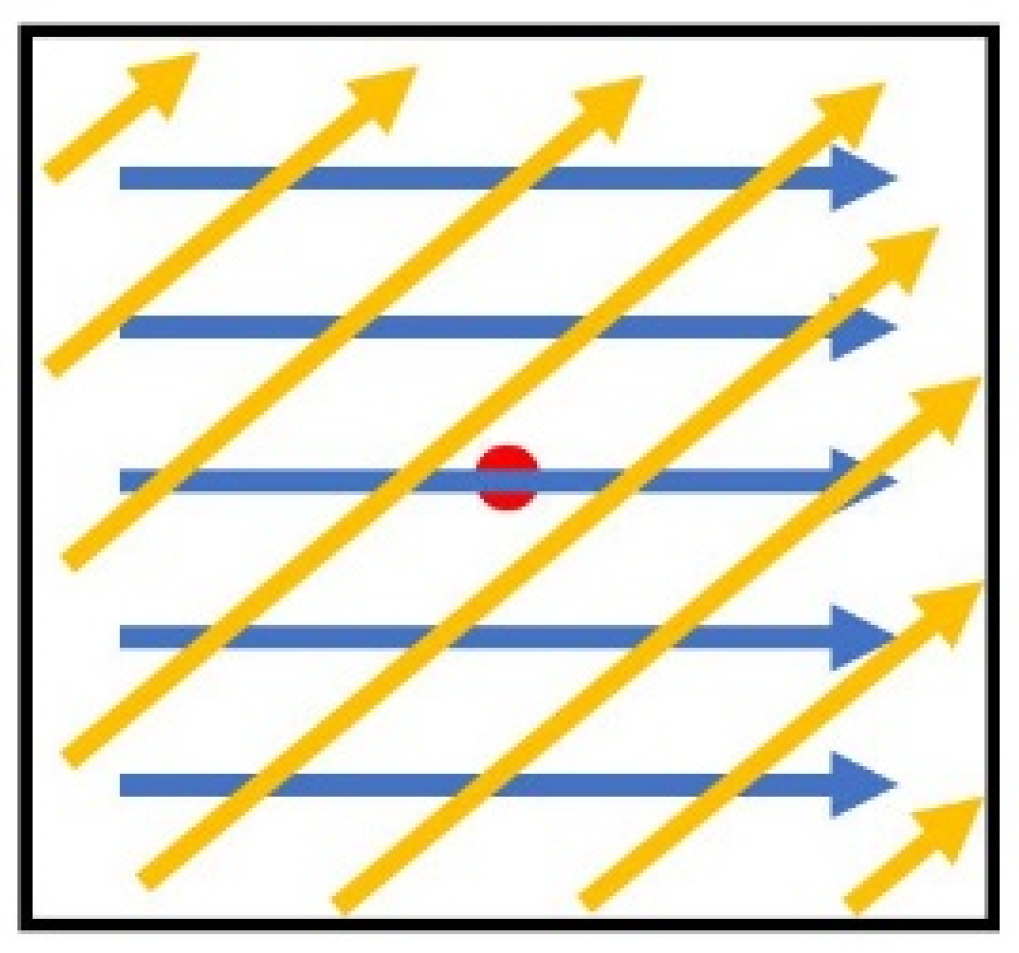

2. Methods

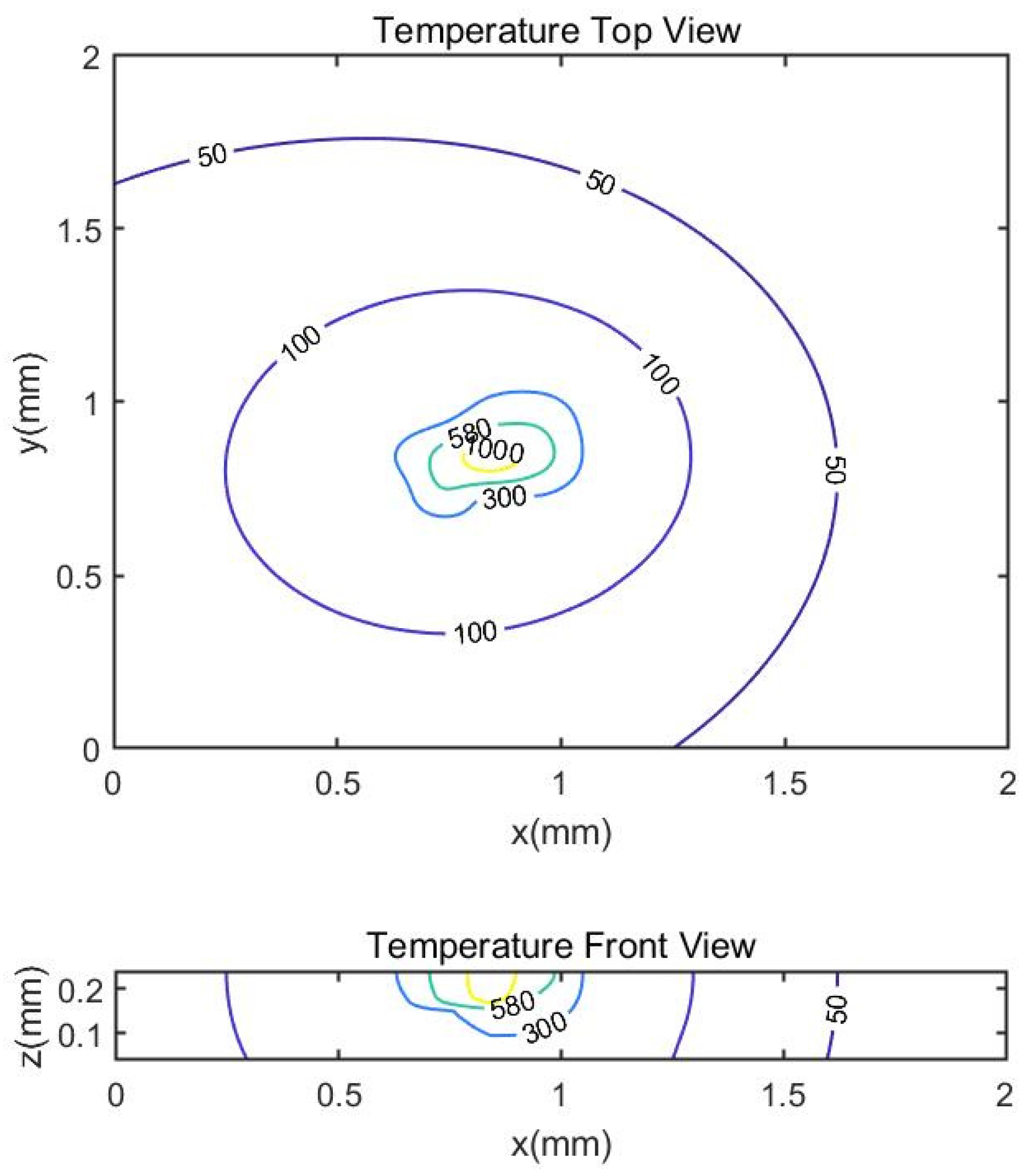

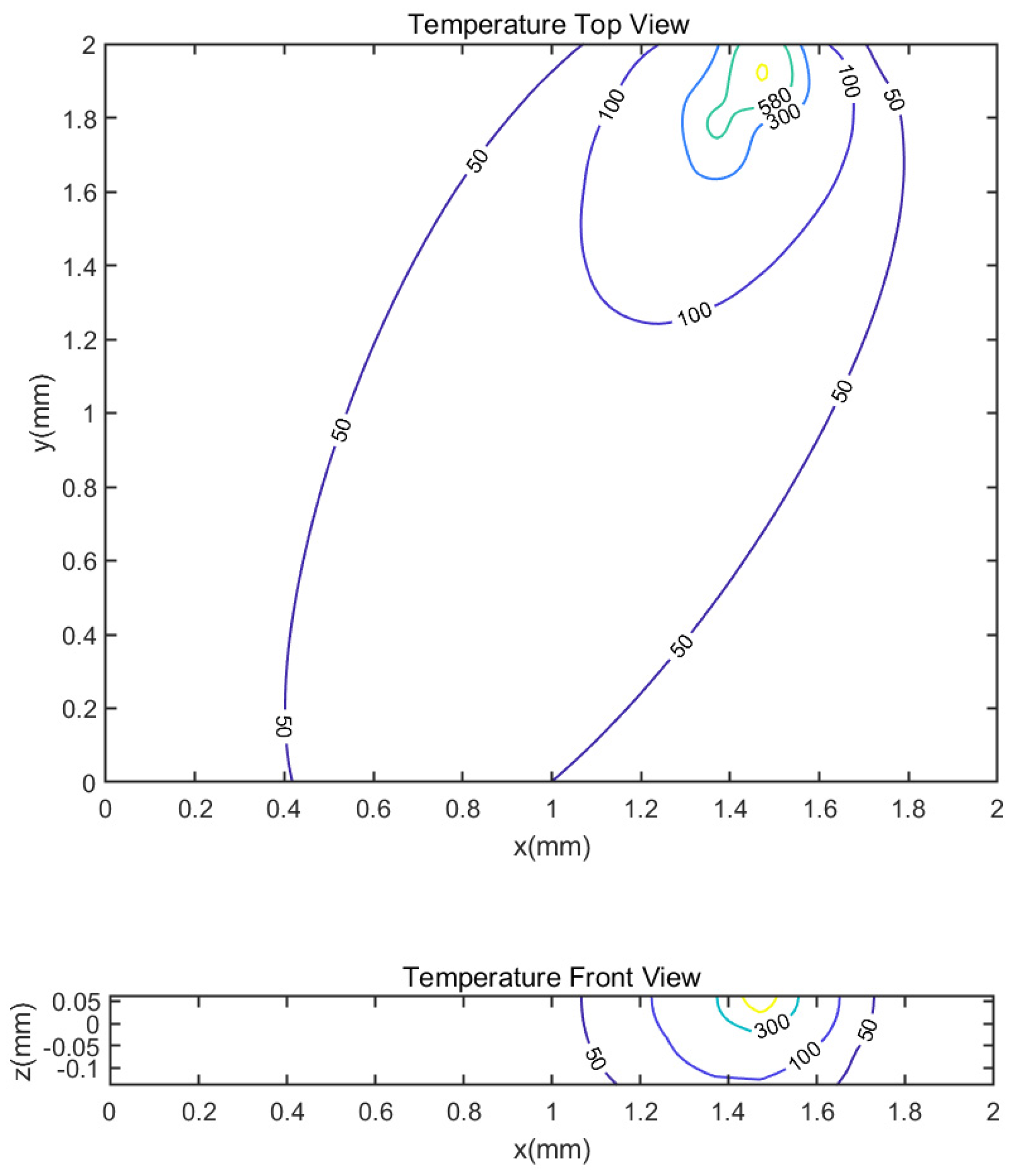

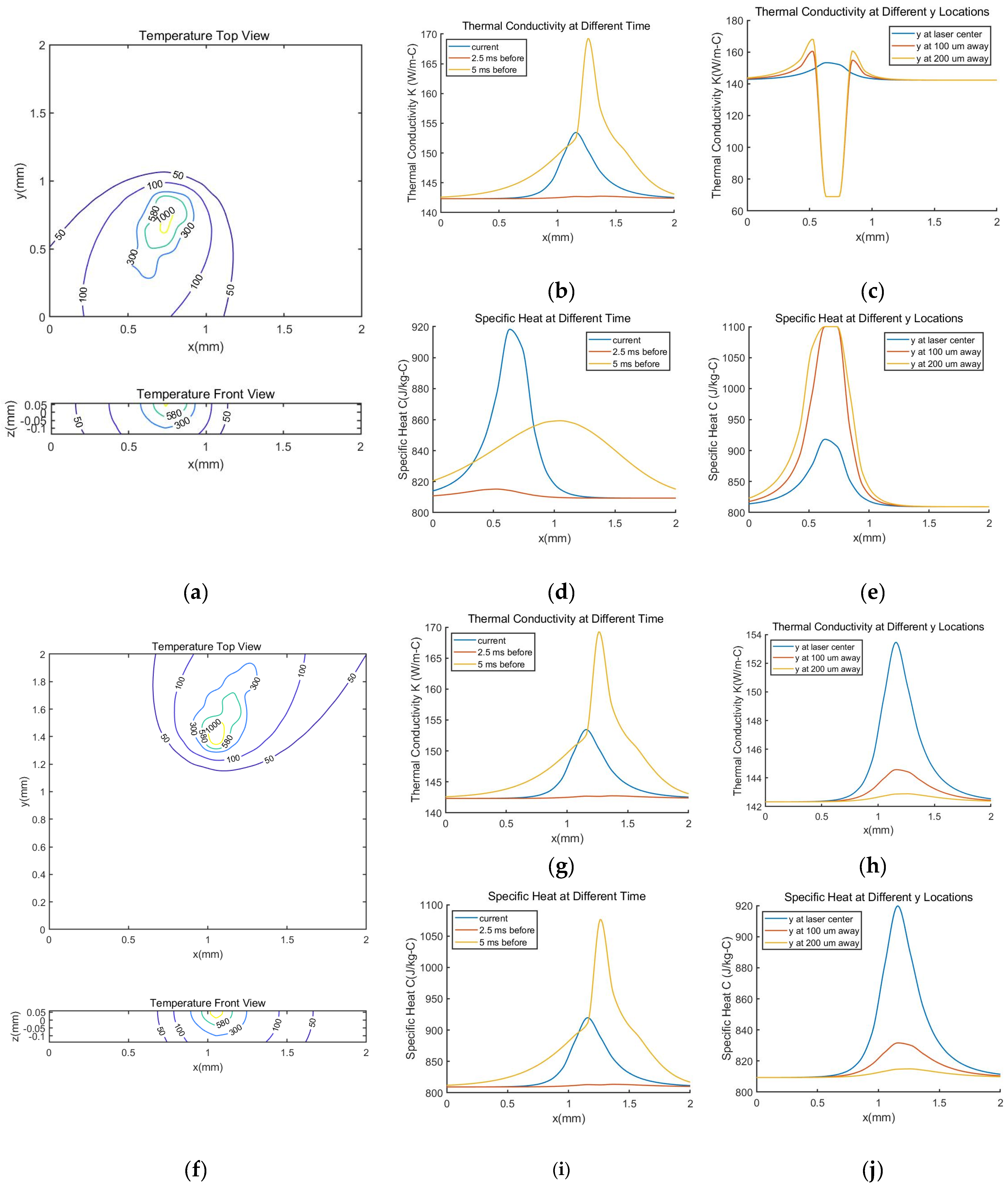

3. Results

4. Discussion

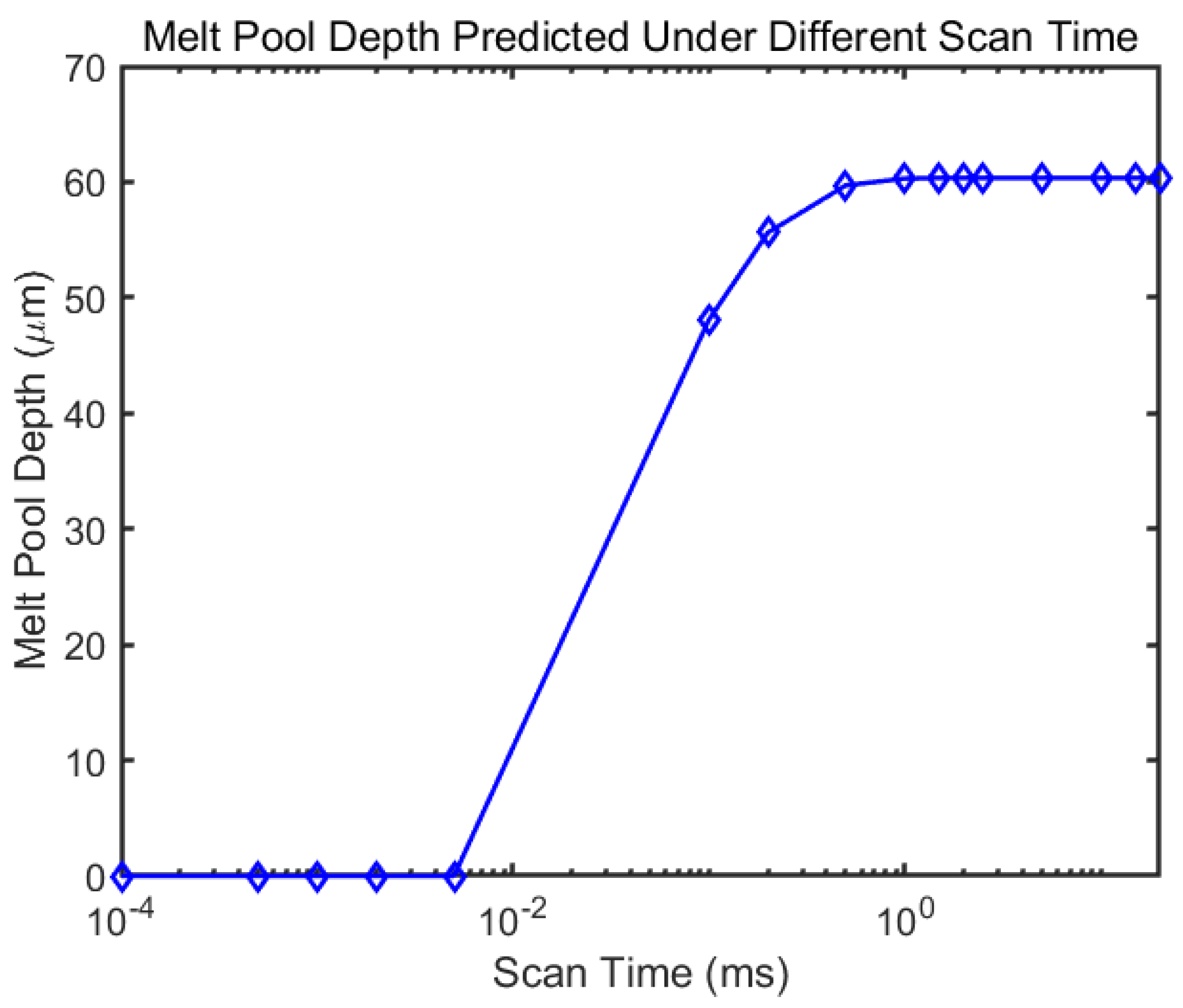

4.1. The Effect of Laser Power and Scan Speed to the Melt Pool Depth

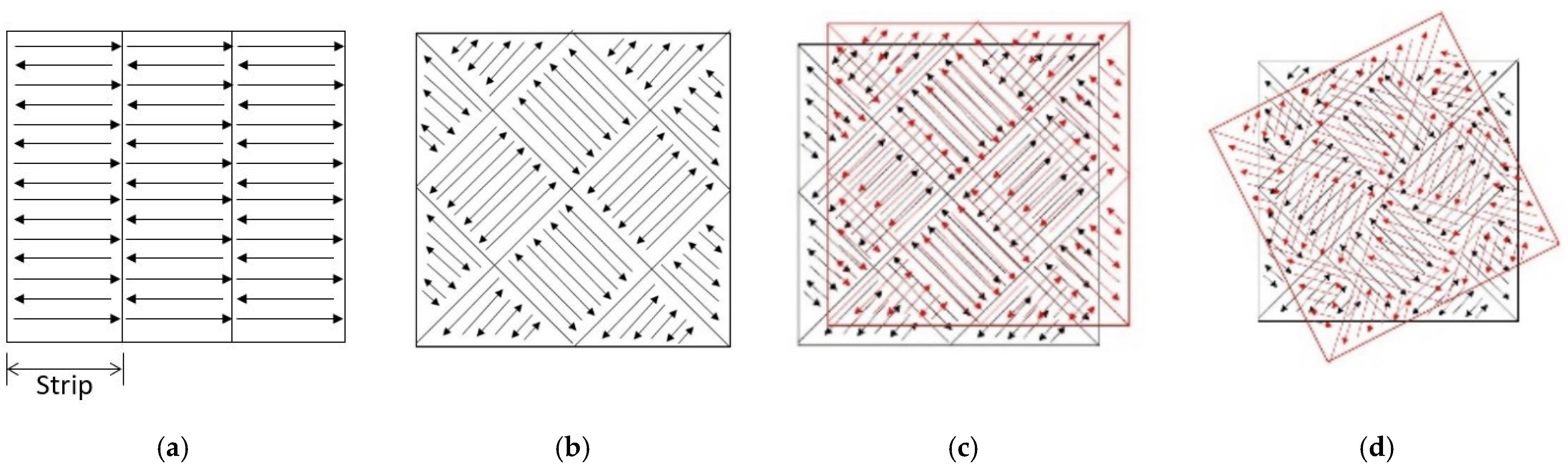

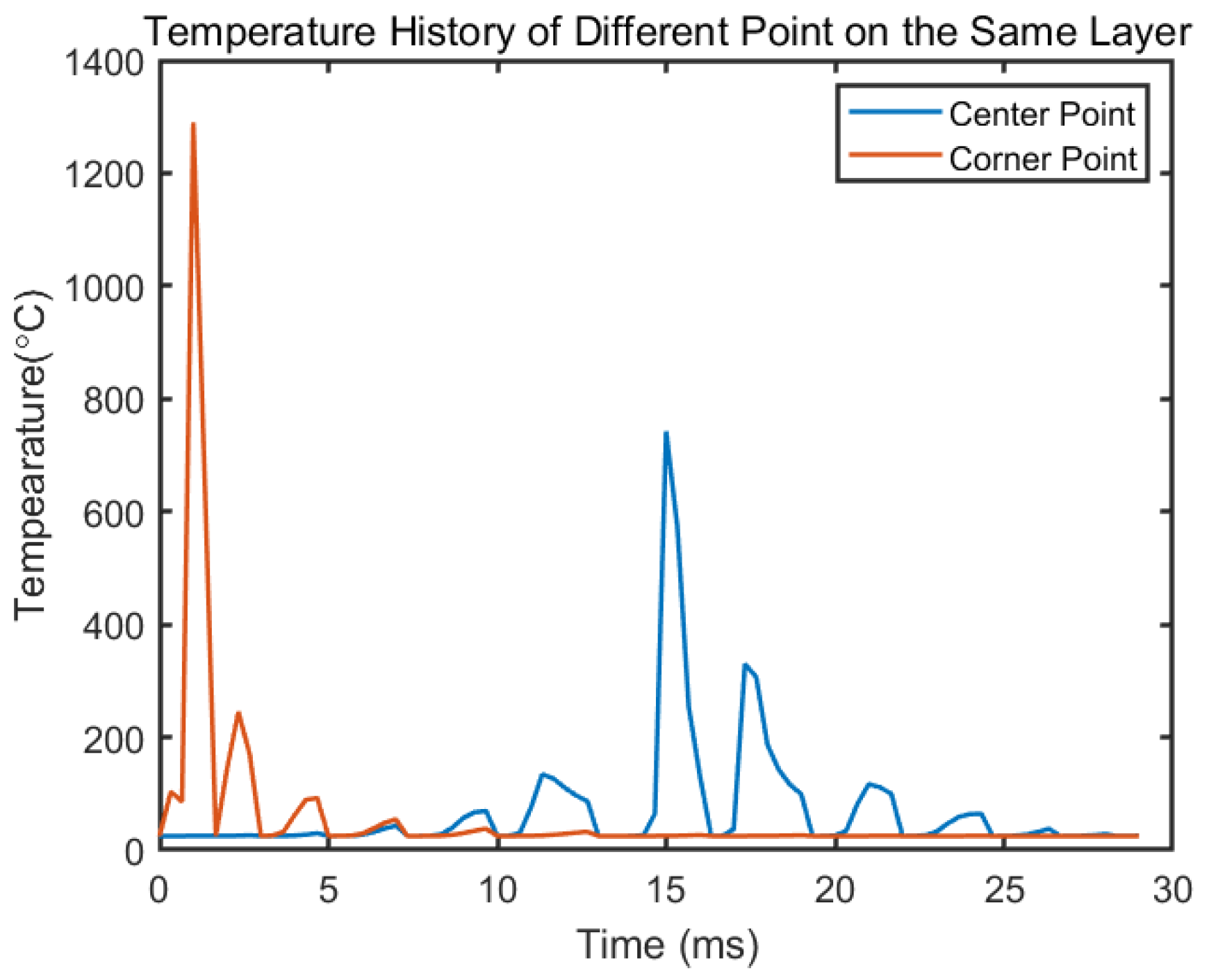

4.2. The Effect of Uni- or Bi-Directional Scan Direction on the Same Layer

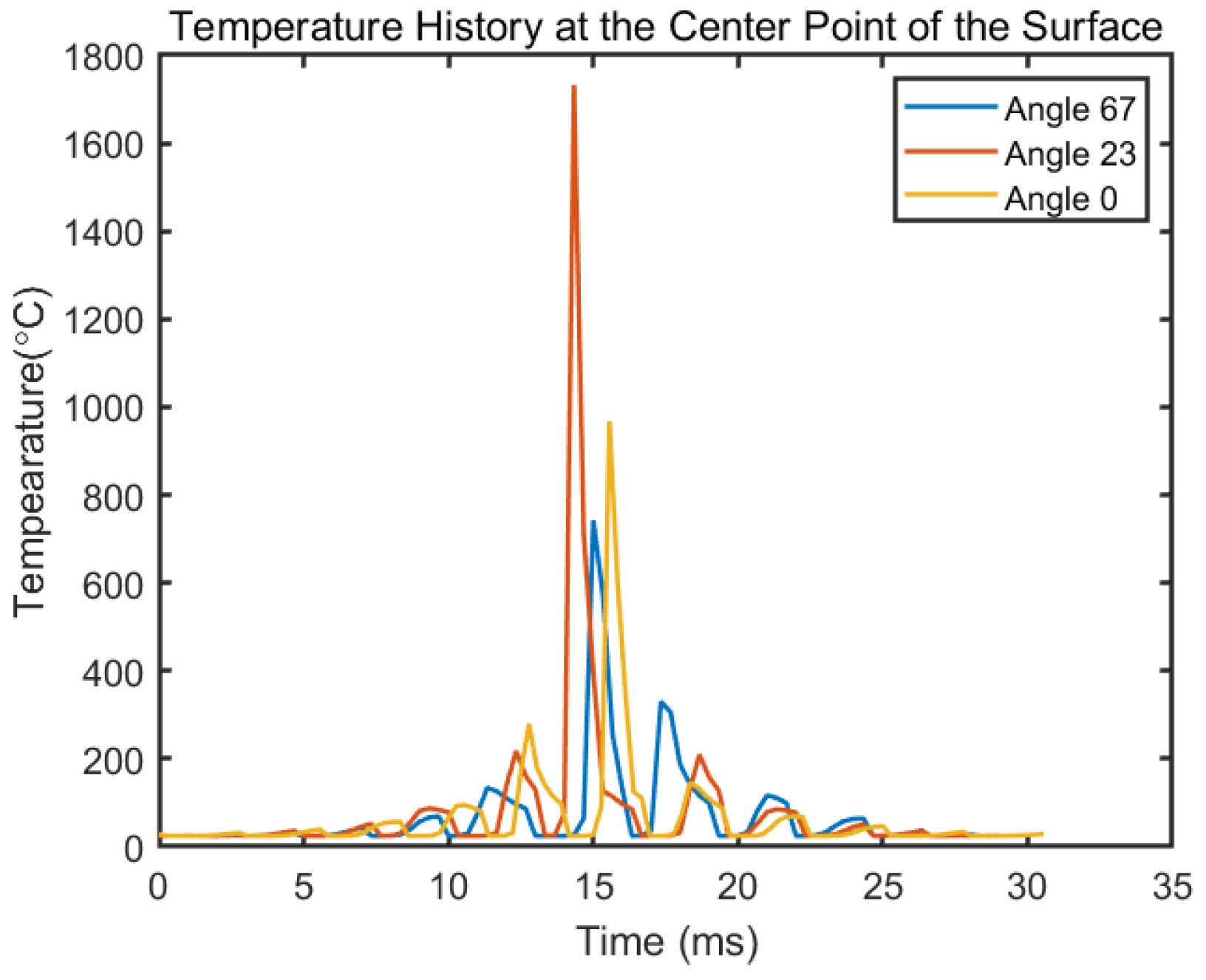

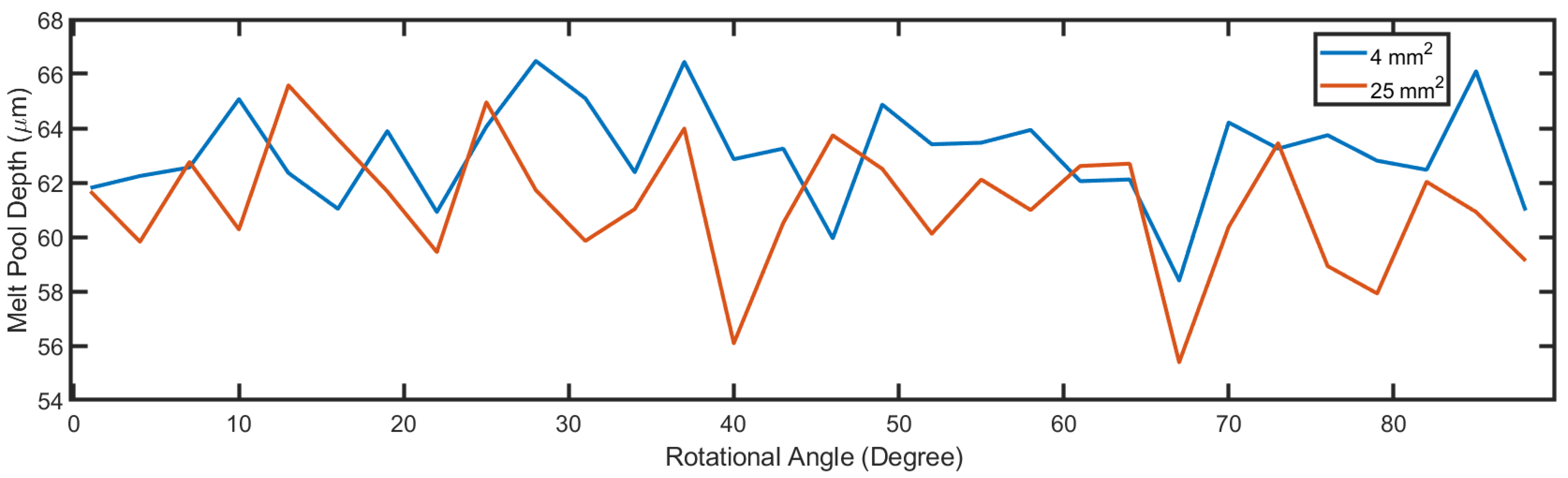

4.3. The Effect of Rotation angle on the Temperature History

4.4. The Effect of Hatch Space on the Temperature History

5. Conclusions

- The increase of applied laser power leads to deeper melt pool while the rotational angle between layers is applied. The decrease of scan speed brings similar effect. It is consistent with other researchers [13,14] done without rotation angle. The application of the rotation angle does not affect general heat absorption trend.

- The impact of uni- and bi-directional scan strategy shows more on the temperature profiles across the part, but it is not significant on the melt pool depth. The calculated melt pool depth difference is less than 1%.

- The rotational angles between layers affect both the track number taken on a layer and the single-track length. This leads to different temperature history on a specific point on the part. It does not vary the melt depth in a large scale but may affect the residual stress and further deflection of the part.

- For a 4 island, the short track length due to rotational angle between layers 67 degrees may result in incomplete melt at corner and edge of the island. This can be solved by an extra contour melting [41].

- Smaller hatching space enlarges the time needed to finish a layer scan. It also creates more heat accumulation on the part, which leads to a higher maximum temperature for the center point of the island.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclatures

| Specific heat | |

| Specific heat at initial time | |

| laser step | |

| Enthalpy | |

| Thermal conductivity | |

| Thermal conductivity at initial time | |

| laser step | |

| Latent heat of fusion | |

| Layer number | |

| Laser power | |

| Volumetric heat source | |

| Distance between the heat source to the point of interest | |

| 𝑇 | Temperature |

| Room temperature | |

| Initial temperature | |

| laser step | |

| Time | |

| Initial time | |

| Time difference between two assumed laser steps | |

| Internal energy | |

| Laser velocity | |

| Heat source velocity | |

| General coordinate | |

| Laser moving coordinate | |

| Laser rotation angle between layers | |

| Thermal diffusivity | |

| Laser absorption rate | |

| Laser rotation angle between first layer and current layer | |

| Material density | |

| Integration variable |

References

- Majeed, A.; Ahmed, A.; Salam, A.; Sheikh, M.Z. Surface quality improvement by parameters analysis, optimization and heat treatment of AlSi10Mg parts manufactured by SLM additive manufacturing. Int. J. Light. Mater. Manuf. 2019, 2, 288–295. [Google Scholar] [CrossRef]

- Sangid, M.D.; Book, T.A.; Naragani, D.; Rotella, J.; Ravi, P.; Finch, A.; Kenesei, P.; Park, J.S.; Sharma, H.; Almer, J.; et al. Role of heat treatment and build orientation in the microstructure sensitive deformation characteristics of IN718 produced via SLM additive manufacturing. Addit. Manuf. 2018, 22, 479–496. [Google Scholar] [CrossRef]

- Strong, D.; Kay, M.; Conner, B.; Wakefield, T.; Manogharan, G. Hybrid manufacturing–integrating traditional manufacturers with additive manufacturing (AM) supply chain. Addit. Manuf. 2018. [Google Scholar] [CrossRef]

- Achillas, C.; Tzetzis, D.; Raimondo, M.O. Alternative production strategies based on the comparison of additive and traditional manufacturing technologies. Int. J. Prod. Res. 2017. [Google Scholar] [CrossRef]

- Günther, D.; Heymel, B.; Günther, J.F.; Ederer, I. Continuous 3D-printing for additive manufacturing. Rapid Prototyp. J. 2014. [Google Scholar] [CrossRef]

- Hawaldar, N.; Zhang, J. A comparative study of fabrication of sand casting mold using additive manufacturing and conventional process. Int. J. Adv. Manuf. Technol. 2018. [Google Scholar] [CrossRef]

- Leary, M.; Mazur, M.; Elambasseril, J.; McMillan, M.; Chirent, T.; Sun, Y.; Qian, M.; Easton, M.; Brandt, M. Selective laser melting (SLM) of AlSi12Mg lattice structures. Mater. Des. 2016. [Google Scholar] [CrossRef]

- Gu, D.; Ma, C.; Xia, M.; Dai, D.; Shi, Q. A Multiscale Understanding of the Thermodynamic and Kinetic Mechanisms of Laser Additive Manufacturing. Engineering 2017. [Google Scholar] [CrossRef]

- Riemer, A.; Leuders, S.; Thöne, M.; Richard, H.A.; Tröster, T.; Niendorf, T. On the fatigue crack growth behavior in 316L stainless steel manufactured by selective laser melting. Eng. Fract. Mech. 2014. [Google Scholar] [CrossRef]

- Shiomi, M.; Osakada, K.; Nakamura, K.; Yamashita, T.; Abe, F. Residual stress within metallic model made by selective laser melting process. CIRP Ann. Manuf. Technol. 2004. [Google Scholar] [CrossRef]

- Li, C.; Fu, C.H.; Guo, Y.B.; Fang, F.Z. A multiscale modeling approach for fast prediction of part distortion in selective laser melting. J. Mater. Process. Technol. 2015. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, K.; Tan, P.; Tor, S.B.; Chua, C.K.; Leong, K.F. Modeling temperature and residual stress fields in selective laser melting. Int. J. Mech. Sci. 2018. [Google Scholar] [CrossRef]

- Liu, B.; Li, B.Q.; Li, Z.; Bai, P.; Wang, Y.; Kuai, Z. Numerical investigation on heat transfer of multi-laser processing during selective laser melting of AlSi10Mg. Results Phys. 2019, 12, 454–459. [Google Scholar] [CrossRef]

- Khan, H.M.; Dirikolu, M.H.; Koç, E.; Oter, Z.C. Numerical investigation of heat current study across different platforms in SLM processed multi-layer AlSi10Mg. Optik (Stuttg.) 2018, 170, 82–89. [Google Scholar] [CrossRef]

- Pan, Z.; Feng, Y.; Lu, Y.T.; Lin, Y.F.; Hung, T.P.; Hsu, F.C.; Liang, S.Y. Force modeling of Inconel 718 laser-assisted end milling under recrystallization effects. Int. J. Adv. Manuf. Technol. 2017. [Google Scholar] [CrossRef]

- Pan, Z.; Feng, Y.; Hung, T.P.; Jiang, Y.C.; Hsu, F.C.; Wu, L.T.; Lin, C.F.; Lu, Y.C.; Liang, S.Y. Heat affected zone in the laser-assisted milling of Inconel 718. J. Manuf. Process. 2017. [Google Scholar] [CrossRef]

- Jeager, J.C. Moving source of heat and temperature of sliding contacts. Proc. Roy. Soc. NSW. 1942, 76, 203–224. [Google Scholar]

- Rosenthal, D. The Theory of Moving Source of Heat and its Application to Metal Treatments. ASME Trans. 1946, 43, 849–866. [Google Scholar]

- Eagar, T.W.; Tsai, N.S. Temperature fields produced by traveling distributed heat sources. Weld. J. (Miami Fla) 1983, 62, 346–355. [Google Scholar]

- Van Elsen, M.; Baelmans, M.; Mercelis, P.; Kruth, J.P. Solutions for modelling moving heat sources in a semi-infinite medium and applications to laser material processing. Int. J. Heat Mass Transf. 2007, 50, 4872–4882. [Google Scholar] [CrossRef]

- Carslaw, H.S.; Jaeger, J.C.; Morral, J.E. Conduction of Heat in Solids, 2nd ed.; Clarendon press: Oxford, UK, 1986. [Google Scholar] [CrossRef]

- Steuben, J.C.; Birnbaum, A.J.; Michopoulos, J.G.; Iliopoulos, A.P. Enriched analytical solutions for additive manufacturing modeling and simulation. Addit. Manuf. 2019, 25, 437–447. [Google Scholar] [CrossRef]

- Mirkoohi, E.; Seivers, D.E.; Garmestani, H.; Liang, S.Y. Heat source modeling in selective laser melting. Materials 2019, 12, 2052. [Google Scholar] [CrossRef]

- Ning, J.; Sievers, D.E.; Garmestani, H.; Liang, S.Y. Analytical modeling of in-process temperature in powder bed additive manufacturing considering laser power absorption, latent heat, scanning strategy, and powder packing. Materials 2019, 12, 808. [Google Scholar] [CrossRef]

- Ning, J.; Sievers, D.E.; Garmestani, H.; Liang, S.Y. Analytical modeling of transient temperature in powder feed metal additive manufacturing during heating and cooling stages. Appl. Phys. A Mater. Sci. Process. 2019, 125, 1–11. [Google Scholar] [CrossRef]

- Ning, J.; Sievers, D.E.; Garmestani, H.; Liang, S.Y. Analytical modeling of in-process temperature in powder feed metal additive manufacturing considering heat transfer boundary condition. Int. J. Precis. Eng. Manuf. Green Technol. 2020, 1–9. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, D.; Cao, M.; Chen, R.; Feng, Z.; Poprawe, R.; Schleifenbaum, J.H.; Ziegler, S. Effect of δ phase on high temperature mechanical performances of Inconel 718 fabricated with SLM process. Mater. Sci. Eng. A 2019, 767, 138327. [Google Scholar] [CrossRef]

- Wang, D.; Wu, S.; Yang, Y.; Dou, W.; Deng, S.; Wang, Z.; Li, S. The effect of a scanning strategy on the residual stress of 316L steel parts fabricated by selective laser melting (SLM). Materials 2018, 11, 1821. [Google Scholar] [CrossRef] [PubMed]

- Ali, H.; Ghadbeigi, H.; Mumtaz, K. Effect of scanning strategies on residual stress and mechanical properties of Selective Laser Melted Ti6Al4V. Mater. Sci. Eng. A 2018, 712, 175–187. [Google Scholar] [CrossRef]

- Gu, D.; Guo, M.; Zhang, H.; Sun, Y.; Wang, R.; Zhang, L. Effects of laser scanning strategies on selective laser melting of pure tungsten. Int. J. Extrem. Manuf. 2020, 2, 025001. [Google Scholar] [CrossRef]

- Rashid, R.; Masood, S.H.; Ruan, D.; Palanisamy, S.; Rahman Rashid, R.A.; Brandt, M. Effect of scan strategy on density and metallurgical properties of 17-4PH parts printed by Selective Laser Melting (SLM). J. Mater. Process. Technol. 2017, 249, 502–511. [Google Scholar] [CrossRef]

- Parry, L.; Ashcroft, I.A.; Wildman, R.D. Understanding the effect of laser scan strategy on residual stress in selective laser melting through thermo-mechanical simulation. Addit. Manuf. 2016, 12, 1–15. [Google Scholar] [CrossRef]

- Song, J.; Wu, W.; Zhang, L.; He, B.; Lu, L.; Ni, X.; Long, Q.; Zhu, G. Role of scanning strategy on residual stress distribution in Ti-6Al-4V alloy prepared by selective laser melting. Optik (Stuttg.) 2018, 170, 342–352. [Google Scholar] [CrossRef]

- De Lange, D.F.; Postma, S.; Meijer, J. Modelling and observation of laser welding: The effect of latent heat. In Proceedings of the ICALEO 22nd International Congress on Applications of Laser and Electro-Optics, Congress Proceedings, Jacksonville, FL, USA, 13–16 October 2003. [Google Scholar]

- Wei, P.; Wei, Z.; Chen, Z.; He, Y.; Du, J. Thermal behavior in single track during selective laser melting of AlSi10Mg powder. Appl. Phys. A Mater. Sci. Process. 2017, 123, 1–15. [Google Scholar] [CrossRef]

- Zhang, X.; Kang, J.; Rong, Y.; Wu, P.; Feng, T. Effect of scanning routes on the stress and deformation of overhang structures fabricated by SLM. Materials 2018, 12, 47. [Google Scholar] [CrossRef] [PubMed]

- Mukherjee, T.; Wei, H.L.; De, A.; DebRoy, T. Heat and fluid flow in additive manufacturing–Part II: Powder bed fusion of stainless steel, and titanium, nickel and aluminum base alloys. Comput. Mater. Sci. 2018, 150, 369–380. [Google Scholar] [CrossRef]

- Rosenthal, I.; Shneck, R.; Stern, A. Heat treatment effect on the mechanical properties and fracture mechanism in AlSi10Mg fabricated by additive manufacturing selective laser melting process. Mater. Sci. Eng. A 2018, 729, 310–322. [Google Scholar] [CrossRef]

- Rosenthal, I.; Stern, A.; Frage, N. Strain rate sensitivity and fracture mechanism of AlSi10Mg parts produced by Selective Laser Melting. Mater. Sci. Eng. A 2017, 682, 509–517. [Google Scholar] [CrossRef]

- Krishnan, M.; Atzeni, E.; Canali, R.; Calignano, F.; Manfredi, D.; Ambrosio, E.P.; Iuliano, L. On the effect of process parameters on properties of AlSi10Mg parts produced by DMLS. Rapid Prototyp. J. 2014. [Google Scholar] [CrossRef]

- Manfredi, D.; Calignano, F.; Krishnan, M.; Canali, R.; Ambrosio, E.P.; Atzeni, E. From powders to dense metal parts: Characterization of a commercial alsimg alloy processed through direct metal laser sintering. Materials 2013, 6, 856–869. [Google Scholar] [CrossRef]

- Tolochko, N.K.; Laoui, T.; Khlopkov, Y.V.; Mozzharov, S.E.; Titov, V.I.; Ignatiev, M.B. Absorptance of powder materials suitable for laser sintering. Rapid Prototyp. J. 2000. [Google Scholar] [CrossRef]

- Boley, C.D.; Khairallah, S.A.; Rubenchik, A.M. Calculation of laser absorption by metal powders in additive manufacturing. Appl. Opt. 2015, 54, 2477–2482. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Van Humbeeck, J.; Kruth, J.P. Processing AlSi10Mg by selective laser melting: Parameter optimisation and material characterisation. Mater. Sci. Technol. 2015, 31, 917–923. [Google Scholar] [CrossRef]

- Lo, Y.L.; Liu, B.Y.; Tran, H.C. Optimized hatch space selection in double-scanning track selective laser melting process. Int. J. Adv. Manuf. Technol. 2019, 105, 2989–3006. [Google Scholar] [CrossRef]

- Marques, B.M.; Andrade, C.M.; Neto, D.M.; Oliveira, M.C.; Alves, J.L.; Menezes, L.F. Numerical Analysis of Residual Stresses in Parts Produced by Selective Laser Melting Process. Procedia Manuf. 2020, 47, 1170–1177. [Google Scholar] [CrossRef]

- Salman, O.O.; Brenne, F.; Niendorf, T.; Eckert, J.; Prashanth, K.G.; He, T.; Scudino, S. Impact of the scanning strategy on the mechanical behavior of 316L steel synthesized by selective laser melting. J. Manuf. Process. 2019, 45, 255–261. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, Y.; Wang, D. A study on the residual stress during selective laser melting (SLM) of metallic powder. Int. J. Adv. Manuf. Technol. 2016, 87, 647–656. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, S.; Gan, Y.; Huang, T.; Yang, C.; Junjie, L.; Lin, J. Study on the microstructure, mechanical property and residual stress of SLM Inconel-718 alloy manufactured by differing island scanning strategy. Opt. Laser Technol. 2015, 75, 197–206. [Google Scholar] [CrossRef]

- Dong, Z.; Liu, Y.; Wen, W.; Ge, J.; Liang, J. Effect of hatch spacing on melt pool and as-built quality during selective laser melting of stainless steel: Modeling and experimental approaches. Materials 2018, 12, 50. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Ashcroft, I.; Tuck, C. Reducing porosity in AlSi10Mg parts processed by selective laser melting. Addit. Manuf. 2014, 1, 77–86. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Density () | 2670 |

| Melting Temperature () | 580 |

| Latent Heat of Fusion () | 423,000 |

| Thermal Conductivity () | |

| Specific Heat () |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, L.; Liang, S.Y. Analytical Modelling of Temperature Distribution in SLM Process with Consideration of Scan Strategy Difference between Layers. Materials 2021, 14, 1869. https://doi.org/10.3390/ma14081869

Cai L, Liang SY. Analytical Modelling of Temperature Distribution in SLM Process with Consideration of Scan Strategy Difference between Layers. Materials. 2021; 14(8):1869. https://doi.org/10.3390/ma14081869

Chicago/Turabian StyleCai, Linger, and Steven Y. Liang. 2021. "Analytical Modelling of Temperature Distribution in SLM Process with Consideration of Scan Strategy Difference between Layers" Materials 14, no. 8: 1869. https://doi.org/10.3390/ma14081869

APA StyleCai, L., & Liang, S. Y. (2021). Analytical Modelling of Temperature Distribution in SLM Process with Consideration of Scan Strategy Difference between Layers. Materials, 14(8), 1869. https://doi.org/10.3390/ma14081869