Tribological Performance of Composites Reinforced with the Agricultural, Industrial and Post-Consumer Wastes: A Review

Abstract

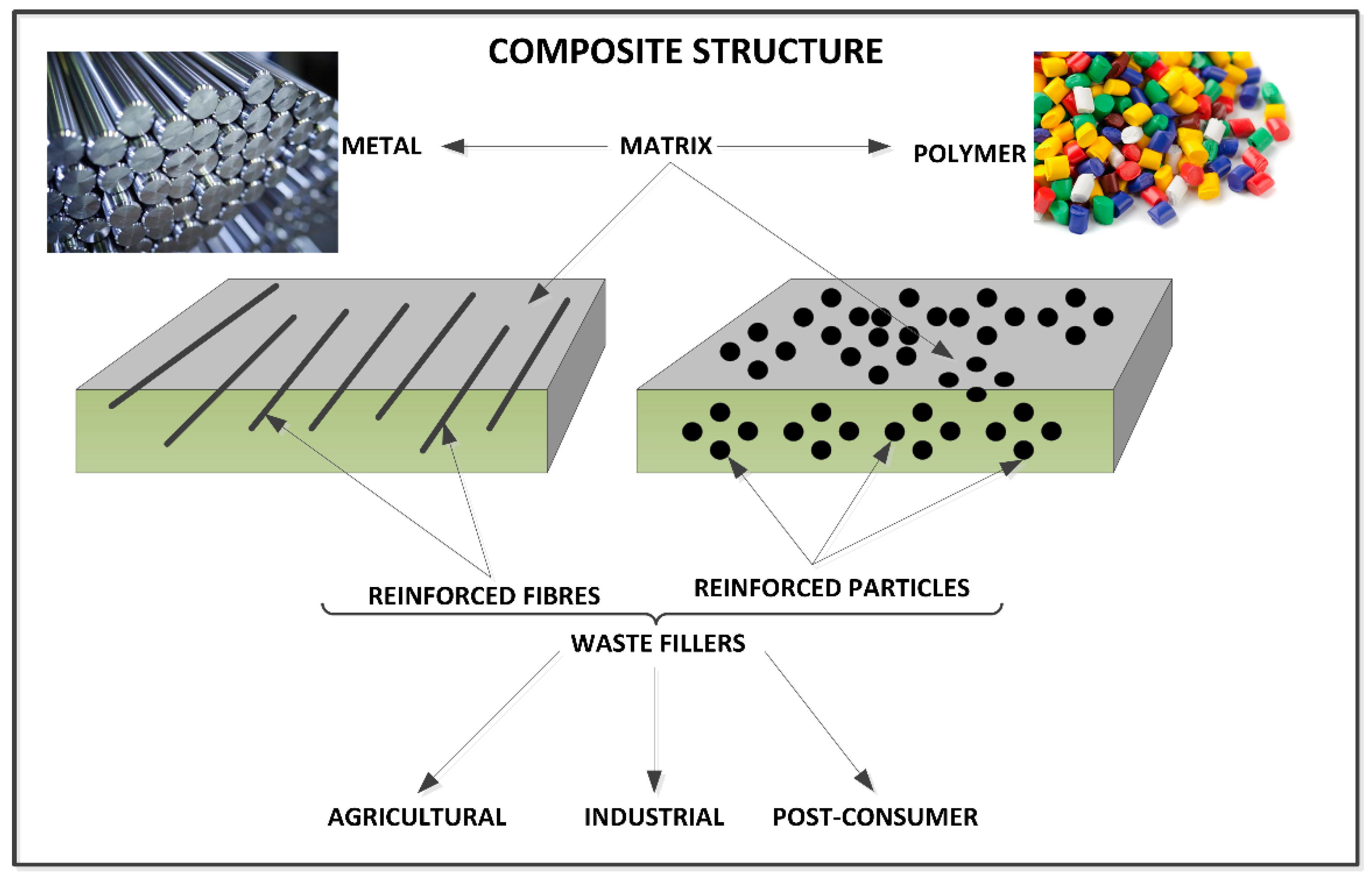

1. Introduction

2. Agricultural Waste Materials

2.1. Metal Matrix Composites

2.1.1. Ashes

2.1.2. Shells

2.2. Polymer Matrix Composites

2.2.1. Plant Fibers or Their Derivatives

2.2.2. Ashes and Shells

2.2.3. Other Agricultural Wastes

3. Industrial Waste Materials

3.1. Metal Matrix Composites

3.2. Polymer Matrix Composites

4. Postconsumer Waste Materials

5. Future Perspectives

6. Conclusions

- This literature review has shown that agricultural, industrial and postconsumer waste is a promising filler material for composites based on both polymer and metal matrices;

- Its use as reinforcement for composites exhibiting desirable tribological properties only gained in popularity in recent years (especially after 2015);

- The reuse of wastes for tribological applications has advantages, such as environmental and economic benefits, an improvement of mechanical and tribological properties and a reduction in the overall weight of the material;

- Wherever the wear of the produced composites is not worse than the reference materials, their application should be considered for ecological and economic reasons;

- There is a great need to find further wastes that can potentially be useful in improving the tribological properties of the currently used materials;

- Future research should focus not only on the waste that is generated in large quantities but also on that available locally to minimize the environmental impact related to the life cycle of tribological materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| BF | Blast furnace |

| CDA | Cow dung ash |

| COF | Coefficient of friction |

| FA | Fly ash |

| HDPE | High-density polyethylene |

| LD | Linz–Donawitz |

| PA | Polyamide |

| PE | Polyethylene |

| PEEK | Polyether ether ketone |

| PP | Polypropylene |

| PTFE | Polytetrafluoroethylene |

| RM | Red mud |

| RHA | Rice husk ash |

| WTD | Waste tire dust |

References

- InterregEurope. Sustainable Waste Management in a Circular Economy. A Policy Brief from the Policy Learning Platform on Environment and Resource Efficiency. 2020. Available online: https://www.interregeurope.eu/fileadmin/user_upload/plp_uploads/policy_briefs/Policy_brief_on_waste_management.pdf (accessed on 15 January 2021).

- Almomani, M.A.; Hayajneh, M.T.; Al-Shrida, M.M. Investigation of mechanical and tribological properties of hybrid green eggshells and graphite-reinforced aluminum composites. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 1–13. [Google Scholar] [CrossRef]

- Manikandan, R.; Arjunan, T.V. Mechanical and tribological behaviours of aluminium hybrid composites reinforced by CDA-B4C. Mater. Res. Express 2020, 7. [Google Scholar] [CrossRef]

- Oladele, I.O.; Olajide, J.L.; Amujede, M. Wear resistance and mechanical behaviour of epoxy/mollusk shell biocomposites developed for structural applications. Tribol. Ind. 2016, 38, 347–360. [Google Scholar]

- Adesina, A.Y.; Zainelabdeen, I.H.; Dalhat, M.A.; Mohammed, A.S.; Sorour, A.A.; Al-Badou, F.A. Influence of micronized waste tire rubber on the mechanical and tribological properties of epoxy composite coatings. Tribol. Int. 2020, 146. [Google Scholar] [CrossRef]

- Shivamurthy, B.; Murthy, K.; Joseph, P.C.; Rishi, K.; Bhat, K.U.; Anandhan, S. Mechanical properties and sliding wear behavior of jatropha seed cake waste/epoxy composites. J. Mater. Cycles Waste Manag. 2014, 17, 144–156. [Google Scholar] [CrossRef]

- Hrabě, P.; Müller, M. Three-body abrasive wear of polymer matrix composites filled with Jatropha Curcas L. Procedia Eng. 2016, 136, 169–174. [Google Scholar] [CrossRef]

- Müller, M.; Valašek, P.; Tichý, M.; Ruggiero, A.; D’Amato, R. Investigation on Polymer Composite Materials Wear Reinforced by Microparticles of Jatropha Curcas L. Waste. IOP Conf. Ser. Mater. Sci. Eng. 2019, 638. [Google Scholar] [CrossRef]

- Shankar, S.; Balaji, A.; Kawin, N. Investigations on mechanical and tribological properties of Al-Si10-Mg alloy/sugarcane bagasse ash particulate composites. Part. Sci. Technol. 2018, 36, 762–770. [Google Scholar] [CrossRef]

- Harish, T.M.; Mathai, S.; Cherian, J.; Mathew, K.M.; Thomas, T.; Vishnu Prasad, K.V.; Ravi, V.C. Development of aluminium 5056/SiC/bagasse ash hybrid composites using stir casting method. Mater. Today Proc. 2019, 27, 2635–2639. [Google Scholar] [CrossRef]

- Mat Tahir, N.A.; Abdollah Bin, M.F.; Hasan, R.; Amiruddin, H. The effect of sliding distance at different temperatures on the tribological properties of a palm kernel activated carbon-epoxy composite. Tribol. Int. 2016, 94, 352–359. [Google Scholar] [CrossRef]

- Mahmud, D.N.F.; Abdollah Bin, M.F.; Masripan Bin, N.A.; Tamaldin, N.; Amiruddin, H. Influence of contact pressure and sliding speed dependence on the tribological characteristics of an activated carbon-epoxy composite derived from palm kernel under dry sliding conditions. Friction 2019, 7, 227–236. [Google Scholar] [CrossRef]

- Oladele, I.O.; Ayanleye, O.T.; Adediran, A.A.; Makinde-Isola, B.A.; Taiwo, A.S.; Akinlabi, E.T. Characterization of wear and physical properties of pawpaw-Glass fiber hybrid reinforced epoxy composites for structural application. Fibers 2020, 8, 44. [Google Scholar] [CrossRef]

- Prakash, M.O.; Raghavendra, G.; Ojha, S.; Panchal, M.; Kumar, D. Investigation of tribological properties of biomass developed porous nano activated carbon composites. Wear 2020, 203523. [Google Scholar] [CrossRef]

- Kumar, R.A.; Prasad, M. Investigation on Tribological Behaviour of Bio-Based Pongamia Pinnata Seed Cake Waste Incorporated Basalt Epoxy Composites. In Proceedings of the 9th International Conference of Materials Processing and Characterization, ICMPC-2019, Hyderabad, Andhra Pradesh, India, 8–10 March 2019; Volume 18. [Google Scholar]

- Olajide, J.L.; Oladele, I.O.; Odeyemi, O.J.; Babarinsa, S.O. Abrasive wear resistance, mechanical behaviour, water transport phenomena and biocorrosion of epoxy/femora biocomposites. Tribol. Ind. 2017, 39, 400–414. [Google Scholar] [CrossRef][Green Version]

- Ruggiero, A.; Valášek, P.; Müller, M. Exploitation of waste date seeds of Phoenix dactylifera in form of polymeric particle biocomposite: Investigation on adhesion, cohesion and wear. Compos. Part. B Eng. 2016, 104, 9–16. [Google Scholar] [CrossRef]

- Prasad Nanda, B.; Satapathy, A. Wear characteristics of epoxy based hybrid composites reinforced with short hair fibers and glass micro spheres. Mater. Today Proc. 2018, 5, 12588–12594. [Google Scholar] [CrossRef]

- Ranakoti, L.; Rakesh, P.K. Physio-mechanical characterization of tasar silk waste/jute fiber hybrid composite. Compos. Commun. 2020, 22, 100526. [Google Scholar] [CrossRef]

- Sharma, H.; Misra, J.P.; Singh, I. Friction and wear behaviour of epoxy composites reinforced with food waste fillers. Compos. Commun. 2020, 22, 100436. [Google Scholar] [CrossRef]

- Valášek, P.; Ruggiero, A.; Müller, M. Experimental description of strength and tribological characteristic of EFB oil palm fibres/epoxy composites with technologically undemanding preparation. Compos. Part. B Eng. 2017, 122, 79–88. [Google Scholar] [CrossRef]

- Ariharan, S.; Maurya, R.; Sharma, R.K.; Sharma, V.K.; Lohia, S.; Balani, K. Damage mechanics of polypropylene-based composites using progressive- and constant-load scratching. Polym. Compos. 2020, 41, 3830–3841. [Google Scholar] [CrossRef]

- Ibrahim, M.A.; Hirayama, T.; Khalaf, D. An investigation into the tribological properties of wood flour reinforced polypropylene composites. Mater. Res. Express 2019, 7. [Google Scholar] [CrossRef]

- Taqui, S.N.; Yahya, R.; Hassan, A.; Nayak, N.; Syed, A.A. A Novel Sustainable Design to Develop Polypropylene and Unsaturated Polyester Resin Polymer Composites from Waste of Major Polluting Industries and Investigation on Their Physicomechanical and Wear Properties. Polym. Compos. 2019, 40, 1142–1157. [Google Scholar] [CrossRef]

- Prasad, L.; Singh, G.; Yadav, A.; Kumar, V.; Kumar, A. Properties of functionally gradient composites reinforced with waste natural fillers. Acta Period. Technol. 2019, 50, 250–259. [Google Scholar] [CrossRef]

- Agbeboh, N.I.; OlaJide, J.L.; Oladele, I.O.; Babarinsa, S.O. Kinetics of moisture sorption and improved tribological performance of keratinous fiber-reinforced ortho-phthalic polyester biocomposites. J. Nat. Fibers 2019, 16, 744–754. [Google Scholar] [CrossRef]

- Ibrahim, R.A. Tribological performance of polyester composites reinforced by agricultural wastes. Tribol. Int. 2015, 90, 463–466. [Google Scholar] [CrossRef]

- Correa, C.E.; Betancourt, S.; Vázquez, A.; Gañan, P. Wear resistance and friction behavior of thermoset matrix reinforced with Musaceae fiber bundles. Tribol. Int. 2015, 87, 57–64. [Google Scholar] [CrossRef]

- Oladele, I.O.; Adediran, A.A.; Akinwekomi, A.D.; Adegun, M.H.; Olumakinde, O.O.; Daramola, O.O. Development of Ecofriendly Snail Shell Particulate-Reinforced Recycled Waste Plastic Composites for Automobile Application. Sci. World J. 2020, 2020. [Google Scholar] [CrossRef] [PubMed]

- Naghmouchi, I.; Mutjé, P.; Boufi, S. Polyvinyl chloride composites filled with olive stone flour: Mechanical, thermal, and water absorption properties. J. Appl. Polym. Sci. 2014, 131, 1–10. [Google Scholar] [CrossRef]

- Chand, N.; Sharma, P.; Fahim, M. Tribology of maleic anhydride modified rice-husk filled polyvinylchloride. Wear 2010, 269, 847–853. [Google Scholar] [CrossRef]

- Atuanya, C.U.; Aigbodion, V.S. Effect of wear parameter on wear behavior of recycled polyethylene/snail shell waste particulate bio-composites. J. Fail. Anal. Prev. 2014, 14, 509–518. [Google Scholar] [CrossRef]

- Oladele, I.O.; Agbabiaka, O.G.; Adediran, A.A.; Akinwekomi, A.D.; Balogun, A.O. Structural performance of poultry eggshell derived hydroxyapatite based high density polyethylene bio-composites. Heliyon 2019, 5, e02552. [Google Scholar] [CrossRef] [PubMed]

- Sahin, A.E.; Cetin, B.; Sinmazcelik, T. Effect of mussel shell reinforcement on mechanical and tribological behavior of polyphenylene sulfide composites. J. Thermoplast. Compos. Mater. 2020. [Google Scholar] [CrossRef]

- El Mogy, S.A.; Darwish, N.A.; Awad, A. Comparative Study of the Cure Characteristics and Mechanical Properties of Natural Rubber Filled with Different Calcium Carbonate Resources. J. Vinyl Addit. Technol. 2020, 26, 309–315. [Google Scholar] [CrossRef]

- Bakry, M.; Mousa, M.O.; Ali, W.Y. Friction and wear of friction composites reinforced by natural fibres. Materwiss. Werksttech. 2013, 44, 21–28. [Google Scholar] [CrossRef]

- Amirjan, M. Microstructure, wear and friction behavior of nanocomposite materials with natural ingredients. Tribol. Int. 2019, 131, 184–190. [Google Scholar] [CrossRef]

- Ma, Y.; Wu, S.; Zhuang, J.; Tong, J.; Xiao, Y.; Qi, H. The evaluation of physio-mechanical and tribological characterization of friction composites reinforced by waste corn stalk. Materials 2018, 11, 901. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Wu, S.; Zhuang, J.; Tong, J.; Qi, H. Tribological and physio-mechanical characterization of cow dung fibers reinforced friction composites: An effective utilization of cow dung waste. Tribol. Int. 2019, 131, 200–211. [Google Scholar] [CrossRef]

- Craciun, A.L.; Pinca-Bretotean, C.; Utu, D.; Josan, A. Tribological properties of nonasbestos brake pad material by using coconut fiber. IOP Conf. Ser. Mater. Sci. Eng. 2017, 163. [Google Scholar] [CrossRef]

- Arora, G.; Sharma, S. A Comparative Study of AA6351 Mono-Composites Reinforced with Synthetic and Agro Waste Reinforcement. Int. J. Precis. Eng. Manuf. 2018, 19, 631–638. [Google Scholar] [CrossRef]

- Shaikh, M.B.N.; Raja, S.; Ahmed, M.; Zubair, M.; Khan, A.; Ali, M. Rice husk ash reinforced aluminium matrix composites: Fabrication, characterization, statistical analysis and artificial neural network modelling. Mater. Res. Express 2019, 6. [Google Scholar] [CrossRef]

- Prasad, D.S.; Krishna, A.R. Tribological Properties of A356.2/RHA Composites. J. Mater. Sci. Technol. 2012, 28, 367–372. [Google Scholar] [CrossRef]

- Bannaravuri, P.K.; Birru, A.K. Strengthening of mechanical and tribological properties of Al-4.5%Cu matrix alloy with the addition of bamboo leaf ash. Results Phys. 2018, 10, 360–373. [Google Scholar] [CrossRef]

- Kumar, B.P.; Birru, A.K. Tribological behavior of aluminium metal matrix composite with addition of bamboo leaf ash by gra-taguchi method. Tribol. Ind. 2018, 40, 311–325. [Google Scholar] [CrossRef]

- Hayajneh, M.T.; Almomani, M.A.; Al-Shrida, M.M. Effects of waste eggshells addition on microstructures, mechanical and tribological properties of green metal matrix composite. Sci. Eng. Compos. Mater. 2019, 26, 423–434. [Google Scholar] [CrossRef]

- Dwiwedi, S.K.; Srivastava, A.K.; Chopkar, M.K. Wear Study of Chicken Eggshell-Reinforced Al6061 Matrix Composites. Trans. Indian Inst. Met. 2019, 72, 73–84. [Google Scholar] [CrossRef]

- Dwivedi, S.P.; Sharma, S.; Mishra, R.K. Tribological behavior of a newly developed AA2014/waste eggshell/SiC hybrid green metal matrix composite at optimum parameters. Green Process. Synth. 2018, 7, 48–60. [Google Scholar] [CrossRef]

- Panda, B.; Niranjan, C.A.; Vishwanatha, A.D.; Harisha, P.; Chandan, K.R.; Kumar, R. Development of Novel Stir Cast Aluminium Composite with modified Coconut Shell Ash Filler. Mater. Today Proc. 2019, 22, 2715–2724. [Google Scholar] [CrossRef]

- Raju, S.S.; Rao, G.S.; Siva, B.V. Experimental studies of mechanical properties and tribological behaviour of aluminium composite reinforced with coconut shell ash particulates. Int. J. Mater. Eng. Innov. 2018, 9, 140–157. [Google Scholar] [CrossRef]

- Subramaniam, B.; Natarajan, B.; Kaliyaperumal, B.; Chelladurai, S.J.S. Wear behaviour of aluminium 7075—Boron carbide- coconut shell fly ash reinforced hybrid metal matrix composites. Mater. Res. Express 2019, 6. [Google Scholar] [CrossRef]

- Aigbodion, V.S. Bean pod ash nanoparticles a promising reinforcement for aluminium matrix biocomposites. J. Mater. Res. Technol. 2019, 8, 6011–6020. [Google Scholar] [CrossRef]

- Suleiman, I.Y.; Salihu, S.A.; Mohammed, T.A. Investigation of mechanical, microstructure, and wear behaviors of Al-12%Si/reinforced with melon shell ash particulates. Int. J. Adv. Manuf. Technol. 2018, 97, 4137–4144. [Google Scholar] [CrossRef]

- Fono-Tamo, R.S.; Akinlabi, E.T.; Tien-Chien, J. Microstructural and dry sliding friction studies of aluminum matrix composites reinforced pks ash developed via friction stir processing. Miner. Met. Mater. Ser. 2019, 401–406. [Google Scholar] [CrossRef]

- Ramanathan, S.; Vinod, B.; Narayanasamy, P.; Anandajothi, M. Dry Sliding Wear Mechanism Maps of Al–7Si–0.3Mg Hybrid Composite: Novel Approach of Agro-Industrial Waste Particles to Reduce Cost of Material. J. Bio Tribo Corrosion 2019, 5. [Google Scholar] [CrossRef]

- Krushna, M.G.; Shekhar, P.S.; Kumar, S.A. Effect of hot forging on high temperature tribilogical properties of aluminium composite reinforced with agro and industrial waste. Int. J. Eng. Adv. Technol. 2019, 8, 1607–1612. [Google Scholar] [CrossRef]

- Vinod, B.; Ramanathan, S.; Anandajothi, M. Effect of Organic and Inorganic Reinforcement on Tribological Behaviour of Aluminium A356 Matrix Hybrid Composite. J. Bio Tribo Corrosion 2018, 4, 1–13. [Google Scholar] [CrossRef]

- Vinod, B.; Anandajothi, M. Dry Sliding Wear Mechanisms of Incorporated Hydroxyapatite Waste Materials: Synthesis and Characterization of Magnesium Hybrid Composites. Trans. Indian Inst. Met. 2020. [Google Scholar] [CrossRef]

- Anandajothi, M.; Vinod, B. Tribological Behavior of Magnesium Hybrid Composite: Effect of Amorphous Silica-Solid Waste Reinforcement Particles to Reduce Material Cost. Silicon 2020. [Google Scholar] [CrossRef]

- Rozhbiany, F.A.R.; Jalal, S.R. Influence of reinforcement and processing on aluminum matrix composites modified by stir casting route. Adv. Compos. Lett. 2019, 28, 1–8. [Google Scholar] [CrossRef]

- Enyi, C.C.; Aigbodion, V.S.; Akinlabi, E.T.; Mgbemene, C.A. Electrochemical and mechanical study of co-deposited Zn–ZnO-snail shell particles composites coating on mild steel. Int. J. Adv. Manuf. Technol. 2018, 96, 4313–4319. [Google Scholar] [CrossRef]

- Sydow, Z.; Bieńczak, K. The overview on the use of natural fibers reinforced composites for food packaging. J. Nat. Fibers 2019, 16, 1189–1200. [Google Scholar] [CrossRef]

- Pani, B.; Chandrasekhar, P.; Singh, S. A Study on Erosion wear Behavior of Iron-Mud/Glass Fiber Reinforced Epoxy Composite. IOP Conf. Ser. Mater. Sci. Eng. 2018, 455. [Google Scholar] [CrossRef]

- Pani, B.; Chandrasekhar, P.; Singh, S. Three Body Abrasion Wear Behavior of Iron-Mud/Glass Fiber Reinforced Epoxy Composite. Mater. Today Proc. 2018, 5, 27845–27851. [Google Scholar] [CrossRef]

- Pani, B.; Chandrasekhar, P.; Singh, S. Application of box-behnken design and neural computation for tribo-mechanical performance analysis of iron-mud-filled glass-fiber/epoxy composite and parametric optimization using PSO. Polym. Compos. 2019, 40, 1433–1449. [Google Scholar] [CrossRef]

- Pani, B.; Chandrasekhar, P.; Singh, S. Investigation of erosion behaviour of an iron-mud filled glass-fibre epoxy hybrid composite. Bull. Mater. Sci. 2019, 42, 1–13. [Google Scholar] [CrossRef]

- Biswas, S.; Satapathy, A. Tribo performance analysis of red mud filled glass-epoxy composites using Taguchi experimental design. Mater. Des. 2009, 30, 2841–2853. [Google Scholar] [CrossRef]

- Biswas, S.; Satapathy, A. A comparative study on erosion characteristics of red mud filled bamboo-epoxy and glass-epoxy composites. Mater. Des. 2010, 31, 1752–1767. [Google Scholar] [CrossRef]

- Siddhartha, S.; Singh, A.K.; Yadav, S. Exploring the Possibility of Utilization of Red Mud Epoxy Based Functionally Graded Materials as Wear-Resistant Materials Using Taguchi Design of Experiment. Adv. Polym. Technol. 2017, 36, 5–22. [Google Scholar] [CrossRef]

- Pati, P.R.; Satapathy, A. A Study on Processing, Characterization and Erosion Wear Response of Linz-Donawitz Slag Filled Epoxy Composites. Adv. Polym. Technol. 2015, 34, 1–8. [Google Scholar] [CrossRef]

- Pati, P.R.; Satapathy, A. Prediction and simulation of wear response of Linz-Donawitz (LD) slag filled glass-epoxy composites using neural computation. Polym. Adv. Technol. 2015, 26, 121–127. [Google Scholar] [CrossRef]

- Purohit, A.; Satapathy, A. Erosion wear response of epoxy composites filled with steel industry slag and sludge particles: A comparative study. IOP Conf. Ser. Mater. Sci. Eng. 2018, 338. [Google Scholar] [CrossRef]

- Purohit, A.; Satapathy, A. Processing, characterization, and parametric analysis of erosion behavior of epoxy-LD sludge composites using Taguchi technique and response surface method. Polym. Compos. 2018, 39, E2283–E2297. [Google Scholar] [CrossRef]

- Purohit, A.; Satapathy, A. Epoxy matrix composites filled with micro-sized LD sludge: Wear characterization and analysis. IOP Conf. Ser. Mater. Sci. Eng. 2016, 115. [Google Scholar] [CrossRef]

- Purohit, A.; Satapathy, A. Dry Sliding Wear Characteristics of Epoxy Composites Filled with Steel Industry Slag and Sludge Particles: A Comparative Study. Mater. Today Proc. 2018, 5, 11906–11913. [Google Scholar] [CrossRef]

- Erdoğan, A.; Gök, M.S.; Koç, V.; Günen, A. Friction and wear behavior of epoxy composite filled with industrial wastes. J. Clean. Prod. 2019, 237. [Google Scholar] [CrossRef]

- Uygunoglu, T.; Gunes, I.; Brostow, W. Physical and mechanical properties of polymer composites with high content of wastes incluDing boron. Mater. Res. 2015, 18, 1188–1196. [Google Scholar] [CrossRef]

- Uygunoglu, T.; Brostow, W.; Gunes, I. Wear and friction of composites of an epoxy with boron containing wastes. Polimeros 2015, 25, 271–276. [Google Scholar] [CrossRef]

- Ruggiero, A.; D’Agostino, V.; Merola, M.; Valášek, P.; Dedicova, K. Friction and wear characterization of a new ecological composite: Glass waste beads reinforced epoxy. Int. J. Mech. 2016, 10, 27–32. [Google Scholar]

- Pati, P.R. Prediction and wear performance of red brick dust filled glass–epoxy composites using neural networks. Int. J. Plast. Technol. 2019, 23, 253–260. [Google Scholar] [CrossRef]

- Choudhary, M.; Singh, T.; Dwivedi, M.; Patnaik, A. Waste marble dust-filled glass fiber-reinforced polymer composite Part I: Physical, thermomechanical, and erosive wear properties. Polym. Compos. 2019, 40, 4113–4124. [Google Scholar] [CrossRef]

- Ray, S.; Rout, A.K.; Sahoo, A.K. A study on tribological behavior of glass-epoxy composite filled with granite dust. IOP Conf. Ser. Mater. Sci. Eng. 2017, 225, 1–8. [Google Scholar] [CrossRef]

- Das, P.; Satapathy, A.; Mishra, M.K. Development and Sliding Wear Response of Epoxy Composites Filled with Coal Mine Overburden Material. IOP Conf. Ser. Mater. Sci. Eng. 2018, 338. [Google Scholar] [CrossRef]

- Acikbas, G.; Yaman, B. Wear response of glass fiber and ceramic tile-reinforced hybrid epoxy matrix composites. Iran. Polym. J. 2019, 28, 21–29. [Google Scholar] [CrossRef]

- Jena, H.; Pradhan, A.K.; Pandit, M.K. Study of Solid Particle Erosion Wear Behavior of Bamboo Fiber Reinforced Polymer Composite with Cenosphere Filler. Adv. Polym. Technol. 2018, 37, 761–769. [Google Scholar] [CrossRef]

- D’Almeida, J.R.M.; Ribeiro, F.L.; Alves, I.G. Wear behavior of a polymer-matrix composite reinforced with residues from a hydrometallurgical process. Polym. Plast. Technol. Eng. 2009, 48, 1304–1309. [Google Scholar] [CrossRef]

- Pati, P.R.; Prasad Satpathy, M.; Satapathy, A. Experimental investigation on Linz-Donawitz slag filled polypropylene composites using teaching-learning based optimization approach. Polym. Compos. 2018, 39, 3944–3951. [Google Scholar] [CrossRef]

- Padhi, P.K.; Satapathy, A. Processing and wear analysis of blast furnace slag filled polypropylene composites using Taguchi model and ANN. Int. Polym. Process. 2014, 29, 233–244. [Google Scholar] [CrossRef]

- Samat, N.; Sabaruddin, F.A.; Meor Yusoff, M.S.; Dayang Habibah, A.I.H. Evaluation of Waste from Aluminum Industry as Filler in Polypropylene Composites. JOM 2017, 69, 790–795. [Google Scholar] [CrossRef]

- Aslan, M.; Tufan, M.; Küçükömeroğlu, T. Tribological and mechanical performance of sisal-filled waste carbon and glass fibre hybrid composites. Compos. Part B Eng. 2018, 140, 241–249. [Google Scholar] [CrossRef]

- Erdogan, A.; Gök, M.S.; Kurşuncu, B.; Kiraz, T.; Demirel, B. Mechanical and tribological properties of waste iron scale reinforced polypropylene composite. Ind. Lubr. Tribol. 2020. [Google Scholar] [CrossRef]

- Sufian, A.S.; Samat, N.; Sulaiman, M.Y.M.; Paulus, W. Alumina Recovery from Industrial Waste: Study on the Thermal, Tensile and Wear Properties of Polypropylene/Alumina Nanocomposites. Int. J. Precis. Eng. Manuf. Green Technol. 2020, 7, 163–172. [Google Scholar] [CrossRef]

- Ray, S.; Kumar Rout, A.; Kumar Sahoo, A. A comparative analysis of the abrasion wear characteristics of industrial wastes filled glass/polyester composites based on the design of experiment and neural network. Polym. Compos. 2020, 1–15. [Google Scholar] [CrossRef]

- Bishoyee, N.; Dash, A.; Mishra, A.; Patra, S.; Mahapatra, S.S. A Grey-Based taguchi approach for characterization of erosive wear phenomenon of Glass-Polyester fly ash filled composites. J. Polym. Environ. 2010, 18, 177–187. [Google Scholar] [CrossRef]

- Ray, S.; Kumar Rout, A.; Kumar Sahoo, A. Development and characterization of glass/polyester composites filled with industrial wastes using statistical techniques. Indian J. Eng. Mater. Sci. 2018, 25, 169–182. [Google Scholar]

- Suresh, S.; Sudhakara, D. Investigation of Mechanical and Tribological Properties of Red Mud-Reinforced Particulate Polymer Composite. J. Bio Tribo Corros. 2019, 5. [Google Scholar] [CrossRef]

- Richard, S.; SelwinRajadurai, J.; Manikandan, V.; Chithambara Thanu, M.; Arumugaprabu, V.; Deepak Joel Johnson, R. Study of Tribological Properties of Nano-Sized Red Mud Particle-Reinforced Polyester Composites. Trans. Indian Inst. Met. 2019, 72, 2417–2431. [Google Scholar] [CrossRef]

- Sundarakannan, R.; Arumugaprabu, V.; Manikandan, V.; Deepak Joel Johnson, R. Tribo Performance Studies on Redmud Filled Pineapple Fiber Composite. Mater. Today Proc. 2020, 24, 1225–1234. [Google Scholar] [CrossRef]

- Nayak, S.K.; Satapathy, A.; Mantry, S. Processing and wear response study of glass-polyester composites with waste marble dust as particulate filler. Polym. Compos. 2020, 41, 2263–2273. [Google Scholar] [CrossRef]

- Nayak, S.K.; Satapathy, A.; Mantry, S. Wear characteristics of glass-polyester-based hybrid composites: A parametric analysis using response surface method and fuzzy logic. Polym. Compos. 2020, 41, 3687–3697. [Google Scholar] [CrossRef]

- Alameri, I.; Oltulu, M. Mechanical properties of polymer composites reinforced by silica-based materials of various sizes. Appl. Nanosci. 2020, 10, 4087–4102. [Google Scholar] [CrossRef]

- Chand, N.; Sharma, P.; Fahim, M. Correlation of mechanical and tribological properties of organosilane modified cenosphere filled high density polyethylene. Mater. Sci. Eng. A 2010, 527, 5873–5878. [Google Scholar] [CrossRef]

- Binda, F.F.; De Alvarenga Oliveira, V.; Fortulan, C.A.; Palhares, L.B.; Dos Santos, C.G. Friction elements based on phenolic resin and slate powder. J. Mater. Res. Technol. 2020, 9, 3378–3383. [Google Scholar] [CrossRef]

- Xiang, D.; Tao, K. The mechanical and tribological properties of PTFE filled with PTFE waste powders. J. Appl. Polym. Sci. 2007, 103, 1035–1041. [Google Scholar] [CrossRef]

- Myalski, J.; Godzierz, M.; Olesik, P. Effect of carbon fillers on the wear resistance of pa6 thermoplastic composites. Polymers 2020, 12, 2264. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Schlarb, A.K. Recycled carbon fibers as reinforcements for hybrid PEEK composites with excellent friction and wear performance. Wear 2019, 432–433, 202928. [Google Scholar] [CrossRef]

- Uthayakumar, M.; Kumaran, S.T.; Aravindan, S. Dry sliding friction and wear studies of fly ash reinforced AA-6351 metal matrix composites. Adv. Tribol. 2013, 2013. [Google Scholar] [CrossRef]

- Rani Panda, S.; Bhusan Rajguru Mohapatro, M.; Chandra Mishra, P. Investigation on frictional and machining characteristics of novel ALFA composite reinforced with treated waste fly ash. Mater. Today Proc. 2018, 5, 19728–19737. [Google Scholar] [CrossRef]

- Dinaharan, I.; Nelson, R.; Vijay, S.J.; Akinlabi, E.T. Microstructure and wear characterization of aluminum matrix composites reinforced with industrial waste fly ash particulates synthesized by friction stir processing. Mater. Charact. 2016, 118, 149–158. [Google Scholar] [CrossRef]

- Patil, N.A.; Pedapati, S.R.; Bin Mamat, O.; Hidayat Syah Lubis, A.M. Effect of SiC/fly ash reinforcement on surface properties of aluminum 7075 hybrid composites. Coatings 2020, 10, 541. [Google Scholar] [CrossRef]

- Bera, T.; Acharya, S.K. Utilization of Fly Ash Cenosphere as Reinforcement for Abrasive Wear Behaviour of LM6 Al Alloy Metal Matrix Composites. Iran. J. Sci. Technol. Trans. Mech. Eng. 2019, 43, 273–280. [Google Scholar] [CrossRef]

- Devi Chinta, N.; Selvaraj, N.; Mahesh, V. Characterization of aluminium-red mud-tungsten carbide hybrid metal matrix composite. In Proceedings of the 2016 International Conference on Electrical, Electronics, and Optimization Techniques (ICEEOT), Chennai, India, 3–5 March 2016; pp. 3722–3725. [Google Scholar] [CrossRef]

- Singla, Y.K.; Chhibber, R.; Bansal, H.; Kalra, A. Wear Behavior of Aluminum Alloy 6061-Based Composites Reinforced with SiC, Al2O3, and Red Mud: A Comparative Study. JOM 2015, 67, 2160–2169. [Google Scholar] [CrossRef]

- Kumar, H.; Prasad, R.; Kumar, P.; Tewari, S.P.; Singh, J.K. Mechanical and tribological characterization of industrial wastes reinforced aluminum alloy composites fabricated via friction stir processing. J. Alloys Compd. 2020, 831. [Google Scholar] [CrossRef]

- Prabhakaran, A.; Arul, S. Characterisation of aluminium alloy (Lm6) metal matrix composite reinforced with copper slag/ferro sand. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 3579–3583. [Google Scholar] [CrossRef]

- Lokanadham, D.; Subbaiah, K.V. Estimation of wear behavioural response of al-limestone slurry composite using taguchi orthogonal array. Tribol. Ind. 2020, 42, 419–427. [Google Scholar] [CrossRef]

- Ashok Kumar, R.; Devaraju, A. Modeling of Mechanical Properties and High Temperature Wear Behavior of Al7075/SiC/CRS Composite Using RSM. Silicon 2020. [Google Scholar] [CrossRef]

- Mandal, A.K.; Sinha, O.P. New-Generation Aluminum Composite with Bottom Ash Industrial Waste. JOM 2018, 70, 811–816. [Google Scholar] [CrossRef]

- Sridhar Raja, K.S.; Bupesh Raja, V.K.; Gupta, M. Using anthropogenic waste (steel slag) to enhance mechanical and wear properties of a commercial aluminium alloy A356. Arch. Metall. Mater. 2019, 64, 279–284. [Google Scholar] [CrossRef]

- Xavier, L.F.; Suresh, P. Wear Behavior of Aluminium Metal Matrix Composite Prepared from Industrial Waste. Sci. World J. 2016, 2016. [Google Scholar] [CrossRef] [PubMed]

- Satyanarayana, T.; Rao, P.S.; Krishna, M.G. Influence of wear parameters on friction performance of A356 aluminum-graphite/granite particles reinforced metal matrix hybrid composites. Heliyon 2019, 5, e01770. [Google Scholar] [CrossRef]

- Krishnan, P.K.; Christy, J.V.; Arunachalam, R.; Mourad, A.H.I.; Muraliraja, R.; Al-Maharbi, M.; Murali, V.; Chandra, M.M. Production of aluminum alloy-based metal matrix composites using scrap aluminum alloy and waste materials: Influence on microstructure and mechanical properties. J. Alloys Compd. 2019, 784, 1047–1061. [Google Scholar] [CrossRef]

- Zheng, K.L.; Wei, X.S.; Yan, B.; Yan, P.F. Ceramic waste SiC particle-reinforced Al matrix composite brake materials with a high friction coefficient. Wear 2020, 458–459, 203424. [Google Scholar] [CrossRef]

- Aherwar, A.; Patnaik, A.; Pruncu, C.I. Effect of B4C and waste porcelain ceramic particulate reinforcements on mechanical and tribological characteristics of high strength AA7075 based hybrid composite. J. Mater. Res. Technol. 2020, 9, 9882–9894. [Google Scholar] [CrossRef]

- Zikin, A.; Ilo, S.; Kulu, P.; Hussainova, I.; Katsich, C.; Badisch, E. Plasma transferred arc (PTA) hardfacing of recycled hardmetal reinforced nickel-matrix surface composites. Medziagotyra 2012, 18, 12–17. [Google Scholar] [CrossRef]

- Gangwar, S.; Bhat, I.K.; Patnaik, A. Tribological and Microstructure Examination of Environmental Waste (Marble Dust) Filled Silicon Bronze Alloy for Wear Resistant Applications. Silicon 2017, 9, 249–263. [Google Scholar] [CrossRef]

- Rajak, S.K.; Aherwar, A.; Pruncu, C.I. Mechanical and tribological properties of composite made of marble dust-reinforced C93200 copper alloy. Mater. Res. Express 2019, 7. [Google Scholar] [CrossRef]

- Khan, A.; Jagdale, P.; Rovere, M.; Nogués, M.; Rosso, C.; Tagliaferro, A. Carbon from waste source: An eco-friendly way for strengthening polymer composites. Compos. Part. B Eng. 2018, 132, 87–96. [Google Scholar] [CrossRef]

- Khan, A.; Jagdale, P.; Castellino, M.; Rovere, M.; Jehangir, Q.; Mandracci, P.; Rosso, C.; Tagliaferro, A. Innovative functionalized carbon fibers from waste: How to enhance polymer composites properties. Compos. Part. B Eng. 2018, 139, 31–39. [Google Scholar] [CrossRef]

- Sabaa, Z.M.; Fahad, B.M. Glass and Porcelain Waste as Abrasives Investigated at Different Conditions. IOP Conf. Ser. Mater. Sci. Eng. 2018, 454. [Google Scholar] [CrossRef]

- Sivaraos; Yap, T.C.; Qumrul; Amran, M.A.; Anand, T.J.S.; Izamshah, R.; Aziz, A.A. Friction performance analysis of waste tire rubber powder reinforced polypropylene using pin-on-disk tribometer. Procedia Eng. 2013, 68, 743–749. [Google Scholar] [CrossRef]

- Mutlu, I.; Sugözü, I.; Keskin, A. The effects of porosity in friction performance of brake pad using waste tire dust. Polimeros 2015, 25, 440–446. [Google Scholar] [CrossRef]

- Olesik, P.; Godzierz, M.; Kozioł, M. Preliminary characterization of novel LDPE-based wear-resistant composite suitable for FDM 3D printing. Materials 2019, 12, 2520. [Google Scholar] [CrossRef] [PubMed]

- Petrova, P.N.; Okhlopkova, A.A.; Fedorov, A.L. Prospective uses of waste engine oils to improve the wear resistance of polytetrafluoroethylene. J. Frict. Wear 2015, 36, 9–14. [Google Scholar] [CrossRef]

- Ruzaidi, C.M.; Khoni, N.A.A.; Suriani, M.J.; Abdullah, W.R.W.; Abdullah, M.M.A. Effect of Waste Tire Dust on the Hardness and Wear Rate of Palm Slag Friction Composites. IOP Conf. Ser. Mater. Sci. Eng. 2020, 864. [Google Scholar] [CrossRef]

- Gopal, P.M.; Kavimani, V. Influence of Silica Rich CRT and BN on Mechanical, Wear and Corrosion Characteristics of Copper- Surface Composite Processed Through Friction Stir Processing. Silicon 2020. [Google Scholar] [CrossRef]

- Saravanan, S.D.; Senthilkumar, M.; Shankar, S. Effect of particle size on tribological behavior of rice husk ash-reinforced aluminum alloy (alsi10mg) matrix composites. Tribol. Trans. 2013, 56, 1156–1167. [Google Scholar] [CrossRef]

- Slorach, P.C.; Jeswani, H.K.; Cuéllar-Franca, R.; Azapagic, A. Environmental and economic implications of recovering resources from food waste in a circular economy. Sci. Total Environ. 2019, 693. [Google Scholar] [CrossRef]

- Fidelis, M.; de Moura, C.; Kabbas, T.; Pap, N.; Mattila, P.; Mäkinen, S.; Putnik, P.; Kovačević, D.B.; Tian, Y.; Yang, B.; et al. Fruit seeds as sources of bioactive compounds: Sustainable production of high value-added ingredients from by-products within circular economy. Molecules 2019, 24, 3854. [Google Scholar] [CrossRef]

- Ordoudi, S.A.; Bakirtzi, C.; Tsimidou, M.Z. The potential of tree fruit stone and seed wastes in Greece as sources of bioactive ingredients. Recycling 2018, 3, 9. [Google Scholar] [CrossRef]

- Yılmaz, F.M.; Görgüç, A.; Karaaslan, M.; Vardin, H.; Ersus Bilek, S.; Uygun, Ö.; Bircan, C. Sour Cherry By-products: Compositions, Functional Properties and Recovery Potentials–A Review. Crit. Rev. Food Sci. Nutr. 2019, 59, 3549–3563. [Google Scholar] [CrossRef] [PubMed]

- Stanescu, M.D. State of the art of post-consumer textile waste upcycling to reach the zero waste milestone. Environ. Sci. Pollut. Res. 2021. [Google Scholar] [CrossRef]

| Matrix/Mixture | Waste Filler | Reference | |

|---|---|---|---|

| Epoxy | Jatropha curcas L. fibers | [6,7,8] | |

| Sugarcane bagasse ash | [9,10] | ||

| Palm kernel fibers | [11,12] | ||

| Pawpaw stem fibers | [13] | ||

| Arhar stalks | [14] | ||

| Pongamia pinnata seed cake | [15] | ||

| Bovine femur ash | [16] | ||

| Phoenix dactylifera (L.) fruits (dates): date Stones, date flesh | [17] | ||

| Human hair | [18] | ||

| Tasar silk and jute fiber | [19] | ||

| Citrus limetta peel | [20] | ||

| Oil palm fruits | [21] | ||

| African land snail shells/mollusk shell | [4] | ||

| Polypropylene | Rice husk ash | [22] | |

| Wood flour | [23] | ||

| Nutraceutical industrial coriander seed spent, and congo red dye adsorbed onto nutraceutical industrial coriander seed | [24] | ||

| Polyester | Soap nuts, Aegle marmelos, Terminalia chebula seeds | [25] | |

| Bovine hair fibers | [26] | ||

| Palm fronds and mango’s dry leaves | [27] | ||

| Colombian Musaceae | [28] | ||

| Recycled waste plastics (type non-specified) | Mussel shells | [29] | |

| Polyvinyl chloride | Olive stone flour | [30] | |

| Rice husk ash | [31] | ||

| Polyethylene | Snail shell | [32] | |

| Chicken eggshell | [33] | ||

| Polyphenylene sulfide | Mussel shells | [34] | |

| Rubber mix | Eggshells, fishbones | [35] | |

| Mixture: silica from Aswan desert; commercial carbon; barium sulfate; metallic powder, phenol–formaldehyde resins | Fibers of corn, palm, and sugar bars | [36] | |

| Mixture: Al2O3, rock wool, carbon fiber, glass fiber, steel fiber, SiO2, MgO, graphite, brass powder, vermiculite, phenolic resin, calcium carbonate and barite | Banana peel, bagasse fiber | [37] | |

| Mixture: vermiculite powder, compound mineral fibers, calcium carbonate, coke, graphite, friction powder, zirconium silicate, alumina, barium sulfate, zinc stearate, phenolic resin | Cornstalk | [38] | |

| Mixture: graphite, coke, zinc stearate, vermiculite powder, calcium carbonate, zirconium silicate, alumina, compound mineral fibers, friction powder, phenolic resin and barium sulfate. | Cow dung fibers, corn stalk fibers | [39] | |

| Mixture: aluminum, graphite, zirconia oxide, silicon carbide, titanium oxide, phenolic resin | Coconut fiber | [40] | |

| Aluminum | AA6351 | Rice husk ash | [41] |

| pure aluminum | [42] | ||

| A356.2 | [43] | ||

| Al-4.5% Cu | Bamboo leaf ash | [44,45] | |

| Pure aluminum | Eggshell | [2] | |

| Al-1.5Sn-1.5Mg | [46] | ||

| Al6061 | [47] | ||

| AA2014 | [48] | ||

| AA1200 | Coconut shell ash | [49] | |

| Al110 | [50] | ||

| Al7075 | [51] | ||

| Al-Si10-Mg | Sugarcane bagasse ash | [9] | |

| Al5056 | [10] | ||

| A2009 | Bean pod ash | [52] | |

| Al-12% Si | Melon shell ash | [53] | |

| Al7075 | Cow dung ash | [3] | |

| Al1100 | Palm kernel shell ash | [54] | |

| Al-7Si-0.3Mg | Rice husk ash, fly ash (industrial waste) | [55] | |

| Al6061 | [56] | ||

| A356 | [57] | ||

| AZ91D | Eggshell, rice husk ash | [58,59] | |

| Al6063 | Straw ash, met coke ash (industrial waste) | [60] | |

| Zn-ZnO | Snail shell | [61] | |

| Matrix | Waste Filler | Reference | |

|---|---|---|---|

| Epoxy resin | Iron mud | [63,64,65,66] | |

| Red mud | [67,68,69] | ||

| Linz–Donawitz slag | [70,71,72] | ||

| Linz–Donawitz sludge | [72,73,74,75] | ||

| Blast furnace slag | [72,75,76] | ||

| Ferrochromium slag | [76] | ||

| Converter slag | [76] | ||

| Boron wastes | [77,78] | ||

| Glass beads | [79] | ||

| Red brick dust | [80] | ||

| Marble dust | [81] | ||

| Granite dust | [82] | ||

| Coal mine overburden | [83] | ||

| Glass fiber waste and wall tile waste | [84] | ||

| Cenosphere (from power plants) | [85] | ||

| Wastes from hydrometallurgical zinc plant | [86] | ||

| Polypropylene | Linz–Donawitz slag | [87] | |

| Blast furnace slag | [88] | ||

| White aluminum dross | [89] | ||

| E-glass fiber, carbon fibers | [90] | ||

| Iron scale | [91] | ||

| Alumina | [92] | ||

| Polyester | Fly ash | [93,94,95] | |

| Granite dust | [93,95] | ||

| Red mud | [96,97,98] | ||

| Marble dust | [99,100,101] | ||

| Polyethylene | Fly ash cenosphere | [102] | |

| Phenolic resin | Slate powder | [103] | |

| Polytetrafluoroethylene | Waste polytetrafluoroethylene | [104] | |

| Polyamide | Biocarbon obtained from the pyrolysis of polymer wastes | [105] | |

| Polyether ether ketone polymer matrix | Recycled carbon fibers | [106] | |

| Aluminum | AA6351 | Fly ash | [107] |

| Al-Si | [108] | ||

| AA6061 | [109] | ||

| Al7075 | [110] | ||

| AlLM6 | [111] | ||

| Pure aluminum | Red mud | [112] | |

| Al6061 | [113] | ||

| A356 | Fly ash and red mud | [114] | |

| AlLM6 | Copper slag | [115] | |

| Al-Mg-Si | Limestone slurry powder | [116] | |

| Al7075 | Crushed rock sand | [117] | |

| Pure aluminum | Bottom ash from a pulverized coal combustion boiler | [118] | |

| AlA356 | Furnace steel slag | [119] | |

| Al6063 | Wet grinder stone dust | [120] | |

| AlA356 | Granite particulate | [121] | |

| AlSi7M | Spent alumina catalyst waste from oil refineries | [122] | |

| Al-Si | Ceramic particulates | [123] | |

| AA7075 | [124] | ||

| Nickel alloy | Recycled tungsten carbide and cobalt hard metal powder | [125] | |

| Silicon bronze alloy | Marble dust | [126] | |

| Copper alloy | Marble dust | [127] | |

| Matrix/Mixture | Waste Filler | Reference |

|---|---|---|

| Epoxy | Polyethylene bags | [128] |

| Waste clothes | [129] | |

| Porcelain tiles and window glass wastes | [130] | |

| Tire rubber | [5] | |

| Polypropylene | Tire rubber | [131] |

| Phenolic resin | Tire rubber | [132] |

| Polyethylene | Laminated car glass | [133] |

| Polytetrafluoroethylene | Waste engine oil used as a modifier of polytetrafluoroethylene | [134] |

| Mixture: polyester, metal fiber, alumina, graphite | Tire rubber, palm slag | [135] |

| Copper | Cathode ray tube | [136] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sydow, Z.; Sydow, M.; Wojciechowski, Ł.; Bieńczak, K. Tribological Performance of Composites Reinforced with the Agricultural, Industrial and Post-Consumer Wastes: A Review. Materials 2021, 14, 1863. https://doi.org/10.3390/ma14081863

Sydow Z, Sydow M, Wojciechowski Ł, Bieńczak K. Tribological Performance of Composites Reinforced with the Agricultural, Industrial and Post-Consumer Wastes: A Review. Materials. 2021; 14(8):1863. https://doi.org/10.3390/ma14081863

Chicago/Turabian StyleSydow, Zuzanna, Mateusz Sydow, Łukasz Wojciechowski, and Krzysztof Bieńczak. 2021. "Tribological Performance of Composites Reinforced with the Agricultural, Industrial and Post-Consumer Wastes: A Review" Materials 14, no. 8: 1863. https://doi.org/10.3390/ma14081863

APA StyleSydow, Z., Sydow, M., Wojciechowski, Ł., & Bieńczak, K. (2021). Tribological Performance of Composites Reinforced with the Agricultural, Industrial and Post-Consumer Wastes: A Review. Materials, 14(8), 1863. https://doi.org/10.3390/ma14081863