Microstructure Dependence of Effective Thermal Conductivity of EB-PVD TBCs

Abstract

1. Introduction

2. Experiments and Modeling

2.1. Specimen Preparation and Micrography Characterization

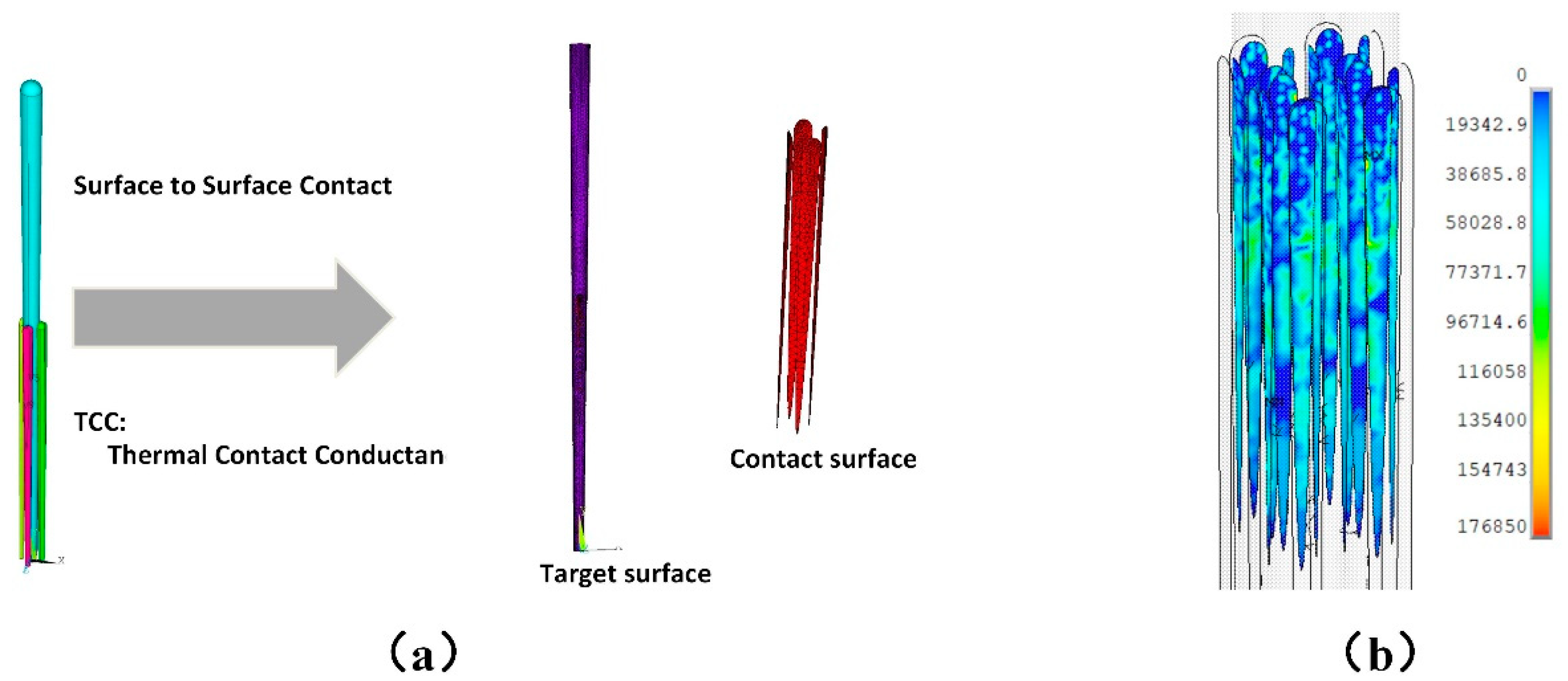

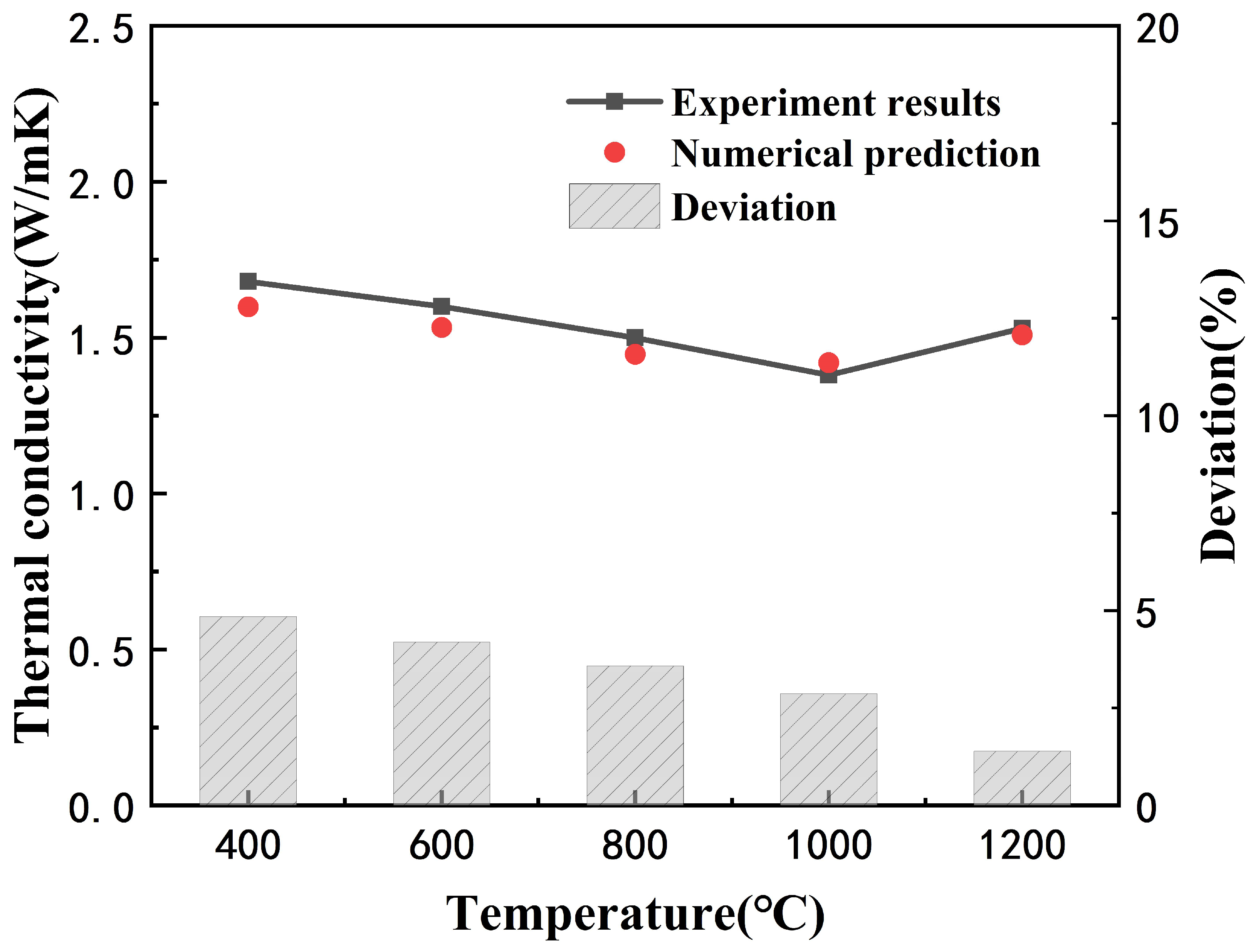

2.2. Modeling and Verification

3. Results and Discussion

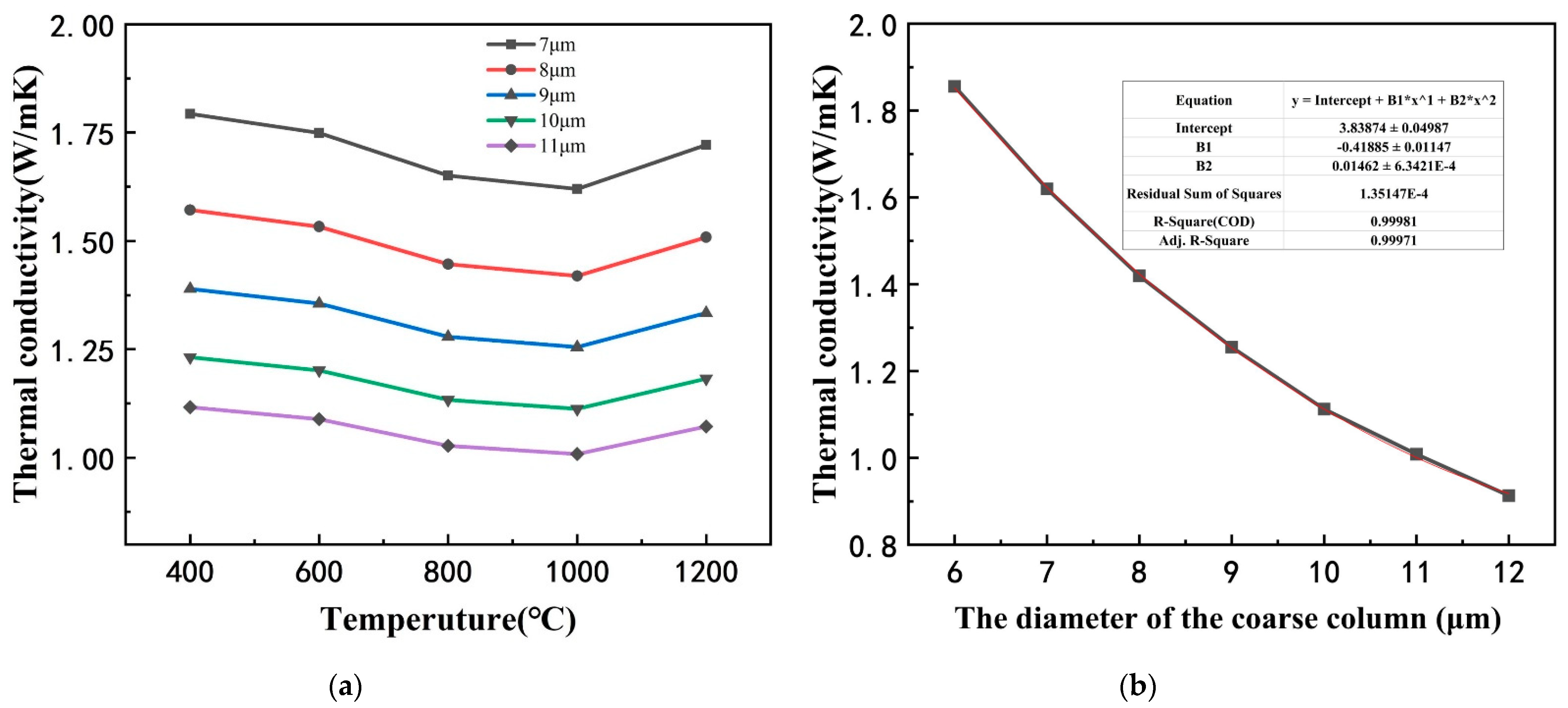

3.1. The Effect of Coarse Column Diameter on Effective Thermal Conductivity

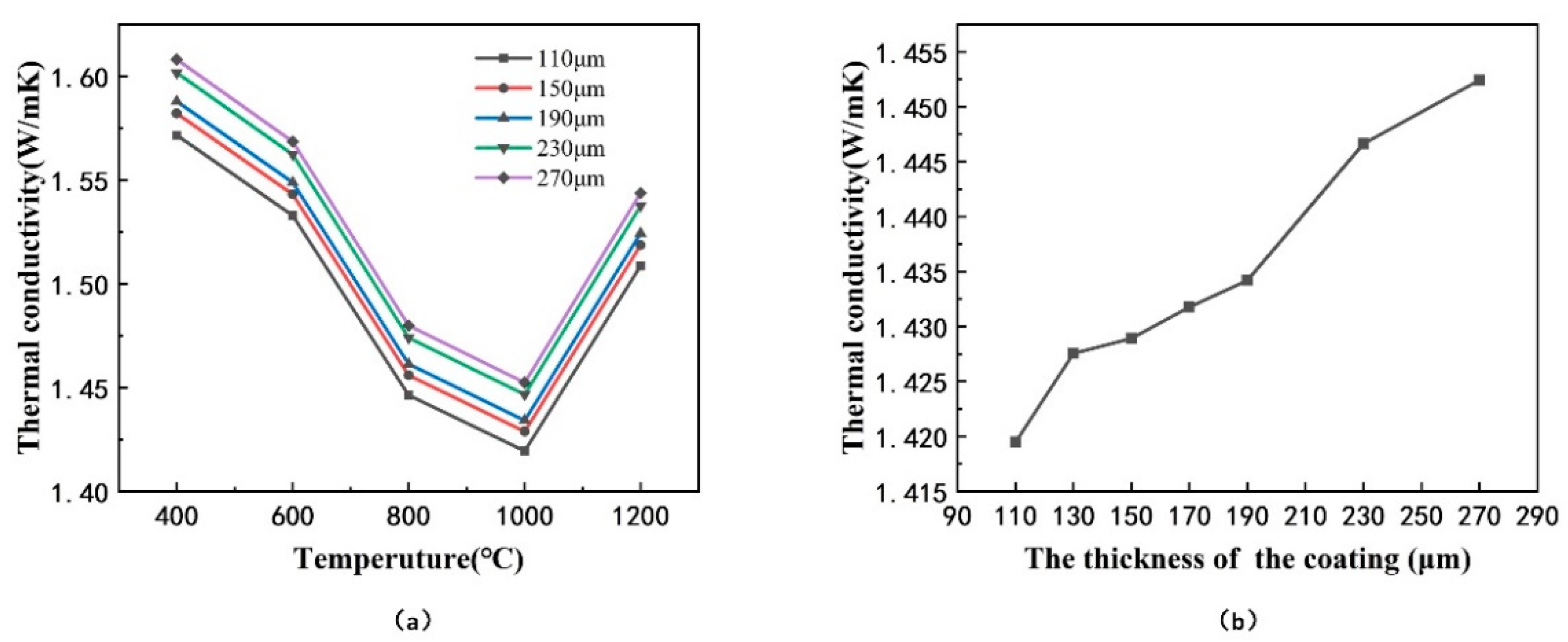

3.2. The Effect of the Thickness of Coatings on Effective Thermal Conductivity

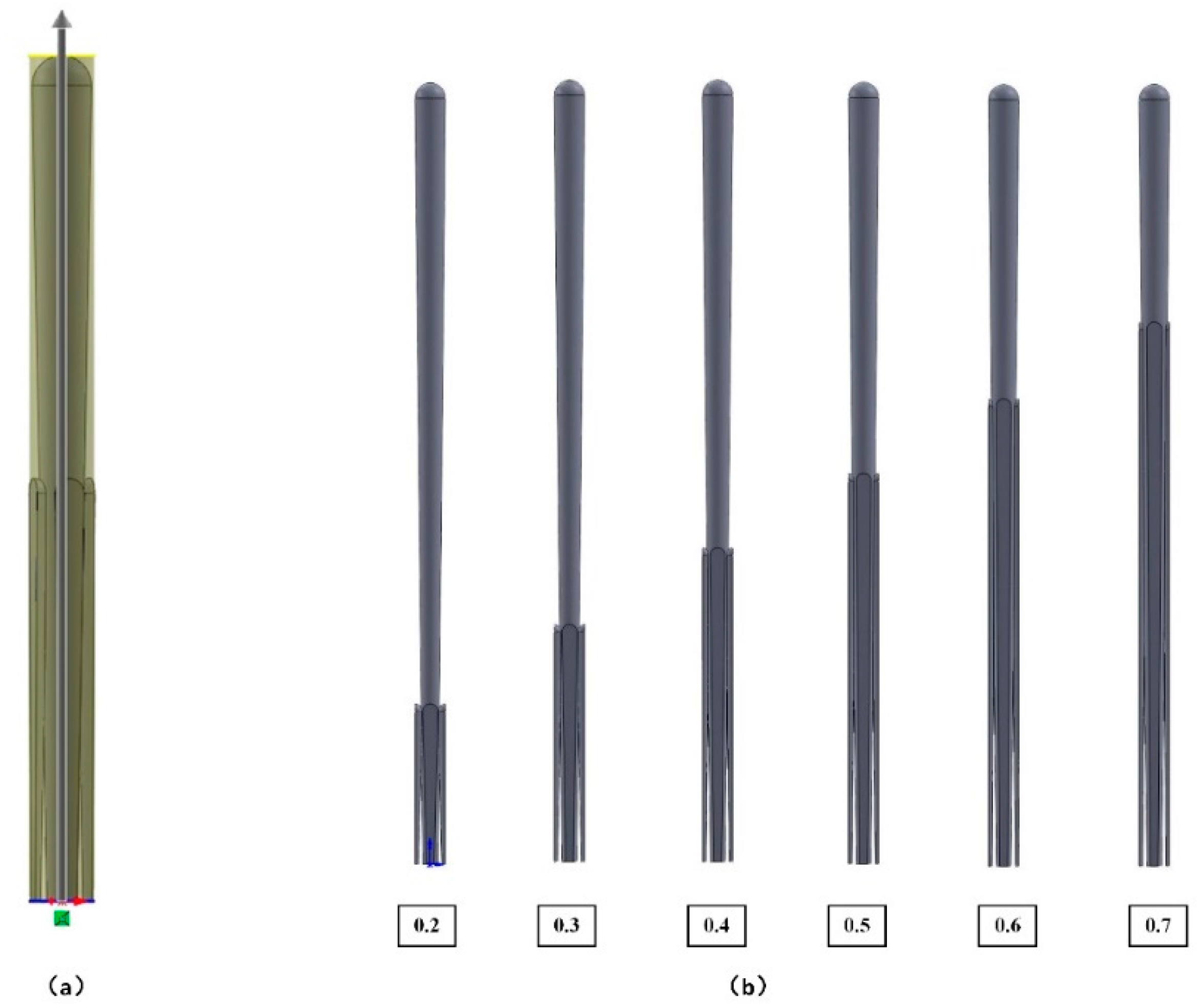

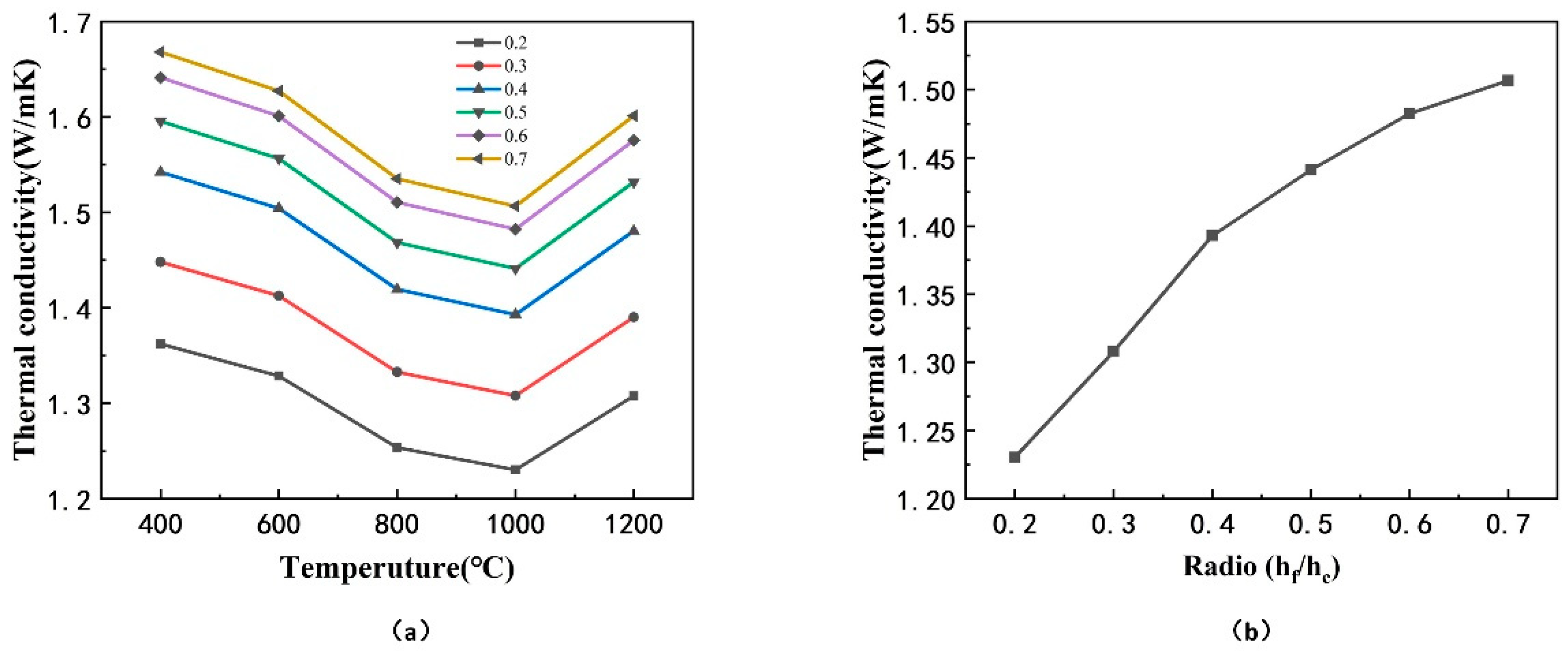

3.3. The Effect of the Ratio γ of the Height of Fine Column to Coarse Column on Effective Thermal Conductivity

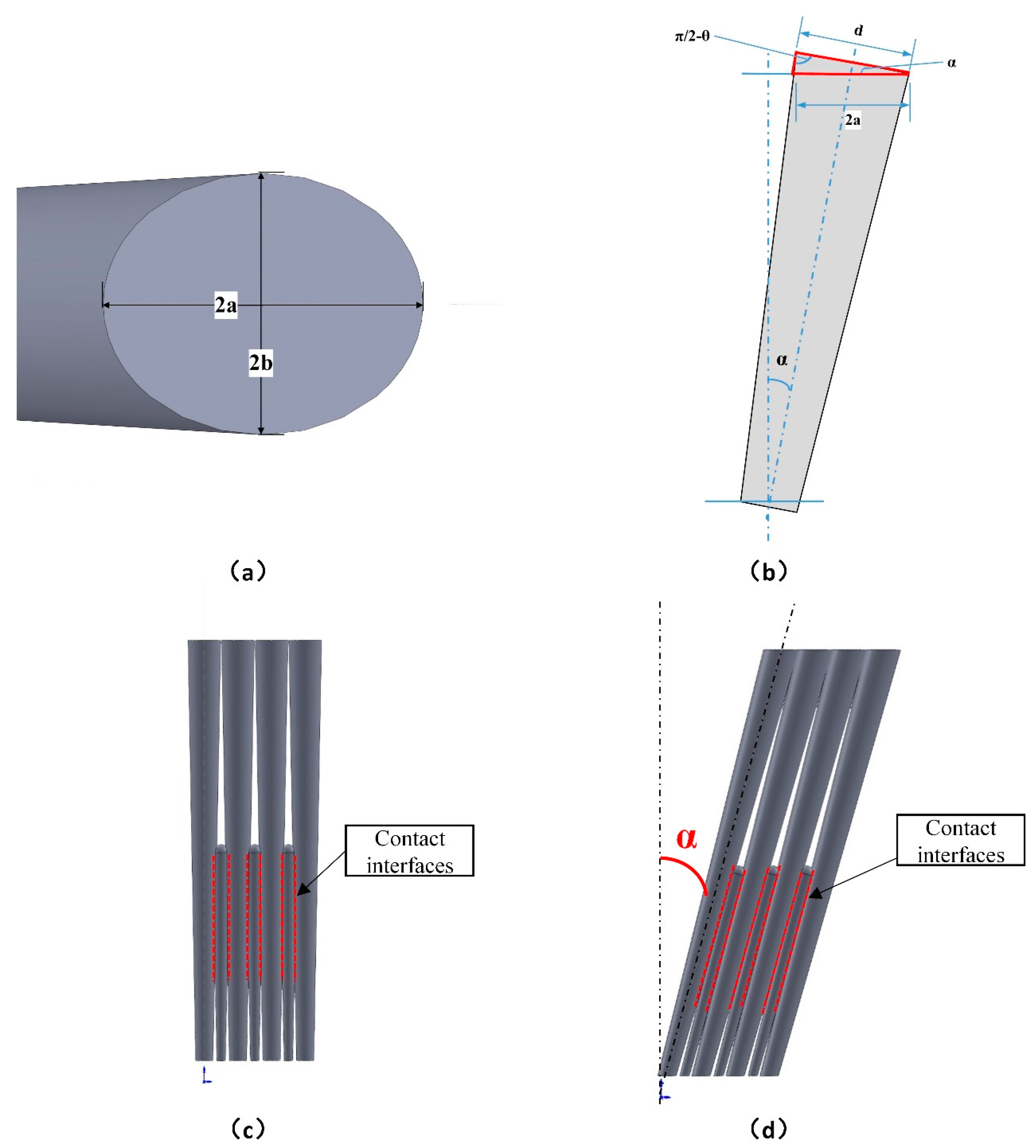

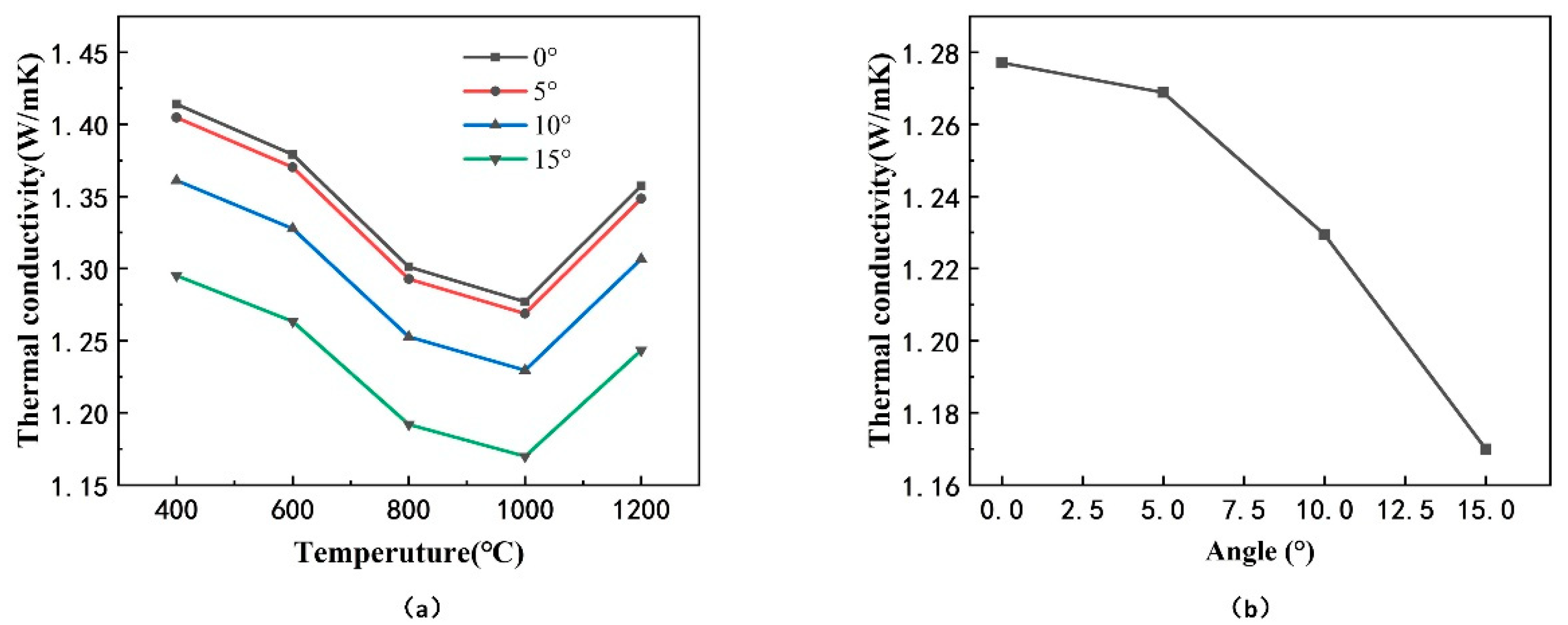

3.4. The Effect of the Inclination Angle α on Effective Thermal Conductivity

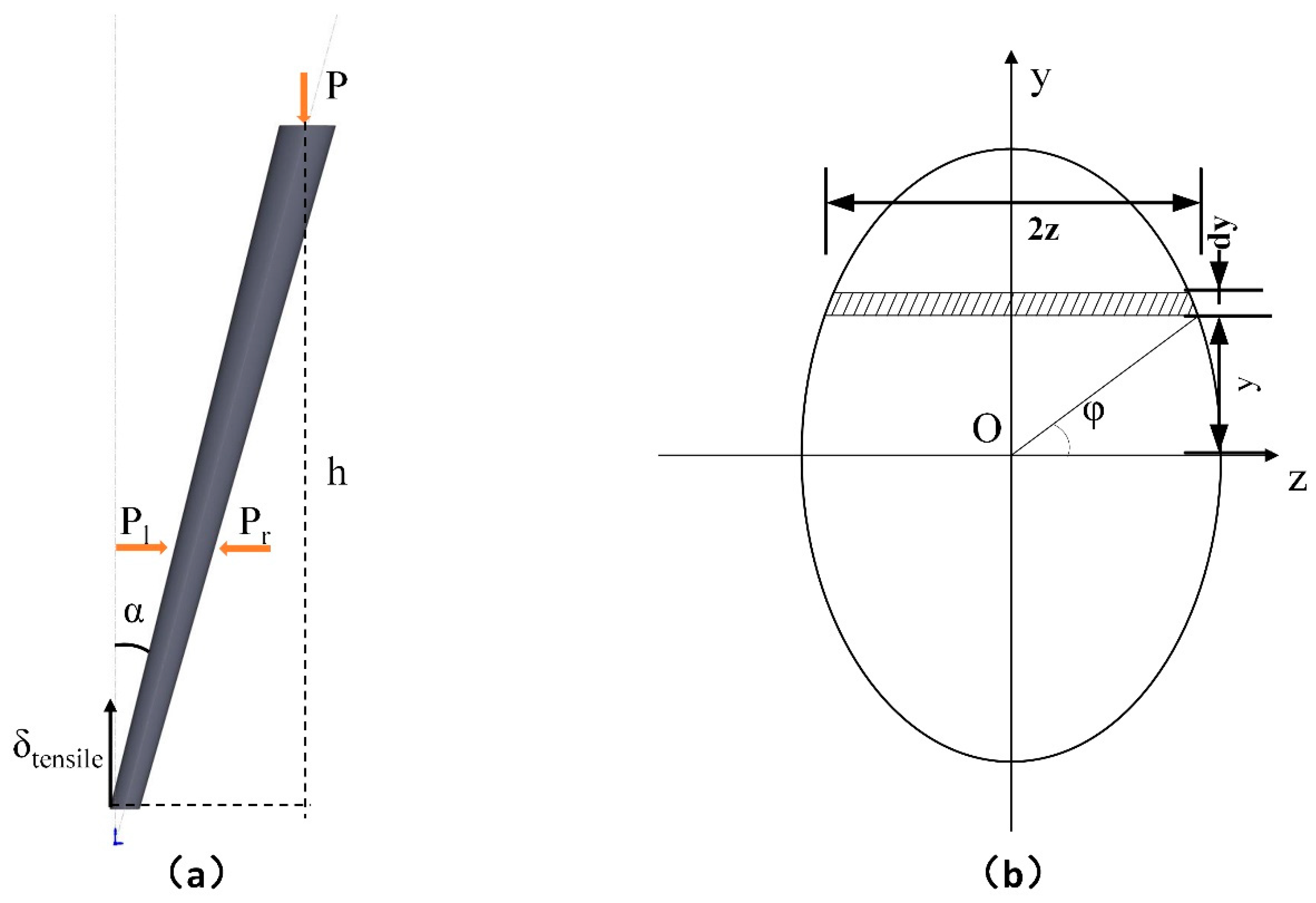

3.5. The Effect of Microstructural Parameters on Mechanical Stress

4. Conclusions

- (1)

- Increasing the inclination angle α (from 0° to 15°) of the columns could result in a decline of effective thermal conductivity (from 1.277 W/mK to 1.169 W/mK, at 1000 °C) and an increase of the mechanical stress at the root of the coating. The optimization of the inclination angle of the coating is proposed as:

- (2)

- Increasing the diameter of the coarse column could result in a decline of effective thermal conductivity, and an increase of the mechanical stress at the root of the coating when the columns of the coating is inclined. The function of effective thermal conductivity and column head diameter are shown in the following formula:

- (3)

- Increasing the thickness of the coating would lead to an increase of the effective thermal conductivity, and an increase of the mechanical stress at the root of the coating when the columns of the coating are inclined.

- (4)

- Increasing the ratio γ (from 0.2 to 0.7) of the height of fine column to coarse column in the coating would make the effective thermal conductivity (from 1.231 W/mK to 1.507 W/mK, at 1000 °C) increase, since the porosity decreases and the discontinuity in the horizontal direction of the coating decreases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| thermal conductivity | |

| effective thermal conductivity | |

| temperature difference per unit thickness | |

| density of the coating material | |

| specific heat capacity of the coating material | |

| total heat flow | |

| area of the top surface of the model | |

| temperature difference | |

| θ | taper of the coarse column |

| S | the longest heat transfer path per unit thickness |

| γ | ratio of the height of fine column to coarse column |

| p | porosity of the coating |

| height of the coarse column | |

| diameter of the coarse column | |

| height of the fine column | |

| diameter of the fine column | |

| α | inclination angle of the entire columns |

| stress of the root of column | |

| bending moment | |

| moment of inertia of section to neutral axis z | |

| p | external pressure on the top of the coating |

| diameter of the root of the column | |

| rectangle factor of the column |

References

- Jones, R.L. Thermal barrier coatings. In Metallurgical and Ceramic Protective Coatings; Stern, K.H., Ed.; Springer: Dordrecht, The Netherlands, 1996; pp. 194–235. [Google Scholar]

- Evans, A.G.; Mumm, D.R.; Hutchinson, J.W.; Meier, G.H.; Pettit, F.S. Mechanisms controlling the durability of thermal barrier coatings. Prog. Mater. Sci. 2011, 46, 505–553. [Google Scholar] [CrossRef]

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal Barrier Coatings for Gas-Turbine Engine Applications. Science 2002, 296, 280. [Google Scholar] [CrossRef] [PubMed]

- Tahir, A.; Li, G.R.; Liu, M.J.; Yang, G.J.; Li, C.X.; Wang, Y.Y.; Li, C.J. Improving WC–Co coating adhesive strength on rough substrate: Finite element modeling and experiment. J. Mater. Sci. Technol. 2020, 37, 1–8. [Google Scholar] [CrossRef]

- Meng, G.H.; Zhang, B.Y.; Liu, H.; Yang, G.J.; Xu, T.; Li, C.X.; Li, C.J. Vacuum heat treatment mechanisms promoting the adhesion strength of thermally sprayed metallic coatings. Surf. Coat. Technol. 2018, 344, 102–110. [Google Scholar] [CrossRef]

- Li, G.R.; Yang, G.J.; Li, C.X.; Li, C.J. Force transmission and its effect on structural changes in plasma-sprayed lamellar ceramic coatings. J. Eur. Ceram. Soc. 2017, 37, 2877. [Google Scholar] [CrossRef]

- Chen, L.; Yang, G.J. Epitaxial growth and cracking of highly tough 7YSZ splats by thermal spray technology. J. Adv. Ceram. 2018, 7, 17–29. [Google Scholar] [CrossRef]

- Strangman, T.E. Thermal barrier coatings for turbine airfoils. Thin Solid Film 1985, 127, 93–106. [Google Scholar] [CrossRef]

- Wang, M.; Wang, J.; Pan, N. Mesoscopic predictions of the effective thermal conductivity for microscale random porous media. Phys. Rev. E 2007, 75, 36–42. [Google Scholar] [CrossRef] [PubMed]

- Schulz, U.; Terry, S.G.; Levi, C.G. Microstructure and texture of EB-PVD TBCs grown under different rotation modes. Mater. Sci. Eng. A 2003, 360, 319–329. [Google Scholar] [CrossRef]

- Singh, J.; Wolfe, D.E.; Singh, J. Architecture of thermal barrier coatings produced by electron beam-physical vapor deposition (EB-PVD). J. Mater. Sci. 2002, 37, 3261. [Google Scholar] [CrossRef]

- Morrel, P.; Rickerby, D.S. Advantage & Disadvantages of Various TBC Systems as Perceived by the Engine Manufacturer; NATO Workshop on Thermal Barrier Coatings: Aalborg, Denmark, 1998; p. 20. [Google Scholar]

- Alperine, S.; Derrien, M.; Jaslier, Y.; Mevrel, R. Thermal Barrier Coatings: The Thermal Conductivity Challenge; NATO Workshop on Thermal Barrier Coatings: Aalborg, Denmark, 1998; p. 1. [Google Scholar]

- Hass, D.D.; Slifka, A.J.; Wadley, H.N.G. Low thermal conductivity vapor deposited zirconia microstructures. Acta Mater. 2001, 49, 973–983. [Google Scholar] [CrossRef]

- Singh, J.; Wolfe, D.E.; Miller, R.A.; Eldridge, J.I.; Zhu, D.M. Tailored microstructure of zirconia and hafnia-based thermal barrier coatings with low thermal conductivity and high hemispherical reflectance by EB-PVD. J. Mater. Sci. 2004, 39, 1975–1985. [Google Scholar] [CrossRef]

- Nicholls, J.R.; Lawson, K.J.; Johnstone, A.; Rickerby, D.S. Methods to reduce the thermal conductivity of EB-PVD TBCs. Surf. Coat. Technol. 2002, 151, 383–391. [Google Scholar] [CrossRef]

- Lawson, K.J.; Nicholls, J.R.; Rickerby, D.S. The effect of coating thickness on the thermal conductivity of CVD and PVD coatings. In Proceedings of the 4th International Conference on Advanced in Surface Engineering, Newcastle, UK, 14–17 May 1996. [Google Scholar]

- Tamarin, Y.A.; Kachanov, E.B.; Zherzdev, S.V. Thermophysical properties of ceramic layers in EB-TBC in 4th International Symposium on High Temperature Corrosion (Les Embiez, France, May 1996). Mater. Sci. Forum 1997, 251, 949–956. [Google Scholar] [CrossRef]

- Rickerby, D.S. A Metallic Article Having a Thermal Barrier Coating and a Method of Application Thereof. European Patent EP 0 825 271 A1, 5 June 2002. [Google Scholar]

- Nicholls, J.R.; Lawson, K.J.; Rickerby, D.S.; Morrel, P. Advanced Processing of TBC’s for Reduced Thermal Conductivity; NATO Workshop on Thermal Barrier Coatings: Aalborg, Denmark, 1998; p. 6. [Google Scholar]

- Nicholls, J.R.; Lawson, K.J.; Johnstone, A.; Rickerby, D.S. Low thermal conductivity EB-PVD thermal barrier coatings. In Proceedings of the EPRI Conference, New Orleans, LA, USA, 22–26 May 2000. [Google Scholar]

- Rickerby, D.S. A Coated Article. European Patent EP 0628090 B1, 15 May 1996. [Google Scholar]

- Kabacoff, L.T. Thermally Sprayed Nano-Structured Thermal Barrier Coatings; NATO Workshop on Thermal Barrier Coatings: Aaalborg, Denmark, 1998; p. 12. [Google Scholar]

- Rätzer-Scheibe, H.J.; Schulz, U.; Krell, T. The effect of coating thickness on the thermal conductivity of EB-PVD PYSZ thermal barrier coatings. Surf. Coatings Technol. 2006, 200, 5636–5644. [Google Scholar] [CrossRef]

- Renteria, A.F.; Saruhan, B.; Schulz, U.; Raetzer-Scheibe, H.J.; Haug, J.; Wiedenmann, A. Effect of morphology on thermal conductivity of EB-PVD PYSZ TBCs. Surf. Coat. Technol. 2006, 201, 2611–2620. [Google Scholar] [CrossRef]

- Gu, S.; Lu, T.J.; Hass, D.D.; Wadley, H.N.G. Thermal conductivity of zirconia coatings with zig-zag pore microstructures. Acta Mater. 2001, 49, 2539–2547. [Google Scholar] [CrossRef]

- Singh, J.; Wolfe, D.E. Nanostructured Component Fabrication by Electron Beam-Physical Vapor Deposition. J. Mater. Eng. Perform. 2005, 14, 448–459. [Google Scholar] [CrossRef]

- Josell, D.; Bonevich, J.E.; Nguyen, T.M.; Johnson, R.N. Heat transfer through nanoscale multilayered thermal barrier coatings at elevated temperatures. Surf. Coat. Technol. 2015, 275, 75–83. [Google Scholar] [CrossRef]

- Jang, B.-K. Influence of temperature on thermophysical properties of EB-PVD porous coatings and dense ceramics of 4mol% Y2O3-stabilized ZrO2. J. Alloy Compd. 2009, 480, 806–809. [Google Scholar] [CrossRef]

- Jang, B.-K. Thermal conductivity of nanoporous ZrO2–4 mol% Y2O3 multilayer coatings fabricated by EB-PVD. Surf. Coat. Technol. 2008, 202, 1568–1573. [Google Scholar] [CrossRef]

- Qiu, S.-y.; Liu, Y.-C.; Guo, H.-b.; Huang, C.-G.; Ma, Y.; Wu, C.-W. Effect of splat-interface discontinuity on effective thermal conductivity of plasma sprayed thermal barrier coating. Ceram. Int. 2020, 46, 4824–4831. [Google Scholar] [CrossRef]

- Ganvir, A.; Kumara, C.; Gupta, M.; Nylen, P. Thermal Conductivity in Suspension Sprayed Thermal Barrier Coatings: Modeling and Experiments. J. Therm. Spray Technol. 2016, 26, 71–82. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Liu, H.; Weng, Y. Study on thermal resistance performance of 8YSZ thermal barrier coatings. Int. J. Therm. Sci. 2017, 122, 12–25. [Google Scholar] [CrossRef]

- Cho, J.; Terry, S.G.; LeSar, R.; Levi, C.G. A kinetic Monte Carlo simulation of film growth by physical vapor deposition on rotating substrates. Mater. Sci. Eng. A 2005, 391, 390–401. [Google Scholar] [CrossRef]

- Bobzin, K.; Bagcivan, N.; Brögelmann, T.; Yildirim, B. Influence of temperature on phase stability and thermal conductivity of single- and double-ceramic-layer EB–PVD TBC top coats consisting of 7YSZ, Gd2Zr2O7 and La2Zr2O7. Surf. Coat. Technol. 2013, 237, 56–64. [Google Scholar] [CrossRef]

- Sun, Y.; Lin, X.; He, X.; Zhang, J.; Li, M.; Song, G.; Li, X.; Zhao, Y. Effects of substrate rotation on the microstructure of metal sheet fabricated by electron beam physical vapor deposition. Appl. Surf. Sci. 2009, 255, 5831–5836. [Google Scholar] [CrossRef]

| Element | Ni | Cr | Co | Al | W | Mo | Ti | Fe |

|---|---|---|---|---|---|---|---|---|

| wt. % | Bal. | 10.0–12.0 | 4.5–6.0 | 5.3–5.9 | 4.8–5.5 | 3.8–4.5 | 2.3–2.9 | ≤2.0 |

| Element | Ni | Co | Cr | Al | Y |

|---|---|---|---|---|---|

| wt. % | 49 | 20 | 22 | 8 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, S.-Y.; Wu, C.-W.; Huang, C.-G.; Ma, Y.; Guo, H.-B. Microstructure Dependence of Effective Thermal Conductivity of EB-PVD TBCs. Materials 2021, 14, 1838. https://doi.org/10.3390/ma14081838

Qiu S-Y, Wu C-W, Huang C-G, Ma Y, Guo H-B. Microstructure Dependence of Effective Thermal Conductivity of EB-PVD TBCs. Materials. 2021; 14(8):1838. https://doi.org/10.3390/ma14081838

Chicago/Turabian StyleQiu, Shi-Yi, Chen-Wu Wu, Chen-Guang Huang, Yue Ma, and Hong-Bo Guo. 2021. "Microstructure Dependence of Effective Thermal Conductivity of EB-PVD TBCs" Materials 14, no. 8: 1838. https://doi.org/10.3390/ma14081838

APA StyleQiu, S.-Y., Wu, C.-W., Huang, C.-G., Ma, Y., & Guo, H.-B. (2021). Microstructure Dependence of Effective Thermal Conductivity of EB-PVD TBCs. Materials, 14(8), 1838. https://doi.org/10.3390/ma14081838