Investigation of the Microstructural Evolution during Hot Stamping of a Carburized Complex Phase Steel by Laser-Ultrasonics

Abstract

1. Introduction

2. Materials and Methods

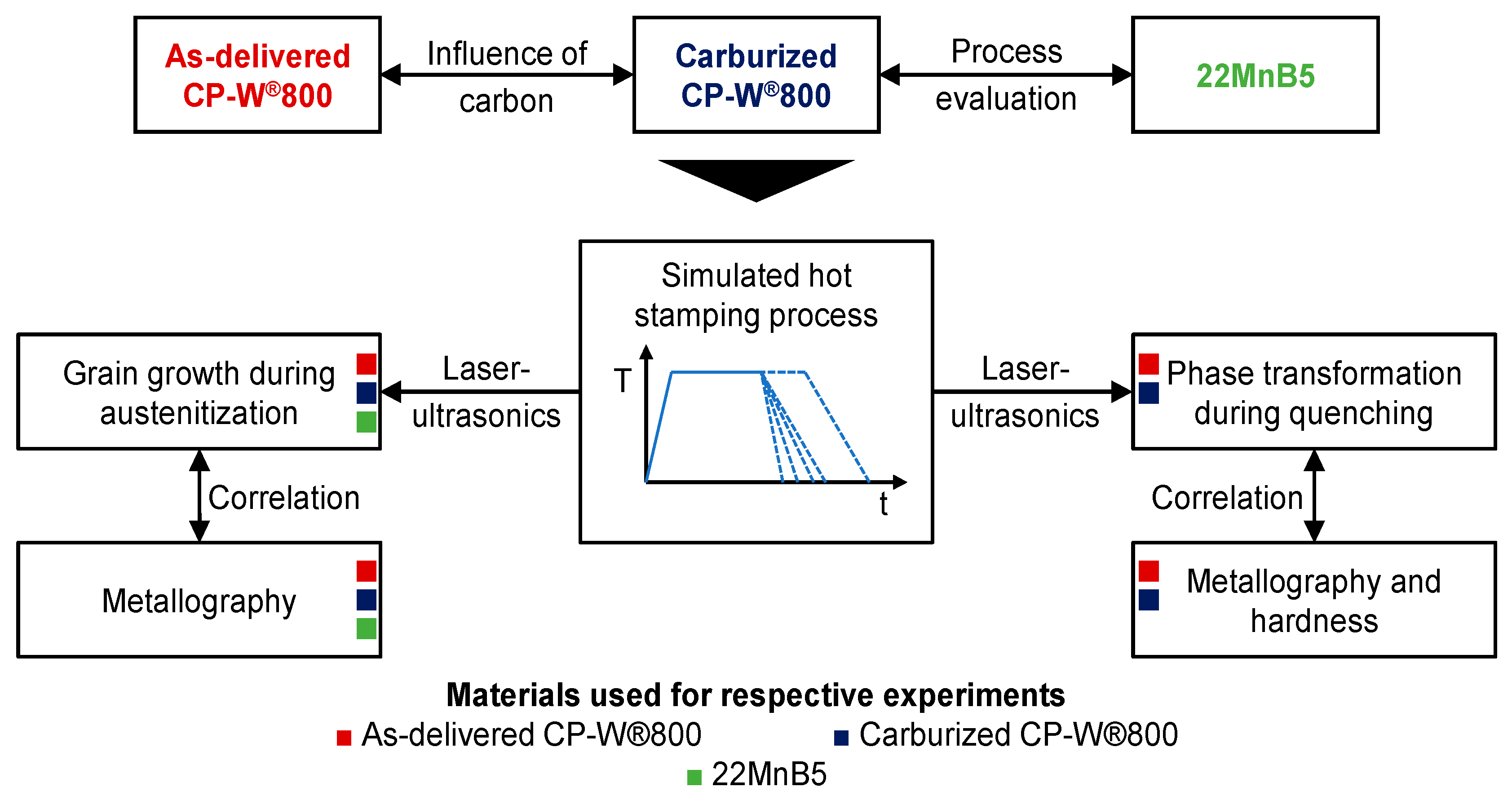

2.1. Methodology

2.2. Materials

2.2.1. Investigated Materials

2.2.2. Mechanical Properties of Carburized Complex Phase Steel

2.3. Experimental Methods

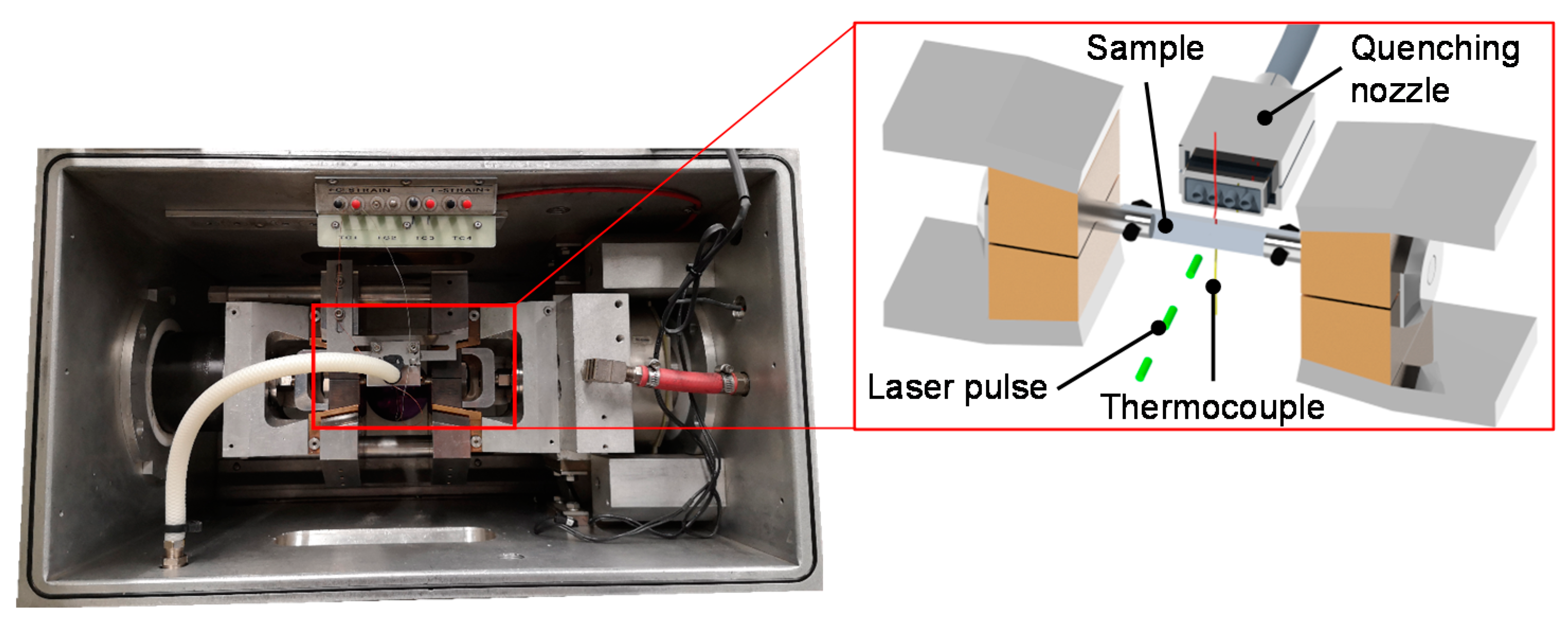

2.3.1. Simulation of the Thermal Treatment during the Hot Stamping Process

2.3.2. In-Situ Analysis of the Microstructure by Laser-Ultrasonics

2.3.3. Supplementary Experiments

3. Results and Discussion

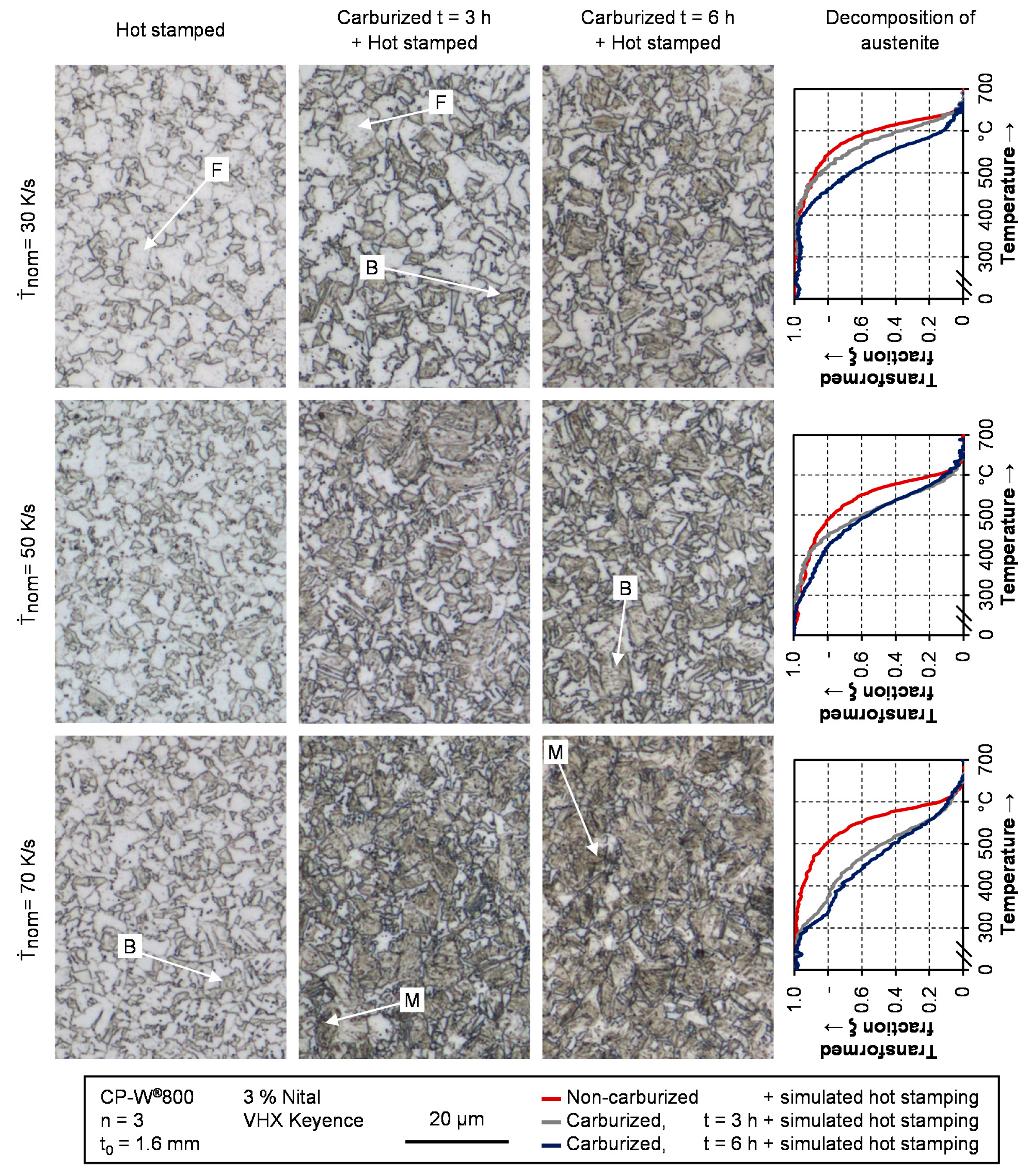

3.1. Phase Transformation during Hot Stamping

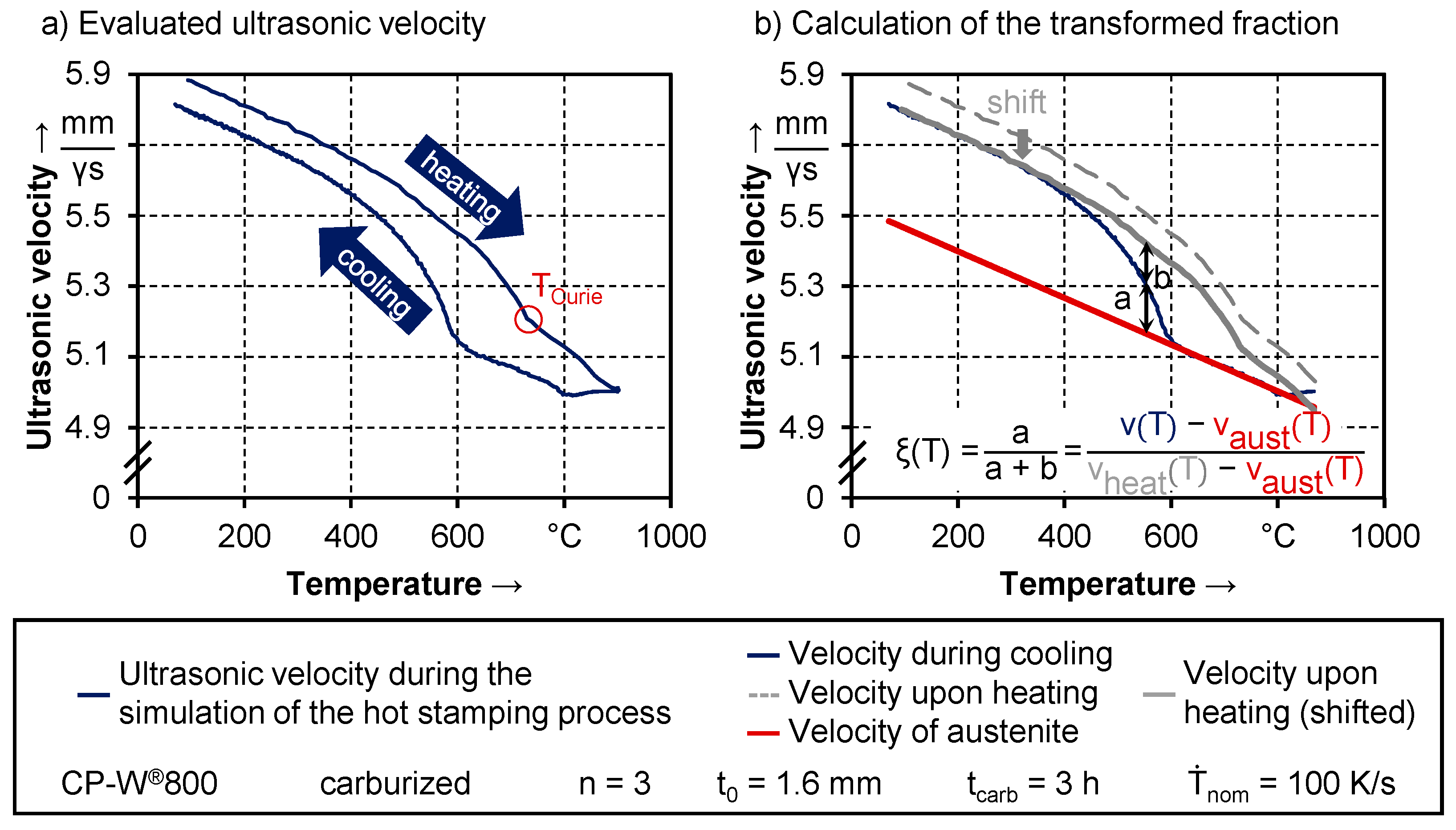

3.1.1. Procedure for the Evaluation of the Testing Results

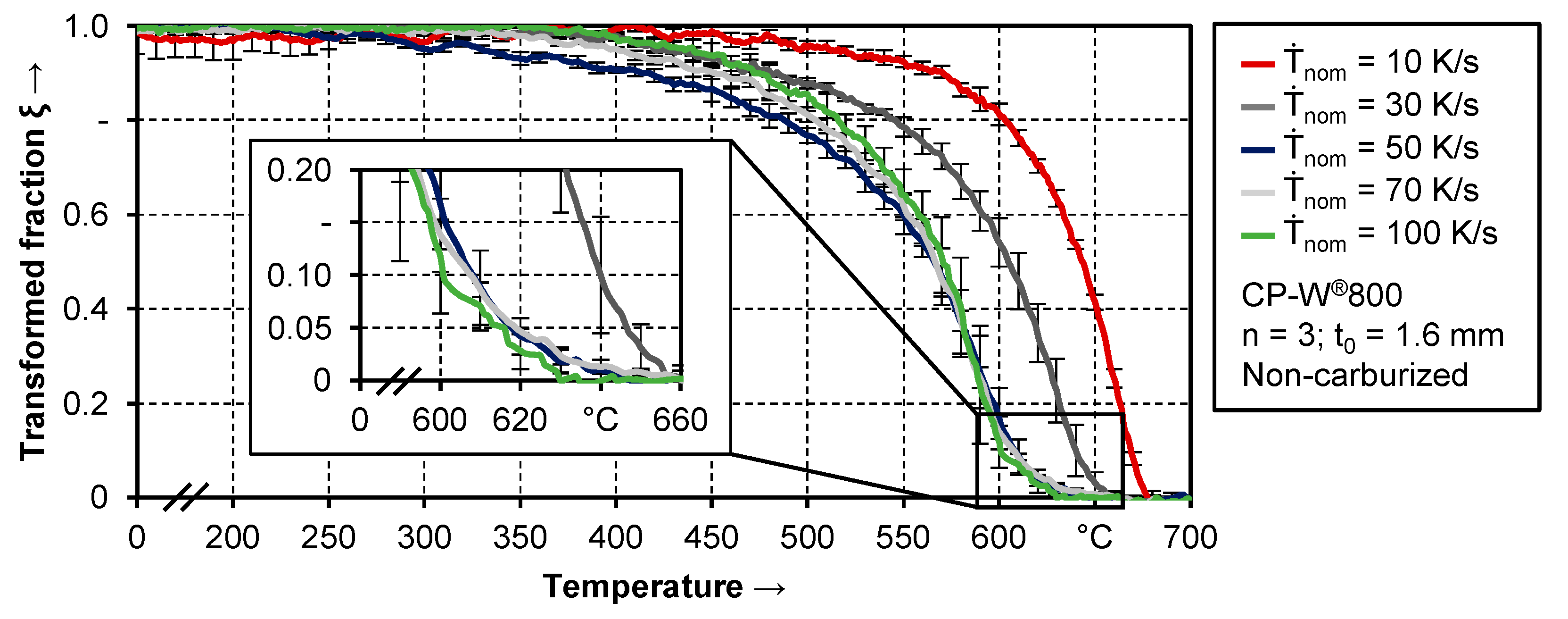

3.1.2. Phase Transformation of Non-Carburized CP-W®800 during Conventional Hot Stamping

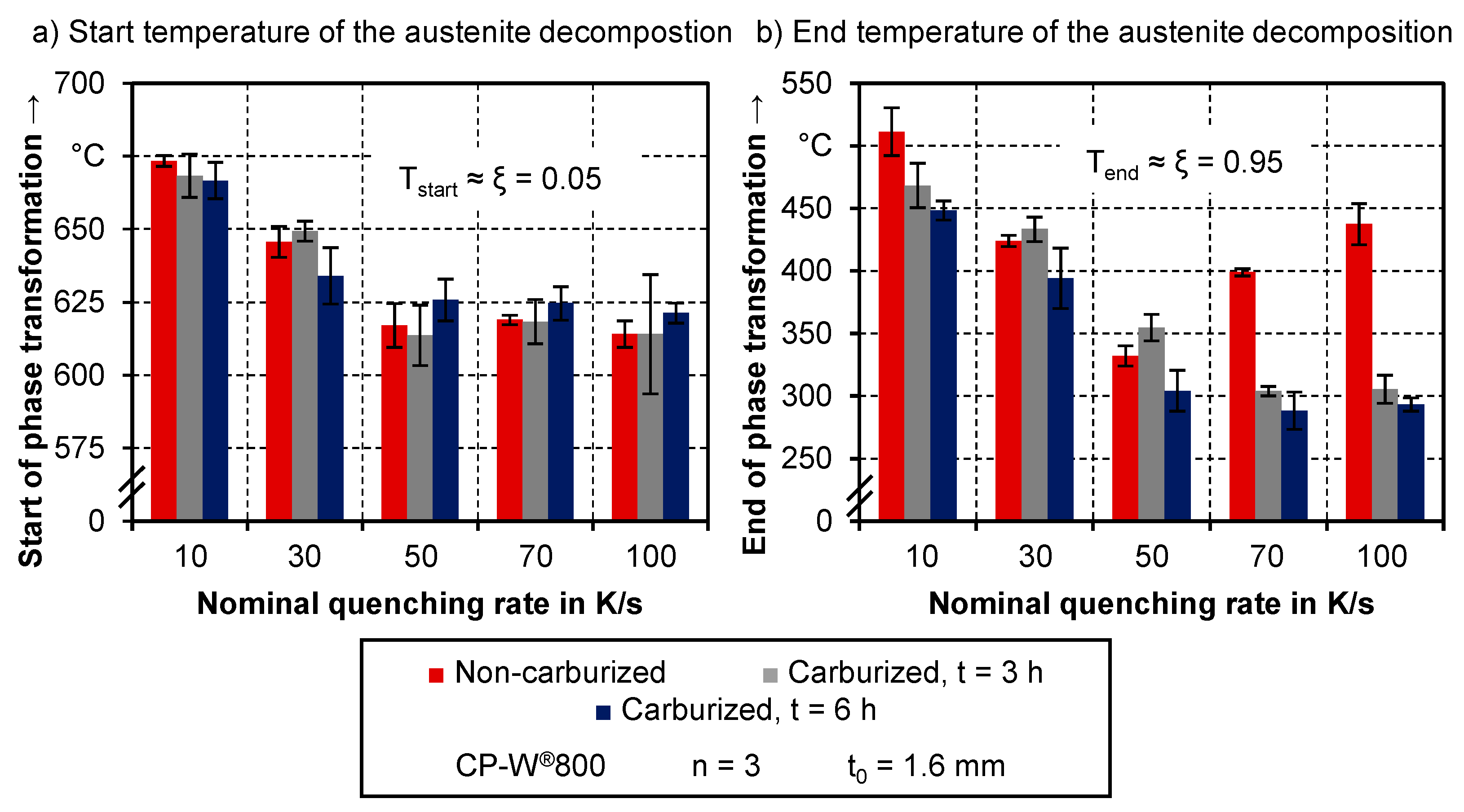

3.1.3. Comparison of Start and End Temperatures of the Phase Transformation of Carburized and Non-Carburized Semi-Finished Parts during Simulated Hot Stamping

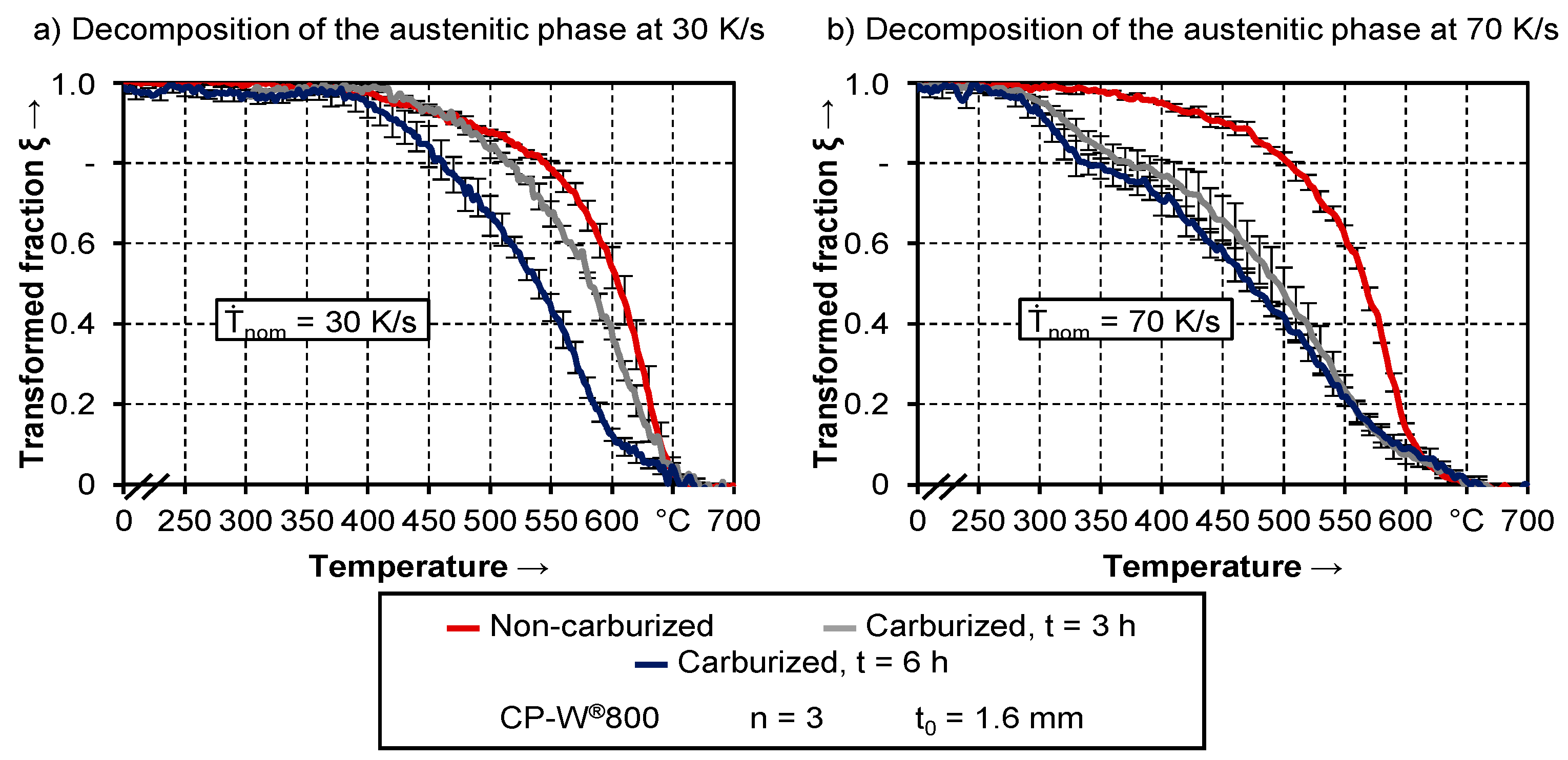

3.1.4. Comparison of the Austenitic Decomposition of Carburized and Non-Carburized Semi-Finished Parts during Simulated Hot Stamping

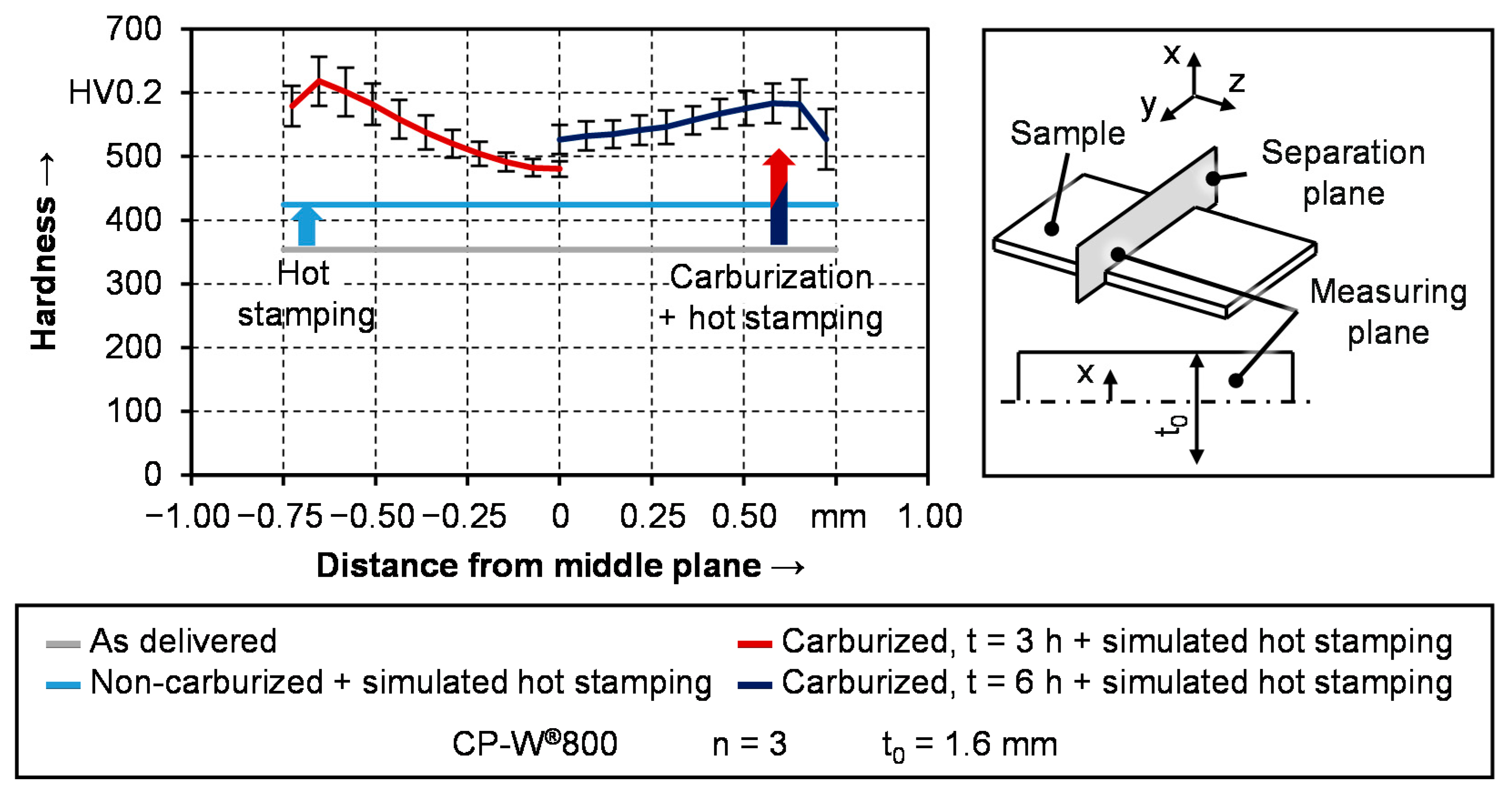

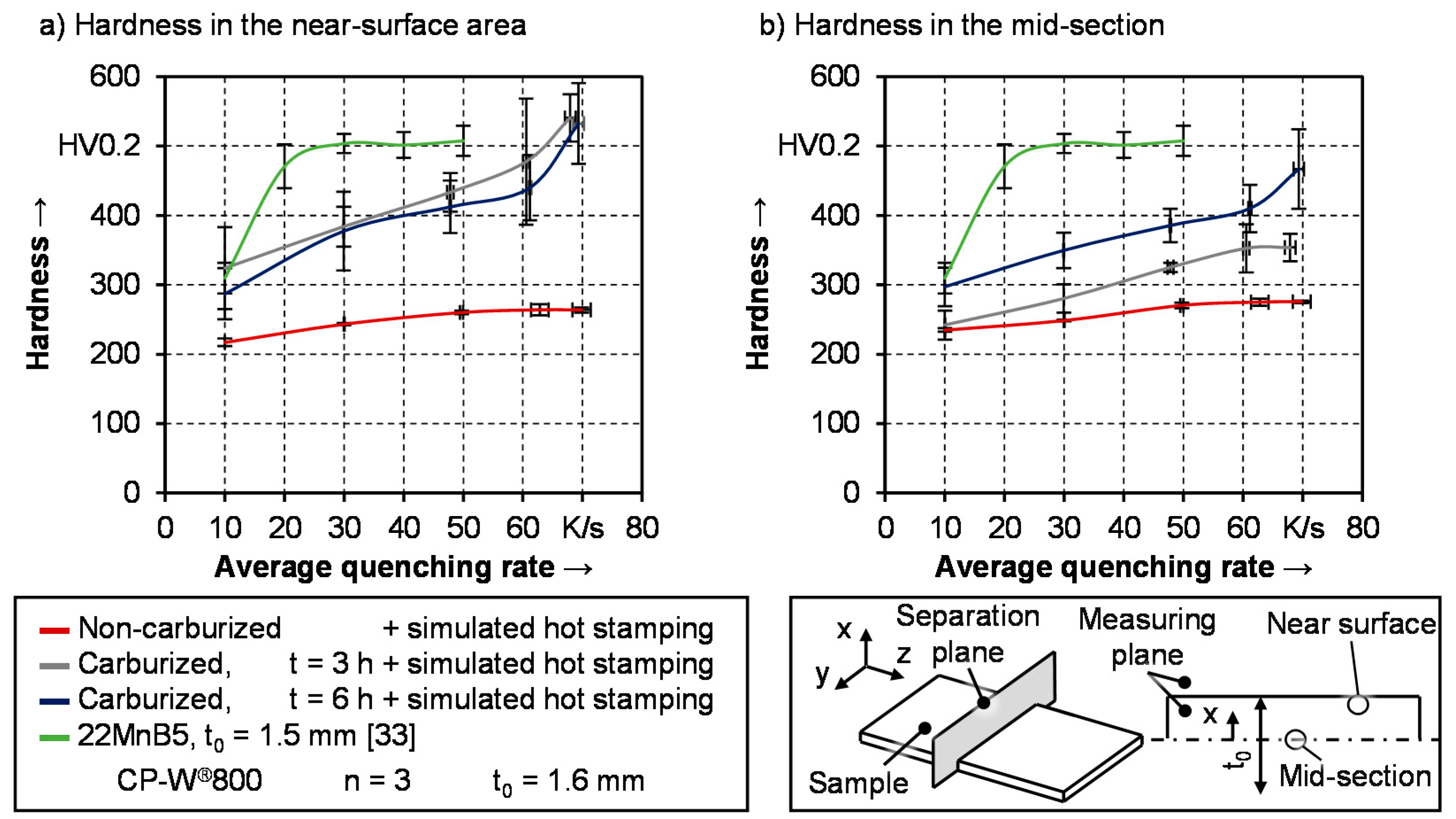

3.2. Hardness of As-Quenched Samples

3.3. Metallographic Analysis

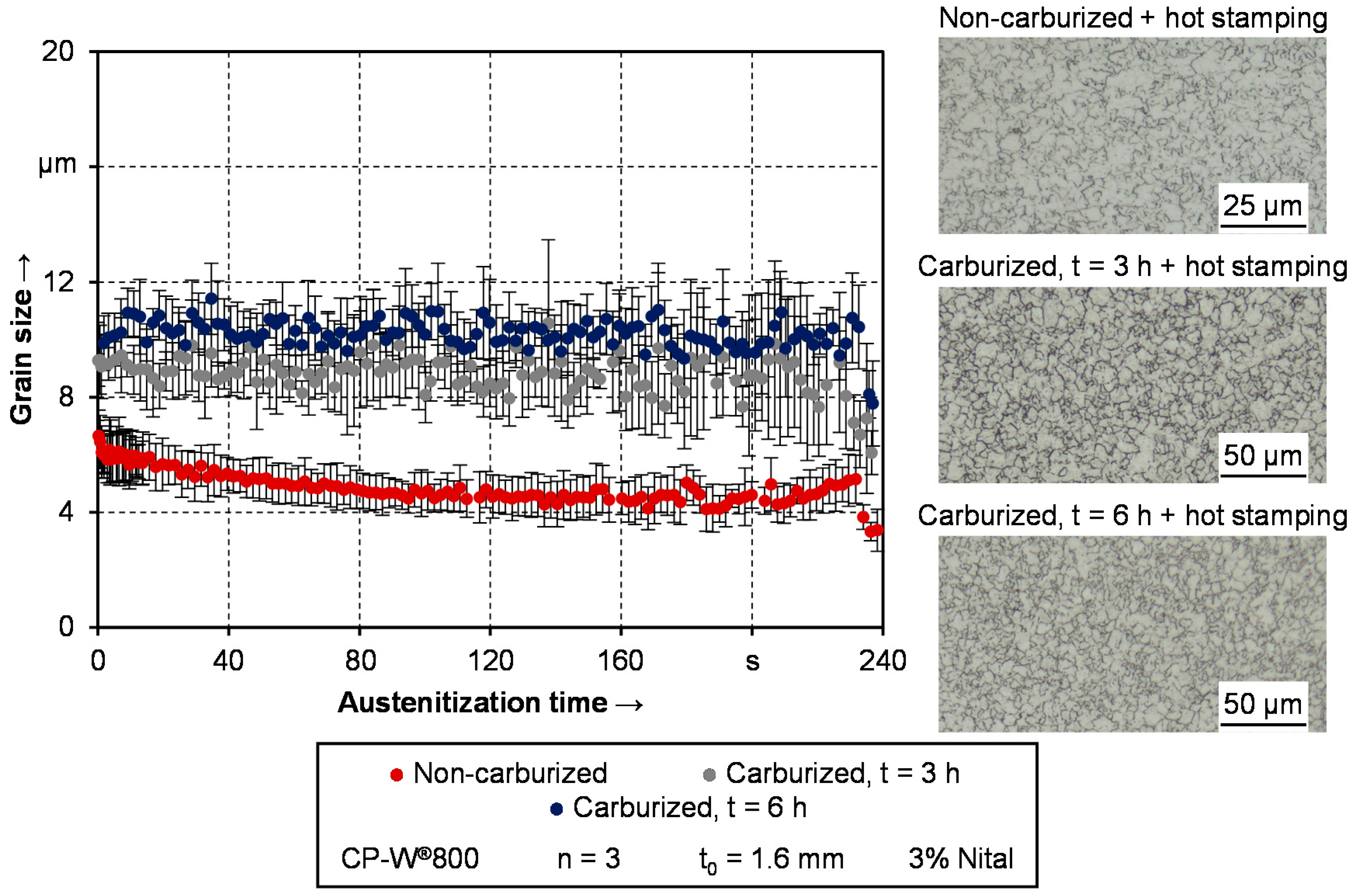

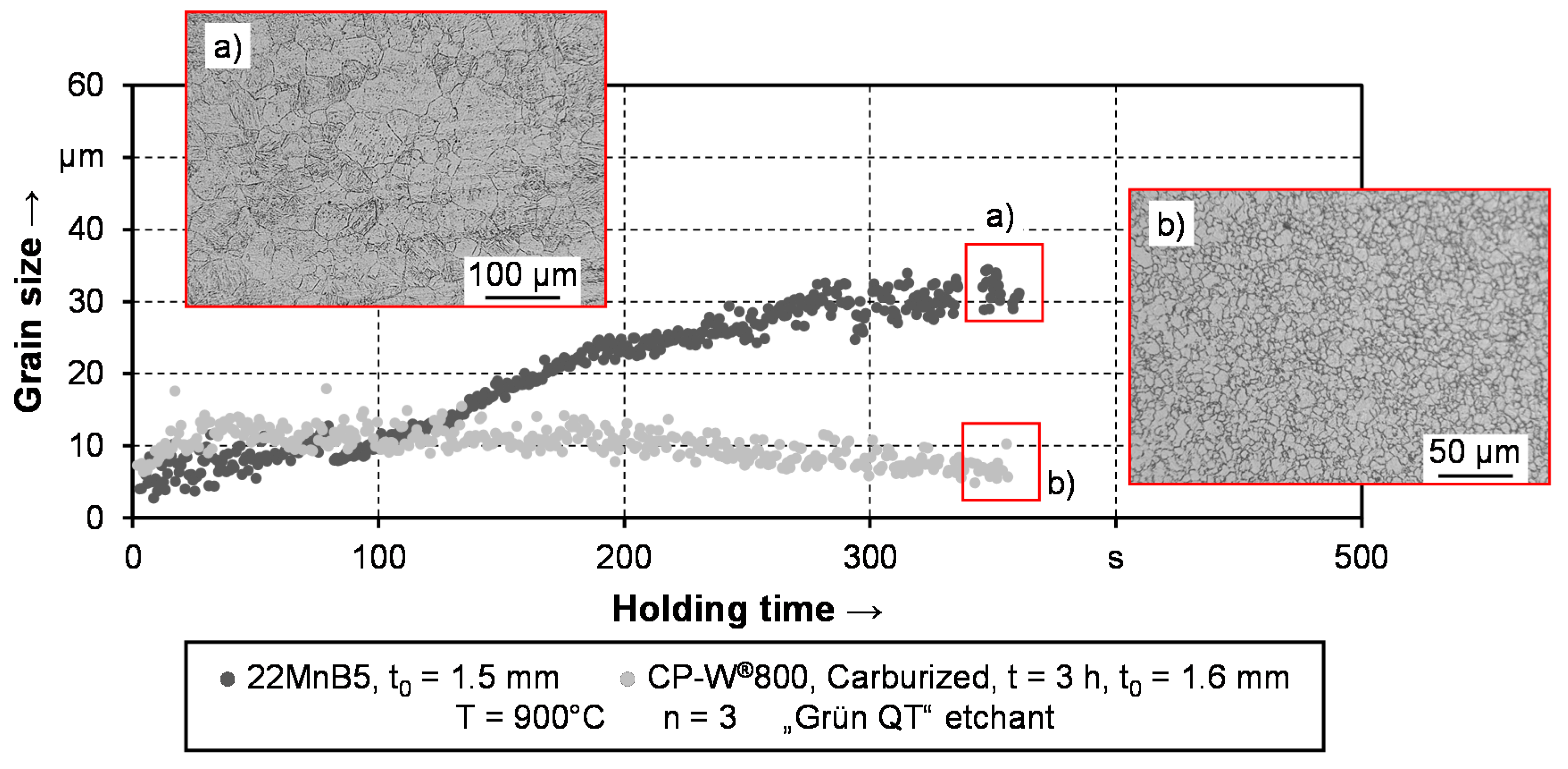

3.4. Assessment of Grain Growth

4. Conclusions

- Additional carburization enhances the hardenability of the CP-W®800 steel sheets. For a given quenching rate, the phase transformation is shifted to lower temperatures, which is accompanied by the formation of harder phases.

- Due to a gradient in carbon content, the hardenability varies along the sheet thickness.

- Although a multiphase microstructure was present for all quenching rates and material conditions, the hardness of fully martensitic 22MnB5 could partially be exceeded, which is a consequence of the influence of carbon content on martensitic hardness.

- Special care has to be taken in terms of the process design to ensure a sufficient heat transfer during cooling since the mechanical properties exhibited a distinctive dependence from the quenching rates within the investigated range of parameters.

- The in-situ study of the grain growth behavior showed that the additional carburization process leads to an increase in prior austenite grain size from 4 μm to 10 μm after hot stamping. However, grain size stability was not affected by the carburization process. Compared to the conventional 22MnB5 the carburized complex phase steel exhibits higher process robustness in terms of austenite grain size control while having comparable mechanical properties.

- The material behavior of CP-W®800 during hot stamping underlines the suitability of the recommended scope of application in small batch size productions and prototyping. The robustness regarding the grain size during austenitization is advantageous in these manufacturing processes where fluctuations in the heat treatment can occur due to a lower degree of automation. Furthermore, cycling time is not an issue and so a sufficient cooling performance of tools can be ensured.

5. Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tisza, M.; Czinege, I. Comparative study of the application of steels and aluminium in lightweight production of automotive parts. Int. J. Lightweight Mater. Manuf. 2018, 1, 229–238. [Google Scholar] [CrossRef]

- Sun, X.; Meng, F.; Liu, J.; McKechnie, J.; Yang, J. Life cycle energy use and greenhouse gas emission of lightweight vehicle—A body-in-white design. J. Clean. Prod. 2019, 220, 1–8. [Google Scholar] [CrossRef]

- Hein, P.; Wilsius, J. Status and Innovation Trends in Hot Stamping of USIBOR 1500 P. Steel Res. Int. 2008, 79, 85–91. [Google Scholar] [CrossRef]

- Karbasian, H.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Merklein, M.; Wieland, M.; Lechner, M.; Bruschi, S.; Ghiotti, A. Hot stamping of boron steel sheets with tailored properties: A review. J. Mater. Process. Technol. 2016, 228, 11–24. [Google Scholar] [CrossRef]

- Xu, F.; Zhang, X.; Zhang, H. A review on functionally graded structures and materials for energy absorption. Eng. Struct. 2018, 171, 309–325. [Google Scholar] [CrossRef]

- Maikranz-Valentin, M.; Weidig, U.; Schoof, U.; Becker, H.-H.; Steinhoff, K. Components with Optimised Properties due to Advanced Thermo-mechanical Process Strategies in Hot Sheet Metal Forming. Steel Res. Int. 2008, 79, 92–97. [Google Scholar] [CrossRef]

- Omer, K.; ten Kortenaar, L.; Butcher, C.; Worswick, M.; Malcolm, S.; Detwiler, D. Testing of a hot stamped axial crush member with tailored properties—Experiments and models. Int. J. Impact Eng. 2017, 103, 12–28. [Google Scholar] [CrossRef]

- Mori, K.; Bariani, P.F.; Behrens, B.-A.; Brosius, A.; Bruschi, S.; Maeno, T.; Merklein, M.; Yanagimoto, J. Hot stamping of ultra-high strength steel parts. CIRP Ann. 2017, 66, 755–777. [Google Scholar] [CrossRef]

- Merklein, M.; Svec, T. Hot stamping: Manufacturing functional optimized components. Prod. Eng. 2012, 7, 141–151. [Google Scholar] [CrossRef]

- Rolfe, B.; Abdollahpoor, A.; Wang, Y.; Pereira, M.; Kong, H.; Fabijanic, D.; Hu, K.; Han, R.; Gao, K.; Liu, A.; et al. Local Patchworking of Sheet Properties Combining Carburization and Hot Stamping. In Proceedings of the 3rd International Conference on Advanced High Strength Steel and Press Hardening, Xi’an, China, 25–27 August 2016; pp. 346–351. [Google Scholar]

- Zhu, J.; Zhang, X.; Luo, H.; Sahraei, E. Investigation of the deformation mechanisms of lithium-ion battery components using in-situ micro tests. Appl. Energy 2018, 224, 251–266. [Google Scholar] [CrossRef]

- Horn, A.; Merklein, M. Functional optimization of hot-stamped components by local carburization. Int. J. Lightweight Mater. Manuf. 2020, 3, 43–54. [Google Scholar] [CrossRef]

- Hairer, F.; Karelova, A.; Krempaszky, C.; Werner, E.; Hebesberger, T.; Pichler, A. Influence of heat treatment on the microstructure and hardness of a low alloyed complex phase steel. In Proceedings of the International Doctoral Seminar, Smolenice, Slovakia, 17–19 May 2009; pp. 78–83. [Google Scholar]

- Kang, H.C.; Park, B.J.; Jang, J.H.; Jang, K.S.; Lee, K.J. Determination of the continuous cooling transformation diagram of a high strength low alloyed steel. Metals Mater. Int. 2016, 22, 949–955. [Google Scholar] [CrossRef]

- Nanda, T.; Singh, V.; Singh, V.; Chakraborty, A.; Sharma, S. Third generation of advanced high-strength steels: Processing routes and properties. J. Mater. Design Appl. 2016, 233, 209–238. [Google Scholar] [CrossRef]

- Yogo, Y.; Tanaka, K. In Situ Observation for Abnormal Grain Coarsening in Vacuum-Carburizing Process. Metall. Mater. Trans. A 2014, 45, 2834–2841. [Google Scholar] [CrossRef]

- thyssenkrupp. Product Information for Complex-Phase Steels. Available online: https://www.thyssenkrupp-steel.com/en/products/sheet-coated-products/multiphase-steel/complex-phase-steel/ (accessed on 12 October 2017).

- thyssenkrupp. Product Information for Manganese-Boron Steels for Hot Forming. Available online: https://www.thyssenkrupp-steel.com/en/products/sheet-coated-products/manganese-boron-steel-for-hot-forming/mbw-manganese-boron-steel-for-hot-forming/ (accessed on 5 March 2020).

- Merklein, M.; Svec, T. Prozessfenster zur Verarbeitung alternativer stahlgüten im presshärtprozess. In Proceedings of the 7th Erlanger Workshop Warmblechumformung, Erlangen, Germany, 20 November 2012; pp. 55–70. [Google Scholar]

- ISO—International Organization for Standardization. ISO 18203: Steel—Determination of the Thickness of Surface-Hardened Layers; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- Toozandehjani, M.; Matori, K.A.; Ostovan, F.; Mustapha, F.; Zahari, N.I.; Oskoueian, A. On the correlation between microstructural evolution and ultrasonic properties: A review. J. Mater. Sci. 2015, 50, 2643–2665. [Google Scholar] [CrossRef]

- Shinbine, A.; Garcin, T.; Sinclair, C. In-situ laser ultrasonic measurement of the hcp to bcc transformation in commercially pure titanium. Mater. Charact. 2016, 117, 57–64. [Google Scholar] [CrossRef]

- Davies, S.J.; Edwards, C.; Taylor, G.S.; Palmer, S.B. Laser-generated ultrasound: Its properties, mechanisms and multifarious applications. J. Phys. D Appl. Phys. 1993, 26, 329. [Google Scholar] [CrossRef]

- Dubois, M.; Moreau, A.; Bussière, J.F. Ultrasonic velocity measurements during phase transformations in steels using laser ultrasonics. J. Appl. Phys. 2001, 89, 6487–6495. [Google Scholar] [CrossRef]

- Militzer, M.; Garcin, T.; Kulakov, M.; Poole, W. Laser ultrasonics for in-situ monitoring of microstructure evolution in steels. In Proceedings of the 5th Baosteel Biennial Academic Conference, Beijing, China, 10–14 August 2013. [Google Scholar]

- Kruger, S.E.; Damm, E.B. Monitoring austenite decomposition by ultrasonic velocity. Mater. Sci. Eng. A 2006, 425, 238–243. [Google Scholar] [CrossRef]

- Kruger, S.; Moreau, A.; Monchalin, J.P. Laser-Ultrasonic Monitoring of Metallurgical Transformations in Advanced Ultra-High Strength Steels. In Proceedings of the 1st International Symposium on Laser Ultrasonics: Science, Technology and Applications, Montreal, QC, Canada, 16–18 July 2008. [Google Scholar]

- Arnoult, W.J.; McLellan, R.B. Variation of the Young’s Modulus of Austenite with carbon concentration. Acta Metall. 1975, 23, 51–56. [Google Scholar] [CrossRef]

- Dubois, M.; Militzer, M.; Moreau, A.; Bussière, J.F. A new technique for the quantitative real-time monitoring of austenite grain growth in steel. Scr. Mater. 2000, 42, 867–874. [Google Scholar] [CrossRef]

- Garcin, T.; Ueda, K.; Militzer, M. Reverse Austenite Transformation and Grain Growth in a Low-Carbon Steel. Metall. Trans. A 2016, 48, 796–808. [Google Scholar] [CrossRef]

- Garcin, T.; Schmitt, J.H.; Militzer, M. In-situ laser ultrasonic grain size measurement in superalloy INCONEL 718. J. Alloys Compd. 2016, 670, 329–336. [Google Scholar] [CrossRef]

- Aranda, L.G.; Chastel, Y.; Pascual, J.F.; Negro, T.D. Experiments and Simulation of Hot Stamping of Quenchable Steels. In Proceedings of the 7th International Conference on Technology of Plasticity, Yokohama, Japan, 27 October–1 November 2002; pp. 1135–1140. [Google Scholar]

- Nikravesh, M.; Naderi, M.; Akbari, G.H.; Bleck, W. Phase transformations in a simulated hot stamping process of the boron bearing steel. Mater. Des. 2015, 84, 18–24. [Google Scholar] [CrossRef]

- Horn, A.; Hart-Rawung, T.; Buhl, J.; Bambach, M.; Merklein, M. Investigation of the phase transformation in hot stamping processes with regard to the testing facility. In Proceedings of the Congress of the German Academic Association for Production Technology, Dresden, Germany, 23–24 September 2020; Springer: Berlin/Heidelberg, Germany, 2020; pp. 76–85. [Google Scholar]

- Cai, M.-h.; Ding, H.; Lee, Y.-k.; Tang, Z.-y.; Zhang, J.-s. Effects of Si on Microstructural Evolution and Mechanical Properties of Hot-rolled Ferrite and Bainite Dual-phase Steels. ISIJ Int. 2011, 51, 476–481. [Google Scholar] [CrossRef]

- Yakubtsov, I.A.; Boyd, J.D. Effect of alloying on microstructure and mechanical properties of bainitic high strength plate steels. Mater. Sci. Technol. 2013, 24, 221–227. [Google Scholar] [CrossRef]

- Pichler, A.; Traint, S.; Stiaszny, P.; Werner, E.; Arnoldner, M.; Pippan, R. Phase transformations during annealing of a cold-rolled DP steel grade. In Proceedings of the Mechanical Working and Steel Processing Conference Proceedings, Toronto, ON, Canada, 22–25 October 2000; pp. 573–594. [Google Scholar]

- He, B. On the Factors Governing Austenite Stability: Intrinsic versus Extrinsic. Materials 2020, 13, 3440. [Google Scholar] [CrossRef]

- Naderi, M. Hot Stamping of Ultra High Strength Steels. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2007. [Google Scholar]

- Barcellona, A.; Palmeri, D. Effect of Plastic Hot Deformation on the Hardness and Continuous Cooling Transformations of 22MnB5 Microalloyed Boron Steel. Metall. Trans. A 2009, 40, 1160–1174. [Google Scholar] [CrossRef]

- Nikravesh, M.; Naderi, M.; Akbari, G.H. Influence of hot plastic deformation and cooling rate on martensite and bainite start temperatures in 22MnB5 steel. Mater. Sci. Eng. A 2012, 540, 24–29. [Google Scholar] [CrossRef]

- Naderi, M.; Saeed-Akbari, A.; Bleck, W. The effects of non-isothermal deformation on martensitic transformation in 22MnB5 steel. Mater. Sci. Eng. A 2008, 487, 445–455. [Google Scholar] [CrossRef]

- Kop, T.A.; Sietsma, J.; Van Der Zwaag, S. Dilatometric analysis of phase transformations in hypo-eutectoid steels. J. Mater. Sci. 2001, 36, 519–526. [Google Scholar] [CrossRef]

- Krauss, G. Martensite in steel: Strength and structure. Mater. Sci. Eng. A 1999, 273–275, 40–57. [Google Scholar] [CrossRef]

- Heibel, S.; Dettinger, T.; Nester, W.; Clausmeyer, T.; Tekkaya, A.E. Damage Mechanisms and Mechanical Properties of High-Strength Multiphase Steels. Materials 2018, 11, 761. [Google Scholar] [CrossRef]

- Knaislova, A.; Rudomilova, D.; Novak, P.; Prosek, T.; Michalcova, A.; Beran, P. Critical Assessment of Techniques for the Description of the Phase Composition of Advanced High-Strength Steels. Materials 2019, 12, 4033. [Google Scholar] [CrossRef]

- Sarkar, S.; Moreau, A.; Militzer, M.; Poole, W.J. Evolution of Austenite Recrystallization and Grain Growth Using Laser Ultrasonics. Metall. Trans. A 2008, 39, 897–907. [Google Scholar] [CrossRef]

- Wan, T.; Naoe, T.; Wakui, T.; Futakawa, M.; Obayashi, H.; Sasa, T. Effects of Grain Size on Ultrasonic Attenuation in Type 316L Stainless Steel. Materials 2017, 10, 753. [Google Scholar] [CrossRef]

- Fu, L.M.; Wang, H.R.; Wang, W.; Shan, A.D. Austenite grain growth prediction coupling with drag and pinning effects in low carbon Nb microalloyed steels. Mater. Sci. Technol. 2013, 27, 996–1001. [Google Scholar] [CrossRef]

- Enloe, C.M.; Findley, K.O.; Speer, J.G. Austenite Grain Growth and Precipitate Evolution in a Carburizing Steel with Combined Niobium and Molybdenum Additions. Metall. Mater. Trans. A 2015, 46, 5308–5328. [Google Scholar] [CrossRef]

- Alogab, K.A.; Matlock, D.K.; Speer, J.G.; Kleebe, H.J. The Influence of Niobium Microalloying on Austenite Grain Coarsening Behavior of Ti-modified SAE 8620 Steel. ISIJ Int. 2007, 47, 307–316. [Google Scholar] [CrossRef]

- Militzer, M.; Maalekian, M.; Moreau, A. Laser-Ultrasonic Austenite Grain Size Measurements in Low-Carbon Steels. Mater. Sci. Forum 2012, 715–716, 407–414. [Google Scholar] [CrossRef]

- Chen, R.; Zheng, Z.; Li, J.; Li, N.; Feng, F. In Situ Investigation of Grain Evolution of 300M Steel in Isothermal Holding Process. Materials 2018, 11, 1862. [Google Scholar] [CrossRef]

- Tokizane, M.; Matsumura, N.; Tsuzaki, K.; Maki, T.; Tamura, I. Recrystallization and formation of austenite in deformed lath martensitic structure of low carbon steels. Metall. Trans. A 1982, 13, 1379–1388. [Google Scholar] [CrossRef]

- Furuhara, T.; Kikumoto, K.; Saito, H.; Sekine, T.; Ogawa, T.; Morito, S.; Maki, T. Phase Transformation from Fine-grained Austenite. ISIJ Int. 2008, 48, 1038–1045. [Google Scholar] [CrossRef]

- Meza-García, E.; Rautenstrauch, A.; Bräunig, M.; Kräusel, V.; Landgrebe, D. Energetic evaluation of press hardening processes. Procedia Manuf. 2019, 33, 367–374. [Google Scholar] [CrossRef]

- Cai, H.L.; Du, P.J.; Yi, H.L.; Wu, D. Effects of Austenitizing Temperature on Microstructure and Properties of Hot-Formed Steel. Adv. Mater. Res. 2014, 1063, 88–92. [Google Scholar] [CrossRef]

- Celada-Casero, C.; Sietsma, J.; Santofimia, M.J. The role of the austenite grain size in the martensitic transformation in low carbon steels. Mater. Des. 2019, 167, 107625. [Google Scholar] [CrossRef]

- Mohrbacher, H. Property Optimization in As-Quenched Martensitic Steel by Molybdenum and Niobium Alloying. Metals 2018, 8, 234. [Google Scholar] [CrossRef]

| Material | C | Si | Mn | P | S | Al | Ti + Nb | Cr + Mo | V | B |

|---|---|---|---|---|---|---|---|---|---|---|

| CP-W®800 | 0.14 | 1.00 | 2.20 | 0.080 | 0.015 | 0.015–2.0 | 0.25 | 1.00 | 0.20 | 0.005 |

| 22MnB5 | 0.25 | 0.40 | 1.4 | 0.025 | 0.010 | 0.015 | -- | 0.50 | -- | 0.005 |

| Nominal Quenching Rate in K/s | 10 | 30 | 50 | 70 | 100 |

|---|---|---|---|---|---|

| Non-carburized + simulated hot stamping | 10.0 | 30.0 ± 0.1 | 49.7 ± 0.3 | 62.8 ± 1.5 | 69.8 ± 1.5 |

| Carburized, t = 3 h + simulated hot stamping | 10.0 | 29.9 | 47.8 ± 0.5 | 60.6 ± 0.5 | 67.9 ± 0.9 |

| Carburized, t = 6 h + simulated hot stamping | 10.0 | 29.9 | 47.8 ± 0.2 | 61.2 ± 0.3 | 69.3 ± 0.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Horn, A.; Merklein, M. Investigation of the Microstructural Evolution during Hot Stamping of a Carburized Complex Phase Steel by Laser-Ultrasonics. Materials 2021, 14, 1836. https://doi.org/10.3390/ma14081836

Horn A, Merklein M. Investigation of the Microstructural Evolution during Hot Stamping of a Carburized Complex Phase Steel by Laser-Ultrasonics. Materials. 2021; 14(8):1836. https://doi.org/10.3390/ma14081836

Chicago/Turabian StyleHorn, Alexander, and Marion Merklein. 2021. "Investigation of the Microstructural Evolution during Hot Stamping of a Carburized Complex Phase Steel by Laser-Ultrasonics" Materials 14, no. 8: 1836. https://doi.org/10.3390/ma14081836

APA StyleHorn, A., & Merklein, M. (2021). Investigation of the Microstructural Evolution during Hot Stamping of a Carburized Complex Phase Steel by Laser-Ultrasonics. Materials, 14(8), 1836. https://doi.org/10.3390/ma14081836