The Influence of Sub-Zero Conditions on the Mechanical Properties of Polylactide-Based Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Methods

3. Results

3.1. Linseed Oil Evaluation

3.2. Evaluation of Polymeric Composites

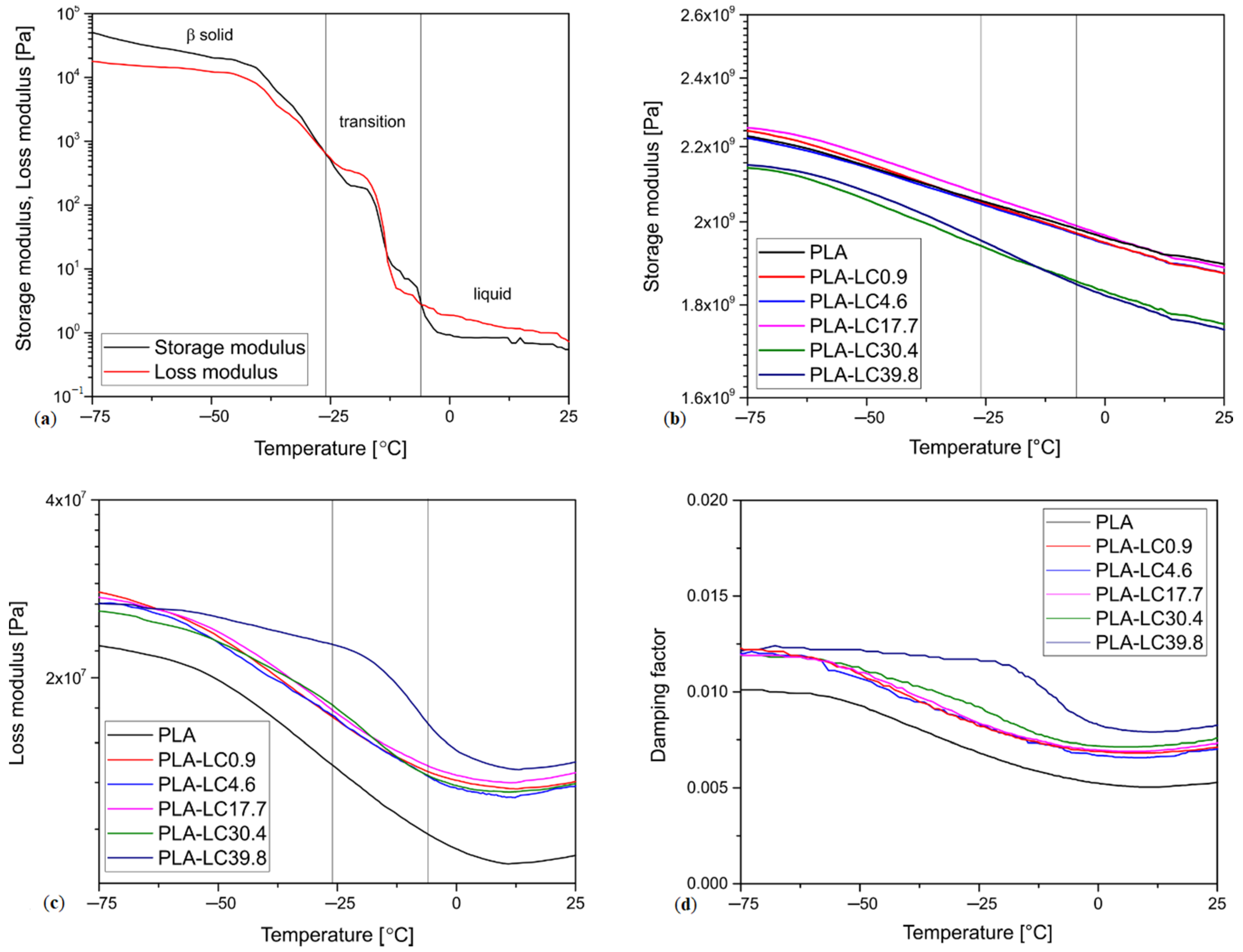

3.2.1. Dynamic Mechanical Analysis

3.2.2. Impact Strength Evaluation

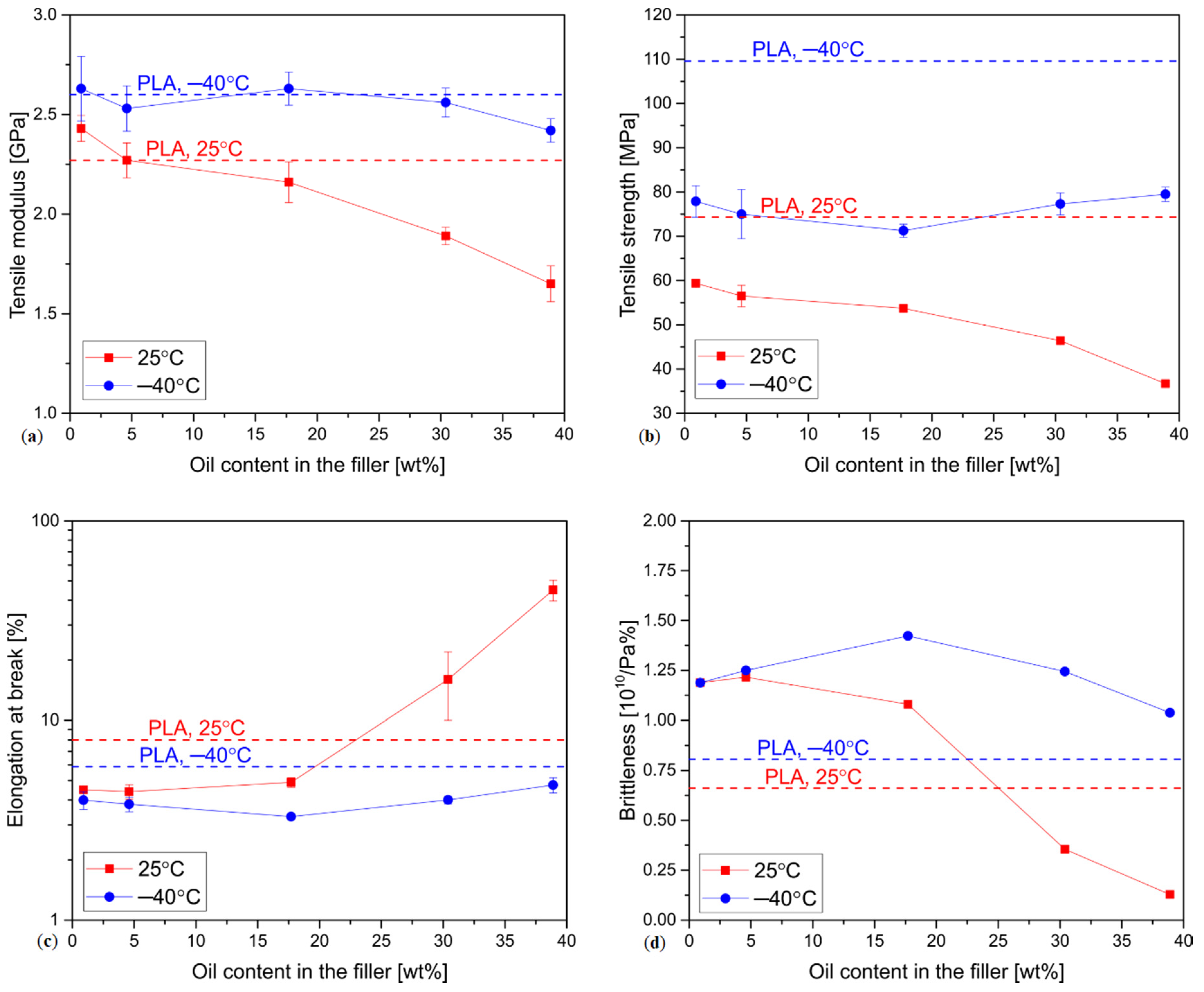

3.2.3. Tensile Strength Evaluation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Auras, R.; Harte, B.; Selke, S. An overview of polylactides as packaging materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef] [PubMed]

- Carrasco, F.; Pagès, P.; Gámez-Pérez, J.; Santana, O.O.; Maspoch, M.L. Processing of poly(lactic acid): Characterization of chemical structure, thermal stability and mechanical properties. Polym. Degrad. Stab. 2010, 95, 116–125. [Google Scholar] [CrossRef]

- Castro-Aguirre, E.; Iñiguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)—Mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef]

- Bałdowska-Witos, P.; Kruszelnicka, W.; Kasner, R.; Tomporowski, A.; Flizikowski, J.; Kłos, Z.; Piotrowska, K.; Markowska, K. Application of LCA method for assessment of environmental impacts of a polylactide (PLA) bottle shaping. Polymers 2020, 12, 388. [Google Scholar] [CrossRef]

- Czarnecka-Komorowska, D.; Wiszumirska, K. Zrównoważone projektowanie opakowań z tworzyw sztucznych w gospodarce cyrkularnej. Polimery 2020, 65, 8–17. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Duart, S.; Montanes, N.; Torres-Giner, S.; Balart, R. Enhancement of the mechanical and thermal properties of injection-molded polylactide parts by the addition of acrylated epoxidized soybean oil. Mater. Des. 2018, 140, 54–63. [Google Scholar] [CrossRef]

- Lim, L.-T.; Auras, R.; Rubino, M. Processing technologies for poly(lactic acid). Prog. Polym. Sci. 2008, 33, 820–852. [Google Scholar] [CrossRef]

- Iozzino, V.; De Meo, A.; Pantani, R. Micromolded Polylactid Acid With Selective Degradation Rate. Front. Mater. 2019, 6, 305. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Sammon, C.; Balart, R.; Torres-Giner, S. Compatibilization of highly sustainable polylactide/almond shell flour composites by reactive extrusion with maleinized linseed oil. Ind. Crops Prod. 2018, 111, 878–888. [Google Scholar] [CrossRef]

- Bulanda, K.; Oleksy, M.; Oliwa, R.; Budzik, G.; Gontarz, M. Biodegradable polymer composites based on polylactide used in selected 3D technologies (Rapid communication). Polimery/Polymers 2020, 65, 557–562. [Google Scholar]

- Benwood, C.; Anstey, A.; Andrzejewski, J.; Misra, M.; Mohanty, A.K. Improving the Impact Strength and Heat Resistance of 3D Printed Models: Structure, Property, and Processing Correlationships during Fused Deposition Modeling (FDM) of Poly(Lactic Acid). ACS Omega 2018, 3, 4400–4411. [Google Scholar] [CrossRef] [PubMed]

- Andrzejewski, J.; Cheng, J.; Anstey, A.; Mohanty, A.K.; Misra, M. Development of Toughened Blends of Poly(lactic acid) and Poly(butylene adipate- co -terephthalate) for 3D Printing Applications: Compatibilization Methods and Material Performance Evaluation. ACS Sustain. Chem. Eng. 2020, 8, 6576–6589. [Google Scholar] [CrossRef]

- Cicala, G.; Giordano, D.; Tosto, C.; Filippone, G.; Recca, A.; Blanco, I. Polylactide (PLA) filaments a biobased solution for additive manufacturing: Correlating rheology and thermomechanical properties with printing quality. Materials 2018, 11, 1191. [Google Scholar] [CrossRef] [PubMed]

- Kulinski, Z.; Piorkowska, E. Crystallization, structure and properties of plasticized poly(l-lactide). Polymer 2005, 46, 10290–10300. [Google Scholar] [CrossRef]

- Huang, H.; Chen, L.; Song, G.; Tang, G. An efficient plasticization method for poly(lactic acid) using combination of liquid-state and solid-state plasticizers. J. Appl. Polym. Sci. 2018, 135, 46669. [Google Scholar] [CrossRef]

- Zubrowska, A.; Piorkowska, E.; Kowalewska, A.; Cichorek, M. Novel blends of polylactide with ethylene glycol derivatives of POSS. Colloid Polym. Sci. 2014, 293, 23–33. [Google Scholar] [CrossRef]

- Saad, G.R.; Elsawy, M.A.; Aziz, M.S.A. Nonisothermal crystallization behavior and molecular dynamics of poly(lactic acid) plasticized with jojoba oil. J. Therm. Anal. Calorim. 2017, 128, 211–223. [Google Scholar] [CrossRef]

- Najafi, N.; Heuzey, M.C.; Carreau, P.J.; Wood-Adams, P.M. Control of thermal degradation of polylactide (PLA)-clay nanocomposites using chain extenders. Polym. Degrad. Stab. 2012, 97, 554–565. [Google Scholar] [CrossRef]

- Gui, Z.; Lu, C.; Cheng, S. Comparison of the effects of commercial nucleation agents on the crystallization and melting behaviour of polylactide. Polym. Test. 2013, 32, 15–21. [Google Scholar] [CrossRef]

- Courgneau, C.; Ducruet, V.; Averous, L.; Grenet, J.; Domenek, S. Nonisothermal crystallization kinetics of poly(lactide)—Effect of plasticizers and nucleating agnet. Polym. Eng. Sci. 2012, 53, 1085–1098. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Crystallization behavior and morphology of polylactic acid (PLA) with aromatic sulfonate derivative. J. Appl. Polym. Sci. 2016, 133, 43673. [Google Scholar] [CrossRef]

- Singh, S.K.; Anthony, P.; Chowdhury, A. High molecular weight poly(lactic acid) synthesized with apposite catalytic combination and longer time. Orient. J. Chem. 2018, 34, 1984–1990. [Google Scholar] [CrossRef]

- Cicala, G.; Saccullo, G.; Blanco, I.; Samal, S.; Battiato, S.; Dattilo, S.; Saake, B. Polylactide/lignin blends: Effects of processing conditions on structure and thermo-mechanical properties. J. Therm. Anal. Calorim. 2017, 130, 515–524. [Google Scholar] [CrossRef]

- Blanco, I. End-life prediction of commercial pla used for food packaging through short term TGA experiments: Real chance or low reliability. Chin. J. Polym. Sci. 2014, 32, 681–689. [Google Scholar] [CrossRef]

- Ahmed, I.; Cronin, P.S.; Abou Neel, E.A.; Parsons, A.J.; Knowles, J.C.; Rudd, C.D. Retention of mechanical properties and cytocompatibility of a phosphate-based glass fiber/polylactic acid composite. J. Biomed. Mater. Res. Part B Appl. Biomater. 2009, 89B, 18–27. [Google Scholar] [CrossRef]

- Orue, A.; Eceiza, A.; Arbelaiz, A. Preparation and characterization of poly(lactic acid) plasticized with vegetable oils and reinforced with sisal fibers. Ind. Crops Prod. 2018, 112, 170–180. [Google Scholar] [CrossRef]

- Duan, J.; Wu, H.; Fu, W.; Hao, M. Mechanical Properties of Hybrid Sisal/Coir Fibers Reinforced Polylactide Biocomposites. Polym. Compos. 2018, 39, E188–E199. [Google Scholar] [CrossRef]

- Arbelaiz, A.; Trifol, J.; Peña-Rodriguez, C.; Labidi, J.; Eceiza, A. Modification of Poly(Lactic Acid) Matrix by Chemically Modified Flax Fiber Bundles and Poly(Ethylene Glycol) Plasticizer. In Polyethylene-Based Biocomposites and Bionanocomposites; Scrivener Publishing: Beverly, MA, USA, 2016; pp. 429–445. ISBN 9781119038467. [Google Scholar]

- Stepczyńska, M.; Rytlewski, P. Enzymatic degradation of flax-fibers reinforced polylactide. Int. Biodeterior. Biodegrad. 2018, 126, 160–166. [Google Scholar] [CrossRef]

- Xia, X.; Liu, W.; Zhou, L.; Hua, Z.; Liu, H.; He, S. Modification of flax fiber surface and its compatibilization in polylactic acid/flax composites. Iran. Polym. J. 2016, 25, 25–35. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Szostak, M. Preparation of hybrid poly(lactic acid)/flax composites by the insert overmolding process: Evaluation of mechanical performance and thermomechanical properties. J. Appl. Polym. Sci. 2020 , 138, 49646. [Google Scholar] [CrossRef]

- Kuciel, S.; Mazur, K.; Hebda, M. The Influence of Wood and Basalt Fibres on Mechanical, Thermal and Hydrothermal Properties of PLA Composites. J. Polym. Environ. 2020, 28, 1204–1215. [Google Scholar] [CrossRef]

- Oza, S.; Ning, H.; Ferguson, I.; Lu, N. Effect of surface treatment on thermal stability of the hemp-PLA composites: Correlation of activation energy with thermal degradation. Compos. Part B Eng. 2014, 67, 227–232. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Mamun, A.A.; Volk, J. Barley husk and coconut shell reinforced polypropylene composites: The effect of fibre physical, chemical and surface properties. Compos. Sci. Technol. 2010, 70, 840–846. [Google Scholar] [CrossRef]

- Mittal, V.; Chaudhry, A.U.; Matsko, N.B. True biocomposites with biopolyesters and date seed powder: Mechanical, thermal, and degradation properties. J. Appl. Polym. Sci. 2014, 131, 40816. [Google Scholar] [CrossRef]

- Mittal, V.; Luckachan, G.E.; Chernev, B.; Matsko, N.B. Bio-polyester-date seed powder composites: Morphology and component migration. Polym. Eng. Sci. 2015, 55, 877–888. [Google Scholar] [CrossRef]

- Balart, J.F.; Fombuena, V.; Fenollar, O.; Boronat, T.; Sánchez-Nacher, L. Processing and characterization of high environmental efficiency composites based on PLA and hazelnut shell flour (HSF) with biobased plasticizers derived from epoxidized linseed oil (ELO). Compos. Part B Eng. 2016, 86, 168–177. [Google Scholar] [CrossRef]

- Sanchez-Olivares, G.; Rabe, S.; Pérez-Chávez, R.; Calderas, F.; Schartel, B. Industrial-waste agave fibres in flame-retarded thermoplastic starch biocomposites. Compos. Part B Eng. 2019, 177, 107370. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Kairytė, A. Effect of walnut shells and silanized walnut shells on the mechanical and thermal properties of rigid polyurethane foams. Polym. Test. 2020, 87, 106534. [Google Scholar] [CrossRef]

- Członka, S.; Bertino, M.F.; Strzelec, K.; Strąkowska, A.; Masłowski, M. Rigid polyurethane foams reinforced with solid waste generated in leather industry. Polym. Test. 2018, 69, 225–237. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Barczewski, M. Utilization of linseed cake as a postagricultural functional filler for poly(lactic acid) green composites. J. Appl. Polym. Sci. 2019, 136, 47152. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Barczewski, M.; Skórczewska, K.; Szulc, J.; Kloziński, A. Accelerated weathering of polylactide-based composites filled with linseed cake: The influence of time and oil content within the filler. Polymers 2019, 11, 1495. [Google Scholar] [CrossRef] [PubMed]

- European Bioplastics. Bioplastics Market Data 2019. In Global Production Capacities of Bioplastics 2019–2024; European Bioplastics: Berlin, Germany, 2020. [Google Scholar]

- Tábi, T.; Zarrelli, M. Development of poly(Lactic acid) filled with basalt fibres and talc for engineering applications. Mater. Sci. Forum 2017, 885, 303–308. [Google Scholar] [CrossRef]

- Sinha Ray, S.; Yamada, K.; Okamoto, M.; Ogami, A.; Ueda, K. New polylactide/layered silicate nanocomposites. 3. High-performance biodegradable materials. Chem. Mater. 2003, 15, 1456–1465. [Google Scholar] [CrossRef]

- Tang, Z.; Zhang, C.; Liu, X.; Zhu, J. The crystallization behavior and mechanical properties of polylactic acid in the presence of a crystal nucleating agent. J. Appl. Polym. Sci. 2012, 125, 1108–1115. [Google Scholar] [CrossRef]

- Rahman, M.; Brazel, C.S. The plasticizer market: An assessment of traditional plasticizers and research trends to meet new challenges. Prog. Polym. Sci. 2004, 29, 1223–1248. [Google Scholar] [CrossRef]

- Nassu, R.T.; Gonçalves, L.A.G. Determination of melting point of vegetable oils and fats by differential scanning calorimetry (DSC) technique. Grasas y Aceites 1999, 50, 16–22. [Google Scholar] [CrossRef]

- Sharma, M.; Lokesh, B.R. Effect of enzymatic trans- and interesterification on the thermal properties of groundnut and linseed oils and their blends. JAOCS J. Am. Oil Chem. Soc. 2012, 89, 805–813. [Google Scholar] [CrossRef]

- Ustrnul, Z.; Czekierda, D.; Wypych, A. Extreme values of air temperature in Poland according to different atmospheric circulation classifications. Phys. Chem. Earth 2010, 35, 429–436. [Google Scholar] [CrossRef]

- Brostow, W.; Hagg Lobland, H.E. Sliding wear, viscoelasticity, and brittleness of polymers. J. Mater. Res. 2006, 21, 2422–2428. [Google Scholar] [CrossRef]

- Bayés-García, L.; Sato, K.; Ueno, S. Polymorphism of Triacylglycerols and Natural Fats. In Bailey’s Industrial Oil and Fat Products; Wiley: Hoboken, NJ, USA, 2020; pp. 1–49. ISBN 047167849X. [Google Scholar]

- Hashempour-Baltork, F.; Torbati, M.; Azadmard-Damirchi, S.; Savage, G.P. Chemical, rheological and nutritional characteristics of sesame and olive oils blended with linseed oil. Adv. Pharm. Bull. 2018, 8, 107–113. [Google Scholar] [CrossRef] [PubMed]

- Skrzyńska, E.; Matyja, M. Porównanie właściwości fizykochemicznych wybranych tłuszczy naturalnych oraz ich estrów metylowych. Chemik 2011, 65, 923–935. [Google Scholar]

- Bell, A.; Gordon, M.H.; Jirasubkunakorn, W.; Smith, K.W. Effects of composition on fat rheology and crystallisation. Food Chem. 2007, 101, 799–805. [Google Scholar] [CrossRef]

- Borwankar, R.P.; Frye, L.A.; Blaurock, A.E.; Sasevich, F.J. Rheological Characterization of Melting of Margarines and Tablespreads. Rheol. Foods 1992, 16, 55–74. [Google Scholar]

- Andrzejewski, J.; Barczewski, M.; Szostak, M. Injection molding of highly filled polypropylene-based biocomposites. Buckwheat husk and wood flour filler: A comparison of agricultural and wood industry waste utilization. Polymers 2019, 11, 1881. [Google Scholar] [CrossRef] [PubMed]

- Salasinska, K.; Ryszkowska, J. The effect of filler chemical constitution and morphological properties on the mechanical properties of natural fiber composites. Compos. Interfaces 2015, 22, 39–50. [Google Scholar] [CrossRef]

- Piorkowska, E.; Kulinski, Z.; Galeski, A.; Masirek, R. Plasticization of semicrystalline poly(l-lactide) with poly(propylene glycol). Polymer 2006, 47, 7178–7188. [Google Scholar] [CrossRef]

- Badia, J.-D.; Santonja-Blasco, L.; Martinez-Felipe, A.; Ribes-Greus, A. Dynamic Mechanical Thermal Analysis in Polymer Blends. In Characterization of Polymer Blends: Miscibility, Morphology and Interfaces; Wiley-VCH: Wenheim, Germany, 2015; pp. 365–392. [Google Scholar]

- Liang, J.Z.; Yang, Q.Q. Mechanical properties of carbon black-filled high-density polyethylene antistatic composites. J. Reinf. Plast. Compos. 2009, 28, 295–304. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Misra, M.; Mohanty, A.K. Polycarbonate biocomposites reinforced with a hybrid filler system of recycled carbon fiber and biocarbon: Preparation and thermomechanical characterization. J. Appl. Polym. Sci. 2018, 135, 46449. [Google Scholar] [CrossRef]

- Eslami-Farsani, R.; Reza Khalili, S.M.; Hedayatnasab, Z.; Soleimani, N. Influence of thermal conditions on the tensile properties of basalt fiber reinforced polypropylene-clay nanocomposites. Mater. Des. 2014, 53, 540–549. [Google Scholar] [CrossRef]

- Chieng, B.W.; Ibrahim, N.A.; Then, Y.Y.; Loo, Y.Y. Epoxidized vegetable oils plasticized poly(lactic acid) biocomposites: Mechanical, thermal and morphology properties. Molecules 2014, 19, 16024–16038. [Google Scholar] [CrossRef]

- Al-Mulla, E.A.J.; Yunus, W.M.Z.W.; Ibrahim, N.A.B.; Rahman, M.Z.A. Properties of epoxidized palm oil plasticized polytlactic acid. J. Mater. Sci. 2010, 45, 1942–1946. [Google Scholar] [CrossRef]

- Soleimani, N.; Khalili, S.M.; Farsani, R.E.; Nasab, Z.H. Mechanical properties of nanoclay reinforced polypropylene composites at cryogenic temperature. J. Reinf. Plast. Compos. 2012, 31, 967–976. [Google Scholar] [CrossRef]

- Brostow, W.; Hagg Lobland, H.E. Brittleness of materials: Implications for composites and a relation to impact strength. J. Mater. Sci. 2010, 45, 242–250. [Google Scholar] [CrossRef]

| Impact Strength [kJ/m2] | PLA | PLA-LC0.9 | PLA-LC4.6 | PLA-LC17.7 | PLA-LC30.4 | PLA-LC39.8 |

|---|---|---|---|---|---|---|

| 25 °C | 2.38 ± 0.2 | 1.83 ± 0.3 | 2.17 ± 0.4 | 2.34 ± 0.4 | 2.42 ± 0.4 | 3.12 ± 0.1 |

| −40 °C | 2.24 ± 0.1 | 1.95 ± 0.3 | 2.19 ± 0.1 | 2.18 ± 0.1 | 2.63 ± 0.3 | 2.35 ± 0.2 |

| p-value | 0.2617 | 0.6078 | 0.9448 | 0.4587 | 0.4115 | 0.0002 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mysiukiewicz, O.; Barczewski, M.; Kloziński, A. The Influence of Sub-Zero Conditions on the Mechanical Properties of Polylactide-Based Composites. Materials 2020, 13, 5789. https://doi.org/10.3390/ma13245789

Mysiukiewicz O, Barczewski M, Kloziński A. The Influence of Sub-Zero Conditions on the Mechanical Properties of Polylactide-Based Composites. Materials. 2020; 13(24):5789. https://doi.org/10.3390/ma13245789

Chicago/Turabian StyleMysiukiewicz, Olga, Mateusz Barczewski, and Arkadiusz Kloziński. 2020. "The Influence of Sub-Zero Conditions on the Mechanical Properties of Polylactide-Based Composites" Materials 13, no. 24: 5789. https://doi.org/10.3390/ma13245789

APA StyleMysiukiewicz, O., Barczewski, M., & Kloziński, A. (2020). The Influence of Sub-Zero Conditions on the Mechanical Properties of Polylactide-Based Composites. Materials, 13(24), 5789. https://doi.org/10.3390/ma13245789