Exploring Structural Evolution of Portland Cement Blended with Supplementary Cementitious Materials in Seawater

Abstract

1. Introduction

2. Research Significance

3. Materials and Methods

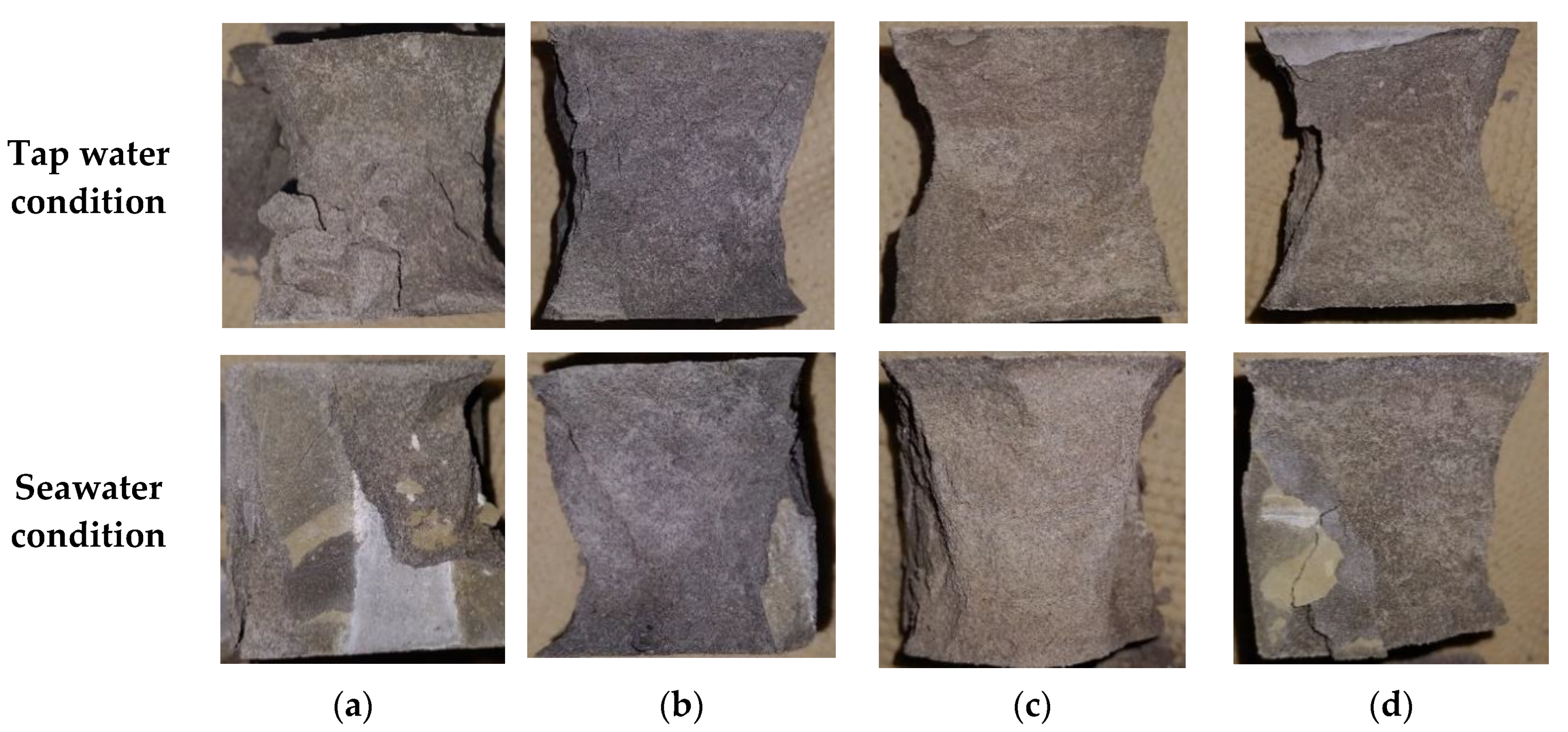

4. Results

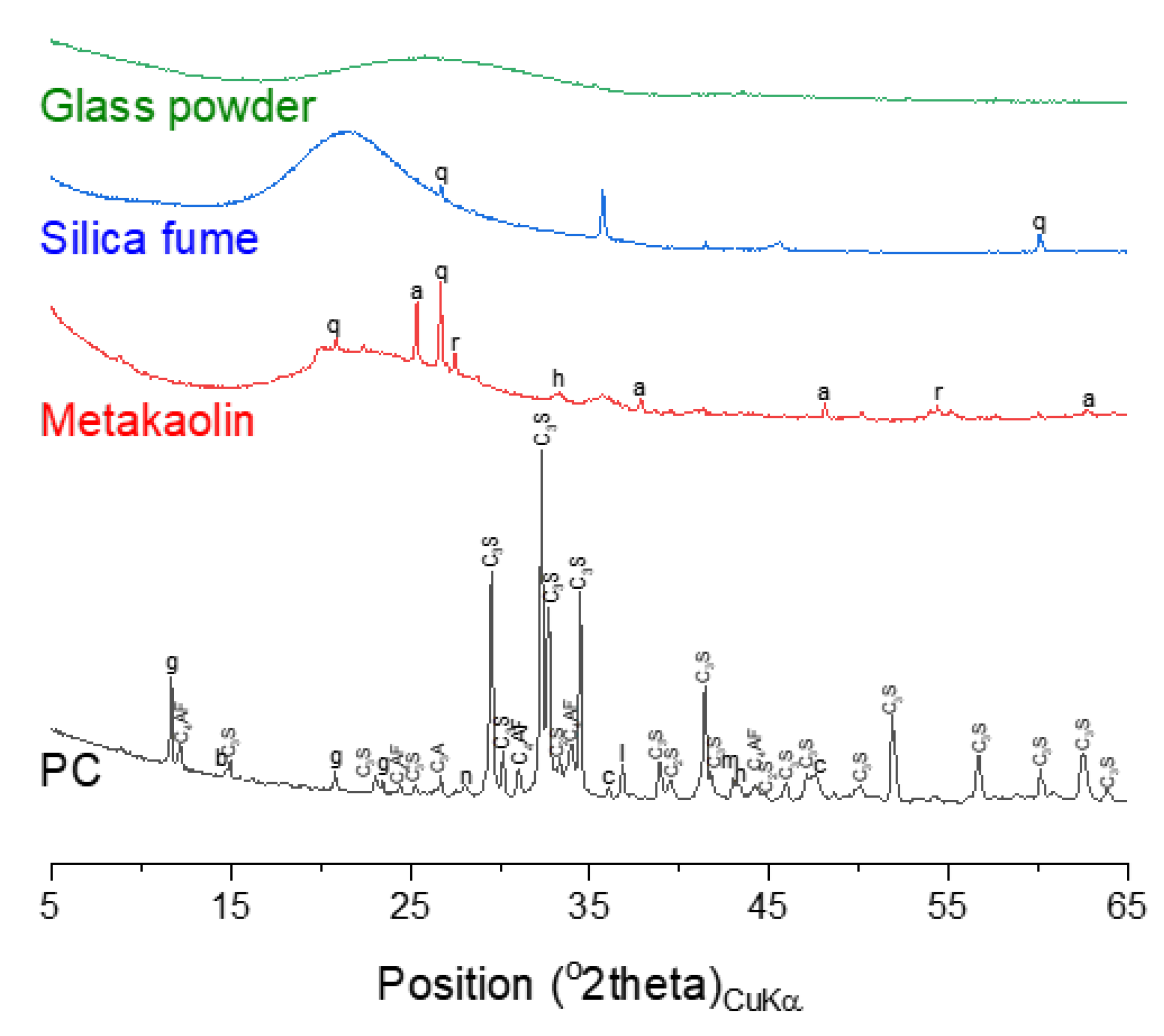

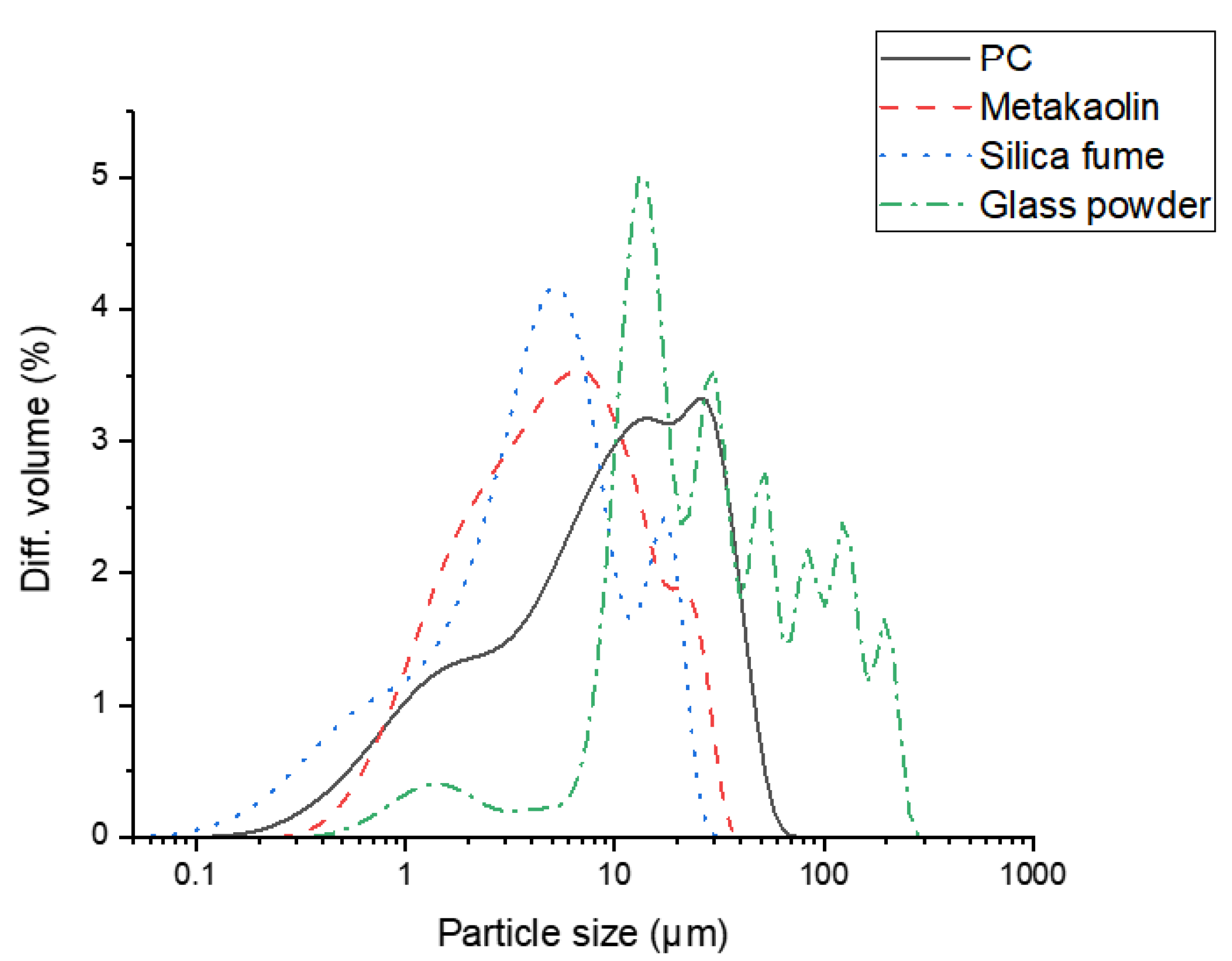

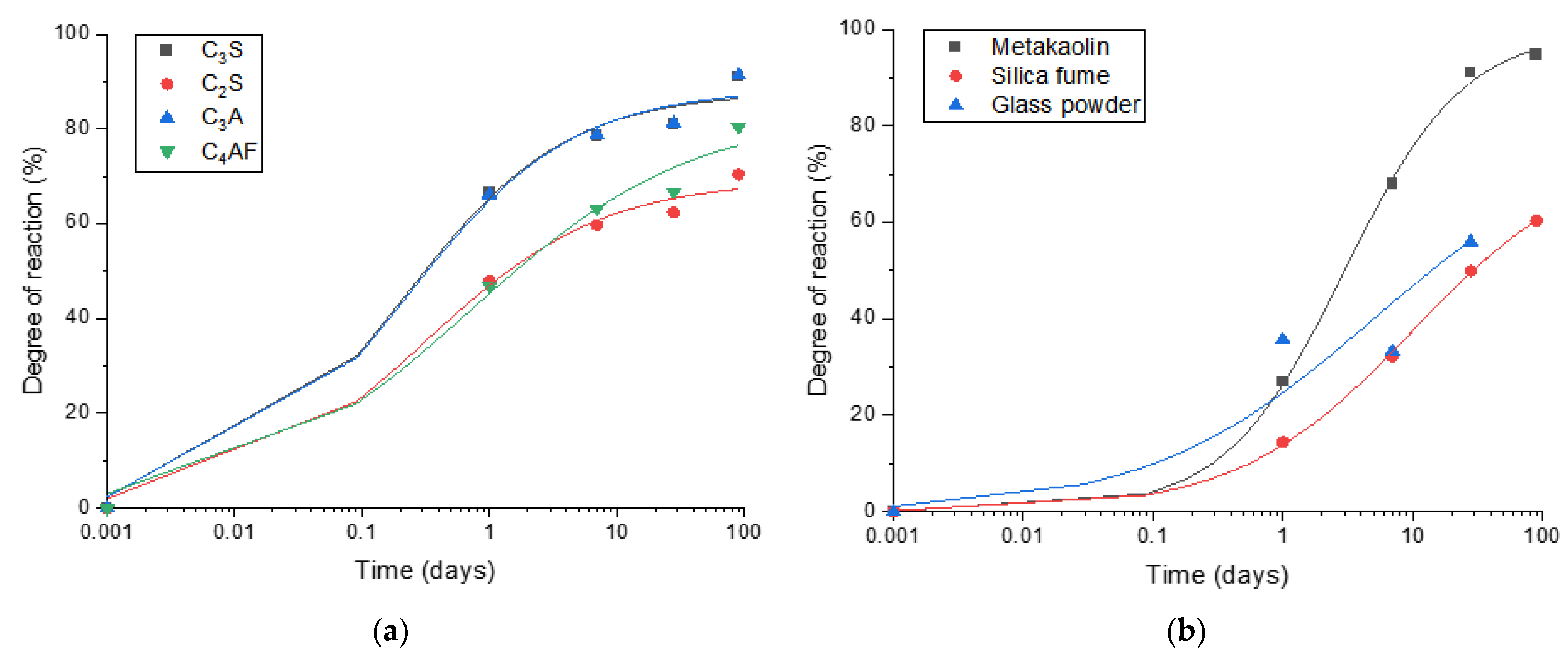

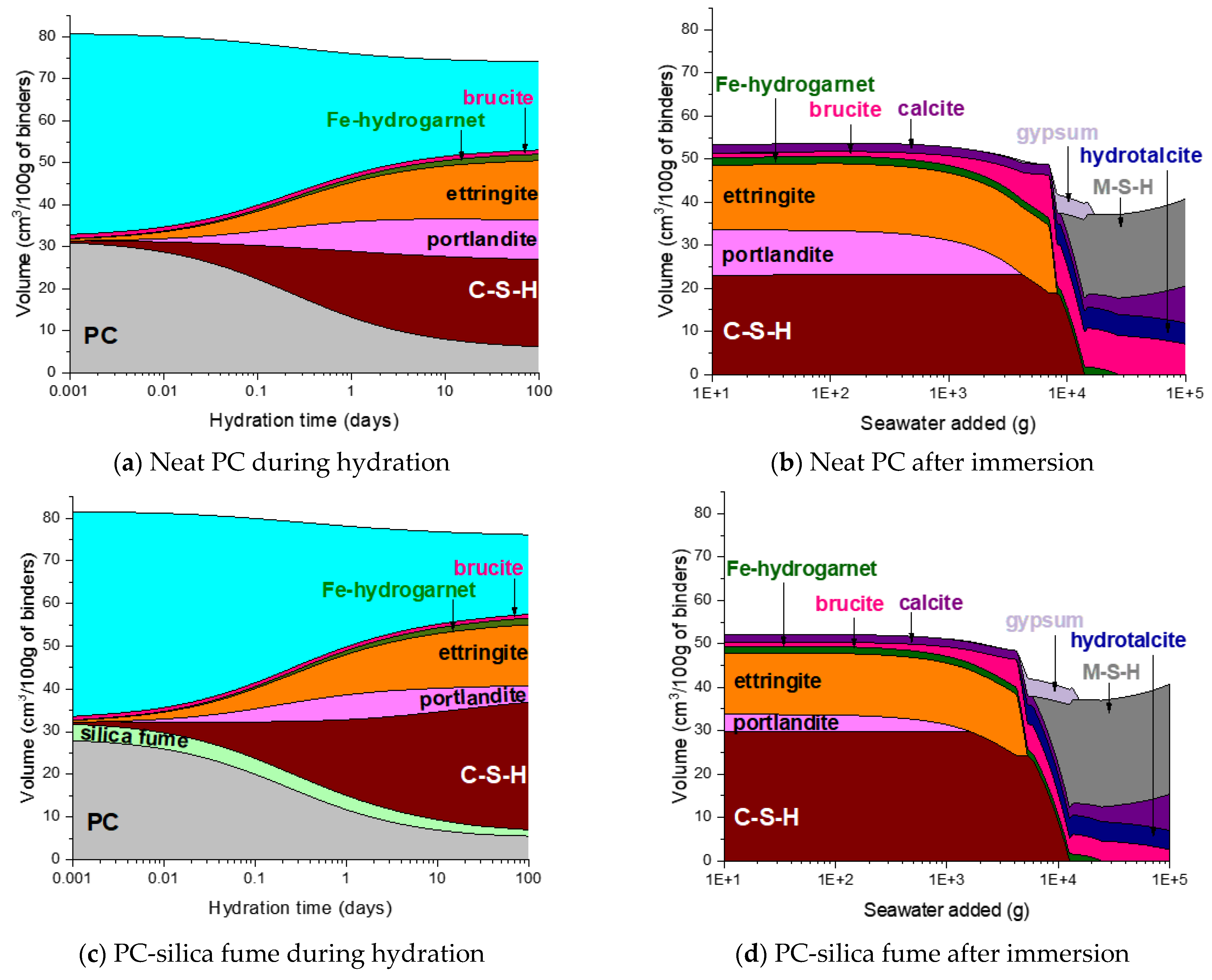

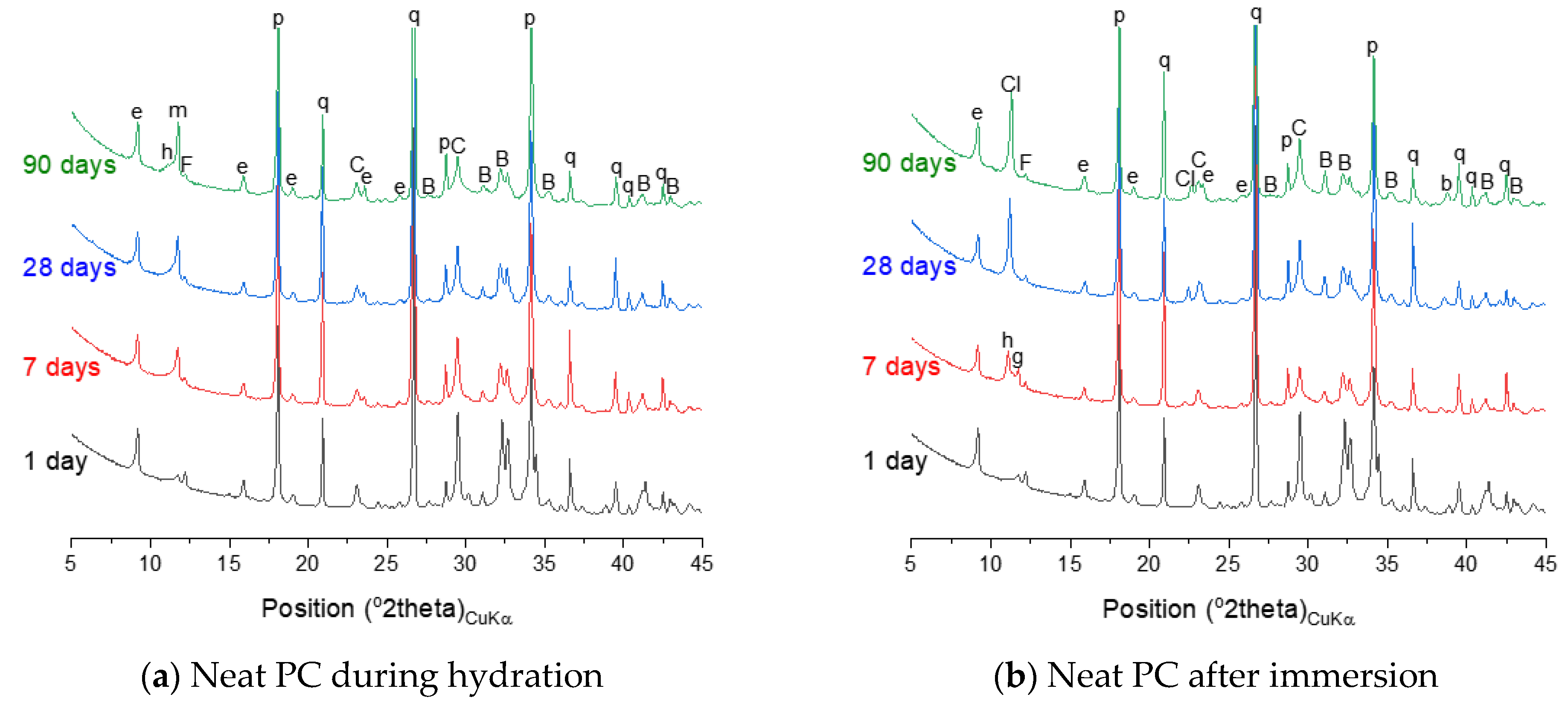

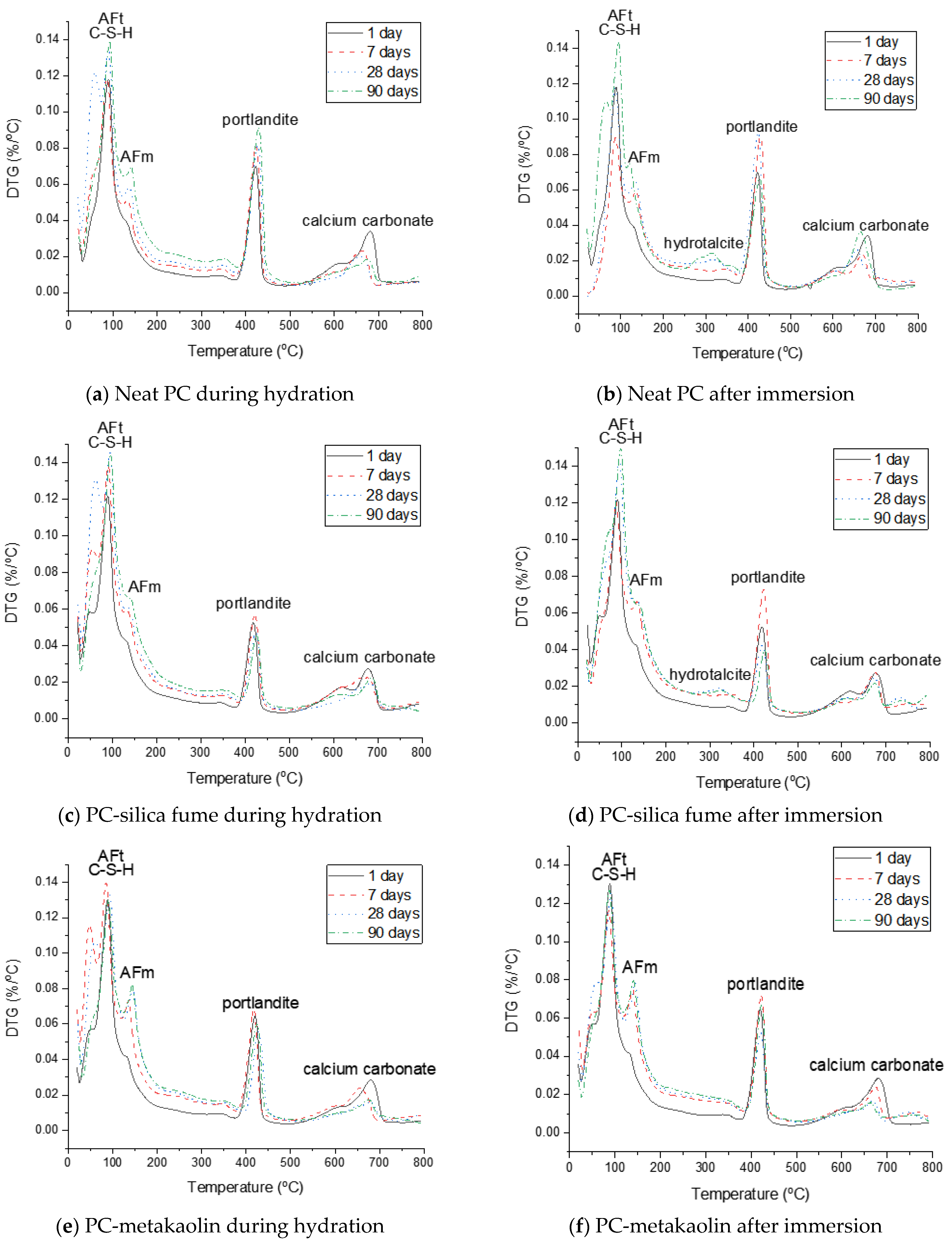

4.1. Phase Assemblage of Neat PC

4.2. Phase Assemblage of PC-Silica Fume

4.3. Phase Assemblage of PC-Metakaolin

4.4. Phase Assemblage of PC-Glass Powder

5. Discussion

6. Conclusions

- The strength development of the neat PC samples was faster when exposed to seawater, while other samples incorporating SCMs exhibited the slower strength development.

- The control exposed to seawater exhibited 14.82% and 12.14% higher compressive strengths compared to those cured in tap water at 7 and 28 days.

- The samples incorporating metakaolin showed the highest compressive strength of 76.60 MPa at 90 days tap water curing and this was 17% higher than that of control.

- The obtained characterization and modelling results show that the phase assemblages of the samples are similar, while there is a quantitative difference in the AFm-related phases.

- The amount of portlandite is highest in the PC-glass powder system due to the high Ca content of the glass powder.

- The main reaction product experimentally observed during the immersion in seawater over 90 days is Cl-AFm and brucite.

- The modelling results predict that M-S-H, calcite and hydrotalcite are to increasingly form at an extended timescale.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- De Weerdt, K.; Lothenbach, B.; Geiker, M.R. Comparing chloride seawater and NaCl solution in Portland cement mortar. Cem. Concr. Res. 2019, 115, 80–89. [Google Scholar] [CrossRef]

- Maes, M.; Mittermayr, F.; De Belie, N. The influence of sodium and magnesium sulphate on the penetration of chlorides in mortar. Mater. Struct. 2017, 50, 153. [Google Scholar] [CrossRef]

- Bai, J.; Wild, S.; Sabir, B. Chloride ingress and strength loss in concrete with different PC–PFA–MK binder compositions exposed to synthetic seawater. Cem. Concr. Res. 2003, 33, 353–362. [Google Scholar] [CrossRef]

- Chen, H.-J.; Huang, S.-S.; Tang, C.-W.; Malek, M.A.; Ean, L.-W. Effect of curing environments on strength, porosity and chloride ingress resistance of blast furnace slag cement concretes: A construction site study. Constr. Build. Mater. 2012, 35, 1063–1070. [Google Scholar] [CrossRef]

- Yang, J.M.; Tang, Q.Q.; Wu, Q.S.; Li, X.H.; Sun, Z.X. The effect of seawater curing on properties of magnesium potassium phosphate cement. Constr. Build. Mater. 2017, 141, 470–478. [Google Scholar] [CrossRef]

- De Weerdt, K.; Justnes, H.; Geiker, M.R. Changes in the phase assemblage of concrete exposed to sea water. Cem. Concr. Compos. 2014, 47, 53–63. [Google Scholar] [CrossRef]

- De Weerdt, K.; Justnes, H. The effect of sea water on the phase assemblage of hydrated cement paste. Cem. Concr. Compos. 2015, 55, 215–222. [Google Scholar] [CrossRef]

- Thomas, M.D.; Scott, A.; Bremner, T.; Bilodeau, A.; Day, D. Performance of slag concrete in marine environment. ACI Mater. J. 2008, 105, 628–634. [Google Scholar]

- Thomas, M.D.A.; Hooton, R.D.; Scott, A.; Zibara, H. The effect of supplementary cementitious materials on chloride binding in hardened cement paste. Cem. Concr. Res. 2012, 42, 1–7. [Google Scholar] [CrossRef]

- Elahi, A.; Basheer, P.A.M.; Nanukuttan, S.V.; Khan, Q.U.Z. Mechanical and durability properties of high performance concretes containing supplementary cementitious materials. Constr. Build. Mater. 2010, 24, 292–299. [Google Scholar] [CrossRef]

- Adu-Amankwah, S.; Zajac, M.; Stabler, C.; Lothenbach, B. Influence of limestone on the hydration of ternary slag cements. Cem. Concr. Res. 2017, 100, 96–109. [Google Scholar] [CrossRef]

- De Weerdt, K.; Haha, M.B.; Le Saout, G.; Kjellsen, K.O.; Justnes, H.; Lothenbach, B. Hydration mechanisms of ternary Portland cements containing limestone powder and fly ash. Cem. Concr. Res. 2011, 41, 279–291. [Google Scholar] [CrossRef]

- Deschner, F.; Lothenbach, B.; Winnefeld, F.; Neubauer, J. Effect of temperature on the hydration of Portland cement blended with siliceous fly ash. Cem. Concr. Res. 2013, 52, 169–181. [Google Scholar] [CrossRef]

- Yoon, H.; Seo, J.; Kim, S.; Lee, H.-K.; Park, S. Characterization of blast furnace slag-blended Portland cement for immobilization of Co. Cem. Concr. Res. 2020, 134, 106089. [Google Scholar] [CrossRef]

- Shi, Z.; Geiker, M.R.; De Weerdt, K.; Østnor, T.A.; Lothenbach, B.; Winnefeld, F.; Skibsted, J. Role of calcium on chloride binding in hydrated Portland cement–metakaolin–limestone blends. Cem. Concr. Res. 2017, 95, 205–216. [Google Scholar] [CrossRef]

- Shi, Z.G.; Lothenbach, B.; Geiker, M.R.; Kaufmann, J.; Leemann, A.; Ferreiro, S.; Skibsted, J. Experimental studies and thermodynamic modeling of the carbonation of Portland cement, metakaolin and limestone mortars. Cem. Concr. Res. 2016, 88, 60–72. [Google Scholar] [CrossRef]

- Leng, F.; Feng, N.; Lu, X. An experimental study on the properties of resistance to diffusion of chloride ions of fly ash and blast furnace slag concrete. Cem. Concr. Res. 2000, 30, 989–992. [Google Scholar] [CrossRef]

- Li, H.; Farzadnia, N.; Shi, C. The role of seawater in interaction of slag and silica fume with cement in low water-to-binder ratio pastes at the early age of hydration. Constr. Build. Mater. 2018, 185, 508–518. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Properties of high volume glass powder concrete. Cem. Concr. Compos. 2017, 75, 22–29. [Google Scholar] [CrossRef]

- Sikora, P.; Cendrowski, K.; Elrahman, M.A.; Chung, S.-Y.; Mijowska, E.; Stephan, D. The effects of seawater on the hydration, microstructure and strength development of Portland cement pastes incorporating colloidal silica. Appl. Nanosci. 2019, 3, 1–12. [Google Scholar] [CrossRef]

- Shakiba, M.; Rahgozar, P.; Elahi, A.R.; Rahgozar, R. Effect of activated pozzolan with Ca(OH)2 and nano-SiO2 on microstructure and hydration of high-volume natural pozzolan paste. Civ. Eng. J. 2018, 4, 2437–2449. [Google Scholar] [CrossRef]

- Singh, L.; Karade, S.; Bhattacharyya, S.; Yousuf, M.; Ahalawat, S. Beneficial role of nanosilica in cement based materials—A review. Constr. Build. Mater. 2013, 47, 1069–1077. [Google Scholar] [CrossRef]

- Abousnina, R.; Manalo, A.; Ferdous, W.; Lokuge, W.; Benabed, B.; Al-Jabri, K.S. Characteristics, strength development and microstructure of cement mortar containing oil-contaminated sand. Constr. Build. Mater. 2020, 252, 119155. [Google Scholar] [CrossRef]

- Siddika, A.; Mamun, M.A.A.; Ferdous, W.; Saha, A.K.; Alyousef, R. 3D-printed concrete: Applications, performance, and challenges. J. Sustain. Cem. Based Mater. 2019, 24, 1–38. [Google Scholar] [CrossRef]

- Lothenbach, B.; Kulik, D.A.; Matschei, T.; Balonis, M.; Baquerizo, L.; Dilnes, B.; Miron, J.D.; Myers, R.J. Cemdata18: A chemical thermodynamic database for hydrated Portland cements and alkali-activated materials. Cem. Concr. Res. 2019, 115, 472–506. [Google Scholar] [CrossRef]

- Parrot, L.J.; Killoh, D.C. Prediction of cement hydration. Br. Ceram. Proc. 1984, 35, 41–53. [Google Scholar]

- Lothenbach, B.; Matschei, T.; Möschner, G.; Glasser, F.P. Thermodynamic modelling of the effect of temperature on the hydration and porosity of Portland cement. Cem. Concr. Res. 2008, 38, 1–18. [Google Scholar] [CrossRef]

- Lothenbach, B.; Winnefeld, F. Thermodynamic modelling of the hydration of Portland cement. Cem. Concr. Res. 2006, 36, 209–226. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.; Hooton, R. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Benli, A.; Karataş, M.; Gurses, E. Effect of sea water and MgSO4 solution on the mechanical properties and durability of self-compacting mortars with fly ash/silica fume. Constr. Build. Mater. 2017, 146, 464–474. [Google Scholar] [CrossRef]

- Li, Q.; Geng, H.; Huang, Y.; Shui, Z. Chloride resistance of concrete with metakaolin addition and seawater mixing: A comparative study. Constr. Build. Mater. 2015, 101, 184–192. [Google Scholar] [CrossRef]

| Composition | Cement | Silica Fume | Metakaolin | Glass Powder |

|---|---|---|---|---|

| CaO | 61.0 | 0.2 | 0.6 | 30.1 |

| SiO2 | 17.2 | 92.8 | 48.5 | 51.9 |

| Al2O3 | 4.8 | 0.2 | 43.4 | 13.5 |

| Fe2O3 | 4.1 | 2.2 | 3.2 | 0.3 |

| SO3 | 3.3 | 0.6 | 0.1 | - |

| Na2O | 0.2 | 0.2 | 0.1 | 0.6 |

| K2O | 1.2 | 0.3 | 0.3 | 0.1 |

| MgO | 2.4 | 0.2 | 0.1 | 1.2 |

| SrO | 0.1 | - | - | 0.4 |

| TiO2 | 0.4 | - | 2.3 | 0.4 |

| Others | 0.9 | 0.2 | 0.4 | 0.5 |

| LOI | 4.4 | 3.1 | 1.1 | 1.1 |

| Sieve Size | Mass Retained (%) | Cumulative Mass Retained (%) |

|---|---|---|

| 1.0 mm | 0.00 | 0.00 |

| 850 µm | 0.01 | 0.01 |

| 600 µm | 1.20 | 1.21 |

| 425 µm | 6.50 | 7.71 |

| 300 µm | 28.00 | 35.71 |

| 212 µm | 33.94 | 69.65 |

| 150 µm | 21.05 | 90.70 |

| 106 µm | 7.50 | 98.20 |

| 75 µm | 1.50 | 99.70 |

| Pan | 0.30 | 100.00 |

| Ions | Concentration (mg/L) |

|---|---|

| Cl− | 21,075 ± 829 |

| Br− | 51 ± 2 |

| SO42− | 2258 ± 147 |

| Na+ | 17,075 ± 1798 |

| K+ | 549 ± 40 |

| Ca2+ | 364 ±12 |

| Mg2+ | 973 ± 41 |

| Parameters | A | B | C | D | R2 |

|---|---|---|---|---|---|

| C3S | 0 | 0.676 | 0.205 | 87.878 | 0.991 |

| C2S | 0 | 0.616 | 0.300 | 69.407 | 0.992 |

| C3A | 0 | 0.665 | 0.218 | 88.502 | 0.991 |

| C4AF | 0 | 0.498 | 0.707 | 83.434 | 0.986 |

| Metakaolin | 0.082 | 0.941 | 2.975 | 99.844 | 0.999 |

| Silica fume | 0 | 0.644 | 10 | 75.111 | 0.999 |

| Glass powder * | 0.008 | 0.5 | 5 | 80 | - |

| Type | Compressive Strength (MPa) | |||||||

|---|---|---|---|---|---|---|---|---|

| Tap Water | Seawater | |||||||

| 1 Day | 7 Days | 28 Days | 90 Days | 1 Day | 7 Days | 28 Days | 90 Days | |

| Portland Cement | 21.27 | 41.81 | 50.88 | 65.33 | 21.27 | 46.53 | 52.09 | 58.70 |

| Silica Fume | 20.48 | 53.12 | 64.42 | 71.25 | 20.48 | 54.61 | 62.13 | 67.58 |

| Metakaolin | 19.51 | 52.84 | 66.77 | 76.60 | 19.51 | 52.83 | 61.27 | 74.75 |

| Glass Powder | 16.49 | 46.94 | 53.79 | 66.67 | 16.49 | 41.02 | 53.12 | 65.81 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.; Park, J.K.; Lee, N.; Kim, M.O. Exploring Structural Evolution of Portland Cement Blended with Supplementary Cementitious Materials in Seawater. Materials 2021, 14, 1210. https://doi.org/10.3390/ma14051210

Park S, Park JK, Lee N, Kim MO. Exploring Structural Evolution of Portland Cement Blended with Supplementary Cementitious Materials in Seawater. Materials. 2021; 14(5):1210. https://doi.org/10.3390/ma14051210

Chicago/Turabian StylePark, Solmoi, Jun Kil Park, Namkon Lee, and Min Ook Kim. 2021. "Exploring Structural Evolution of Portland Cement Blended with Supplementary Cementitious Materials in Seawater" Materials 14, no. 5: 1210. https://doi.org/10.3390/ma14051210

APA StylePark, S., Park, J. K., Lee, N., & Kim, M. O. (2021). Exploring Structural Evolution of Portland Cement Blended with Supplementary Cementitious Materials in Seawater. Materials, 14(5), 1210. https://doi.org/10.3390/ma14051210