The Rheometric Analysis of the Polymer Modifier’s Properties in the Environment of Hydrated Cement

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

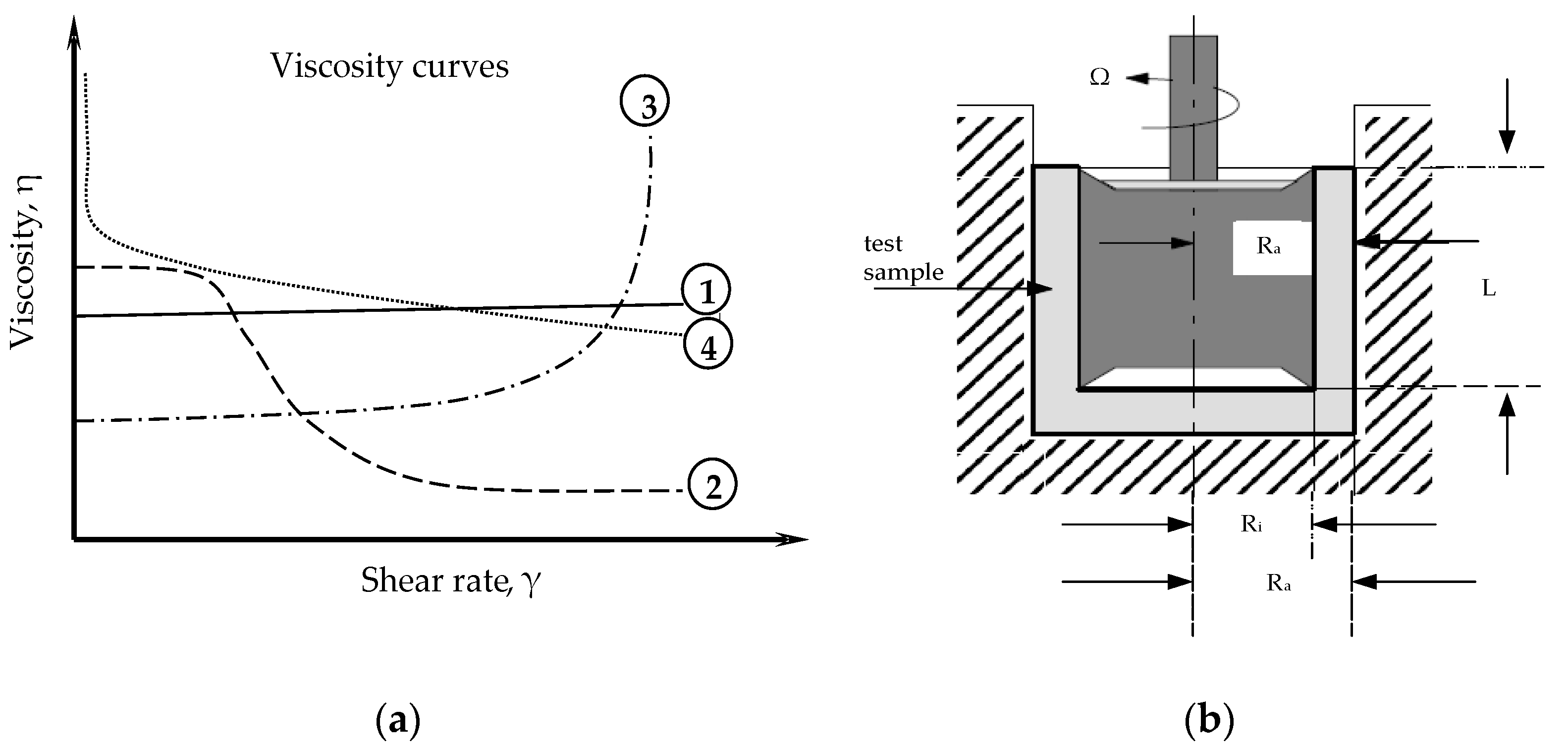

2.2. Testing Method

3. Results

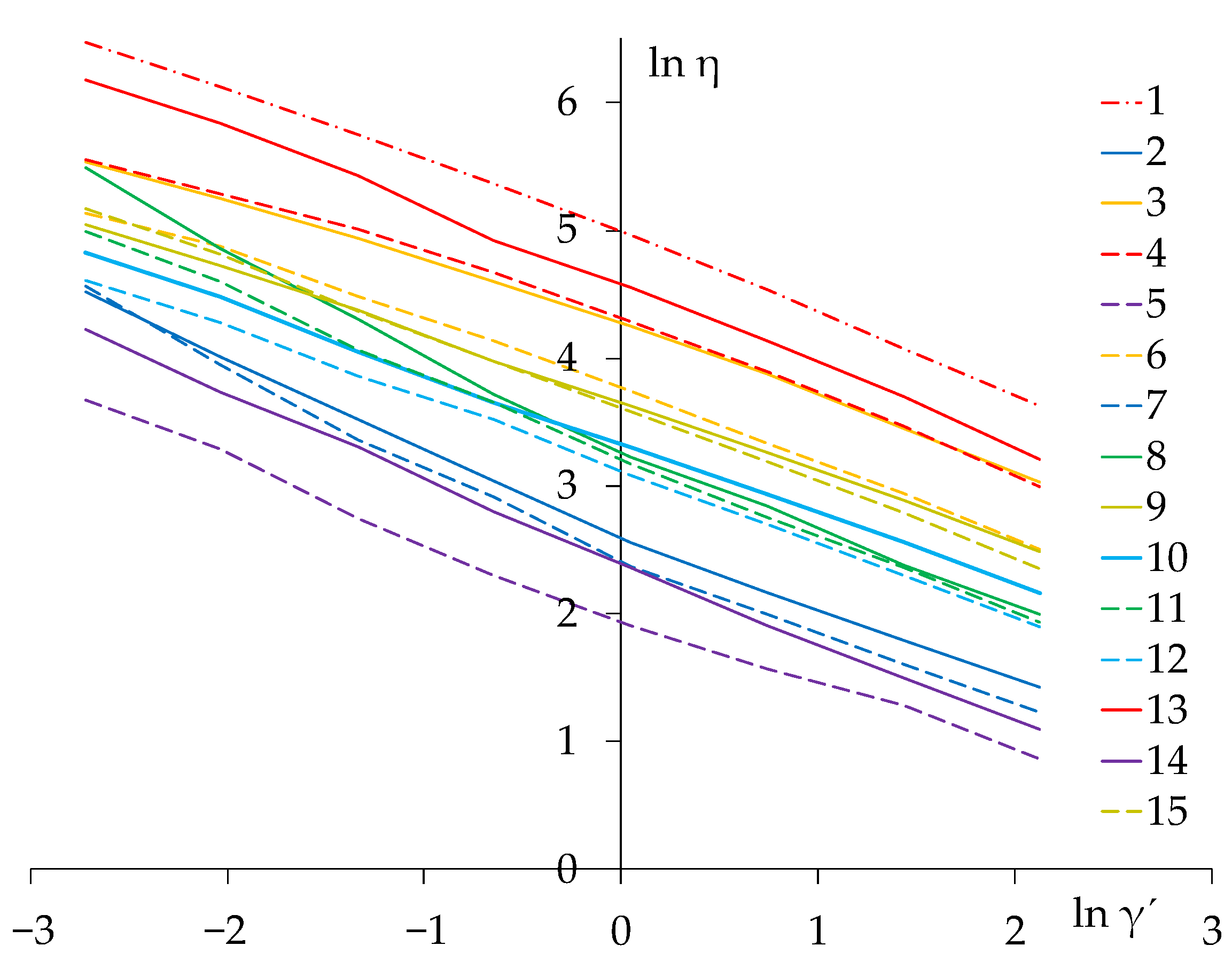

3.1. Rheology of Modified Emulsions

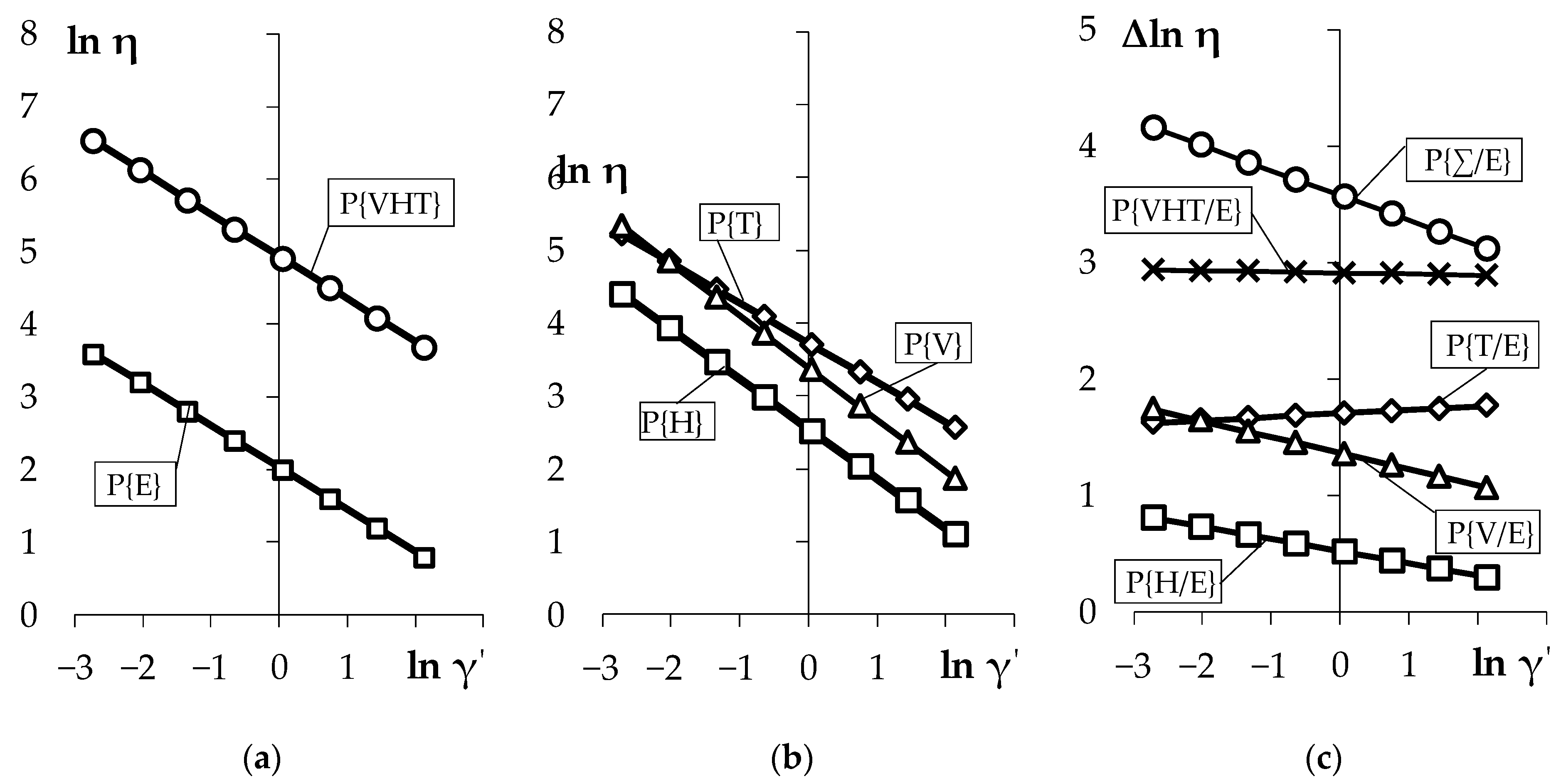

3.2. Effect of Additives on Destruction of the Structure

4. Conclusions

- In polymer emulsions, the greatest influence on viscosity is exerted by a water-retaining additive Tylose P{T}/P{E} = 5.5, indicating a fairly “strong” frame created by cellulose ethers and this effect is greatly dependent on the amount of the cellulose additive. Cellulose reacts a lot more with water due to the preponderance of hydroxyl functional groups. Due to steric interactions of the cellulose chains, the CaOH2 grains and aggregates of another polymer additives move apart. However, the longer the cellulose chains are, the greater their interaction becomes, leading then to a more stable emulsion.

- For emulsions with high viscosity, high values of the rate of structural failure are also characteristic. However, the rate of |m| can be relatively low. Emulsion No. 9, with maximum dosage of vinylacetate Vinnapas (12.5 w.p.), an average dosage of hydrophobic agent (sodium salt) Hostapur (0.15 w.p.) and cellulose Tylose (1.25 w.p.), demonstrates a good stabilized structure with |m| = 0.53 at a viscosity of η = 37.7 Pa∙s. Polymers can create a stable and strong connection with each other due to theirs segments distributed along the chain that tend to interact with each other.

- The viscosity of emulsions increases about 18 times when switching from a minimum to a maximum content of polymer components. Presumably the reference emulsion contains a mosaic structure with weak intermolecular bonds, which increase with increasing concentration of polymers. However, the additivity hypothesis from the simultaneous introduction of all three polymer modifiers in the maximum amount in an emulsion is not confirmed.

- The plasticizing effect of Hostapur is not explicitly detected. The chemical structure of this polymer additive does not significantly effect the rheological behavior of the whole investigated system. However, we have noticed that adding sodium salt enhanced intramolecular association in the solutions while delaying the increase of the viscosity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kozlov, V.V. Sukhye Stroytelnye Smesy; Assotsyatsyya Stroytelnykh Vuzov: Moscow, Russia, 2000; 96p. (In Russian) [Google Scholar]

- Bazhenov, Y.M.; Korovyakov, V.F.; Denisov, G.A. Tekhnologiya Sukhikh Stroitelnykh Smesey; Assotsyatsyya Stroy-Telnykh Vuzov: Moscow, Russia, 2003; 112p. (In Russian) [Google Scholar]

- Karapuzov, Y.K.; Lutts, G.; Gerold, K. Sukhiye Stroitelnyye Smesi; Tekhnika: Kyiv, Ukraine, 2000; 226p. (In Russian) [Google Scholar]

- Runova, R.F.; Nosovskyy, Y.L. Tekhnolohiya Modyfikovanykh Budivelnykh Rozchyniv; KNUBiA: Kyiv, Ukraine, 2007; 256p. (In Ukranian) [Google Scholar]

- Domanskaya, I.; Gerasimova, E.S. Portland Cement with Mineral Fillers and Polymer Additives. Solid State Phenom. 2018, 284, 1063–1068. [Google Scholar] [CrossRef]

- Ohama, Y.; Masahiro, O. Recent Trends in Research and Development Activities of Polymer-Modified Paste, Mortar and Concrete in Japan. Adv. Mater. Res. 2013, 687, 26–34. [Google Scholar] [CrossRef]

- Parikova, Y.V.; Bezborodov, V.A. Vliyaniye mineralnykh i organicheskikh dobavok na svoystva sukhikh stroitelnykh gip-sovykh stroitelnykh smesey. Stroitenyye Mater. 2005, 9, 8–10. Available online: http://rifsm.ru/u/f/sm_09_05.pdf (accessed on 20 December 2020). (In Russian).

- Dong, W.; Fang, C.; Hu, R. Influence of Redispersible Powder on Properties of Self-Leveling Mortar of Ternary Cementitious System. Materials 2020, 13, 5703. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://www.wacker.com/cms/en-us/products/brands/vinnapas/vinnapas.html (accessed on 25 December 2020).

- Vyšvařil, M.; Hegrová, M.; Žižlavský, T. Influence of Cellulose Ethers on Fresh State Properties of Lime Mortars. Solid State Phenom. 2018, 276, 69–74. [Google Scholar] [CrossRef]

- Chernykh, T.N.; Trofimov, B.Y.; Kramar, L.Y. Vliyaniye efirov tsellyulozy na svoystva rastvornykh smesey i rastvorov. Stroitenyye Mater. 2004, 4, 42–43. Available online: http://rifsm.ru/u/f/sm_04_04.pdf (accessed on 25 December 2020). (In Russian).

- Saarinen, T.; Lille, M.; Seppälä, J. Technical aspects on rheological characterization of microfibrillar cellulose water suspen-sions. Annu. Trans. Nord. Rheol. Soc. 2009, 17, 121–128. Available online: https://nrs.blob.core.windows.net/pdfs/nrspdf-4ee0bf9e-940b-4548-8c74-59418beeb9c2.pdf (accessed on 28 December 2020).

- Patural, L.; Marchal, P.; Govin, A.; Grosseau, P.; Ruot, B.; Devès, O. Cellulose ethers influence on water retention and consistency in cement-based mortars. Cem. Concr. Res. 2011, 41, 46–55. [Google Scholar] [CrossRef]

- Nguyen, D.D.; Devlin, L.P.; Koshy, P.; Sorrell, C.C. Impact of water-soluble cellulose ethers on polymer-modified mortars. J. Mater. Sci. 2013, 49, 923–951. [Google Scholar] [CrossRef]

- Patural, L.; Korb, J.-P.; Govin, A.; Grosseau, P.; Ruot, B.; Devès, O. Nuclear magnetic relaxation dispersion investigations of water retention mechanism by cellulose ethers in mortars. Cem. Concr. Res. 2012, 42, 1371–1378. [Google Scholar] [CrossRef]

- Brumaud, C.; Bessaies-Bey, H.; Mohler, C.; Baumann, R.; Schmitz, M.; Radler, M.; Roussel, N. Cellulose ethers and water retention. Cem. Concr. Res. 2013, 53, 176–184. [Google Scholar] [CrossRef]

- Brachaczek, W. Influence of Cellulose Ethers on the Consistency, Water Retention and Adhesion of Renovating Plasters. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Prague, Czech Republic, 18–22 June 2018; Materials Science and Engineering 471. IOP Publishing: Prague, Czech Republic, 2019; p. 032020. [Google Scholar] [CrossRef]

- Palacios, M.; Flatt, R.J. 20-Working mechanism of viscosity-modifying admixtures. In Science and Technology of Concrete Admixtures; Aïtcin, P.-C., Flatt, R.J., Eds.; Woodhead Publishing: Cambridge, UK, 2016; pp. 415–432. ISBN 9780081006931. [Google Scholar] [CrossRef]

- Lowys, M.-P.; Desbrieres, J.; Rinaudo, M. Rheological characterization of cellulosic microfibril suspensions. Role of polymeric additives. Food Hydrocoll. 2001, 15, 25–32. [Google Scholar] [CrossRef]

- Zakharov, V.A.; Pustovgar, A.P. Reologiya stroitelnykh rastvorov dlya mekhanizirovannogo naneseniya. Stroitenyye Mater. 2008, 2, 8–9. Available online: http://rifsm.ru/u/f/sm_02_08.pdf (accessed on 18 December 2020). (In Russian).

- Ferraris, C.F. Measurement of the rheological properties of high performance concrete: State of the art report. J. Res. Natl. Inst. Stand. Technol. 1999, 104, 461–478. [Google Scholar] [CrossRef]

- Haist, M.; Müller, H.S.; Küchenmeister, C.; Plog, J.P. Rheological Properties of Fresh Building Materials. Annu. Trans. Nord. Rheol. Soc. 2009, 17, 229–234. Available online: https://nordicrheologysociety.org/Content/Transactions/2009/Posters/Haist%20et%20al%202009.pdf (accessed on 4 February 2021).

- Mikhailova, O.; Rovnaník, P. Influence of Polymer Admixtures on the Rheological Properties and Heat of Hydration of Alkali Activated Slag Pastes. Solid State Phenom. 2018, 276, 217–222. [Google Scholar] [CrossRef]

- Buczynski, P.; Iwanski, M. Rheological properties of mineral-cement mix with foamed bitumen with the addition of redispersible polymer powder. IOP Conf. Series Mater. Sci. Eng. 2019, 471, 032013. [Google Scholar] [CrossRef]

- Kulesza, M.; Dębski, D.; Fangrat, J. Effect of redispersible polymer powder on setting time of thin-bed mortars. MATEC Web Conf. 2018, 163, 04005. [Google Scholar] [CrossRef]

- Hostapur OSB. Surfactant/Wetting Agent. Available online: https://www.clariant.com/en/Solutions/Products/2013/12/09/18/28/Hostapur-OSB (accessed on 15 December 2020).

- Methylhydroxyethyl Cellulose (MHEC). Available online: https://www.setylose.com/en/products/industrial/tylose-methylcellulose/tylose-mhec (accessed on 15 December 2020).

- Montgomery, D.C. Design and Analysis of Experiments, 8th ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2013; p. 724. [Google Scholar]

- Uryev, N.B.; Ivanov, Y.P. Strukturoobrazovaniye i Reologiya Neorganicheskikh Dispersnykh Sistem i Materialov; BAN: Sofia, Bulgaria, 1991; 210p. (In Russian) [Google Scholar]

- Schramm, G. A Practical Approach to Rheology and Rheometry, 2nd ed.; Gebrueder Haake: Karlsruhe, Germany, 2000; 290p. [Google Scholar]

- Heiner, A.P.; Teleman, O. Interface between Monoclinic Crystalline Cellulose and Water: Breakdown of the Odd/Even Duplicity. Langmuir 1997, 13, 511–518. [Google Scholar] [CrossRef]

- Chassenieux, C.; Nicolai, T.; Benyahia, L. Rheology of associative polymer solutions. Curr. Opin. Colloid Interface Sci. 2011, 16, 18–26. [Google Scholar] [CrossRef]

- Moskalova, C.; Popov, O.; Rozhnyiuk, E. Role of polymer components of mixture as Non-Newtonian fluids. Ovidius Univ. Ann. Ser. Civ. Eng. 2016, 1, 85–91. [Google Scholar]

- Khazraji, A.C.; Robert, S. Self-Assembly and Intermolecular Forces When Cellulose and Water Interact Using Molecular Modeling. J. Nanomater. 2013, 2013, 1–12. [Google Scholar] [CrossRef]

| Property | Vinnapas 5034N | Hostapur OSB | Tylose MH60010 P4 |

|---|---|---|---|

| physical condition and color | white to light beige powder | white–slightly beige dry powder | white powder |

| contain of active substance | min. 98% copolymer powder of vinyl acetate and ethylene | 90–98% olefin sulphonate, sodium salt | 90–95% cellulose methyl ether, 2-hydroxyethyl ether |

| bulk density | 400–550 kg/m3 | 300 kg/m3 | 200–600 kg/m3 |

| particle size | >400 µm | 72 µm | <125 µm: min 90% |

| water solubility | Not applicable | 400 g/L (25 °C) | >10 g/L (20 °C) |

| Type of Admixture | Variation Levels of Polymer Additives | Additive Content Used by Weight from 100 w.p. of Emulsion | ||||

|---|---|---|---|---|---|---|

| x1 (V) | x2 (H) | x3 (T) | X1 (Vinnapas 5034N) | X2 (Hostapur OSB) | X3 (Tylose MH60010 P4) | |

| 1 | + | + | + | 12.5 | 0.25 | 2 |

| 2 | + | + | − | 12.5 | 0.25 | 0.8 |

| 3 | + | − | + | 12.5 | 0.05 | 2 |

| 4 | − | + | + | 3.5 | 0.25 | 2 |

| 5 | − | − | − | 3.5 | 0.05 | 0.8 |

| 6 | − | − | + | 3.5 | 0.05 | 2 |

| 7 | − | + | − | 3.5 | 0.25 | 0.8 |

| 8 | + | − | − | 12.5 | 0.05 | 0.8 |

| 9 | + | 0 | 0 | 12.5 | 0.15 | 1.25 |

| 10 | − | 0 | 0 | 3.5 | 0.15 | 1.25 |

| 11 | 0 | + | 0 | 8 | 0.25 | 1.25 |

| 12 | 0 | − | 0 | 8 | 0.05 | 1.25 |

| 13 | 0 | 0 | + | 8 | 0.15 | 2 |

| 14 | 0 | 0 | − | 8 | 0.15 | 0.8 |

| 15 | 0 | 0 | 0 | 8 | 0.15 | 1.25 |

| No. of Experiment | Ostwald-de-Waele Function | Sna | Results of Experiment | |

|---|---|---|---|---|

| η (Pa∙s) in γ′ = 1 s−1 | |m| | |||

| 1 | 4.94 − 0.59 γ′ | 0.052 | 142.6 | 0.59 |

| 2 | 2.69 − 0.64 γ′ | 0.077 | 12.9 | 0.64 |

| 3 | 4.21 − 0.52 γ′ | 0.064 | 67.36 | 0.52 |

| 4 | 4.24 − 0.53 γ′ | 0.092 | 73.04 | 0.53 |

| 5 | 2.03 − 0.58 γ′ | 0.091 | 6.71 | 0.58 |

| 6 | 3.73 − 0.55 γ′ | 0.053 | 42.14 | 0.55 |

| 7 | 2.55 − 0.68 γ′ | 0.118 | 10.69 | 0.68 |

| 8 | 3.39 − 0.72 γ′ | 0.113 | 25.2 | 0.72 |

| 9 | 3.64 − 0.53 γ′ | 0.023 | 37.7 | 0.53 |

| 10 | 3.33 − 0.55 γ′ | 0.021 | 27.25 | 0.55 |

| 11 | 3.25 − 0.64 γ′ | 0.039 | 23.94 | 0.64 |

| 12 | 3.11 − 0.56 γ′ | 0.025 | 21.89 | 0.56 |

| 13 | 4.56 − 0.61 γ′ | 0.043 | 94.89 | 0.61 |

| 14 | 2.42 − 0.65 γ′ | 0.038 | 10.56 | 0.65 |

| 15 | 3.61 − 0.58 γ′ | 0.017 | 36.08 | 0.58 |

| Formula | Ostwald-de-Waele Function | η (Pa∙s) in γ′ = 1 s−1 | Formula Number |

|---|---|---|---|

| P{VHT}/P{E} | 2.91 − 0.01 lnγ′ | 18.4 | (3a) |

| P{V}/P{E} | 1.36 − 0.14 lnγ′ | 3.9 | (3b) |

| P{H}/P{E} | 0.52 − 0.11 lnγ′ | 1.7 | (3c) |

| P{T}/P{E} | 1.7 − 0.03 lnγ′ | 5.5 | (3d) |

| (3b) + (3c) + (3d) | 3.58 − 0.21 lnγ′ | 35.9 | (3e) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moskalova, K.; Aniskin, A.; Kozina, G.; Soldo, B. The Rheometric Analysis of the Polymer Modifier’s Properties in the Environment of Hydrated Cement. Materials 2021, 14, 1064. https://doi.org/10.3390/ma14051064

Moskalova K, Aniskin A, Kozina G, Soldo B. The Rheometric Analysis of the Polymer Modifier’s Properties in the Environment of Hydrated Cement. Materials. 2021; 14(5):1064. https://doi.org/10.3390/ma14051064

Chicago/Turabian StyleMoskalova, Khrystyna, Aleksej Aniskin, Goran Kozina, and Božo Soldo. 2021. "The Rheometric Analysis of the Polymer Modifier’s Properties in the Environment of Hydrated Cement" Materials 14, no. 5: 1064. https://doi.org/10.3390/ma14051064

APA StyleMoskalova, K., Aniskin, A., Kozina, G., & Soldo, B. (2021). The Rheometric Analysis of the Polymer Modifier’s Properties in the Environment of Hydrated Cement. Materials, 14(5), 1064. https://doi.org/10.3390/ma14051064