Tribological Performance of Additively Manufactured AISI H13 Steel in Different Surface Conditions

Abstract

1. Introduction

2. Materials and Methods

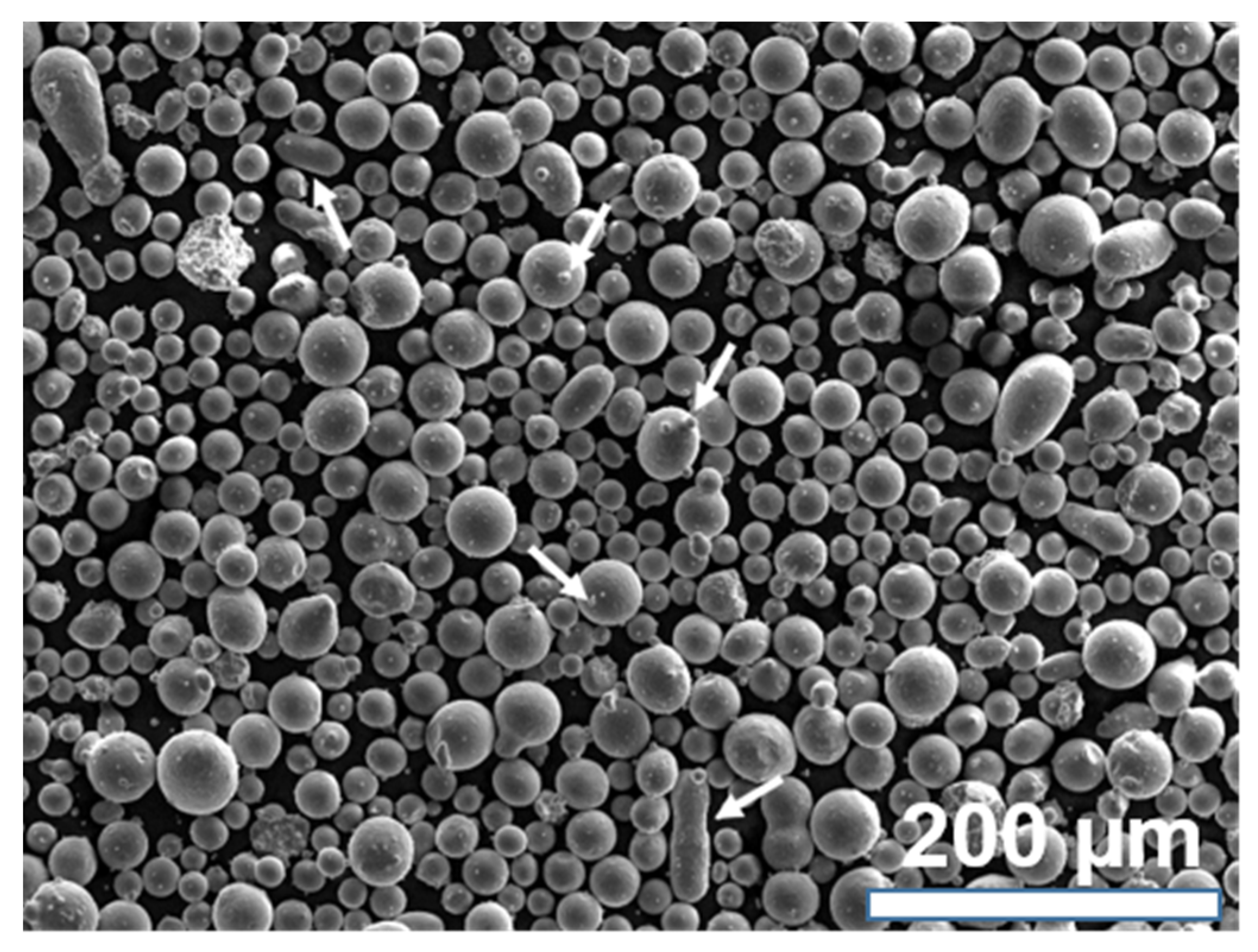

2.1. Additive Manufactoring

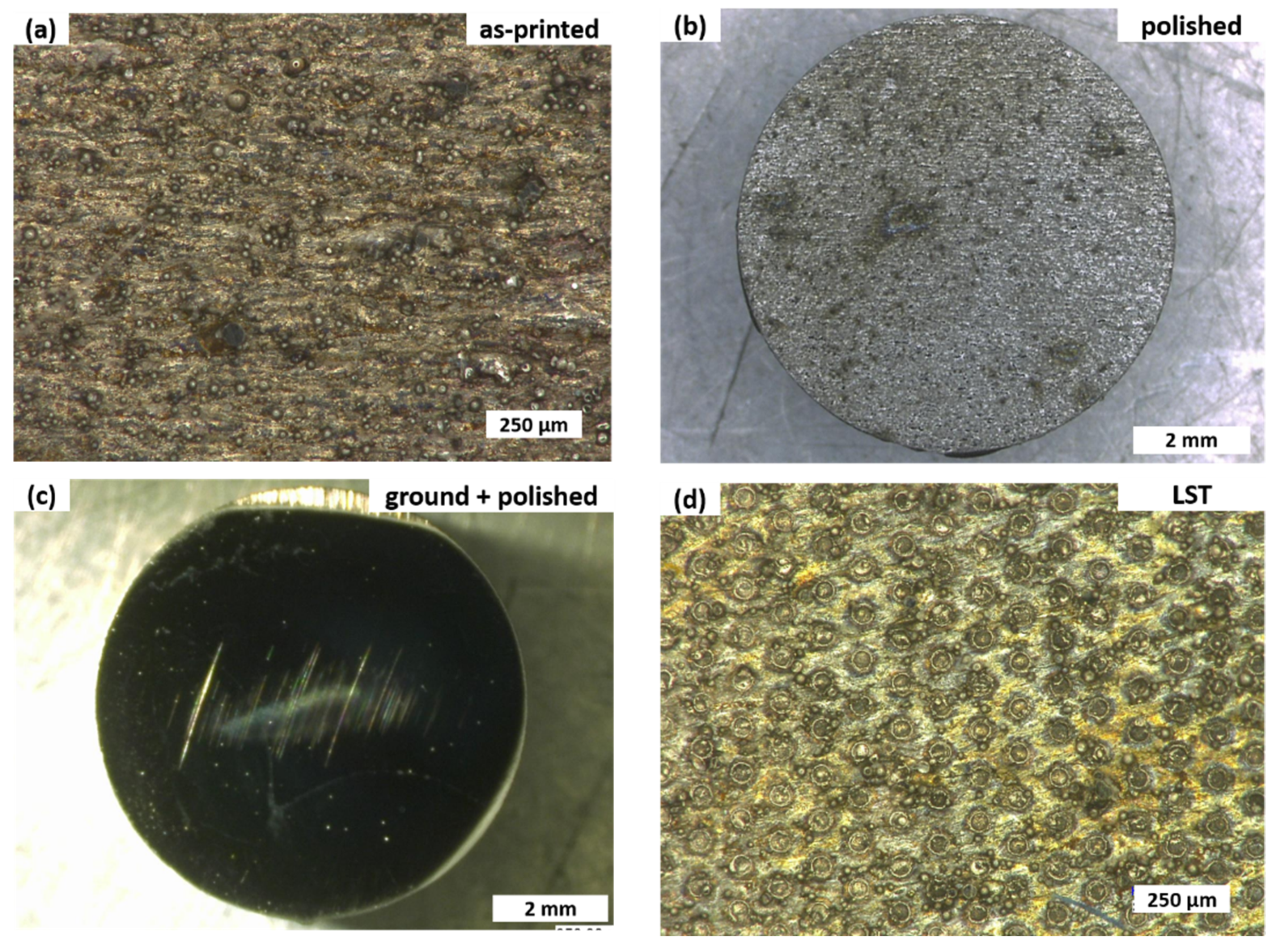

2.2. Surface Treatment and Characterization

2.3. Tribological Testing

2.4. Laser Surface Texturing

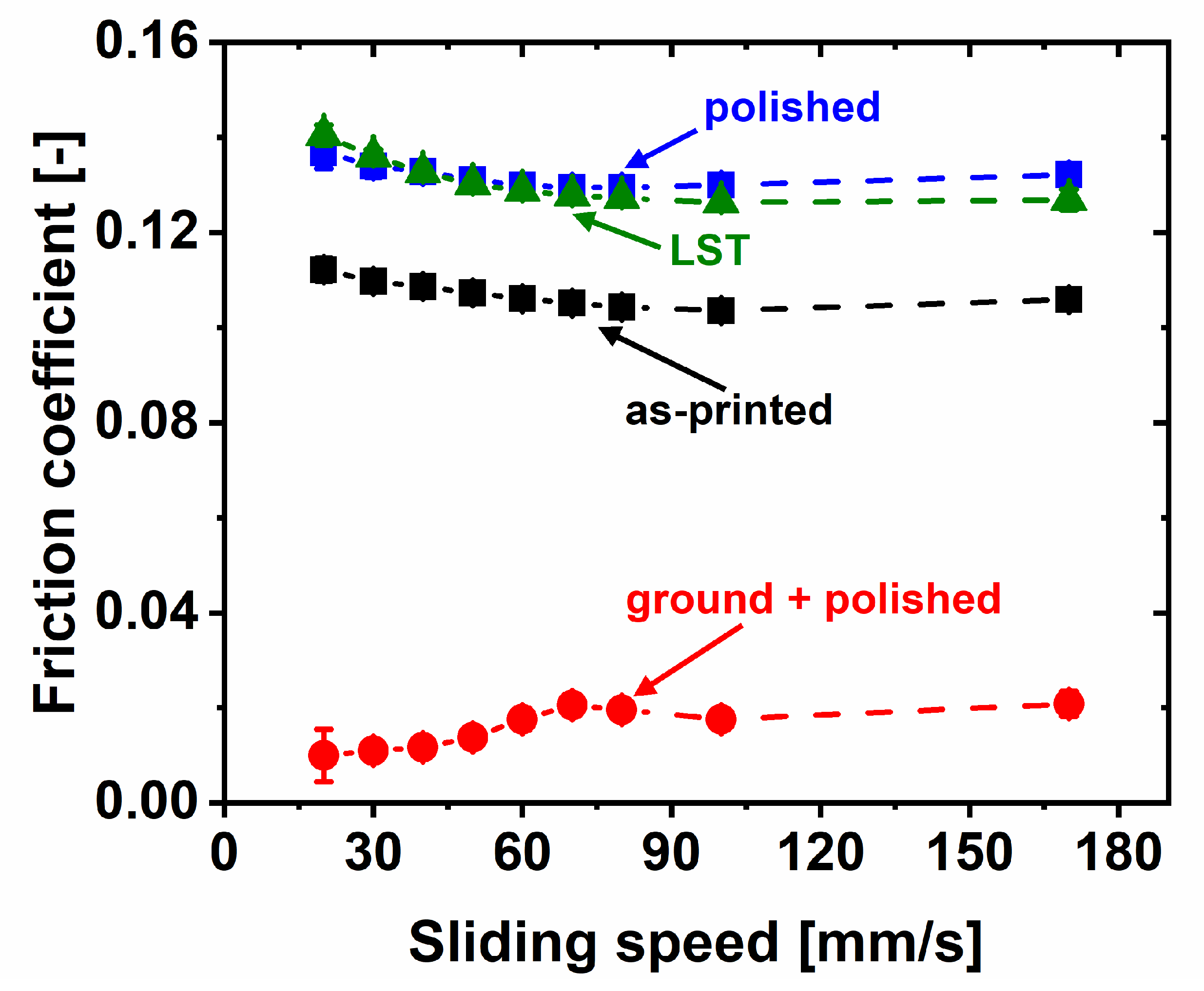

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bajaj, P.; Hariharan, A.; Kini, A.; Kürnsteiner, P.; Raabe, D.; Jägle, E.A. Steels in additive manufacturing: A review of their microstructure and properties. Mater. Sci. Eng. A 2020, 772, 138633. [Google Scholar] [CrossRef]

- Cao, J.; Brinksmeier, E.; Fu, M.; Gao, R.X.; Liang, B.; Merklein, M.; Schmidt, M.; Yanagimoto, J. Manufacturing of advanced smart tooling for metal forming. Cirp Ann. 2019, 68, 605–628. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Strano, G.; Hao, L.; Everson, R.M.; Evans, K.E. Surface roughness analysis, modelling and prediction in selective laser melting. J. Mater. Process. Technol. 2013, 213, 589–597. [Google Scholar] [CrossRef]

- Yasa, E.; Kruth, J.P. Microstructural investigation of Selective Laser Melting 316L stainless steel parts exposed to laser remelting. Procedia Eng. 2011, 19, 389–395. [Google Scholar] [CrossRef]

- Qiu, C.; Panwisawas, C.; Ward, M.; Basoalto, H.C.; Brooks, J.W.; Attallah, M.M. On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Mater. 2015, 96, 72–79. [Google Scholar] [CrossRef]

- Rathod, H.J.; Nagaraju, T.; Prashanth, K.G.; Ramamurty, U. Tribological properties of selective laser melted Al12Si alloy. Tribol. Int. 2019, 137, 94–101. [Google Scholar] [CrossRef]

- Zhu, Y.; Zou, J.; Chen, X.; Yang, H. Tribology of selective laser melting processed parts: Stainless steel 316L under lubricated conditions. Wear 2016, 350–351, 46–55. [Google Scholar] [CrossRef]

- Chandramohan, P.; Bhero, S.; Obadele, B.A.; Olubambi, P.A. Laser additive manufactured Ti–6Al–4V alloy: Tribology and corrosion studies. Int. J. Adv. Manuf. Technol. 2017, 92, 3051–3061. [Google Scholar] [CrossRef]

- Zhu, Y.; Lin, G.; Khonsari, M.M.; Zhang, J.; Yang, H. Material characterization and lubricating behaviors of porous stainless steel fabricated by selective laser melting. J. Mater. Process. Technol. 2018, 262, 41–52. [Google Scholar] [CrossRef]

- Yan, X.; Chen, C.; Bolot, R.; Ma, W.; Deng, C.; Wang, J.; Ren, Z.; Liao, H.; Liu, M. Improvement of tribological performance by micro-arc oxidation treatment on selective laser melting Ti6Al4V alloy. Mater. Res. Express 2019, 6, 096509. [Google Scholar] [CrossRef]

- Li, H.; Ramezani, M.; Li, M.; Ma, C.; Wang, J. Tribological performance of selective laser melted 316L stainless steel. Tribol. Int. 2018, 128, 121–129. [Google Scholar] [CrossRef]

- Hao, J.; Hu, F.; Le, X.; Liu, H.; Yang, H.; Han, J. Microstructure and high-temperature wear behaviour of Inconel 625 multi-layer cladding prepared on H13 mould steel by a hybrid additive manufacturing method. J. Mater. Process. Technol. 2021, 291, 117036. [Google Scholar] [CrossRef]

- King, D.; Middendorf, J.; Cissel, K.; Key, T.; Carney, C. Selective laser melting for the preparation of an ultra-high temperature ceramic coating. Ceram. Int. 2019, 45, 2466–2473. [Google Scholar] [CrossRef]

- Lee, J.; Terner, M.; Copin, E.; Lours, P.; Hong, H.-U. A novel approach to the production of NiCrAlY bond coat onto IN625 superalloy by selective laser melting. Addit. Manuf. 2020, 31, 100998. [Google Scholar] [CrossRef]

- Casati, R.; Coduri, M.; Lecis, N.; Andrianopoli, C.; Vedani, M. Microstructure and mechanical behavior of hot-work tool steels processed by Selective Laser Melting. Mater. Charact. 2018, 137, 50–57. [Google Scholar] [CrossRef]

- Geenen, K.; Röttger, A.; Feld, F.; Theisen, W. Microstructure, mechanical, and tribological properties of M3:2 high-speed steel processed by selective laser melting, hot-isostatic pressing, and casting. Addit. Manuf. 2019, 28, 585–599. [Google Scholar] [CrossRef]

- Stribeck, R. Die Wesentlichen Eigenschaften der Gleit- und Rollenlager. Z. Ver. Deut. Ing. 1902, 46. [Google Scholar]

- Iquebal, A.S.; Sagapuram, D.; Bukkapatnam, S.T.S. Surface plastic flow in polishing of rough surfaces. Sci. Rep. 2019, 9, 10617. [Google Scholar] [CrossRef]

- Jones, M.R.; Nation, B.L.; Wellington-Johnson, J.A.; Curry, J.F.; Kustas, A.B.; Lu, P.; Chandross, M.; Argibay, N. Evidence of Inverse Hall-Petch Behavior and Low Friction and Wear in High Entropy Alloys. Sci. Rep. 2020, 10, 10151. [Google Scholar] [CrossRef] [PubMed]

- Konovalov, S.; Osintsev, K.; Golubeva, A.; Smelov, V.; Ivanov, Y.; Chen, X.; Komissarova, I. Surface modification of Ti-based alloy by selective laser melting of Ni-based superalloy powder. J. Mater. Res. Technol. 2020, 9, 8796–8807. [Google Scholar] [CrossRef]

- Etsion, I. State of the Art in Laser Surface Texturing; Tsinghua University Press: Beijing, China, 2009; pp. 761–762. [Google Scholar]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372, 21–41. [Google Scholar] [CrossRef]

- Wang, L. Use of structured surfaces for friction and wear control on bearing surfaces. Surf. Topogr. Metrol. Prop. 2014, 2, 043001. [Google Scholar] [CrossRef]

- Breidenstein, B.; Brenne, F.; Wu, L.; Niendorf, T.; Denkena, B. Effect of Post-Process Machining on Surface Properties of Additively Manufactured H13 Tool Steel. HTM J. Heat Treat. Mater. 2018, 73, 173–186. [Google Scholar] [CrossRef]

- Braun, D.; Greiner, C.; Schneider, J.; Gumbsch, P. Efficiency of laser surface texturing in the reduction of friction under mixed lubrication. Tribol. Int. 2014, 77, 142–147. [Google Scholar] [CrossRef]

- Schneider, J.; Braun, D.; Greiner, C. Laser textured surfaces for mixed lubrication: Influence of aspect ratio, textured area and dimple arrangement. Lubricants 2017, 5, 32. [Google Scholar] [CrossRef]

- Snyder, J.C.; Thole, K.A. Understanding Laser Powder Bed Fusion Surface Roughness. J. Manuf. Sci. Eng. 2020, 142, 7. [Google Scholar] [CrossRef]

- Greiner, C.; Merz, T.; Braun, D.; Codrignani, A.; Magagnato, F. Optimum dimple diameter for friction reduction with laser surface texturing: The effect of velocity gradient. Surf. Topogr. Metrol. Prop. 2015, 3, 044001. [Google Scholar] [CrossRef]

- Codrignani, A.; Frohnapfel, B.; Magagnato, F.; Schreiber, P.; Schneider, J.; Gumbsch, P. Numerical and experimental investigation of texture shape and position in the macroscopic contact. Tribol. Int. 2018, 122, 46–57. [Google Scholar] [CrossRef]

- Blau, P.J. The significance and use of the friction coefficient. Tribol. Int. 2001, 34, 585–591. [Google Scholar] [CrossRef]

- Zhang, Z.F.; Zhang, L.C.; Mai, Y.W. Particle effects on friction and wear of aluminium matrix composites. J. Mater. Sci. 1995, 30, 5999–6004. [Google Scholar] [CrossRef]

- Gropper, D.; Wang, L.; Harvey, T.J. Hydrodynamic lubrication of textured surfaces: A review of modeling techniques and key findings. Tribol. Int. 2016, 94, 509–529. [Google Scholar] [CrossRef]

- Arghir, M.; Roucou, N.; Helene, M.; Frene, J. Theoretical Analysis of the Incompressible Laminar Flow in a Macro-Roughness Cell. J. Tribol. 2003, 125, 309–318. [Google Scholar] [CrossRef]

- Qiu, Y.; Khonsari, M.M. Performance Analysis of Full-Film Textured Surfaces With Consideration of Roughness Effects. J. Tribol. 2011, 133, 021704. [Google Scholar] [CrossRef]

- Emmens, W.C. Tribology of Flat Contacts and Its Application in Deep Drawing. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 1997. [Google Scholar]

- Patir, N.; Cheng, H.S. An Average Flow Model for Determining Effects of Three-Dimensional Roughness on Partial Hydrodynamic Lubrication. J. Tribol. 1978, 100, 12–17. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. Application of average flow model to lubrication between rough sliding surfaces. J. Lubr. Technol. 1979, 101, 220–229. [Google Scholar] [CrossRef]

- Tripp, J.H. Surface roughness effects in hydrodynamic lubrication: The flow factor method. J. Lubr. Technol. 1983, 105, 458–463. [Google Scholar] [CrossRef]

- Bowden, F.P.; Tabor, D. The Friction and Lubrication of Solids; Clarendon Press: Oxford, UK, 1950. [Google Scholar]

- Eder, S.J.; Grutzmacher, P.G.; Ripoll, M.R.; Dini, D.; Gachot, C. Effect of Temperature on the Deformation Behavior of Copper Nickel Alloys under Sliding. Materials 2021, 14, 16. [Google Scholar]

- Beilby, G.T. Surface flow in crystalline solids under mechanical disturbance. Proc. R. Soc. Lond. 1904, 72, 218–225. [Google Scholar]

| Area | Power, W | Velocity, mm/s | Hatch Distance, mm | Layer Thickness, µm |

|---|---|---|---|---|

| Volume | 270 | 700 | 0.12 | 30 |

| Contour | 100 | 400 | - | 30 |

| Unit | As-Printed | Polished | Ground and Polished | Laser-Textured |

|---|---|---|---|---|

| Sa,before(µm) | 5.74 ± 0.40 | 5.64 ± 0.30 | 0.15 ± 0.05 | 3.80 ± 0.90 |

| Sa,after(µm) | 6.70 ± 0.30 | 6.10 ± 0.40 | 0.06 ± 0.01 | 5.3 ± 0.60 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guenther, E.; Kahlert, M.; Vollmer, M.; Niendorf, T.; Greiner, C. Tribological Performance of Additively Manufactured AISI H13 Steel in Different Surface Conditions. Materials 2021, 14, 928. https://doi.org/10.3390/ma14040928

Guenther E, Kahlert M, Vollmer M, Niendorf T, Greiner C. Tribological Performance of Additively Manufactured AISI H13 Steel in Different Surface Conditions. Materials. 2021; 14(4):928. https://doi.org/10.3390/ma14040928

Chicago/Turabian StyleGuenther, Elisabeth, Moritz Kahlert, Malte Vollmer, Thomas Niendorf, and Christian Greiner. 2021. "Tribological Performance of Additively Manufactured AISI H13 Steel in Different Surface Conditions" Materials 14, no. 4: 928. https://doi.org/10.3390/ma14040928

APA StyleGuenther, E., Kahlert, M., Vollmer, M., Niendorf, T., & Greiner, C. (2021). Tribological Performance of Additively Manufactured AISI H13 Steel in Different Surface Conditions. Materials, 14(4), 928. https://doi.org/10.3390/ma14040928