Optimization of Mechanical Properties and Damage Tolerance in Polymer-Mineral Multilayer Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

2.2. Testing Methods

3. Results and Discussion

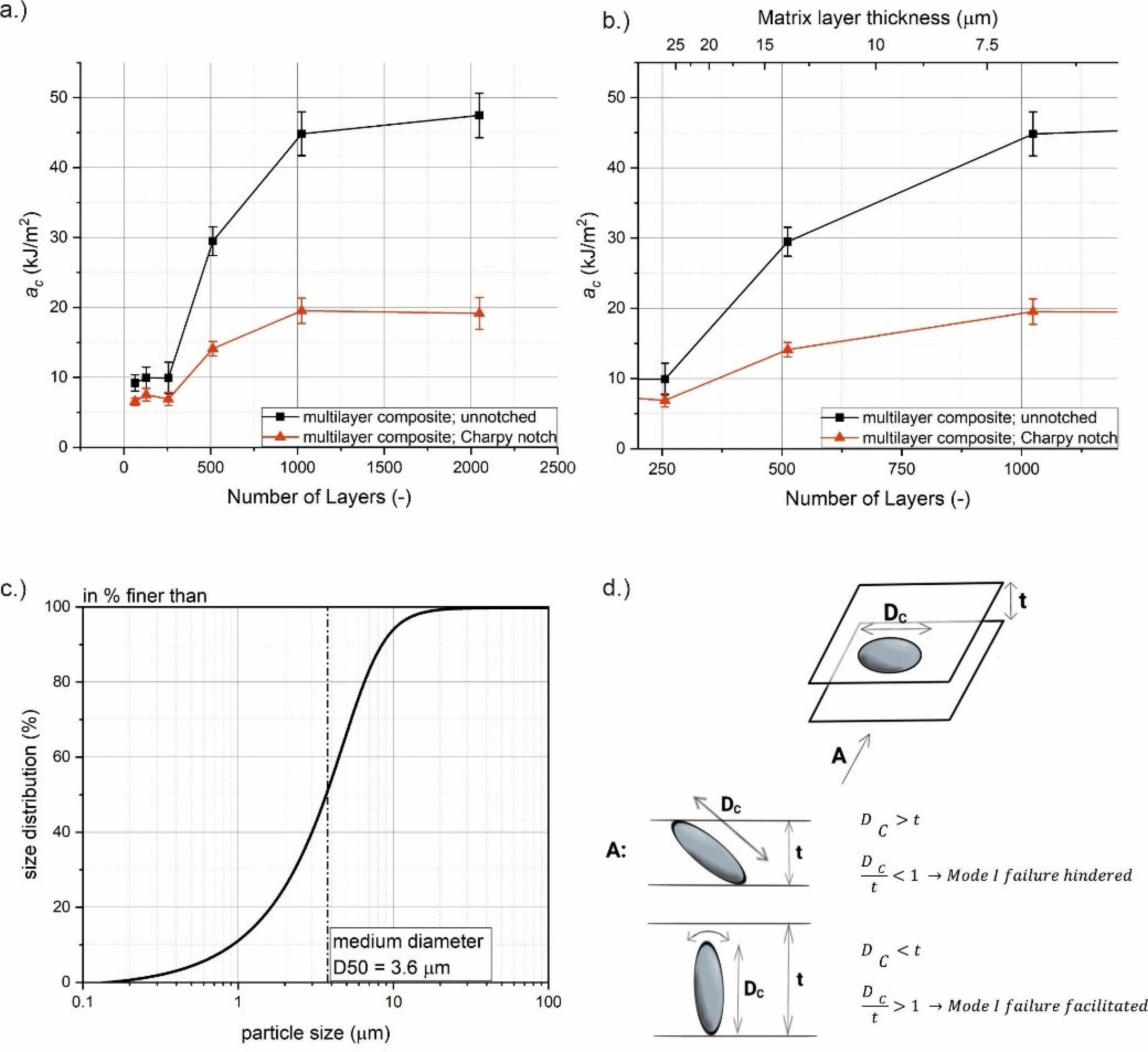

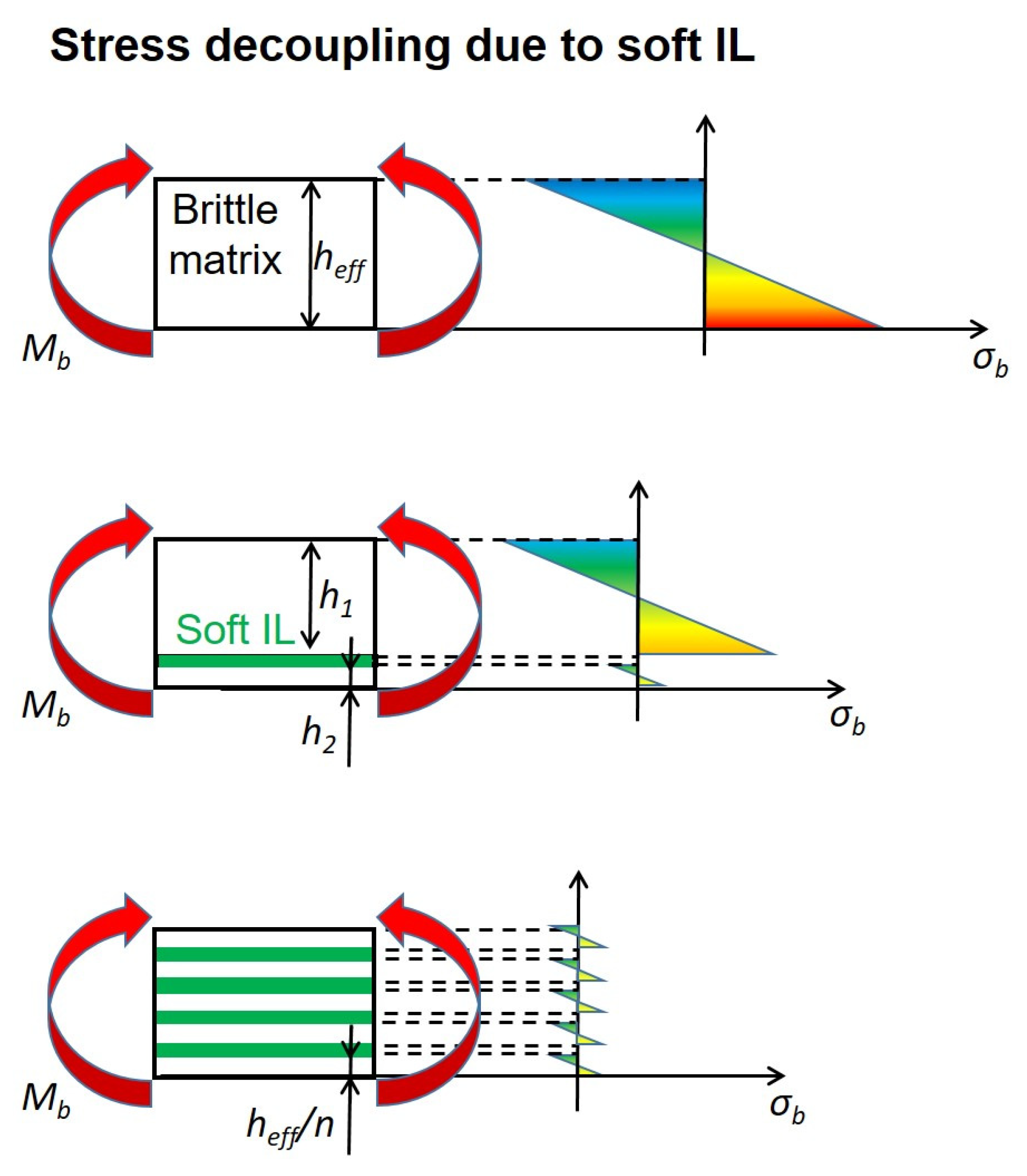

3.1. Impact Strength of Multilayer Composites

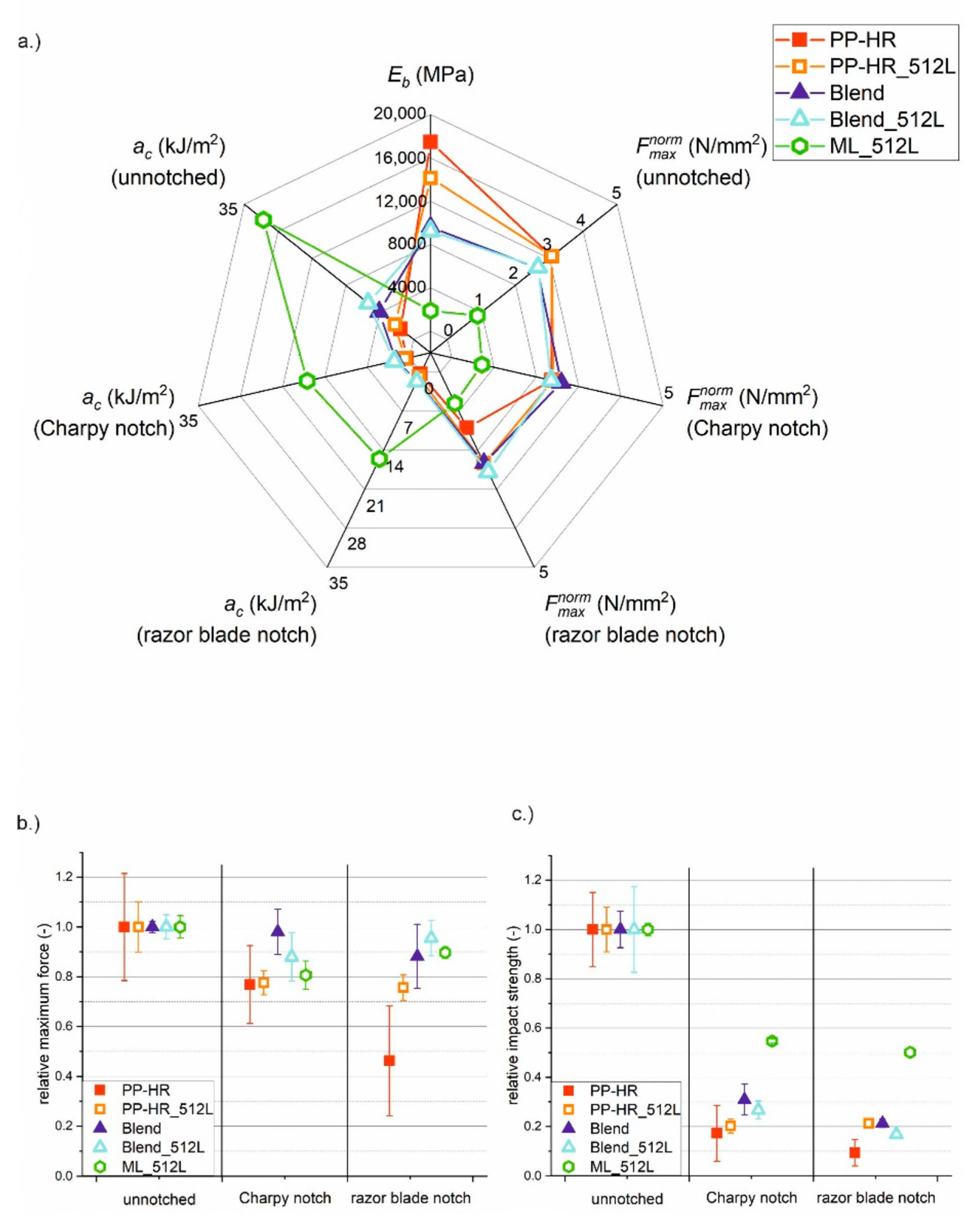

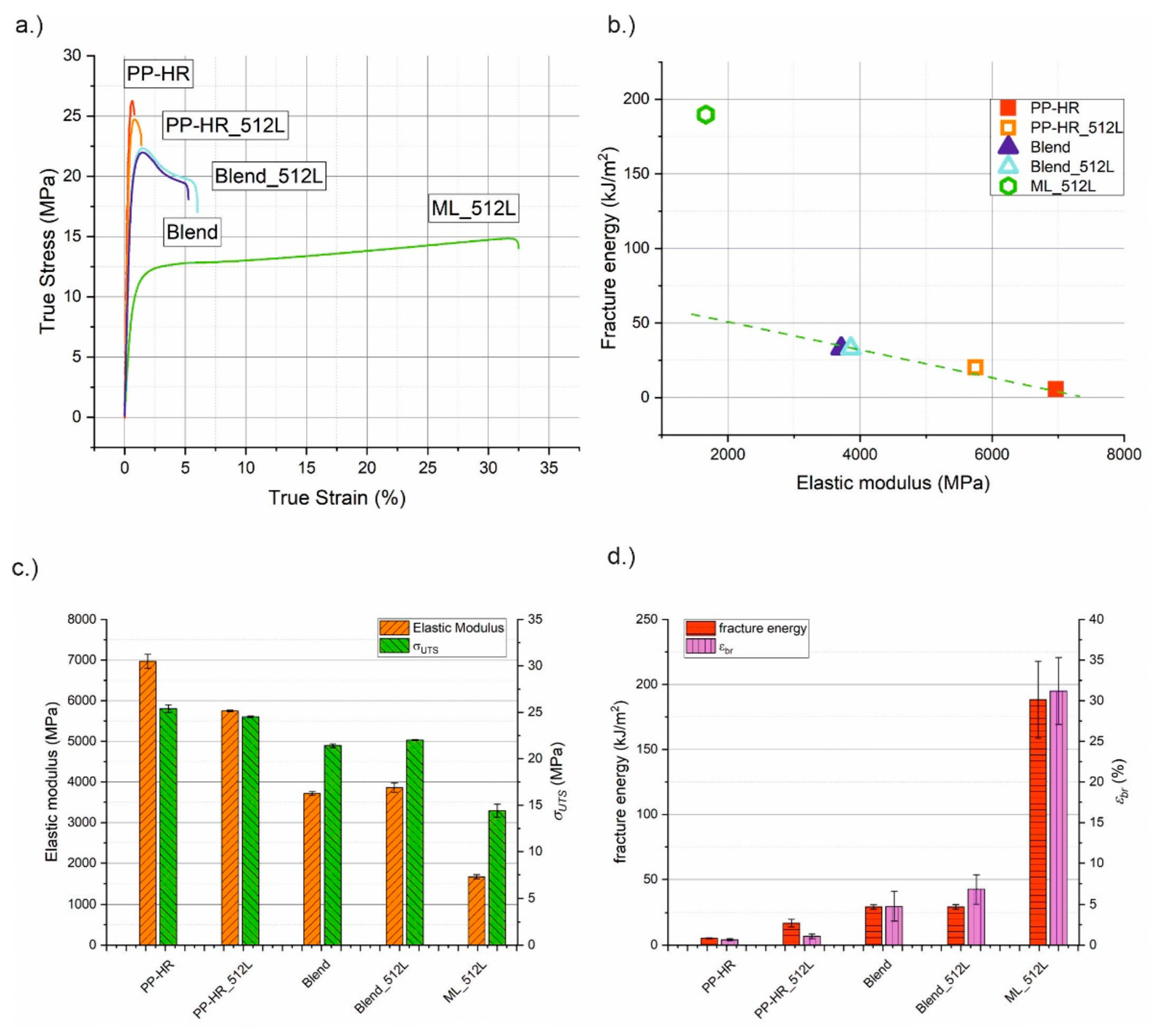

3.2. Comparison of Single and 512-Layer Coextruded Materials

3.3. Synergistic Effect of Layered Architecture

3.4. Influence of Loading Direction

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1. Materials

Appendix A.2. Preparation of Materials via Multilayer Co-Extrusion

Appendix A.3. Specimen Preparation

Appendix A.4. Charpy Measurements

Appendix A.5. Instrumented Charpy Experiments

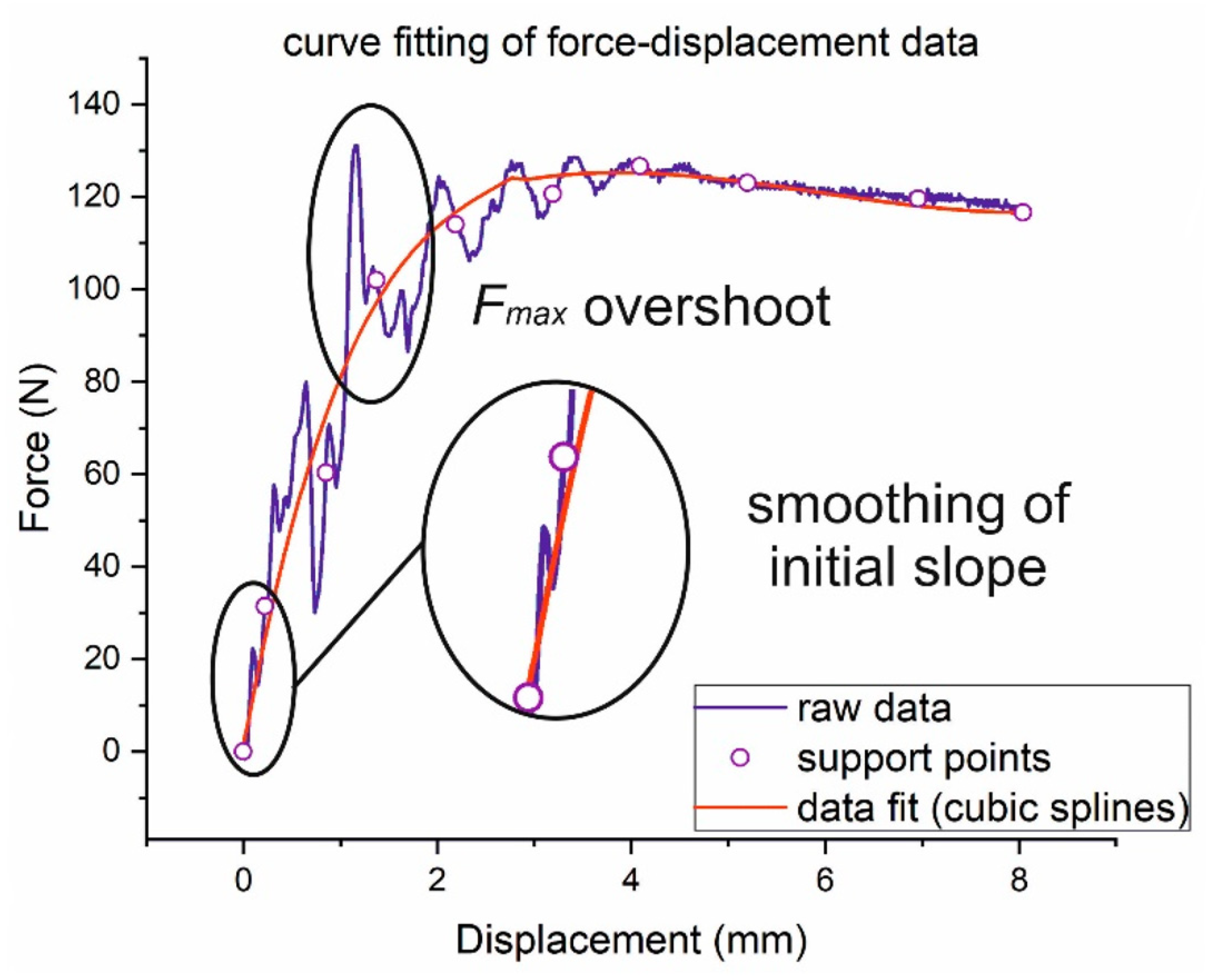

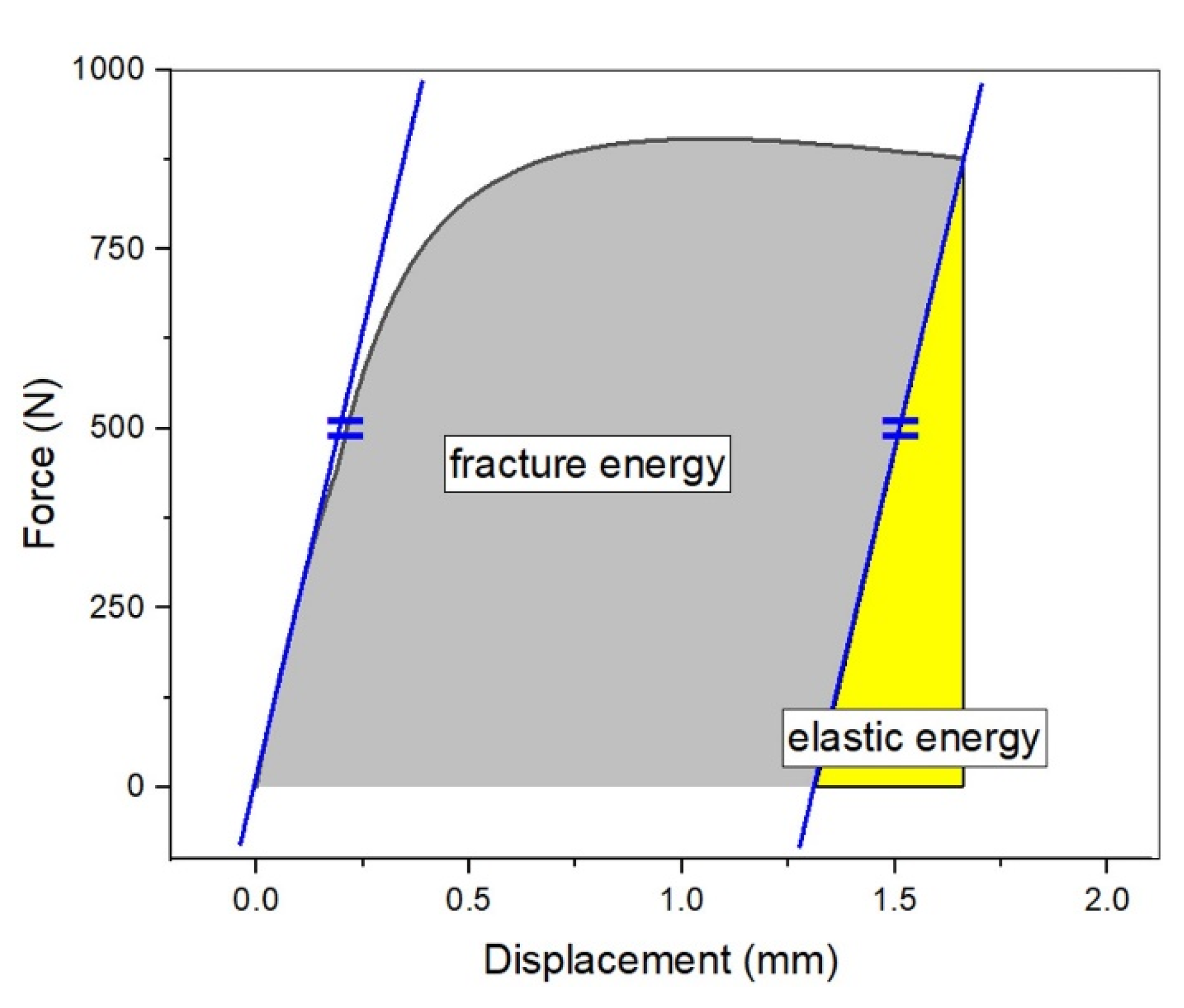

Appendix A.6. Data Treatment

Appendix A.7. Normalization of Parameters

Appendix A.8. Tensile Tests

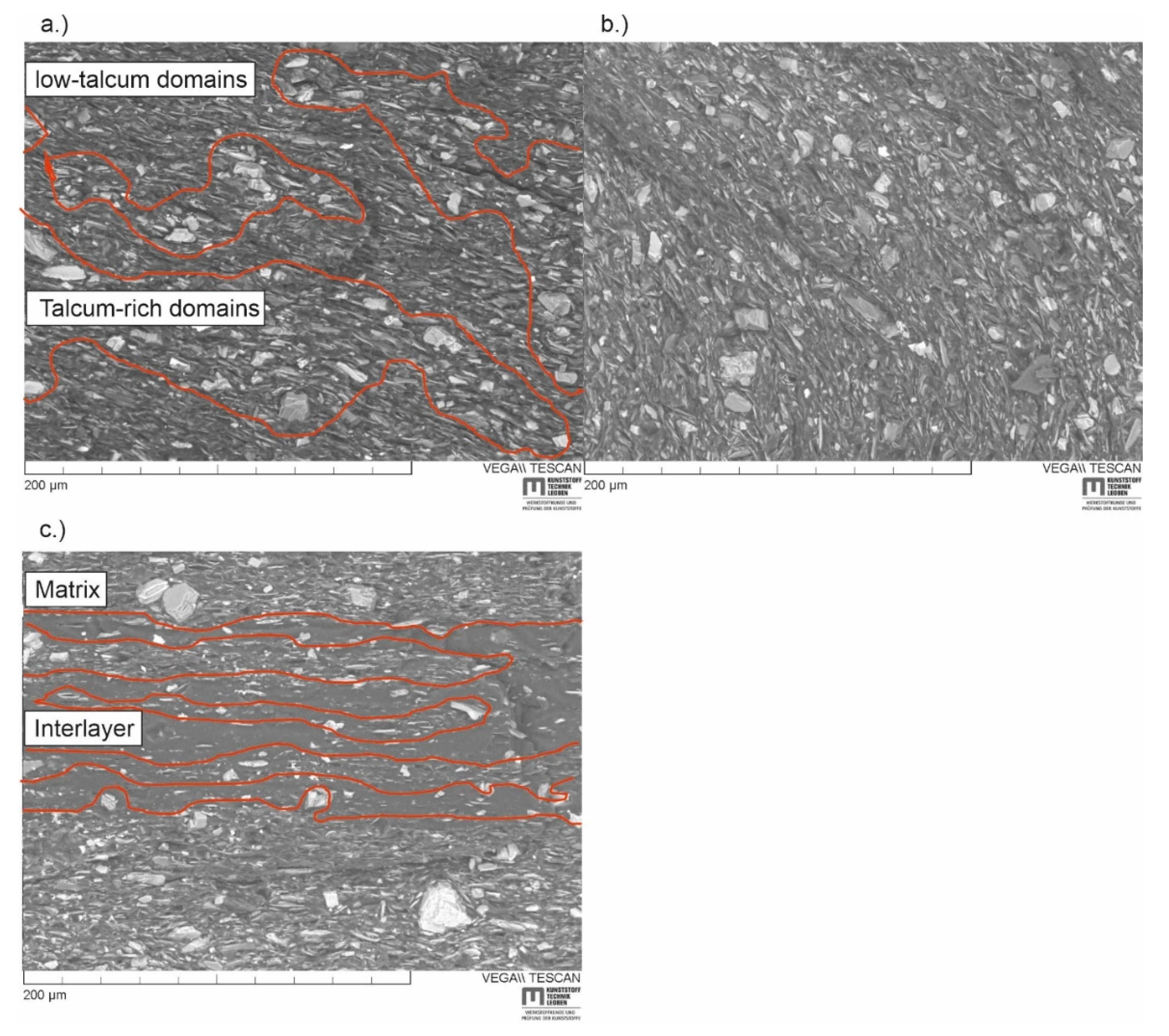

Appendix A.9. SEM-Micrographs

Appendix B

| Material | Eb (MPa) | Notch Type | (N/mm2) | ac (kJ/m2) |

|---|---|---|---|---|

| PP-HR | 17,475 ± 4056 | NoNotch | 3.07 ± 0.66 | 2.66 ± 0.40 |

| Charpy | 2.36 ± 0.48 | 0.46 ± 0.30 | ||

| Razor | 1.42 ± 0.68 | 0.25 ± 0.14 | ||

| PP-HR_512L | 14,141 ± 794 | NoNotch | 3.08 ± 0.31 | 3.86 ± 0.35 |

| Charpy | 2.39 ± 0.15 | 0.78 ± 0.11 | ||

| Razor | 2.33 ± 0.16 | 0.82 ± 0.06 | ||

| Blend | 9635 ± 894 | NoNotch | 2.64 ± 0.06 | 7.14 ± 0.53 |

| Charpy | 2.59 ± 0.24 | 2.21 ± 0.45 | ||

| Razor | 2.33 ± 0.34 | 1.52 ± 0.12 | ||

| Blend_512L | 9258 ± 1268 | NoNotch | 2.67 ± 0.13 | 9.39 ± 1.63 |

| Charpy | 2.35 ± 0.26 | 2.51 ± 0.34 | ||

| Razor | 2.55 ± 0.19 | 1.58 ± 0.13 | ||

| ML_512L | 1903 ± 457 | NoNotch | 0.88 ± 0.04 | 30.99 ± 0.80 |

| Charpy | 0.71 ± 0.05 | 16.95 ± 0.26 | ||

| Razor | 0.79 ± 0.02 | 15.53 ± 0.62 |

Appendix C

| E (MPa) | εbr (MPa) | σUTS (MPa) | Fracture Energy Per Area (kJ/m2) | |

|---|---|---|---|---|

| Absolute Values: | ||||

| PP-HR | 6967 ± 173 | 0.67 ± 0.11 | 25.4 ± 0.4 | 5.3 ± 0.3 |

| PP-HR_512L | 5748 ± 23 | 1.08 ± 0.30 | 24.5 ± 0.1 | 16.9 ± 2.9 |

| Blend | 3714 ± 45 | 4.75 ± 1.79 | 21.4 ± 0.2 | 29.4 ± 1.6 |

| Blend_512L | 3862 ± 111 | 6.81 ± 1.76 | 22.0 ± 0.04 | 29.4 ± 1.7 |

| ML_512L | 1666 ± 50 | 31.19 ± 4.13 | 14.4 ± 0.7 | 188.2 ± 29.6 |

| Relative values (PP-HR as reference): | ||||

| PP-HR | 1 | 1 | 1 | 1 |

| PP-HR_512L | 0.83 | 1.61 | 0.96 | 3.54 |

| Blend | 0.53 | 7.09 | 0.84 | 5.79 |

| Blend_512L | 0.55 | 10.16 | 0.87 | 5.79 |

| ML_512L | 0.24 | 46.55 | 0.57 | 33.28 |

References

- Kausch, H.H.; Béguelin, P.; Fischer, M. Failure of particulate reinforced polymers. Mech. Compos. Mater. 2000, 36, 177–184. [Google Scholar] [CrossRef]

- Chan, J.X.; Wong, J.F.; Hassan, A.; Mohamad, Z.; Othman, N. Mechanical properties of wollastonite reinforced thermoplastic composites: A review. Polym. Compos. 2020, 41, 395–429. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, J.-L.; Friedrich, K. Creep resistant polymeric nanocomposites. Polymer 2004, 45, 3481–3485. [Google Scholar] [CrossRef]

- Raghavan, J.; Meshii, M. Creep of polymer composites. Compos. Sci. Technol. 1998, 57, 1673–1688. [Google Scholar] [CrossRef]

- Ehrenstein, G.W. Polymer-Werkstoffe: Struktur-Eigenschaften-Anwendung, 3rd ed.; Carl Hanser Verlag: München, Germany, 2011. [Google Scholar]

- Domininghaus, H.; Elsner, P.; Eyerer, P.; Hirth, T. (Eds.) Kunststoffe: Eigenschaften und Anwendungen; Springer: Heidelberg, Germany, 2012. [Google Scholar]

- Baer, E.; Hiltner, A.; Jarus, D. Relationship of hierarchical structure to mechanical properties. Macromol. Symp. 1999, 147, 37–61. [Google Scholar] [CrossRef]

- Mueller, C.D.; Nazarenko, S.; Ebeling, T.; Schuman, T.L.; Hiltner, A.; Baer, E. Novel structures by microlayer coextrusion–talc-filled PP, PC/SAN, and HDPE/LLDPE. Polym. Eng. Sci. 1997, 37, 355–362. [Google Scholar] [CrossRef]

- Paul, D.R.; Barlow, J.W. Polymer Blends. J. Macromol. Sci. Part C 1980, 18, 109–168. [Google Scholar] [CrossRef]

- Hara, M.; Sauer, J.A. Synergism in Mechanical Properties of Polymer/Polymer Blends. J. Macromol. Sci. Part C 1998, 38, 327–362. [Google Scholar] [CrossRef]

- Barlow, J.W.; Paul, D.R. Polymer blends and alloys—A review of selected considerations. Polym. Eng. Sci. 1981, 21, 985–996. [Google Scholar] [CrossRef]

- Köpplmayr, T.; Miethlinger, J. Modeling viscoelastic flow in a multiflux static mixer. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2014; pp. 556–559. [Google Scholar]

- Köpplmayr, T.; Mayrhofer, E.; Unterweger, C. Thermo-mechanical properties of β-nucleated polypropylene multilayers. Polym. Test. 2014, 39, 79–85. [Google Scholar] [CrossRef]

- Libonati, F.; Buehler, M.J. Advanced Structural Materials by Bioinspiration. Adv. Eng. Mater. 2017, 19, 1600787. [Google Scholar] [CrossRef]

- Müller, W.E.G.; Wang, X.; Kropf, K.; Ushijima, H.; Geurtsen, W.; Eckert, C.; Tahir, M.N.; Tremel, W.; Boreiko, A.; Schlossmacher, U.; et al. Bioorganic/inorganic hybrid composition of sponge spicules: Matrix of the giant spicules and of the comitalia of the deep sea hexactinellid Monorhaphis. J. Struct. Biol. 2008, 161, 188–203. [Google Scholar] [CrossRef] [PubMed]

- Fratzl, P.; Gupta, H.S.; Fischer, F.D.; Kolednik, O. Hindered Crack Propagation in Materials with Periodically Varying Young’s Modulus—Lessons from Biological Materials. Adv. Mater. 2007, 19, 2657–2661. [Google Scholar] [CrossRef]

- Kolednik, O.; Predan, J.; Fischer, F.D.; Fratzl, P. Bioinspired Design Criteria for Damage-Resistant Materials with Periodically Varying Microstructure. Adv. Funct. Mater. 2011, 21, 3634–3641. [Google Scholar] [CrossRef]

- Barthelat, F.; Espinosa, H.D. An Experimental Investigation of Deformation and Fracture of Nacre—Mother of Pearl. Exp. Mech. 2007, 47, 311–324. [Google Scholar] [CrossRef]

- Yadav, R.; Goud, R.; Dutta, A.; Wang, X.; Naebe, M.; Kandasubramanian, B. Biomimicking of Hierarchal Molluscan Shell Structure Via Layer by Layer 3D Printing. Ind. Eng. Chem. Res. 2018, 57, 10832–10840. [Google Scholar] [CrossRef]

- Aizenberg, J.; Weaver, J.C.; Thanawala, M.S.; Sundar, V.C.; Morse, D.E.; Fratzl, P. Skeleton of Euplectella sp.: Structural Hierarchy from the Nanoscale to the Macroscale. Science 2005, 309, 275–278. [Google Scholar] [CrossRef]

- Levi, C.; Barton, J.L.; Guillemet, C.; Le Bras, E.; Lehuede, P. A remarkably strong natural glassy rod: The anchoring spicule of the Monorhaphis sponge. J. Mater. Sci. Lett. 1989, 8, 337–339. [Google Scholar] [CrossRef]

- Miserez, A.; Weaver, J.C.; Thurner, P.J.; Aizenberg, J.; Dauphin, Y.; Fratzl, P.; Morse, D.E.; Zok, F.W. Effects of Laminate Architecture on Fracture Resistance of Sponge Biosilica: Lessons from Nature. Adv. Funct. Mater. 2008, 18, 1241–1248. [Google Scholar] [CrossRef]

- Müller, W.E.G.; Wang, X.; Cui, F.-Z.; Jochum, K.P.; Tremel, W.; Bill, J.; Schröder, H.C.; Natalio, F.; Schlossmacher, U.; Wiens, M. Sponge spicules as blueprints for the biofabrication of inorganic—organic composites and biomaterials. Appl. Microbiol. Biotechnol. 2009, 83, 397–413. [Google Scholar] [CrossRef] [PubMed]

- Woesz, A.; Weaver, J.C.; Kazanci, M.; Dauphin, Y.; Aizenberg, J.; Morse, D.E.; Fratzl, P. Micromechanical properties of biological silica in skeletons of deep-sea sponges. J. Mater. Res. 2006, 21, 2068–2078. [Google Scholar] [CrossRef]

- Libonati, F.; Gu, G.X.; Qin, Z.; Vergani, L.; Buehler, M.J. Bone-Inspired Materials by Design: Toughness Amplification Observed Using 3D Printing and Testing. Adv. Eng. Mater. 2016, 18, 1354–1363. [Google Scholar] [CrossRef]

- Morgan, E.F.; Barnes, G.L.; Einhorn, T. The Bone Organ System. In Osteoporosis, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 3–20. [Google Scholar] [CrossRef]

- Gu, G.X.; Takaffoli, M.; Buehler, M.J. Hierarchically Enhanced Impact Resistance of Bioinspired Composites. Adv. Mater. 2017, 29, 1700060. [Google Scholar] [CrossRef] [PubMed]

- Jia, Z.; Wang, L. 3D printing of biomimetic composites with improved fracture toughness. Acta Mater. 2019, 173, 61–73. [Google Scholar] [CrossRef]

- Jia, Z.; Yu, Y.; Hou, S.; Wang, L. Biomimetic architected materials with improved dynamic performance. J. Mech. Phys. Solids 2019, 125, 178–197. [Google Scholar] [CrossRef]

- Jia, Z.; Yu, Y.; Wang, L. Learning from nature: Use material architecture to break the performance tradeoffs. Mater. Des. 2019, 168, 107650. [Google Scholar] [CrossRef]

- Zhao, H.; Yang, Z.; Guo, L. Nacre-inspired composites with different macroscopic dimensions: Strategies for improved mechanical performance and applications. NPG Asia Mater. 2018, 10, 1–22. [Google Scholar] [CrossRef]

- Kolednik, O.; Kasberger, R.; Sistaninia, M.; Predan, J.; Kegl, M. Development of Damage-Tolerant and Fracture-Resistant Materials by Utilizing the Material Inhomogeneity Effect. J. Appl. Mech. 2019, 86, 1–32. [Google Scholar] [CrossRef]

- Song, J.; Fan, C.; Ma, H.; Liang, L.; Wei, Y. Crack deflection occurs by constrained microcracking in nacre. Acta Mech. Sin. 2018, 34, 143–150. [Google Scholar] [CrossRef]

- Dutta, A.; Tekalur, S.A. Crack tortuousity in the nacreous layer-Topological dependence and biomimetic design guideline. Int. J. Solids Struct. 2014, 51, 325–335. [Google Scholar] [CrossRef]

- Dutta, A.; Tekalur, S.A.; Miklavcic, M. Optimal overlap length in staggered architecture composites under dynamic loading conditions. J. Mech. Phys. Solids 2013, 61, 145–160. [Google Scholar] [CrossRef]

- Kolednik, O. The yield stress gradient effect in inhomogeneous materials. Int. J. Solids Struct. 2000, 37, 781–808. [Google Scholar] [CrossRef]

- Sistaninia, M.; Kolednik, O. Effect of a single soft interlayer on the crack driving force. Eng. Fract. Mech. 2014, 130, 21–41. [Google Scholar] [CrossRef]

- Wiener, J.; Arbeiter, F.J.; Tiwari, A.; Kolednik, O.; Pinter, G. Bioinspired toughness improvement through soft interlayers in mineral reinforced polypropylene. Mech. Mater. 2020, 140, 103243. [Google Scholar] [CrossRef]

- Tiwari, A.; Wiener, J.; Arbeiter, F.; Pinter, G.; Kolednik, O. Application of the material inhomogeneity effect for the improvement of fracture toughness of a brittle polymer. Eng. Fract. Mech. 2020, 224, 106776. [Google Scholar] [CrossRef]

- Arbeiter, F.J.; Petersmann, S.; Wiener, J.; Oesterreicher, F.; Spoerk, M.; Pinter, G. Using Compliant Interlayers as Crack Arresters in 3-D-Printed Polymeric Structures. Mater. Perform. Charact. 2020, 9, 20190201. [Google Scholar] [CrossRef]

- Mueller, C.; Topolkaraev, V.; Soerens, D.; Hiltner, A.; Baer, E. Breathable polymer films produced by the microlayer coextrusion process. J. Appl. Polym. Sci. 2000, 78, 816–828. [Google Scholar] [CrossRef]

- Jarus, D.; Hiltner, A.; Baer, E. Barrier properties of polypropylene/polyamide blends produced by microlayer coextrusion. Polymer 2002, 43, 2401–2408. [Google Scholar] [CrossRef]

- Giannelis, E.P. Polymer Layered Silicate Nanocomposites. Adv. Mater. 1996, 8, 29–35. [Google Scholar] [CrossRef]

- Gilman, J.W.; Jackson, C.L.; Morgan, A.B.; Harris, R.; Manias, E.; Giannelis, E.P.; Wuthenow, M.; Hilton, D.; Phillips, S.H. Flammability Properties of Polymer−Layered-Silicate Nanocomposites. Polypropylene and Polystyrene Nanocomposites†. Chem. Mater. 2000, 12, 1866–1873. [Google Scholar] [CrossRef]

- Pan, S.J.; Im, J.; Hill, M.J.; Keller, A.; Hiltner, A.; Baer, E. Structure of ultrathin polyethylene layers in multilayer films. J. Polym. Sci. Part B Polym. Phys. 1990, 28, 1105–1119. [Google Scholar] [CrossRef]

- Jin, Y.; Rogunova, M.; Hiltner, A.; Baer, E.; Nowacki, R.; Galeski, A.; Piorkowska, E. Structure of polypropylene crystallized in confined nanolayers. J. Polym. Sci. Part B Polym. Phys. 2004, 42, 3380–3396. [Google Scholar] [CrossRef]

- Qiu, F.; Wang, M.; Hao, Y.; Guo, S. The effect of talc orientation and transcrystallization on mechanical properties and thermal stability of the polypropylene/talc composites. Compos. Part A Appl. Sci. Manuf. 2014, 58, 7–15. [Google Scholar] [CrossRef]

- Langhe, D.S.; Hiltner, A.; Baer, E. Melt crystallization of syndiotactic polypropylene in nanolayer confinement impacting structure. Polymer 2011, 52, 5879–5889. [Google Scholar] [CrossRef]

- Nazarenko, S.; Hiltner, A.; Baer, E. Polymer microlayer structures with anisotropic conductivity. J. Mater. Sci. 1999, 34, 1461–1470. [Google Scholar] [CrossRef]

- Nazarenko, S.; Dennison, M.T.; Schuman, E.V.; Stepanov, A.; Hiltner, E. Baer, Creating layers of concentrated inorganic particles by interdiffusion of polyethylenes in microlayers. J. Appl. Polym. Sci. 1999, 73, 2877–2885. [Google Scholar] [CrossRef]

- Ashby, M.; Cebon, D. Materials selection in mechanical design. J. Phys. IV France 1993, 03, C7-1–C7-9. [Google Scholar] [CrossRef]

- Ritchie, R. The conflicts between strength and toughness. Nat. Mater. 2011, 10, 817–822. [Google Scholar] [CrossRef]

- Koepplmayr, T. Computational and Experimental Modelling of Microlayer Forming Processes. Ph.D. Thesis, Johannes Kepler University, Linz, Austria, 2014. [Google Scholar]

- German Institute for Standardization. Plastics-Determination of Charpy Impact Properties-Part 1: Non-Instrumented Impact Test (German Version ISO 179-1:2010); DIN EN ISO 179-1; DIN: Dublin, Germany, 2010. [Google Scholar]

- Martínez, A.; León, N.; Arencón, D.; Salazar, A.; Rodríguez, J. On the effect of the different notching techniques on the fracture toughness of PETG. Polym. Test. 2013, 32, 1244–1252. [Google Scholar] [CrossRef]

- Martinez, A.B.; Salazar, A.; León, N.; Illescas, S.; Rodríguez, J. Influence of the notch-sharpening technique on styrene-acrylonitrile fracture behavior. J. Appl. Polym. Sci. 2016, 133, 11. [Google Scholar] [CrossRef]

- Salazar, A.; Rodríguez, J.; Arbeiter, F.; Pinter, G.; Martínez, A. Fracture toughness of high density polyethylene: Fatigue pre-cracking versus femtolaser, razor sharpening and broaching. Eng. Fract. Mech. 2015, 149, 199–213. [Google Scholar] [CrossRef]

- German Institute for Standardization. Plastics-Determination of Tensile Properties-Part 1: General Principles (German Version ISO 527-1:2012); DIN EN ISO 527; DIN: Dublin, Germany, 2012. [Google Scholar]

- German Institute for Standardization. Plastics-Determination of Flexural Properties (German Version ISO 178:2019); DIN EN ISO 178; DIN: Dublin, Germany, 2019. [Google Scholar]

| Abbreviation | Depiction | Material Composition | Description | Toughening Mechanism |

|---|---|---|---|---|

| PP-HR |  | Highly reinforced PP | Homogeneous bulk material | - |

| PP-HR_512L |  | Highly reinforced PP | Bulk material processed in 512 identical layers | High orientation |

| Blend |  | Highly reinforced PP and soft PP (87:13) | Blended material | Soft component |

| Blend_512L |  | Highly reinforced PP and soft PP (87:13) | Blended material processed in 512 identical layers | Soft component + high orientation |

| ML_512L |  | Highly reinforced PP:soft PP (87:13) | Two different materials processed in 512 alternating layers | Soft component + high orientation + defined microstructure |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wiener, J.; Kaineder, H.; Kolednik, O.; Arbeiter, F. Optimization of Mechanical Properties and Damage Tolerance in Polymer-Mineral Multilayer Composites. Materials 2021, 14, 725. https://doi.org/10.3390/ma14040725

Wiener J, Kaineder H, Kolednik O, Arbeiter F. Optimization of Mechanical Properties and Damage Tolerance in Polymer-Mineral Multilayer Composites. Materials. 2021; 14(4):725. https://doi.org/10.3390/ma14040725

Chicago/Turabian StyleWiener, Johannes, Hannes Kaineder, Otmar Kolednik, and Florian Arbeiter. 2021. "Optimization of Mechanical Properties and Damage Tolerance in Polymer-Mineral Multilayer Composites" Materials 14, no. 4: 725. https://doi.org/10.3390/ma14040725

APA StyleWiener, J., Kaineder, H., Kolednik, O., & Arbeiter, F. (2021). Optimization of Mechanical Properties and Damage Tolerance in Polymer-Mineral Multilayer Composites. Materials, 14(4), 725. https://doi.org/10.3390/ma14040725