Microstructures and Mechanical Properties of Hybrid, Additively Manufactured Ti6Al4V after Thermomechanical Processing

Abstract

1. Introduction

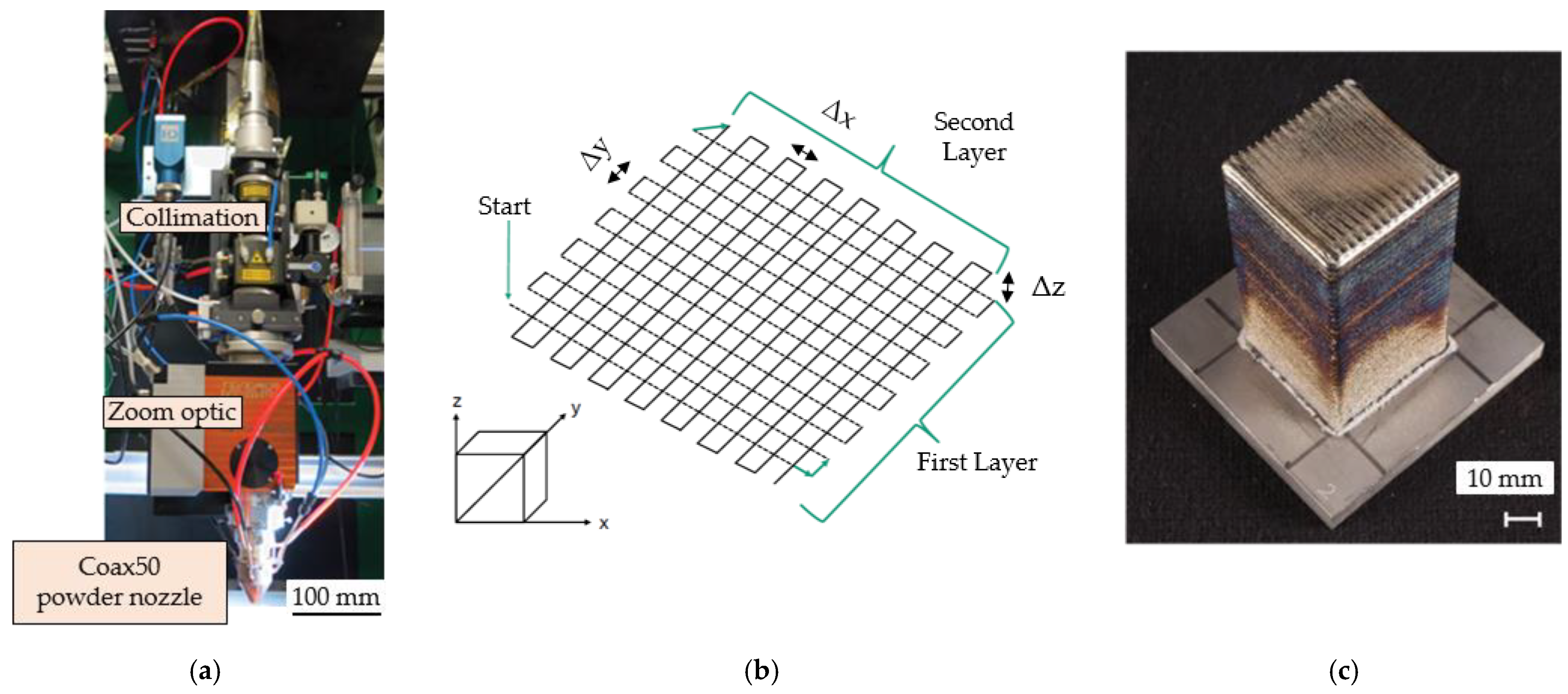

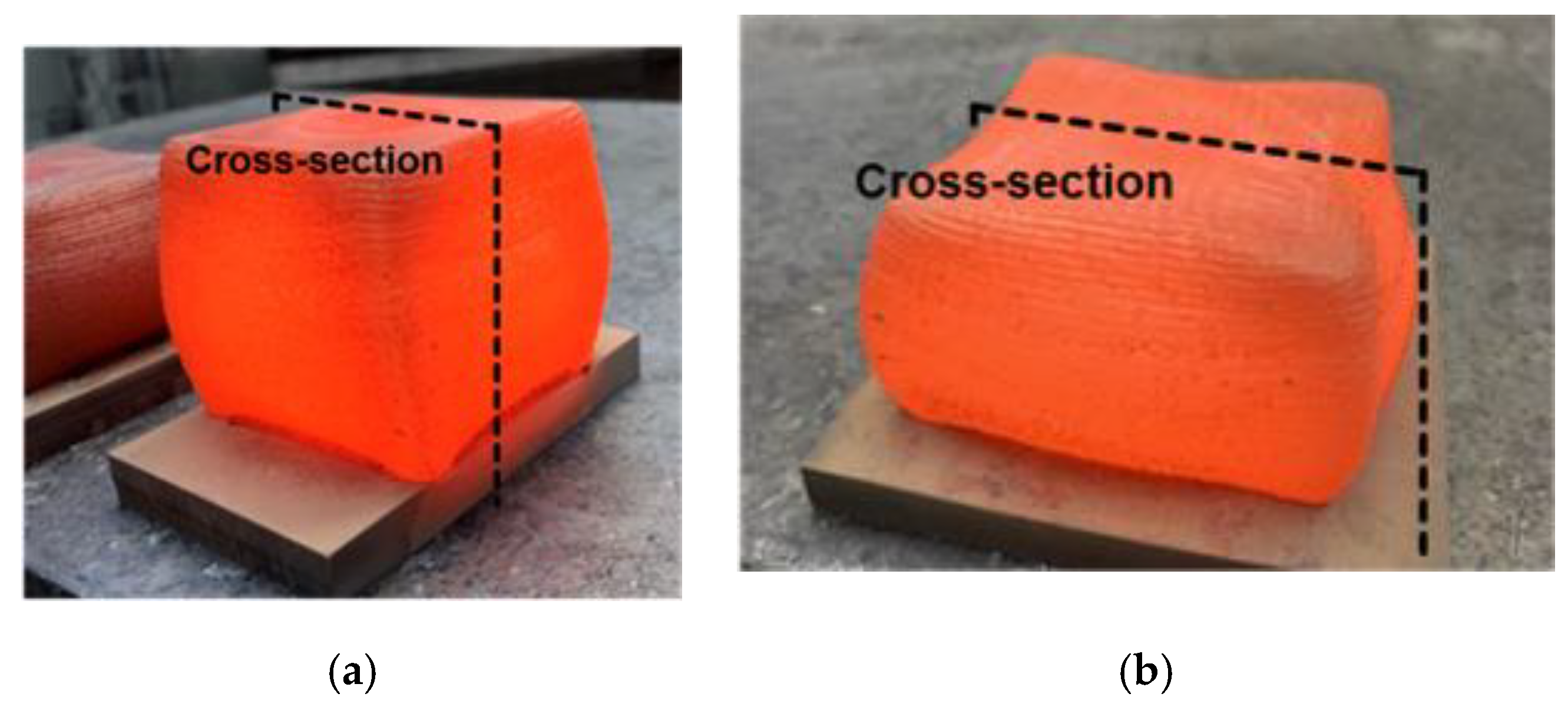

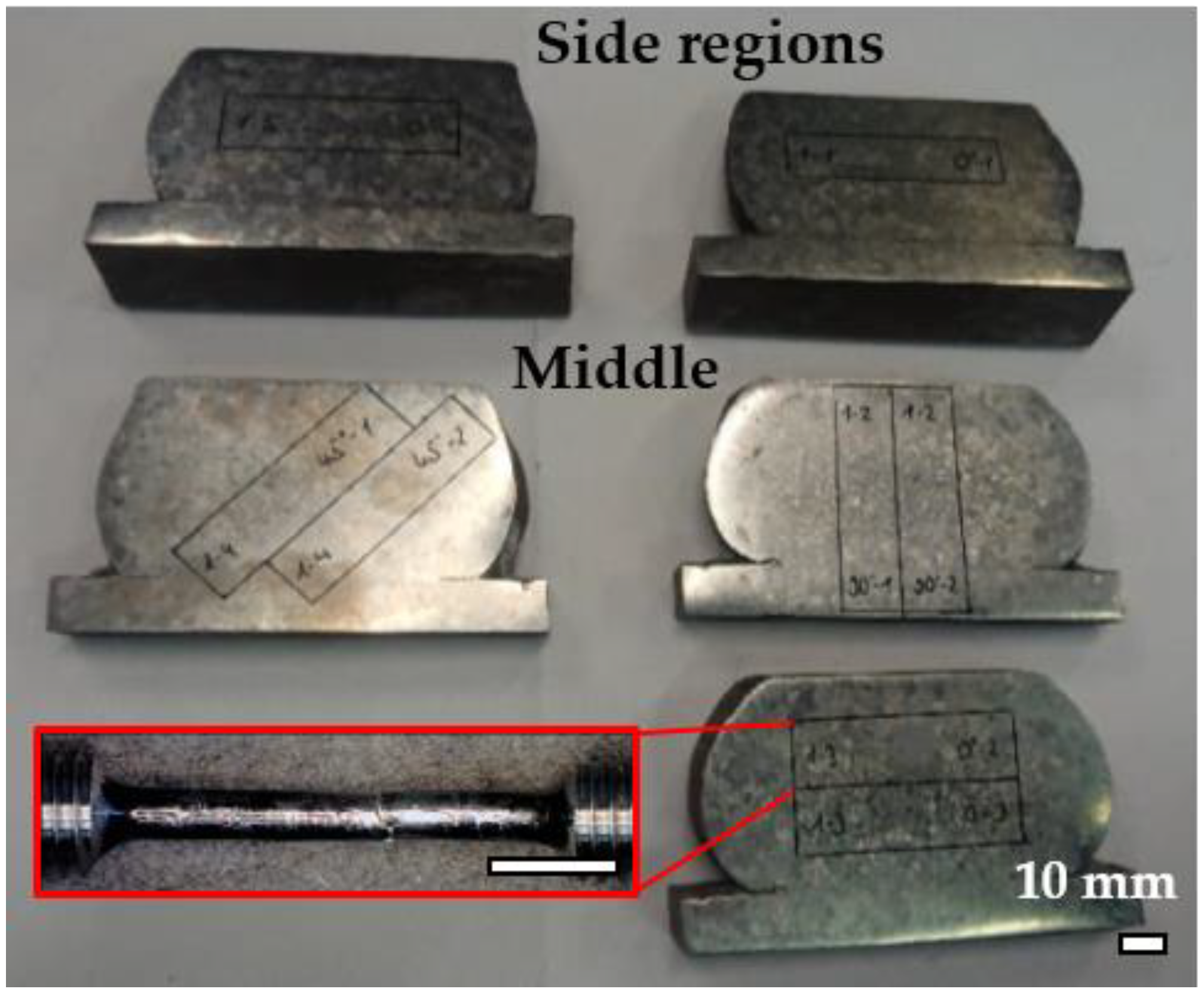

2. Materials and Methods

3. Results and Discussion

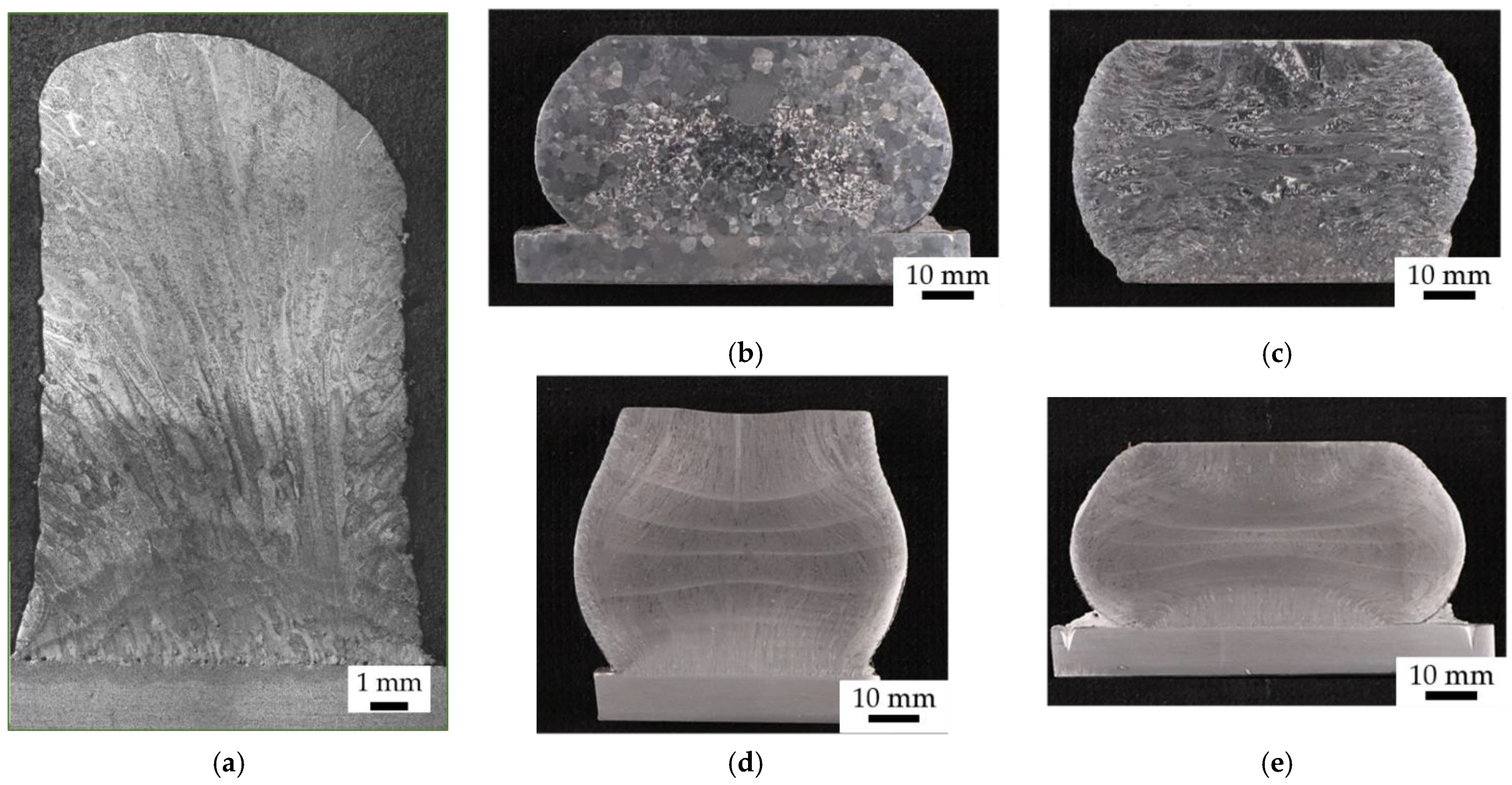

3.1. Macrostructures

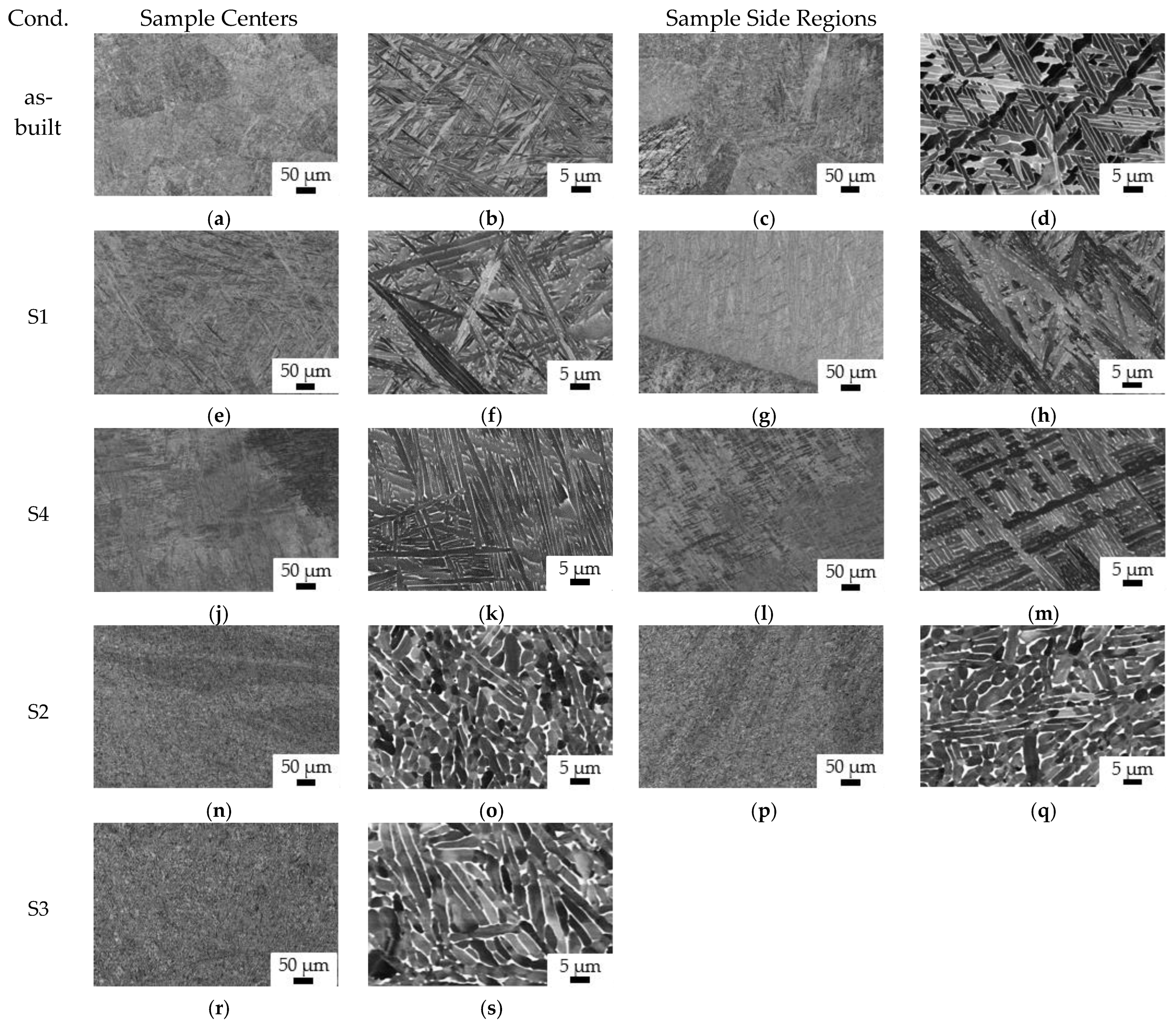

3.2. Microstructural Analysis

3.3. Mechanical Testing

3.3.1. Tensile Tests

3.3.2. Micro-Indentation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Boyer, R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Gurrappa, I. Characterization of titanium alloy Ti-6Al-4V for chemical, marine and industrial applications. Mater. Charact. 2003, 51, 131–139. [Google Scholar] [CrossRef]

- Lütjering, G. Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys. Mater. Sci. Eng. A 1998, 243, 32–45. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Seetharaman, V.; Weiss, I. The thermomechanical processing of alpha/beta titanium alloys. JOM 1997, 49, 33–39. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.; Frazier, W.; Prasad, Y. Microstructural mechanisms during hot working of commercial grade Ti–6Al–4V with lamellar starting structure. Mater. Sci. Eng. A 2002, 325, 112–125. [Google Scholar] [CrossRef]

- Semiatin, S.L. An Overview of the Thermomechanical Processing of α/β Titanium Alloys: Current Status and Future Research Opportunities. Met. Mater. Trans. A 2020, 51, 2593–2625. [Google Scholar] [CrossRef]

- Ali, H.; Ma, L.; Ghadbeigi, H.; Mumtaz, K. In-situ residual stress reduction, martensitic decomposition and mechanical properties enhancement through high temperature powder bed pre-heating of Selective Laser Melted Ti6Al4V. Mater. Sci. Eng. A 2017, 695, 211–220. [Google Scholar] [CrossRef]

- Jackson, M.; Boyer, R.R. Titanium and its Alloys: Processing, Fabrication and Mechanical Performance. Encycl. Aerosp. Eng. 2010. [Google Scholar] [CrossRef]

- Huang, R.; Riddle, M.; Graziano, D.; Warren, J.; Das, S.; Nimbalkar, S.; Cresko, J.; Masanet, E. Energy and emissions saving potential of additive manufacturing: The case of lightweight aircraft components. J. Clean. Prod. 2016, 135, 1559–1570. [Google Scholar] [CrossRef]

- Lütjering, A.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Qian, M.; Xu, W.; Brandt, M.; Tang, H. Additive manufacturing and postprocessing of Ti-6Al-4V for superior mechanical properties. MRS Bull. 2016, 41, 775–784. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of additive manufacturing technologies and applications in the aerospace industry. In Additive Manufacturing for the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2019; pp. 7–31. [Google Scholar]

- Prakash, C.; Singh, S.; Pruncu, C.I.; Mishra, V.; Królczyk, G.; Pimenov, D.Y.; Pramanik, A. Surface Modification of Ti-6Al-4V Alloy by Electrical Discharge Coating Process Using Partially Sintered Ti-Nb Electrode. Materials 2019, 12, 1006. [Google Scholar] [CrossRef] [PubMed]

- Uhlmann, E.; Kersting, R.; Klein, T.B.; Cruz, M.F.; Borille, A.V. Additive Manufacturing of Titanium Alloy for Aircraft Components. Procedia CIRP 2015, 35, 55–60. [Google Scholar] [CrossRef]

- Häfele, T.; Schneberger, J.-H.; Kaspar, J.; Vielhaber, M.; Griebsch, J. Hybrid Additive Manufacturing – Process Chain Correlations and Impacts. Procedia CIRP 2019, 84, 328–334. [Google Scholar] [CrossRef]

- Leary, M. Surface roughness optimisation for selective laser melting (SLM). In Laser Additive Manufacturing; Elsevier BV: Amsterdam, The Netherlands, 2017; pp. 99–118. [Google Scholar]

- Sizova, I.; Bambach, M. Hot workability and microstructure evolution of pre-forms for forgings produced by additive manufacturing. J. Mater. Process. Technol. 2018, 256, 154–159. [Google Scholar] [CrossRef]

- Bambach, M.; Sizova, I.; Szyndler, J.; Bennett, J.; Hyatt, G.; Cao, J.; Papke, T.; Merklein, M. On the hot deformation behavior of Ti-6Al-4V made by additive manufacturing. J. Mater. Process. Technol. 2021, 288, 116840. [Google Scholar] [CrossRef]

- Bambach, M.; Sizova, I.; Emdadi, A. Development of a processing route for Ti-6Al-4V forgings based on pre-forms made by selective laser melting. J. Manuf. Process. 2019, 37, 150–158. [Google Scholar] [CrossRef]

- Saboori, A.; Abdi, A.; Fatemi, S.A.; Marchese, G.; Biamino, S.; Mirzadeh, H. Hot deformation behavior and flow stress modeling of Ti–6Al–4V alloy produced via electron beam melting additive manufacturing technology in single β-phase field. Mater. Sci. Eng. A 2020, 792, 139822. [Google Scholar] [CrossRef]

- Sizova, I.; Hirtler, M.; Günther, M.; Bambach, M. Wire-arc additive manufacturing of pre-forms for forging of a Ti–6Al–4V turbine blade. In Proceedings of the 22nd International Conference on Material Forming (ESAFORM), Vitoria-Gasteiz, Spain, 8–10 May 2019; p. 150017. [Google Scholar]

- Meiners, F.; Ihne, J.; Jürgens, P.; Hemes, S.; Mathes, M.; Sizova, I.; Bambach, M.; Hama-Saleh, R.; Weisheit, A. New Hybrid Manufacturing Routes Combining Forging and Additive Manufacturing to Efficiently Produce High Performance Components from Ti-6Al-4V. Procedia Manuf. 2020, 47, 261–267. [Google Scholar] [CrossRef]

- DIN EN ISO 6892-1:2020-06: Metallische Werkstoffe—Zugversuch—Teil 1: Prüfverfahren bei Raumtemperatur (ISO 6892-1:2019), English Title: Metallic materials—Tensile testing—Part 1: Method of test at room temperature (ISO 6892-1:2019); German version EN ISO 6892-1:2019; Beuth Verlag GmbH: Berlin, Germany, 2020. [CrossRef]

- Oliver, W.; Pharr, G. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Welsch, G.; Boyer, R.; Collings, E.W. Material Properties Handbook: Titanium Alloys; ASM International: Materials Park, OH, USA, 1994; p. 524. [Google Scholar]

- Carroll, B.E.; Palmer, T.A.; Beese, A.M. Anisotropic tensile behavior of Ti–6Al–4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- Kulkarni, K.M.; Kalpakjian, S. A Study of Barreling as an Example of Free Deformation in Plastic Working. J. Eng. Ind. 1969, 91, 743–754. [Google Scholar] [CrossRef]

- Azarniya, A.; Colera, X.G.; Mirzaali, M.J.; Sovizi, S.; Bartolomeu, F.; Mare, K.S.W.; Wits, W.W.; Yap, C.Y.; Ahn, J.; Miranda, G.; et al. Additive manufacturing of Ti–6Al–4V parts through laser metal deposition (LMD): Process, microstructure, and mechanical properties. J. Alloys Compd. 2019, 804, 163–191. [Google Scholar] [CrossRef]

- Mirkoohi, E.; Ning, J.; Bocchini, P.; Fergani, O.; Chiang, K.-N.; Liang, S.Y. Thermal Modeling of Temperature Distribution in Metal Additive Manufacturing Considering Effects of Build Layers, Latent Heat, and Temperature-Sensitivity of Material Properties. J. Manuf. Mater. Process. 2018, 2, 63. [Google Scholar] [CrossRef]

- Galarraga, H.; Warren, R.J.; Lados, D.A.; Dehoff, R.R.; Kirka, M.M.; Nandwana, P. Effects of heat treatments on microstructure and properties of Ti-6Al-4V ELI alloy fabricated by electron beam melting (EBM). Mater. Sci. Eng. A 2017, 685, 417–428. [Google Scholar] [CrossRef]

- Motyka, M.; Baran-Sadleja, A.; Sieniawski, J.; Wierzbinska, M.; Gancarczyk, K. Decomposition of deformed α′(α″) martensitic phase in Ti–6Al–4V alloy. Mater. Sci. Technol. 2018, 35, 260–272. [Google Scholar] [CrossRef]

- Chen, H.-Q.; Cao, C.-X. Characterization of hot deformation microstructures of alpha-beta titanium alloy with equiaxed structure. Trans. Nonferrous Met. Soc. China 2012, 22, 503–509. [Google Scholar] [CrossRef]

- Zhu, Y.; Tian, X.; Li, J.; Wang, H. The anisotropy of laser melting deposition additive manufacturing Ti–6.5Al–3.5Mo–1.5Zr–0.3Si titanium alloy. Mater. Des. 2015, 67, 538–542. [Google Scholar] [CrossRef]

- Hayes, B.J.; Martin, B.W.; Welk, B.; Kuhr, S.J.; Ales, T.K.; Brice, D.A.; Ghamarian, I.; Baker, A.H.; Haden, C.V.; Harlow, D.G.; et al. Predicting tensile properties of Ti-6Al-4V produced via directed energy deposition. Acta Mater. 2017, 133, 120–133. [Google Scholar] [CrossRef]

- Burgers, W.G. On the process of transition of the cubic-body-centred modification into the hexagonal-closed-packed modi-fication of zirconium. Physica I 1934, 36, 561–586. [Google Scholar] [CrossRef]

| Abbreviation | Explanation |

|---|---|

| L-DED | laser directed energy deposition |

| TMP | thermomechanical processing |

| AM | additive manufacturing |

| NNS | near net shape |

| HIP | hot isostatic pressing |

| EDC | electrical discharge coating |

| Ra | arithmetic average deviation of the measured surface roughness profile from the center line of the measured profile |

| LPBF | laser powder bed fusion |

| CNC | computer numerical control |

| BSE | back scattered electron |

| EDX | energy dispersive X-ray |

| UTS (Rm) | ultimate tensile strength or yield strength |

| Rp0.2 | stress resulting in a plastic strain of 0.2% |

| A5 | percentage of plastic plus elastic strain of the gauge (length) at the moment of failure relative to the original gauge length |

| Z | percentage of reduction of the cross-sectional area of the gauge |

| BOR | Burger’s orientation relationship |

| Laser Spot Diameter (mm) | Laser Power (W) | Scanning Speed (mm/min) | Powder Mass Flow (g/min) | Shielding Gas Flow (L/min) (Argon) | Carrier Gas Flow (L/min) (Argon) | Δx/Δy (mm) | Δz (mm) | Stand-off (mm) |

|---|---|---|---|---|---|---|---|---|

| 3.0 | 1680 | 1500 | 8.5 | 10 | 7 | 1.5 | 0.85 | 16 |

| Sample Number | Forging | Heat Treatment |

|---|---|---|

| 1 | Alpha-beta Forging at 930 °C up to 50% compression | Beta annealing at 1050 °C for 3 h + stress relief annealing at 710 °C for 6 h + cooling in air |

| 2 | Alpha-beta forging at 930 °C up to 50% compression | Stress relief annealing at 710 °C for 6 h + cooling in air |

| 3 | Alpha-beta forging at 930 °C up to 25–30% compression | Stress relief annealing at 710 °C for 6 h + cooling in air |

| 4 | Beta forging at 1070 °C up to 50% compression | Stress relief annealing at 710 °C for 6 h + cooling in air |

| Sample No. | Orientation | Rm (Mpa) | Rp0.2 (Mpa) | A5 (%) | Z (%) | No. Samples Analyzed |

|---|---|---|---|---|---|---|

| 1 | Horizontal | 933 | 864 | 4.5 | 11.8 | 4 |

| 45° | 899 | 831 | 5.3 | 11.8 | 2 | |

| Vertical | 938 | 861 | 6.1 | 16.6 | 2 | |

| 2 | Horizontal | 912 | 840 | 13.1 | 38.6 | 4 |

| 45° | 916 | 844 | 13.1 | 32.1 | 2 | |

| vertical | 916 | 838 | 14.5 | 37.5 | 2 | |

| 3 | Horizontal | 886 | 836 | 12.1 | 43.9 | 3 |

| 45° | 893 | 833 | 11.8 | 37.9 | 2 | |

| Vertical | 897 | 816 | 11.9 | 44.9 | 2 | |

| 4 | Horizontal | 884 | 795 | 7.9 | 19.7 | 4 |

| 45° | 864 | 771 | 4.3 | 8.6 | 2 | |

| Vertical | 833 | 749 | 7.2 | 27.9 | 2 |

| Sample Reference | Mean Instrumented Hardness (GPa) | Mean Instrumented Elastic Modulus (GPa) |

|---|---|---|

| 1 | 3.9 (± 0.2) | 132 (± 6) |

| 2 | 3.7 (± 0.4) | 126 (± 5) |

| 3 | 3.6 (± 0.1) | 130 (± 3) |

| 4 | 3.7 (± 0.1) | 128 (± 6) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hemes, S.; Meiners, F.; Sizova, I.; Hama-Saleh, R.; Röhrens, D.; Weisheit, A.; Häfner, C.L.; Bambach, M. Microstructures and Mechanical Properties of Hybrid, Additively Manufactured Ti6Al4V after Thermomechanical Processing. Materials 2021, 14, 1039. https://doi.org/10.3390/ma14041039

Hemes S, Meiners F, Sizova I, Hama-Saleh R, Röhrens D, Weisheit A, Häfner CL, Bambach M. Microstructures and Mechanical Properties of Hybrid, Additively Manufactured Ti6Al4V after Thermomechanical Processing. Materials. 2021; 14(4):1039. https://doi.org/10.3390/ma14041039

Chicago/Turabian StyleHemes, Susanne, Frank Meiners, Irina Sizova, Rebar Hama-Saleh, Daniel Röhrens, Andreas Weisheit, Constantin Leon Häfner, and Markus Bambach. 2021. "Microstructures and Mechanical Properties of Hybrid, Additively Manufactured Ti6Al4V after Thermomechanical Processing" Materials 14, no. 4: 1039. https://doi.org/10.3390/ma14041039

APA StyleHemes, S., Meiners, F., Sizova, I., Hama-Saleh, R., Röhrens, D., Weisheit, A., Häfner, C. L., & Bambach, M. (2021). Microstructures and Mechanical Properties of Hybrid, Additively Manufactured Ti6Al4V after Thermomechanical Processing. Materials, 14(4), 1039. https://doi.org/10.3390/ma14041039