Testing and Assessing Method for the Resistance of Wood-Plastic Composites to the Action of Destroying Fungi

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- ➢

- Sample I—decking profiles made of a composite containing wood flour (45%), polyvinyl chloride (PVC) (45%), pigments (5%), stabilizers, absorbents, fillers (5%),

- ➢

- Sample II—decking profiles made of a composite containing wood flour (60%), HDPE plastic (30%), stabilizers and pigments (10%),

- ➢

- Sample III—decking profiles made of composite with low content of wood flour (49%) and polypropylene (PP),

- ➢

- Sample IV—decking profiles made of a composite containing wood flour (49%) and polyvinyl chloride (PVC) (51%).

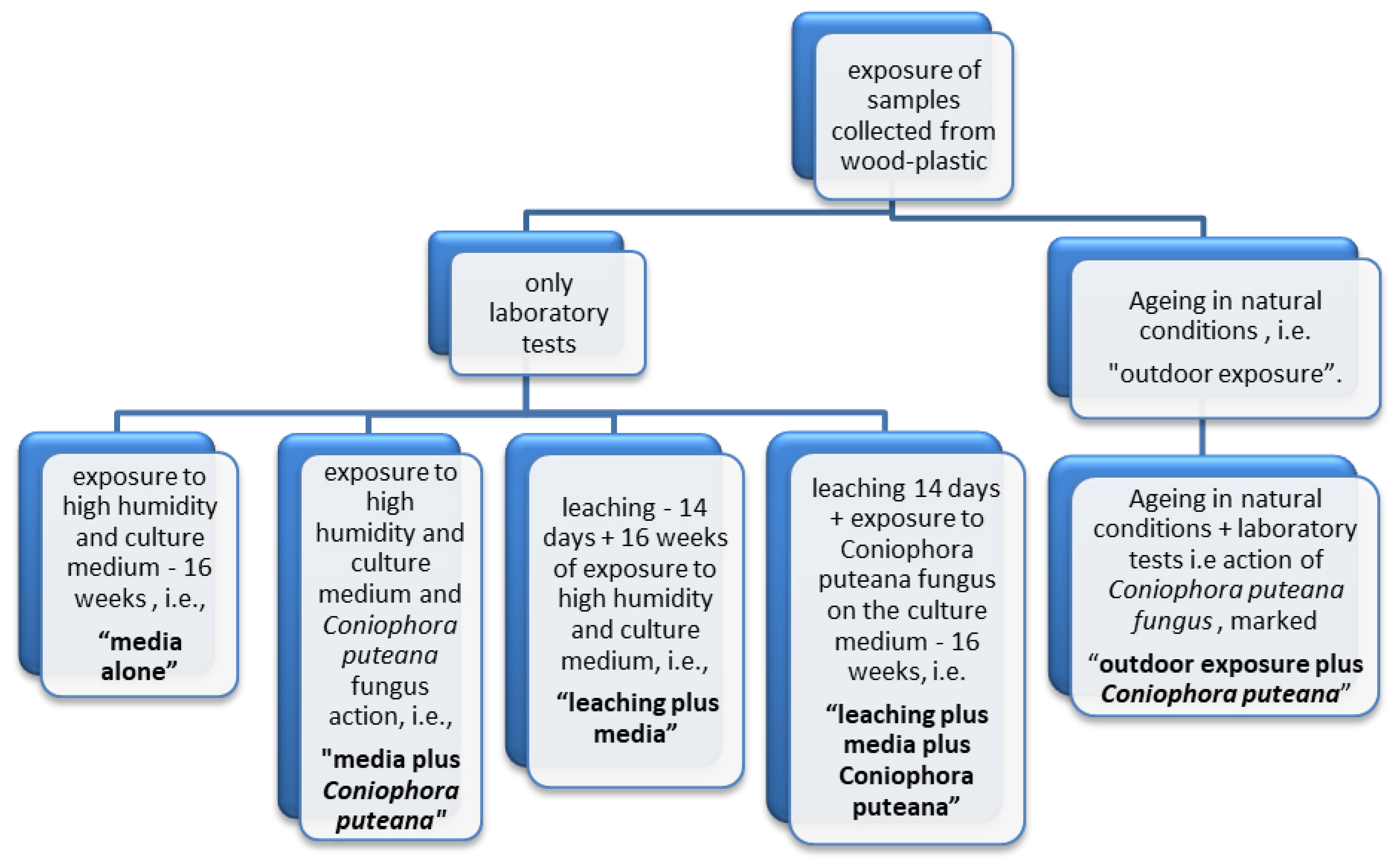

2.2. Environmental Exposure

- exposure to high humidity and culture medium—16 weeks (further marked as “media alone”). The samples are exposed in pairs in a Kolle flask on a culture medium, i.e., a substance composed of 40 g of malt extract, 35 g of agar, and water to 1000 mL at the test conditions at (22 ± 2) °C and (70 ± 5)% humidity, for 16 weeks. The medium (nutrient) is the food and source of moisture for the fungi during the test and simultaneously affects the test samples.

- leaching—14 days + 16 weeks of exposure to high humidity and culture medium (further marked as “leaching plus media”). The samples were immersed in water at (20 ± 2) °C for 14 days, according to the description given in EN 84 [36]. The samples were soaked in water, five volumes of water for one volume of sample, for two weeks. The water was replaced nine times during the cycle. After the end of the cycle, the samples were placed in flasks on maltose agar medium and incubated in the culture chamber at (22 ± 2) °C and (70 ± 5)% for 16 weeks. The leaching aging test according to EN 84 [36] is obligatorily used in tests of impregnated wood for exterior applications;

- exposure to high humidity and culture medium, and Coniophora puteana fungus action (further marked as “media plus Coniophora puteana”)—16 weeks. The samples were placed in Kolle flasks in two, on glass plates on the culture medium completely covered with fungus Coniophora puteana. The flasks with the samples were placed in the culture chamber and incubated for 16 weeks at (22 ± 2) °C and (70 ± 5)% humidity’

- leaching 14 days + exposure to Coniophora puteana fungus on the culture medium—16 weeks (further marked as “leaching plus media plus Coniophora puteana”). The samples were leaching in water for 14 days and then were placed in Kolle flasks in two, on glass plates on the culture medium completely covered with fungus Coniophora puteana. The flasks with the samples were placed in the culture chamber and incubated for 16 weeks at (22 ± 2) °C and (70 ± 5)% humidity;

- aging in natural conditions (further marked as “outdoor exposure”). Three mocks made of decking profiles screwed to composite ground beams were prepared in the test station in natural conditions, on the supports made of hollow bricks. After three years of exposure, the test samples were cut out from the profiles. The arrangement of the samples during the test in natural conditions is shown in Figure 2.

- aging in natural conditions and action of Coniophora puteana fungus (further marked as “outdoor exposure plus Coniophora puteana”). After exposure in natural conditions for three years, test samples were cut out from the profiles and placed in test vessels on the medium covered with Coniophora puteana fungus and exposed in a culture chamber for 16 weeks, as described above.

2.3. Methods of Tests

2.3.1. Testing the Change in the Mass

- -

- exposure to high humidity and culture medium—16 weeks,

- -

- exposure to high humidity and culture medium and Coniophora puteana fungus action—16 weeks,

- -

- leaching—14 days + 16 weeks of exposure to high humidity and culture medium,

- -

- leaching 14 days + exposure to Coniophora puteana fungus on the culture medium—16 weeks.

2.3.2. Bending Strength Tests

- -

- exposure to high humidity and culture medium—16 weeks,

- -

- leaching—14 days + 16 weeks of exposure to high humidity and culture medium,

- -

- leaching 14 days + exposure to Coniophora puteana fungus on the culture medium—16 weeks.

- -

- aging in natural conditions,

- -

- aging in natural conditions for three years, followed by 16 weeks of exposure to fungus on the culture medium.

3. Results

4. Discussion

- Zmg—loss of mass/bending strength reduction as a result of exposure to house fungi, %

- Zx—loss of mass/bending strength reduction after combined exposure of all studied aging factors, %

- Zp—loss of mass/bending strength reduction after exposure to high humidity environmental conditions—(70 ± 5)%, at 22 ± 2 °C, in the presence of the medium, %.

5. Conclusions

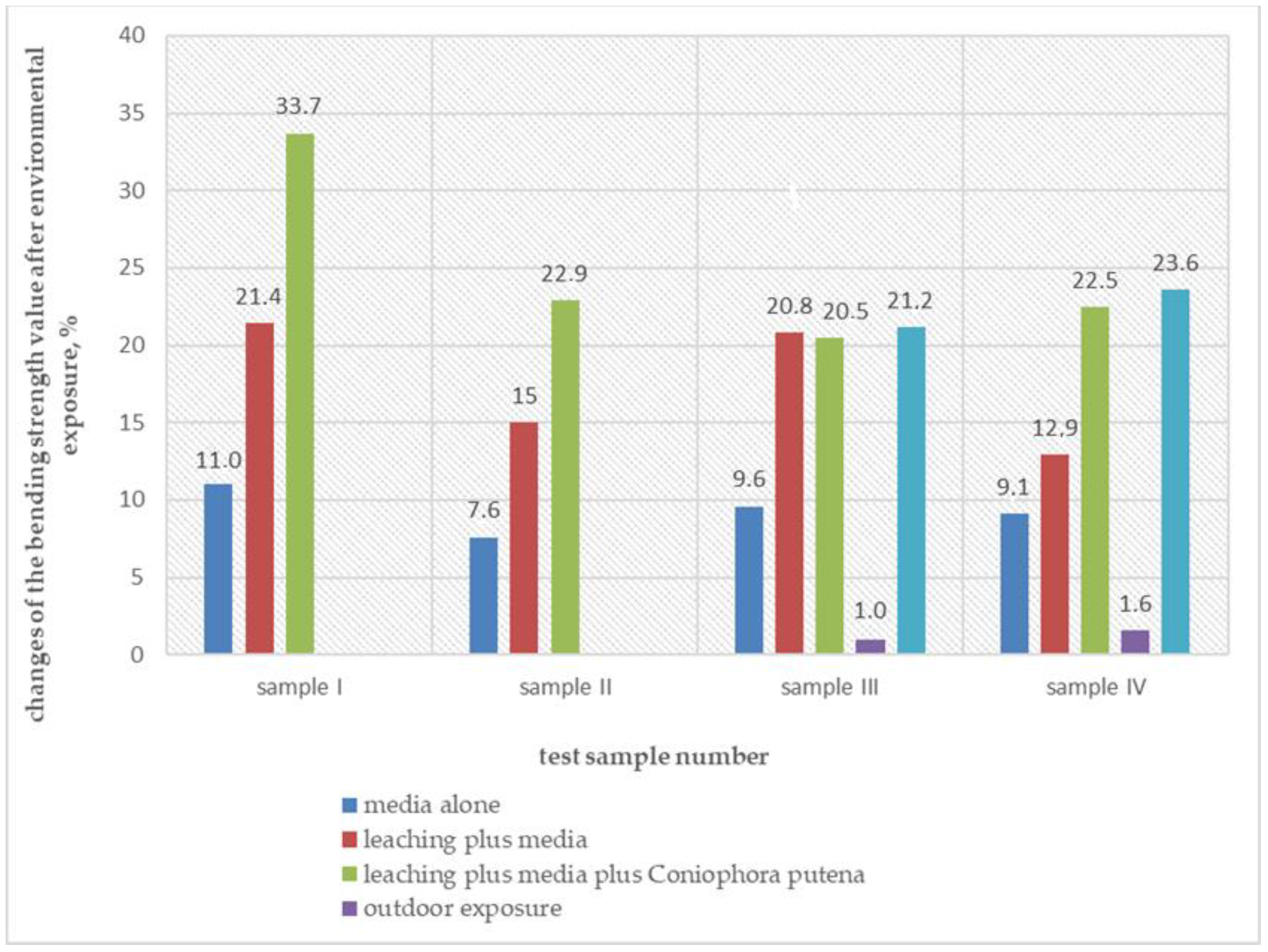

- The proposed assessment method of wood-polymer composites resistance to destroying fungi introduces bending strength test as a supplement to the weight change assessment of samples exposed to environmental impacts both in the laboratory and natural conditions. The assessment of the bending strength decrease renders more accurate results than the method involving loss of mass because the coefficient of variation is lower for such series of results,

- The manuscript presents a modification of assessment of the resistance of wood-polymer composites to destroying fungi which allow one to separate the destructive effect of fungi from the destructive effect of the moisture accompanying the test. It was proved the negative impact of high humidity for 16 weeks constitutes a significant percentage of the test result. In the case of the mass change assessment, it exceeds 50%, whereas for the bending strength change assessment it ranges from 30% to 46%.

- The method of testing wood-plastic composites’ resistance to destroying fungi in laboratory conditions, presented in the paper, renders the results similar to those after three years of use in a natural environment and then infecting them with destroying fungi.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Prochoń, M.; Witczak, M.; Biernacka, A. Wood as a Component of Polymer Biocomposites (In Polish: Drewno Jako Składnik Biokompozytów Polimerowych); Technical University of Łódź: Łódź, Poland, 2017. [Google Scholar]

- Andersson, M.A.; Nikulin, M.; Koljalg, U.; Andersson, M.C.; Rainey, F.; Reijula, K.; Hintikka, E.L.; Salkinoja-Salonen, M. Bacteria, molds, and toxins in water-damaged building materials. Appl. Environ. Microbiol. 1997, 63, 387–393. [Google Scholar] [CrossRef]

- Fisher, M.C.; Henk, D.A.; Briggs, C.J.; Brownstein, J.S.; Madoff, L.C.; McCraw, S.L.; Gurr, S.J. Emerging fungal threats to animal, plant and ecosystem health. Nature 2012, 484, 186–194. [Google Scholar] [CrossRef]

- Tascioglu, C.; Goodell, B.; Lopez-Anido, R.; Peterson, M.; Halteman, W.; Jellison, J. Minitoring fungal degradation of E-glass/phenolic fiber reinforced polymer (FRP) composites used in wood reinforcement. Int. Biodeter. Biodegrad. 2003, 51, 157–165. [Google Scholar] [CrossRef]

- Eder, A.; Carus, M. Global trends in wood-plastic composites (WPC). Bioplast. Mag. 2013, 8, 16–17. [Google Scholar]

- Penczek, S.; Pretula, J.; Lewiński, P. Polymers from renewable raw materials, biodegradable polymers (in Polish: Polimery z odnawialnych surowców, polimery biodegradowalne). Polimery 2013, 58, 833–958. [Google Scholar]

- Orhan, Y.; Buyukgungor, H. Enhancement of biodegradability of disposable polyethylene in controlled biological soil. Int. Biodeterior. Biodegrad. 2000, 45, 49–55. [Google Scholar] [CrossRef]

- Leja, K.; Lewandowicz, G. Polymer biodegradation and biodegradable polymers—A review. Pol. J. Environ. Stud. 2010, 19, 255–266. [Google Scholar]

- Gautam, R.; Bassi, A.S.; Yanful, E.K. A review of biodegradation of synthetic plastic and foams. Appl. Biochem. Biotechnol. 2007, 141, 85–108. [Google Scholar] [CrossRef]

- Wołejko, E.; Matejczyk, M. Civil and Environmental Engineering Reports. Bud. I Inżynieria Środowiska 2011, 2, 191–195. [Google Scholar]

- Silva, A.; Gartner, B.L.; Morrell, J.J. Towards the development of accelerated Methods for Assessing the Durability of wood Plastic Composites. J. Test. Eval. 2007, 35, 1–28. [Google Scholar] [CrossRef]

- Morris, P.I.; Cooper, P. Recycled plastic/wood composite lumber attacked by fungi. For. Prod. J. 1998, 48, 86–88. [Google Scholar]

- Mankowski, M.; Morrell, J.J. Patterns of fungal attack in wood plastic composites following exposure in a soil block test. Wood Fiber Sci. 2000, 32, 340–345. [Google Scholar]

- Pendleton, D.E.; Hoffard, T.A.; Addock, T.; Woodward, B.; Wolcott, M.P. Durability of an extruded HDPE/wood composite. For. Prod. J. 2002, 52, 21–27. [Google Scholar]

- Verhey, S.; Laks, P.; Richter, D. Laboratory decay resistance of woodfiber/ thermoplastic composites. For. Prod. J. 2001, 51, 44–49. [Google Scholar]

- Schirp, A.; Ibach, R.E.; Pendelton, D.E.; Wolcott, M.P. Biological Degradation of Wood-Plastic Composites (WPC) and Strategies for Improving the Resistance of WPC against Biological Decay; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2008; pp. 480–507. [Google Scholar]

- Ibach, R.; Sun, G.; Gnatowski, M.; Glaeser, J.; Leung, M.; Haight, J. Exterior decay of wood–plastic composite boards: Characterization and magnetic resonance imaging. For. Prod. J. 2015, 66, 4–17. [Google Scholar] [CrossRef]

- Wang, W.; Morrell, J.J. Water sorption acharacteristics of two wood-plastic composites. For. Prod. J. 2004, 54, 209–212. [Google Scholar]

- Nuhoglu, Y.; Oguz, E.; Uslu, H.; Ozbek, A.; Ipekoglu, B.; Ocak, I.; Hasenekoglu, I. The accelerating effects of the microorganisms on biodeterioration of stone monuments under air pollution and continental-cold climatic conditions in Erzurum. Turk. Sci. Total Environ. 2006, 364, 272–283. [Google Scholar] [CrossRef]

- Coffta, G.; Borysiak, S.; Doczekalska, B.; Garbarczyk, J. Resistance of polypropylene-wood composites to fungi (in Polish: Odporność kompozytów polipropylen-drewno na rozkład powodowany przez grzyby). Polimery 2006, 51, 276–279. [Google Scholar]

- Falk, R.; Lundin, T.; Felton, C. The Effects of Weathering on Wood-Thermoplastic Composites Intended for Outdoor Applications. In Proceedings of the 2nd Annual Conference Durability and Disaster Mitigation in Wood-Frame Housing, Madison, WI, USA, 6–8 November 2000; pp. 175–179. [Google Scholar]

- Faruk, O.; Błędzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Kamdem, D.P.; Jiang, H.; Cui, W.; Freed, J.; Matuana, L.M. Properties of wood plastic composites made of recycled DHPE and wood Flour from CCA- treated wood removed from service. Composites Part A 2004, 35, 347–355. [Google Scholar] [CrossRef]

- Yildiz, U.C.; Yildiz, S.; Gezer, E.D. Mechanical properties and decay resistance of wood polymer composites prepared from fast growing species in Turkey. Bioresour. Technol. 2005, 96, 1003–1011. [Google Scholar] [CrossRef] [PubMed]

- Clemons, C.M.; Ibach, R.E. Effects of processing method and moisture history on laboratory fungal resistance of wood-HDPE composites. Prod. J. 2004, 54, 50–57. [Google Scholar]

- Sobków, D.; Barton, J.; Czaja, K.; Sudoł, M.; Mazoń, B. Reasearch on the resistance of materials to the effects of the natural environment (in Polish: Badania odporności materiałów na działanie czynników środowiska naturalnego). Chemik 2014, 68, 347–354. [Google Scholar]

- ASTM D-2017. Standard Test Method for Accelerated Laboratory Test of Natural Decay Resistance of Wood; American Society for Testing and Materials: Philadelphia, PA, USA, 2005. [Google Scholar]

- ASTM D-1413. Standard Test Method for Wood Preservatives by Laboratory Soil-Block Cultures; American Society for Testing and Materials: Philadelphia, PA, USA, 2007. [Google Scholar]

- ENV 12038. Durability of Wood and Wood-Based Products—Wood-Based Panels—Method of Test for Determining the Resistance against Wood-Destroying Basidiomycetes; European Committee for Standardization (CEN): Brussels, Belgium, 2002. [Google Scholar]

- Schirp, A.; Wolcott, M.P. Influence of fungal decay and moisture absorption on mechanical properties of extruded wood-plastic composites. Wood Fiber Sci. 2005, 37, 643–652. [Google Scholar]

- Seefeldt, H.; Braun, U. Burning behavior of wood-plastic composite decking boards in end-use conditions; the effects of geometry, material composition and moisture. J. Fire Sci. 2012, 30, 41–54. [Google Scholar] [CrossRef]

- Naumann, A.; Seefeldt, H.; Stephan, I.; Braun, U.; Noll, M. Material resistance of flame retarded wood-plastic composites against fire and fungal decay. Polym. Degrad. Stab. 2012, 97, 1189–1196. [Google Scholar] [CrossRef]

- Chmielnicki, B.; Jurczyk, S. WPC composites as an alternative to wood products (in Polish: Kompozyty WPC jako alternatywa dla wytworów z drewna). Przetwórstwo Tworzyw 2013, 19, 477–484. [Google Scholar]

- Ashori, A.; Behzad, H.M.; Tarmian, A. Effects of chemical preservative treatments on durability of wood flour/HDPE composites. Composites 2013, 47, 308–313. [Google Scholar] [CrossRef]

- Friedrich, D.; Luible, A. Investigations on ageing of wood-plastic composites for outdoor applications: A meta-analysis using empiric data derived from diverse weathering trials. Constr. Build. Mater. 2016, 124, 1142–1152. [Google Scholar] [CrossRef]

- EN 84. Wood Preservatives. Accererated Ageing of Treted Wood Prior to Biological Testing. Leaching Procedurę; European Committee for Standardization (CEN): Brussels, Belgium, 1997. [Google Scholar]

- EN ISO 178. Plastics—Determination of Flexural Properties; European Committee for Standardization (CEN): Brussels, Belgium, 2019. [Google Scholar]

- Sun, G.; Ibach, R.E.; Faillace, M.; Gnatowski, M.; Glaeser, J.A.; Haight, J. Laboratory and exterior decay of wood–plastic composite boards: Voids analysis and computed tomography. Wood Mater. Sci. Eng. 2017, 12, 263–278. [Google Scholar] [CrossRef]

- Ibach, R.; Gnatowski, M.; Sun, G.; Glaeser, J.; Leung, M.; Haight, J. Laboratory and environmental decay of wood–plastic composite boards: Flexural properties. Wood Mater. Sci. Eng. 2018, 13, 81–96. [Google Scholar] [CrossRef]

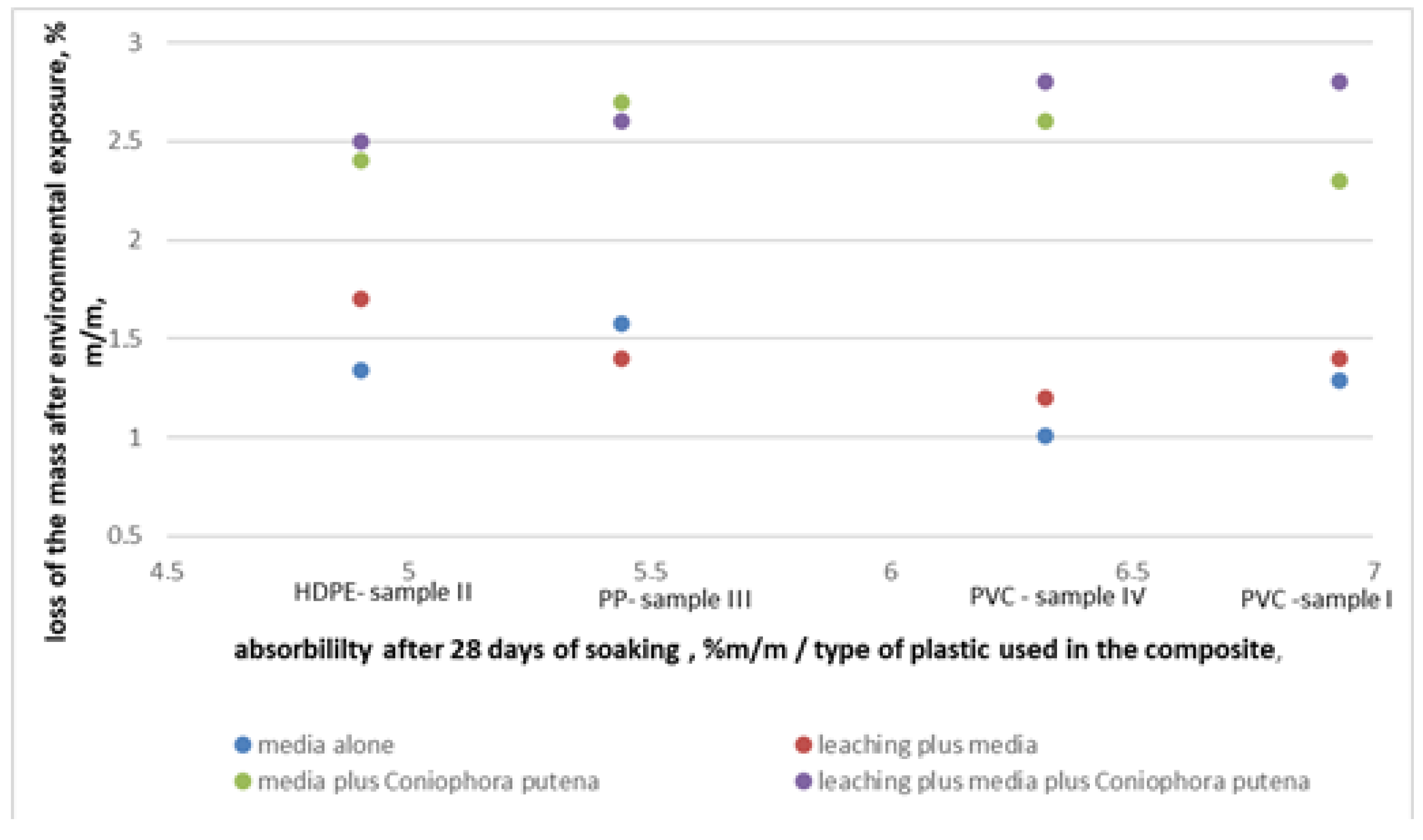

| Test Sample | Water Absorption, % m/m | ||

|---|---|---|---|

| After Immersion in Water for: | After Completion of Environmental Exposures (after Removal of the Fungi) | ||

| 14 Days | 28 Days | ||

| I | 5.78 | 6.93 | 16.98 |

| II | 3.47 | 4.90 | 15.40 |

| III | 5.44 | 4.14 | 16.01 |

| IV | 5.12 | 6.32 | 16.50 |

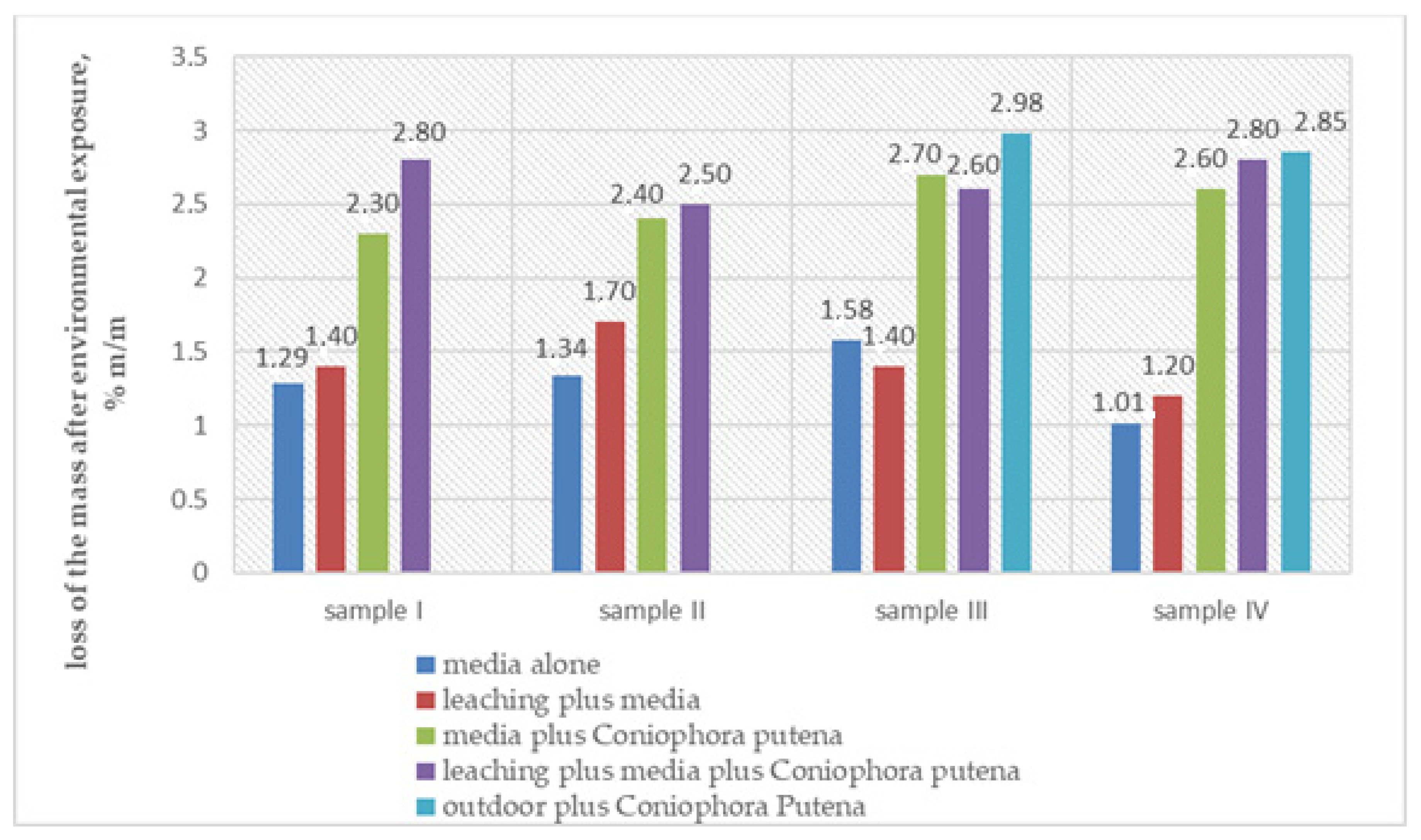

| Test Sample | Average Mass Loss after Exposure to % m/m/Coefficient of Variation [%] | ||||

|---|---|---|---|---|---|

| Media Alone | Leaching Plus Media | Media Plus Coniophora puteana | Leaching Plus Media Plus Coniophora puteana | Outdoor Exposure Plus Media Plus Coniophora puteana | |

| I | −1.29/(13.0) | −1.4/(6.4) | −2.3/(18.7) | −2.8/(17.9) | - |

| II | −1.34/(35.8) | −1.7/(28.2) | −2.4/(3.8) | −2.5/(19.6) | - |

| III | −1.58/(10.1) | −1.4/(25.7) | −2.7/(5.6) | −2.6/(5.4) | −2.98/(13.8) |

| IV | −1.01/(8.9) | −1.2/(2.5) | −2.6/(5.4) | −2.8/(5.4) | −2.85/(10.2) |

| Test Sample | Bending Strength after Exposure: MPa/Coefficient of Variation [%] | |||||

|---|---|---|---|---|---|---|

| Original | Media Alone | Leaching Plus Media | Leaching Plus Media Plus Coniophora puteana | Outdoor Exposure | Outdoor Exposure Plus Media Plus Coniophora puteana | |

| I | 36.5/(8.8) | 32.5/(4.6) | 28.7/(6.6) | 24.2/(10.7) | - | - |

| II | 35.4/(11.0) | 32.7/(5.5) | 30.1/(3.7) | 27.3/(4.4) | - | - |

| III | 29.3/(2.7) | 26.5/(3.4) | 23.2/(4.3) | 23.3/(7.3) | 29.0/(6.6) | 23.1/(3.4) |

| IV | 36.4/(4.1) | 33.1/(6.3) | 31.7/(2.2) | 28.2/(7.1) | 35.8/(5.9) | 27.8/(4.7) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wiejak, A.; Francke, B. Testing and Assessing Method for the Resistance of Wood-Plastic Composites to the Action of Destroying Fungi. Materials 2021, 14, 697. https://doi.org/10.3390/ma14030697

Wiejak A, Francke B. Testing and Assessing Method for the Resistance of Wood-Plastic Composites to the Action of Destroying Fungi. Materials. 2021; 14(3):697. https://doi.org/10.3390/ma14030697

Chicago/Turabian StyleWiejak, Anna, and Barbara Francke. 2021. "Testing and Assessing Method for the Resistance of Wood-Plastic Composites to the Action of Destroying Fungi" Materials 14, no. 3: 697. https://doi.org/10.3390/ma14030697

APA StyleWiejak, A., & Francke, B. (2021). Testing and Assessing Method for the Resistance of Wood-Plastic Composites to the Action of Destroying Fungi. Materials, 14(3), 697. https://doi.org/10.3390/ma14030697