The Influence of a Novel Hydrophobic Agent on the Internal Defect and Multi-Scale Pore Structure of Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Hydrophobic Admixture Preparation

2.2. Concrete Specimens

2.3. Hydrophobic Tests

2.4. Ultrasonic Tests

2.5. Multi-Scale Pore Tests

2.6. Hydration Product Test

3. Results and Discussion

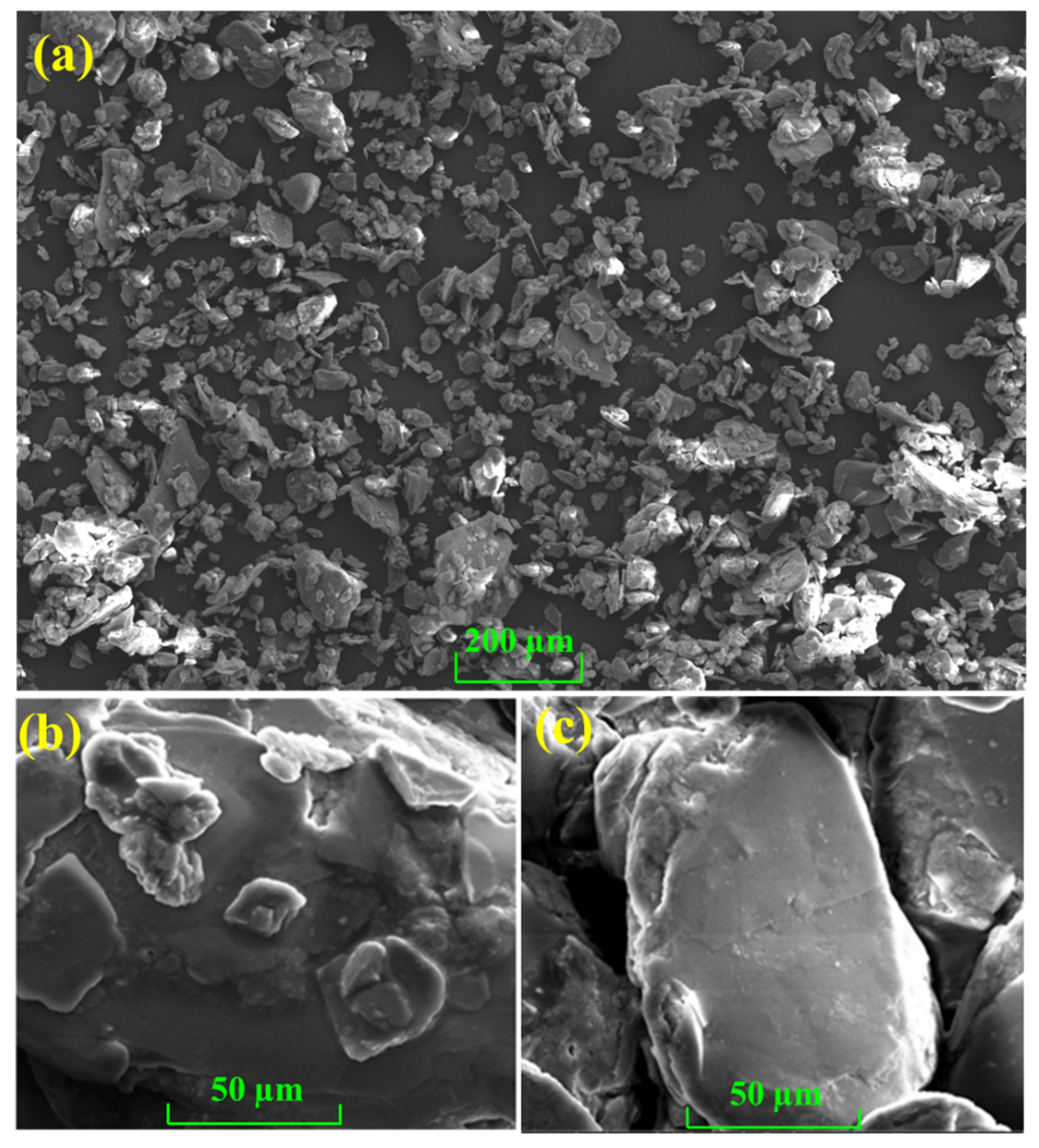

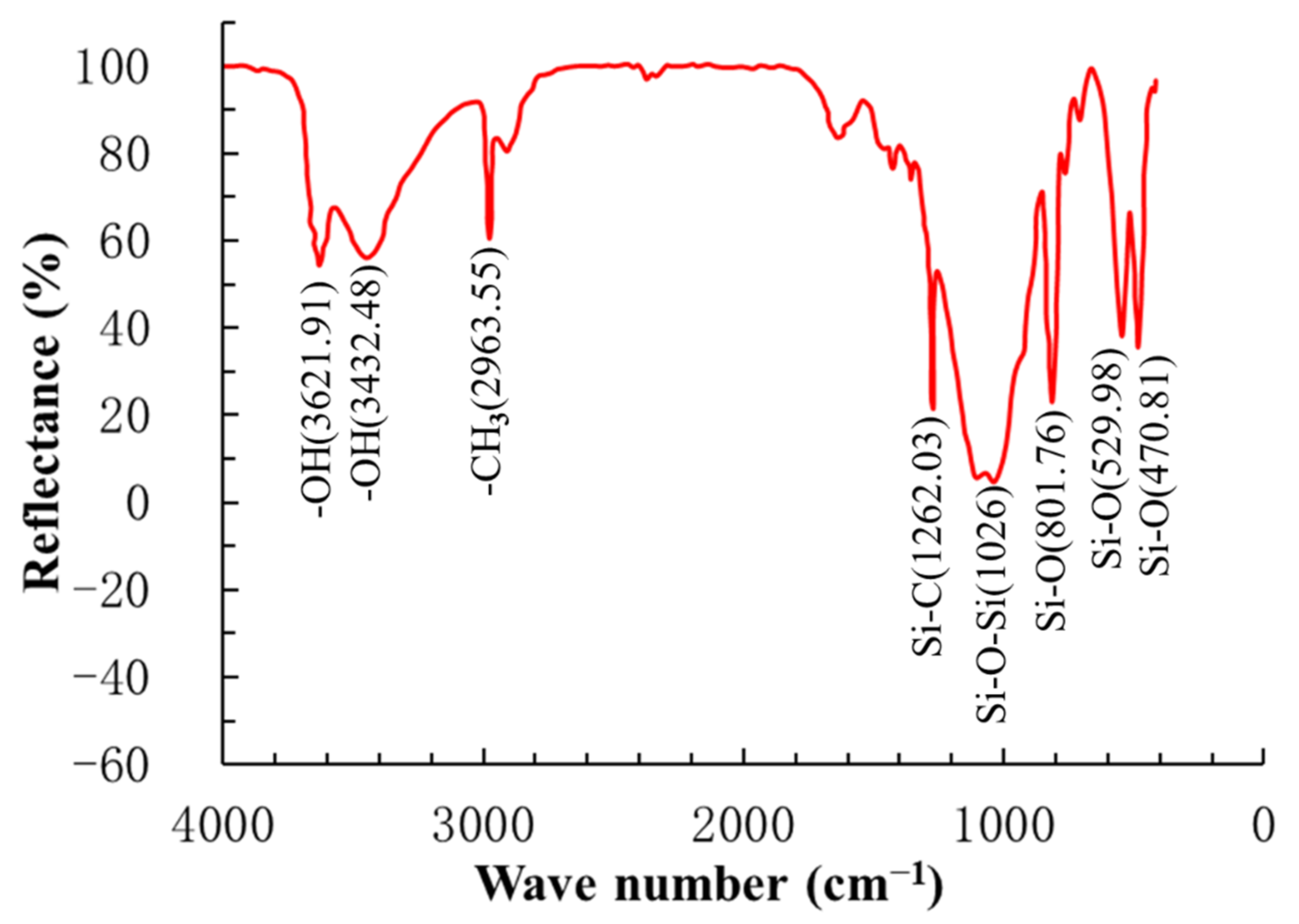

3.1. Microscopic Characteristics and Elemental Composition Analyses of YREC

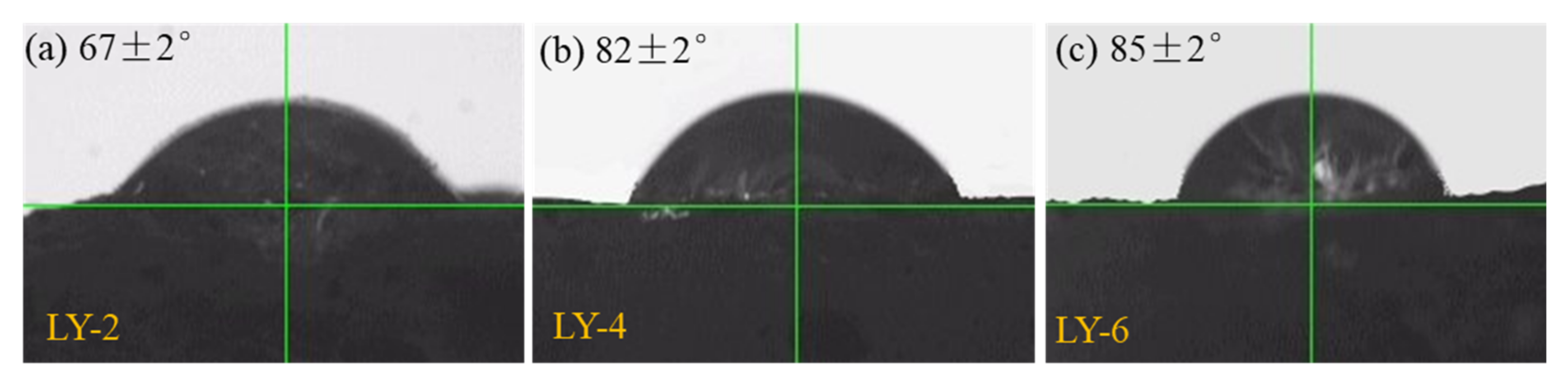

3.2. The Improvement of Impermeability Induced by YREC

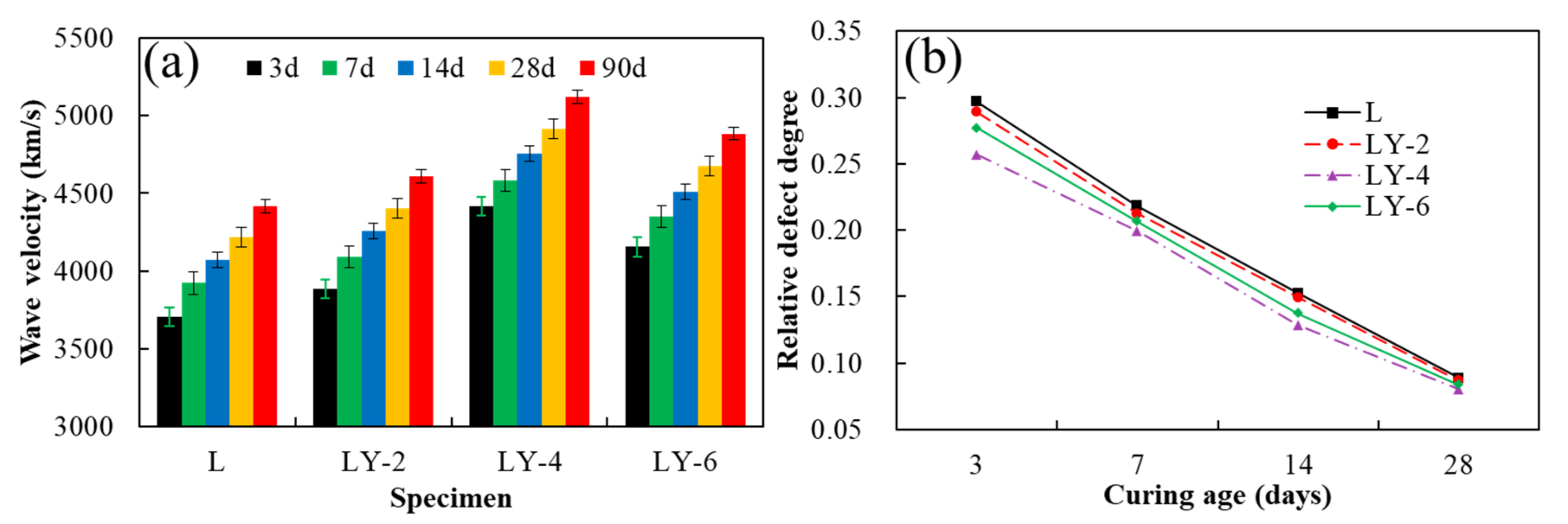

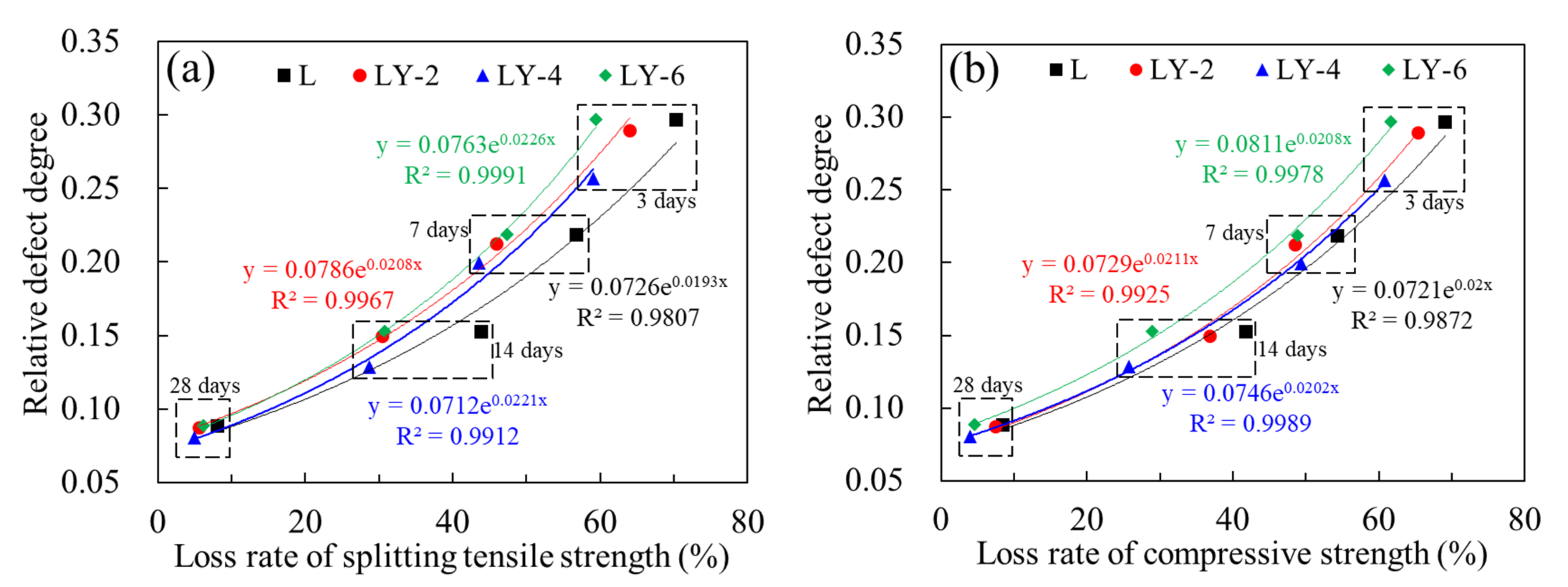

3.3. Mechanical Properties and Internal Defect

3.4. Pore Structure Characteristics

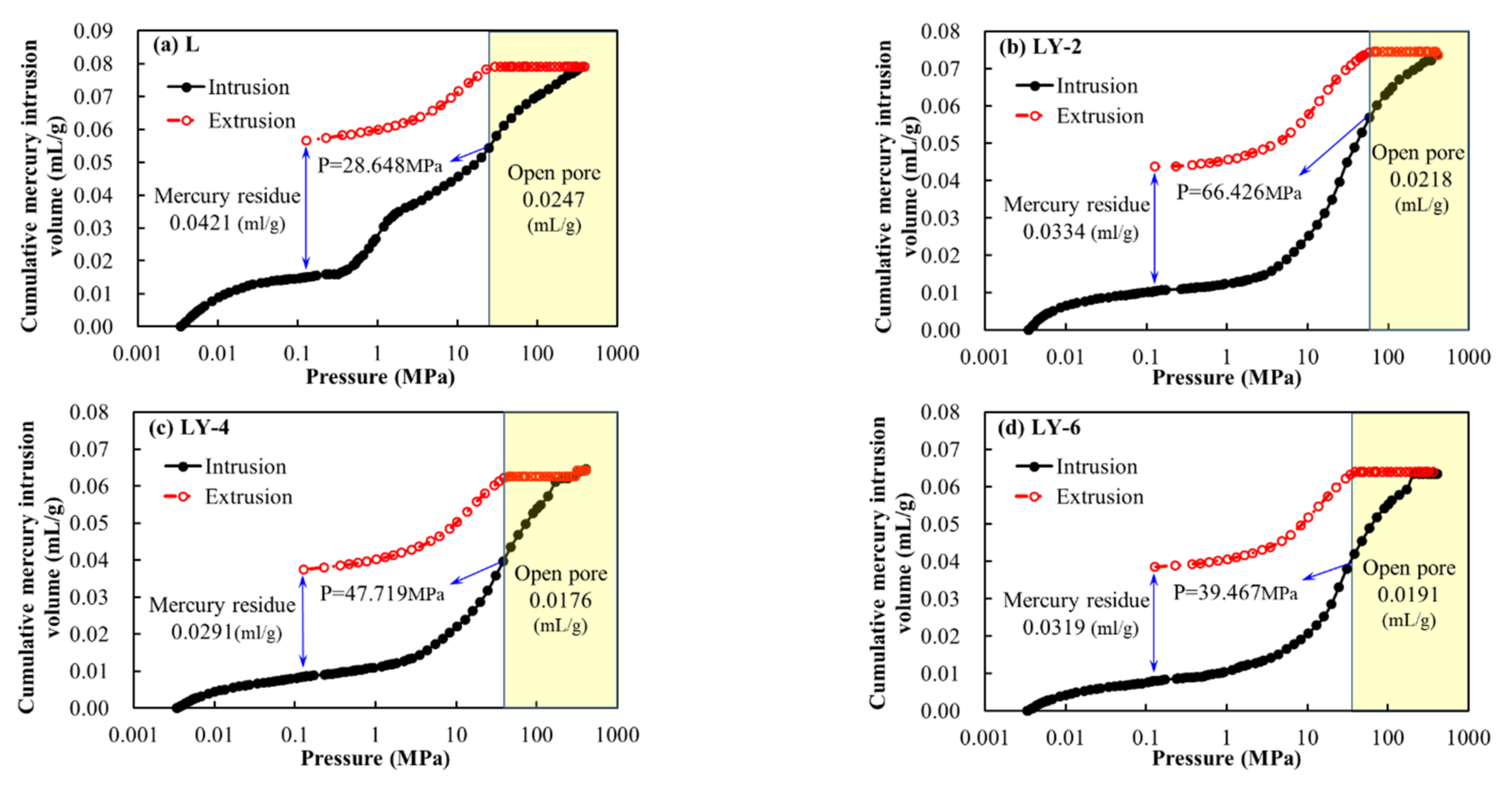

3.4.1. Results From MIP

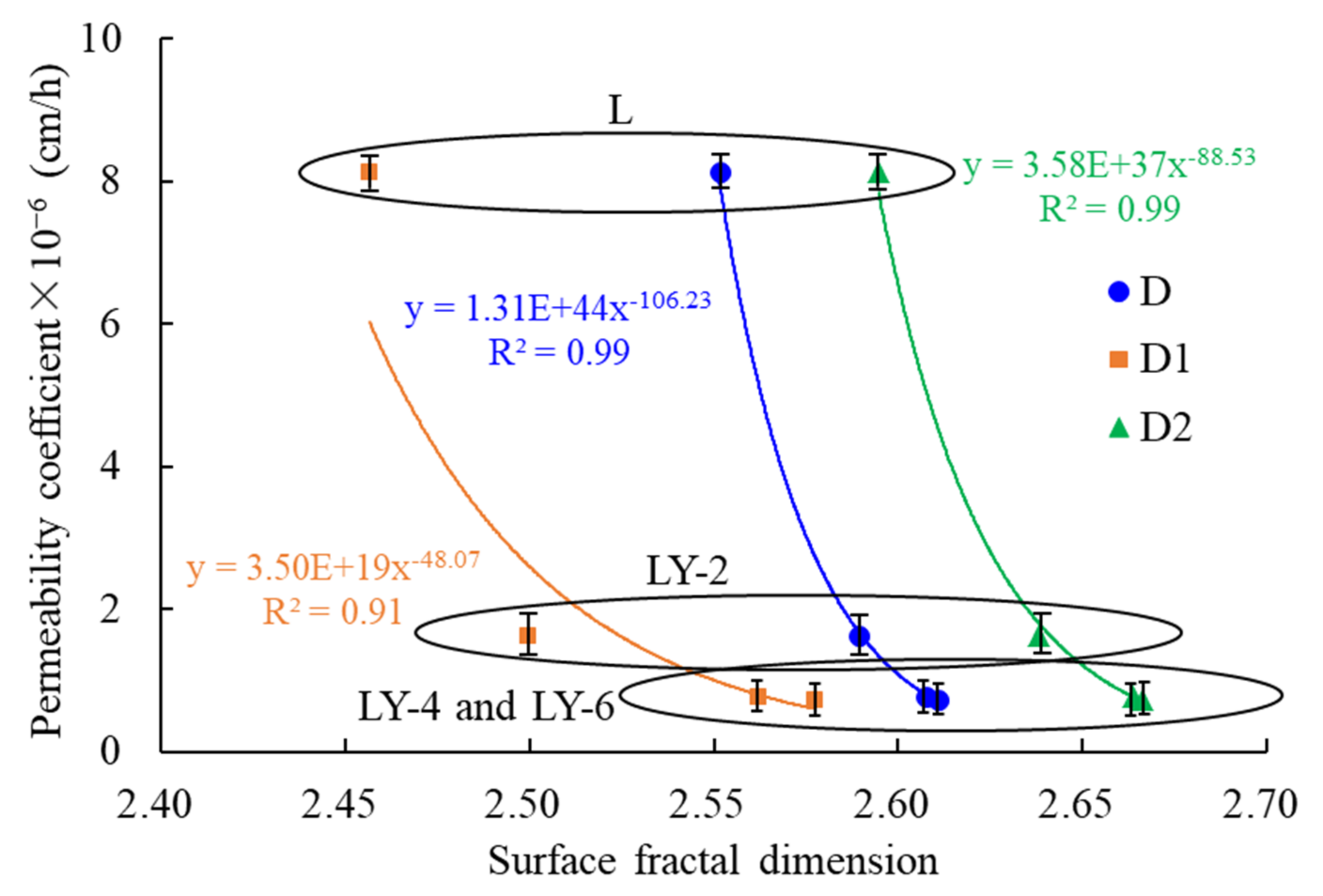

3.4.2. N2 Adsorption Results and Pore Fractal Characteristics

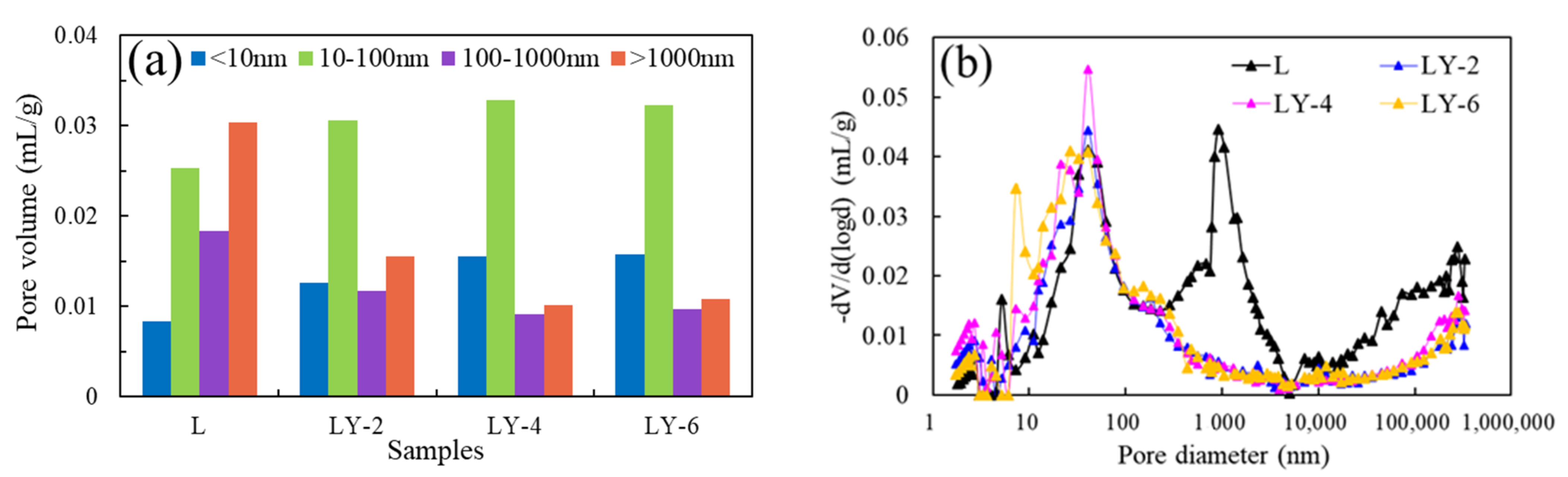

3.4.3. Multi-Scale PSD Analyses

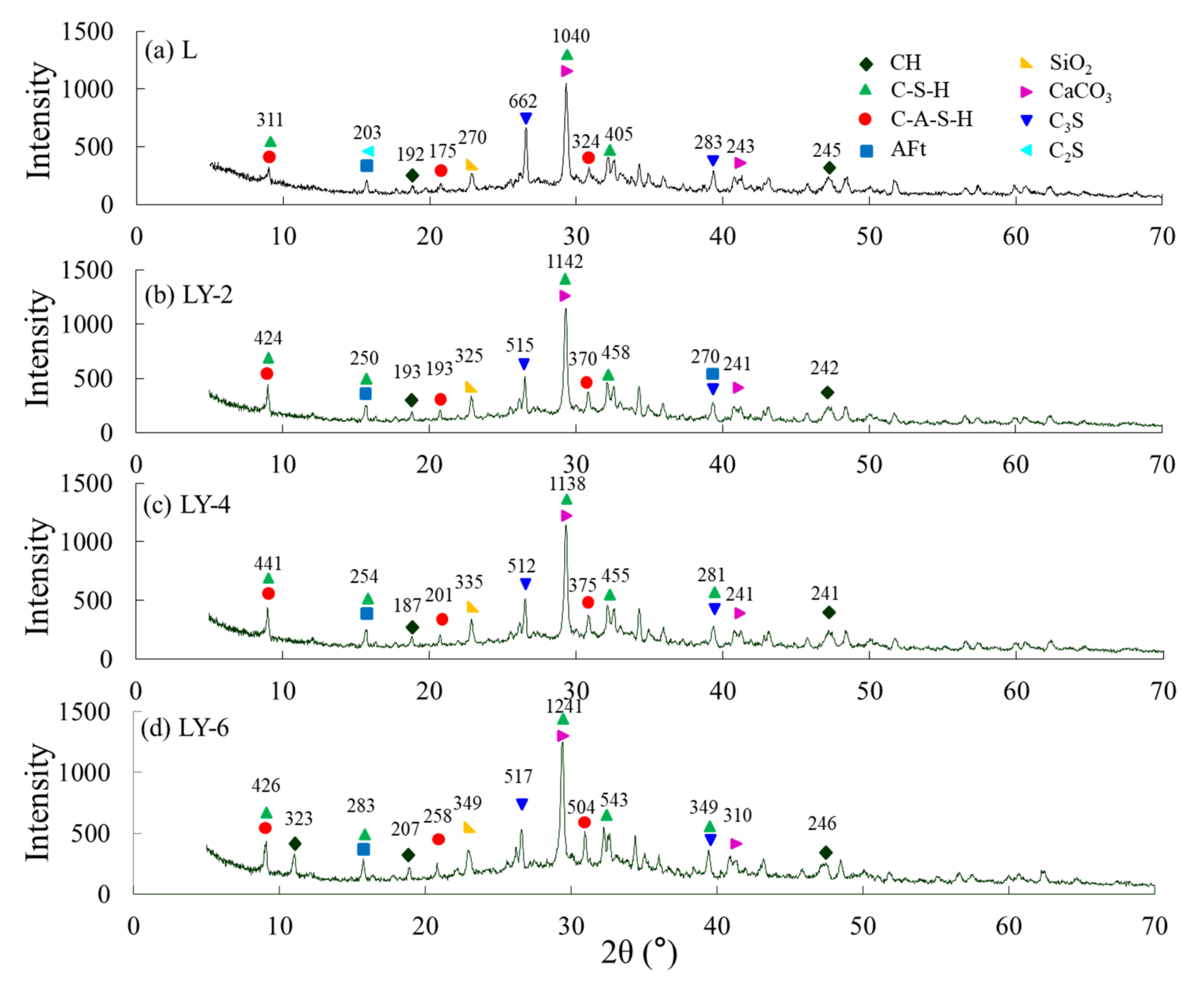

3.5. The Effect of YREC on Hydration Reaction

4. Conclusions

- The components of YREC and a large number of hydrophobic functional groups provided strong hydrophobicity. The structure of YREC particles is favorable for impermeability due to the complex and longer seepage path in concrete based on fractal analysis and hydrophobic tests.

- The defect degree of concrete can be deduced by YREC, and the splitting tensile strength and compressive strength were improved significantly due to the filling effect. The addition of 4% YREC is the most desirable method, which can promote the hydration reaction and further enhance the functionality of concrete.

- The porosity of the mortar matrix materials decreased with the addition of YREC, which inherently affected the diffusion of water. YREC can restrain the formation of harmful pores in concrete mortar matrix, which mainly decreased the pore volume with the pore size larger than 10 µm. Moreover, the more advantage pores (micropores and mesopores) developed in concrete mortar matrix with the addition of YREC.

- YREC can significantly improve the hydrophobicity of concrete materials. The next step is to study the properties of YREC in acidic environment or chlorine salt and sulfate environments. The application range of the material is desirable to further investigated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hsu, T. Unified Theory of Concrete Structures; John Wiley & Sons: Oxford, UK, 2010. [Google Scholar]

- Kurdowski, W. Cement and Concrete Chemistry; Springer: Berlin, Germany, 2014. [Google Scholar]

- Chen, Y.L.; Lin, C.J.; Ko, M.S.; Lai, Y.C. Characterization of mortars from belite-rich clinkers produced from inorganic wastes. Cem. Concr. Compos. 2011, 33, 261–266. [Google Scholar] [CrossRef]

- Codina, M.; Cau-dit-Coumes, C.; Le Bescop, P.; Verdier, J.; Ollivier, J.P. Design and characterization of low-heat and low-alkalinity cements. Cem. Concr. Res. 2008, 38, 437–448. [Google Scholar] [CrossRef]

- Sui, T.; Fan, L.; Wen, Z.; Wang, J.; Zhang, Z. Study on the properties of high strength concrete using high belite cement. J. Adv. Concr. Technol. 2004, 2, 201–206. [Google Scholar] [CrossRef]

- Chatterjee, A.K. High belite cements—Present status and future technological options: Part I. Cem. Concr. Res. 1996, 26, 1213–1225. [Google Scholar] [CrossRef]

- Koumpouri, D.; Angelopoulos, G.N. Effect of boron waste and boric acid addition on the production of low energy belite cement. Cem. Concr. Compos. 2016, 68, 1–8. [Google Scholar] [CrossRef]

- Jiang, L.; Xue, X.; Zhang, W.; Yang, J.; Zhang, H.; Li, Y.; Zhang, R.; Zhang, Z.; Xu, L.; Qu, J.; et al. The investigations of factors affecting the water impermeability of inorganic sodium silicate-based concrete sealers. Constr. Build. Mater. 2015, 93, 729–736. [Google Scholar] [CrossRef]

- Xue, X.; Yang, J.; Zhang, W.; Jiang, L.; Qu, J.; Xu, L.; Zhang, H.; Song, J.; Zhang, R.; Li, Y.; et al. The study of an energy efficient cool white roof coating based on styrene acrylate copolymer and cement for waterproofing purpose—Part I: Optical properties, estimated cooling effect and relevant properties after dirt and accelerated exposures. Constr. Build. Mater. 2015, 98, 176–184. [Google Scholar] [CrossRef]

- Song, Z.; Xue, X.; Li, Y.; Yang, J.; He, Z.; Shen, S.; Jiang, L.; Zhang, W.; Xu, L.; Zhang, H.; et al. Experimental exploration of the waterproofing mechanism of inorganic sodium silicate-based concrete sealers. Constr. Build. Mater. 2015, 104, 276–283. [Google Scholar] [CrossRef]

- Suleiman, A.R.; Soliman, A.M.; Nehdi, M.L. Effect of surface treatment on durability of concrete exposed to physical sulfate attack. Constr. Build. Mater. 2014, 73, 674–681. [Google Scholar] [CrossRef]

- Almusallam, A.A.; Khan, F.M.; Dulaijan, S.U.; Al-Amoudi, O.S.B. Effectiveness of surface coatings in improving concrete durability. Cem. Concr. Compos. 2003, 25, 473–481. [Google Scholar] [CrossRef]

- Medeiros, M.; Helene, P. Efficacy of surface hydrophobic agents in reducing water and chloride ion penetration in concrete. Mater. Struct. 2008, 41, 59–71. [Google Scholar] [CrossRef]

- Dai, J.; Akira, Y.; Wittmann, F.H.; Yokota, H.; Zhang, P. Water repellent surface impregnation for extension of service life of reinforced concrete structures in marine environments: The role of cracks. Cem. Concr. Compos. 2010, 32, 101–109. [Google Scholar] [CrossRef]

- Franzoni, E.; Pigino, B.; Pistolesi, C. Ethyl silicate for surface protection of concrete: Performance in comparison with other inorganic surface treatments. Cem. Concr. Compos. 2013, 44, 69–76. [Google Scholar] [CrossRef]

- Ibrahim, M.; Al-Gahtani, A.S.; Maslehuddin, M.; Almusallam, A.A. Effectiveness of concrete surface treatment materials in reducing chloride-induced reinforcement corrosion. Constr. Build. Mater. 1997, 11, 443–451. [Google Scholar] [CrossRef]

- Ibrahim, M.; Al-Gahtani, A.S.; Maslehuddin, M.; Dakhil, F.H. Use of surface treatment materials to improve concrete durability. J. Mater. Civ. Eng. 1999, 11, 36–40. [Google Scholar] [CrossRef]

- Jones, M.R.; Dhir, R.K.; Gill, J.P. Concrete surface treatment: Effect of exposure temperature on chloride diffusion resistance. Cem. Concr. Res. 1995, 25, 197–208. [Google Scholar] [CrossRef]

- Al-Kheetan, M.J.; Rahman, M.; Muniswamappa, B.N.; Chamberlain, D.A. Performance enhancement of self-compacting concrete in saline environment by hydrophobic surface protection. Can. J. Civ. Eng. 2019, 46, 677–686. [Google Scholar] [CrossRef]

- Herb, H.; Gerdes, A.; Brenner-Wei, G. Characterization of silane-based hydrophobic admixtures in concrete using TOF-MS. Cem. Concr. Res. 2015, 70, 77–82. [Google Scholar] [CrossRef]

- Singh, V.P.; Sandeep, K.; Kuszhwaha, H.S.; Powar, S.; Vaish, R. Photocatalytic, hydrophobic and antimicrobial characteristics of ZnO nano needle embedded cement composites. Constr. Build. Mat. 2018, 158, 285–294. [Google Scholar] [CrossRef]

- Tittarelli, F.; Moriconi, G. The effect of silane-based hydrophobic admixture on corrosion of reinforcing steel in concrete. Cem. Concr. Res. 2008, 38, 1354–1357. [Google Scholar] [CrossRef]

- Di Mundo, R.; Petrella, A.; Notarnicola, M. Surface and bulk hydrophobic cement composites by tyre rubber addition. Constr. Build. Mat. 2018, 172, 176–184. [Google Scholar] [CrossRef]

- Ramachandran, R.; Kozhukhova, M.; Sobolev, K.; Nosonovsky, M. Anti-icing superhydrophobic surfaces: Controlling entropic molecular interactions to design novel icephobic concrete. Entropy 2016, 18, 132. [Google Scholar] [CrossRef]

- Flores-Vivian, I.; Hejazi, V.; Khozhukova, M.I.; Nosonovsky, M.; Sobolev, K. Self-assembling Particle-Siloxane Coatings for Superhydrophobic Concrete. ACS Appl. Mater. Interfaces 2013, 5, 13284–13294. [Google Scholar] [CrossRef] [PubMed]

- Pan, X.Y.; Shi, Z.G.; Shi, C.J.; Ling, T.C.; Li, N. A review on concrete surface treatment part I: Types and mechanisms. Constr. Build. Mater. 2017, 132, 578–590. [Google Scholar] [CrossRef]

- Li, Y.X.; Chen, Y.M.; Wei, J.X.; He, X.Y.; Zhang, H.T.; Zhang, W.S. A study on the relationship between porosity of the cement paste with mineral additives and compressive strength of mortar based on this paste. Cem. Concr. Res. 2006, 36, 1740–1743. [Google Scholar] [CrossRef]

- Tang, S.W.; Li, Z.J.; Chen, E.; Shao, H.Y. Impedance measurement to characterize the pore structure in Portland cement paste. Construct. Build. Mater. 2014, 51, 106–112. [Google Scholar] [CrossRef]

- Yang, T.; Zhu, H.; Zhang, Z.; Yang, T.; Zhu, H.; Zhang, Z.; Yang, T.; Zhu, H.; Zhang, Z. Influence of fly ash on the pore structure and shrinkage characteristics of metakaolin-based geopolymer pastes and mortars. Construct. Build. Mater. 2017, 153, 284–293. [Google Scholar] [CrossRef]

- Mora, E.; González, G.; Romero, P.; Castellón, E. Control of water absorption in concrete materials by modification with hybrid hydrophobic silica particles. Construct. Build. Mater. 2019, 221, 210–218. [Google Scholar] [CrossRef]

- Ferrara, L.; Van Mullem, T.; Alonso, M.C.; Antonaci, P.; Borg, R.P.; Cuenca, E.; Jefferson, A.; Ng, P.L.; Peled, A.; Roig-Flores, M.; et al. Experimental characterization of the self-healing capacity of cement based materials and its effects on the material performance: A state of the art report by COST Action SARCOS WG2. Constr. Build. Mater. 2018, 167, 115–142. [Google Scholar] [CrossRef]

- Borg, R.P.; Cuenca, E.; Gastaldo Brac, E.M.; Ferrara, L. Crack sealing capacity in chloride-rich environments of mortars containing different cement substitutes and crystalline admixtures. J. Sustain. Cem. Based Mater. 2018, 7, 141–159. [Google Scholar] [CrossRef]

- Cuenca, E.; Ferrara, L. Self-healing capacity of fiber reinforced cementitious composites. State of the art and perspectives. KSCE J. Civ. Eng. 2017, 21, 2777–2789. [Google Scholar] [CrossRef]

- Zhou, J.; Ye, G.; Breugel, K.V. Characterization of pore structure in cement-based materials using pressurization–depressurization cycling mercury intrusion porosimetry (PDC-MIP). Cem. Concr. Res. 2010, 40, 1120–1128. [Google Scholar] [CrossRef]

- Pipilikaki, P.; Beazi-Katsioti, M. The assessment of porosity and pore size distribution of limestone Portland cement pastes. Constr. Build. Mater. 2009, 23, 1966–1970. [Google Scholar] [CrossRef]

- Song, Y.; Davy, C.A.; Troadec, D.; Bourbon, X. Pore network of cement hydrates in a High Performance Concrete by 3D FIB/SEM—Implications for macroscopic fluid transport. Cem. Concr. Res. 2019, 115, 308–326. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, G.; Ming, R.; Cui, X. Numerical study on seepage flow in pervious concrete based on 3D CT imaging. Constr. Build. Mater. 2018, 161, 468–478. [Google Scholar] [CrossRef]

- Zhu, H.; Li, Q.; Ma, R.; Yang, L.; Hu, Y.; Zhang, J. Water-repellent additive that increases concrete cracking resistance in dry curing environments. Constr. Build. Mater. 2020, 249, 118704. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Q.B.; Niu, X.J.; Ma, R.; Yang, L.; Hu, Y.; Zhang, J. Influence of a novel hydrophobic agent on freeze–thaw resistance and microstructure of concrete. Constr. Build. Mater. 2020, 121294. [Google Scholar] [CrossRef]

- GB/T 50082-2009, Standard for Test Methods of Long-term Performance and Durability of Ordinary Concrete; Chinese National Standards: Beijing, China, 30 November 2009.

- Avnir, D.; Farin, D.; Pfeifer, P. Chemistry in noninteger dimensions between two and three. II. Fractal surface of adsorbents. J. Chem. Phys. 1983, 78, 3566–3571. [Google Scholar] [CrossRef]

- Pfeifer, P.; Avnir, D. Chemistry in non-integer dimensions between 2 and 3, I: Fractal theory of heterogenous surface. J. Chem. Phys. 1983, 79, 3558–3565. [Google Scholar] [CrossRef]

- Duan, P.; Shui, Z.; Chen, W.; Shen, C. Influence of superplasticizer on composition and pore structure of C-S-H. Constr. Build. Mater. 2013, 44, 87–91. [Google Scholar] [CrossRef]

- Tang, S.W.; He, Z.; Cai, X.H.; Cai, R.J.; Zhou, W.; Li, Z.J. Volume and surface fractal dimensions of pore structure by NAD and LT-DSC in calcium sulfoaluminate cement pastes. Constr. Build. Mater. 2017, 143, 395–418. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Fan, M. Structural analysis for lignin characteristics in biomass straw. Biomass Bioenergy 2013, 57, 264–279. [Google Scholar] [CrossRef]

- Han, B.; Li, Z.; Zhang, L.; Zeng, S.; Yu, X.; Han, B.; Ou, J. Reactive powder concrete reinforced with nano SiO2-coated TiO2. Constr. Build. Mater. 2017, 148, 104–112. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S. Abrasion resistance of concrete containing SiO2 and Al2O3, nanoparticles in different curing media. Energy Build. 2011, 43, 2939–2946. [Google Scholar] [CrossRef]

- Wu, Z.W.; Lian, H.Z. High Performance Concrete; China Railway Press: Beijing, China, 1999. [Google Scholar]

- Feng, Q.; Liu, G.M.; Ba, H.J. Relation of grain grading and deleterious porosity of cement-based materials. J. Tongji Univ. 2004, 32, 1168–1172. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, W.; Ruan, Y.; Yu, X.; Han, B. Enhancements and mechanisms of nanoparticles on wear resistance and chloride penetration resistance of reactive powder concrete. Constr. Build. Mater. 2018, 189, 487–497. [Google Scholar] [CrossRef]

- Haruehansapong, S.; Pulngern, T.; Chucheepsakul, S. Effect of the particle size of nanosilica on the compressive strength and the optimum replacement content of cement mortar containing nano-SiO2. Constr. Build. Mater. 2014, 50, 471–477. [Google Scholar] [CrossRef]

- Han, B.; Zhang, L.; Zeng, S.; Dong, S.; Yu, X.; Yang, R.; Ou, J. Nano-core effect in nano-engineered cementitious composites. Compos. Part A Appl. Sci. Manuf. 2017, 95, 100–109. [Google Scholar] [CrossRef]

| Mix Designation | Water | Cement | Fly Ash | Sand | Gravel | YREC | Water-Binder Ratio |

|---|---|---|---|---|---|---|---|

| L | 130.00 | 169.00 | 91.00 | 727.58 | 1351.23 | 0 | 0.5 |

| LY-2 | 130.00 | 169.00 | 91.00 | 727.58 | 1351.23 | 6.50 | 0.5 |

| LY-4 | 130.00 | 169.00 | 91.00 | 727.58 | 1351.23 | 13.00 | 0.5 |

| LY-6 | 130.00 | 169.00 | 91.00 | 727.58 | 1351.23 | 19.50 | 0.5 |

| Chemical Component | SiO2 | Al2O3 | K2O | Fe2O3 | MgO | Na2O | SO3 | CaO | Others |

|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 62.3696 | 20.4022 | 7.5609 | 5.5509 | 1.0453 | 0.8712 | 0.6152 | 0.2689 | 0.6764 |

| L | LY-2 | LY-4 | LY-6 | |

|---|---|---|---|---|

| D | 2.5515 | 2.5891 | 2.6074 | 2.6109 |

| D1 | 2.4567 | 2.4997 | 2.5621 | 2.5771 |

| D2 | 2.5947 | 2.6381 | 2.6639 | 2.6663 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Li, Q.; Ma, R.; Niu, X.; Yang, L.; Hu, Y.; Zhang, J. The Influence of a Novel Hydrophobic Agent on the Internal Defect and Multi-Scale Pore Structure of Concrete. Materials 2021, 14, 609. https://doi.org/10.3390/ma14030609

Zhang B, Li Q, Ma R, Niu X, Yang L, Hu Y, Zhang J. The Influence of a Novel Hydrophobic Agent on the Internal Defect and Multi-Scale Pore Structure of Concrete. Materials. 2021; 14(3):609. https://doi.org/10.3390/ma14030609

Chicago/Turabian StyleZhang, Bo, Qingbin Li, Rui Ma, Xujing Niu, Lin Yang, Yu Hu, and Jinliang Zhang. 2021. "The Influence of a Novel Hydrophobic Agent on the Internal Defect and Multi-Scale Pore Structure of Concrete" Materials 14, no. 3: 609. https://doi.org/10.3390/ma14030609

APA StyleZhang, B., Li, Q., Ma, R., Niu, X., Yang, L., Hu, Y., & Zhang, J. (2021). The Influence of a Novel Hydrophobic Agent on the Internal Defect and Multi-Scale Pore Structure of Concrete. Materials, 14(3), 609. https://doi.org/10.3390/ma14030609