Impact of Layer Thickness and Storage Time on the Properties of 3D-Printed Dental Dies

Abstract

1. Introduction

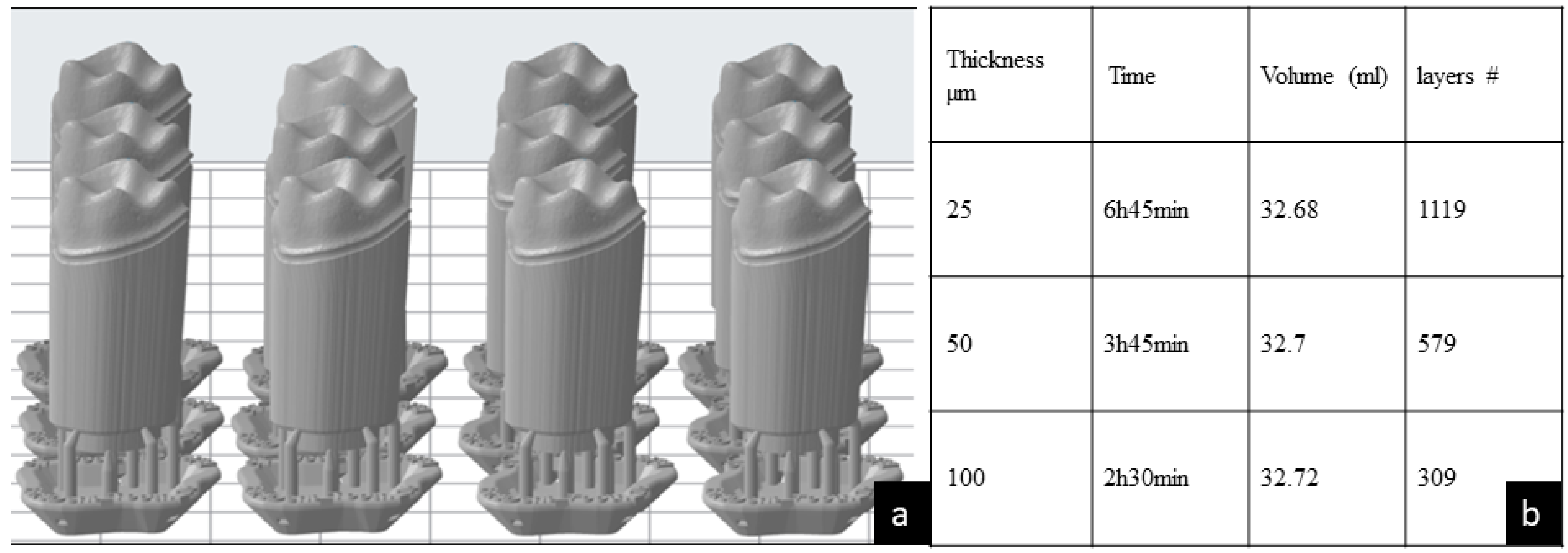

2. Materials and Methods

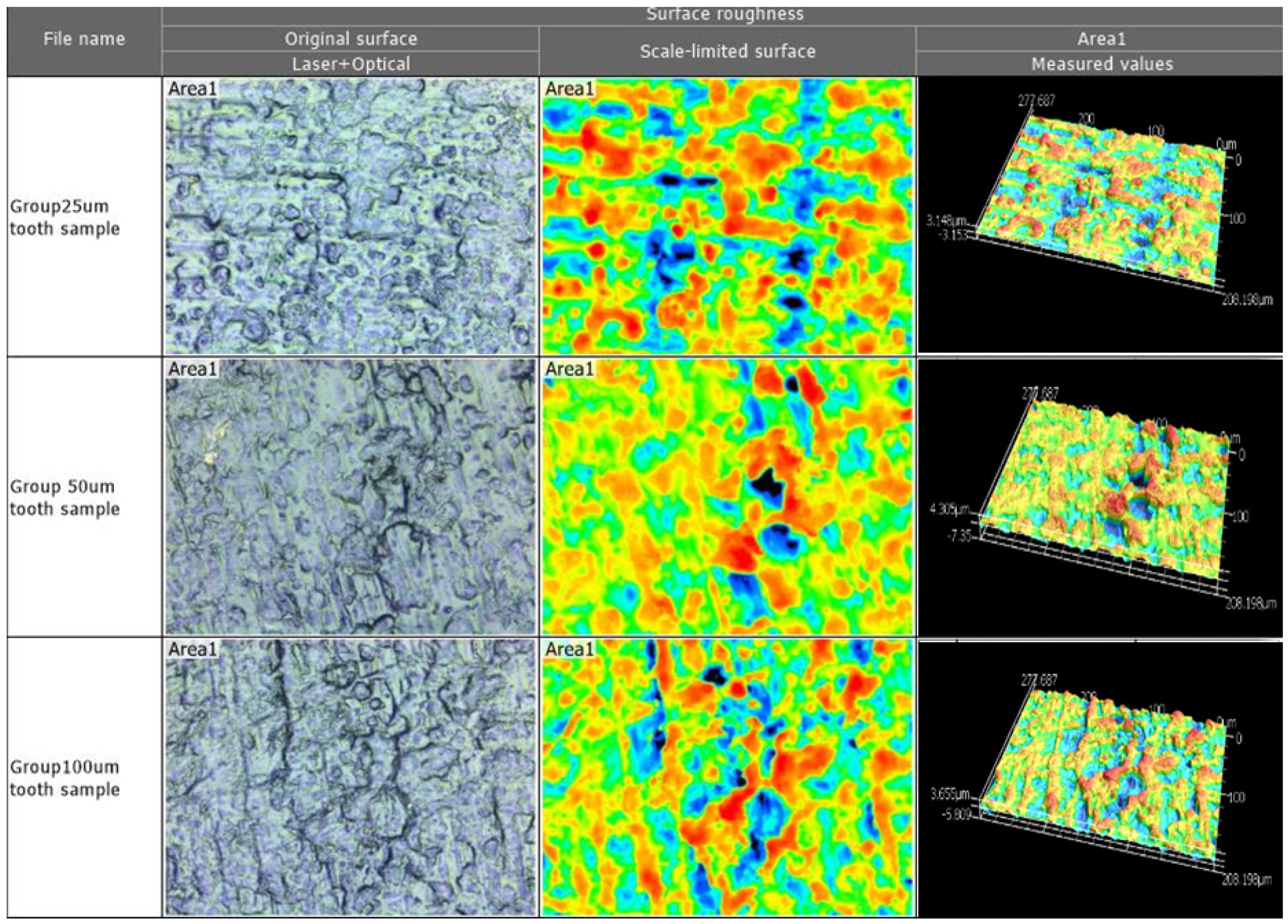

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Annual Report: The Additive Manufacturing Center of Excellence. 2019. Available online: www.amcoe.org (accessed on 17 July 2020).

- Bonsor, S.J.; Pearson, G. A Clinical Guide to Applied Dental Materials E-Book; Elsevier Health Sciences: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Tahayeri, A.; Morgan, M.; Fugolin, A.P.; Bompolaki, D.; Athirasala, A.; Pfeifer, C.S.; Ferracane, J.L.; Bertassoni, L.E. 3D printed versus conventionally cured provisional crown and bridge dental materials. Dent. Mater. 2018, 34, 192–200. [Google Scholar] [CrossRef]

- Bhargav, A.; Sanjairaj, V.; Rosa, V.; Feng, L.; Fuh, Y. Applications of additive manufacturing in dentistry: A review. J. Biomed. Mater. Res. B Appl. Biomater. 2018, 106, 2058–2064. [Google Scholar] [CrossRef]

- Chua, C.K.; Leong, K.F. 3D Printing and Additive Manufacturing: Principles and Applications (with Companion Media Pack) Fourth Edition of Rapid Prototyping Fourth Edition; World Scientific Publishing Company: Singapore, 2014. [Google Scholar]

- Oberoi, G.; Nitsch, S.; Edelmayer, M.; Janjić, K.; Müller, A.; Agis, H. 3D Printing-Encompassing the Facets of Dentistry. Front. Bioeng. Biotechnol. 2018, 6, 172. [Google Scholar] [CrossRef]

- Alexandru, B.; Gasparik, C.; Baciu, S.; Manole, M.; Dudea, D.; Campian, R. Three-Dimensional Accuracy Evaluation of Two Additive Manufacturing Processes in the Production of Dental Models. Key Eng. Mater. 2017, 752, 119–125. [Google Scholar]

- Padilla, M.T.; Bailey, J.H. Margin configuration, die spacers, fitting of retainers/crowns, and soldering. Dent. Clin. N. Am. 1992, 36, 743–764. [Google Scholar]

- Nejatidanesh, F.; Lotfi, H.R.; Savabi, O. Marginal accuracy of interim restorations fabricated from four interim autopolymerizing resins. J. Prosthet Dent. 2006, 95, 364–367. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, K.E. We’re Going Digital: The Current State of CAD/CAM Dentistry in Prosthodontics. Prim. Dent J. 2018, 7, 30–35. [Google Scholar] [CrossRef] [PubMed]

- Guichet, D.L. Digital Workflows in the Management of the Esthetically Discriminating Patient. Dent. Clin. N. Am. 2019, 63, 331–344. [Google Scholar] [CrossRef]

- Rossetti, P.; Valle, A.; Carvalho, R.; Goes, M.; Pegoraro, L. Correlation between margin fit and microleakage in complete crowns cemented with three luting agents. J. Appl. Oral Sci. Rev. FOB 2008, 16, 64–69. [Google Scholar] [CrossRef] [PubMed]

- Niekawa, C.T.; Kreve, S.; A’Vila, G.B.; Godoy, G.G.; Eduardo Vieira da Silva, J.R.; Dias, S.C. Analysis of the Mechanical Behavior and Surface Rugosity of Different Dental Die Materials. J. Int. Soc. Prev. Community Dent. 2017, 7, 34–40. [Google Scholar] [PubMed]

- Queiroz, D.; Cunha, L.; Duarte, J.; Neves, A.; Silva-Concilio, L. Influence of the casting material on the dimensional accuracy of dental dies. Braz. Oral Res. 2011, 25, 357–361. [Google Scholar] [CrossRef][Green Version]

- Prisco, R.; Cozzolino, G.; Vigolo, P. Dimensional accuracy of an epoxy die material using different polymerization methods. J. Prosthodont. 2009, 18, 156–161. [Google Scholar] [CrossRef] [PubMed]

- Bukhari, S.; Goodacre, B.J.; AlHelal, A.; Kattadiyil, M.T.; Richardson, P.M. Three-dimensional printing in contemporary fixed prosthodontics: A technique article. J. Prosthet. Dent. 2018, 119, 530–534. [Google Scholar] [CrossRef] [PubMed]

- Piedra Cascón, W.; Revilla-León, M. Digital workflow for the design and additively manufacture of a splinted framework and custom tray for the impression of multiple implants: A dental technique. J. Prosthet. Dent. 2018, 120, 805–811. [Google Scholar] [CrossRef]

- Serag, M.; Nassar, T.A.; Avondoglio, D.; Weiner, S. A Comparative Study of the Accuracy of Dies Made from Digital Intraoral Scanning vs. Elastic Impressions: An In Vitro Study. J. Prosthod. Off. J. Am. Coll. Prosthodont. 2018, 27, 88–93. [Google Scholar] [CrossRef]

- Kim, D.-Y.; Kim, J.-H.; Kim, H.-Y.; Kim, W.-C. Comparison and evaluation of marginal and internal gaps in cobalt–chromium alloy copings fabricated using subtractive and additive manufacturing. J. Prosthodont. Res. 2018, 62, 56–64. [Google Scholar] [CrossRef]

- Grant, G.T.; Campbell, S.D.; Masri, R.M.; Andersen, M.R. Glossary of Digital Dental Terms: American College of Prosthodontists. J. Prosthodont. 2016, 25 (Suppl. 2), S2–S9. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A. Current status and applications of additive manufacturing in dentistry: A literature-based review. J. Oral Biol. Craniofac. Res. 2019, 9, 179–185. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Zhang, Z.C.; Li, P.L.; Chu, F.T.; Shen, G. Influence of the three-dimensional printing technique and printing layer thickness on model accuracy. J. Orofac. Orthop. 2019, 80, 194–204. [Google Scholar] [CrossRef]

- The Ultimate Guide to Stereolithography (SLA) 3D Printing. Available online: https://formlabs.com/blog/ultimate-guide-to-stereolithography-sla-3d-printing/ (accessed on 15 April 2020).

- Kim, S.Y.; Shin, Y.S.; Jung, H.D.; Hwang, C.J.; Baik, H.S.; Cha, J.Y. Precision and trueness of dental models manufactured with different 3-dimensional printing techniques. Am. J. Orthod. Dentofac. Orthop. 2018, 153, 144–153. [Google Scholar] [CrossRef] [PubMed]

- Nallaswamy, D. Textbook of Prosthodontics; Jaypee Brothers, Medical Publishers Pvt. Limited: New Delhi, India, 2017. [Google Scholar]

- Formlabs, A Guide to Post-Curing Formlabs Resins. Available online: https://www.dynamism.com/download/2016/Post-Cure-Guide-by-Resin.pdf (accessed on 25 February 2020).

- Lenth, R.V. Java Applets for Power and Sample Size [Computer Software]. Retrieved 01/29/2006. Available online: http://www.stat.uiowa.edu/~rlenth/Power (accessed on 29 January 2020).

- Sherman, S.L.; Kadioglu, O.; Currier, G.F.; Kierl, J.; Li, J. Accuracy of digital light processing printing of 3-dimensional dental models. Am. J. Orthod. Dentofac. Orthop. 2020, 157, 422–428. [Google Scholar] [CrossRef] [PubMed]

- Arnold, C.; Monsees, D.; Hey, J.; Schweyen, R. Surface Quality of 3D-Printed Models as a Function of Various Printing Parameters. Materials 2019, 12, 1970. [Google Scholar] [CrossRef] [PubMed]

- Shim, J.S.; Kim, J.E.; Jeong, S.H.; Choi, Y.J.; Ryu, J.J. Printing accuracy, mechanical properties, surface characteristics, and microbial adhesion of 3D-printed resins with various printing orientations. J. Prosthet. Dent. 2020, 124, 468–475. [Google Scholar] [CrossRef]

- Zhao, Z.; Qi, H.J.; Fang, D. A finite deformation theory of desolvation and swelling in partially photo-cross-linked polymer networks for 3D/4D printing applications. Soft. Matter. 2019, 15, 1005–1016. [Google Scholar] [CrossRef] [PubMed]

- Bandyopadhyay, A.; Bose, S. Additive Manufacturing, Second Edition; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Erokhin, K.S.; Gordeev, E.G.; Ananikov, P.V. Revealing interactions of layered polymeric materials at solid-liquid interface for building solvent compatibility charts for 3D printing applications. Sci. Rep. 2019, 9, 20177. [Google Scholar] [CrossRef] [PubMed]

- ISO (Ed.) ISO 5725-3, Accuracy (Trueness and Precision) of Measurement Methods and Results—Part 3: Intermediate Measures of the Precision of a Standard Measurement Method; ISO: London, UK, 2019. [Google Scholar]

- Gojzewski, H.; Guo, Z.; Grzelachowska, W.; Ridwan, M.G.; Hempenius, M.A.; Grijpma, D.W.; Vancso, G.J. Layer-by-Layer Printing of Photopolymers in 3D: How Weak is the Interface? ACS Appl. Mater. Interfaces 2020, 12, 8908–8914. [Google Scholar] [CrossRef]

- Riccitiello, F.; Amato, M.; Leone, R.; Spagnuolo, G.; Sorrentino, R. In vitro Evaluation of the Marginal Fit and Internal Adaptation of Zirconia and Lithium Disilicate Single Crowns: Micro-CT Comparison Between Different Manufacturing Procedures. Open Dent. J. 2018, 12, 160–172. [Google Scholar] [CrossRef]

- Jang, Y.; Sim, J.Y.; Park, J.K.; Kim, W.C.; Kim, H.Y.; Kim, J.H. Evaluation of the marginal and internal fit of a single crown fabricated based on a three-dimensional printed model. J. Adv. Prosthodont. 2018, 10, 367–373. [Google Scholar] [CrossRef]

- Material Data Sheet Standard. Available online: https://formlabs.com/3d-printers/form-3/tech-specs/#data-sheets (accessed on 20 June 2020).

| Layer Thickness | Linear Dimension | Surface Area | ||||

|---|---|---|---|---|---|---|

| Mean ± STDEV (mm) | V (mm2) | IQR (mm) | Mean ± STDEV (mm2) | V (mm4) | IQR (mm2) | |

| 25 µm | 9.63 ± 0.12 | 0.02 | 0.15 | 95.76 ± 0.51 | 0.28 | 0.78 |

| 50 µm | 9.53 ± 0.09 | 0.01 | 0.16 | 95.67 ± 0.65 | 0.46 | 0.61 |

| 100 µm | 9.48 ± 0.081 | 0.01 | 0.11 | 94.99 ± 0.49 | 0.26 | 0.63 |

| Layer Thickness of Groups at T0 | Surface Area | |||

|---|---|---|---|---|

| Mean Difference (mm) | Adjusted p-Value | Mean Diff. (mm2) | Adjusted p-Value | |

| 25 vs. 50 µm | 0.10 | 0.054 | 0.10 | 0.913 |

| 25 vs. 100 µm | 0.15 | 0.002 | 0.78 | 0.007 |

| 50 vs. 100 µm | 0.05 | 0.427 | 0.68 | 0.019 |

| Groups Compared at Different Times | Linear Dimension | Surface Area | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Mean 1st (mm) | Mean 2nd (mm) | Mean Diff. (mm) | Adjusted p-Value/ Significance | Mean 1st (mm2) | Mean 2nd (mm2) | Mean Diff. (mm2) | Adjusted p-Value/ Significance | ||

| 1st | 2nd | ||||||||

| 25 T0 | 25 T1 | 9.63 | 9.67 | −0.04 | 0.821 | 95.76 | 103.9 | −8.09 | 0.001 * |

| 25 T0 | 25 T2 | 9.63 | 9.67 | −0.04 | 0.849 | 95.76 | 104.6 | −8.80 | 0.001 * |

| 25 T0 | 25 T3 | 9.63 | 9.72 | −0.08 | 0.230 | 95.76 | 103.9 | −8.12 | 0.001 * |

| 25 T1 | 25 T2 | 9.67 | 9.67 | 0.00 | 0.999 | 103.9 | 104.6 | −0.717 | 0.791 |

| 25 T1 | 25 T3 | 9.67 | 9.72 | −0.05 | 0.714 | 103.9 | 103.9 | −0.03 | 0.999 |

| 25 T2 | 25 T3 | 9.67 | 9.72 | −0.05 | 0.679 | 104.6 | 103.9 | 0.68 | 0.824 |

| 50 T0 | 50 T1 | 9.53 | 9.66 | −0.13 | 0.001 * | 95.67 | 105.3 | −9.61 | 0.001 * |

| 50 T0 | 50 T2 | 9.53 | 9.64 | −0.10 | 0.006 * | 95.67 | 105.5 | −9.86 | 0.001 * |

| 50 T0 | 50 T3 | 9.53 | 9.67 | −0.14 | 0.001 * | 95.67 | 100.5 | −4.87 | 0.001 * |

| 50 T1 | 50 T2 | 9.66 | 9.64 | 0.03 | 0.770 | 105.3 | 105.5 | −0.25 | 0.888 |

| 50 T1 | 50 T3 | 9.66 | 9.67 | −0.01 | 0.998 | 105.3 | 100.5 | 4.74 | 0.001 * |

| 50 T2 | 50 T3 | 9.64 | 9.67 | −0.03 | 0.670 | 105.5 | 100.5 | 4.99 | 0.001 * |

| 100 T0 | 100 T1 | 9.48 | 9.66 | −0.18 | 0.0001 * | 94.99 | 104.5 | −9.54 | 0.001 * |

| 100 T0 | 100 T2 | 9.48 | 9.61 | −0.13 | 0.001 * | 94.99 | 104.8 | −9.86 | 0.001 * |

| 100 T0 | 100 T3 | 9.48 | 9.71 | −0.22 | 0.0001 * | 94.99 | 101 | −5.99 | 0.001 * |

| 100 T1 | 100 T2 | 9.66 | 9.61 | 0.06 | 0.229 | 104.5 | 104.8 | −0.31 | 0.881 |

| 100 T1 | 100 T3 | 9.66 | 9.71 | −0.042 | 0.478 | 104.5 | 101 | 3.56 | 0.001 * |

| 100 T2 | 100 T3 | 9.61 | 9.71 | −0.10 | 0.009 * | 104.8 | 101 | 3.87 | 0.001 * |

| Group Name and Parameter | Mean 1st | Mean 2nd | Mean Diff. | Adjusted p-Value | |

|---|---|---|---|---|---|

| 1st | 2nd | ||||

| 25 Sa | 50 Sa | 1.136 | 0.88 | 0.25 | 0.114 |

| 25 Sa | 100 Sa | 1.136 | 0.94 | 0.19 | 0.265 |

| 50 Sa | 100 Sa | 0.8838 | 0.94 | −0.06 | 0.880 |

| 25 Sz | 50 Sz | 12.82 | 14.22 | −1.4 | 0.919 |

| 25 Sz | 100 Sz | 12.82 | 12.3 | 0.52 | 0.988 |

| 50 Sz | 100 Sz | 14.22 | 12.3 | 1.92 | 0.853 |

| 25 Str | 50 Str | 0.32 | 0.46 | −0.14 | 0.478 |

| 25 Str | 100 Str | 0.32 | 0.59 | −0.27 | 0.080 |

| 50 Str | 100 Str | 0.46 | 0.59 | −0.13 | 0.536 |

| 25 Spc | 50 Spc | 4637 | 3876 | 760.40 | 0.506 |

| 25 Spc | 100 Scp | 4637 | 3709 | 928.30 | 0.367 |

| 50 Spc | 100 Scp | 3876 | 3709 | 167.90 | 0.966 |

| 25 Sdr | 50 Sdr | 0.48 | 0.54 | −0.05 | 0.954 |

| 25 Sdr | 100 Sdr | 0.48 | 0.35 | 0.13 | 0.752 |

| 50 Sdr | 100 Sdr | 0.54 | 0.35 | 0.18 | 0.575 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sabbah, A.; Romanos, G.; Delgado-Ruiz, R. Impact of Layer Thickness and Storage Time on the Properties of 3D-Printed Dental Dies. Materials 2021, 14, 509. https://doi.org/10.3390/ma14030509

Sabbah A, Romanos G, Delgado-Ruiz R. Impact of Layer Thickness and Storage Time on the Properties of 3D-Printed Dental Dies. Materials. 2021; 14(3):509. https://doi.org/10.3390/ma14030509

Chicago/Turabian StyleSabbah, Aya, Georgios Romanos, and Rafael Delgado-Ruiz. 2021. "Impact of Layer Thickness and Storage Time on the Properties of 3D-Printed Dental Dies" Materials 14, no. 3: 509. https://doi.org/10.3390/ma14030509

APA StyleSabbah, A., Romanos, G., & Delgado-Ruiz, R. (2021). Impact of Layer Thickness and Storage Time on the Properties of 3D-Printed Dental Dies. Materials, 14(3), 509. https://doi.org/10.3390/ma14030509