Mapping of the Micro-Mechanical Properties of Human Root Dentin by Means of Microindentation

Abstract

1. Introduction

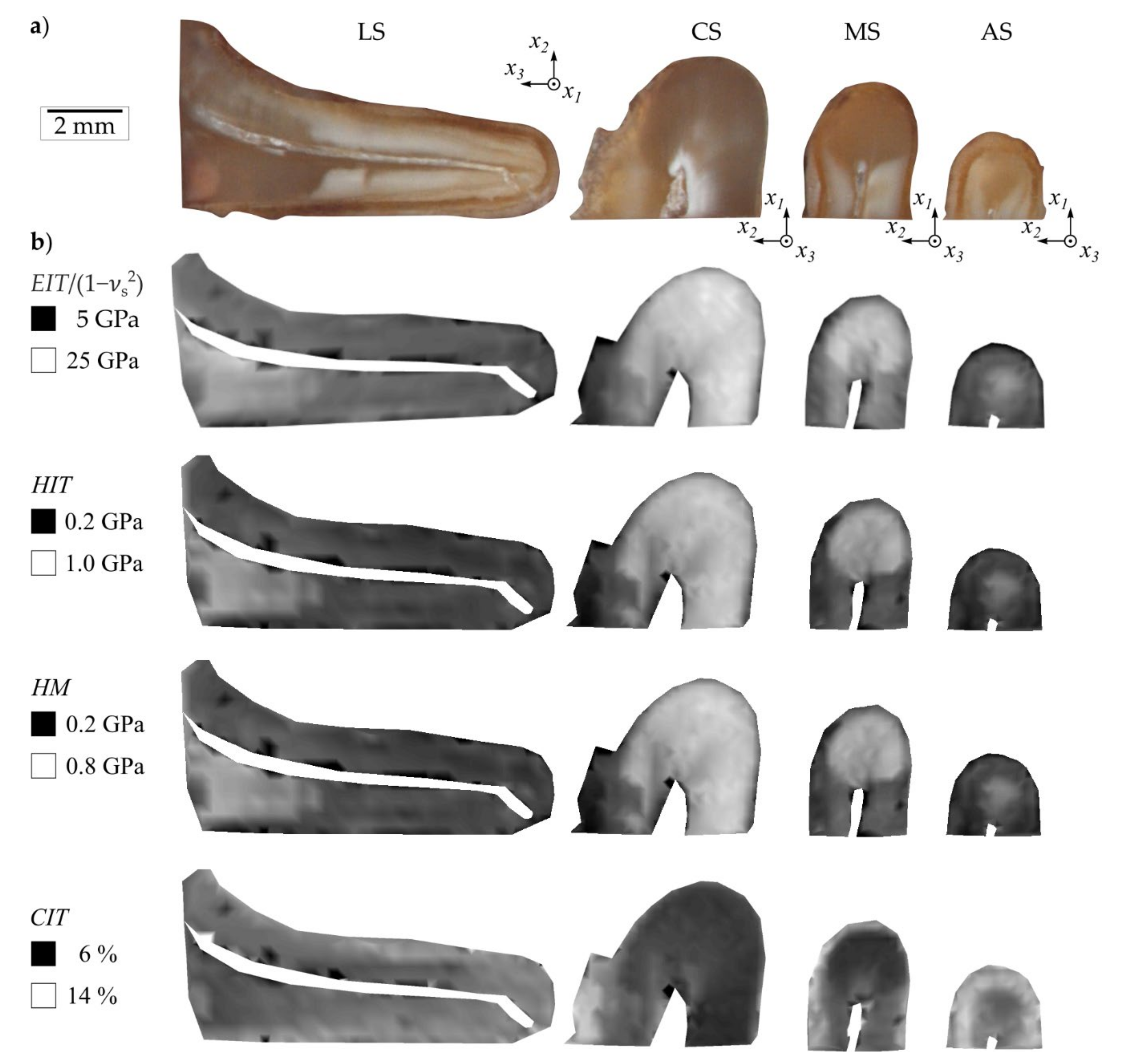

2. Materials and Methods

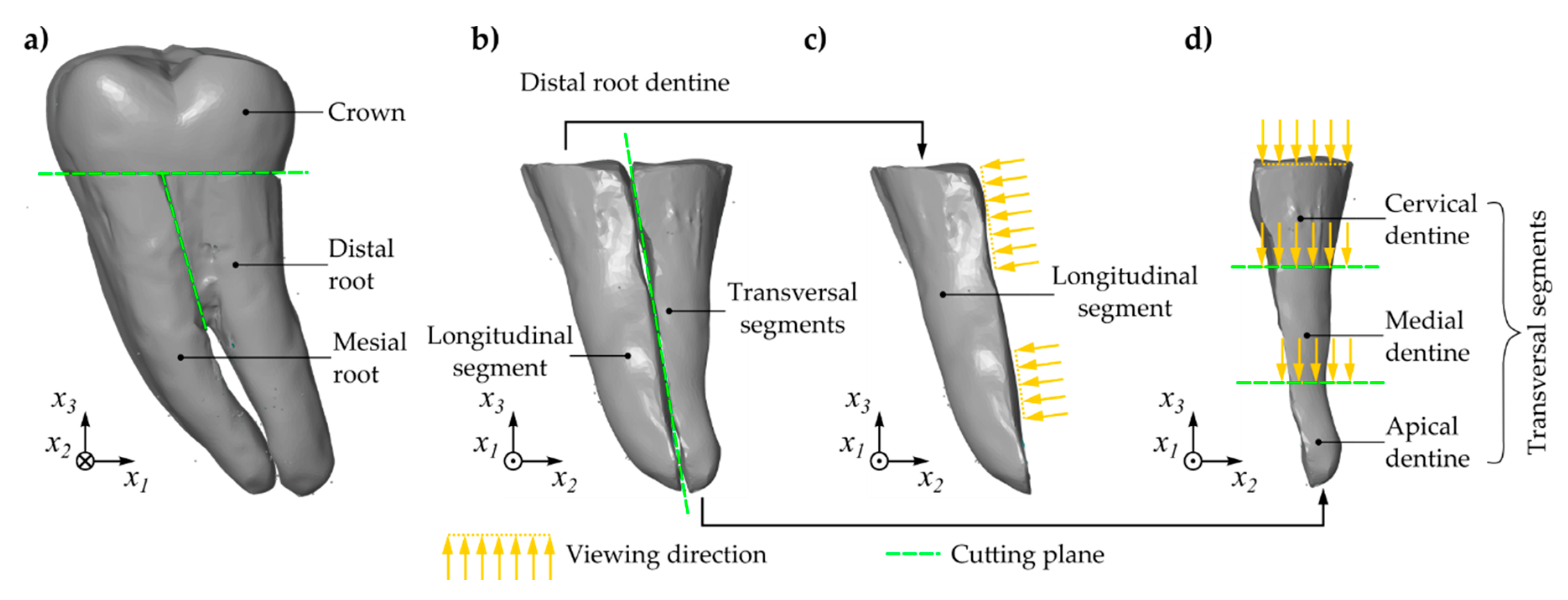

2.1. Sample Preparation

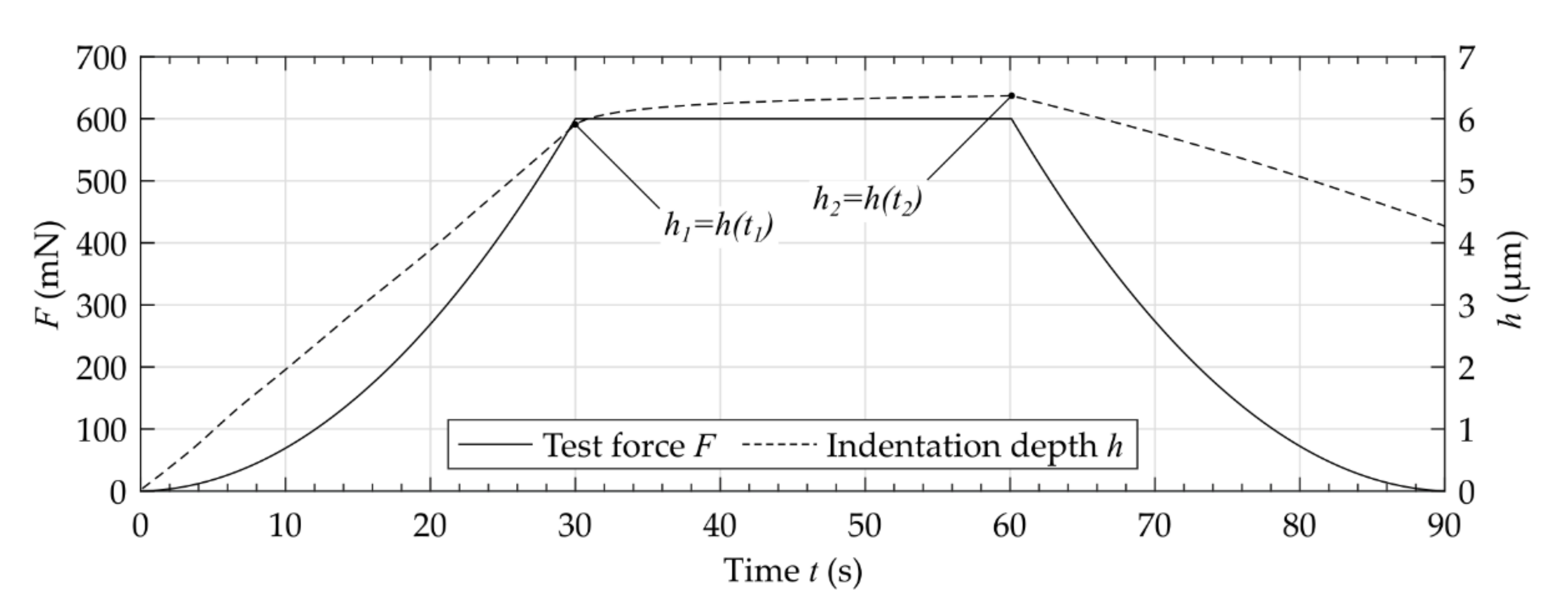

2.2. Microindentation Measurements

2.3. Spatial Analysis of Measured Data

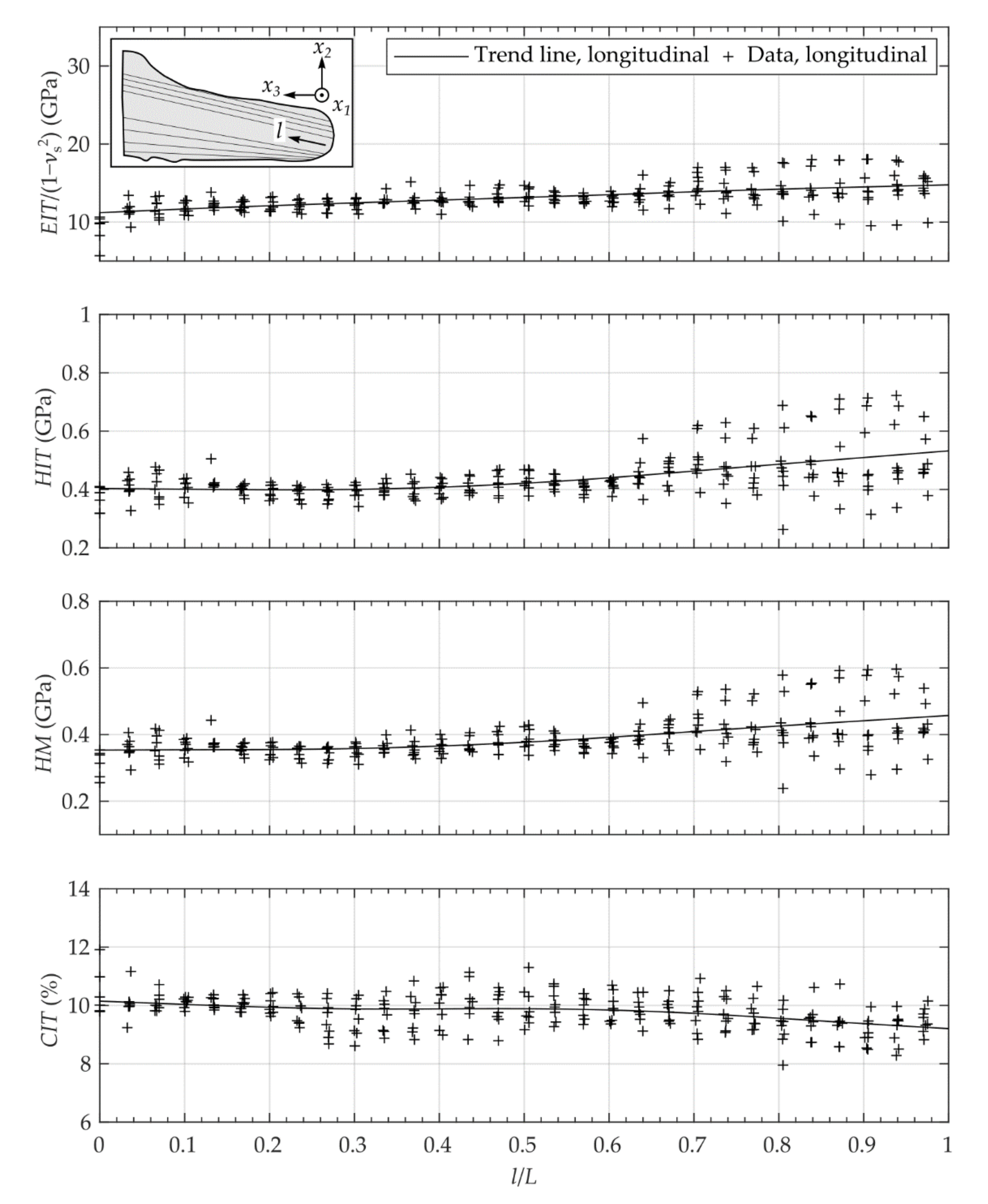

3. Results

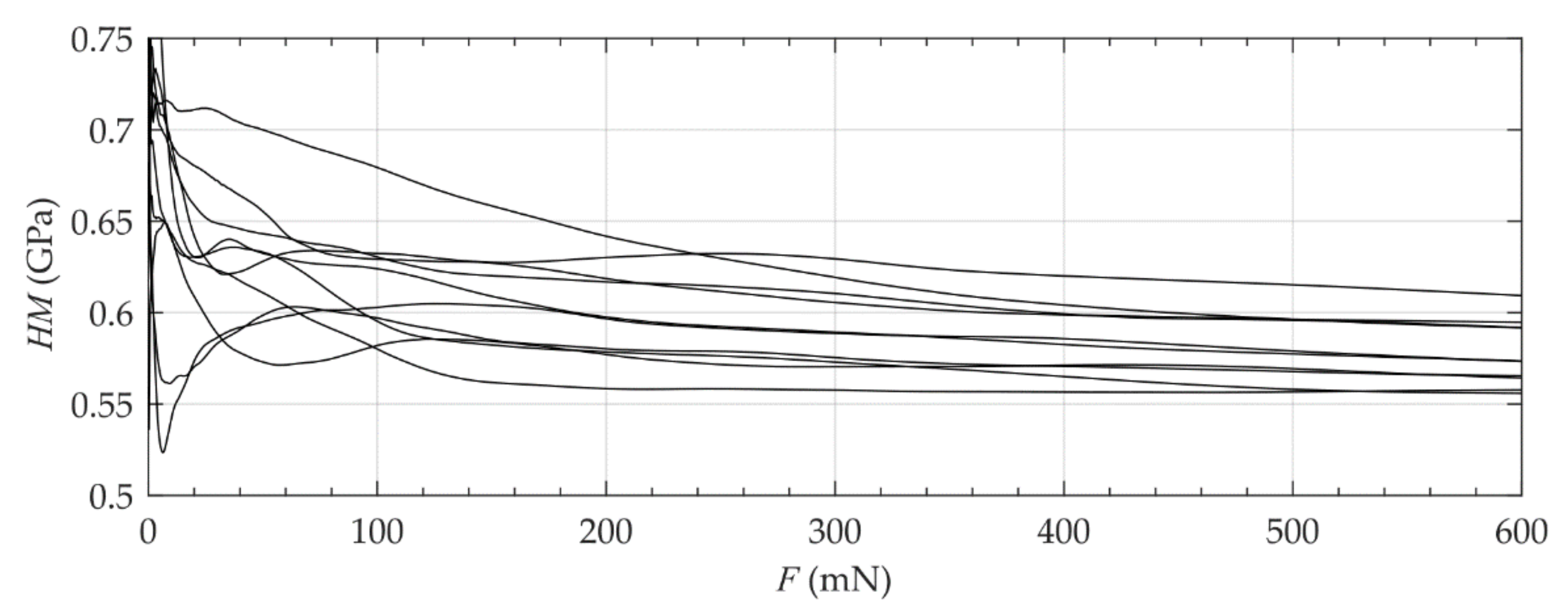

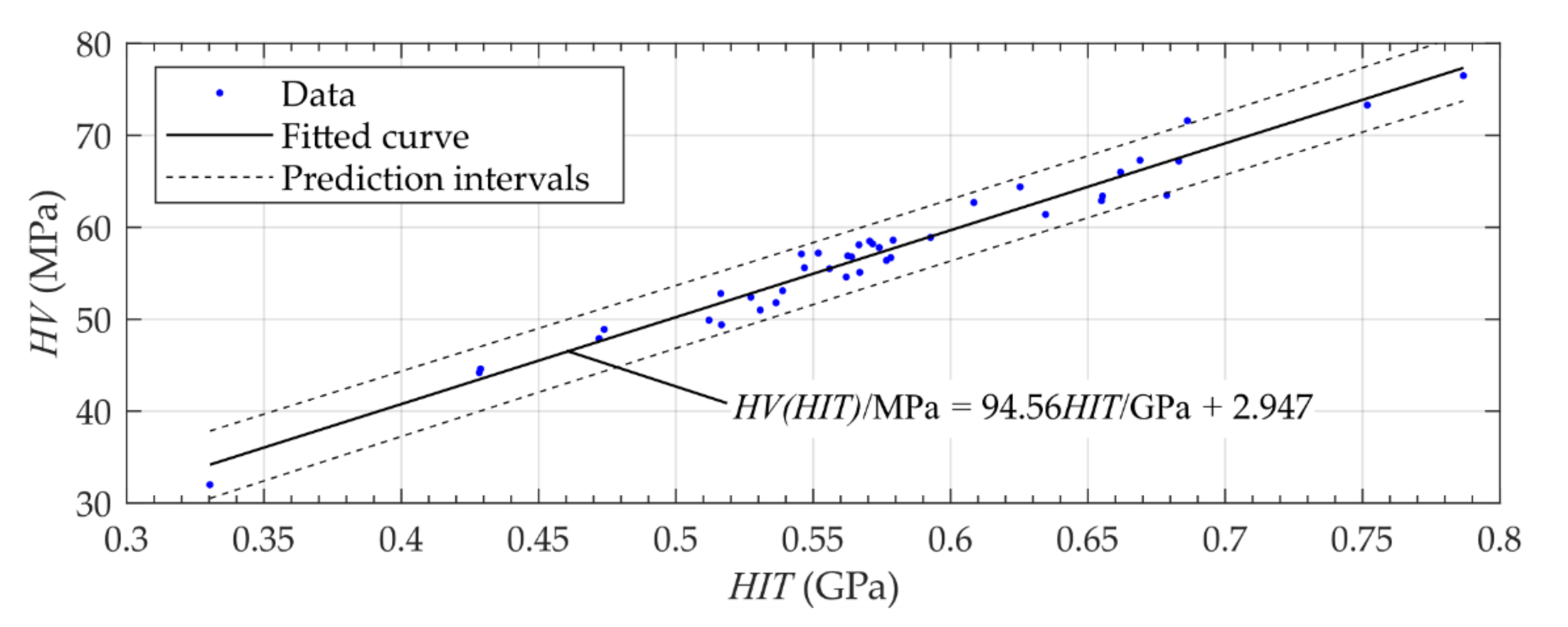

3.1. Mechanical Properties of Human Dentin

3.2. Spatial Description of Mechanical Properties

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kinney, J.H.; Marshall, S.; Marshall, G. The Mechanical Properties of Human Dentin: A Critical Review and Re-evaluation of the Dental Literature. Crit. Rev. Oral Biol. Med. 2003, 14, 13–29. [Google Scholar] [CrossRef] [PubMed]

- Grzebieluch, W.; Romuald, B.; Tomasz, C.; Kaczmarek, U. The mechanical properties of human dentin for 3-D finite element modeling—Numerical and analytical evaluation. Adv. Clin. Exp. Med. 2017, 26, 645–653. [Google Scholar] [CrossRef] [PubMed]

- Kinney, J.; Balooch, M.; Marshall, G.; Marshall, S. A micromechanics model of the elastic properties of human dentine. Arch. Oral Biol. 1999, 44, 813–822. [Google Scholar] [CrossRef]

- Zaytsev, D.; Grigoriev, S.; Panfilov, P. Deformation Behavior of Human Dentin under Uniaxial Compression. Int. J. Biomater. 2012, 2012, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Arola, D.; Reprogel, R. Effects of aging on the mechanical behavior of human dentin. Biomaterias 2005, 26, 4051–4061. [Google Scholar] [CrossRef] [PubMed]

- Arola, D.; Reprogel, R.K. Tubule orientation and the fatigue strength of human dentin. Biomaterias 2006, 27, 2131–2140. [Google Scholar] [CrossRef] [PubMed]

- Craig, R.; Peyton, F. The Microhardness of Enamel and Dentin. J. Dent. Res. 1958, 37, 661–668. [Google Scholar] [CrossRef] [PubMed]

- Fonseca, R.B.; Haiter-Neto, F.; Carlo, H.; Soares, C.J.; Geraldeli, S.; Puppin-Rontani, R.M.; Correr-Sobrinho, L. Radiodensity and hardness of enamel and dentin of human and bovine teeth, varying bovine teeth age. Arch. Oral Biol. 2008, 53, 1023–1029. [Google Scholar] [CrossRef] [PubMed]

- He, B.; Huang, S.; Jing, J.; Hao, Y. Measurement of hydroxyapatite density and Knoop hardness in sound human enamel and a correlational analysis between them. Arch. Oral Biol. 2010, 55, 134–141. [Google Scholar] [CrossRef] [PubMed]

- Saghiri, M.A.; Delvarani, A.; Mehrvarzfar, P.; Malganji, G.; Lotfi, M.; Dadresanfar, B.; Saghiri, A.M.; Dadvand, S. A study of the relation between erosion and microhardness of root canal dentin. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endodontol. 2009, 108, e29–e34. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Smith, D.; Jahanmir, S.; Romberg, E.; Kelly, J.; Thompson, V.; Rekow, E. Indentation Damage and Mechanical Properties of Human Enamel and Dentin. J. Dent. Res. 1998, 77, 472–480. [Google Scholar] [CrossRef] [PubMed]

- Kinney, J.; Balooch, M.; Marshall, S.; Marshall, G.; Weihs, T. Hardness and young’s modulus of human peritubular and intertubular dentine. Arch. Oral Biol. 1996, 41, 9–13. [Google Scholar] [CrossRef]

- Liang, X.; Zhang, J.Y.; Cheng, I.K.; Li, J.Y. Effect of high energy X-ray irradiation on the nano-mechanical properties of human enamel and dentine. Braz. Oral Res. 2016, 30. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wang, K.; Xu, W.; Gong, X.; Zhang, F. Mapping the mechanical gradient of human dentin-enamel-junction at different intratooth locations. Dent. Mater. 2018, 34, 376–388. [Google Scholar] [CrossRef] [PubMed]

- Cuy, J.; Mann, A.; Livi, K.; Teaford, M.; Weihs, T.P. Nanoindentation mapping of the mechanical properties of human molar tooth enamel. Arch. Oral Biol. 2002, 47, 281–291. [Google Scholar] [CrossRef]

- VDI/VDE 2616 Blatt 2 Verein Deutscher Ingenieure e.V. Hardness Testing of Plastics and Elastomers; Beuth: Berlin, Germany, 2014. [Google Scholar]

- DIN EN ISO 14577-1 Deutsches Institut für Normung e.V. Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters—Part. 1: Test. Method; Beuth: Berlin, Germany, 2015. [Google Scholar]

- DIN EN ISO 4287 Deutsches Institut für Normung e.V. Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters; Beuth: Berlin, Germany, 2010. [Google Scholar]

- Kucher, M.; Dannemann, M.; Modler, N.; Haim, D.; Hannig, C.; Weber, M.-T. Continuous Measurement of Three-Dimensional Root Canal Curvature Using Cone-Beam Computed and Micro-Computed Tomography: A Comparative Study. Dent. J. 2020, 8, 16. [Google Scholar] [CrossRef] [PubMed]

- Constantino, P.J.; Lee, J.J.-W.; Gerbig, Y.; Hartstone-Rose, A.; Talebi, M.; Lawn, B.R.; Lucas, P.W. The role of tooth enamel mechanical properties in primate dietary adaptation. Am. J. Phys. Anthropol. 2012, 148, 171–177. [Google Scholar] [CrossRef] [PubMed]

| Value. | Longitudinal | Cervical | Medial | Apical |

|---|---|---|---|---|

| Evaluation of Entire Area | ||||

| in GPa | 13.7 ± 2.34 | 17.8 ± 4.38 | 16 ± 3.09 | 12.2 ± 1.96 |

| in GPa | 0.47 ± 0.102 | 0.64 ± 0.171 | 0.54 ± 0.133 | 0.4 ± 0.072 |

| in MPa | 47 ± 12.6 | 63.5 ± 19.13 | 53.7 ± 15.55 | 41.2 ± 9.78 |

| in GPa | 0.41 ± 0.081 | 0.54 ± 0.136 | 0.47 ± 0.101 | 0.36 ± 0.058 |

| in % | 9.5 ± 0.82 | 8.6 ± 1.21 | 9.1 ± 1.3 | 10.7 ± 1.03 |

| Evaluation of Lines | ||||

| in GPa | 13.1 ± 1.72 ( < 0.01) | 16.9 ±4.13 ( < 0.01) | 15.3 ± 3.36 ( = 0.04) | 11.8 ± 1.99 ( = 0.3) |

| in GPa | 0.43 ± 0.077 ( < 0.01) | 0.61 ± 0.168 ( < 0.01) | 0.51 ± 0.137 ( = 0.25) | 0.39 ± 0.069 ( = 0.13) |

| in MPa | 44.5 ± 10.2 ( < 0.01) | 60.6 ± 18.79 ( < 0.01) | 51.8 ± 15.92 ( = 0.25) | 40.1 ± 9.51 ( = 0.13) |

| in GPa | 0.38 ± 0.06 ( < 0.01) | 0.52 ± 0.132 ( < 0.01) | 0.45 ± 0.108 ( = 0.13) | 0.35 ± 0.057 ( < 0.09) |

| in % | 9.8 ± 0.57 ( < 0.01) | 8.6 ± 1.25 ( = 0.48) | 9 ± 1.09 ( = 0.99) | 10.6 ± 0.91 ( = 0.26) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kucher, M.; Dannemann, M.; Modler, N.; Bernhard, M.R.; Hannig, C.; Weber, M.-T. Mapping of the Micro-Mechanical Properties of Human Root Dentin by Means of Microindentation. Materials 2021, 14, 505. https://doi.org/10.3390/ma14030505

Kucher M, Dannemann M, Modler N, Bernhard MR, Hannig C, Weber M-T. Mapping of the Micro-Mechanical Properties of Human Root Dentin by Means of Microindentation. Materials. 2021; 14(3):505. https://doi.org/10.3390/ma14030505

Chicago/Turabian StyleKucher, Michael, Martin Dannemann, Niels Modler, Martina Romy Bernhard, Christian Hannig, and Marie-Theres Weber. 2021. "Mapping of the Micro-Mechanical Properties of Human Root Dentin by Means of Microindentation" Materials 14, no. 3: 505. https://doi.org/10.3390/ma14030505

APA StyleKucher, M., Dannemann, M., Modler, N., Bernhard, M. R., Hannig, C., & Weber, M.-T. (2021). Mapping of the Micro-Mechanical Properties of Human Root Dentin by Means of Microindentation. Materials, 14(3), 505. https://doi.org/10.3390/ma14030505