Studies on the Volumetric Stability and Mechanical Properties of Cement-Fly-Ash-Stabilized Steel Slag

Abstract

:1. Introduction

2. Materials and Methods

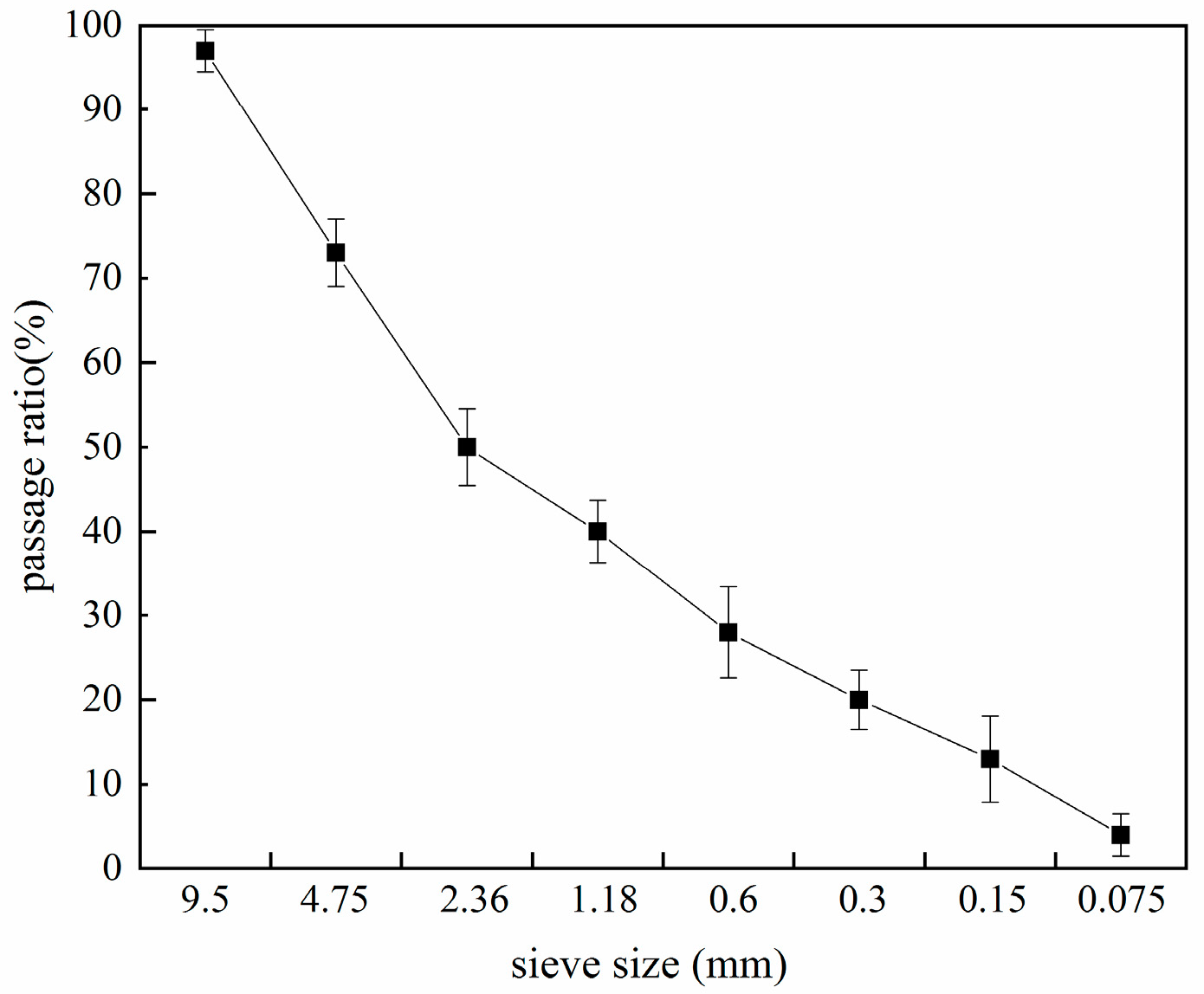

2.1. Materials

2.2. Mix Formulas and Experimental Method

2.2.1. Mix Formulas

2.2.2. Strength Test

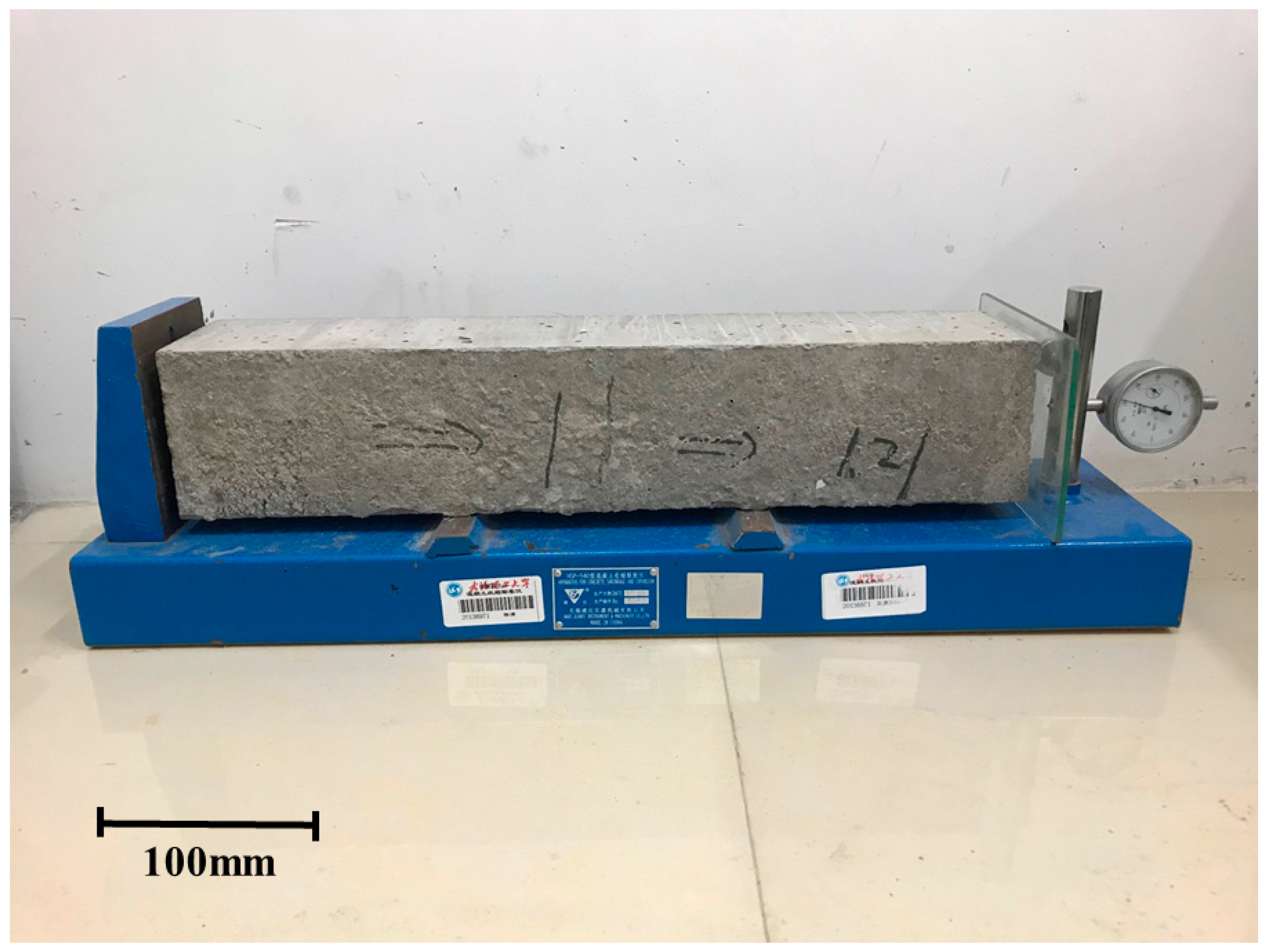

2.2.3. Expansion Behavior of Materials under Standard Curing Conditions

2.2.4. X-CT

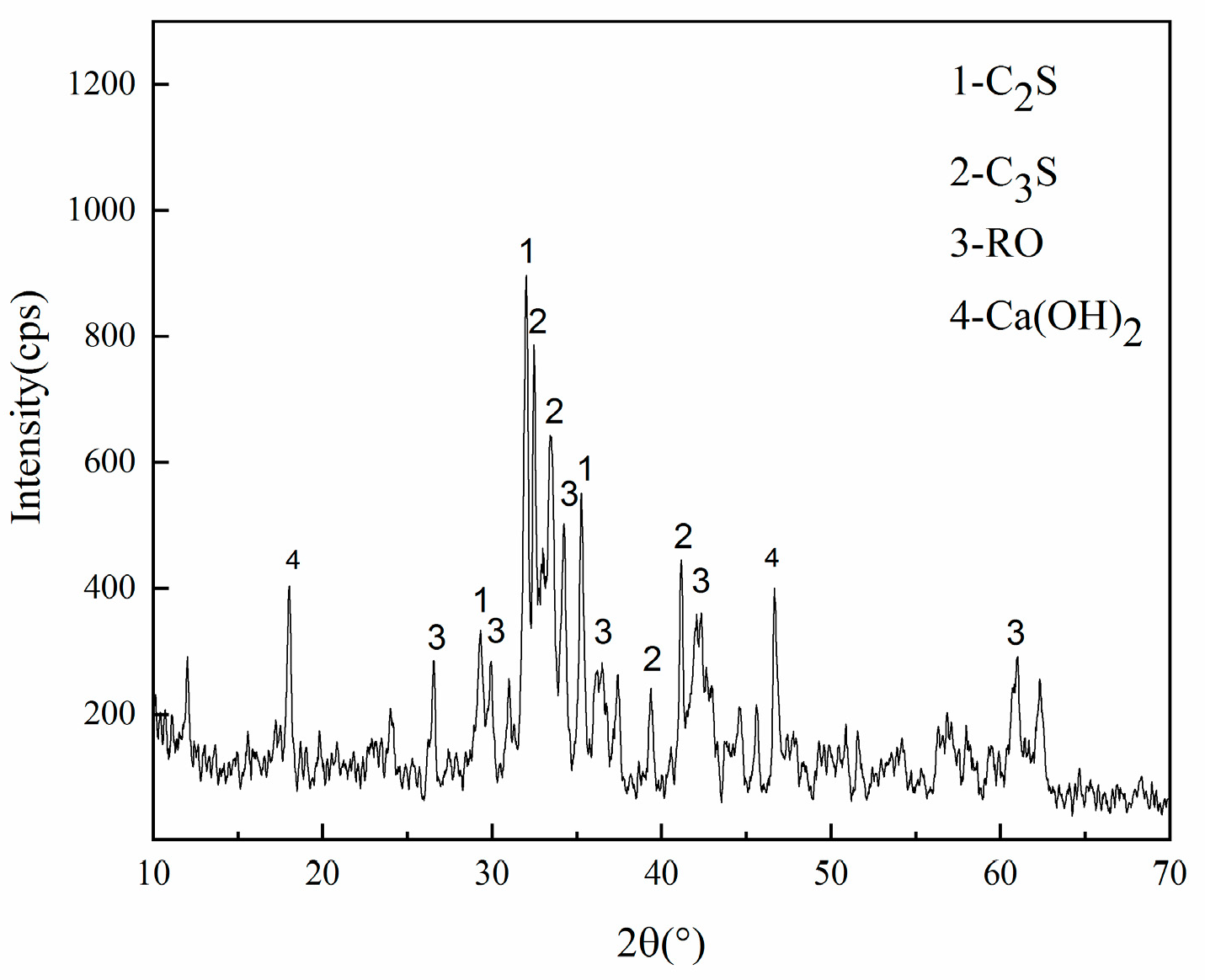

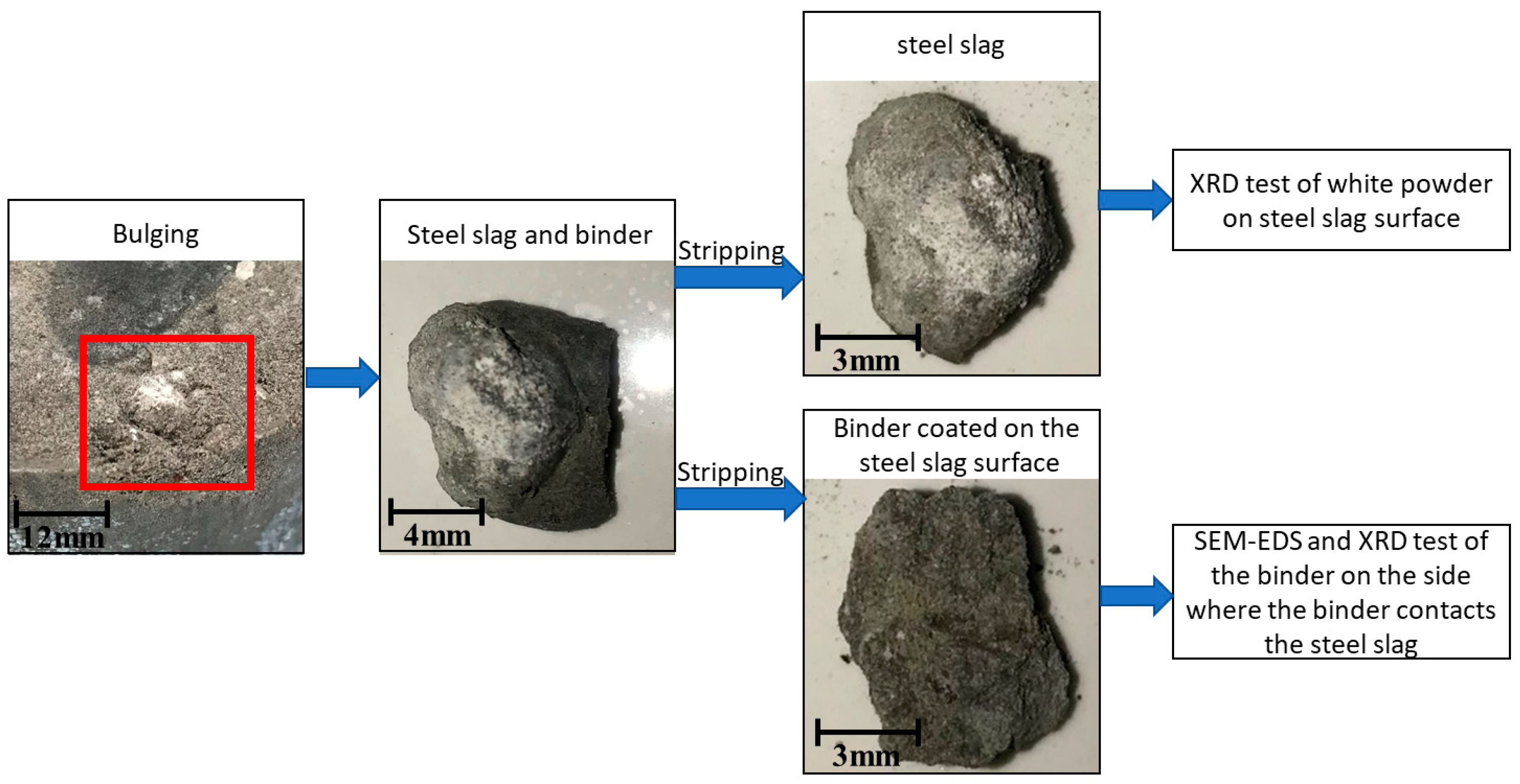

2.2.5. XRD and SEM-EDS

3. Results and Discussion

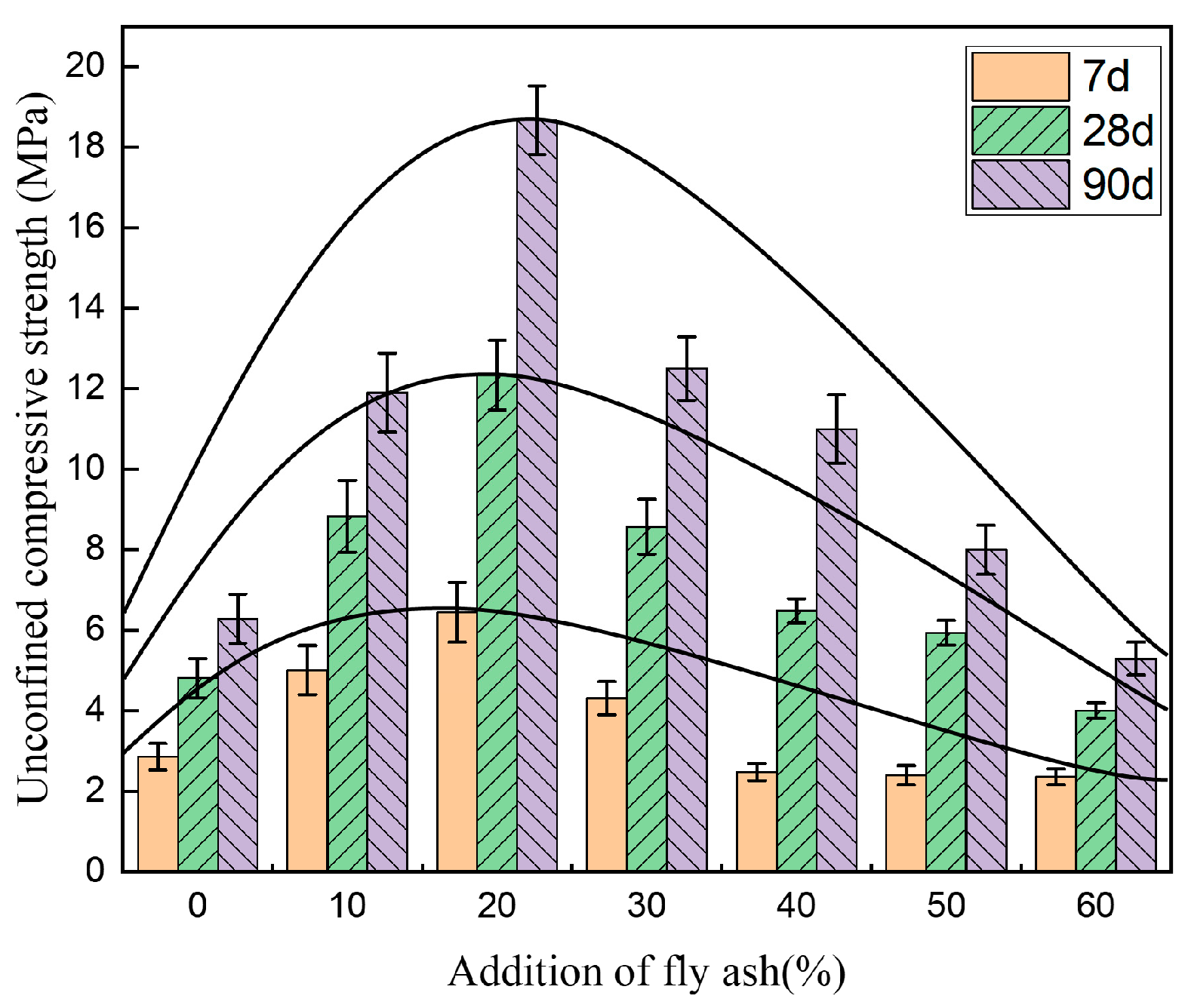

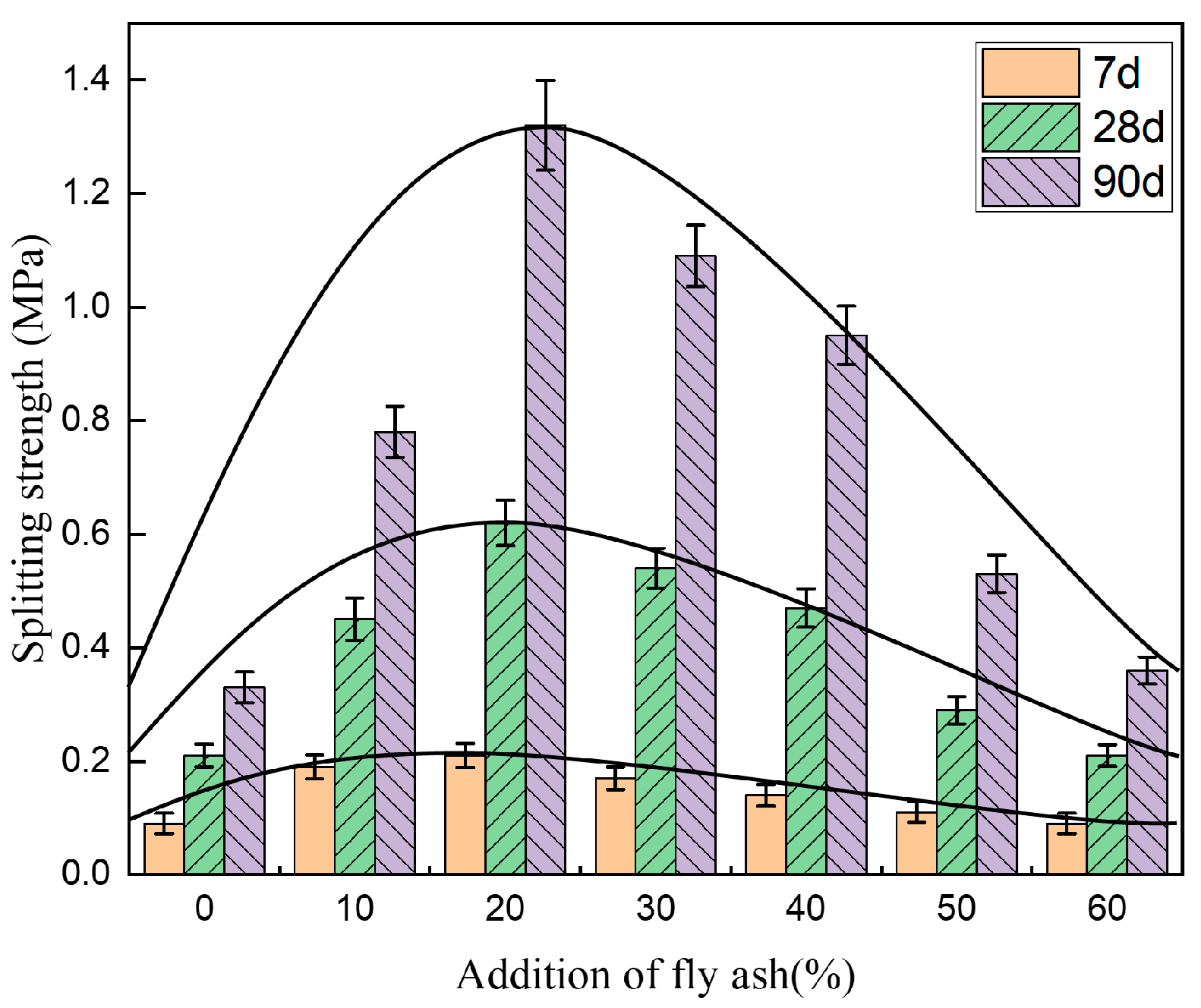

3.1. Effect of Fly Ash on the Mechanical Properties of Cement-Stabilized Steel Slag

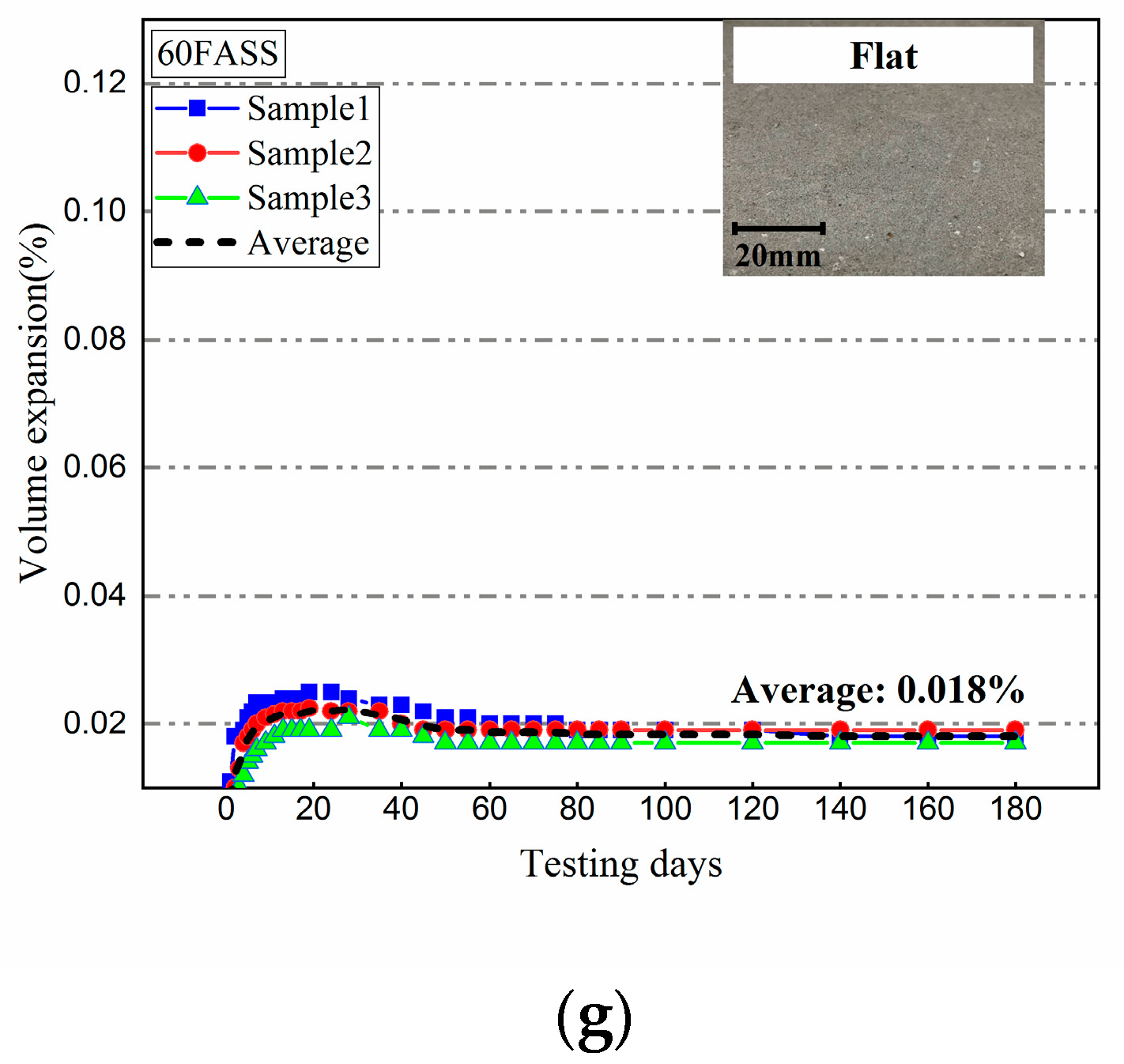

3.2. Effect of Fly Ash on Expansion Behavior of Cement-Stabilized Steel Slag

3.3. Inhibition Mechanism of Fly Ash on Expansion Behavior of Cement-Stabilized Steel Slag

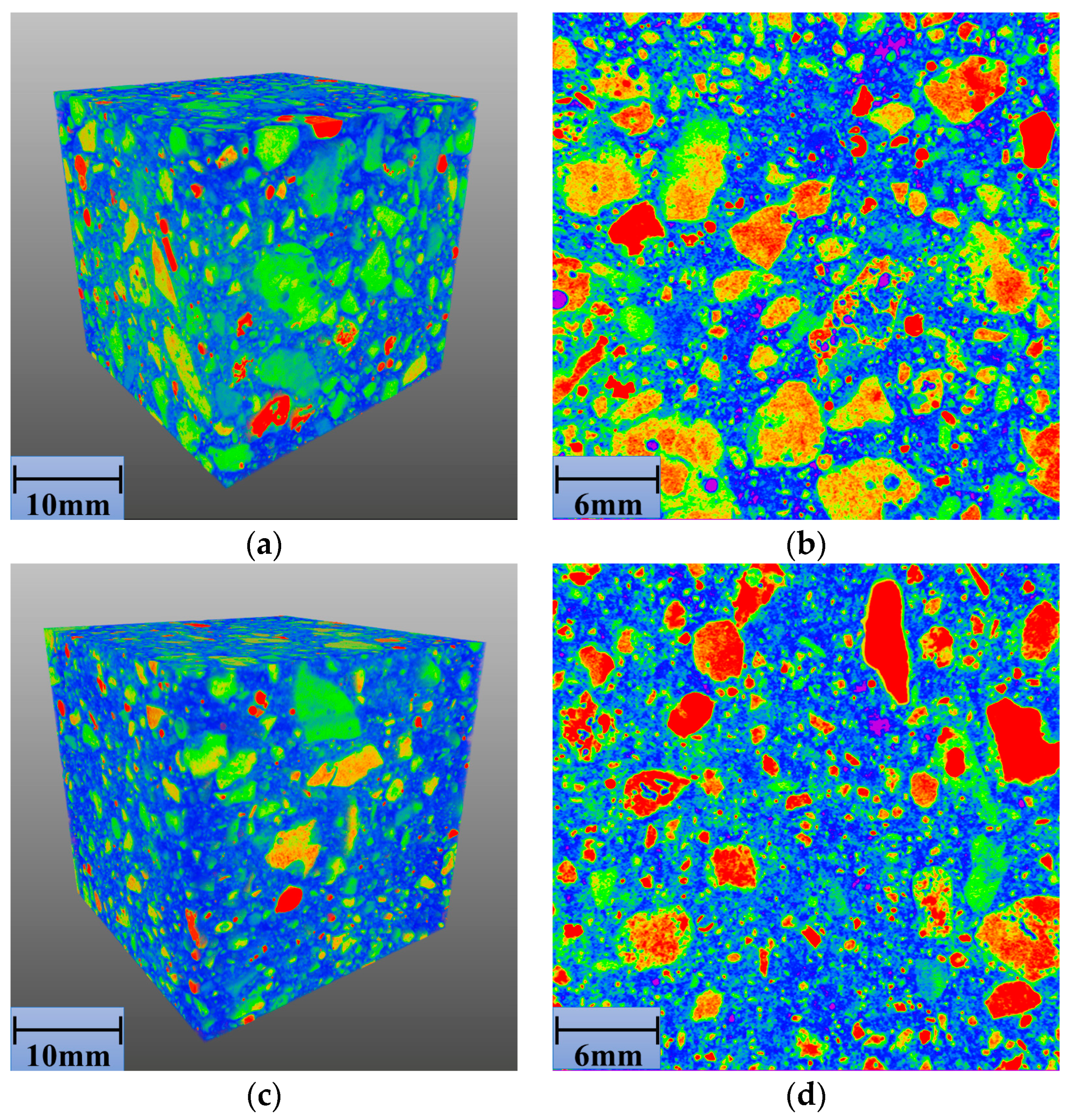

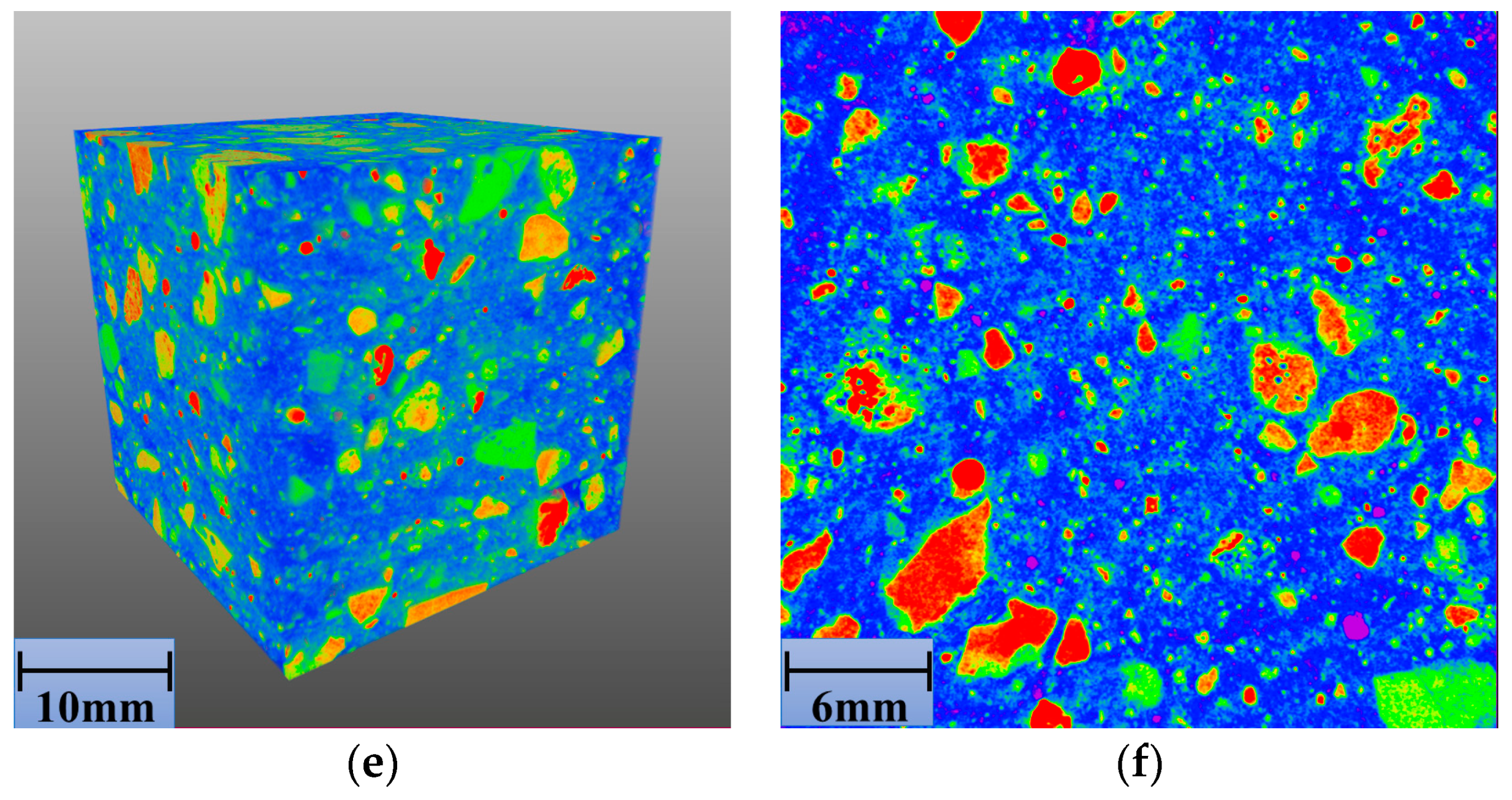

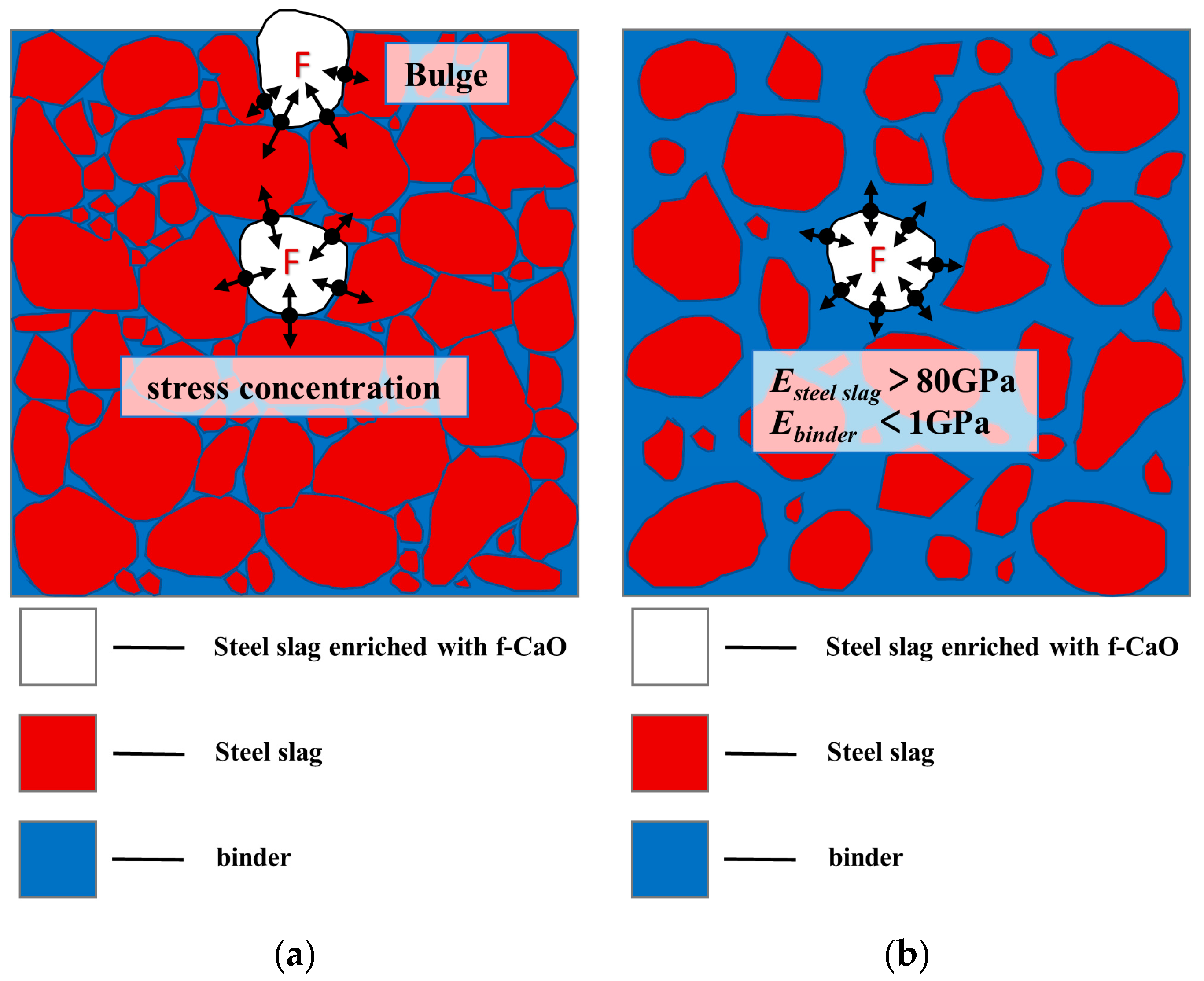

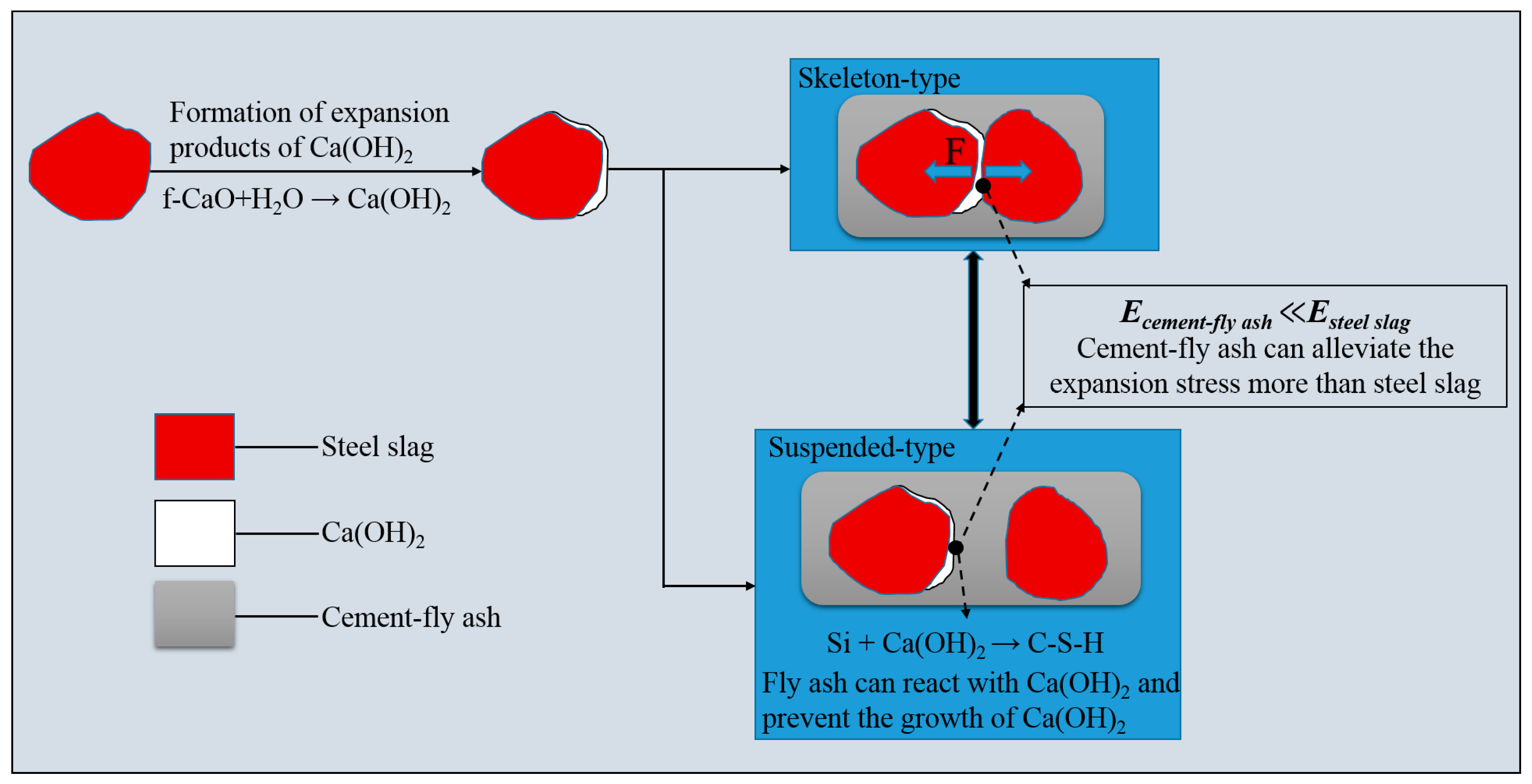

3.3.1. Inhibition Mechanism of Macro Structure on Expansion Behavior of Cement-Fly-Ash-Stabilized Steel Slag

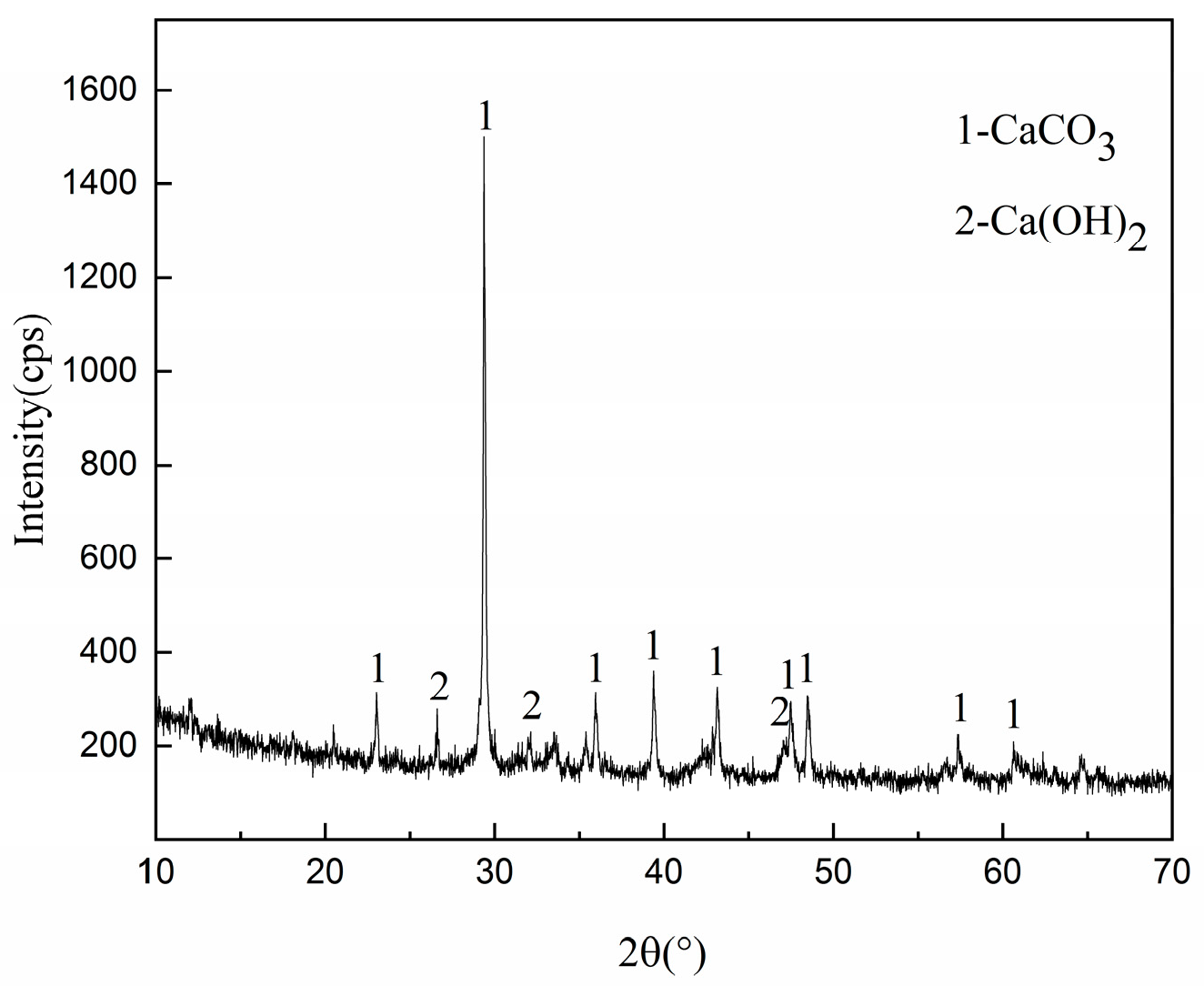

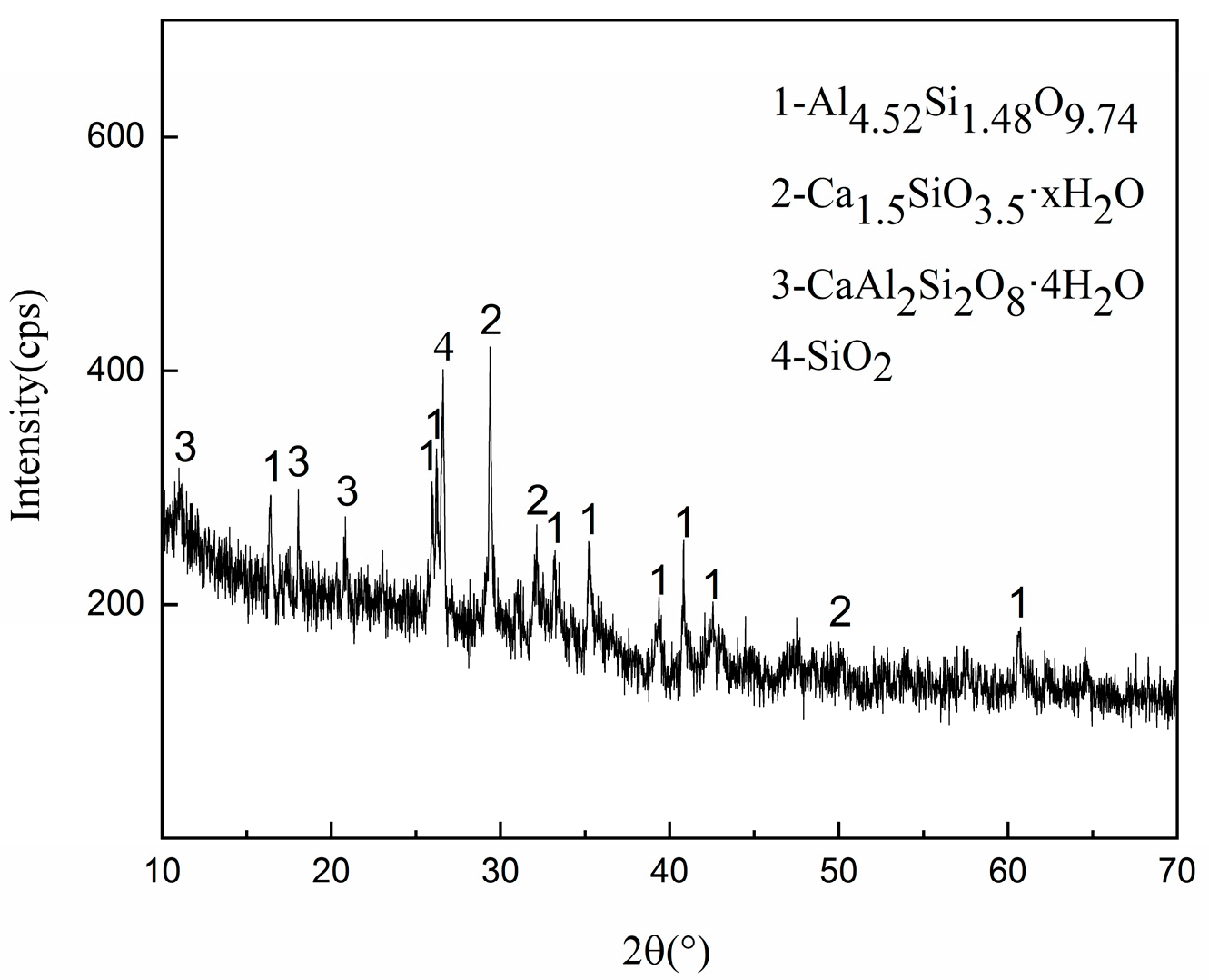

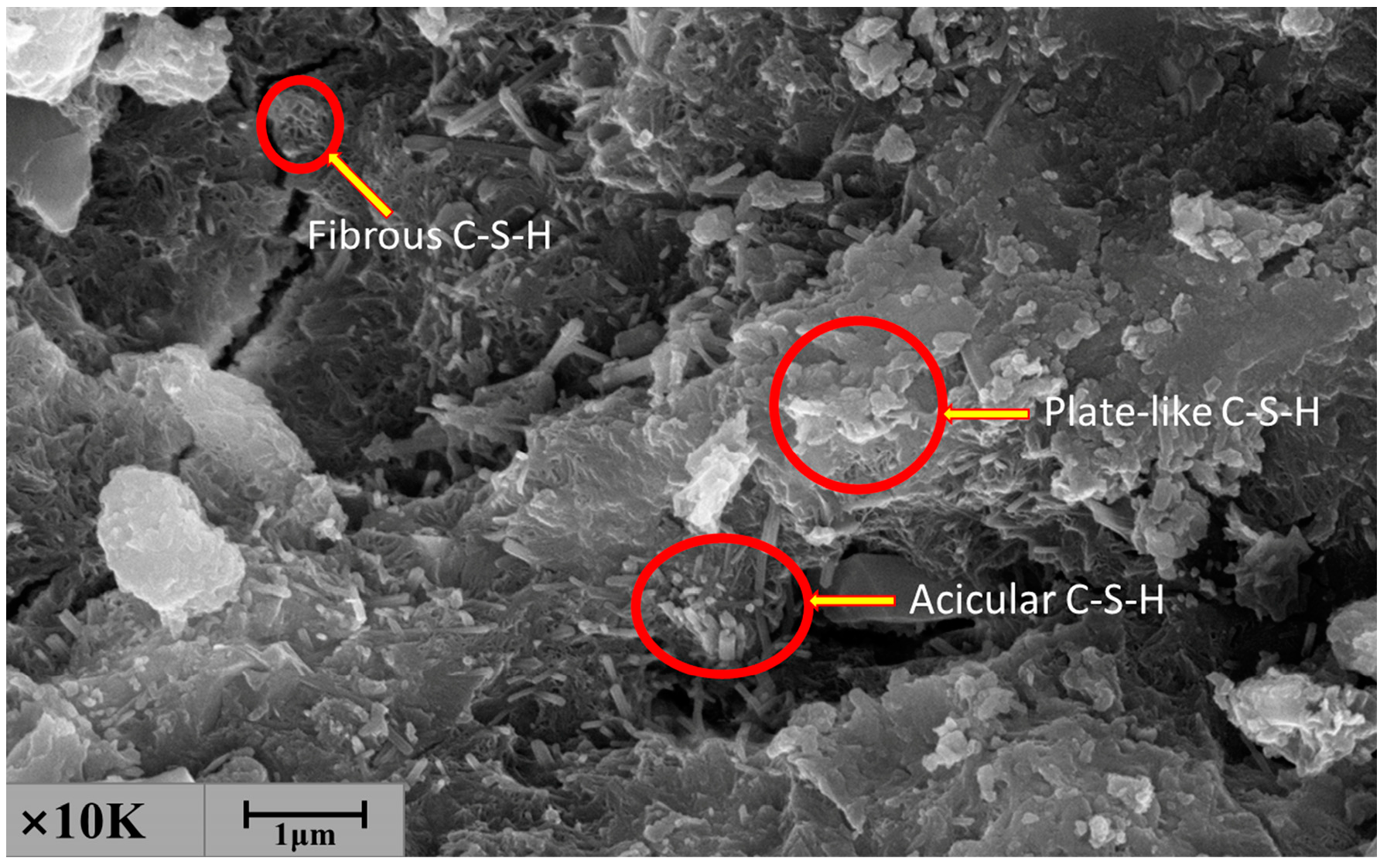

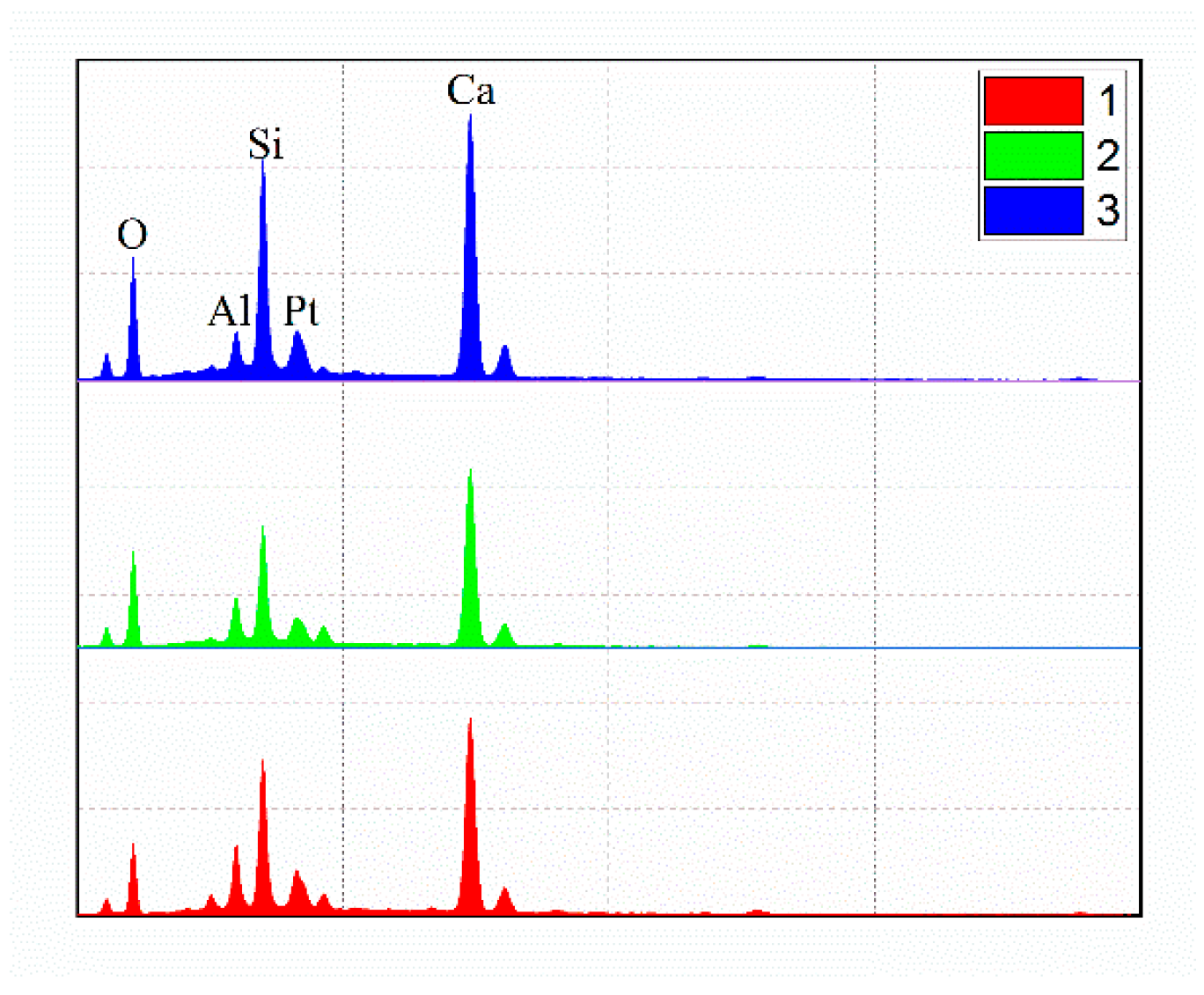

3.3.2. Reaction Mechanism of Fly Ash and Steel Slag

4. Conclusions

- (1)

- The unconfined compressive strength, splitting strength, and compressive modulus of resilience of the cement-fly-ash-stabilized steel slag increased initially and subsequently decreased with an increase in fly-ash content. It reached a peak value when the content of fly ash was 20% (20FASS). In general, the cement-fly-ash-stabilized steel slag (30FASS) with 30% fly ash content not only exhibited a good volumetric stability, but also possessed good mechanical properties. Its compressive strength at 7 d, 28 d and 90 d was 4.31 MPa, 8.57 MPa, and 12.5 MPa, respectively.

- (2)

- The average expansion rate, dispersion rate, and number of bulges of the cement-fly-ash-stabilized steel slag decreased with an increase in the concentration of the fly-ash content. The volumetric stability of the stabilized material increased gradually. The cement-fly-ash-stabilized steel slag (fly-ash content ≥30%, suspension type) exhibited a low expansion rate, and the stabilized material was not damaged during the expansion process.

- (3)

- The mechanism by which the fly ash inhibited the expansion of the steel slag had two aspects. (A) The increase of fly-ash content possibly reduced the probability of the formation of a skeleton in the steel-slag particles, and the binder wrapped with steel slag produced an elastic-plastic deformation to accommodate the expansive component of the steel slag to alleviate the expansion stress. (B) Fly ash reacted with the expansive component of the steel slag.

- (4)

- Currently, relevant research is focused on cement-stabilized steel slag, which can be easily damaged due to expansion. Our study revealed the inhibition mechanism of fly ash on the expansion behavior of the cement-stabilized steel slag, which provides a theory and reference for the use of steel slag. However, there are many kinds of steel slag and fly ash, and the reaction rate of different types of fly ash and steel slag can vary. Future research needs to be focused on the inhibition effect of different kinds of fly ash on the expansion of different kinds of steel slag. Also, the raw material standard of cement-fly-ash-stabilized steel slag should be established to increase the application of steel slag in road-base materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, Y.; Xu, G.P.; Cheng, H.G.; Wang, J.; Wan, Y.; Chen, H. An overview of utilization of steel slag. Procedia Environ. Sci. 2012, 16, 791–801. [Google Scholar]

- Cao, L.; Shen, W.; Huang, J.; Yang, Y.; Zhang, D.; Huang, X.; Lv, Z.; Ji, X. Process to utilize crushed steel slag in cement industry directly: Multi-phased clinker sintering technology. J. Clean. Prod. 2019, 217, 520–529. [Google Scholar] [CrossRef]

- Sas, W.; Głuchowski, A.; Radziemska, M.; Dzięcioł, J.; Szymański, A. Environmental and geotechnical assessment of the steel slags as a material for road structure. Materials 2015, 8, 4857–4875. [Google Scholar] [CrossRef]

- Jiang, Y.; Ling, T.-C.; Shi, C.; Pan, S.-Y. Characteristics of steel slags and their use in cement and concrete-a review. Resour. Conserv. Recycl. 2018, 136, 187–197. [Google Scholar] [CrossRef]

- Liu, J.; Bin, Y.; Qian, W. Application of steel slag in cement treated aggregate base course. J. Clean. Prod. 2020, 269, 121733. [Google Scholar] [CrossRef]

- Li, W.; Lang, L.; Lin, Z.; Wang, Z.; Zhang, F. Characteristics of dry shrinkage and temperature shrinkage of cement-stabilized steel slag. Constr. Build. Mater. 2017, 134, 540–548. [Google Scholar] [CrossRef]

- Tan, J.W. Application of steel slag backfill in No.3 Steelmaking project of WISCO. Wisco Technol. 1998, 7, 39–43. [Google Scholar]

- Liu, R.J. Study on road performance of cement stabilized steel slag macadam base for asphalt pavement. Commun. Sci. Technol. Heilongjiang 2019, 42, 16–17. [Google Scholar]

- Erlin, B.; Jana, D. Forces of hydration that can cause havoc in concrete. Concr. Int. 2003, 25, 51–57. [Google Scholar]

- Brand, A.S.; Roesler, J.R. Steel furnace slag aggregate expansion and hardened concrete properties. Cem. Concr. Compos. 2015, 60, 1–9. [Google Scholar] [CrossRef]

- Fang, Y.; Yu, F.; Xiang, G.S.; Wang, X.G. Forecast the f-CaO content of hot Disintegration steel slag in natural aging by cubic exponential smoothing model based on grey theory. Bull. Chin. Ceram. Soc. 2019, 38, 634–639. [Google Scholar]

- Han, Y.M.; Jung, H.Y.; Seong, S.K. A fundamental study on the steel slag aggregate for concrete. Geosyst. Eng. 2002, 5, 38–45. [Google Scholar]

- Lun, Y.; Zhou, M.; Cai, X.; Xu, F. Methods for improving volume stability of steel slag as fine aggregate. J. Wuhan Univ. Technol. 2008, 737–742. [Google Scholar] [CrossRef]

- Pang, B.; Zhou, Z.H.; Xu, H.X. Utilization of carbonated and granulated steel slag aggregate in concrete. Constr. Build. Mater. 2015, 84, 454–467. [Google Scholar] [CrossRef]

- Shen, W.; Liu, Y.; Wu, M.; Zhang, D.; Du, X.; Zhao, D.; Xu, G.; Zhang, B.; Xiong, X. Ecological carbonated steel slag pervious concrete prepared as a key material of sponge city. J. Clean. Prod. 2020, 256, 120244. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, S.; Zhao, X.; He, T. Cementitious property modification of basic oxygen furnace steel slag. Constr. Build. Mater. 2013, 48, 575–579. [Google Scholar] [CrossRef]

- Wang, Q.; Yan, P.; Yang, J. Comparison of hydration properties between cement-GGBS-fly ash blended binder and cement-GGBS-steel slag blended binder. J. Wuhan Univ. Technol. 2014, 29, 273–277. [Google Scholar] [CrossRef]

- Xiao, Q.Z. Expansion failure and control of steel slag. J. Chin. Ceram. Soc. 1996, 6, 29–34. [Google Scholar]

- Zhu, G.Y.; Wang, Y.G.; Huang, K.J.; Zhang, G.Q.; Hu, Y.F. The inhibitory effect of fine mineral admixture on the expansibility of steel slag aggregate. For. Eng. 2019, 35, 87–92. [Google Scholar]

- Sharma, A.K.; Sivapullaiah, P.V. Strength development in fly ash and slag mixtures with lime. Ground Improv. Proc. Inst. Civ. Eng. 2016, 169, 194–205. [Google Scholar] [CrossRef]

- Shen, W.; Zhou, M.; Ma, W.; Hu, J.; Cai, Z. Investigation on the application of steel slag-fly ash-phosphogypsum solidified material as road base material. J. Hazard. Mater. 2009, 164, 94–104. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Zhou, M.K.; Shen, W.G.; Zhu, J.; Li, J. Research on road base material with inorganic binder stabilized steel slag sand. Highway 2007, 6, 149–153. [Google Scholar]

- Guo, X.L.; Shi, H.S. Modification of steel slag powder by mineral admixture and chemical activators to utilize in cement-based materials. Mater. Struct. 2013, 46, 1265–1273. [Google Scholar] [CrossRef]

- Chen, X.; Zhou, M.K. Structure and composition of cement-fly ash stabilized crushed stones. Highway 2008, 12, 173–178. [Google Scholar]

- Guo, J.L.; Bao, Y.P.; Wang, M. Steel slag in China: Treatment, recycling, and management. Waste Manag. 2018, 78, 318–330. [Google Scholar] [CrossRef] [PubMed]

- Cikmit, A.A.; Tsuchida, T.; Hashimoto, R.; Honda, H.; Kang, G.; Sogawa, K. Expansion characteristic of steel slag mixed with soft clay. Constr. Build. Mater. 2019, 227, 116799. [Google Scholar] [CrossRef]

- Varga, I.D.L.; Castro, J.; Bentz, D.; Weiss, J. Application of internal curing for mixtures containing high volumeshrings of fly ash. Cem. Concr. Compos. 2012, 34, 1001–1008. [Google Scholar] [CrossRef]

- Chen, X.; Wang, G.; Dong, Q.; Zhao, X.; Wang, Y. Microscopic characterizations of pervious concrete using recycled steel slag aggregate. J. Clean. Prod. 2020, 254, 120149. [Google Scholar] [CrossRef]

- Betrancourt, D.; Chicot, D.; Kossman, S.; Louis, G.; Roudet, F.; Bulteel, D. Instrumented indentation study of slag in view of a better valorization. Constr. Build. Mater. 2019, 199, 349–358. [Google Scholar] [CrossRef]

- Logon, D.; Schabowicz, K.; Wroblewski, K. Assessment of the mechanical properties of ESD pseudoplastic resins for joints in working elements of concrete structures. Materials 2020, 13, 2426. [Google Scholar] [CrossRef]

- Shin, K.J.; Bucher, B.; Weiss, J. Role of lightweight synthetic particles on the restrained shrinkage cracking behavior of mortar. J. Mater. Civ. Eng. 2011, 23, 597–605. [Google Scholar] [CrossRef]

- Yang, Z.Z.; Zhao, L.; Liu, C.L.; Chen, D. The volume deformation of scrap tire particles modified steel slag concrete. Constr. Technol. 2015, 44, 59–62. [Google Scholar]

- Peng, J.L.; Li, S.Q. Research and application of high temperature low-density elastoplasticity cement slurry. Reserv. Eval. Dev. 2020, 10, 104–108. [Google Scholar]

- Bakare, M.D.; Pai, R.R.; Patel, S.; Shahu, J.T. Environmental sustainability by bulk utilization of fly ash and GBFS as road subbase materials. J. Hazard. Toxic Radioact. Waste 2019, 23, 04019011. [Google Scholar] [CrossRef]

- Shi, X.T.; Yu, G.Y.; Bi, Z.Q.; Du, Z.W.; Yin, D.W.; Feng, F. The effect of early strength agent on the macro mechanical properties and microstructure of filling paste. Min. Res. Dev. 2020, 40, 135–139. [Google Scholar]

- Bao, Y.L.; Guo, J.L. Experimental study of influences of fly ash dosage on properties of dry-mixed mortar. Fly Ash Compr. Util. 2013, 4, 34–36. [Google Scholar]

- Mallick, S.; Anoop, M.B.; Rao, B.K. Creep of cement paste containing fly ash-an investigation using microindentation technique. Cem. Concr. Res. 2019, 121, 21–36. [Google Scholar] [CrossRef]

- Kumarappa, B.; Peethamparan, S. Characteristics and brittleness index of alkali-activated slag/class C fly ash mortars. J. Build. Eng. 2020, 32, 101595. [Google Scholar] [CrossRef]

- Bilir, T.; Gencel, O.; Topcu, L.B. Properties of mortars with fly ash as fine aggregate. Constr. Build. Mater. 2015, 93, 782–789. [Google Scholar] [CrossRef]

- Hu, Z.; Hilaire, A.; Wyrzykowski, M.; Lura, P.; Scrivener, K. Visco-elastic behavior of blended cement pastes at early ages. Cem. Concr. Compos. 2020, 107, 103497. [Google Scholar] [CrossRef]

- Waligora, J.; Bulteel, D.; Degrugilliers, P.; Damidot, D.; Potdevin, J.L.; Measson, M. Chemical and mineralogical characterizations of LD converter steel slags: A multi-analytical techniques approach. Mater. Charact. 2010, 61, 39–48. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, D.; Zhuang, S.Y. The soundness of steel slag with different free CaO and MgO contents. Constr. Build. Mater. 2017, 151, 138–146. [Google Scholar] [CrossRef]

- Özhkan, Ö.; Saribiyik, M. Alkali silica reaction of BOF and BFS wastes combination in cement. J. Civ. Eng. Manag. 2013, 19, 113–120. [Google Scholar] [CrossRef]

- Zhang, T.; Yu, Q.; Wei, J.; Li, J. Investigation on mechanical properties, durability and micro-structural development of steel slag blended cements. J. Therm. Anal. Calorim. 2012, 110, 633–639. [Google Scholar] [CrossRef]

| Materials | LOSS | Fe2O3 | Al2O3 | CaO | SiO2 | MgO | TiO2 | K2O | SO3 | P2O5 |

|---|---|---|---|---|---|---|---|---|---|---|

| Steel slag | 0.72 | 25.02 | 6.07 | 42.72 | 15.77 | 4.79 | 0.67 | 0.08 | 0.50 | 0.86 |

| Fly ash | 2.97 | 6.13 | 31.71 | 3.45 | 50.94 | 0.61 | 1.14 | 1.49 | 0.54 | 0.19 |

| Cement | 3.418 | 3.34 | 6.65 | 57.92 | 21.96 | 2.57 | 0.30 | 0.40 | 2.46 | 0.17 |

| Property | Steel Slag |

|---|---|

| Apparent density (cm3) | 3.14–3.28 |

| Water absorption rate (%) | 4.44–4.52 |

| Void rate (%) | 36.3–38.1 |

| f-CaO (%) | 0.71–86 |

| Water-immersion expansion rate (%) | 0.06–1.25 |

| Setting Time (min) | Flexural Strength (MPa) | Compressive Strength (MPa) | Soundness | |||

|---|---|---|---|---|---|---|

| Initial setting | Final setting | 3d | 28d | 3d | 28d | Qualified |

| 165 | 260 | 5.5 | 12.5 | 24.4 | 48.5 | |

| Number | Cement: Fly Ash: Steel Slag Ratio | Filling Factor | Structure Type | Maximum Dry Density (kg·m3) | Optimum Moisture Content (%) |

|---|---|---|---|---|---|

| 0FASS | 4:0:100 | 0.13 | Skeleton-pore | 2.30 | 7 |

| 10FASS | 4:10:90 | 0.50 | Skeleton-pore | 2.29 | 7.609 |

| 20FASS | 4:20:80 | 0.96 | Skeleton-dense | 2.26 | 9.5 |

| 30FASS | 4:30:70 | 1.56 | Suspended-dense | 2.11 | 10.01 |

| 40FASS | 4:40:60 | 2.33 | Suspended-dense | 2.03 | 12.09 |

| 50FASS | 4:50:50 | 3.52 | Suspended-dense | 1.78 | 12.6 |

| 60FASS | 4:60:40 | 5.26 | Suspended-dense | 1.64 | 15.8 |

| Addition of Fly Ash (%) | Sample No. | Expansion Rate (%) | Average (%) | Dispersion Coefficient (CV) | Description | Number of Bulges |

|---|---|---|---|---|---|---|

| 0% | 1 | 0.104 | 0.093 | 0.250 | Bulge/crack | 6 |

| 2 | 0.086 | bulge | ||||

| 3 | 0.115 | bulge | ||||

| 10% | 1 | 0.104 | 0.068 | 0.373 | bulge | 3 |

| 2 | 0.046 | |||||

| 3 | 0.055 | bulge/crack | ||||

| 20% | 1 | 0.087 | 0.060 | 0.314 | bulge | 1 |

| 2 | 0.045 | |||||

| 3 | 0.049 | |||||

| 30% | 1 | 0.032 | 0.031 | 0.109 | flat | 0 |

| 2 | 0.03 | |||||

| 3 | 0.028 | |||||

| 40% | 1 | 0.02 | 0.023 | 0.107 | 0 | |

| 2 | 0.026 | flat | ||||

| 3 | 0.024 | |||||

| 50% | 1 | 0.021 | 0.019 | 0.090 | 0 | |

| 2 | 0.02 | flat | ||||

| 3 | 0.015 | |||||

| 60% | 1 | 0.018 | 0.018 | 0.045 | 0 | |

| 2 | 0.019 | flat | ||||

| 3 | 0.017 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, M.; Cheng, X.; Chen, X. Studies on the Volumetric Stability and Mechanical Properties of Cement-Fly-Ash-Stabilized Steel Slag. Materials 2021, 14, 495. https://doi.org/10.3390/ma14030495

Zhou M, Cheng X, Chen X. Studies on the Volumetric Stability and Mechanical Properties of Cement-Fly-Ash-Stabilized Steel Slag. Materials. 2021; 14(3):495. https://doi.org/10.3390/ma14030495

Chicago/Turabian StyleZhou, Mingkai, Xu Cheng, and Xiao Chen. 2021. "Studies on the Volumetric Stability and Mechanical Properties of Cement-Fly-Ash-Stabilized Steel Slag" Materials 14, no. 3: 495. https://doi.org/10.3390/ma14030495

APA StyleZhou, M., Cheng, X., & Chen, X. (2021). Studies on the Volumetric Stability and Mechanical Properties of Cement-Fly-Ash-Stabilized Steel Slag. Materials, 14(3), 495. https://doi.org/10.3390/ma14030495