Vulcanization Properties

The effects of temperature on the mechanical properties of the vulcanizates were illustrated in

Figure 3, and the mechanical properties including tensile strength and elongation at break were summarized in

Table 5. Generally, the higher the testing temperature, the lower the tensile strength and stress at certain elongation. This causes the damage resistance of the compound decrease with temperature increasing, revealing that both the thermal accumulation and the actual temperature directly affect the strength of the compound, and thus the tire performance. The results in

Figure 3 also indicate that although the stress of formulation A-2 at a certain strain was lower than that of formulation A-1, its tensile strength and elongation at break were greater than those of A-1. Compared with A-3 and A-4, formulation A-2 had greater tensile strength and greater elongation at break. The reason for these differences may be the high content of NR in A-2, as the tensile crystallization property of NR made it have stronger mechanical strength than BR.

The loss factor (tan δ) and the dynamic modulus (E’Mpa) of A-1 and A-4 in dynamic mechanical analysis temperature scanning were presented in

Table 5. An analysis of the results indicates that the dynamic modulus tends to decrease with increasing test temperature. From

Figure 4, the reduction in dynamic modulus can be seen to vary greatly at the two key temperature points of 100 °C and 160 °C, while only small variations were observed between those temperatures. In contrast, the loss factor was found to decrease with increasing temperature, and the rate of change was relatively consistent. As expected, the dynamic modulus and loss factor of formulation A-1, A-2, A-3, and A-4 decreased in turn, due to the inclusion N550 carbon black offering low heat generation and a lower filler content in formulation A-2, A-3, A-4.

Due to the varying loads across different tire applications, the performance of the four compounds cannot be accurately evaluated in practical conditions. The tests were performed based on ideal conditions of the same deformation and frequency. This was understandable as the tire was tested with the same loading. In other words, the tire compound was subjected to the same force.

To evaluate the performance of the compound under real-world conditions, the loss factor of the vulcanizates must take the actual deformation of the compound into consideration. Thus, energy dissipation △E was used to evaluate a strain period, and was expressed in Equation (5).

where σ0 was the maximum amplitude of stress and γ0 was the maximum amplitude of strain.

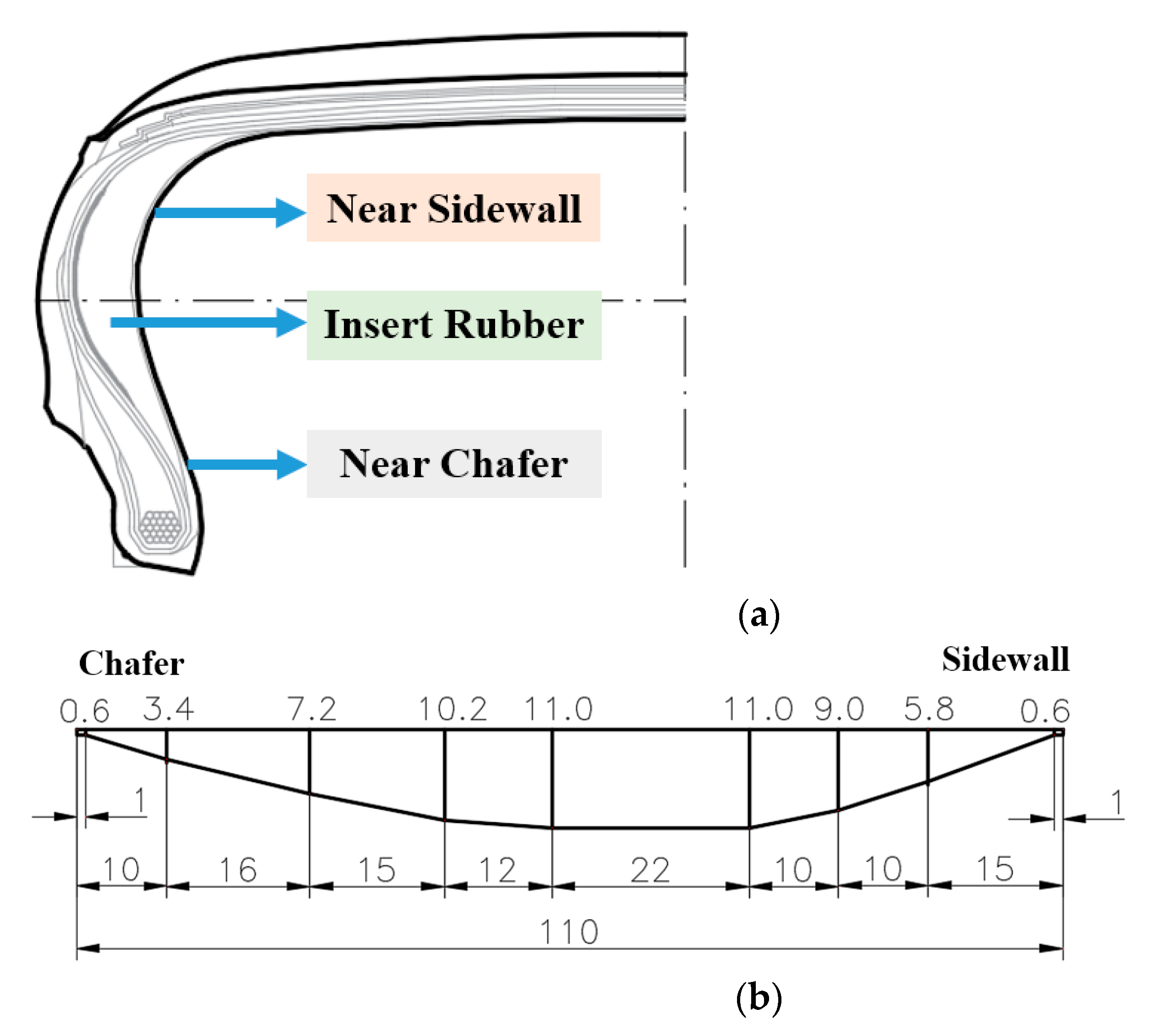

Subsequently, four compounds of insert rubber with different modulus and heat-generation were designed to investigate the roles and impacts of deformation and loss factor of a tire which was shown in

Figure 4.

Table 6 was the summarize of dynamic modulus (E’) and loss factor (tan δ) of the vulcanizates at various temperatures

Strictly speaking, the fatigue failure of rubber is a kind of mechanical process. The stress relaxation process produced in the material was often too late to complete in the deformation cycle under the repeated cyclic deformation of rubber. As a result, the internal generated stress could not be dispersed in time, and it might be concentrated in some defects (such as cracks, weak bonds, etc.), which caused fracture failure.

Figure 5 shows the simulation results of six tire models (size = 245/45/R18 96W) based on

Table 1. The results of stress distribution of tire sidewall show that the stress was mainly concentrated in the insert compound in both the B-1 and B-2 structures which was shown in

Figure 2. Surprisingly, using the A-1 compounds with the B-1 structure resulted in a more uniform stress distribution of the tire sidewall. This was because in the flexure test of the tire side adhesive, the stress was mainly concentrated on the insert support with high hardness, as shown in model 5. At the same time, compared with B-2, B-1 structure had a longer supporting compound, a larger amount of padding between the tread and the bead apex, and a better rigid transition with the tire sidewall, that was why the deformation of model 5 and model 6 on tire sidewall was greater than that of model 1, model 2, and model 3. Model 3 and model 4 used similar insert compound with soft hardness under the structure of B-2, the rigidity of the tire sidewall was weak, and the stress was concentrated on the weakest point of rigidity during flexion, which can be clearly seen from

Figure 5a,b. The results of

Table 6 also indicated that the actual stresses of the different compounds at the same part of the tire were different during the actual movement of the tire. This demonstrates why the loss factor cannot be directly used under the same deformation in the dynamic mechanical analysis test to evaluate the tire’s thermal performance.

Strain energy density of bead apex and insert rubber of tire were also shown in

Figure 5c. Compared to model 5 and model 6, the strain energy density distribution of other models were more concentrated, suggesting a greater likelihood for the formation of a failure point.

Table 7 shows the summary of the analytical and quantitative results of the groups of analysis models. It is generally considered that the maximum stress and strain energy density at the bead apex rubber and support compound are the most important indexes related to the zero pressure durability of tire. The maximum stress and strain energy density of model 5 and model 6 under structure B-1 were smaller than those of other schemes, which indicates that the influence of structural rigidity is greater than that of the hardness of insert rubber. At the same time, under the same structure, the higher the hardness of the insert rubber, the smaller the stress and strain energy density, which can be found from the comparison of the previous four models.

Figure 6 shows the shear stress distribution of the six models. There were no obvious benefits of reducing the length of the insert compound with respect to the direction of the shear force on each part of the tire sidewall, particularly between the insert rubber and bead apex. Delamination was easily induced by applying different directions of shear stress, causing damage points and premature damage. Compared with the first four models, model 5 and model 6 use B-1 structure, which had a longer contact surface with bead apex rubber, which effectively avoids the shear stress of relative slip between the two interfaces due to uneven stress. In model 3 and model 4, due to the use of insert rubber with lower hardness, the shear stress between the various parts of sidewall was small, mainly concentrated in the inner side of the tire at the center of sidewall.

Based on the six simulation models, six actual tires under the structure of

Table 2 were produced for testing, named as T-1, T-2, T-3, T-4, T-5, and T-6.

Table 8 and

Table 9 show the basic characteristics of the tires under a conventional static load and a zero-pressure static load. The static radius was most heavily influenced by the subsidence and subsidence rate under static load, and the structure of the insert rubber which provide structural rigidity to the tire. Further, it can be seen that under the same structure, the static load radius and sinkage of the tire were directly proportional to the rigidity of the insert rubber. Especially under the condition of zero pressure load, the stiffness of the insert rubber directly affects the static load radius and sinkage representing the tire deformation. Therefore, in comparison with T-5 and T-6, the greater deformation of T-1, T-2, T-3, and T-4 may lead to increases in heat generation.

The curves of temperature rise of the tire sidewall and bead during the zero-pressure durability test were shown in

Figure 7. The sidewall and bead temperatures of T-1, T-2, T-3, and T-4 increase to a higher value over time, compared to T-5 and T-6. This was mainly due to the weaker structural rigidity of B-2 and the larger sinkage of the tire, in addition to higher energy loss according to the energy loss formula. Moreover, the results in

Figure 7 reveal that although the loss factor of A-2 was lower than that of A-1, the difference in heat generation at the sidewalls of T-1 and T-2 was minimal, mainly due to the larger sinkage and the greater deformation of T-2, which led to higher energy loss. The comparison data of T-5 and T-6 with stronger tire structure can also prove this conclusion. The results further prove that the loss factor and deformation should be considered comprehensively in the energy loss of the rubber compound.

Table 10 summarizes the zero-pressure durability test results of the tires. It was evident that under the same rubber conditions, the results of the zero-pressure durability test were directly related to the rate of temperature rise of the tire sidewall. As the temperature increases, the resistance to damage of the compound decreases, which was clearly proven by the test results. At the same time, the stress distribution of tire sidewall was also found to directly affect results of the zero-pressure durability test. Although the difference of heat generated at the sidewall between T-1 and T-2 was minimal, an analysis of the strain energy density of bead apex and insert rubber of tire shown in

Figure 5 suggested that the stress concentration in T-2 may lead to early tire failure. The test results of T-5 and T-6 can also prove this point. In addition, the zero pressure durability of T-5 and T-6 was better than that of T-1 and T-2 under the strong structural rigidity of B-1, which can also prove the effect of strain energy density. Compared with A-1 and A-2, the rigidity of A-3 and A-4 was lower. Although it can be seen from

Table 6 that the loss factor of A-3 and A-4 was lower, the sidewall shape of the tire changed greatly, and the temperature rise in

Figure 7 was faster, which led to the faster damage of the insert rubber.