The Effect of Heat Treatment on the Corrosion Resistance of Fe-Based Amorphous Alloy Coating Prepared by High Velocity Oxygen Fuel Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of the Fe-Based Amorphous Alloy Coating

2.2. Characterization Analysis of the Fe-Based Amorphous Alloy Coating

3. Results

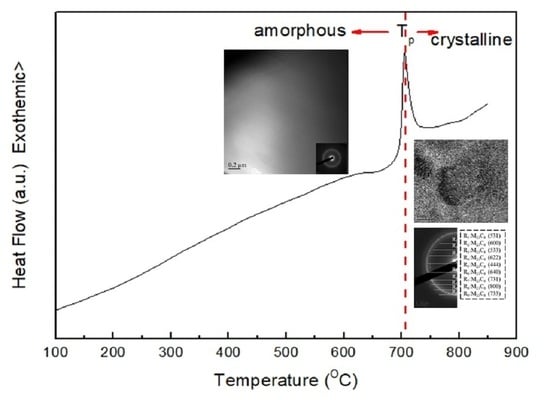

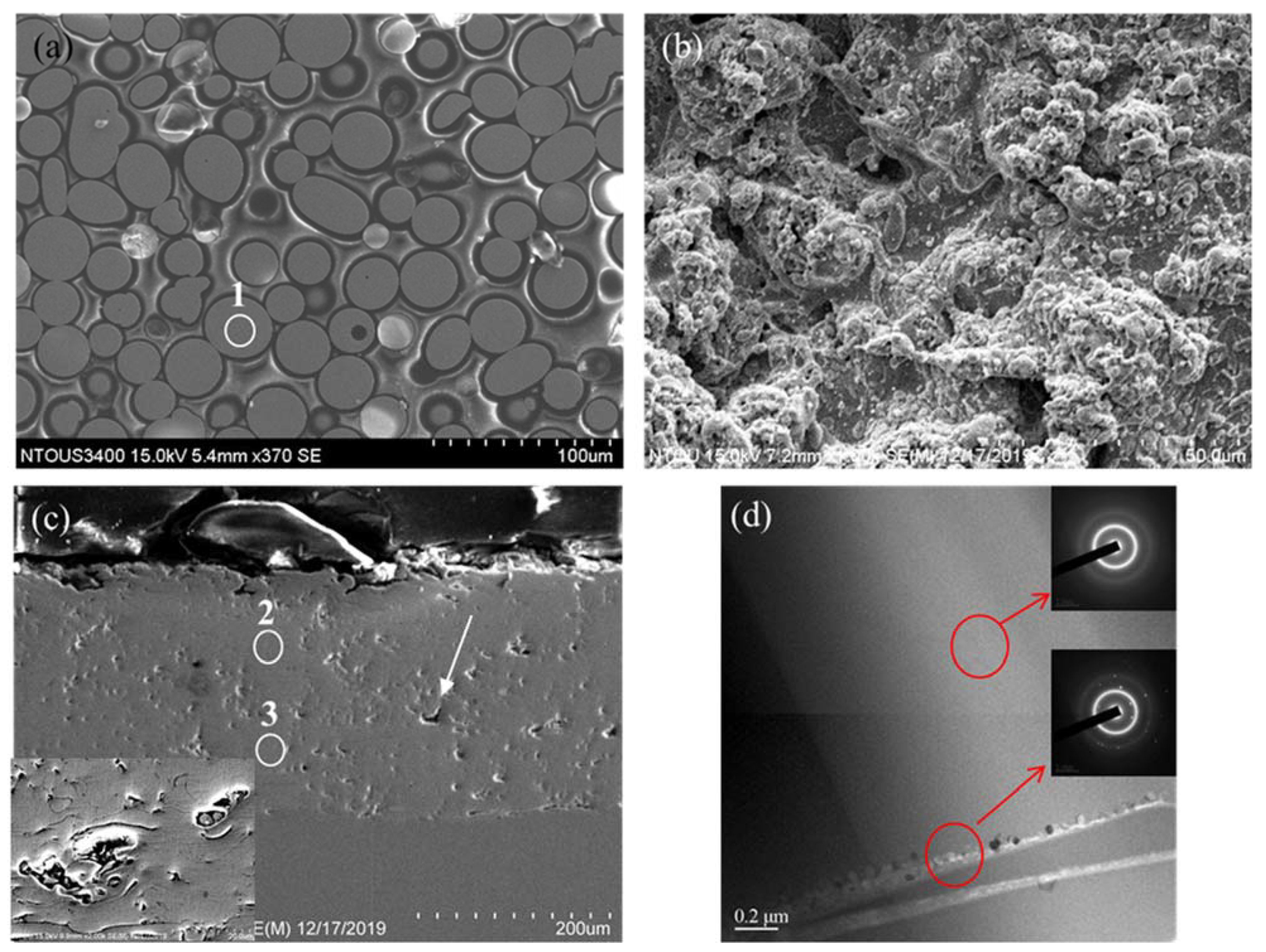

3.1. Morphologies of Fe-Based Amorphous Alloy

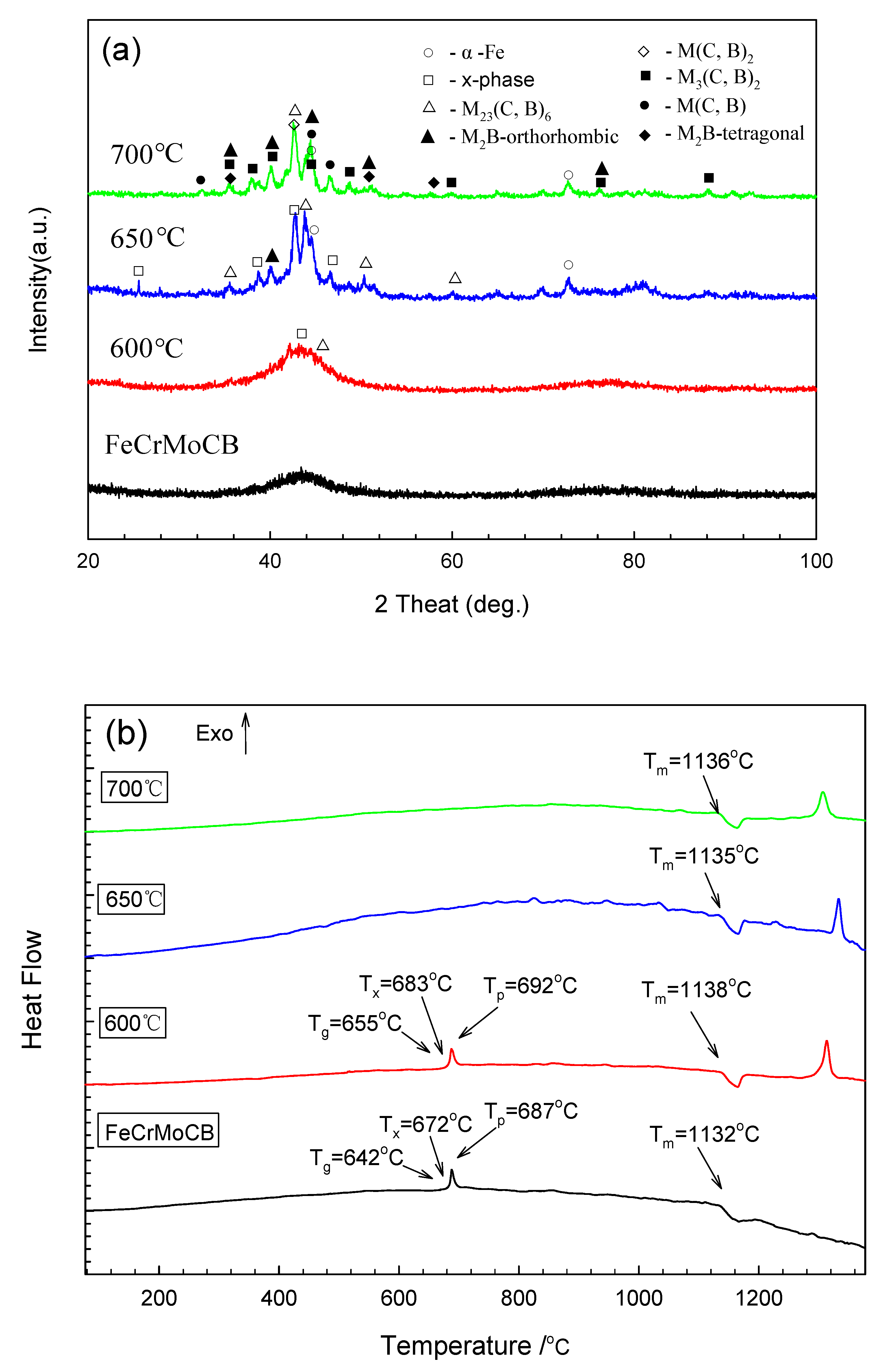

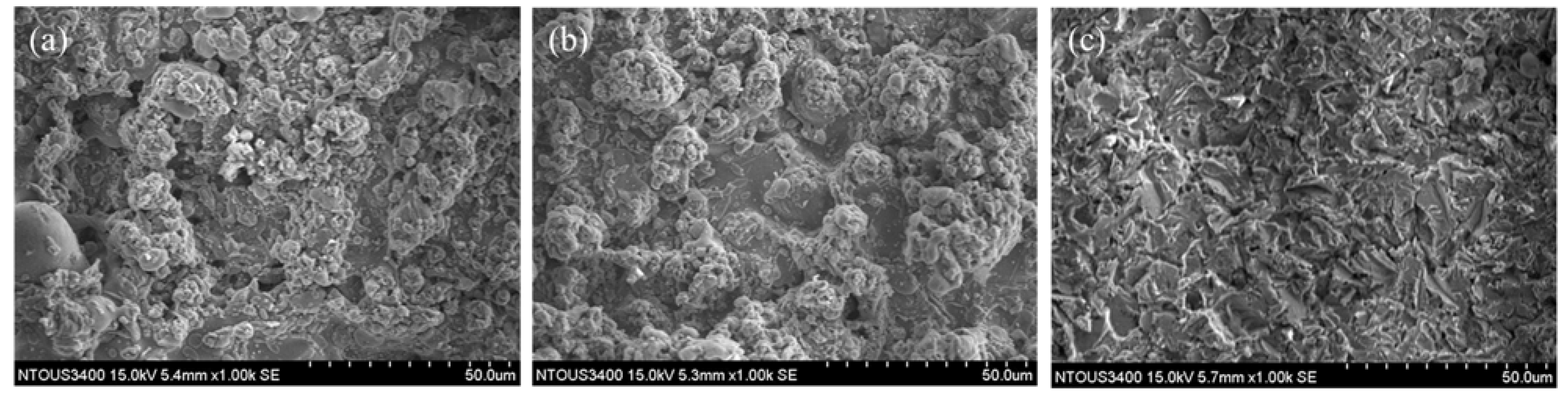

3.2. Microstructure of Fe-Based Amorphous Alloy Coatings after Annealing

3.3. Corrosion Resistance of Fe-Based Amorphous Alloy Coatings after Annealing

4. Discussion

4.1. Calculation of Activation Energy for Recrystallization of Fe-Based Amorphous Alloys

4.2. Microstructure Analysis of Fe-Based Amorphous Alloy Coatings after Annealing

4.3. Corrosion Behavior of Fe-Based Amorphous Alloy Coatings after Annealing

5. Conclusions

- The Fe-based amorphous alloy coating will start to undergo recrystallization and carbide phase precipitation reactions when the annealing temperature is above 650 °C.

- The results of the corrosion polarization curve show that the corrosion current density of the coating after annealing only increased by 9.13 μA/cm2, which indicates that the coating after annealing treatment still has excellent corrosion resistance. It also proves that the Fe-based amorphous alloy coating can be used in high-temperature environments.

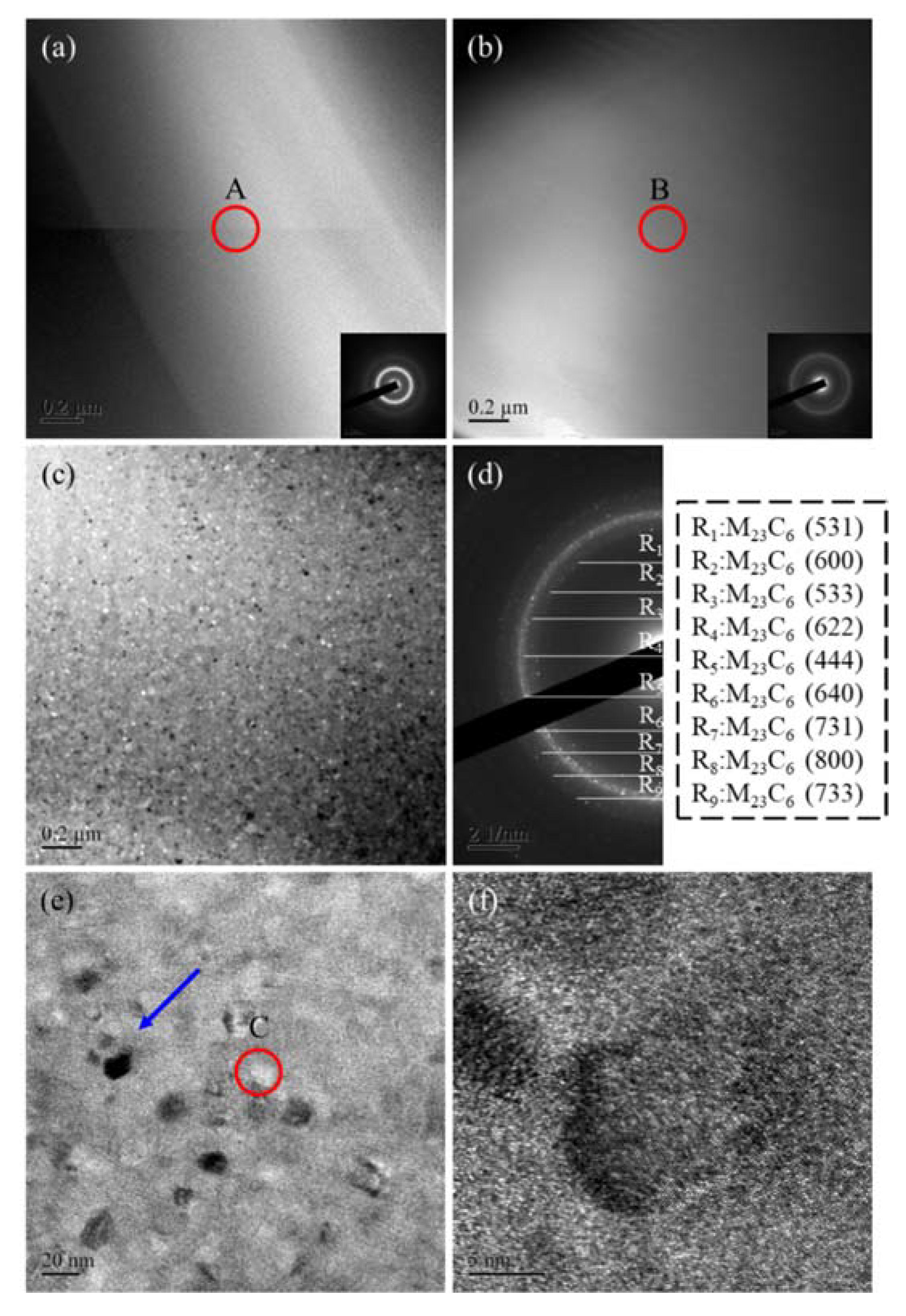

- TEM observation results show that the Fe-based amorphous alloy coating still maintains an amorphous structure after annealing at 600 °C. When the annealing temperature is increased to 700 °C, a carbide phase will form in the amorphous coating. SAED analysis shows that the carbide phase is composed of M23C6 crystals with different crystal lattice directions.

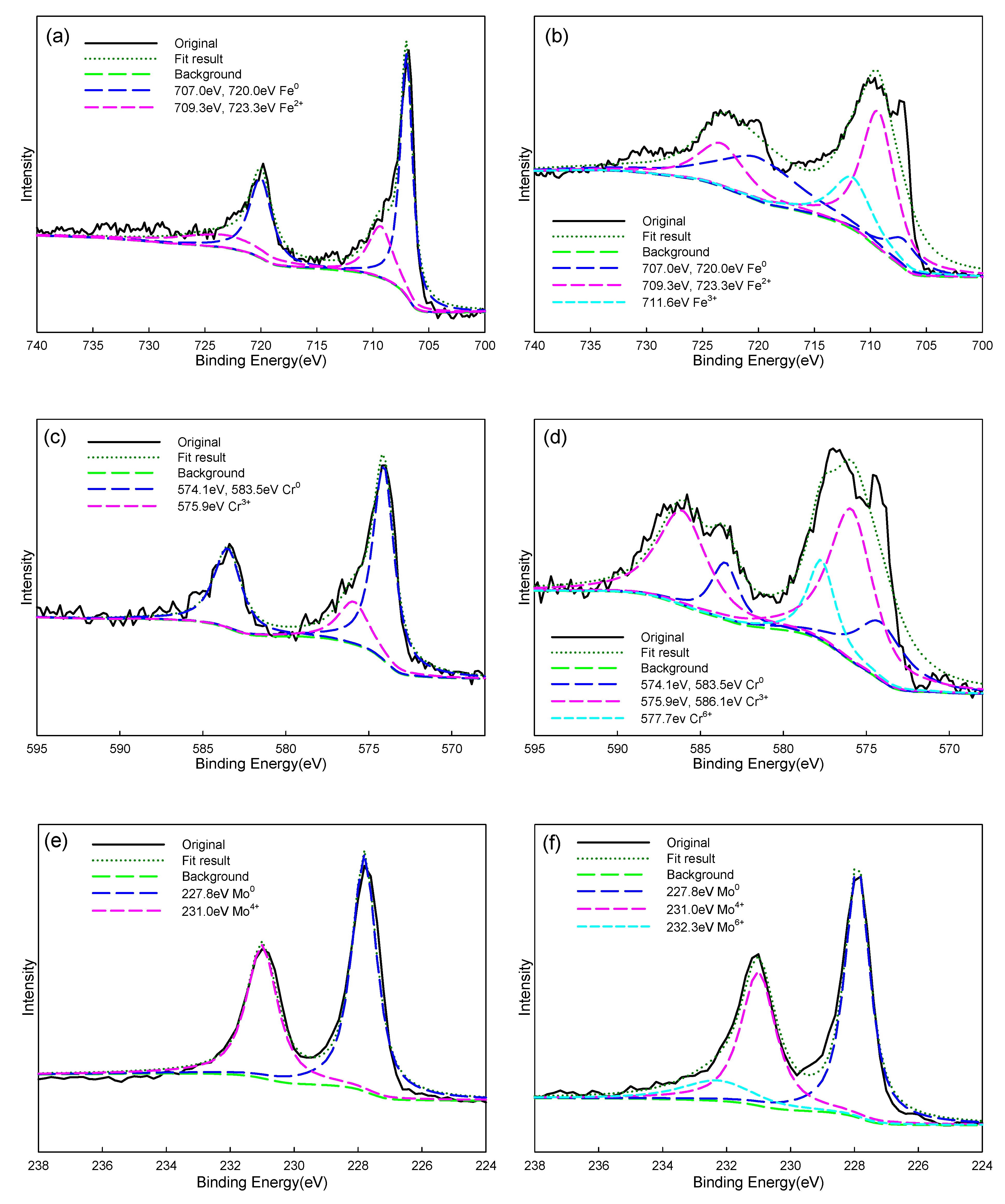

- According to XPS analysis, the corrosion resistance is reduced due to the formation of a large amount of iron oxides in the coating after annealing at 700 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lin, T.J.; Sheu, H.H.; Lee, C.Y.; Lee, H.B. The study of mechanical properties and corrosion behavior of the Fe-based amorphous alloy coatings using high velocity oxygen fuel spraying. J. Alloys Compd. 2021, 867, 159132. [Google Scholar] [CrossRef]

- Si, C.; Duana, B.; Zhang, Q.; Cai, J.; Wu, W. Microstructure, corrosion-resistance, and wear-resistance properties of subsonic flame sprayed amorphous Fe–Mo–Cr–Co coating with extremely high amorphous rate. J. Mater. Res. Technol. 2020, 9, 3292–3303. [Google Scholar] [CrossRef]

- Shi, L.; Qin, X.; Yao, K. Tailoring soft magnetic properties of Fe-based amorphous alloys through C addition. Prog. Nat. Sci. Mater. Int. 2020, 30, 208–212. [Google Scholar] [CrossRef]

- Zhou, Y.K.; Liu, X.B.; Kang, J.J.; Yue, W.; Qin, W.B.; Ma, G.; Fu, Z.Q.; Zhu, L.N.; She, D.S.; Wang, H.D.; et al. Corrosion behavior of HVOF sprayed WC-10Co4Cr coatings in the simulated seawater drilling fluid under the high pressure. Eng. Fail. Anal. 2020, 109, 104338. [Google Scholar] [CrossRef]

- Farmer, J.; Choi, J.S.; Saw, C.; Haslam, J.; Day, D.; Hailey, P.; Lian, T.; Rebak, R.; Perepezko, J.; Payer, J.; et al. Iron-Based Amorphous Metals: High-Performance Corrosion-Resistant Material Development. Metall. Mater. Trans. A 2009, 40, 1289–1305. [Google Scholar] [CrossRef]

- Tsai, P.H.; Xiao, A.C.; Li, J.B.; Jang, J.S.C.; Chu, J.P.; Huang, J.C. Prominent Fe-based bulk amorphous steel alloy with large supercooled liquid region and superior corrosion resistance. J. Alloys Compd. 2014, 586, 94–98. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, M.; Song, J.; Deng, C.; Deng, C. Microstructure and corrosion behavior of Fe-Based Amorphous coating prepared by HVOF. J. Alloys Compd. 2017, 721, 506–511. [Google Scholar] [CrossRef]

- Ji, X.; Luo, C.; Sun, Y.; Zhao, J. Corrosive wear of multi-layer Fe-based coatings laser cladded from amorphous powders. Wear 2019, 438, 203113. [Google Scholar] [CrossRef]

- Qiao, L.; Wu, Y.; Hong, S.; Qin, Y.; Shi, W.; Li, G. Corrosion Behavior of HVOF-Sprayed Fe-Based Alloy Coating in Various Solutions. J. Mater. Eng. Perform. 2017, 26, 3813–3820. [Google Scholar] [CrossRef]

- Kumar, A.; Nayak, S.K.; Bijalwan, P.; Dutta, M.; Banerjee, A.; Laha, T. Optimization of mechanical and corrosion properties of plasma sprayed lowchromium containing Fe-based amorphous/nanocrystalline composite coating. Surf. Coat. Technol. 2019, 370, 255–268. [Google Scholar] [CrossRef]

- Cheng, J.; Wu, Y.; Shen, W.; Hong, S.; Qiao, L.; Wang, Y. A study on hot corrosion performance of high velocity arc-sprayed FeCrNiAlMnB/Cr3C2 coating exposed to Na2SO4+K2SO4 and Na2SO4+NaCl. Surf. Coat. Technol. 2020, 397, 126015. [Google Scholar] [CrossRef]

- Sultan, A.M.; Hashmi, M.S.J.; Yilbas, B.S.; Stokes, J. Microstructural Characterization of HVOF/Plasma Thermal Spray of Micro/Nano WC-12%Co Powders. Surf. Coat. Technol. 2015, 264, 175–186. [Google Scholar]

- Iqbal, A.; Siddiqu, S.; Maqsood, M.; Rehman, M.A.U.; Yasir, M. Comparative Analysis on the Structure and Properties of Iron-Based Amorphous Coating Sprayed with the Thermal Spraying Techniques. Coatings 2020, 10, 1006–1018. [Google Scholar] [CrossRef]

- Zhang, S.D.; Wu, J.; Qi, W.B.; Wang, J.Q. Effect of porosity defects on the long-term corrosion behaviour of Fe-based amorphous alloy coated mild steel. Corros. Sci. 2016, 110, 57–70. [Google Scholar] [CrossRef]

- Lee, H.B.; Lin, T.J.; Lee, C.Y. Corrosion of high-velocity-oxygen-fuel (HVOF) sprayed non-crystalline alloy coating in marine environment. Surf. Coat. Technol. 2021, 409, 126896. [Google Scholar] [CrossRef]

- Wu, Z.W.; Lu, Z.C.; Ni, X.J.; Li, D.R.; Feng, S.; Qi, Y.H. Effect of Heat Treatment on Corrosion Behaviour of Amorphous Metal Fibers. J. Iron Steel Res. Int. 2014, 21, 1030–1034. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Peng, Y.; Yu, Y.; Liu, L. Effects of crystallization on the corrosion resistance of Fe-based amorphous coatings. Corros. Sci. 2012, 59, 10–19. [Google Scholar] [CrossRef]

- Liang, D.; Tseng, J.C.; Liu, X.; Cai, Y.; Xu, G.; Shen, J. Investigation of the Structural Heterogeneity and Corrosion Performance of the Annealed Fe-Based Metallic Glasses. Materials 2021, 14, 929–942. [Google Scholar] [CrossRef] [PubMed]

- Belkhaouda, M.; Bazzi, L.; Benlhachemi, A.; Salghi, R.; Hammouti, B.; Kertit, S. Effect of the heat treatment on the corrosion behaviour of amorphous Fe–Cr–P–C–Si alloy in 0.5 M H2SO4. Appl. Surf. Sci. 2006, 252, 7921–7925. [Google Scholar] [CrossRef]

- Kang, Y.; Chen, Y.; Wen, Y.; Wu, B.; Song, M. Effects of structural relaxation and crystallization on the corrosion resistance of an Fe-based amorphous coating. J. Non-Cryst. Solids 2020, 550, 120378. [Google Scholar] [CrossRef]

- Koga, G.Y.; Ferreira, T.; Guo, Y.; Coimbrao, D.D.; Jorg, A.M., Jr.; Kiminami, C.S.; Bolfarini, C.; Botta, W.J. Challenges in optimizing the resistance to corrosion and wear of amorphous Fe-Cr-Nb-B alloy containing crystalline phases. J. Non-Cryst. Solids 2021, 555, 120537. [Google Scholar] [CrossRef]

- Liu, S.; Zhu, Y.; Lai, X.; Zheng, X.; Jia, R.; Yuan, X. Influence of Di erent Heat Treatment Temperatures on the Microstructure, Corrosion, and Mechanical Properties Behavior of Fe-Based Amorphous/Nanocrystalline Coatings. Coatings 2018, 9, 858–870. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Z.B.; Zheng, Y.G.; Sun, W.H.; Wang, J.Q. Effect of heat treatment on the structure, cavitation erosion and erosion-corrosion behavior of Fe-based amorphous coatings. Tribol. Int. 2015, 90, 393–403. [Google Scholar] [CrossRef]

- Wang, Q.Y.; Xi, Y.C.; Zhao, Y.H.; Liu, S.; Bai, S.L.; Liu, Z.D. Effects of laser re-melting and annealing on microstructure, mechanical property and corrosion resistance of Fe-based amorphous/crystalline composite coating. Mater. Charact. 2017, 127, 239–247. [Google Scholar] [CrossRef]

- Huang, F.; Kang, J.J.; Yue, W.; Liu, X.B.; Fu, Z.Q.; Zhu, L.N.; She, D.S.; Ma, G.Z.; Wang, H.D.; Liang, J.; et al. Effect of heat treatment on erosion-corrosion of Fe-based amorphous alloy coating under slurry impingement. J. Alloys Compd. 2020, 820, 153132. [Google Scholar] [CrossRef]

- Coimbrao, D.D.; Zepon, G.; Koga, G.Y.; Perez, D.A.G.; de Almeida, F.H.P.; Roche, V.; Lepretre, J.C.; Jorg, A.M., Jr.; Kiminami, C.S.; Bolfarini, C.; et al. Corrosion properties of amorphous, partially, and fully crystallized Fe68Cr8Mo4Nb4B16 alloy. J. Alloys Compd. 2020, 826, 154123. [Google Scholar] [CrossRef]

- Kanno, H. A simple derivation of the empirical rule Tg/Tm = 2/3. J. Non-Cryst. Solids 1981, 44, 409–413. [Google Scholar] [CrossRef]

- Nyby, C.; Guo, X.; Saal, J.E.; Chien, S.-C.; Gerard, A.Y.; Ke, H.; Li, T.; Lu, P.; Oberdorfer, C.; Sahu, S.; et al. Electrochemical metrics for corrosion resistant alloys. Sci. Data 2021, 8, 58. [Google Scholar] [CrossRef]

- Kissinger, H.E. Variation of Peak Temperature with Heating Rate in Differential Thermal Analysis. J. Res. Natl. Bur. Stand. 1956, 57, 217–221. [Google Scholar] [CrossRef]

- Vyazovkin, S. Kissinger Method in Kinetics of Materials: Things to Beware and Be Aware of. Molecules 2020, 25, 2813–2831. [Google Scholar] [CrossRef]

- Dong, Q.; Song, P.; Tan, J.; Qin, X.M.; Li, C.J.; Gao, P.; Feng, Z.X.; Calin, M.; Eckert, J. Non-isothermal crystallization kinetics of a Fe-Cr-Mo-B-C amorphous powder. J. Alloys Compd. 2020, 823, 153783. [Google Scholar] [CrossRef]

- Paul, T.; Loganathan, A.; Agarwal, A.; Harimkar, S.P. Kinetics of isochronal crystallization in a Fe-based amorphous alloy. J. Alloys Compd. 2018, 753, 679–687. [Google Scholar] [CrossRef]

- Fu, B.Y.; He, D.Y.; Zhao, L.D. Effect of heat treatment on the microstructure and mechanical properties of Fe-based amorphous coatings. J. Alloys Compd. 2009, 480, 422–427. [Google Scholar] [CrossRef]

- Xia, H.; Chen, Q.; Wang, C. Evaluating corrosion resistances of Fe-based amorphous alloys by YCr/Mo values. J. Rare Earths 2017, 35, 406–411. [Google Scholar] [CrossRef]

- Tian, W.P.; Yang, H.W.; Zhang, S.D. Synergistic Effect of Mo, W, Mn and Cr on the Passivation Behavior of a Fe-Based Amorphous Alloy Coating. Acta Metall. Sin. 2018, 31, 308–320. [Google Scholar] [CrossRef]

- Yang, B.; Wu, Y.; Li, X.; Yu, R. Chemical Synthesis of High-Stable Amorphous FeCo Nanoalloys with Good Magnetic Properties. Nanomaterials 2018, 8, 154–168. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ning, W.; Zhai, H.; Xiao, R.; He, D.; Liang, G.; Wu, Y.; Li, W.; Li, X. The Corrosion Resistance Mechanism of Fe-Based Amorphous Coatings Synthesised by Detonation Gun Spraying. J. Mater. Eng. Perform. 2020, 29, 3921–3929. [Google Scholar] [CrossRef]

- Ha, H.M.; Miller, J.R.; Payer, J.H. Devitrification of Fe-Based Amorphous Metal SAM 1651 and the Effect of Heat-Treatment on Corrosion Behavior. J. Electrochem. Soc. 2009, 156, 246–252. [Google Scholar] [CrossRef]

- Lee, C.Y.; Lin, T.J.; Sheu, H.H.; Lee, H.B. Study on corrosion and corrosion-wear behavior of Fe-based amorphous alloy coating prepared by high velocity oxygen fuel method. J. Mater. Res. Technol. 2021, 15, 4880–4895. [Google Scholar] [CrossRef]

| Elements (At.%) | Fe | Cr | Mo | C | O | Total | |

|---|---|---|---|---|---|---|---|

| Position | |||||||

| Raw material particles | |||||||

| 1 | 41.58 | 18.49 | 17.33 | 17.93 | 4.67 | 100.00 | |

| As-sprayed coating | |||||||

| 2 | 39.98 | 19.59 | 18.99 | 15.13 | 6.31 | 100.00 | |

| 3 | 40.98 | 19.22 | 18.28 | 14.92 | 6.60 | 100.00 | |

| Average | 40.48 ± 0.001 | 19.41 ± 0.001 | 18.64 ± 0.001 | 15.03 ± 0.001 | 6.46 ± 0.001 | 100.00 | |

| Tg (K) | Tx (K) | ΔTx (K) | Tm (K) | Tg/Tm | Tp (K) | |

|---|---|---|---|---|---|---|

| FeCrMoCB | 915 | 945 | 30 | 1405 | 0.651 | 960 |

| 600 °C annealed | 928 | 956 | 28 | 1411 | 0.658 | 965 |

| 650 °C annealed | - | - | - | 1408 | - | - |

| 700 °C annealed | - | - | - | 1409 | - | - |

| At.% | Fe | Cr | Mo | C | O | Total |

|---|---|---|---|---|---|---|

| As-sprayed | 40.48 | 19.41 | 18.64 | 15.03 | 6.46 | 100.00 |

| 600 °C annealed | 23.40 | 19.05 | 15.29 | 11.99 | 30.27 | 100.00 |

| 650 °C annealed | 20.98 | 22.68 | 6.02 | 13.10 | 37.21 | 100.00 |

| 700 °C annealed | 20.54 | 23.58 | 5.71 | 7.40 | 42.77 | 100.00 |

| Ecorr (VSCE) | icorr (A/cm2) | ipass (A/cm2) | Epit | |

|---|---|---|---|---|

| FeCrMoCB | −0.78 | 29.18 × 10−6 | 1.11 × 10−4 | 0.545 |

| 600 °C annealed | −0.51 | 33.93 × 10−6 | 28.61 × 10−4 | 0.642 |

| 650 °C annealed | −0.55 | 36.35 × 10−6 | 80.82 × 10−4 | 0.693 |

| 700 °C annealed | −0.63 | 38.31 × 10−6 | 10.46 × 10−4 | 0.831 |

| At.% | Fe | Cr | Mo | C | O | Total |

|---|---|---|---|---|---|---|

| A | 47.29 | 22.01 | 18.55 | 9.75 | 2.40 | 100.00 |

| B | 33.30 | 15.74 | 15.35 | 24.81 | 10.80 | 100.00 |

| C | 29.62 | 13.62 | 15.98 | 27.18 | 13.60 | 100.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.-Y.; Sheu, H.-H.; Tsay, L.-W.; Hsiao, P.-S.; Lin, T.-J.; Lee, H.-B. The Effect of Heat Treatment on the Corrosion Resistance of Fe-Based Amorphous Alloy Coating Prepared by High Velocity Oxygen Fuel Method. Materials 2021, 14, 7818. https://doi.org/10.3390/ma14247818

Lee C-Y, Sheu H-H, Tsay L-W, Hsiao P-S, Lin T-J, Lee H-B. The Effect of Heat Treatment on the Corrosion Resistance of Fe-Based Amorphous Alloy Coating Prepared by High Velocity Oxygen Fuel Method. Materials. 2021; 14(24):7818. https://doi.org/10.3390/ma14247818

Chicago/Turabian StyleLee, Chun-Ying, Hung-Hua Sheu, Leu-Wen Tsay, Po-Sen Hsiao, Tzu-Jing Lin, and Hung-Bin Lee. 2021. "The Effect of Heat Treatment on the Corrosion Resistance of Fe-Based Amorphous Alloy Coating Prepared by High Velocity Oxygen Fuel Method" Materials 14, no. 24: 7818. https://doi.org/10.3390/ma14247818

APA StyleLee, C.-Y., Sheu, H.-H., Tsay, L.-W., Hsiao, P.-S., Lin, T.-J., & Lee, H.-B. (2021). The Effect of Heat Treatment on the Corrosion Resistance of Fe-Based Amorphous Alloy Coating Prepared by High Velocity Oxygen Fuel Method. Materials, 14(24), 7818. https://doi.org/10.3390/ma14247818