Investigations of Model Multilayer Ceramic Casting Molds in a Raw State by Nondestructive Methods

Abstract

:1. Introduction

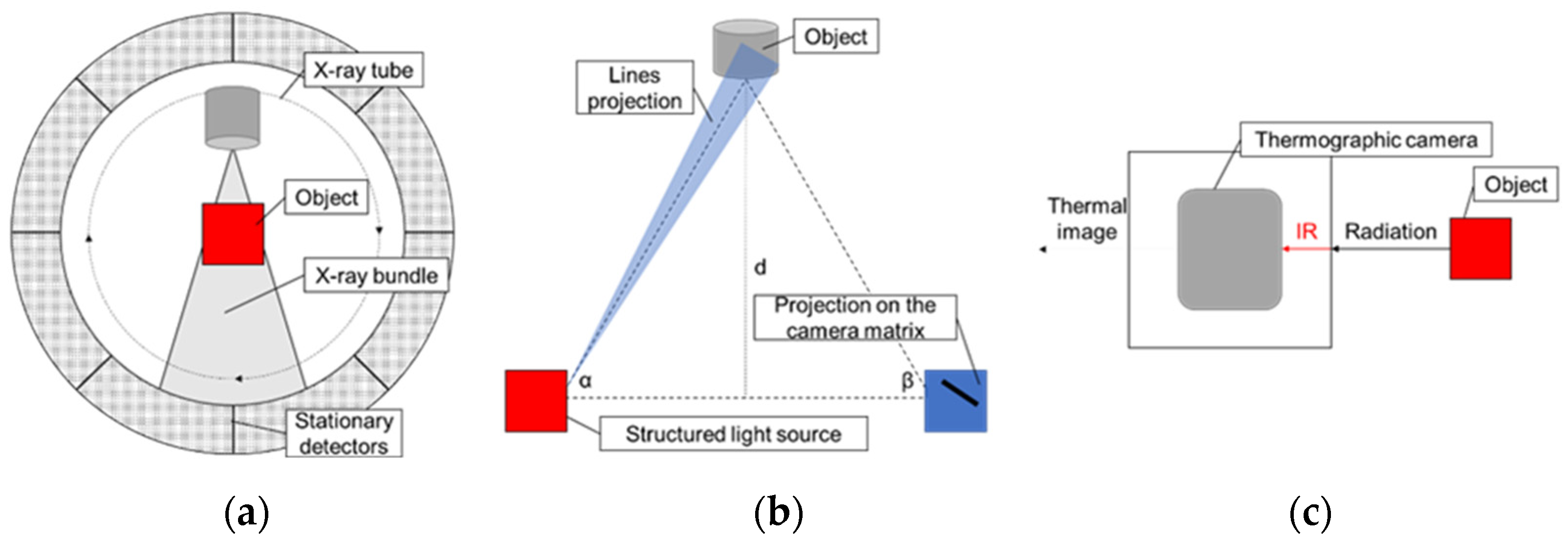

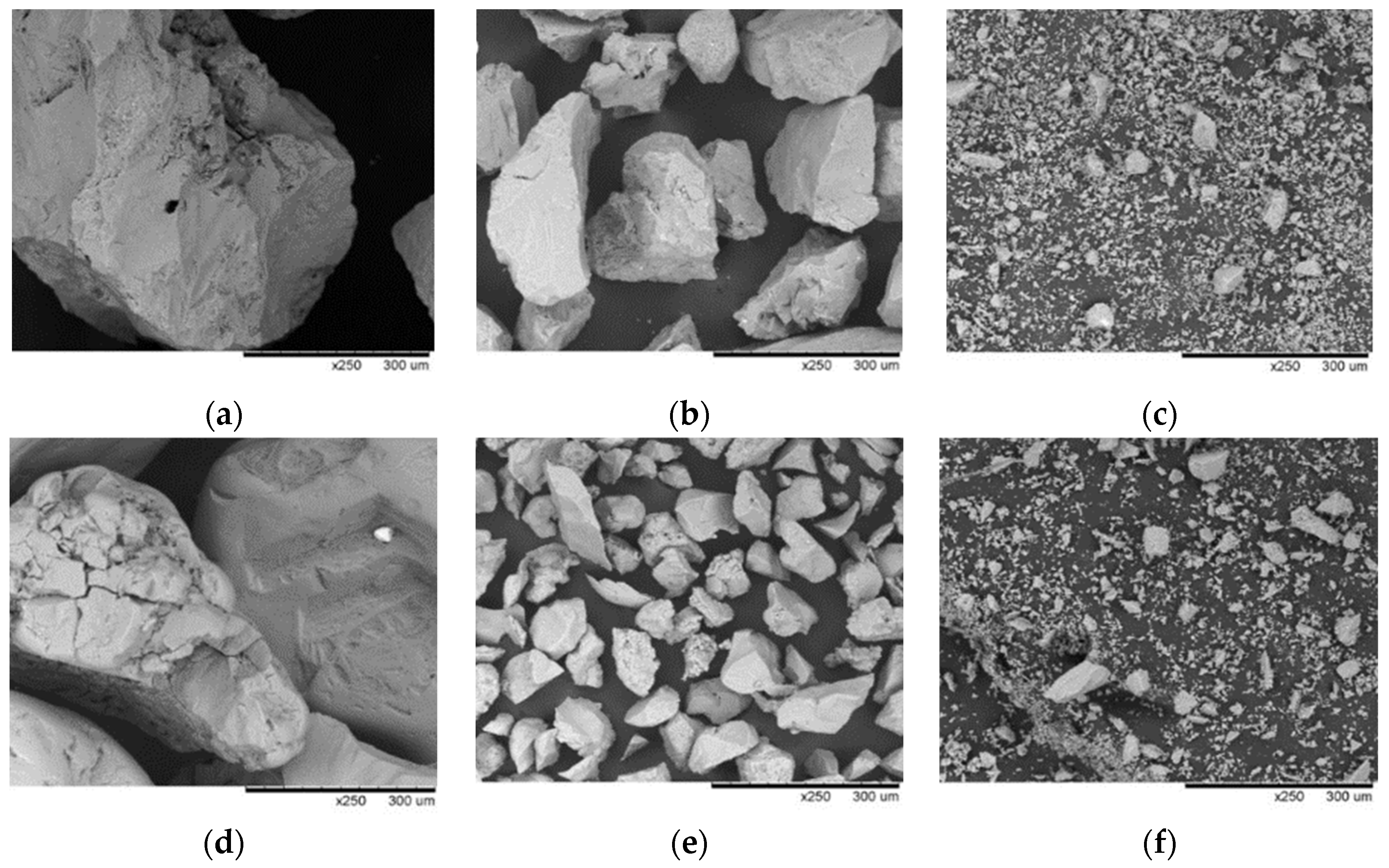

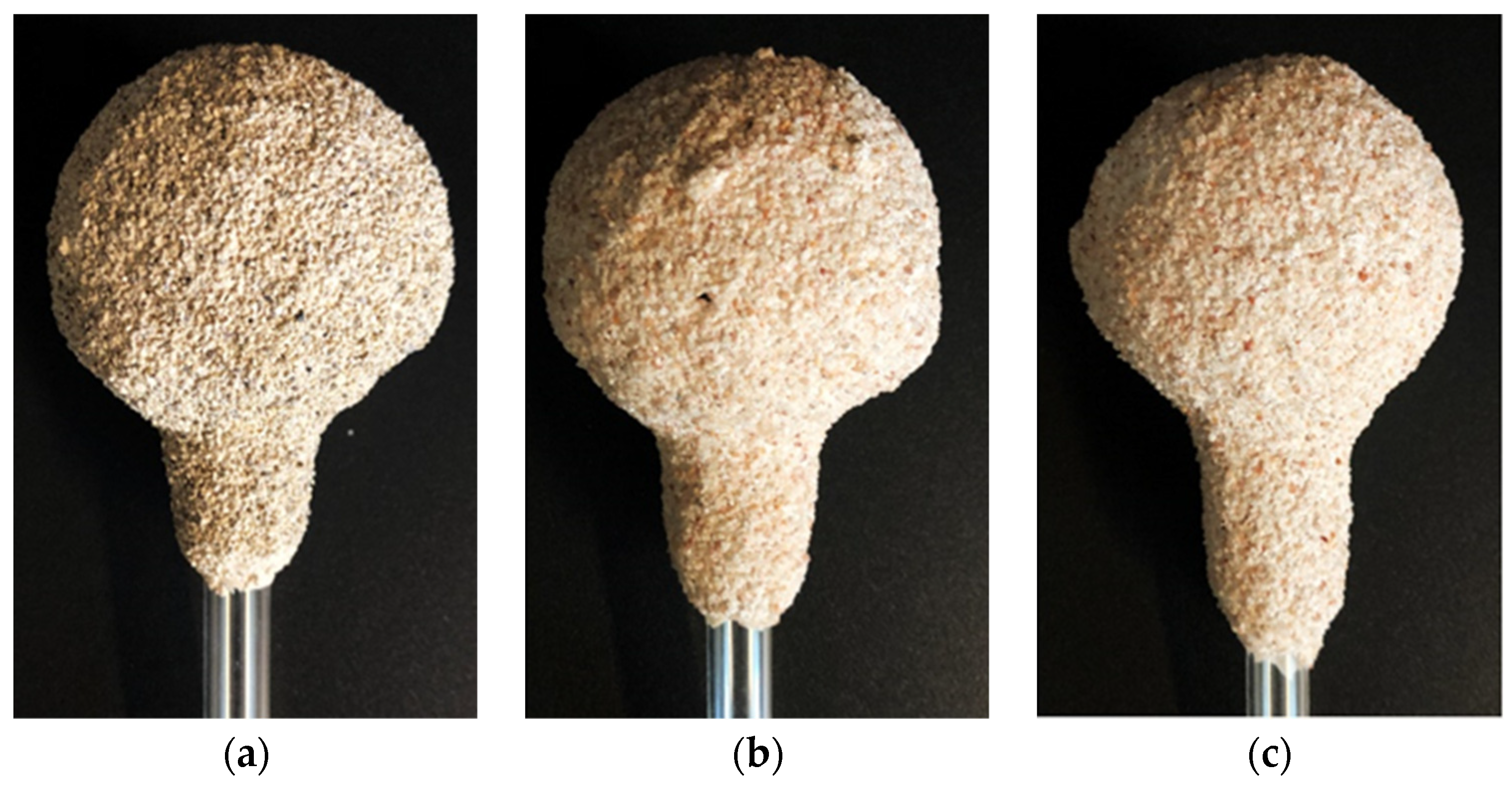

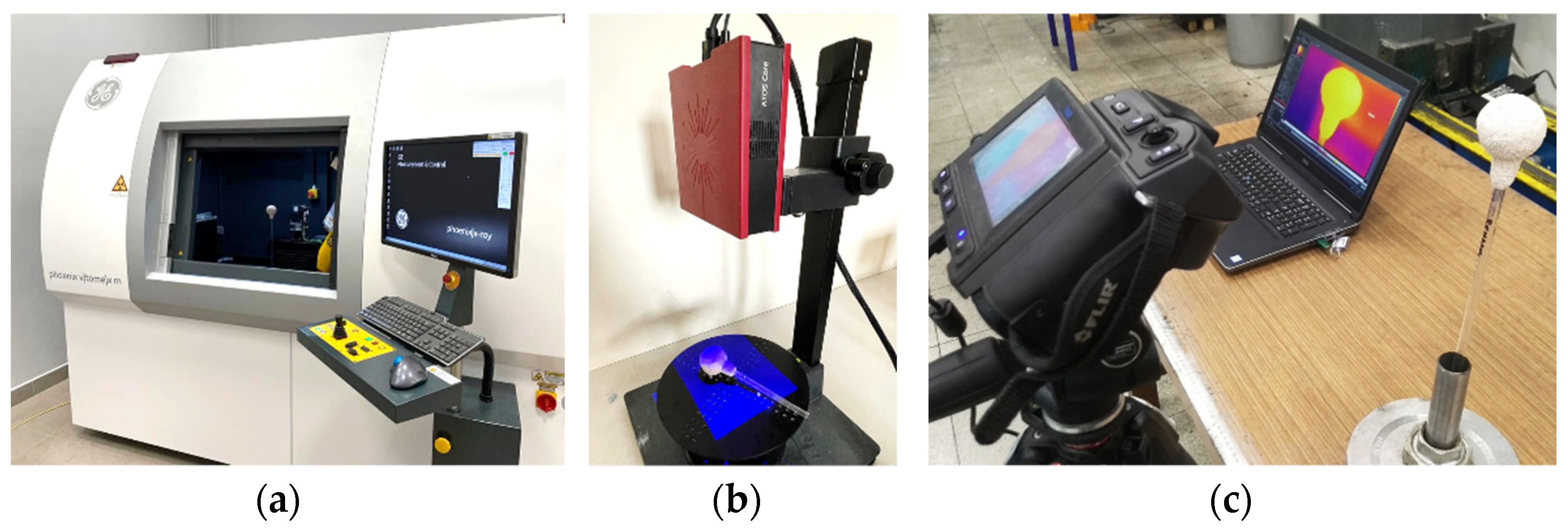

2. Materials and Methods

3. Results and Discussion

3.1. Results of Chemical Compositions of Molds

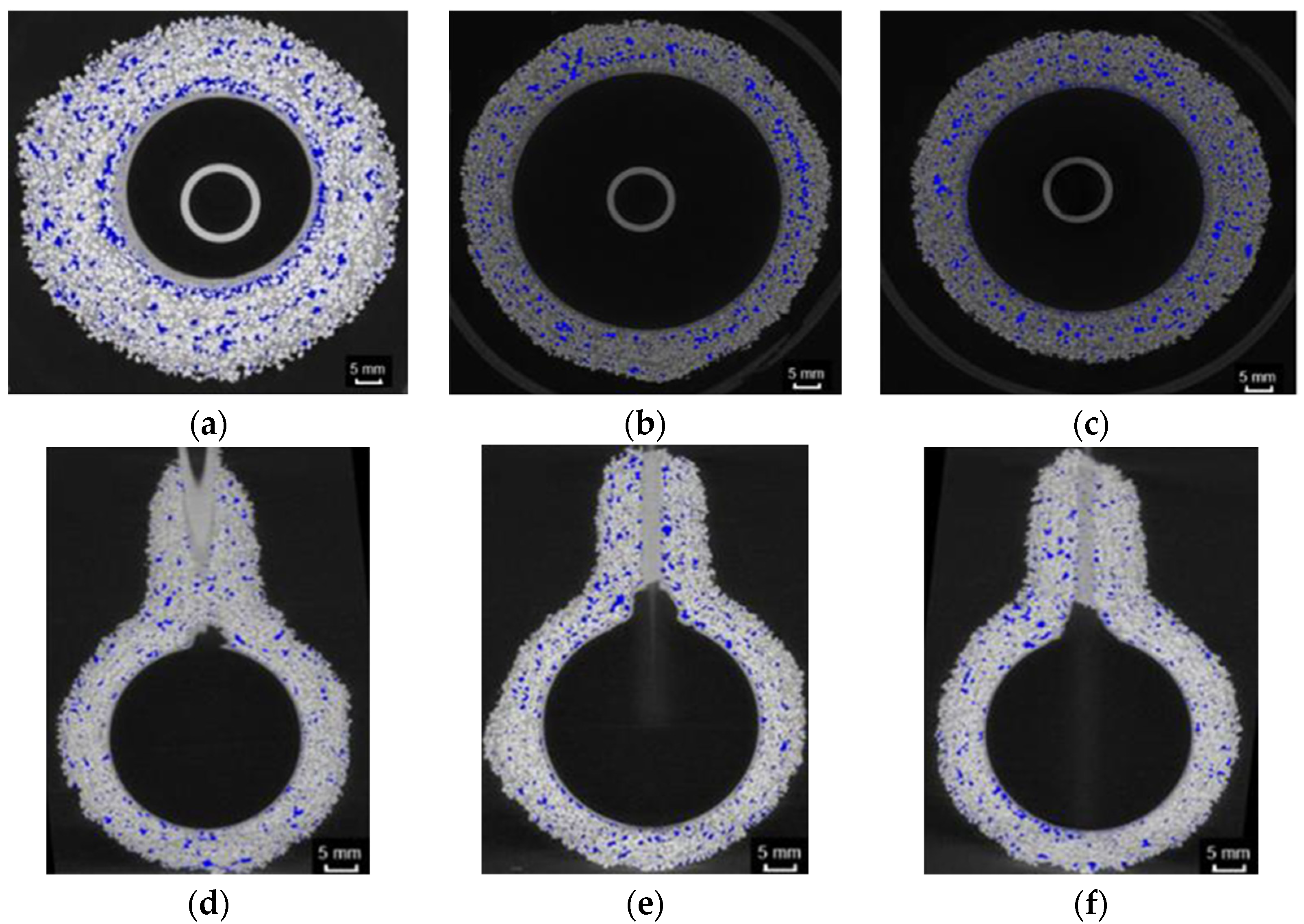

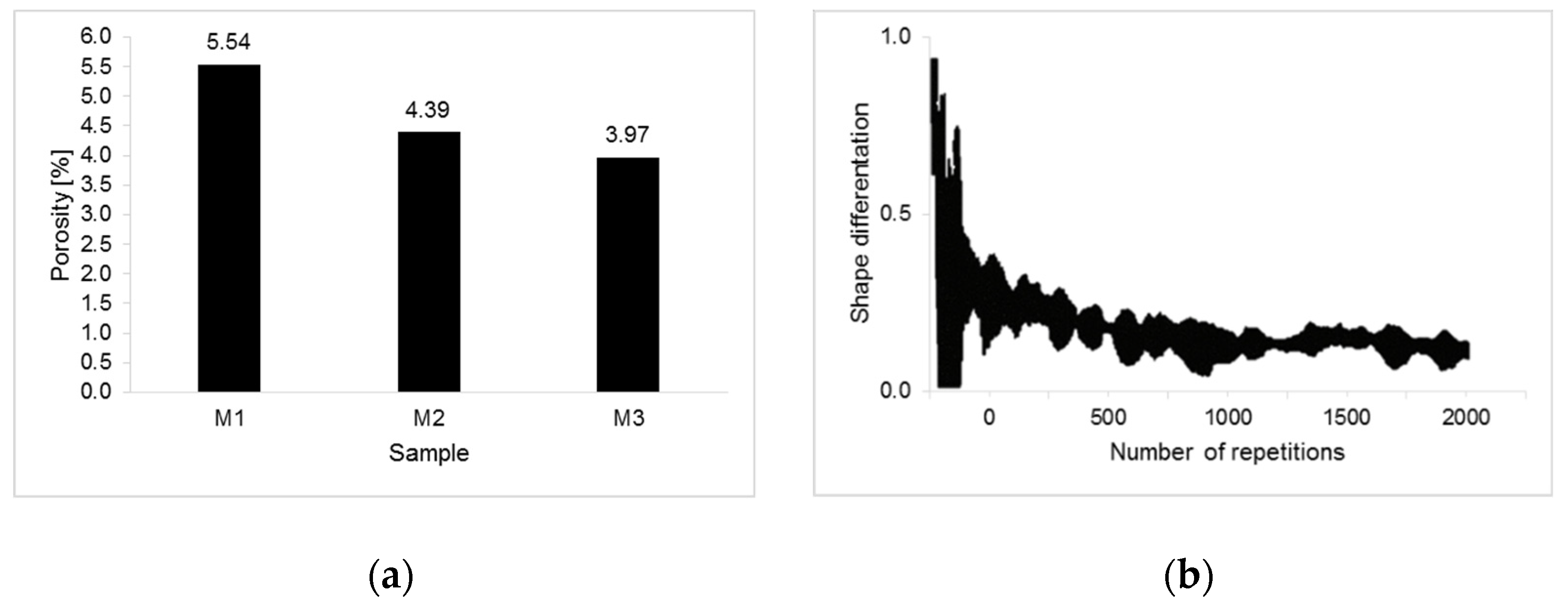

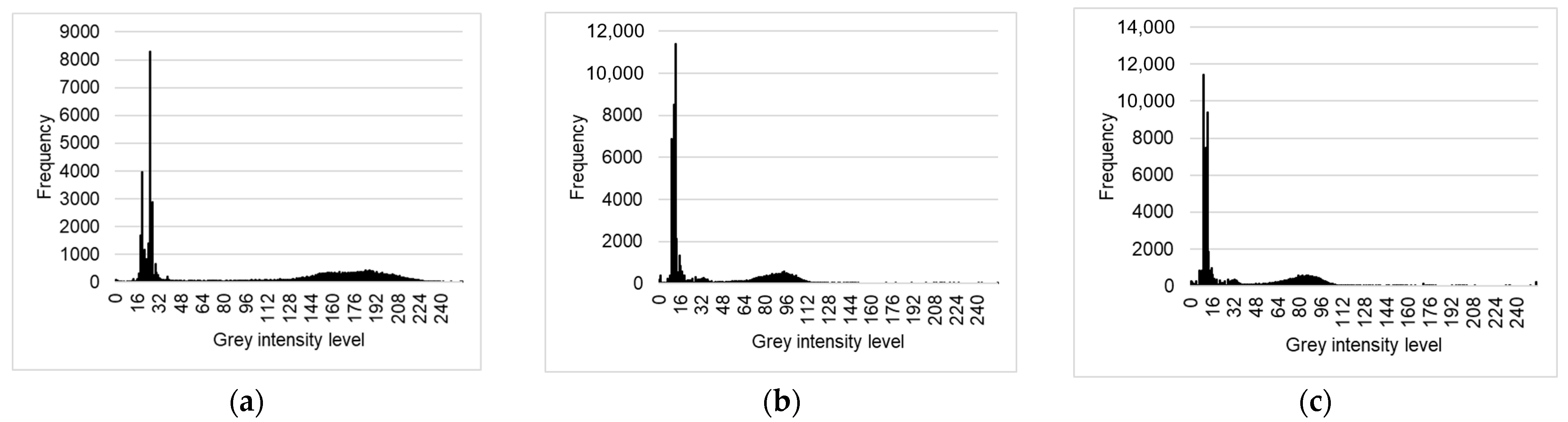

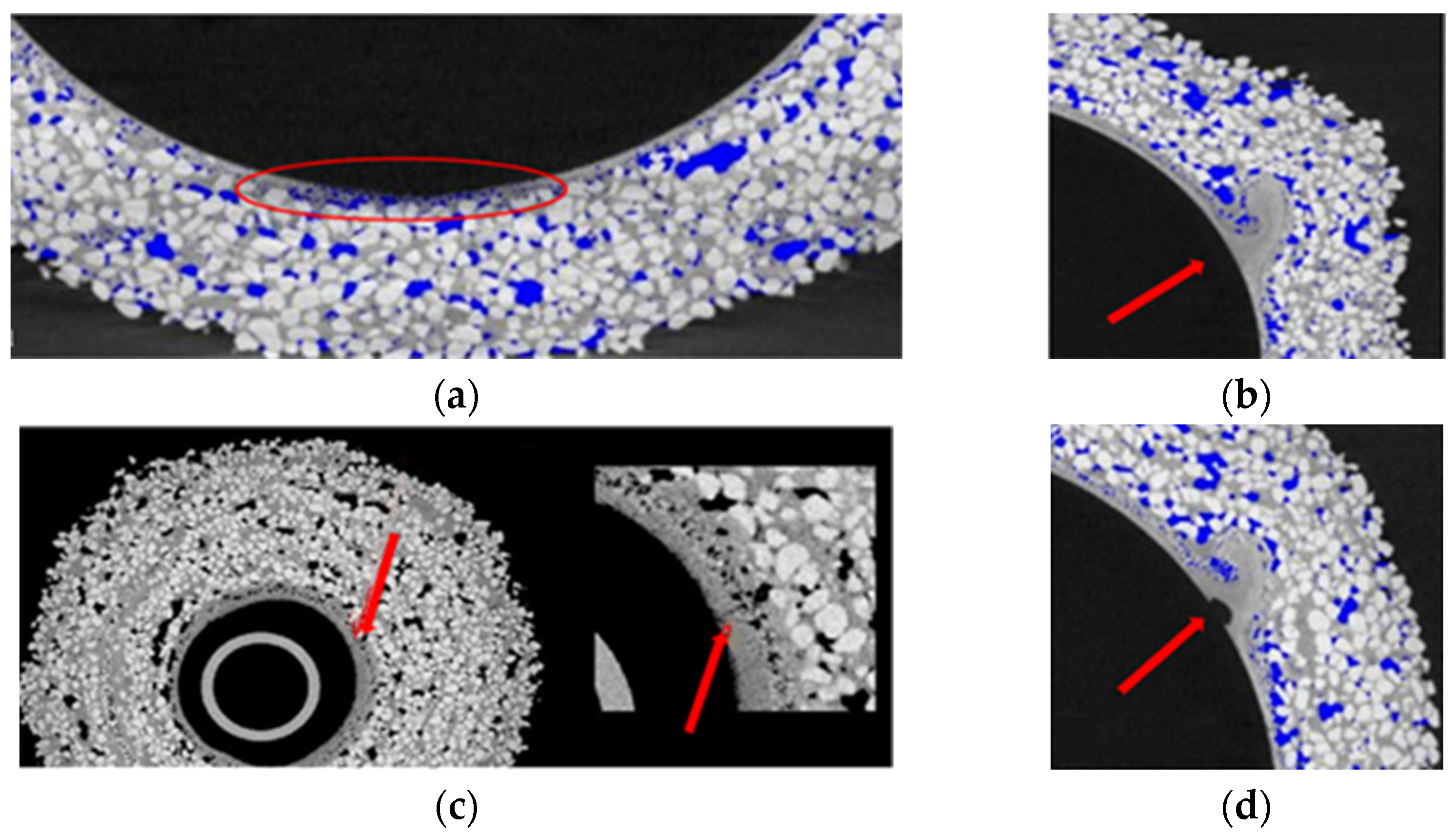

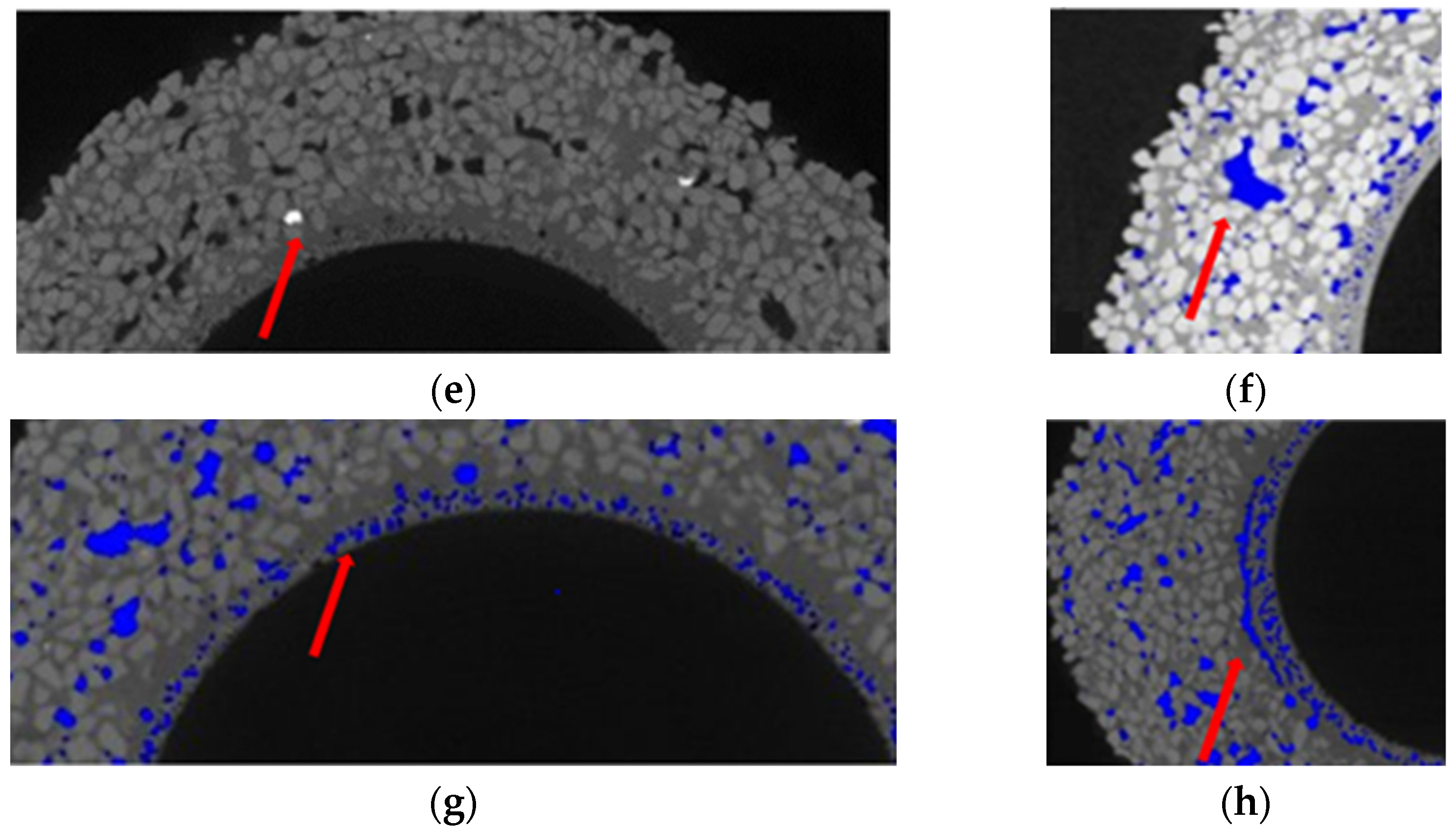

3.2. Results of CT Research

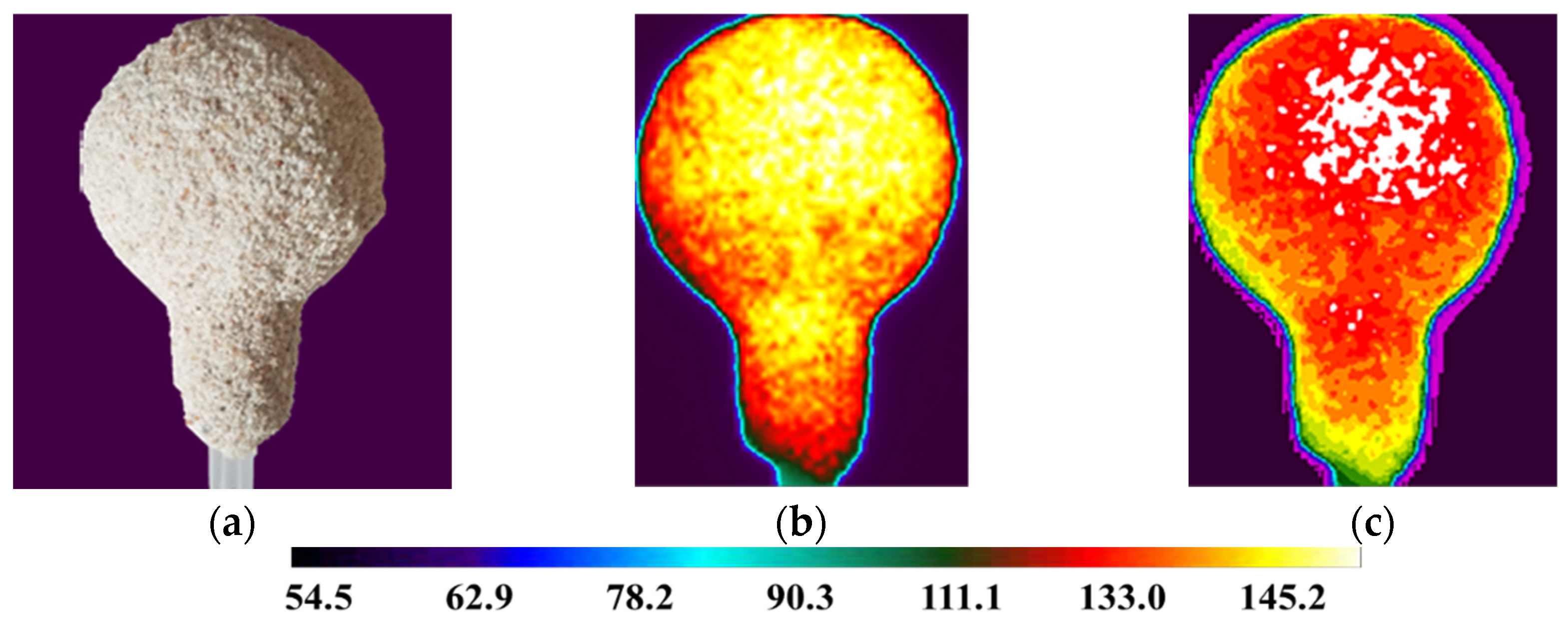

3.3. Results of 3D Scanning Research

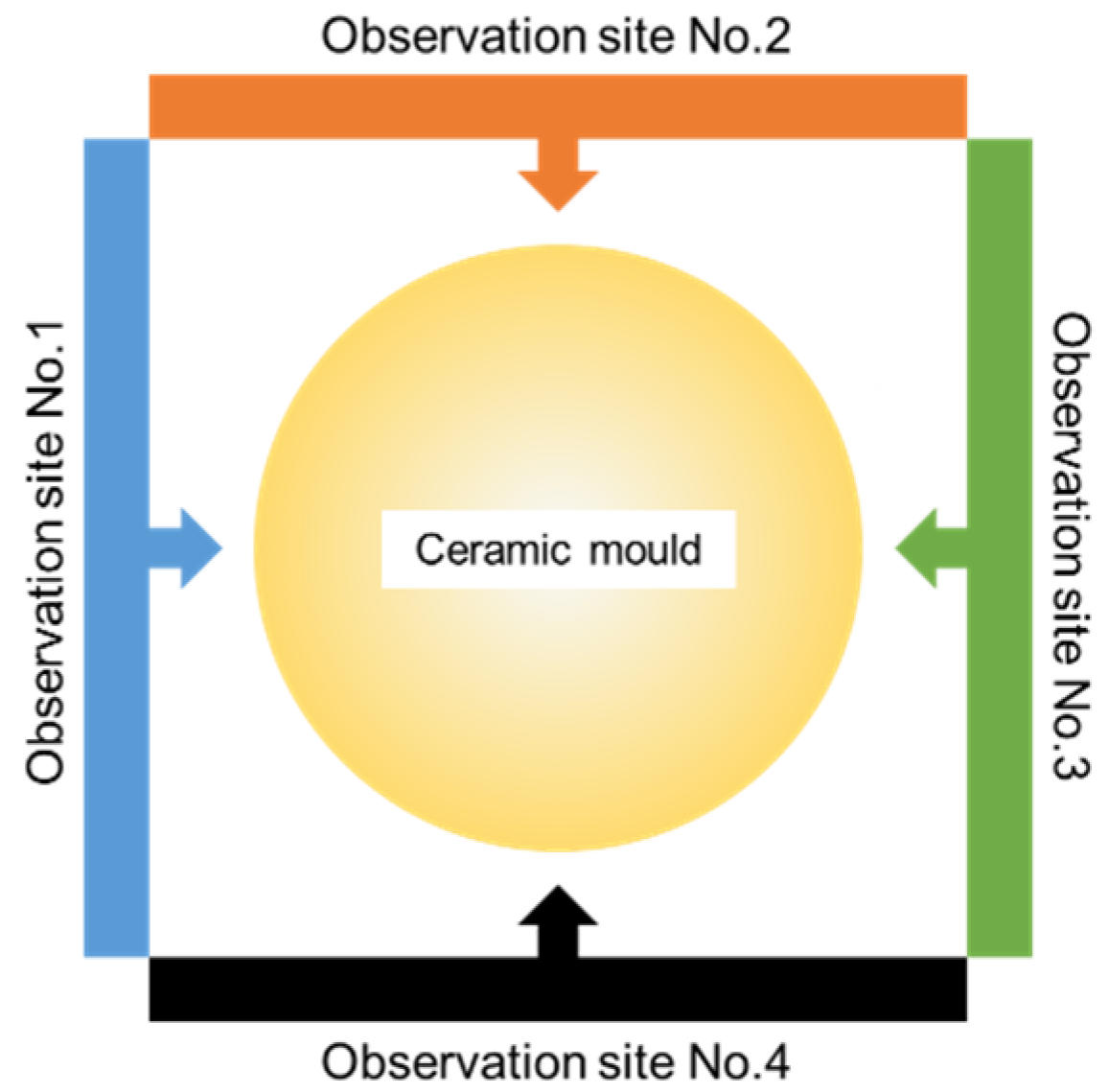

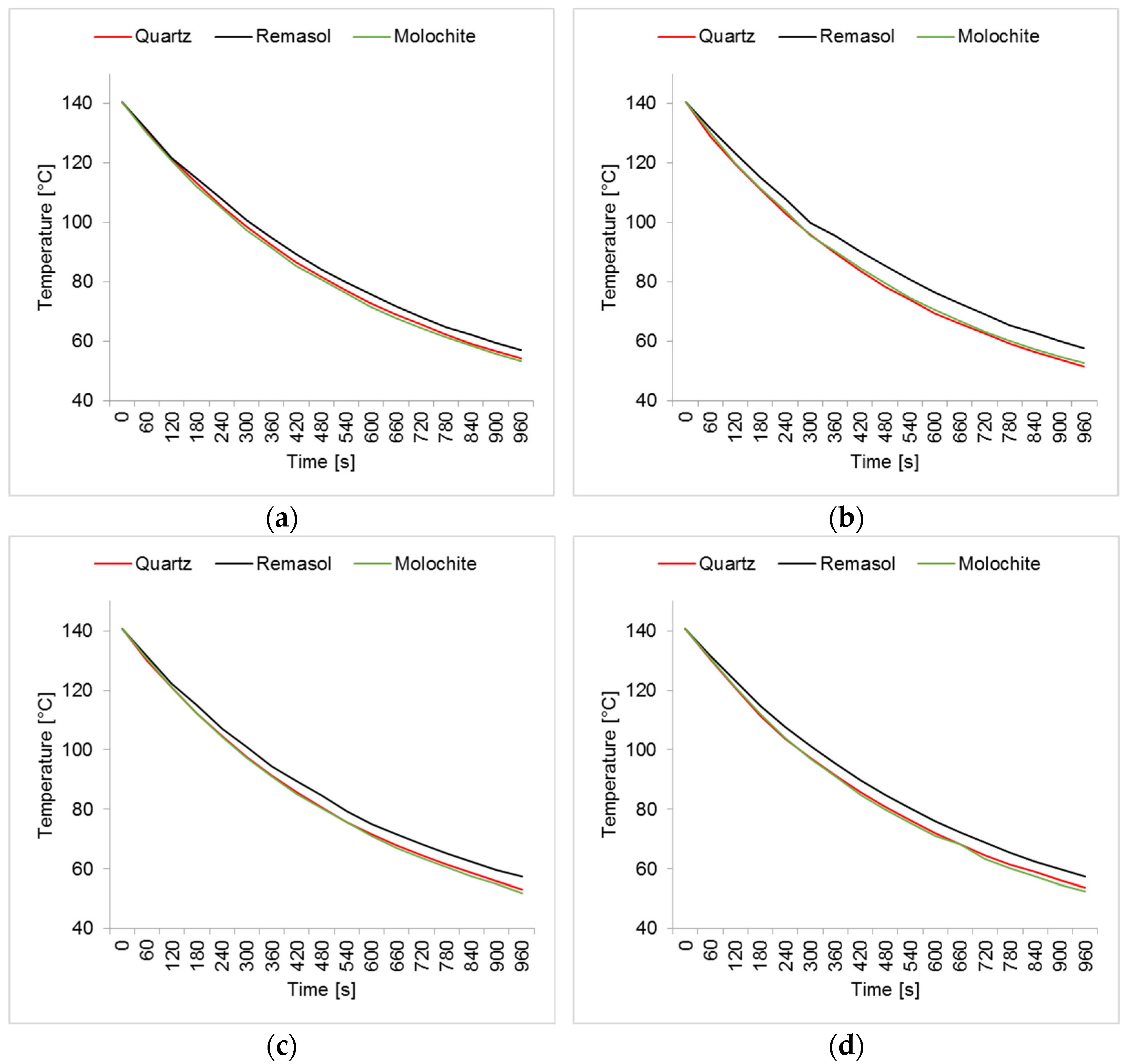

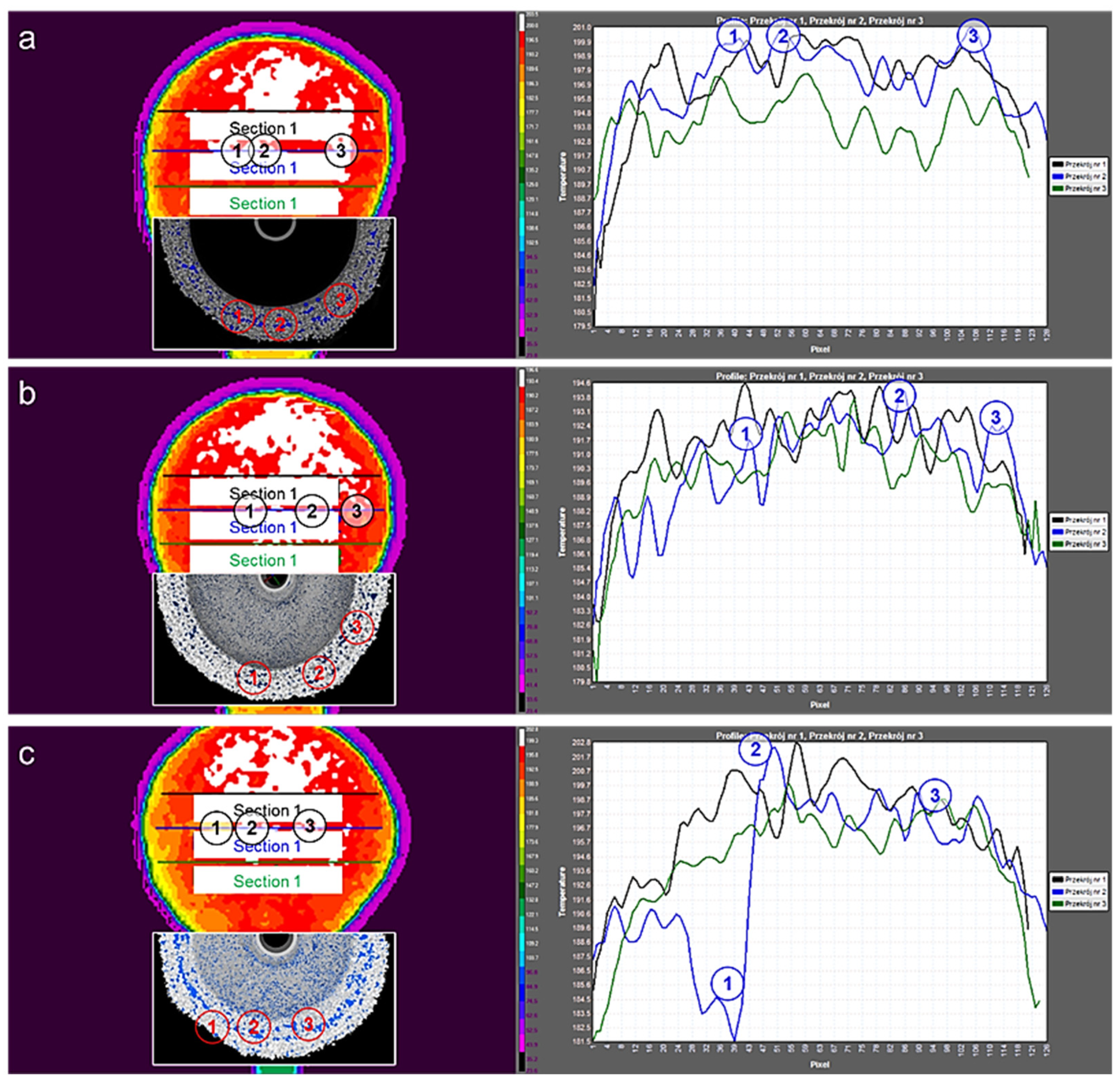

3.4. Results of Thermography Research

3.5. Results of Comparative Tests of NDT Methods Used

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bemblage, O.; Karunakar, D.B. A Study on the Blended Wax Patterns in Investment Casting Process. In Proceedings of the World Congress on Engineering, London, UK, 6–8 July 2011. [Google Scholar]

- Karwiński, A.; Młodecki, S.; Pabiś, R.; Robak, I.; Kubosz, G. New generation of pattern materials for investment casting. Arch. Foundry Eng. 2011, 11, 53–56. [Google Scholar]

- Sandhu, C.S.; Sharma, A. Investigation of Optimize Wax Pattern in the Investment Casting by Using the Different Form of Waxes. IOSR J. Mech. Civ. Eng. 2012, 3, 1–6. [Google Scholar] [CrossRef]

- Sharma, P.; Kasana, D.; Kumar, V.; Goel, C. Analysis the Properties of Lost Wax Process and Its Use ability Exploring Possibilities. Int. J. Eng. Sci. Invent. 2013, 2, 32–35. [Google Scholar]

- Guler, K.A.; Taslicukur, Z.; Ozer, G. Expanded Polystyrene (EPS) Pattern Application in Investment Casting and Chemical Removing. Ceram. Mater. 2011, 63, 138–142. [Google Scholar]

- Matysiak, H.; Haratym, R.; Biernacki, R. Evaluation of wax pattern properties in the lost–wax process. Arch. Foundry Eng. 2011, 11, 85–88. [Google Scholar]

- Zych, J.; Kolczyk, J.; Snopkiewicz, T. Methods Investigations of Properties of Wax Mixtures Used in the Investment Casting Technology–New Investigation. Arch. Foundry Eng. 2012, 12, 133–138. [Google Scholar] [CrossRef]

- Wawulska-Marek, P. A study on technological properties of investment casting waxes. Adv. Appl. Plasma Sci. 2015, 10, 37–40. [Google Scholar]

- Kolczyk, J.; Zych, J. High temperature strength of ceramic moulds applied in the investment casting method. Arch. Foundry Eng. 2011, 11, 121–124. [Google Scholar]

- Małek, M.; Wiśniewski, P.; Matysiak, H.; Zielinska, M.; Kurzydłowski, K.J. Yttrium (III) oxide application for manufacturing prime coat of ceramic shell moulds used in investment casting. Glass Ceram. 2013, 6, 8–11. [Google Scholar]

- Wiśniewski, P.; Małek, M.; Matysiak, H.; Zielinska, M.; Kurzydłowski, K.J. The Technological Properties of SiC Based Slurries for Manufacturing of Ceramic Shell Moulds for Aerospace Industry. Glass Ceram. 2014, 3, 11–15. [Google Scholar]

- Szeliga, D.; Kubiak, K. Investigation of casting–ceramic shell mould interface thermal resistance during solidification process of nickel based superalloy. Exp. Therm. Fluid Sci. 2017, 87, 149–160. [Google Scholar] [CrossRef]

- Rakoczy, Ł.; Grudzień, M.; Cygan, R. Influence of Melt-Pouring Temperature and Composition of Primary Coating of Shell Mould on Tensile Strength and Creep Resistance of Ni-Based Superalloy. J. Mater. Eng. Perform. 2019, 28, 3826–3834. [Google Scholar] [CrossRef]

- Haratym, R. Procesy Odlewania Precyzyjnego w Formy Ceramiczne; Oficyna Wydawnicza Politechniki Warszawskiej: Warszawa Poland, 1997. [Google Scholar]

- Cantatore, A.; Müller, P. Introduction to computed tomography. In Kgs.Lyngby: DTU Mechanical Engineering; DTU Mechanical Engineering: Copenhagen, Denmark, 2011. [Google Scholar]

- Cierniak, R. Tomografia Komputerowa: Budowa Urządzeń CT: Algorytmy Rekonstrukcyjne; Akademicka Oficyna Wydawnictwa EXIT: Katowice, Poland, 2005. [Google Scholar]

- Christoph, R.; Neumann, H.J. X–ray Tomography in Industrial Metrology; Süddeutscher Verlag Onpact GmbH: Freising, Germany, 2011. [Google Scholar]

- Stock, S. Microcomputed Tomography: Methodology and Applications; Taylor Francis Inc.: Abingdon-on-Thames, UK, 2019. [Google Scholar]

- Ratajczyk, E.; Woźniak, A. Współrzędnościowe Systemy Pomiarowe; OWPW: Warsaw, Poland, 2016. [Google Scholar]

- Bauer, W.; Bessler, F.T.; Zabler, E.; Bergmann, R.B. Computer tomography for nondestructive testing in the automotive industry. Dev. X-ray Tomogr. IV Int. Soc. Opt. Photonics 2004, 5535, 464–472. [Google Scholar]

- Ewert, U.; Fuchs, T. Progress in Digital Industrial Radiology Part II: Computed tomography (CT). Bad. Nieniszcz. Diagn. 2017, 1–2, 7–14. [Google Scholar]

- Yeung, H.Y.; Qin, L.; Lee, K.M.; Leung, K.-S.; Cheng, J.C.-Y. Quantification of Porosity, Connectivity and Material Density of Calcium Phosphate Ceramic Implants Using Micro–Computed Tomography. In Advanced Bioimaging Technologies in Assessment of the Quality of Bone and Scaffold Materials; Springer: Berlin/Heidelberg, Germany, 2007; pp. 289–305. [Google Scholar]

- Boden, S.; Bieberle, M.; Weickert, G.; Hampel, U. Three–dimensional analysis of macroporosity distributions in polyolefin particles using X–ray microtomography. Powder Technol. 2008, 188, 81–88. [Google Scholar] [CrossRef]

- Schock, J.; Liebl, S.; Achterhold, K.; Pfeiffer, F. Obtaining the spacing factor of microporous concrete using high–resolution Dual Energy X–ray Micro CT. Cem. Concr. Res. 2016, 89, 200–205. [Google Scholar] [CrossRef]

- Bartscher, M.; Neuschaefer-Rube, U.; Wäldele, F. Computed Tomography—A highly potential tool for industrial quality control and production near measurements. VDI–Berichte 2004, 1860, 477–482. [Google Scholar]

- Mikulski, S. Triangulation method to three-dimensional laser scanners. Comput. Appl. Electr. Eng. Proc. 2013, 75, 239–245. [Google Scholar]

- Helle, R.H.; Lemu, H.G. A case study on use of 3D scanning for reverse engineering and quality control. Mater. Today Proc. 2021, 45, 5255–5262. [Google Scholar] [CrossRef]

- Yao, A.W.L. Applications of 3D scanning and reverse engineering techniques for quality control of quick response products. Int. J. Adv. Manuf. Technol. 2005, 26, 1284–1288. [Google Scholar] [CrossRef]

- Starnes, M.A.; Carino, N.J.; Kausel, E.A. Preliminary Thermography Studies for Quality Control of Concrete Structures Strengthened with Fiber-Reinforced Polymer Composites. J. Mater. Civ. Eng. 2003, 15, 266–273. [Google Scholar] [CrossRef] [Green Version]

- Kachel, S.; Kozakiewicz, A.; Łącki, T.; Olejnik, A. Zastosowanie inżynierii odwrotnej do procesu odtwarzania geometrii układu wlotowego silnika RD-33 w samolocie MIG-29. Pr. Inst. Odlew. 2011, 213, 66–84. [Google Scholar]

- Milavanovic, B.; Pecur, I.B. Review of Active IR Thermography for Detection and Characterization of Defects in Reinfroced Concrete. J. Imaging 2016, 2, 11. [Google Scholar] [CrossRef]

- Maldague, X.P.V. Nondestructive Evaluation of Materials by Infrared Thermography; Springer: London, UK, 1993. [Google Scholar]

- Koralnik, M.K.; Wiśniewski, P.; Moszczyńska, D.; Mizera, J. Thermovisual estimation of the time necessary for drying the two outer layers of a ceramic casting die. Szkło Ceram. 2017, 1, 6–10. [Google Scholar]

- Wiśniewski, P.; Sitek, R.; Koralnik, M.; Spychalski, W.; Moszczyńska, D.; Mizera, J. Investigations of cooling process of ceramic shell samples by using a thermographic camera. Ceram. Mater. 2017, 69, 146–153. [Google Scholar]

- Żaba, K.; Włodarska, J.; Puchlerska, S. Selected Methods of NDT Uncertainty Analysis for Quality Rating in Multilayer Ceramic Moulds; METAL 2018; TANGER Ltd., Cop.: Ostrava, Czech Republic, 2018; pp. 1788–1794. [Google Scholar]

- Żaba, K.; Gracz, D.; Zych, Ł.; Książek, M.; Mizera, J. Porosity Analysis of Multilayer Ceramic Moulds Used in Investment Casting of Aircraft Engine Parts; METAL 2018; TANGER Ltd., Cop.: Ostrava, Czech Republic, 2018; pp. 1551–1556. [Google Scholar]

- Tchórz, A.; Książek, M.; Krzak, I.; Szczepaniak-Lalewicz, K.; Zaba, K. Evaluation of the internal structure of the multilayer ceramic mould for precision casting critical parts of aircraft engines by X-ray computed tomography. J. Powder Metall. Min. 2018, 7, 1–7. [Google Scholar]

- Żaba, K.; Balcerzak, M.; Puchlerska, S.; Pieja, T. Application of 3D Scanning to Evaluating the Quality of Ceramic Forms; METAL 2018; TANGER Ltd., Cop.: Ostrava, Czech Republic, 2018; pp. 1460–1465. [Google Scholar]

- Liu, C.; Jin, S.; Lai, X.; Wang, F.; Li, F. Permafrost Analysis Methodology (Pam) For Ceramic Shell Deformation in the Firing Process. Int. J. Metalcast. 2019, 13, 953–968. [Google Scholar] [CrossRef]

- Bansode, S.N.; Phalle, V.M.; Mantha, S.S. Influence of Slurry Composition on Mould Properties and Shrinkage of Investment Casting. Trans. Indian Inst. Met. 2020, 73, 763–773. [Google Scholar] [CrossRef]

- Kanyo, J.E.; Schafföner, S.; Uwanyuze, S.R.; Leary, K.S. An overview of ceramic molds for investment casting of nickel superalloys. J. Eur. Ceram. Soc. 2020, 40, 4955–4973. [Google Scholar] [CrossRef]

- Wiśniewski, P.; Sitek, R.; Towarek, A.; Choinska, E.; Moszczyńska, D.; Mizera, J. Molding Binder Influence on the Porosity and Gas Permeability of Ceramic Casting Molds. Materials 2020, 13, 2735. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Karunakar, D.B. Characterization and Properties of Ceramic Shells in Investment Casting Process. Int. J. Metalcast. 2020, 15, 1–10. [Google Scholar] [CrossRef]

- Kaila, V.N.; Dave, I.B. The influence of coating sand materials on shell mold properties of Investment casting process. Mater. Today Proc. 2021, 43, 800–804. [Google Scholar] [CrossRef]

- Park, K.; Withey, P. General View of Rhenium-Rich Particles along Defect Grain Boundaries Formed in Nickel-Based Single-Crystal Superalloy Turbine Blades: Formation, Dissolution and Comparison with Other Phases. Crystals 2021, 11, 1201. [Google Scholar] [CrossRef]

- Pereira, J.C.; Aranzabe, J.; Taboada, M.C.; Ruiz, N.; Rodriguez, P.P. Analysis of Microstructure and Mechanical Properties in As-Built/As-Cast and Heat-Treated Conditions for IN718 Alloy Obtained by Selective Laser Melting and Investment Casting Processes. Crystals 2021, 11, 1196. [Google Scholar] [CrossRef]

| Sample | Coat | Binder | Ceramic Material |

|---|---|---|---|

| M1 | 1 | Ludox PX 30 + molochite flour | molochite sand 0.1–0.3 mm |

| 2 | ZKE + molochite flour | molochite sand 0.1–0.3 mm | |

| 3 | Ludox PX 30 + molochite flour | molochite sand 0.5–1.0 mm | |

| 4–7 | alternately Ludox PX 30 i ZKE | molochite sand 0.5–1.0 mm | |

| M2 | 1 | hydrolyzed ethyl silicate | quartz sand 0.1–0.3 mm |

| 2 | ZKE + quartz flour | quartz sand 0.1–0.3 mm | |

| 3 | Ludox PX 30 + quartz flour | quartz sand 0.5–1.0 mm | |

| 4–7 | alternately Ludox PX 30 i ZKE | quartz sand 0.5–1.0 mm | |

| M3 | 1 | Remasol Plus + quartz flour | quartz sand 0.1–0.3 mm |

| 2 | Remasol Plus + quartz flour | quartz sand 0.1–0.3 mm | |

| 3–7 | Remasol Premium + quartz flour | quartz sand 0.5–1.0 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Żaba, K.; Puchlerska, S.; Książek, M.; Sitek, R.; Wiśniewski, P.; Mizera, J. Investigations of Model Multilayer Ceramic Casting Molds in a Raw State by Nondestructive Methods. Materials 2021, 14, 7761. https://doi.org/10.3390/ma14247761

Żaba K, Puchlerska S, Książek M, Sitek R, Wiśniewski P, Mizera J. Investigations of Model Multilayer Ceramic Casting Molds in a Raw State by Nondestructive Methods. Materials. 2021; 14(24):7761. https://doi.org/10.3390/ma14247761

Chicago/Turabian StyleŻaba, Krzysztof, Sandra Puchlerska, Marzanna Książek, Ryszard Sitek, Paweł Wiśniewski, and Jarosław Mizera. 2021. "Investigations of Model Multilayer Ceramic Casting Molds in a Raw State by Nondestructive Methods" Materials 14, no. 24: 7761. https://doi.org/10.3390/ma14247761

APA StyleŻaba, K., Puchlerska, S., Książek, M., Sitek, R., Wiśniewski, P., & Mizera, J. (2021). Investigations of Model Multilayer Ceramic Casting Molds in a Raw State by Nondestructive Methods. Materials, 14(24), 7761. https://doi.org/10.3390/ma14247761