Effect of μPlasma Modification on the Wettability and the Ageing Behaviour of Glass Fibre Reinforced Polyamide 6 (GFPA6)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

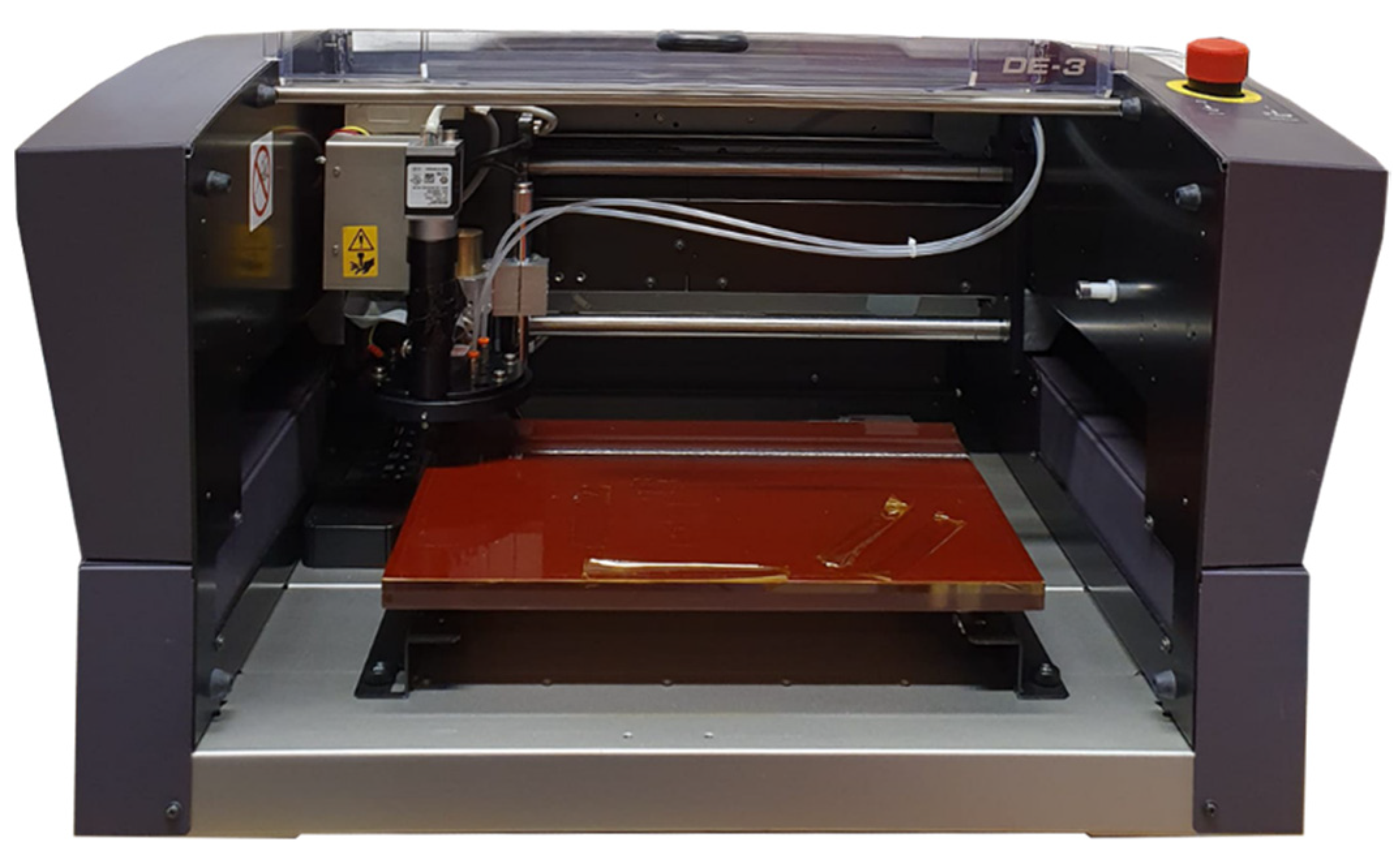

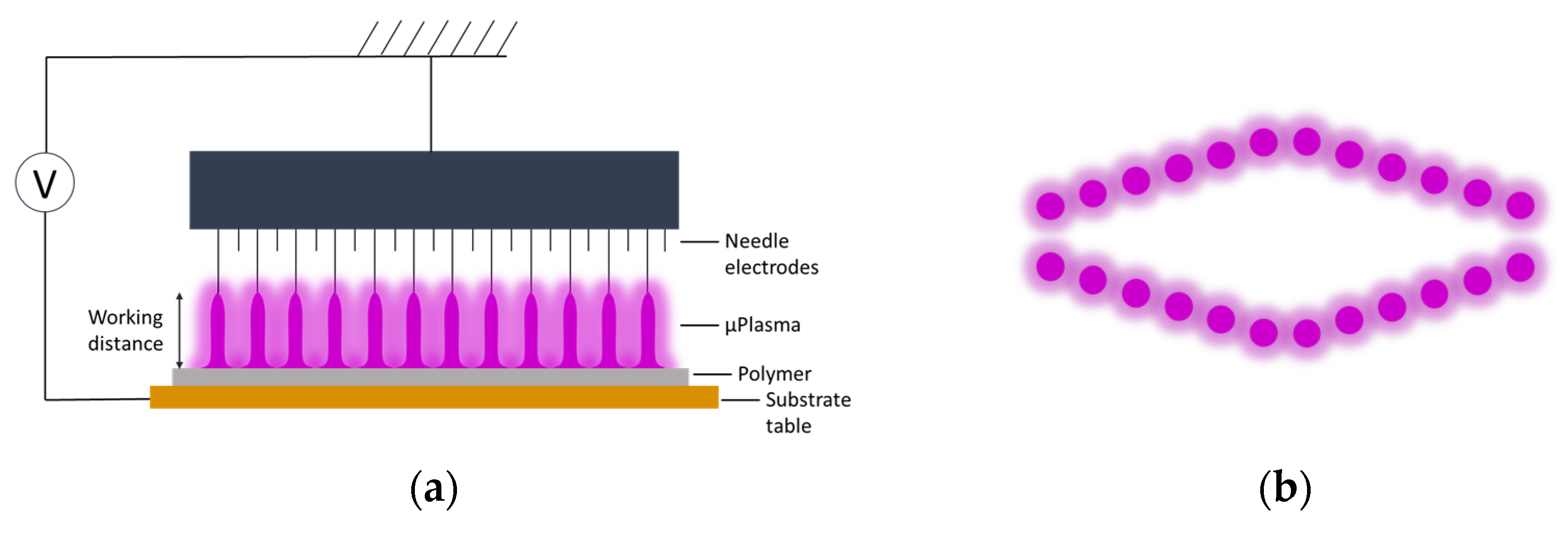

2.2. μPlasma Modification

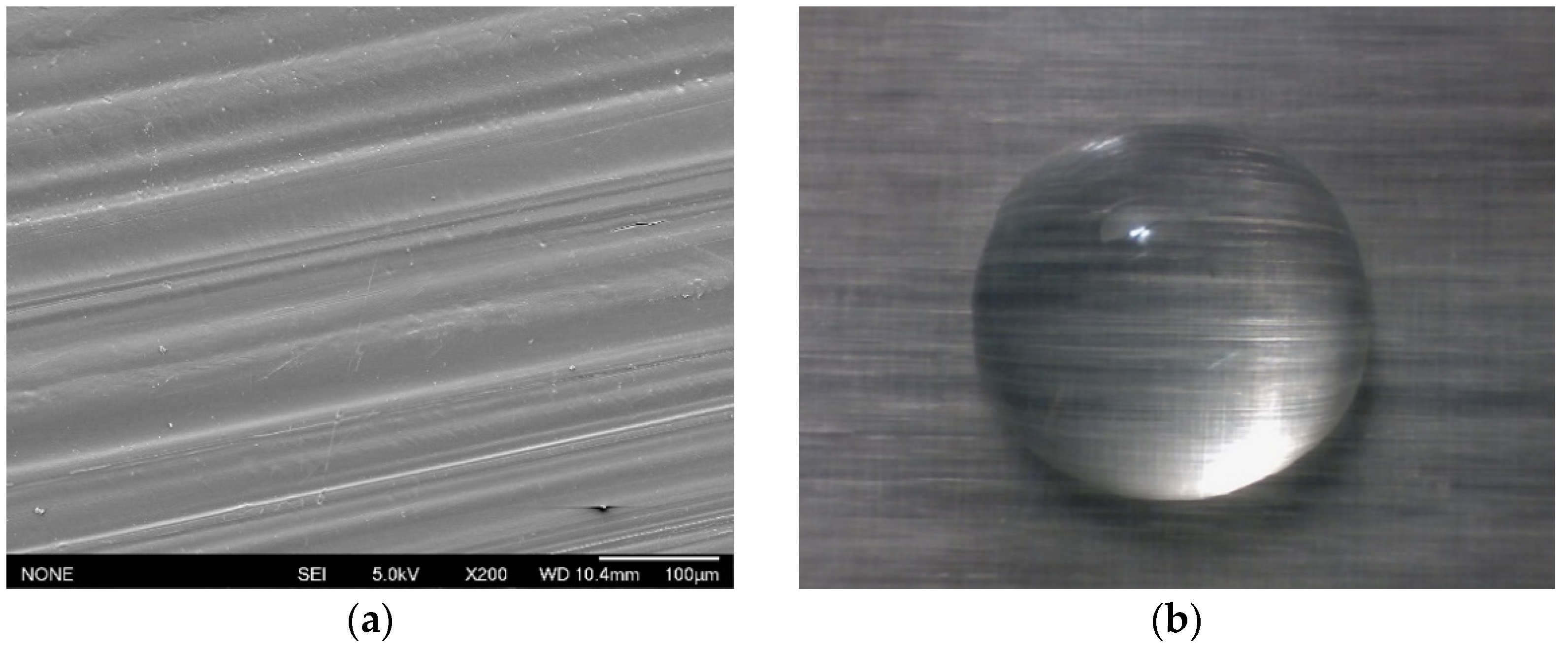

2.3. Scanning Electron Microscopy (SEM)

2.4. Contact Angle Testing

2.5. Wetting Envelope and Surface Free Energy

3. Results and Discussion

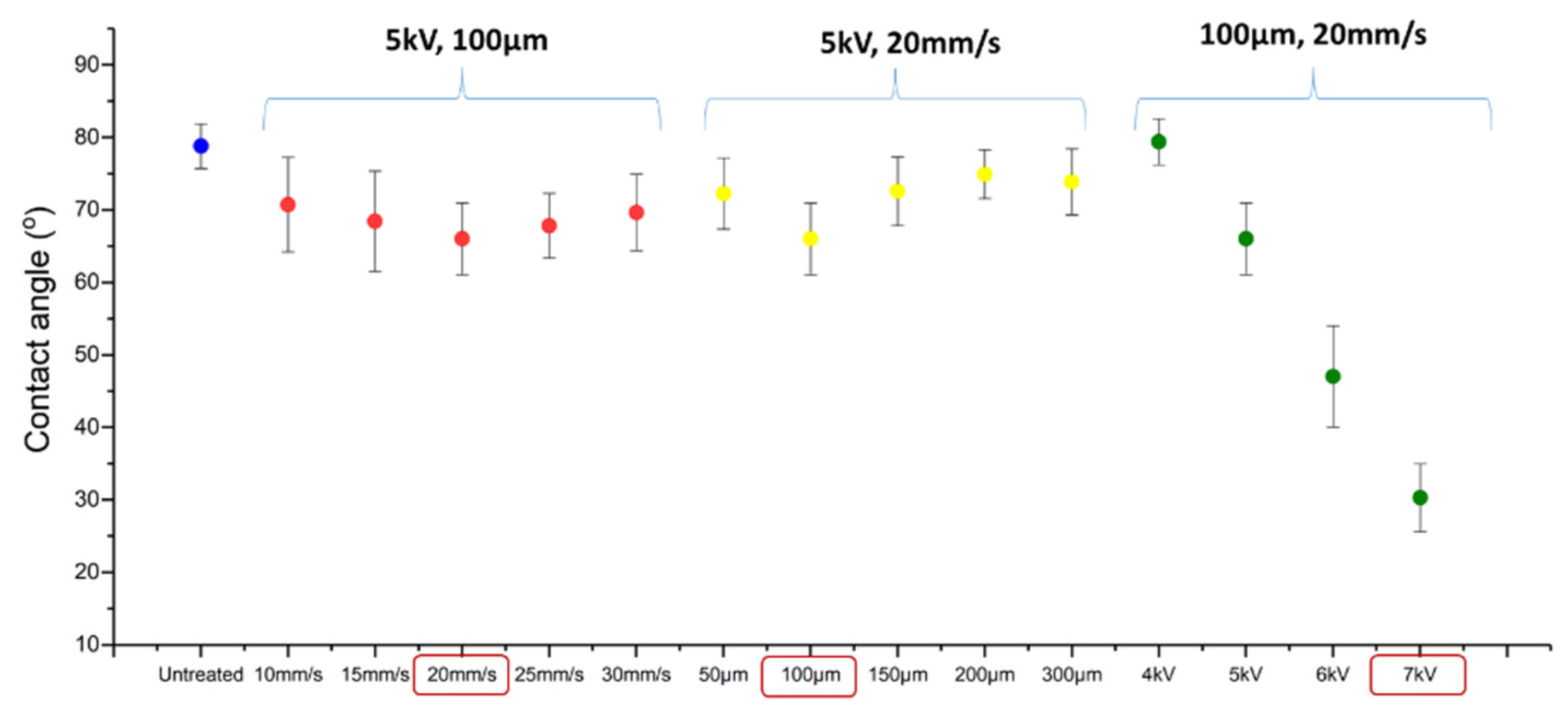

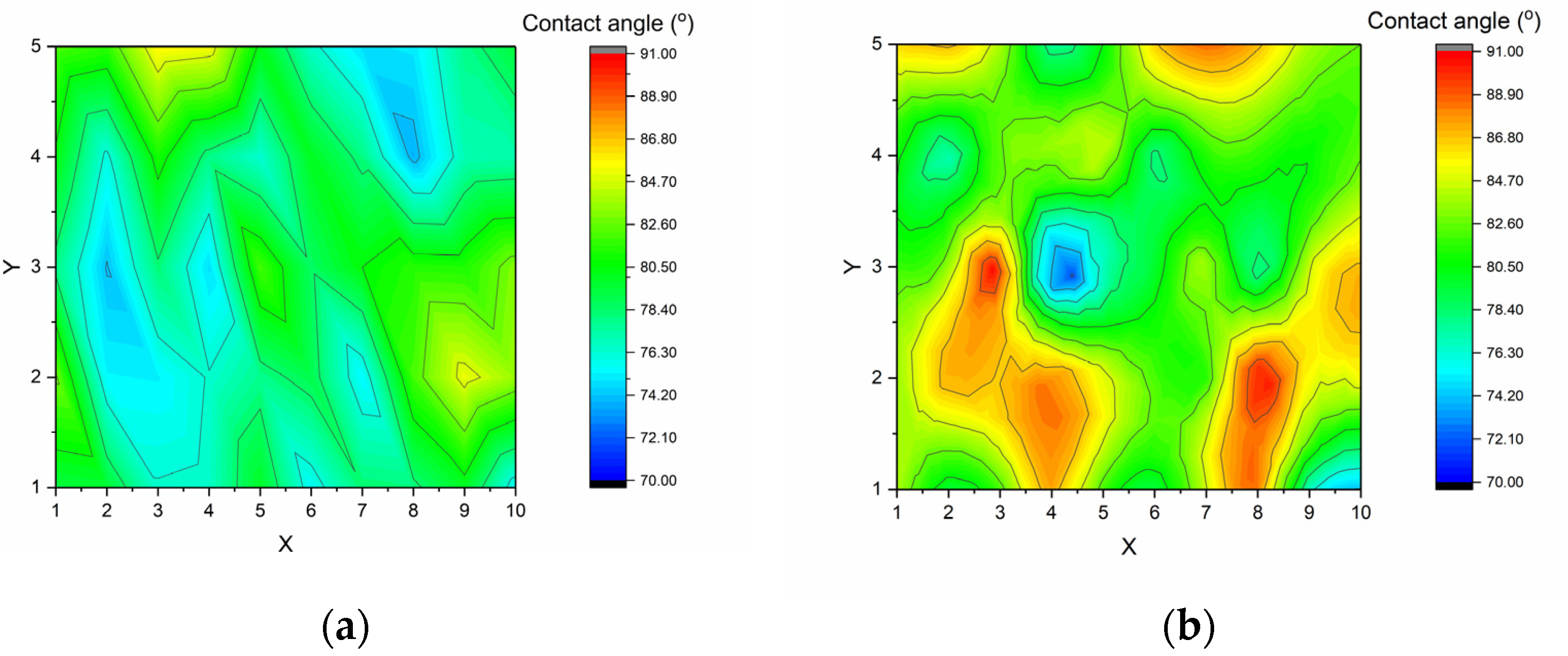

3.1. μPlasma Modification Process Optimisation

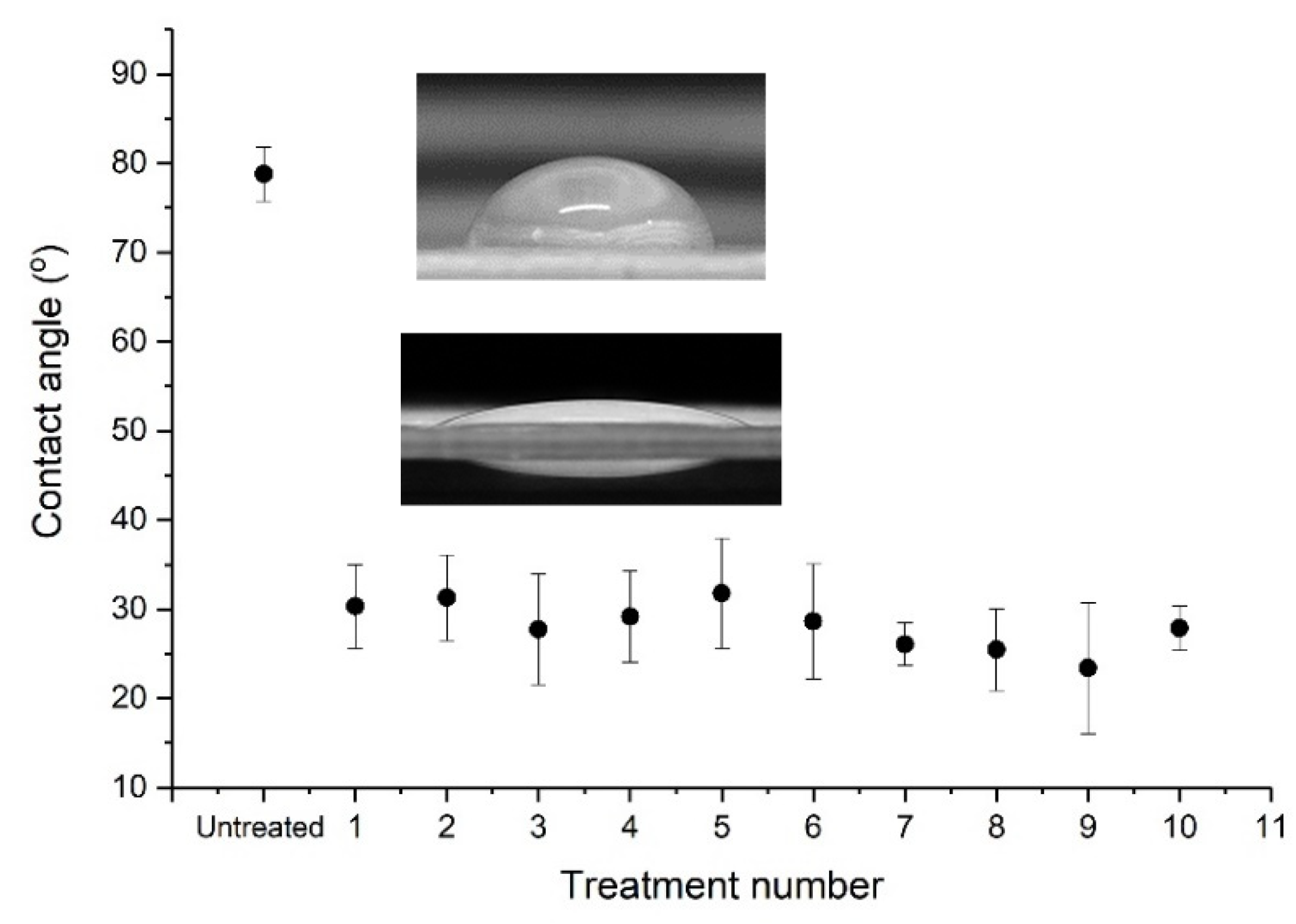

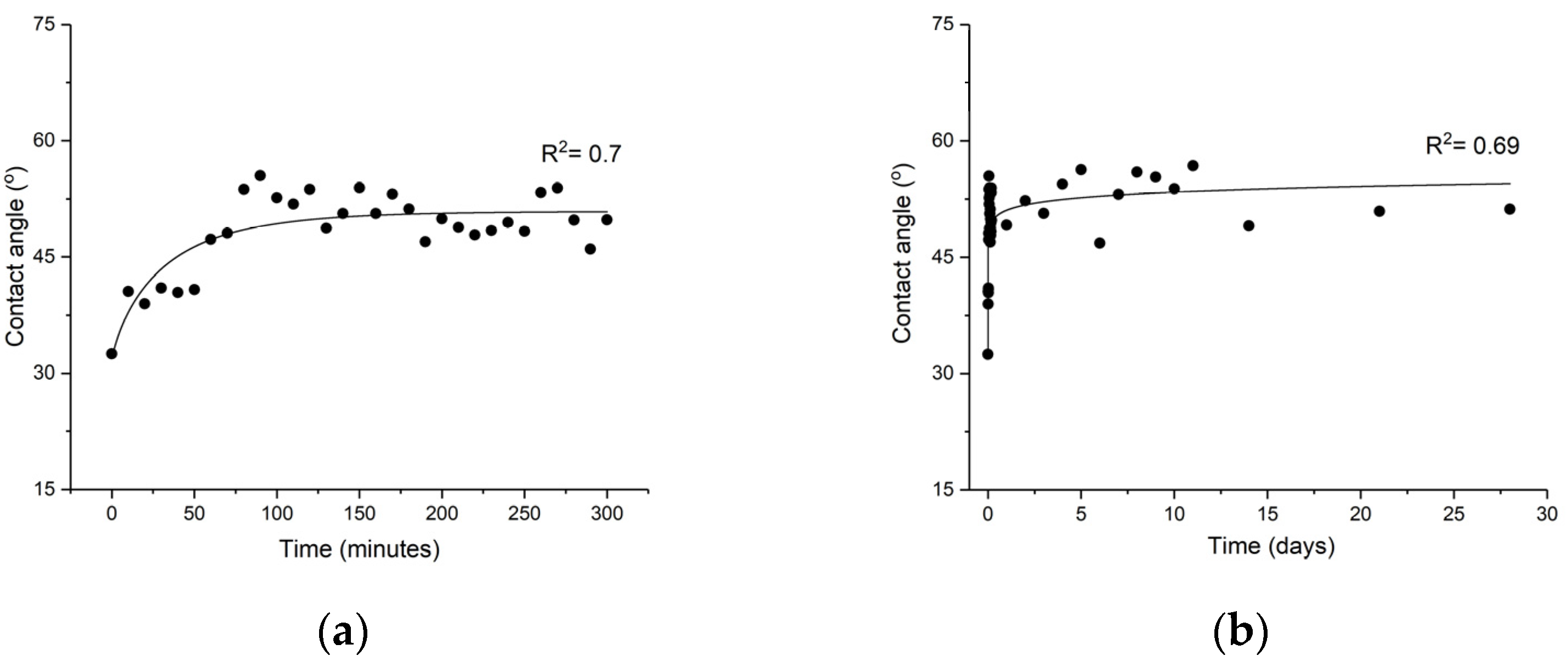

3.2. Ageing of GFPA6 Surface after μPlasma Modification

3.3. Optimisation of the Contact Angle Measurement Procedure

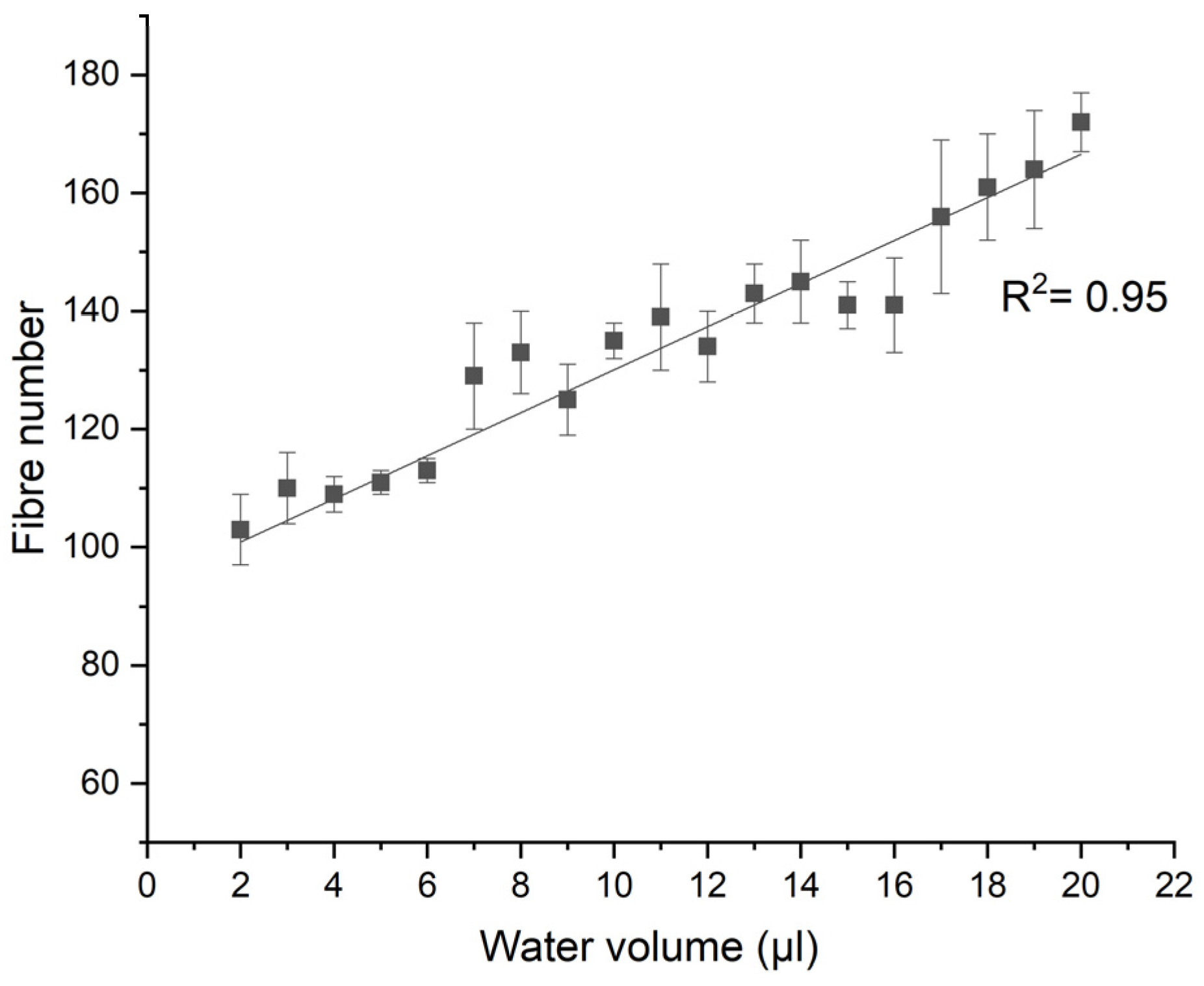

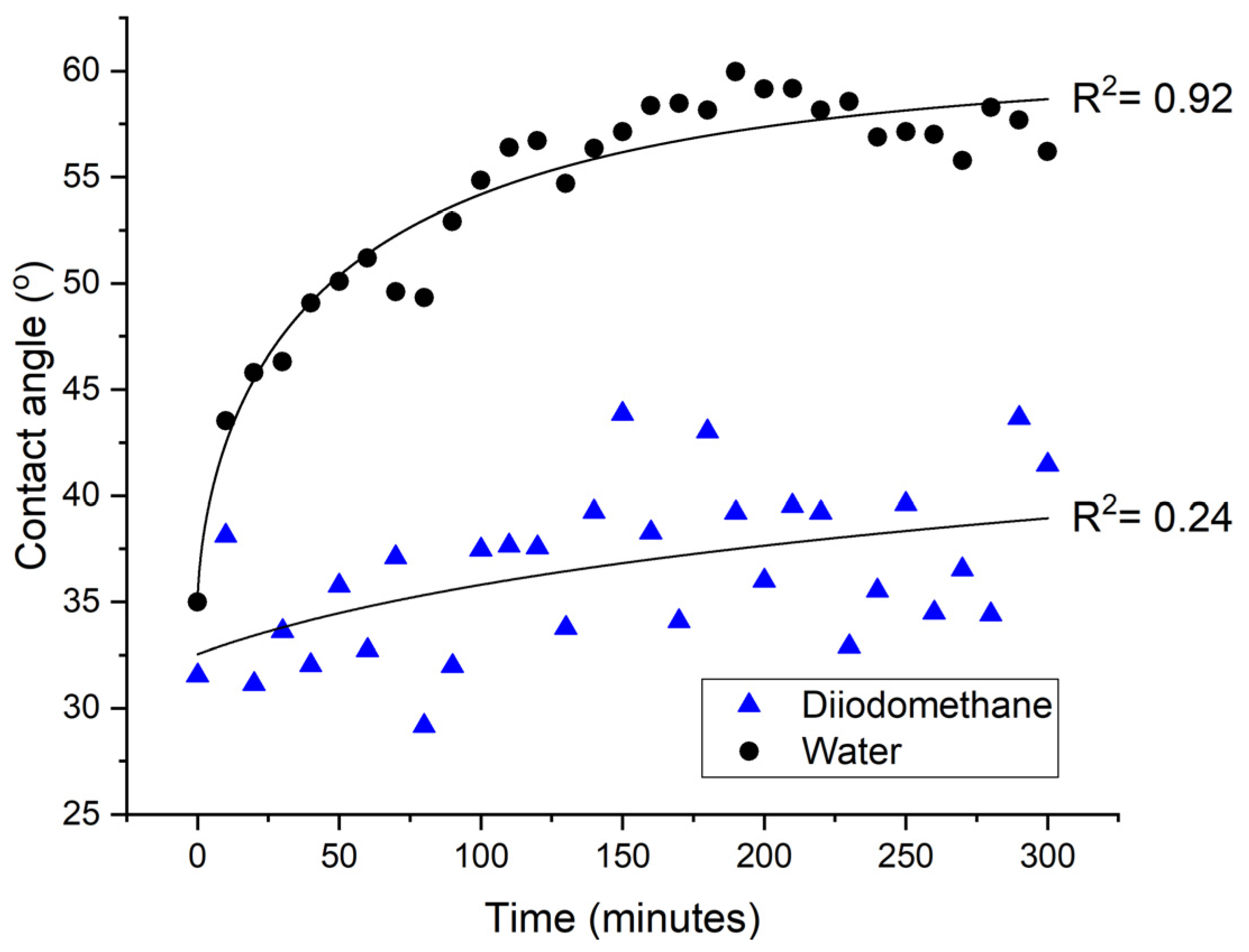

3.3.1. Optimisation of the Contact Angle Measurement Protocol

3.3.2. Optimisation of the Wettability Ageing of GFPA6 Samples

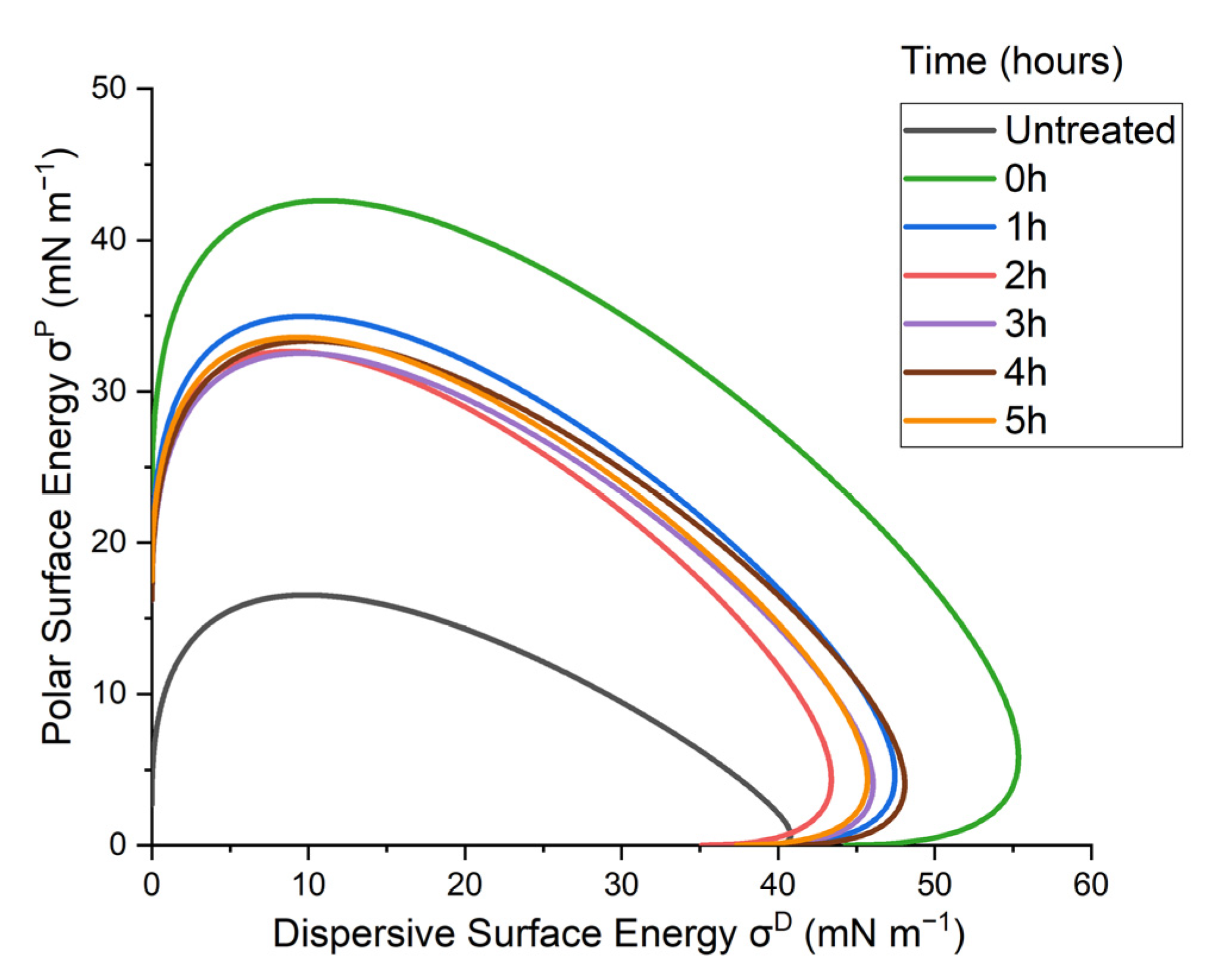

3.4. Wetting Envelope and Surface Energy

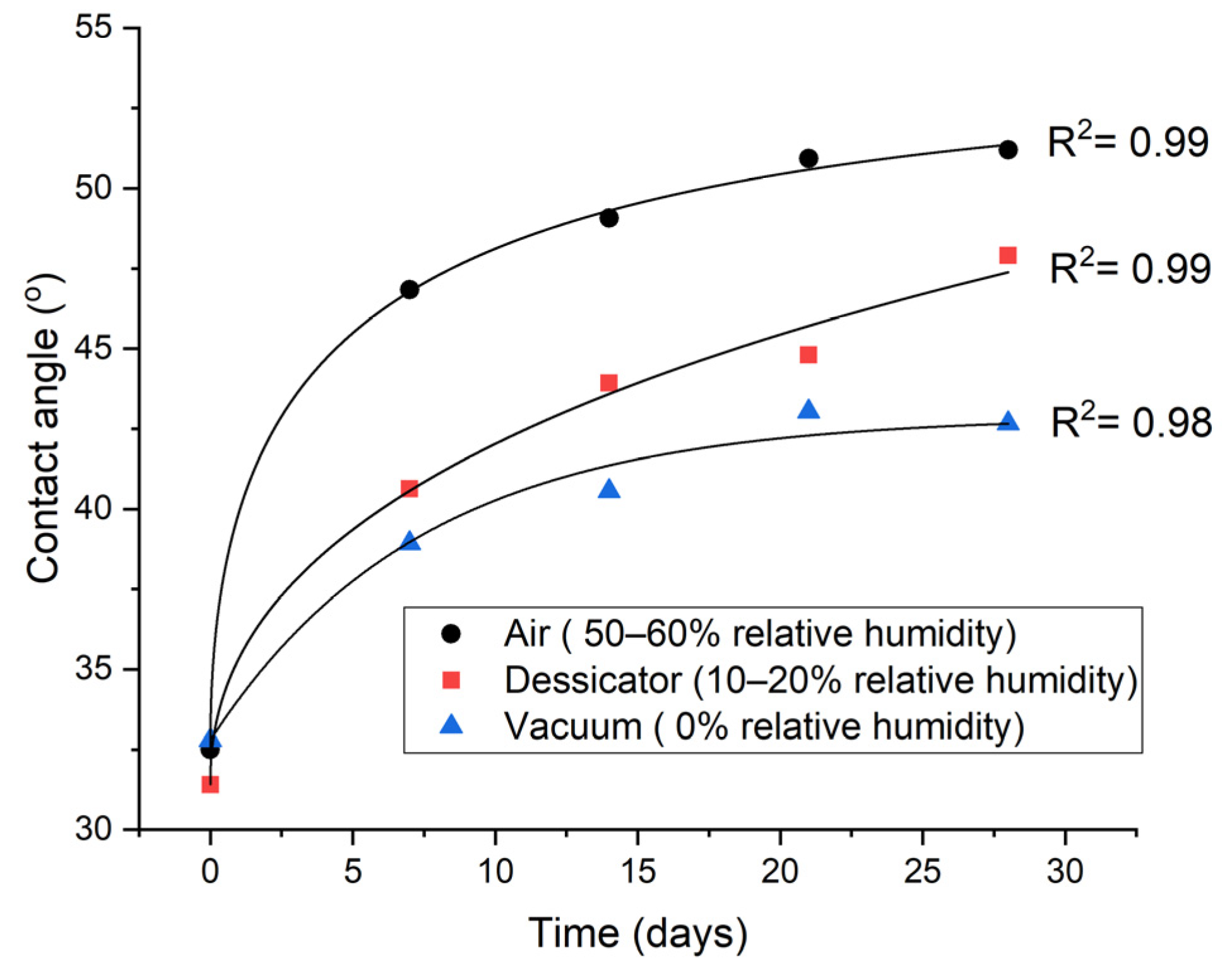

3.5. Storage of Treated GFPA6

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kiss, P.; Schoefer, J.; Stadlbauer, W.; Burgstaller, C.; Archodoulaki, V.-M. An experimental study of glass fibre roving sizings and yarn finishes in high-performance GF-PA6 and GF-PPS composite laminates. Compos. Part B Eng. 2021, 204, 108487. [Google Scholar] [CrossRef]

- Cartledge, H.C.; Baillie, C.; Mai, Y.-W. Friction and wear mechanisms of a thermoplastic composite GF/PA6 subjected to different thermal histories. Wear 1996, 194, 178–184. [Google Scholar] [CrossRef]

- Thomason, J. The influence of fibre length, diameter and concentration on the modulus of glass fibre reinforced polyamide 6, 6. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1732–1738. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Gao, H. Fibre Reinforced Polymer Composites. In Advances in Machining of Composite Materials; Springer: Berlin/Heidelberg, Germany, 2021; pp. 15–43. [Google Scholar]

- Wei, X.-F.; Kallio, K.J.; Bruder, S.; Bellander, M.; Olsson, R.T.; Hedenqvist, M.S. High-performance glass-fibre reinforced biobased aromatic polyamide in automotive biofuel supply systems. J. Clean. Prod. 2020, 263, 121453. [Google Scholar] [CrossRef]

- Mouhmid, B.; Imad, A.; Benseddiq, N.; Benmedakhène, S.; Maazouz, A. A study of the mechanical behaviour of a glass fibre reinforced polyamide 6, 6: Experimental investigation. Polym. Test. 2006, 25, 544–552. [Google Scholar] [CrossRef]

- Thomason, J. The influence of fibre properties of the performance of glass-fibre-reinforced polyamide 6, 6. Compos. Sci. Technol. 1999, 59, 2315–2328. [Google Scholar] [CrossRef]

- Xiao, Y.; Mu, X.; Wang, B.; Hu, W.; Wang, J.; Zhou, F.; Ma, C.; Hu, Y.; Song, L. A novel phosphorous-containing polymeric compatibilizer: Effective reinforcement and flame retardancy in glass fiber reinforced polyamide 6 composites. Compos. Part B Eng. 2021, 205, 108536. [Google Scholar] [CrossRef]

- Myshkin, N.; Kovalev, A. Adhesion and surface forces in polymer tribology—A review. Friction 2018, 6, 143–155. [Google Scholar] [CrossRef]

- Canal, C.; Molina, R.; Bertran, E.; Erra, P. Wettability, ageing and recovery process of plasma-treated polyamide 6. J. Adhes. Sci. Technol. 2004, 18, 1077–1089. [Google Scholar] [CrossRef]

- Dashtbozorg, B.; Penchev, P.; Romano, J.-M.; Li, X.; Sammons, R.L.; Dimov, S.; Dong, H. Development of surfaces with antibacterial durability through combined S phase plasma hardening and athermal femtosecond laser texturing. Appl. Surf. Sci. 2021, 565, 150594. [Google Scholar] [CrossRef]

- Erfani Gahrooei, H.R.; Ghazanfari, M.H.; Karimi Malekabadi, F. Wettability alteration of reservoir rocks to gas wetting condition: A comparative study. Can. J. Chem. Eng. 2018, 96, 997–1004. [Google Scholar] [CrossRef]

- Kim, J.W.; Yoo, S.H.; Kong, Y.B.; Cho, S.O.; Lee, E.J. Hydrophilicity Improvement of Polymer Surfaces Induced by Simultaneous Nuclear Transmutation and Oxidation Effects Using High-Energy and Low-Fluence Helium Ion Beam Irradiation. Polymers 2020, 12, 2770. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Yin, X.; Jin, J. A Study on the Wettability of Ion-Implanted Stainless and Bearing Steels. Metals 2019, 9, 208. [Google Scholar] [CrossRef] [Green Version]

- Abbasi, F.; Mirzadeh, H.; Katbab, A.A. Modification of polysiloxane polymers for biomedical applications: A review. Polym. Int. 2001, 50, 1279–1287. [Google Scholar] [CrossRef]

- Dong, H.; Bell, T. State-of-the-art overview: Ion beam surface modification of polymers towards improving tribological properties. Surf. Coat. Technol. 1999, 111, 29–40. [Google Scholar] [CrossRef]

- Liston, E.; Martinu, L.; Wertheimer, M. Plasma surface modification of polymers for improved adhesion: A critical review. J. Adhes. Sci. Technol. 1993, 7, 1091–1127. [Google Scholar] [CrossRef]

- Fu, X.; Sammons, R.L.; Bertóti, I.; Jenkins, M.J.; Dong, H. Active screen plasma surface modification of polycaprolactone to improve cell attachment. J. Biomed. Mater. Res. Part B Appl. Biomater. 2012, 100, 314–320. [Google Scholar] [CrossRef]

- Ito, M.; Oh, J.S.; Ohta, T.; Shiratani, M.; Hori, M. Current status and future prospects of agricultural applications using atmospheric-pressure plasma technologies. Plasma Process. Polym. 2018, 15, 1700073. [Google Scholar] [CrossRef]

- Verkuijlen, R.; Van Dongen, M.; Stevens, A.; Van Geldrop, J.; Bernards, J. Surface modification of polycarbonate and polyethylene naphtalate foils by UV-ozone treatment and μPlasma printing. Appl. Surf. Sci. 2014, 290, 381–387. [Google Scholar] [CrossRef]

- Weltmann, K.D.; Kolb, J.F.; Holub, M.; Uhrlandt, D.; Šimek, M.; Ostrikov, K.; Hamaguchi, S.; Cvelbar, U.; Černák, M.; Locke, B. The future for plasma science and technology. Plasma Process. Polym. 2019, 16, 1800118. [Google Scholar] [CrossRef] [Green Version]

- Lucas, N.; Franke, R.; Hinze, A.; Klages, C.P.; Frank, R.; Büttgenbach, S. Microplasma Stamps for Area-Selective Modification of Polymer Surfaces. Plasma Process. Polym. 2009, 6, S370–S374. [Google Scholar] [CrossRef]

- Mozetič, M. Surface modification to improve properties of materials. Materials 2019, 12, 441. [Google Scholar] [CrossRef] [Green Version]

- Iqbal, M.; Dinh, D.K.; Abbas, Q.; Imran, M.; Sattar, H.; Ul Ahmad, A. Controlled surface wettability by plasma polymer surface modification. Surfaces 2019, 2, 349–371. [Google Scholar] [CrossRef] [Green Version]

- Brennan, W.; Feast, W.; Munro, H.; Walker, S. Investigation of the ageing of plasma oxidized PEEK. Polymer 1991, 32, 1527–1530. [Google Scholar] [CrossRef]

- Carrino, L.; Polini, W.; Sorrentino, L. Ageing time of wettability on polypropylene surfaces processed by cold plasma. J. Mater. Process. Technol. 2004, 153, 519–525. [Google Scholar] [CrossRef]

- Cowie, J.; Ferguson, R. Physical ageing of poly (methyl methacrylate) from enthalpy relaxation measurements. Polymer 1993, 34, 2135–2141. [Google Scholar] [CrossRef]

- Jama, C.; Dessaux, O.; Goudmand, P.; Gengembre, L.; Grimblot, J. Treatment of poly (ether ether ketone)(PEEK) surfaces by remote plasma discharge. XPS investigation of the ageing of plasma-treated PEEK. Surf. Interface Anal. 1992, 18, 751–756. [Google Scholar] [CrossRef]

- Schalken, J.; Creatore, M.; Verhoeven, P.; Stevens, A. μPlasma Printing Deposition of Amine-Containing Organo-Silane Polymers by Means of 3-Aminopropyl Trimethoxysilane. Nanosci. Nanotechnol. Lett. 2015, 7, 62–66. [Google Scholar] [CrossRef]

- Novák, I.; Števiar, M.; Chodák, I. Surface energy and adhesive properties of polyamide 12 modified by barrier and radio-frequency discharge plasma. Mon. Chem. 2006, 137, 943–952. [Google Scholar] [CrossRef]

- Periyasamy, S.; ASM, R.; Patil, P.G. Submicron surface roughening of aliphatic polyamide 6, 6 fabric through low temperature plasma and its effect on interfacial bonding in rubber composite. J. Ind. Text. 2018, 47, 2029–2049. [Google Scholar] [CrossRef]

- Mandolfino, C.; Lertora, E.; Gambaro, C. Influence of cold plasma treatment parameters on the mechanical properties of polyamide homogeneous bonded joints. Surf. Coat. Technol. 2017, 313, 222–229. [Google Scholar] [CrossRef]

- Oliveira, F.R.; Zille, A.; Souto, A.P. Dyeing mechanism and optimization of polyamide 6, 6 functionalized with double barrier discharge (DBD) plasma in air. Appl. Surf. Sci. 2014, 293, 177–186. [Google Scholar] [CrossRef] [Green Version]

- Gao, Z. Modification of surface properties of polyamide 6 films with atmospheric pressure plasma. Appl. Surf. Sci. 2011, 257, 6068–6072. [Google Scholar] [CrossRef]

- Murakami, T.; Kuroda, S.-I.; Osawa, Z. Dynamics of polymeric solid surfaces treated with oxygen plasma: Effect of aging media after plasma treatment. J. Colloid Interface Sci. 1998, 202, 37–44. [Google Scholar] [CrossRef]

- Marques, I.R.; Silveira, C.; Leite, M.J.; Piacentini, A.M.; Binder, C.; Dotto, M.E.; Ambrosi, A.; Di Luccio, M.; da Costa, C. Simple approach for the plasma treatment of polymeric membranes and investigation of the aging effect. J. Appl. Polym. Sci. 2021, 138, 50558. [Google Scholar] [CrossRef]

- Nakamatsu, J.; Delgado-Aparicio, L.F.; Da Silva, R.; Soberon, F. Ageing of plasma-treated poly (tetrafluoroethylene) surfaces. J. Adhes. Sci. Technol. 1999, 13, 753–761. [Google Scholar] [CrossRef]

- Garbassi, F.; Morra, M.; Occhiello, E.; Garbassi, F. Polymer Surfaces: From Physics to Technology; Wiley: New York, NY, USA, 1998. [Google Scholar]

- Thompson, R.; Austin, D.; Wang, C.; Neville, A.; Lin, L. Low-frequency plasma activation of nylon 6. Appl. Surf. Sci. 2021, 544, 148929. [Google Scholar] [CrossRef]

- Tušek, L.; Nitschke, M.; Werner, C.; Stana-Kleinschek, K.; Ribitsch, V. Surface characterisation of NH3 plasma treated polyamide 6 foils. Colloids Surf. A Physicochem. Eng. Asp. 2001, 195, 81–95. [Google Scholar] [CrossRef]

- Pappas, D.; Bujanda, A.; Demaree, J.D.; Hirvonen, J.K.; Kosik, W.; Jensen, R.; McKnight, S. Surface modification of polyamide fibers and films using atmospheric plasmas. Surf. Coat. Technol. 2006, 201, 4384–4388. [Google Scholar] [CrossRef]

- Baek, Y.; Kang, J.; Theato, P.; Yoon, J. Measuring hydrophilicity of RO membranes by contact angles via sessile drop and captive bubble method: A comparative study. Desalination 2012, 303, 23–28. [Google Scholar] [CrossRef]

- Li, Q.; Pan, X.; Qu, Z.; Zhao, X.; Jin, Y.; Dai, H.; Yang, B.; Wang, X. Understanding the dependence of contact angles of commercially RO membranes on external conditions and surface features. Desalination 2013, 309, 38–45. [Google Scholar] [CrossRef]

- British Standard. EN ISO 19403-2:2020. Paints and Varnishes—Wettability. Part 2: Determination of the Surface Free Energy of Solid Surfaces by Measuring the Contact Angle; British Standard: London, UK, 2020. [Google Scholar]

- Károly, Z.; Kalácska, G.; Zsidai, L.; Mohai, M.; Klébert, S. Improvement of adhesion properties of polyamide 6 and polyoxymethylene-copolymer by atmospheric cold plasma treatment. Polymers 2018, 10, 1380. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Jin, S.; Yokozeki, T.; Ueda, M.; Yang, Y.; Elbadry, E.A.; Hamada, H.; Sugahara, T. Effect of hot water on the mechanical performance of unidirectional carbon fiber-reinforced nylon 6 composites. Compos. Sci. Technol. 2020, 200, 108426. [Google Scholar] [CrossRef]

- De Geyter, N.; Morent, R.; Leys, C. Influence of ambient conditions on the ageing behaviour of plasma-treated PET surfaces. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2008, 266, 3086–3090. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Che, C.; Dashtbozorg, B.; Li, X.; Dong, H.; Jenkins, M. Effect of μPlasma Modification on the Wettability and the Ageing Behaviour of Glass Fibre Reinforced Polyamide 6 (GFPA6). Materials 2021, 14, 7721. https://doi.org/10.3390/ma14247721

Che C, Dashtbozorg B, Li X, Dong H, Jenkins M. Effect of μPlasma Modification on the Wettability and the Ageing Behaviour of Glass Fibre Reinforced Polyamide 6 (GFPA6). Materials. 2021; 14(24):7721. https://doi.org/10.3390/ma14247721

Chicago/Turabian StyleChe, Chang, Behnam Dashtbozorg, Xiaoying Li, Hanshan Dong, and Mike Jenkins. 2021. "Effect of μPlasma Modification on the Wettability and the Ageing Behaviour of Glass Fibre Reinforced Polyamide 6 (GFPA6)" Materials 14, no. 24: 7721. https://doi.org/10.3390/ma14247721

APA StyleChe, C., Dashtbozorg, B., Li, X., Dong, H., & Jenkins, M. (2021). Effect of μPlasma Modification on the Wettability and the Ageing Behaviour of Glass Fibre Reinforced Polyamide 6 (GFPA6). Materials, 14(24), 7721. https://doi.org/10.3390/ma14247721