Tribological Characterization of the Heat-Assisted Single Point Incremental Forming Process Applied to the Ti6Al4V Alloy with the Definition of an Adhesion Parameter for the Tool Surface

Abstract

:1. Introduction

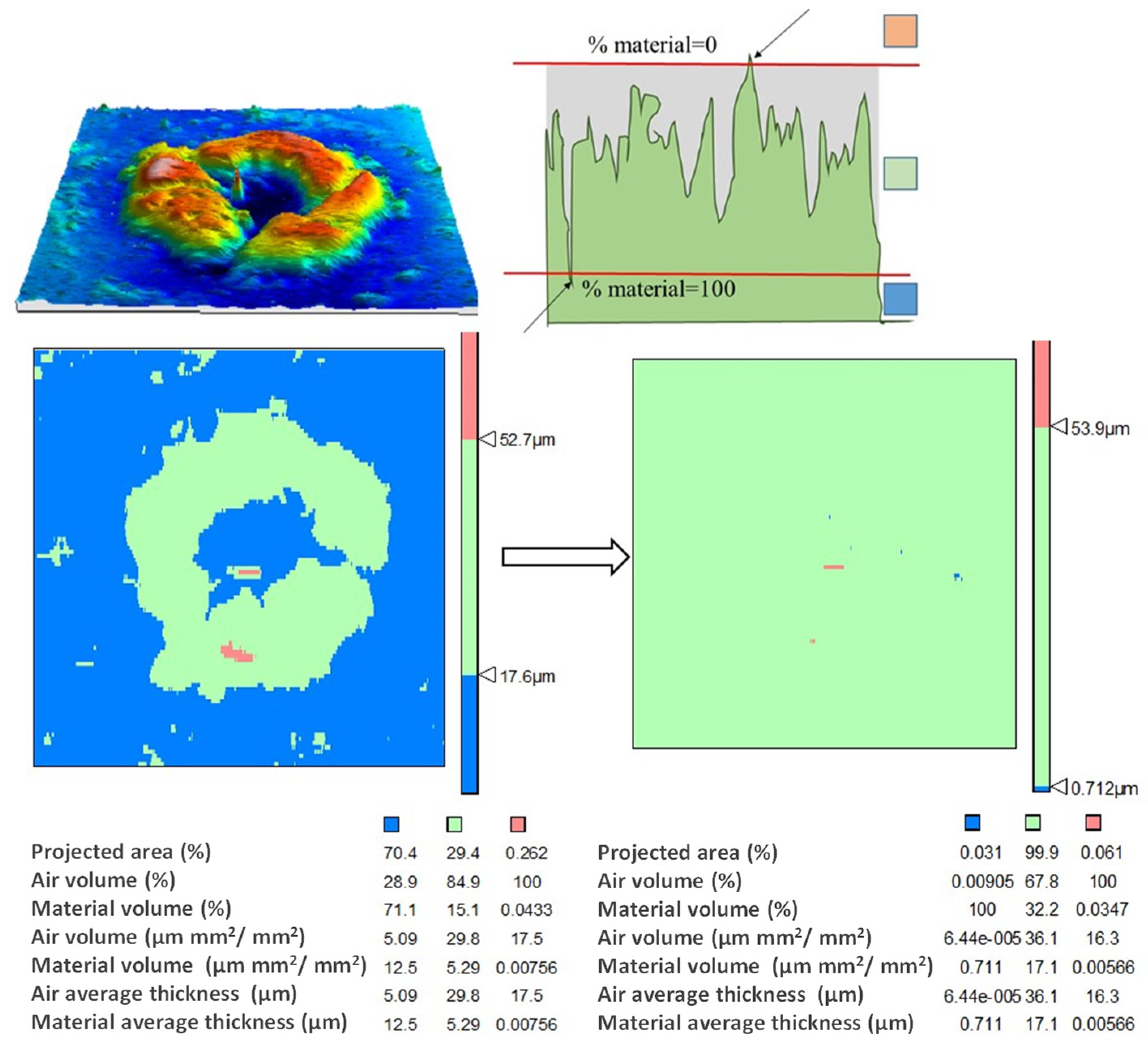

- Once the adhesive character tool-alloy during friction has been stated, a new parameter based on the material adhered to the tool surface is defined. The parameter consists of an average film thickness of the adhered material observed on the tool surface once the HA-SPIF process has finished.

- The influence of the temperature on the surface finish of Ti6Al4V parts obtained by the HA-SPIF process is characterized. A moderate temperature range, from room temperature to 400 °C, is covered.

- The changes in the morphology of the external surface layer promoted by the HA-SPIF process on Ti6Al4V parts are analyzed.

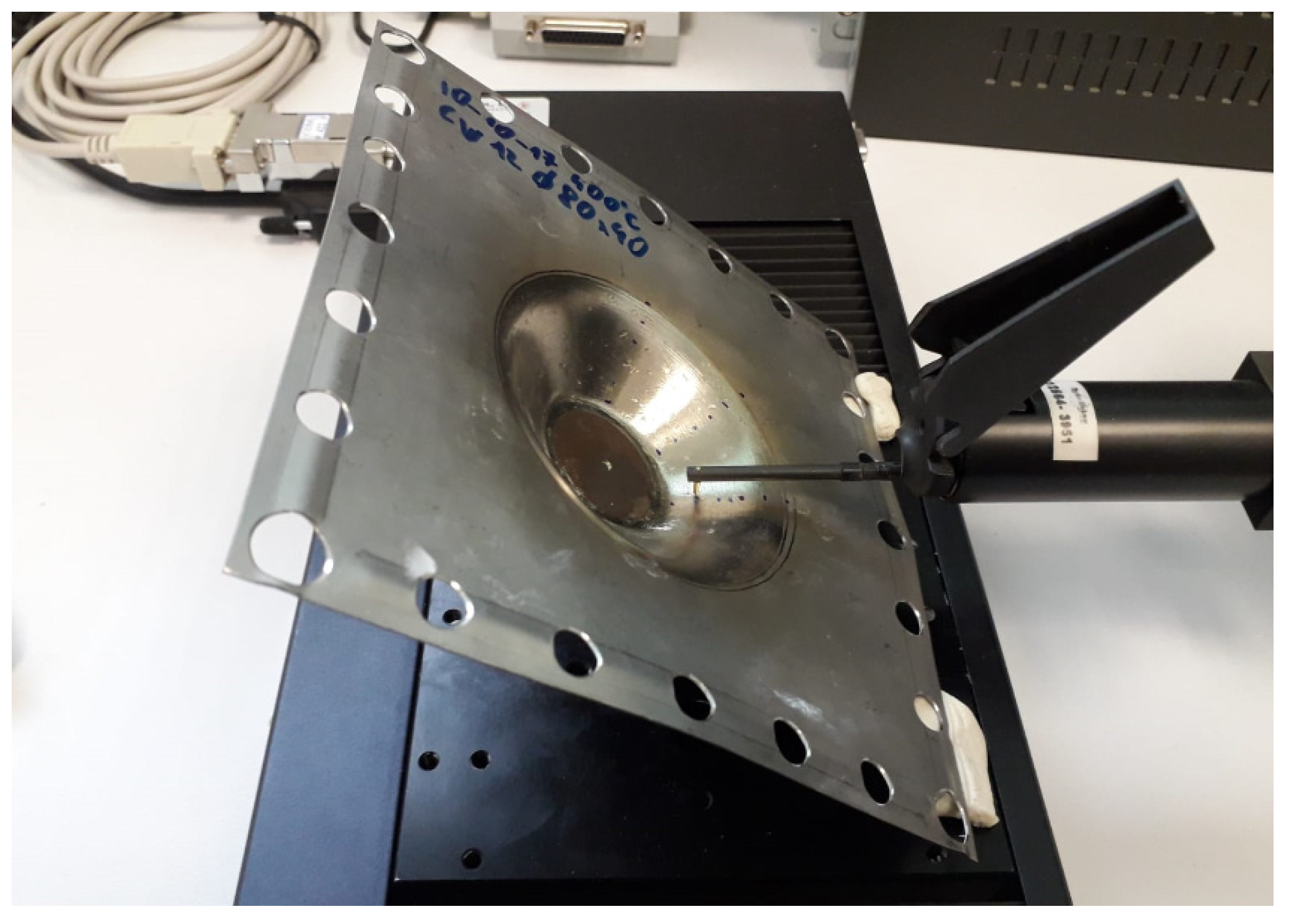

2. Methodology and Experimental Details

3. Results and Discussion

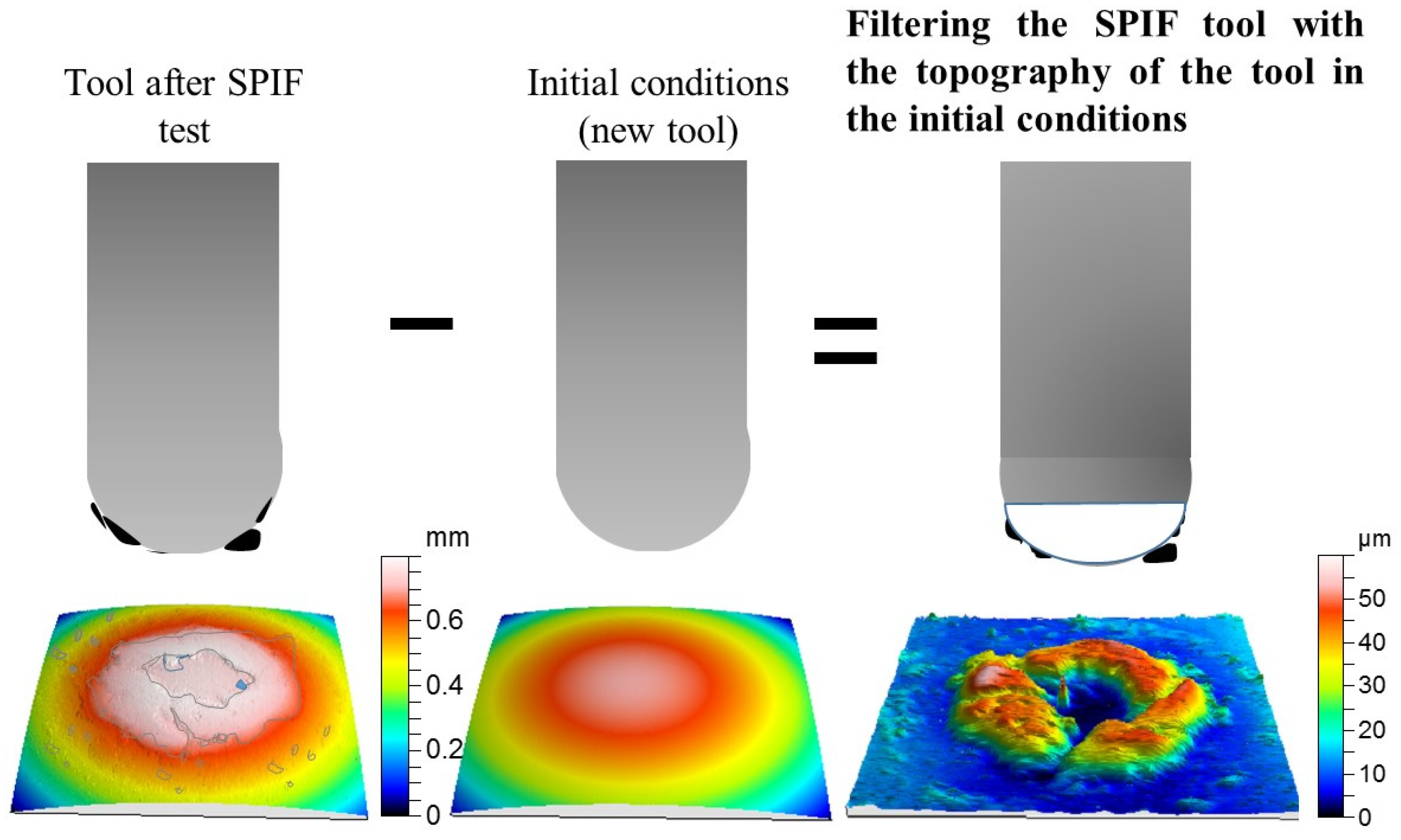

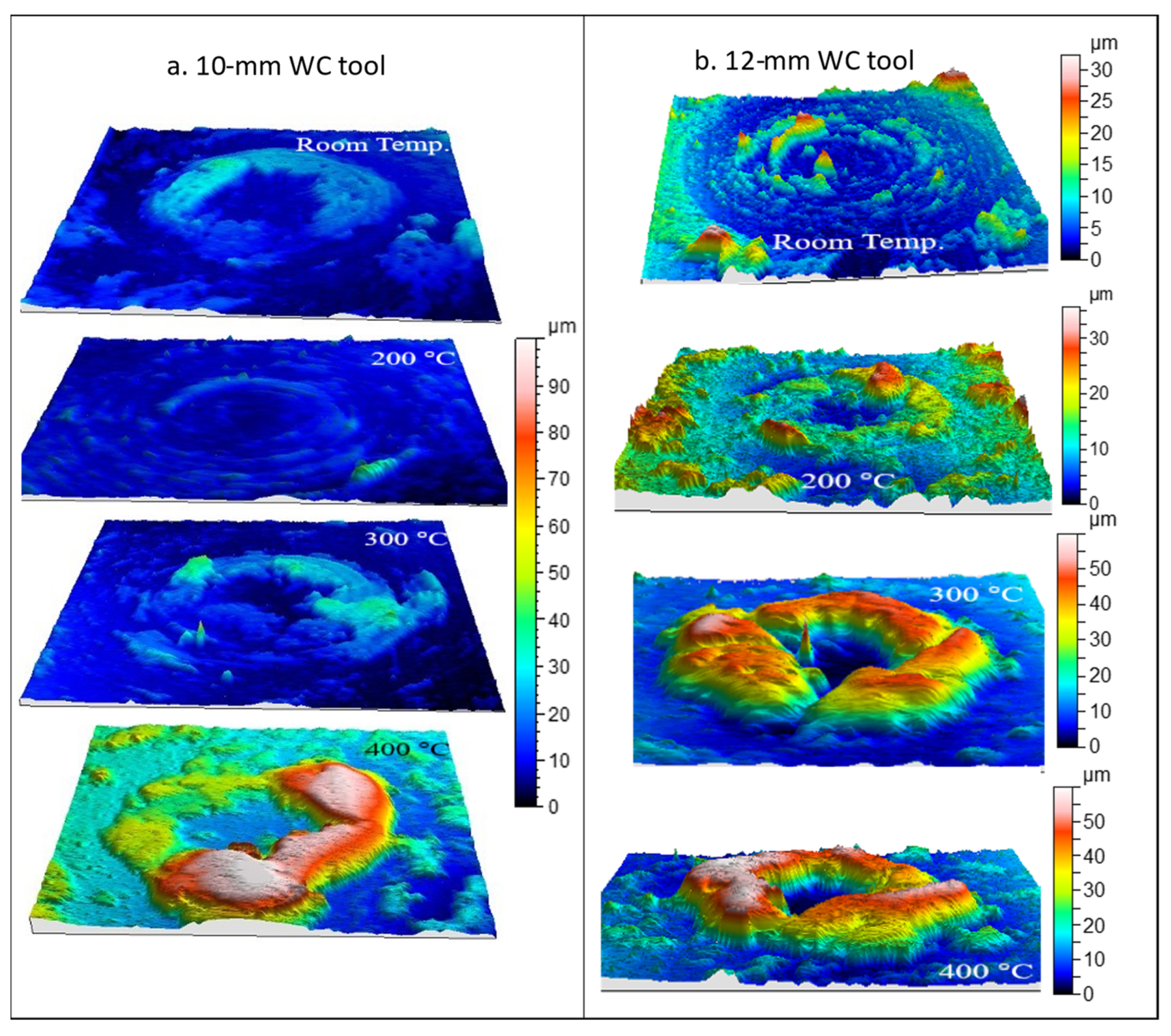

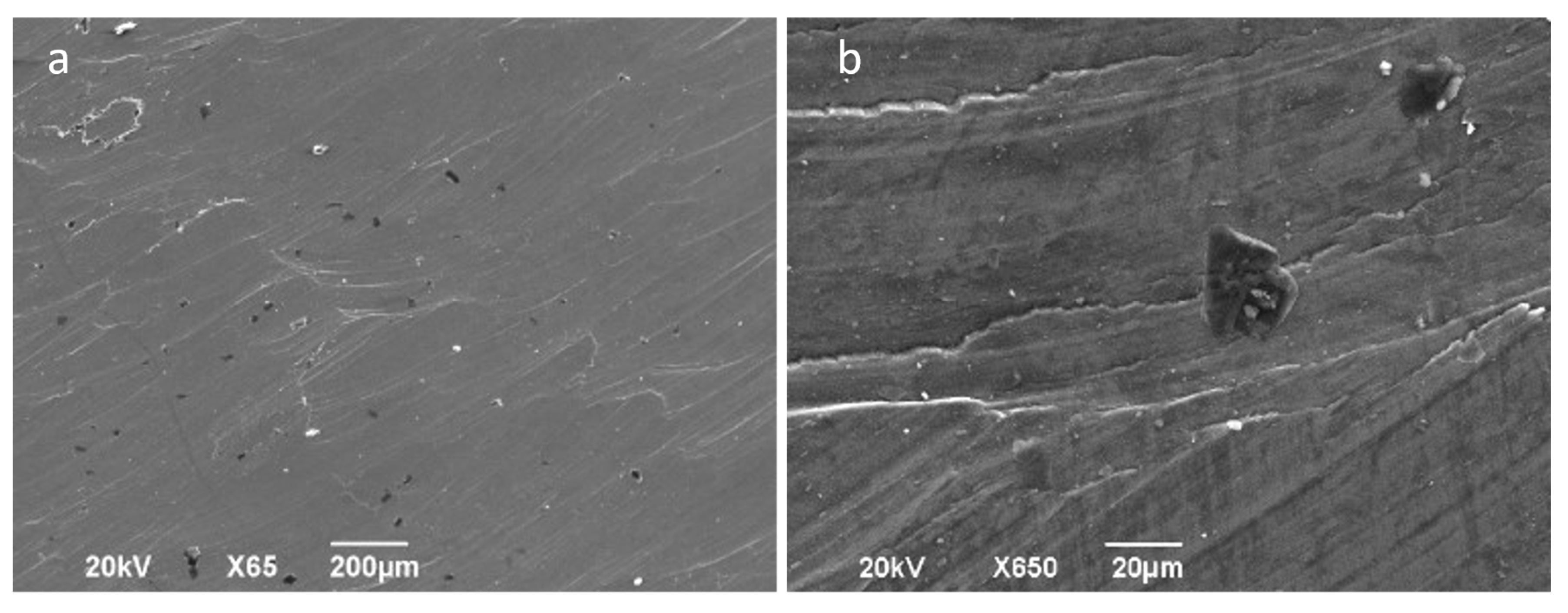

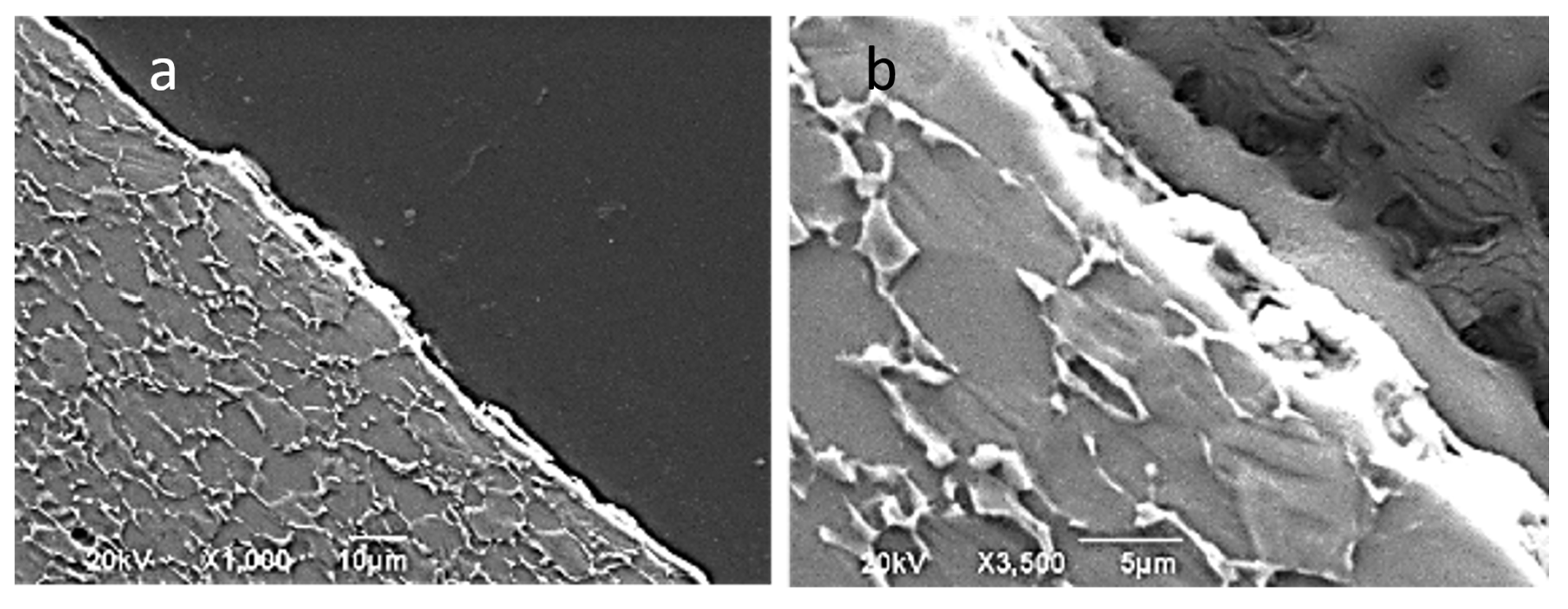

3.1. Characterization of the Tool Surface Evolution

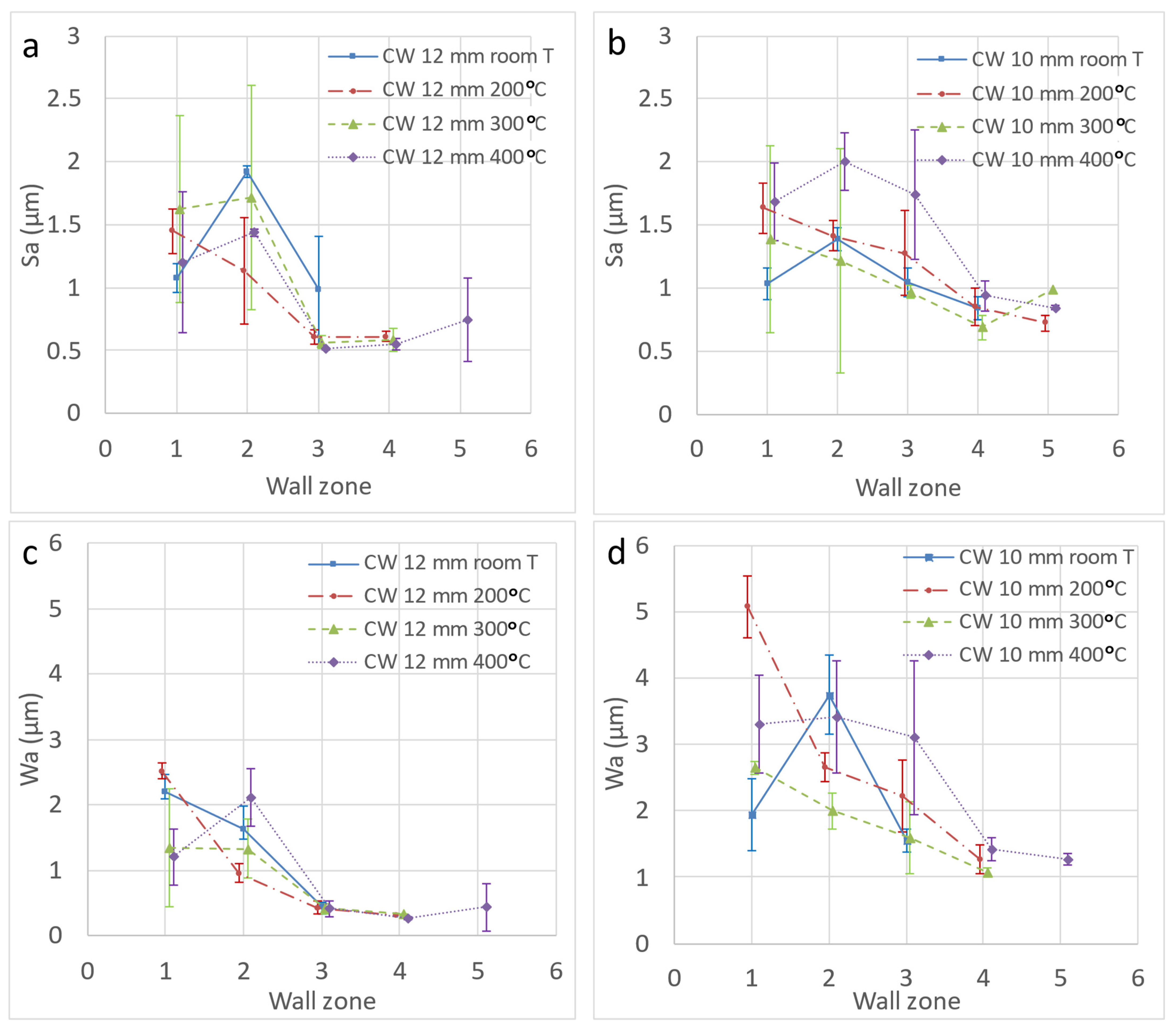

3.2. Variation of the Surface Finish of HA-SPIF Parts

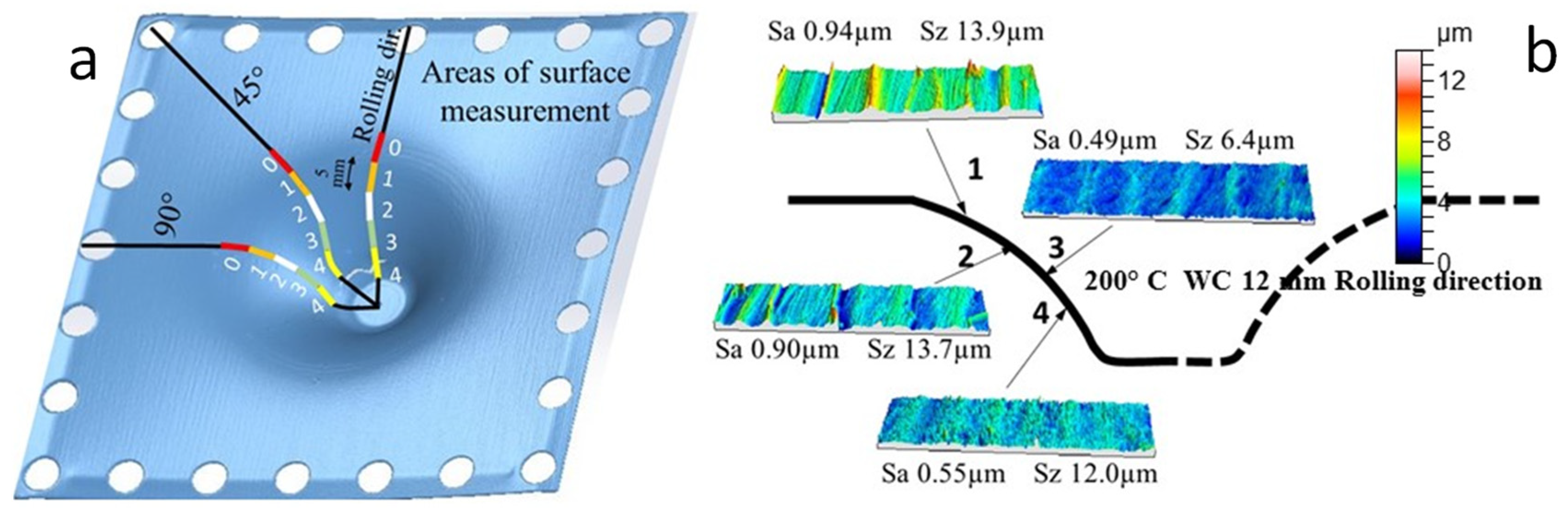

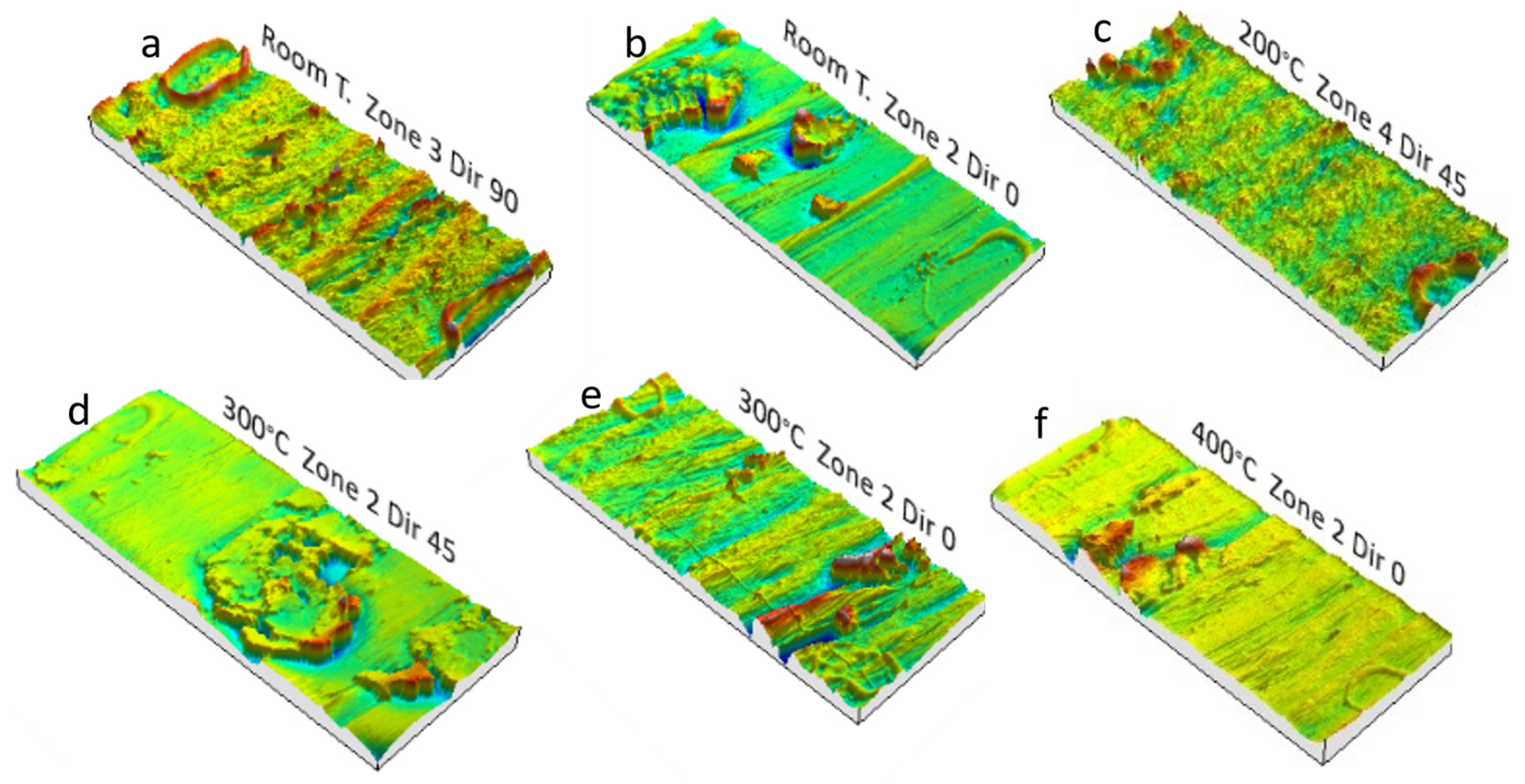

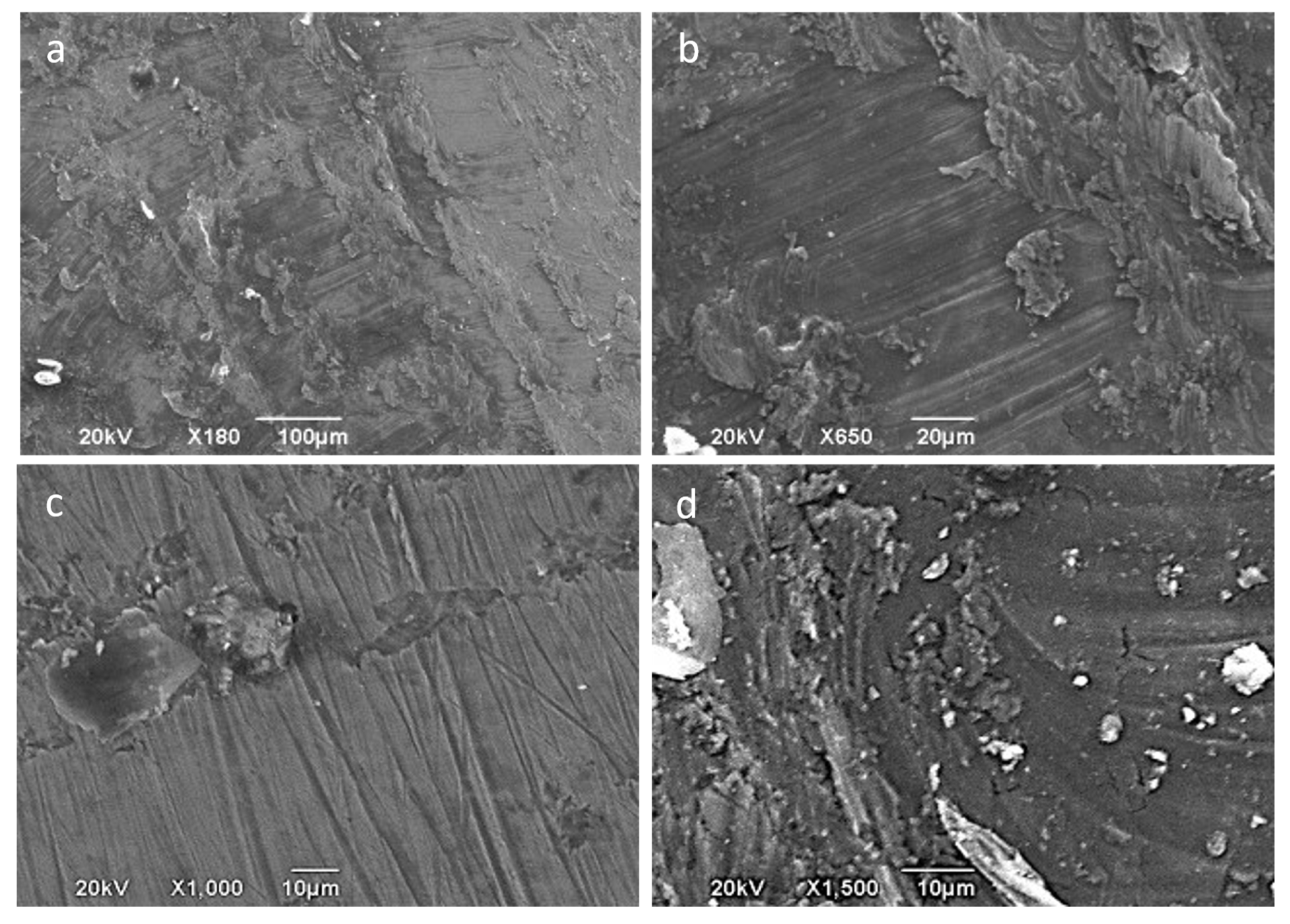

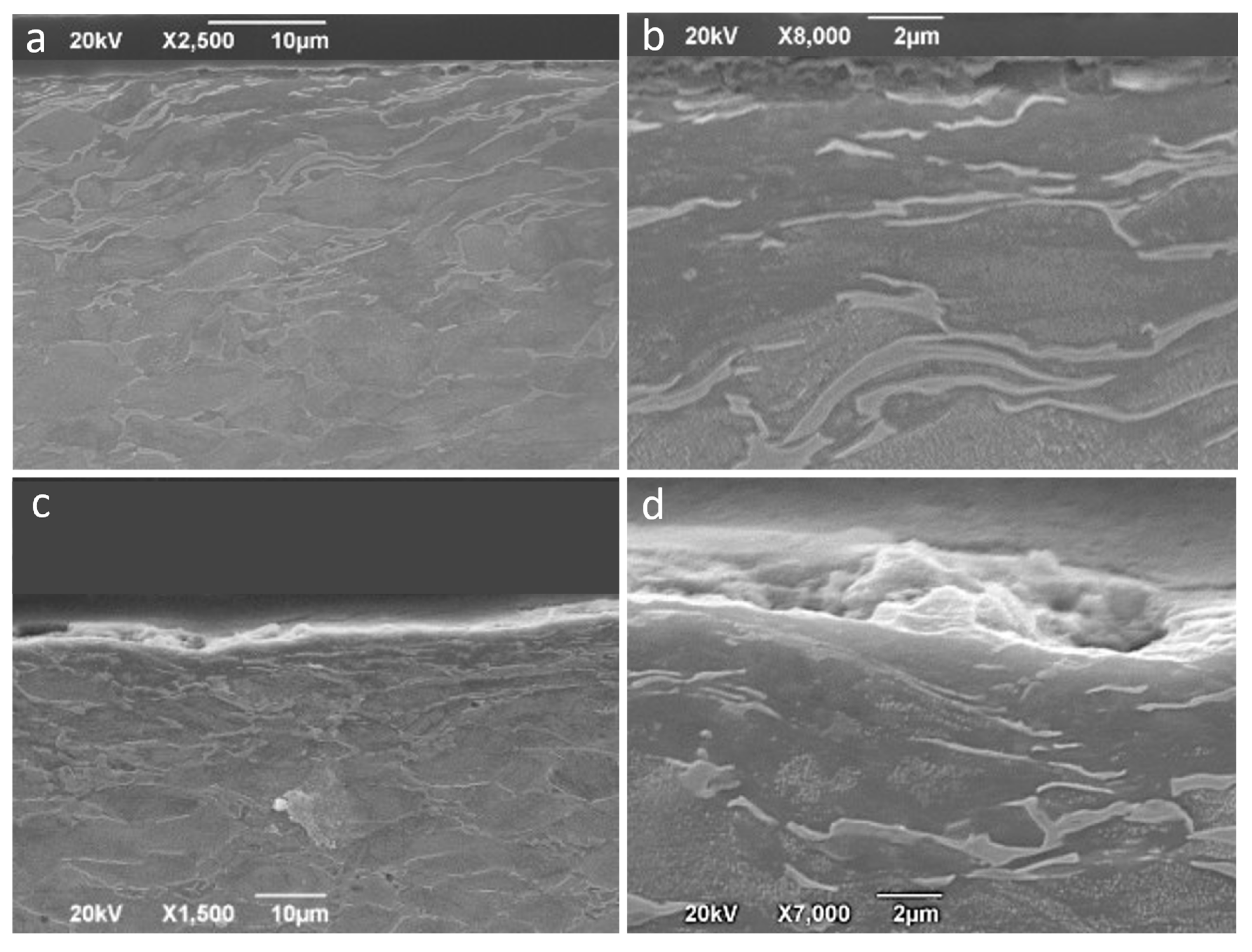

3.3. Characterization of the Part Surfaces

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Badr, O.M.; Rolfe, B.; Hodgson, P.; Weiss, M. Forming of high strength titanium sheet at room temperature. Mater. Des. 2015, 66, 618–626. [Google Scholar] [CrossRef]

- Göttmann, A.; Diettrich, J.; Bergweiler, G.; Bambach, M.; Hirt, G.; Loosen, P.; Poprawe, R. Laser-assisted asymmetric incremental sheet forming of titanium sheet metal parts. Prod. Eng. 2011, 5, 263–271. [Google Scholar] [CrossRef]

- Duflou, J.; Callebaut, B.; Verbert, J.; de Baerdemaeker, H. Laser Assisted Incremental Forming: Formability and Accuracy Improvement. CIRP Ann. 2007, 56, 273–276. [Google Scholar] [CrossRef]

- Fan, G.; Gao, L.; Hussain, G.; Wu, Z. Electric hot incremental forming: A novel technique. Int. J. Mach. Tools Manuf. 2008, 48, 1688–1692. [Google Scholar] [CrossRef]

- Fan, G.; Sun, F.; Meng, X.; Gao, L.; Tong, G. Electric hot incremental forming of Ti-6Al-4V titanium sheet. Int. J. Adv. Manuf. Technol. 2009, 49, 941–947. [Google Scholar] [CrossRef]

- Fan, G.; Gao, L. Mechanical property of Ti-6Al-4V sheet in one-sided electric hot incremental forming. Int. J. Adv. Manuf. Technol. 2014, 72, 989–994. [Google Scholar] [CrossRef]

- Magnus, C.S. Joule heating of the forming zone in incremental sheet metal forming: Part 1. Int. J. Adv. Manuf. Technol. 2017, 91, 1309–1319. [Google Scholar] [CrossRef]

- Magnus, C.S. Joule heating of the forming zone in incremental sheet metal forming: Part 2. Int. J. Adv. Manuf. Technol. 2017, 89, 295–309. [Google Scholar] [CrossRef]

- Honarpisheh, M.; Abdolhoseini, M.J.; Amini, S. Experimental and numerical investigation of the hot incremental forming of Ti-6Al-4V sheet using electrical current. Int. J. Adv. Manuf. Technol. 2015, 83, 2027–2037. [Google Scholar] [CrossRef]

- Ambrogio, G.; Filice, L.; Gagliardi, F. Formability of lightweight alloys by hot incremental sheet forming. Mater. Des. 2012, 34, 501–508. [Google Scholar] [CrossRef]

- Francesco, G.; Giuseppina, A.; Luigino, F. Incremental Forming with Local Induction Heating on Materials with Magnetic and Non-magnetic Properties. Procedia Eng. 2017, 183, 143–148. [Google Scholar] [CrossRef]

- Durante, M.; Formisano, A.; Langella, A.; Minutolo, F.M.C. The influence of tool rotation on an incremental forming process. J. Mater. Process. Technol. 2009, 209, 4621–4626. [Google Scholar] [CrossRef]

- Palumbo, G.; Brandizzi, M. Experimental investigations on the single point incremental forming of a titanium alloy component combining static heating with high tool rotation speed. Mater. Des. 2012, 40, 43–51. [Google Scholar] [CrossRef]

- Göttmann, A.; Bailly, D.; Bergweiler, G.; Bambach, M.; Stollenwerk, J.; Hirt, G.; Loosen, P. A novel approach for temperature control in ISF supported by laser and resistance heating. Int. J. Adv. Manuf. Technol. 2013, 67, 2195–2205. [Google Scholar] [CrossRef]

- Lu, B.; Fang, Y.; Xu, D.; Chen, J.; Ou, H.; Moser, N.; Cao, J. Mechanism investigation of friction-related effects in single point incremental forming using a developed oblique roller-ball tool. Int. J. Mach. Tools Manuf. 2014, 85, 14–29. [Google Scholar] [CrossRef]

- Dakhli, M.; Boulila, A.; Manach, P.-Y.; Tourki, Z. Optimization of processing parameters and surface roughness of metallic sheets plastically deformed by incremental forming process. Int. J. Adv. Manuf. Technol. 2019, 102, 977–990. [Google Scholar] [CrossRef]

- Jawale, K.; Duarte, J.; Reis, A.; Silva, M.B. Microstructural investigation and lubrication study for single point incremental forming of copper. Int. J. Solids Struct. 2018, 151, 145–151. [Google Scholar] [CrossRef]

- Nath, M.; Shin, J.; Bansal, A.; Banu, M.; Taub, A. Comparison of Texture and Surface Finish Evolution During Single Point Incremental Forming and Formability Testing of AA 7075. In TMS Annual Meeting & Exhibition; The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2018; pp. 225–232. [Google Scholar] [CrossRef]

- Da Silva, P.J.; Alvares, A.J. Investigation of tool wear in single point incremental sheet forming. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 234, 170–188. [Google Scholar] [CrossRef]

- Daleffe, A.; Schaeffer, L.; Fritzen, D.; Castelan, J. Analysis of the Incremental Forming of Titanium F67 Grade 2 Sheet. Key Eng. Mater. 2013, 554–557, 195–203. [Google Scholar] [CrossRef]

- Vahdani, M.; Mirnia, M.J.; Gorji, H.; Jooybari, M.B. Experimental Investigation of Formability and Surface Finish into Resistance Single-Point Incremental Forming of Ti–6Al–4V Titanium Alloy Using Taguchi Design. Trans. Indian Inst. Met. 2019, 72, 1031–1041. [Google Scholar] [CrossRef]

- Ortiz, M.; Penalva, M.; Iriondo, E.; de Lacalle, L.N.L. Accuracy and Surface Quality Improvements in the Manufacturing of Ti-6Al-4V Parts Using Hot Single Point Incremental Forming. Metals 2019, 9, 697. [Google Scholar] [CrossRef] [Green Version]

- Naranjo, J.A.; Miguel, V.; Martínez, A.; Coello, J.; Manjabacas, M.C. Evaluation of the Formability and Dimensional Accuracy Improvement of Ti6Al4V in Warm SPIF Processes. Metals 2019, 9, 272. [Google Scholar] [CrossRef] [Green Version]

- Naranjo, J.; Miguel, V.; Martínez, A.; Coello, J.; Manjabacas, M.; Valera, J. Influence of temperature on alloy Ti6Al4V formability during the warm SPIF process. Procedia Eng. 2017, 207, 866–871. [Google Scholar] [CrossRef]

- Long, M.; Rack, H. Friction and surface behavior of selected titanium alloys during reciprocating-sliding motion. Wear 2001, 249, 157–167. [Google Scholar] [CrossRef]

- Bansal, D.; Eryilmaz, O.; Blau, P. Surface engineering to improve the durability and lubricity of Ti–6Al–4V alloy. Wear 2011, 271, 2006–2015. [Google Scholar] [CrossRef]

- Findik, F. Latest progress on tribological properties of industrial materials. Mater. Des. 2014, 57, 218–244. [Google Scholar] [CrossRef]

- Le Mercier, K.; Dubar, M.; Mocellin, K.; Dubois, A.; Dubar, L. Quantitative analysis of galling in cold forging of a commercial Al-Mg-Si alloy. Procedia Eng. 2017, 207, 2298–2303. [Google Scholar] [CrossRef]

- Martínez, A.; Miguel, V.; Coello, J. A new approach to evaluate bending forces for deep-drawing operations of a TRIP700 + EBT steel sheet. Int. J. Mater. Form. 2018, 11, 619–641. [Google Scholar] [CrossRef]

- Budinski, K.G. Tribological properties of titanium alloys. Wear 1991, 151, 203–217. [Google Scholar] [CrossRef]

- Straffelini, G.; Molinari, A. Dry sliding wear of Ti–6Al–4V alloy as influenced by the counterface and sliding conditions. Wear 1999, 236, 328–338. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, S.; Chen, W.; Jiang, W.; Wang, L.; Chen, K.; Cui, X. Comparative research on the effect of an oxide coating and a tribo-oxide layer on dry sliding wear of Ti–6Al–4V alloy. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 1569–1580. [Google Scholar] [CrossRef]

- Zhang, Q.; Ding, H.; Zhou, G.; Guo, X.; Zhang, M.; Li, N.; Wu, H.; Xia, M. Dry Sliding Wear Behavior of a Selected Titanium Alloy Against Counterface Steel of Different Hardness Levels. Met. Mater. Trans. A 2018, 50, 220–233. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naranjo, J.A.; Miguel, V.; Coello, J.; Manjabacas, M.C.; Martínez-Martínez, A.; García-Martínez, E. Tribological Characterization of the Heat-Assisted Single Point Incremental Forming Process Applied to the Ti6Al4V Alloy with the Definition of an Adhesion Parameter for the Tool Surface. Materials 2021, 14, 7641. https://doi.org/10.3390/ma14247641

Naranjo JA, Miguel V, Coello J, Manjabacas MC, Martínez-Martínez A, García-Martínez E. Tribological Characterization of the Heat-Assisted Single Point Incremental Forming Process Applied to the Ti6Al4V Alloy with the Definition of an Adhesion Parameter for the Tool Surface. Materials. 2021; 14(24):7641. https://doi.org/10.3390/ma14247641

Chicago/Turabian StyleNaranjo, Jesús Andrés, Valentín Miguel, Juana Coello, María Carmen Manjabacas, Alberto Martínez-Martínez, and Enrique García-Martínez. 2021. "Tribological Characterization of the Heat-Assisted Single Point Incremental Forming Process Applied to the Ti6Al4V Alloy with the Definition of an Adhesion Parameter for the Tool Surface" Materials 14, no. 24: 7641. https://doi.org/10.3390/ma14247641

APA StyleNaranjo, J. A., Miguel, V., Coello, J., Manjabacas, M. C., Martínez-Martínez, A., & García-Martínez, E. (2021). Tribological Characterization of the Heat-Assisted Single Point Incremental Forming Process Applied to the Ti6Al4V Alloy with the Definition of an Adhesion Parameter for the Tool Surface. Materials, 14(24), 7641. https://doi.org/10.3390/ma14247641