Study on Improving the Precise Machinability of Single Crystal SiC by an Ultrasonic-Assisted Hybrid Process

Abstract

:1. Introduction

2. Experimental Procedures

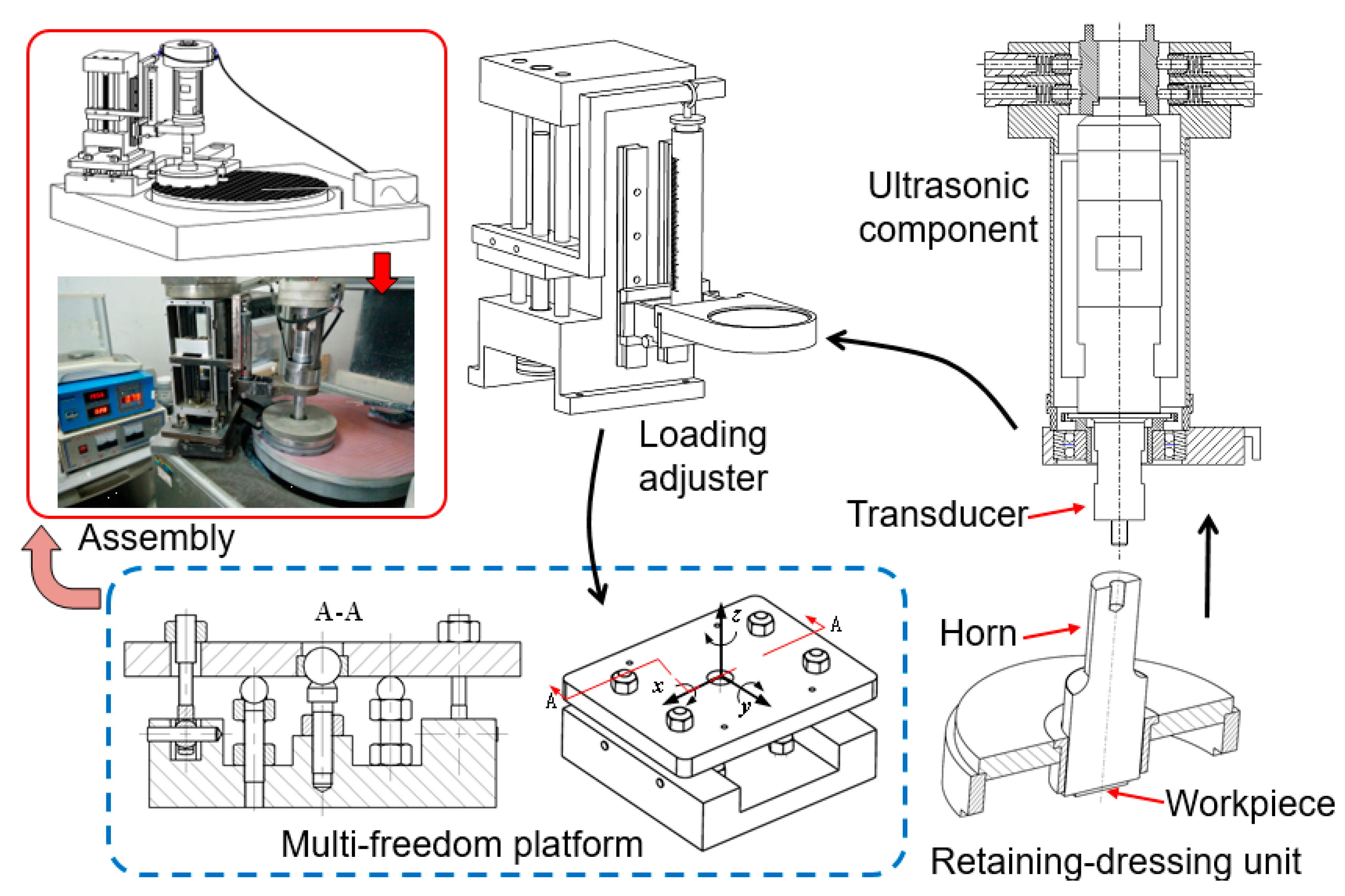

3. Establishing the Ultrasonic Vibration-Assisted Device

3.1. Facility Design

- (1)

- The workpiece is mounted on the stepped horn through paraffin wax.

- (2)

- The horn is installed on the ultrasonic transducer through a set screw.

- (3)

- Adjust the rocker arm of the machine and place the retaining ring therein.

- (4)

- Adjust the multifreedom platform, place the horn and workpiece on the rotational plate of BNI62 machine through the retaining-dressing unit.

- (5)

- Adjust the loading adjuster, set the lapping or polishing pressure, supply the processing fluid, set the speed, and start the machine.

3.2. Design of the Stepped Horn and Its Performance Test

4. Results and Discussion

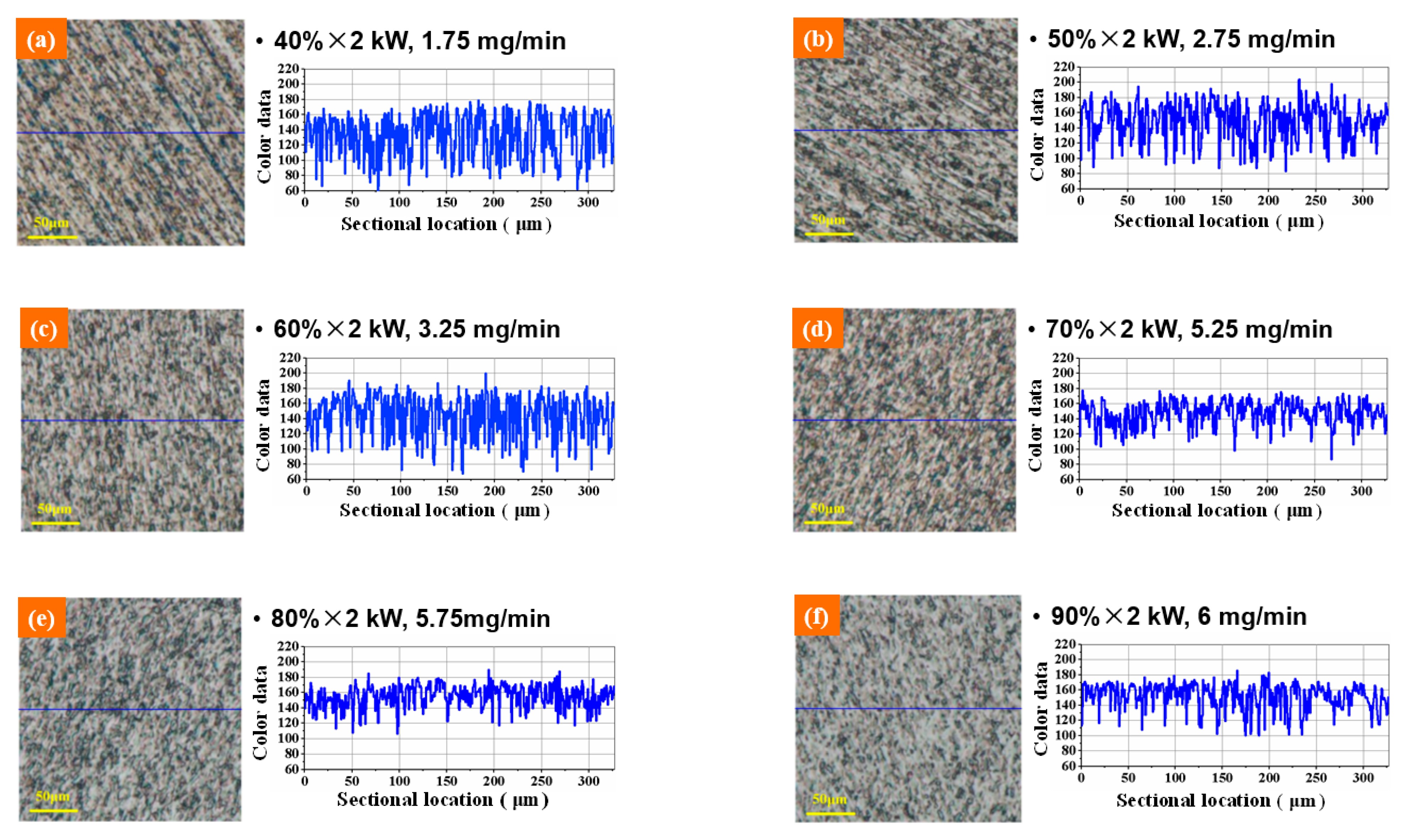

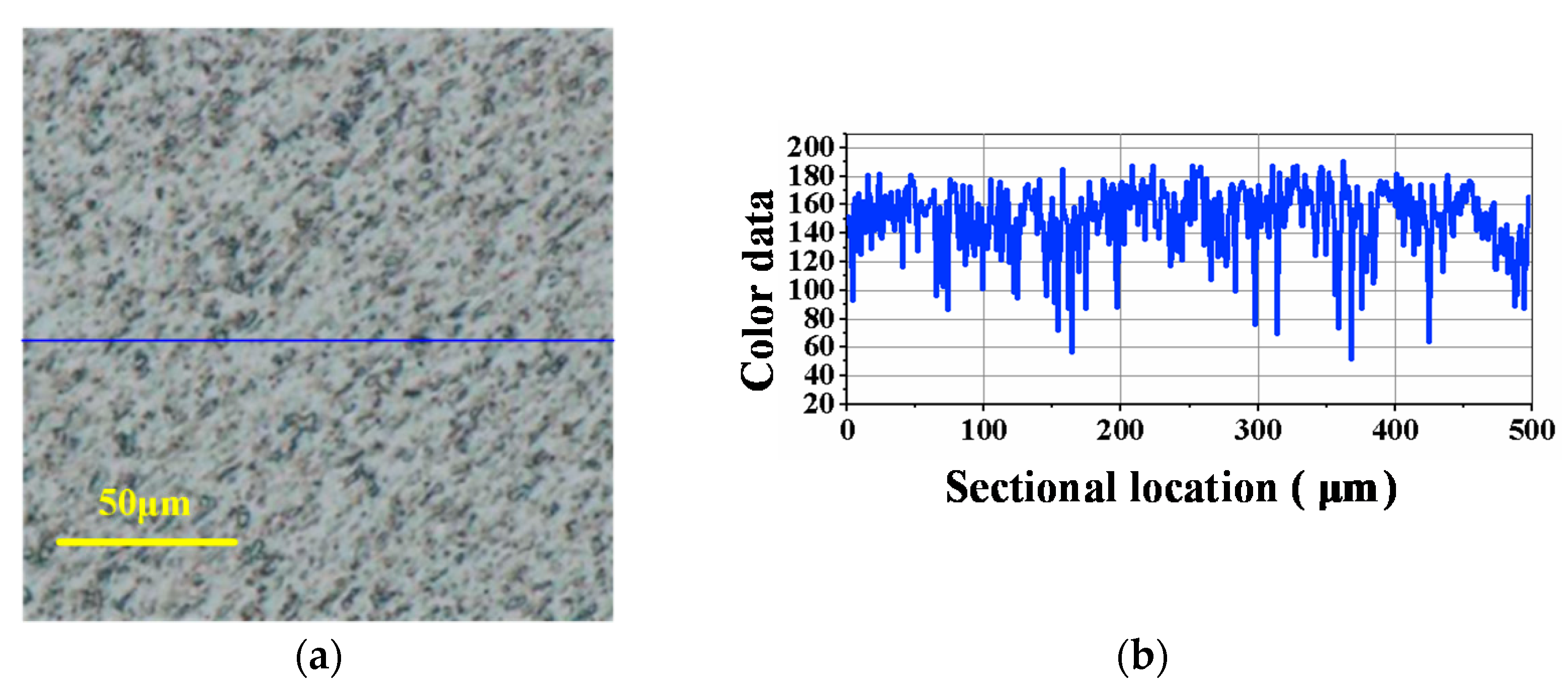

4.1. Effects of the Vibrated Amplitude

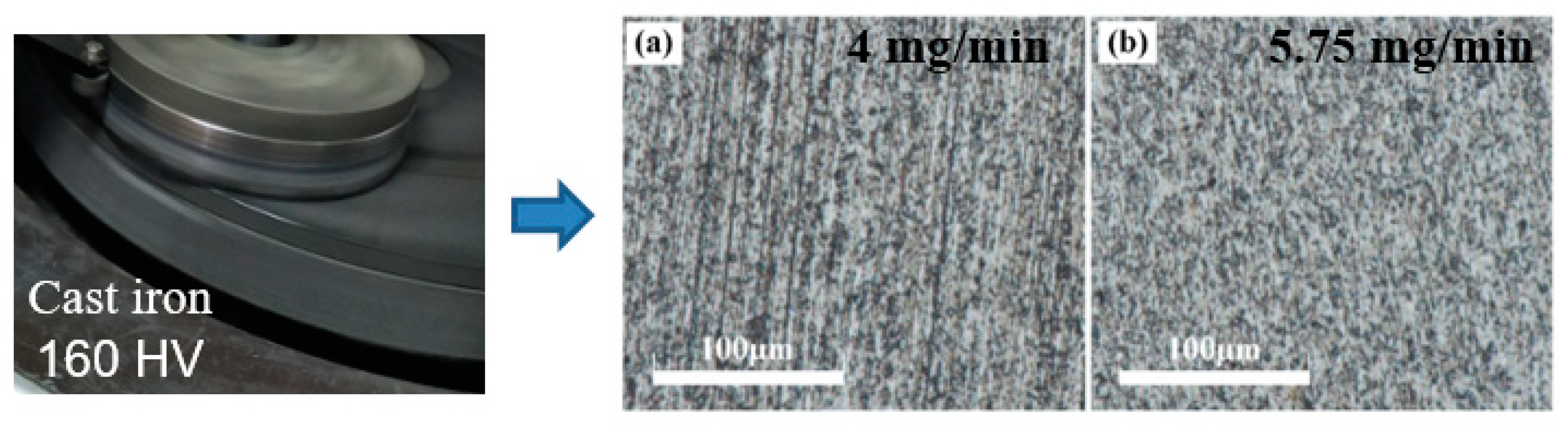

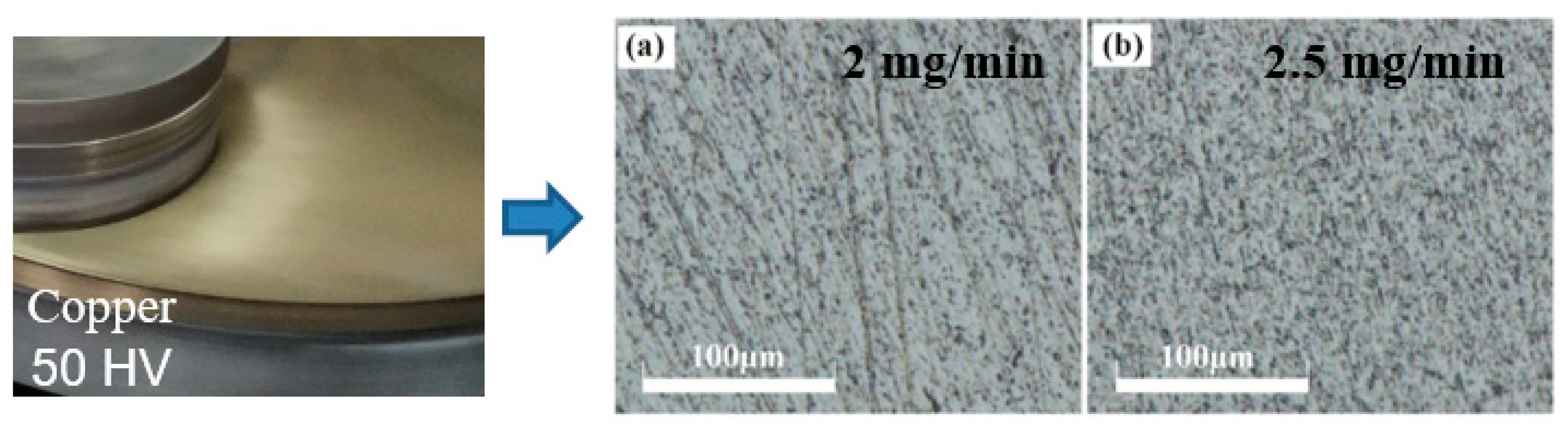

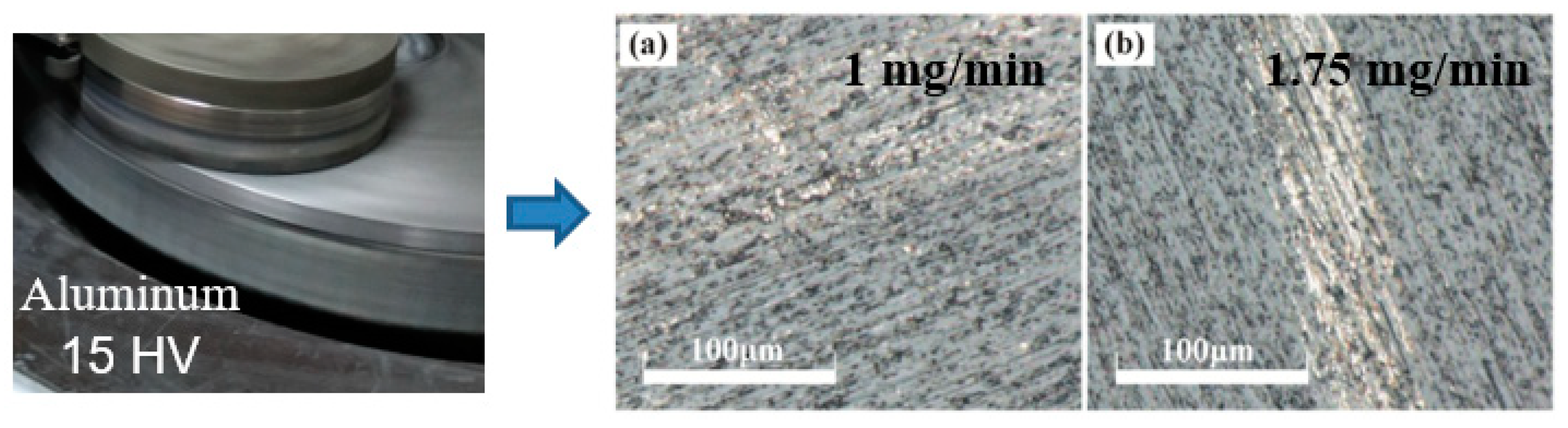

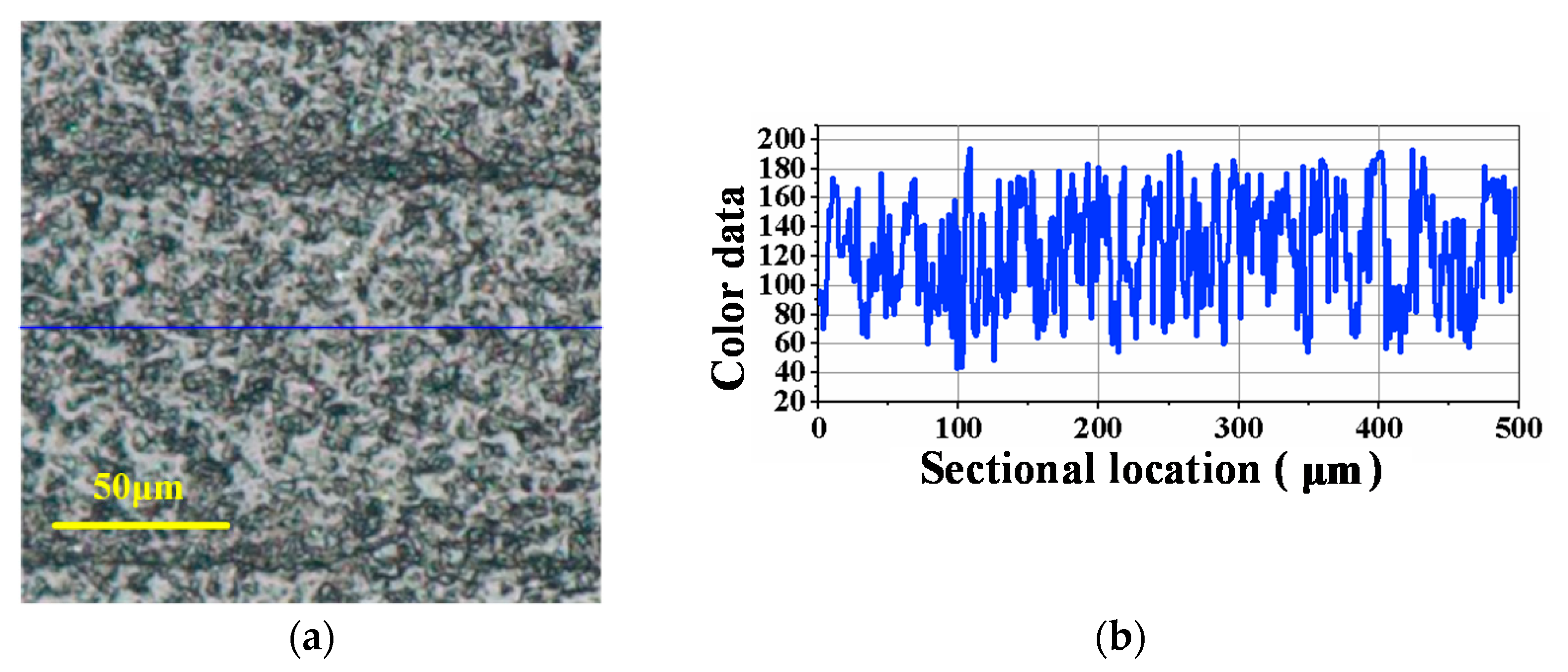

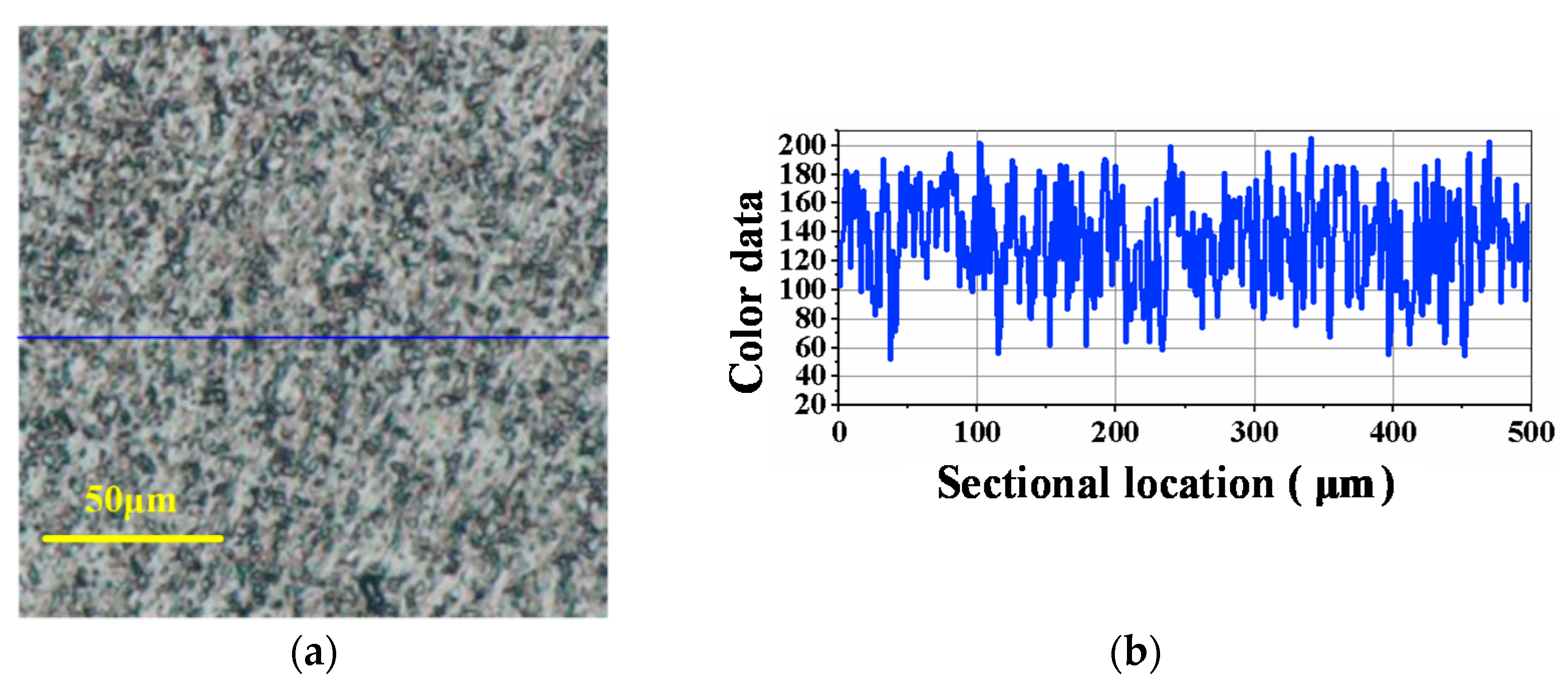

4.2. Effects of Lapping Disc Material

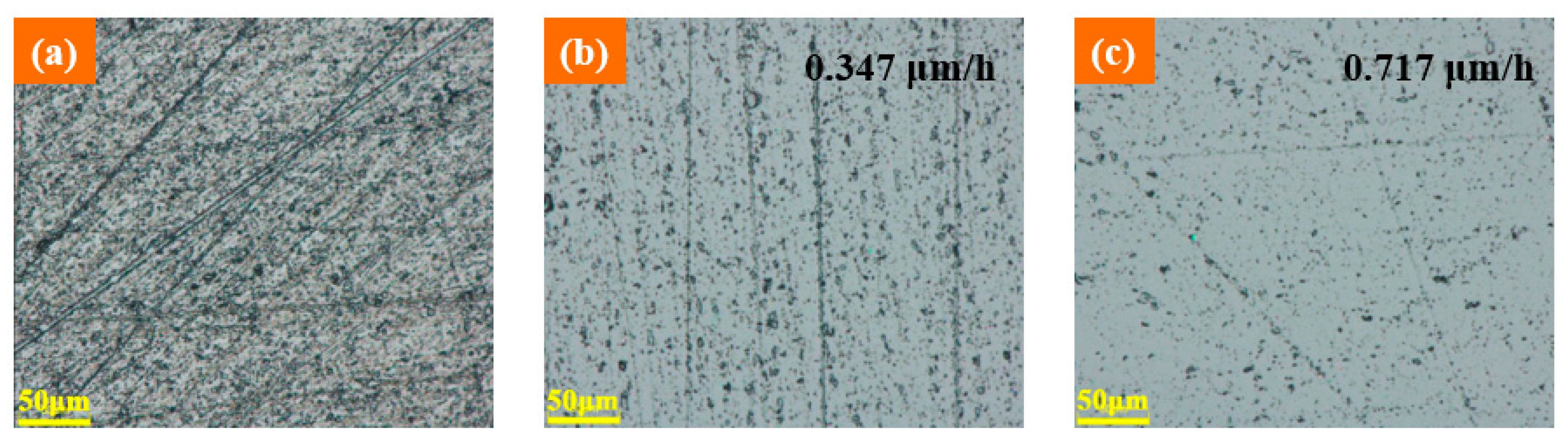

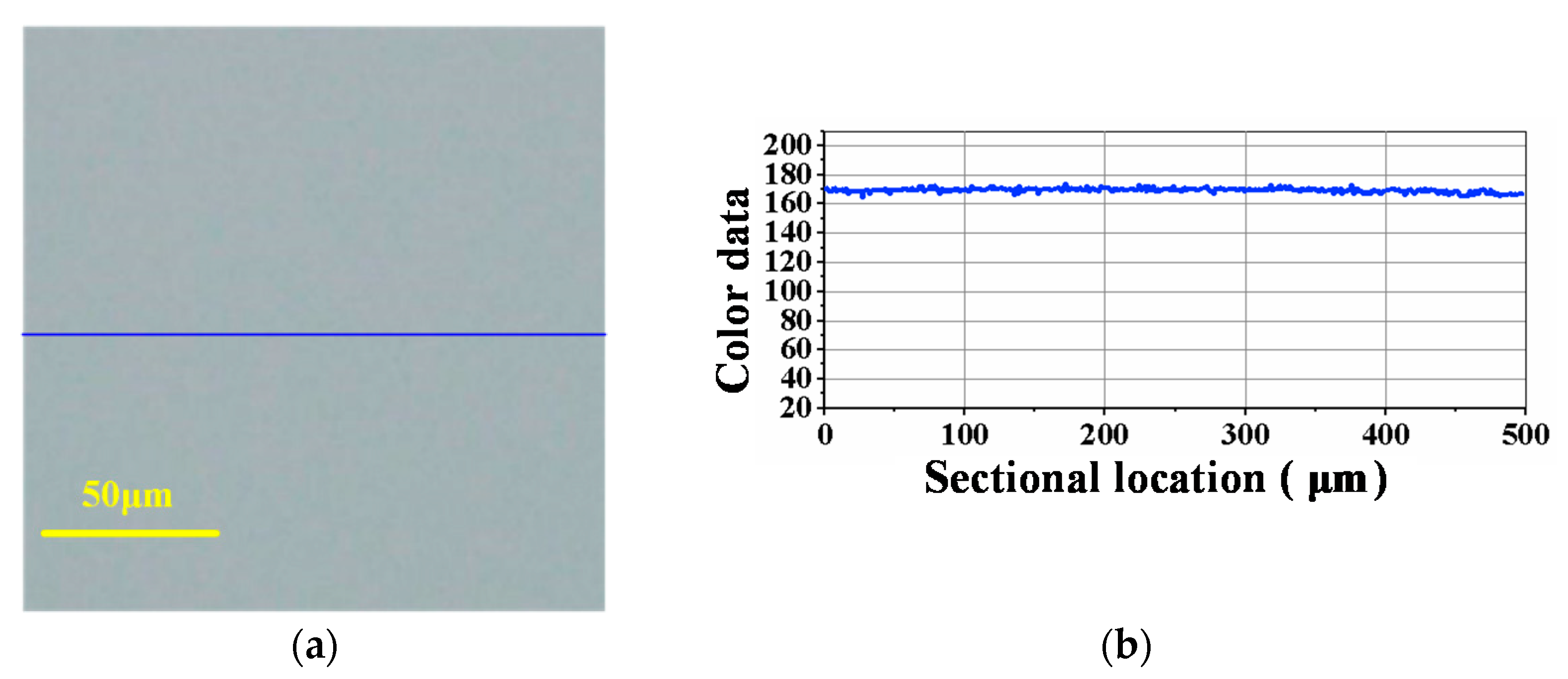

4.3. Effects of Vibrated Lapping Followed by Vibrated CMP

5. Conclusions

- The established ultrasonic vibration-assisted device can cause the workpiece to longitudinally vibrate with an amplitude from 0 μm to about 3.5 μm.

- Increasing amplitude can increase the processing efficiency of SiC lapping. When the amplitude increases to 2 μm or a higher value, the surface defects and damages can be reduced.

- Ultrasonic-assisted lapping with a proper amplitude can comprehensively improve machining efficiency and surface quality. Less surface damages are beneficial for reducing the subsequent process time. Therefore, ultrasonic assistance promotes the achievement of a finishing surface with a higher MRR.

- Ultrasonic vibration can improve the machining efficiency surface quality of SiC CMP. Due to a higher MRR, the surface defects and damages produced by the former lapping can be quickly removed. Compared with the MRR of 0.347 μm/h in traditional CMP, ultrasonic CMP can achieve a higher MRR of 0.717 μm/h, thus leading to a good surface with less defects.

- The three-step hybrid process, which combines ultrasonic vibration with lapping disc material, can achieve the finishing machining by improving the machining efficiency of lapping and CMP. Ultrasonic lapping using a cast iron disc can quickly remove large surface damages with a high MRR of 10.93 μm/min. Ultrasonic lapping using a copper disc can reduce the residual surface defects with a high MRR of 6.11 μm/min. Ultrasonic CMP can achieve a smooth and less damaged surface, with an MRR of 1.44 μm/h, which is much higher than the 100 nm/h of traditional CMP.

- Thus, this new hybrid process utilizing ultrasonic vibration can significantly improve the precise machinability of single-crystal SiC, and can hopefully achieve high-efficiency and ultraprecise machining.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yin, T.X.; Xu, C.; Lin, L.; Jing, K.Y. A SiC MOSFET and Si IGBT Hybrid Modular Multilevel Converter with Specialized Modulation Scheme. IEEE Trans. Power Electr. 2020, 35, 12623–12628. [Google Scholar] [CrossRef]

- Cabello, M.; Soler, V.; Rius, G.; Montserrat, J.; Rebollo, J.; Godignon, P. Advanced processing for mobility improvement in 4H-SiC MOSFETs: A review. Mat. Sci. Semicond. Proc. 2018, 78, 22–31. [Google Scholar] [CrossRef]

- Pan, G.; Yan, Z.; Luo, G.; Shi, X.; Zou, C.; Hua, G. Chemical mechanical polishing (CMP) of on-axis Si-face 6H-SiC wafer for obtaining atomically flat defect-free surface. J. Mater. Sci. Mater. Electron. 2013, 24, 5040–5047. [Google Scholar] [CrossRef]

- Olejniczak, K.; Flint, T.; Simco, D.; Storkov, S.; McGee, B.; Shaw, R.; Passmore, B.; George, K.; Curbow, A.; McNutt, T. A compact 110 kVA, 140 °C ambient, 105 °C liquid cooled, all-SiC inverter for electric vehicle traction drives. In Proceedings of the 2017 IEEE Applied Power Electronics Conference and Exposition (APEC), Tampa, FL, USA, 26–30 March 2017; pp. 735–742. [Google Scholar] [CrossRef]

- Kimoto, T.; Watanabe, H. Defect engineering in SiC technology for high-voltage power devices. Appl. Phys. Express 2020, 13. [Google Scholar] [CrossRef]

- China Advanced Semiconductor Industry Innovation Alliance (CASA). Third Generation Semiconductor Industry Development Report; China Advanced Semiconductor Industry Innovation Alliance (CASA): Beijing, China, 2019; pp. 38–39. Available online: http://www.casa-china.cn/uploads/soft/190415/6_1547213941.pdf (accessed on 15 December 2019).

- Semiconductor Industry Innovation Alliance (CASA). Third Generation Semiconductor Industry Development Report; China Advanced Semiconductor Industry Innovation Alliance (CASA): Beijing, China, 2021; p. 29. Available online: http://www.casa-china.cn/uploads/soft/210927/6_1522096971.pdf (accessed on 11 April 2021).

- Gao, B.; Zhai, W.J.; Zhai, Q.; Xia, Y.L.; Wang, C.; Peng, K.X. Electro-Chemical Mechanical Polishing of 4H-SiC for Scratch-Free Surfaces with Less Oxide Layer at High Efficiency. ECS J. Solid State Sci. Technol. 2019, 8, 677–684. [Google Scholar] [CrossRef]

- Murata, J.; Nagatomo, D. Investigation of Electrolytic Condition on Abrasive-Free Electrochemical Mechanical Polishing of 4H-SiC Using Ce Thin Film. ECS J. Solid State Sci. Technol. 2020, 9, 034002. [Google Scholar] [CrossRef]

- Yamamura, K.; Takiguchi, T.; Ueda, M.; Deng, H.; Hattori, A.N.; Zettsu, N. Plasma assisted polishing of single crystal SiC for obtaining atomically flat strain-free surface. CIRP Ann. 2011, 60, 571–574. [Google Scholar] [CrossRef]

- Ji, J.W.; Yamamura, K.; Deng, H. Plasma-Assisted Polishing for Atomic Surface Fabrication of Single Crystal SiC. Acta Phys. Sin. 2021, 70, 068102. [Google Scholar] [CrossRef]

- He, Y.; Yuan, Z.W.; Song, S.Y.; Gao, X.J.; Deng, W.J. Investigation on Material Removal Mechanisms in Photocatalysis-Assisted Chemical Mechanical Polishing of 4H-SiC Wafers. Int. J. Precis. Eng. Manuf. 2021, 22, 951–963. [Google Scholar] [CrossRef]

- Yuan, Z.W.; He, Y.; Sun, X.W.; Wen, Q. UV-TiO2 photocatalysis-assisted chemical mechanical polishing 4H-SiC wafer. Mater. Manuf. Process. 2018, 33, 1214–1222. [Google Scholar] [CrossRef]

- Xie, X.Z.; Peng, Q.F.; Chen, G.P.; Li, J.G.; Long, J.Y.; Pan, G.S. Femtosecond laser modification of silicon carbide substrates and its influence on CMP process. Ceram. Int. 2021, 47, 13322–13330. [Google Scholar] [CrossRef]

- Chen, G.P.; Li, J.G.; Long, J.Y.; Luo, H.M.; Zhou, Y.; Xie, X.Z.; Pan, G.S. Surface modulation to enhance chemical mechanical polishing performance of sliced silicon carbide Si-face. Appl. Surf. Sci. 2021, 536, 147963. [Google Scholar] [CrossRef]

- Deng, J.Y.; Pan, J.S.; Zhang, Q.X.; Yan, Q.S.; Lu, J.B. The mechanism of Fenton reaction of hydrogen peroxide with single crystal 6H-SiC substrate. Surf. Interfaces 2020, 21, 100730. [Google Scholar] [CrossRef]

- Xing, M.Y.; Xu, W.J.; Dong, C.C.; Bai, Y.C.; Zeng, J.B.; Zhou, Y.; Zhang, J.L.; Yin, Y.D. Metal Sulfides as Excellent Co-catalysts for H2O2 Decomposition in Advanced Oxidation Processes. Chem 2018, 4, 1359–1372. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.; Sun, R.Y.; Ohkubo, Y.; Kawai, K.; Arima, K.; Endo, K.; Yamamura, K. Investigation of anodic oxidation mechanism of 4H-SiC (0001) for electrochemical mechanical polishing. Electrochim. Acta 2018, 271, 666–676. [Google Scholar] [CrossRef]

- Yang, X.; Yang, X.Z.; Kawai, K.; Arima, K.; Yamamura, K. Novel SiC wafer manufacturing process employing three-step slurryless electrochemical mechanical polishing. J. Manuf. Process. 2021, 70, 350–360. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Abd Elaziz, M.; Vendan, A. Modeling ultrasonic welding of polymers using an optimized artificial intelligence model using a gradient-based optimizer. Weld World 2021, 1–18. [Google Scholar] [CrossRef]

- Hu, Y.; Shi, D.; Hu, Y.; Zhao, H.W.; Sun, X.D. Investigation on the Material Removal and Surface Generation of a Single Crystal SiC Wafer by Ultrasonic Chemical Mechanical Polishing Combined with Ultrasonic Lapping. Materials 2018, 11, 2022. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.; Shi, D.; Hu, Y.; Zhao, H.W.; Sun, X.D.; Wang, M.S. Experimental investigation on the ultrasonically assisted single-sided lapping of monocrystalline SiC substrate. J. Manuf. Process 2019, 44, 299–308. [Google Scholar] [CrossRef]

- Xu, Y.C.; Lu, J.; Xu, X.P.; Chen, C.C.A.; Lin, Y.J. Study on high efficient sapphire wafer processing by coupling SG-mechanical polishing and GLA-CMP. Int. J. Mach. Tools Manuf. 2018, 130, 12–19. [Google Scholar] [CrossRef]

| Ultrasonic Power (×2 kW) | Frequency (kHz) | Actual Value (μm) | Designed Output (Input × 0.35 μm) | Input (μm) |

|---|---|---|---|---|

| 40% | 19.84 | 0.5 | 0.35~0.7 | 1~2 |

| 50% | 19.79 | 0.77 | 0.7~1.4 | 2~4 |

| 60% | 19.75 | 1.1 | 1.4 | 4 |

| 70% | 19.73 | 2 | 2.1 | 6 |

| 80% | 19.72 | 2.6 | 2.8 | 8 |

| 90% | 19.71 | 3.2 | 3.5 | 10 |

| P | n | D | t | v | C |

|---|---|---|---|---|---|

| 40 kPa | 50 rpm | 4 μm | 4 min | 12.5 mL/min | 2 wt% |

| Conditions | Step 1 | Step 2 | Step 3 |

|---|---|---|---|

| Ultrasonic power (×2 kW) | 70% | 70% | 70% |

| Pressure (kPa) | 40 | 40 | 60 |

| Rotational speed (rpm) | 50 | 50 | 50 |

| Machining time (min) | 2 | 4 | 60 |

| Abrasive size (μm) | 6 | 4 | 0.08 |

| Abrasive concentration (wt%) | 4 | 4 | 20 |

| Slurry supplying speed (mL/min) | 12.5 | 12.5 | 25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, D.; Zhao, T.; Ma, T.; Pan, J. Study on Improving the Precise Machinability of Single Crystal SiC by an Ultrasonic-Assisted Hybrid Process. Materials 2021, 14, 7320. https://doi.org/10.3390/ma14237320

Shi D, Zhao T, Ma T, Pan J. Study on Improving the Precise Machinability of Single Crystal SiC by an Ultrasonic-Assisted Hybrid Process. Materials. 2021; 14(23):7320. https://doi.org/10.3390/ma14237320

Chicago/Turabian StyleShi, Dong, Tianchen Zhao, Tengfei Ma, and Jinping Pan. 2021. "Study on Improving the Precise Machinability of Single Crystal SiC by an Ultrasonic-Assisted Hybrid Process" Materials 14, no. 23: 7320. https://doi.org/10.3390/ma14237320

APA StyleShi, D., Zhao, T., Ma, T., & Pan, J. (2021). Study on Improving the Precise Machinability of Single Crystal SiC by an Ultrasonic-Assisted Hybrid Process. Materials, 14(23), 7320. https://doi.org/10.3390/ma14237320