Taurine-Modified Boehmite Nanoparticles for GFRP Wind Turbine Rotor Blade Fatigue Life Enhancement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Matrix Material Modification

2.2. Laminate Fabrication

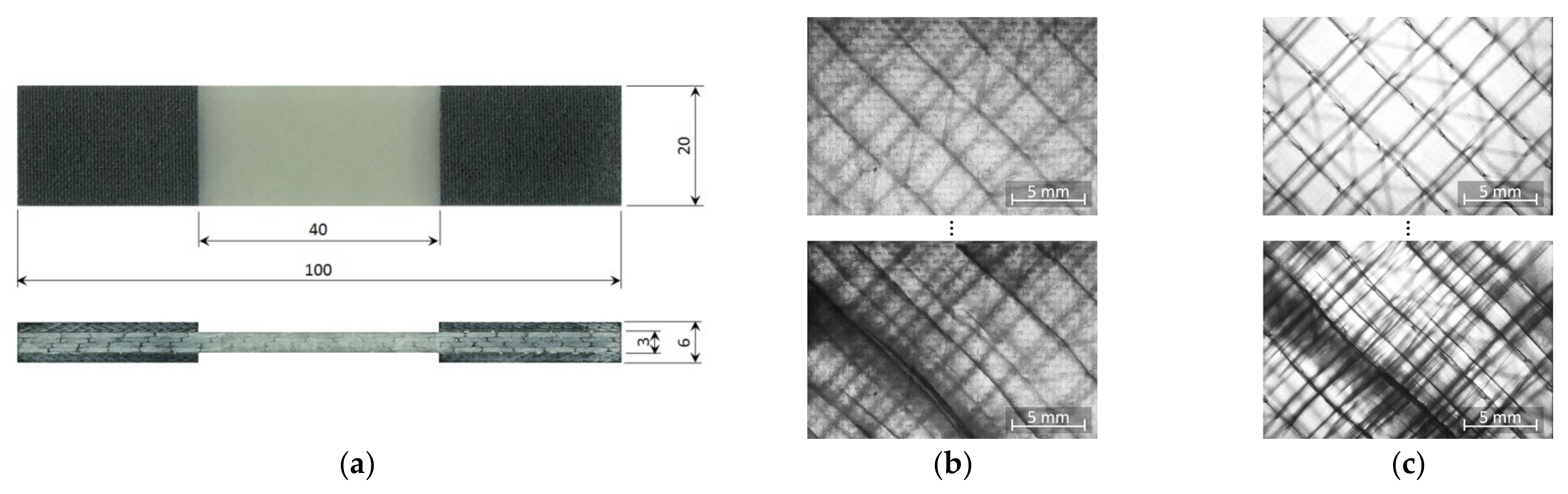

2.3. Specimen Design and Fabrication

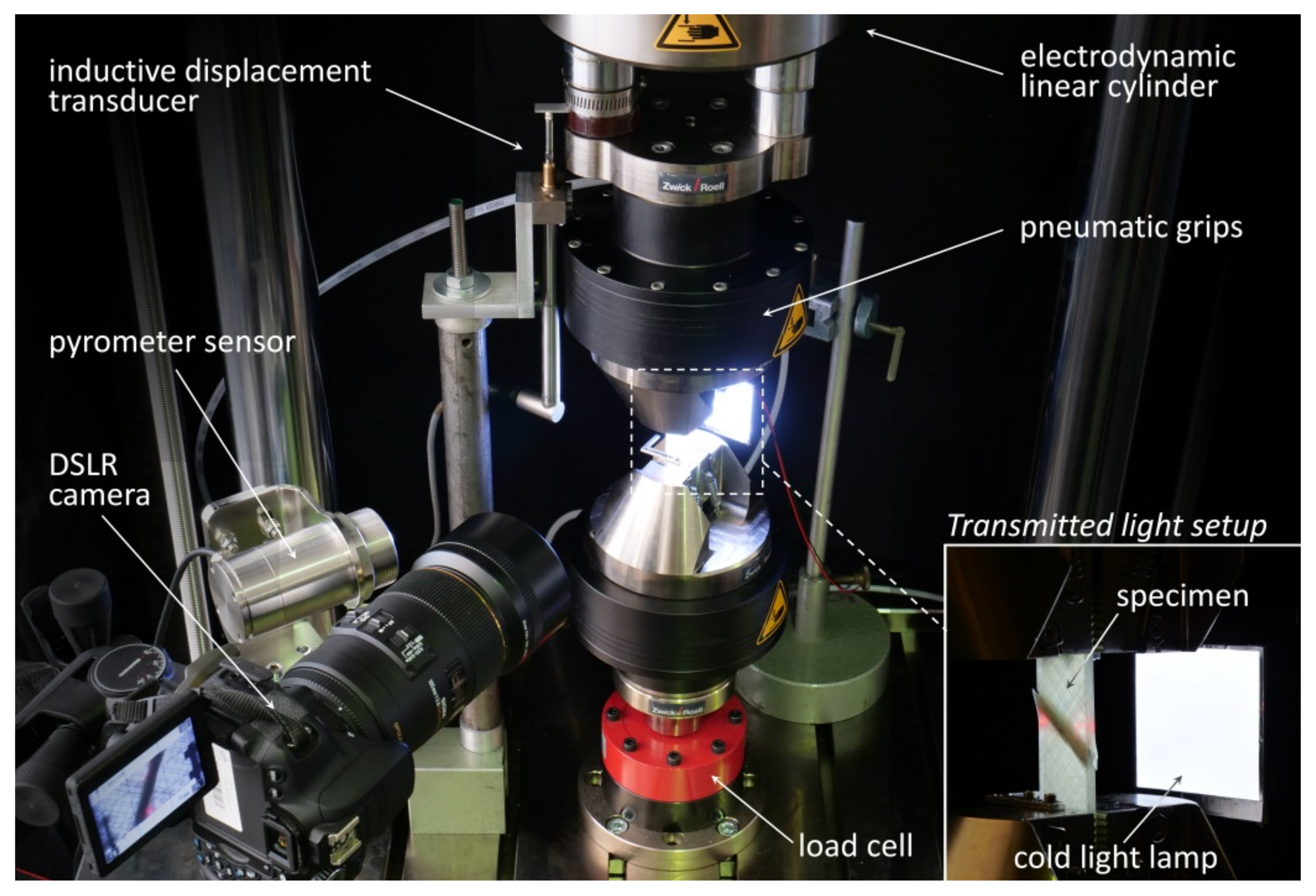

2.4. Experimental Set-Up and Testing Procedures

2.4.1. Static Tests

2.4.2. Fatigue Tests

2.4.3. Thermographic Fatigue Limit Estimation

2.5. Digital Damage Image Analysis

3. Results and Discussion

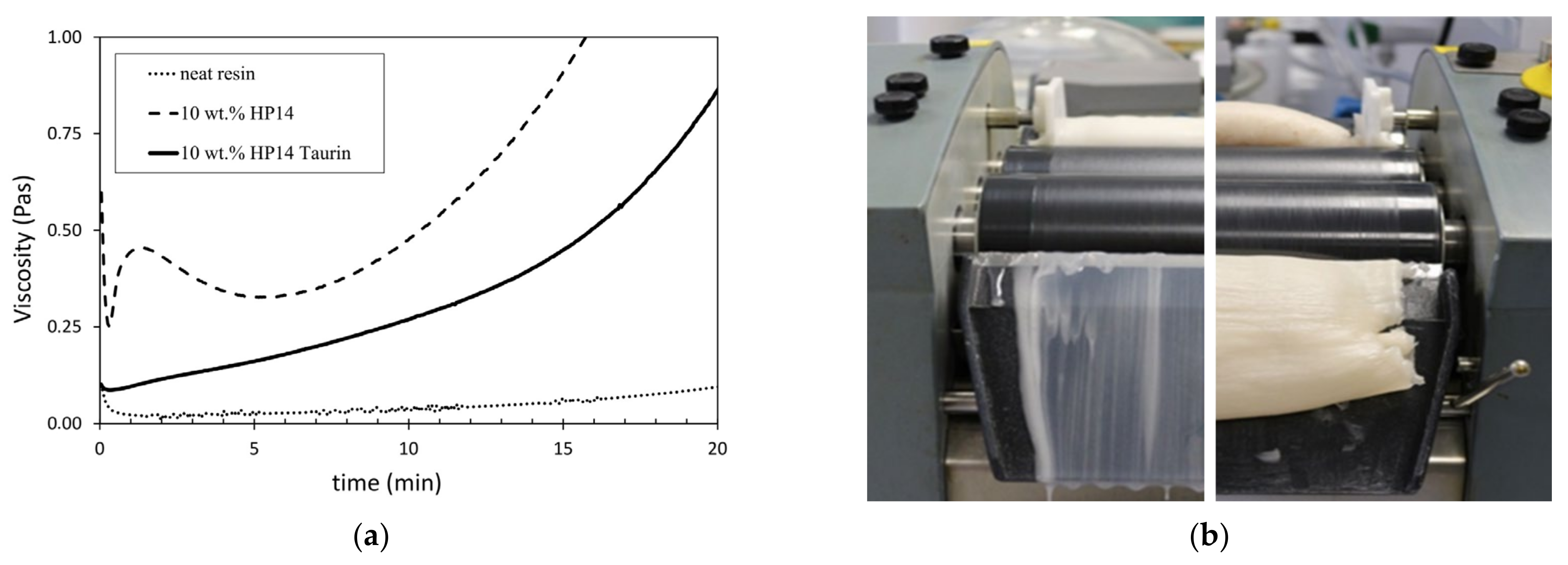

3.1. Rheological Properties

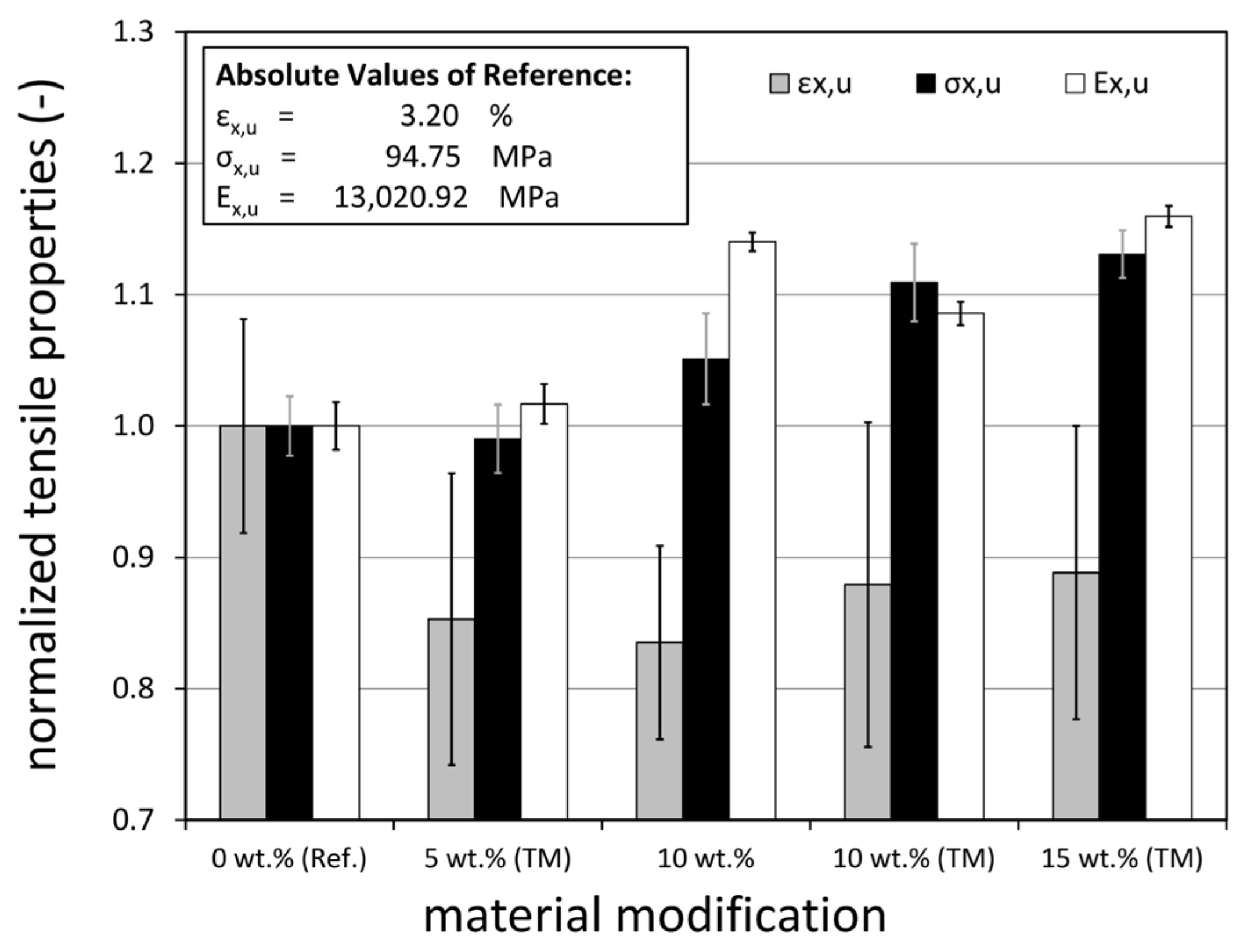

3.2. Static Tensile Properties

3.3. Fatigue Behaviour

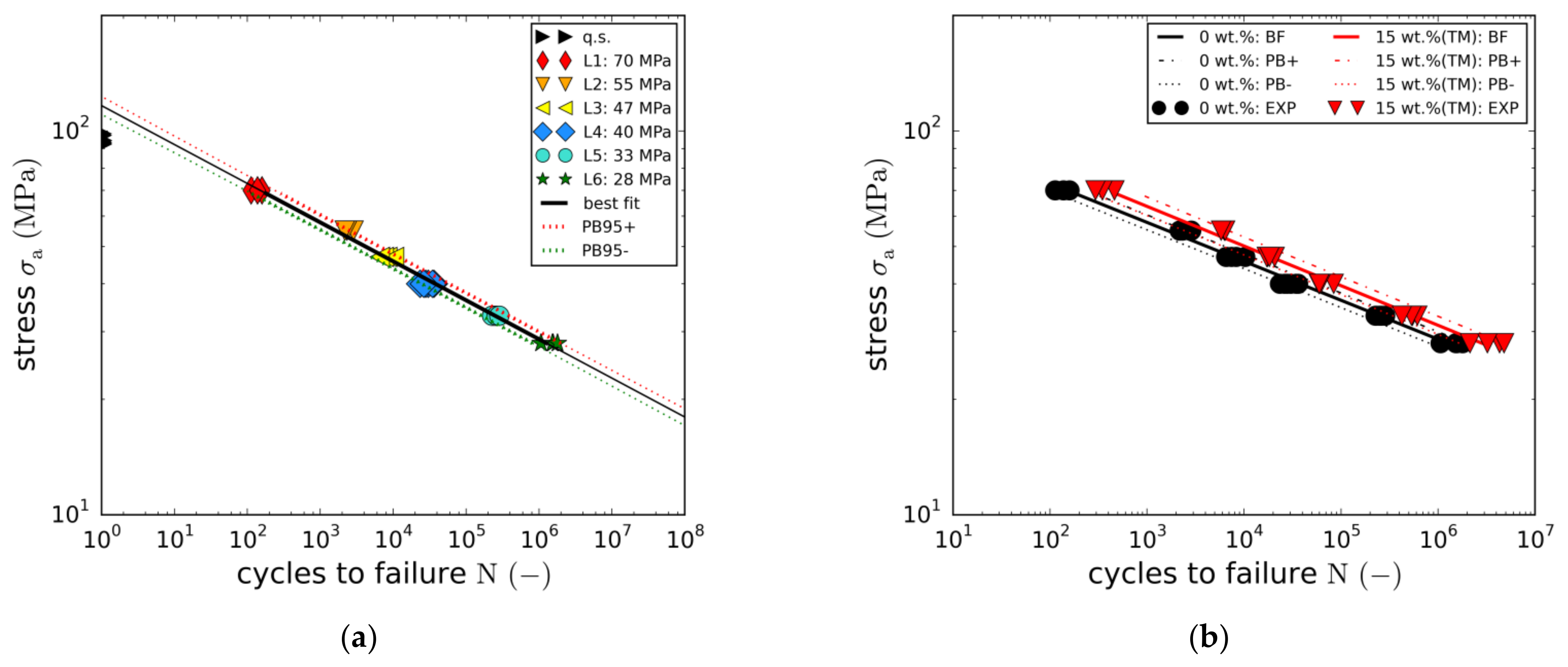

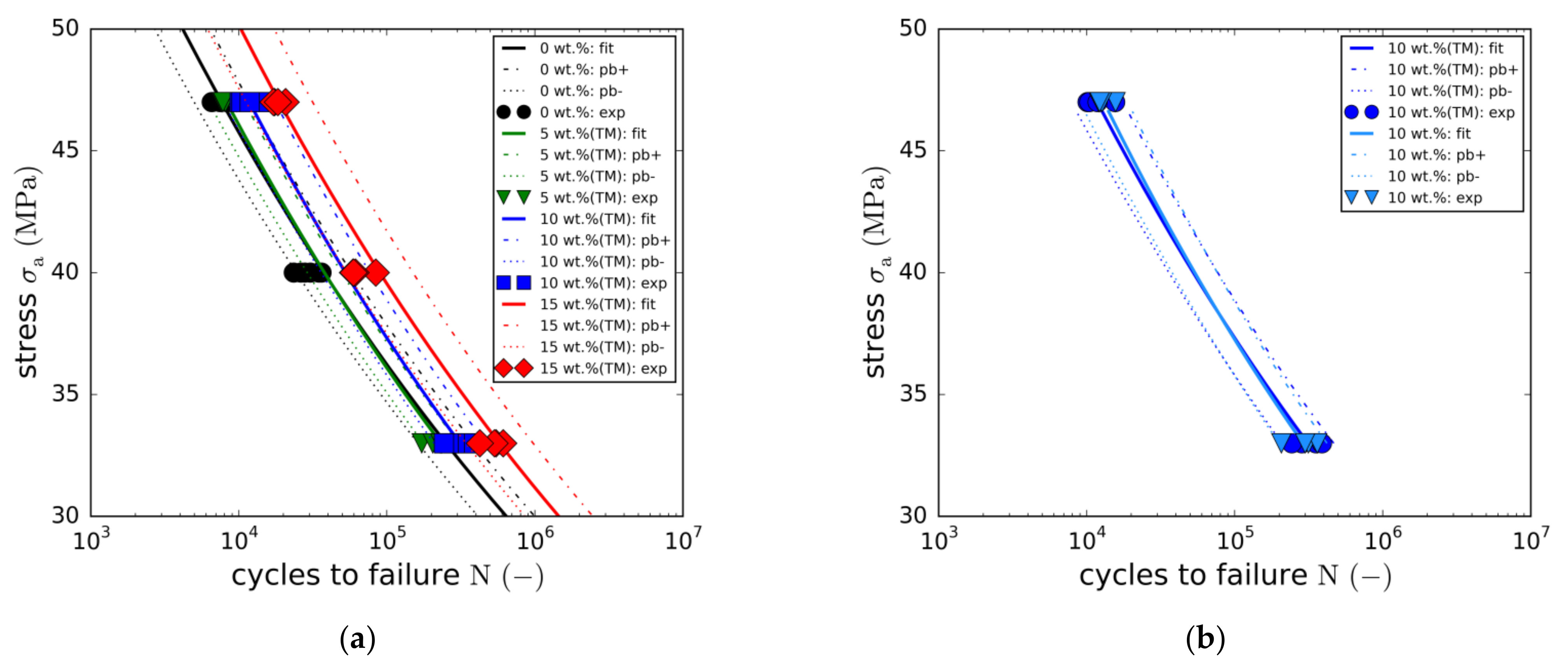

3.3.1. Fatigue Life

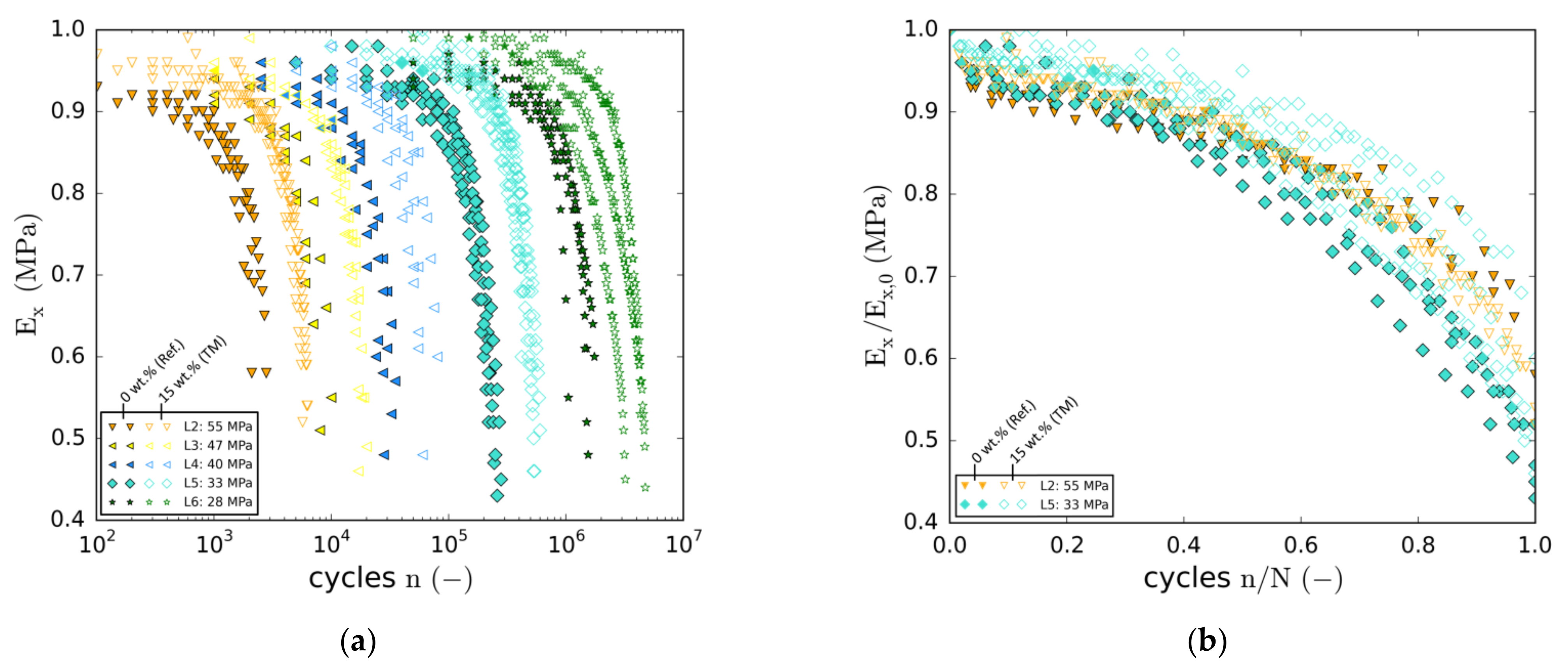

3.3.2. Degradation Behaviour

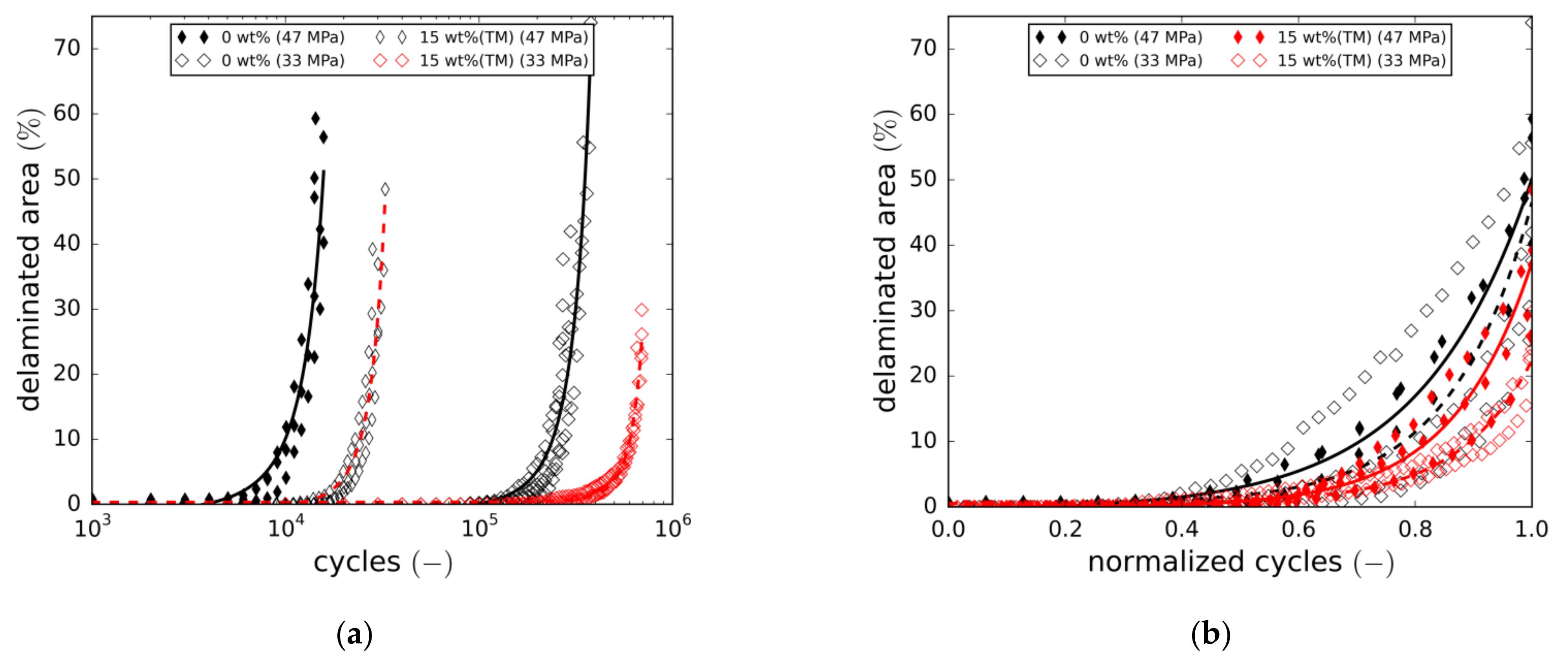

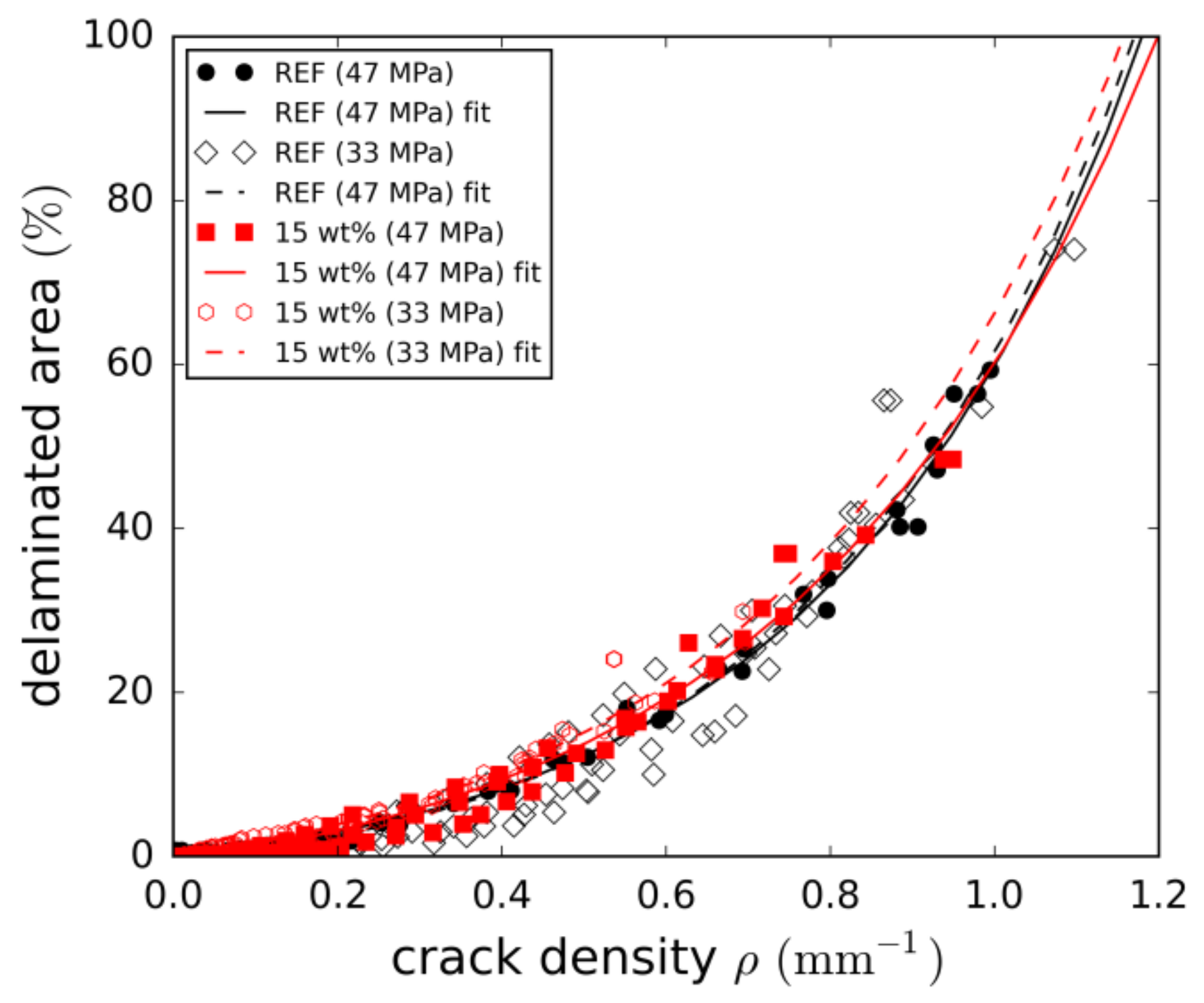

3.3.3. Damage Growth

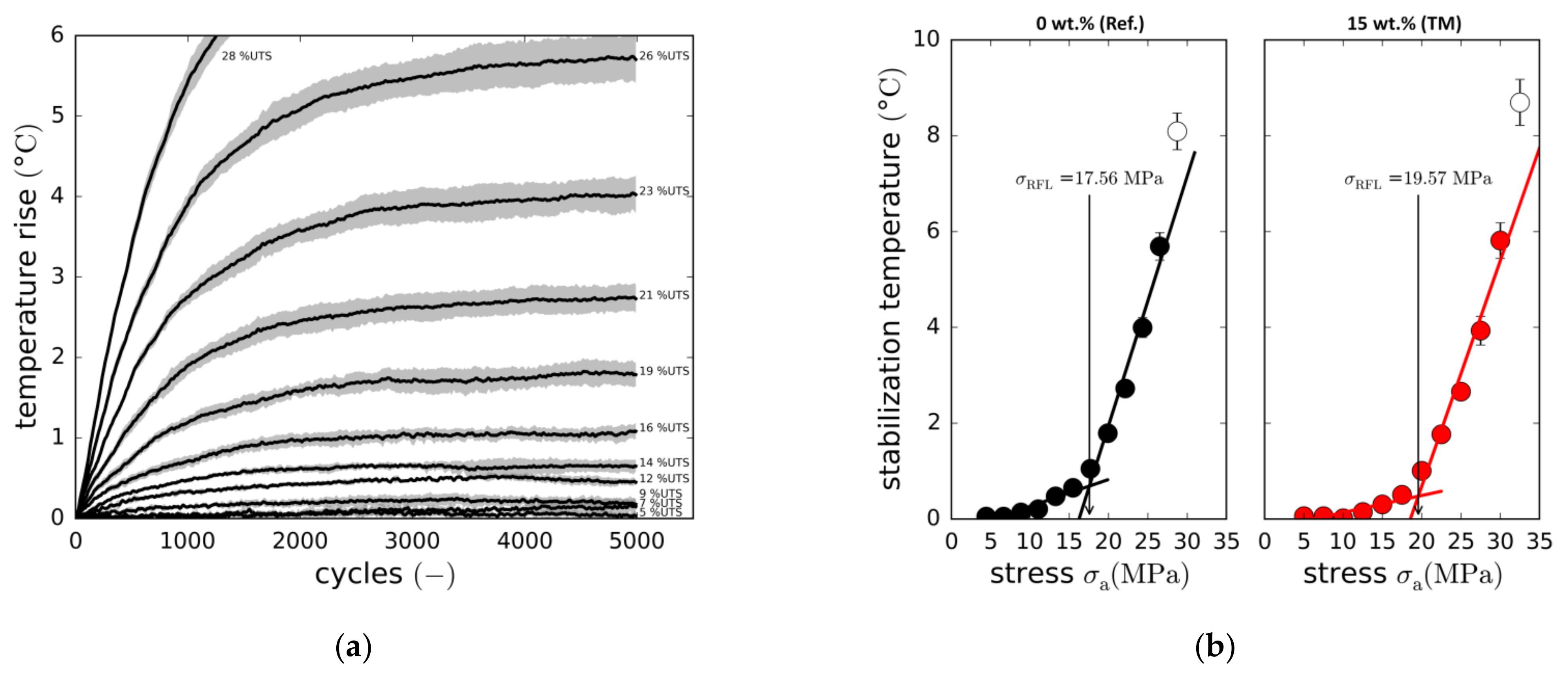

3.3.4. Fatigue Limit

4. Discussion

5. Conclusions and Outlook

- Taurine surface modification of boehmite nanoparticles allows the viscosity of the nanocomposite to be significantly decreased. Using taurine-modified particles, composite laminates with high particle contents of up to 15 wt.% can therefore be fabricated via infusion without the typical infiltration issues.

- The static ultimate tensile stress (UTS) of the laminate increases with particle content.

- Fatigue life can be significantly increased by adding boehmite nanoparticles. For a particle content of 15 wt.%., maximum fatigue life enhancements of up to 270% were observed.

- Results indicate that fatigue life enhancement is load level-dependent. However, this finding could not be completely clarified.

- The taurine modification itself does not influence the fatigue strength.

- Initiation of the damage mechanisms (matrix cracking and delamination) is delayed and growth rates are smaller for the laminates containing boehmite nanoparticles. However, the mechanisms and their accumulation along the relative cycle number do not significantly change.

- Similar to the static strength, boehmite nanoparticles also increase the so-called Risitano fatigue limit.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nijssen, R.P.L. Fatigue Life Prediction and Strength Degradation of Wind Turbine Rotor Blade Composite; Report SAND2006-7810P; Sandia National Laboratories: Albuquerque, NM, USA, 2006.

- Katsaprakakis, D.A.; Papadakis, N.; Ntintakis, I. A Comprehensive Analysis of Wind Turbine Blade Damage. Energies 2021, 14, 5974. [Google Scholar] [CrossRef]

- Mishnaevsky, L., Jr.; Branner, K.; Nørgaard Petersen, H.; Beauson, J.; McGugan, M.; Sørensen, B.F. Materials for Wind Turbine Blades: An Overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wessels, S.; Strobel, M.; van Wingerde, A.; Huessler, I.; Busmann, H.-G. Improved fatigue design methods for offshore wind turbine rotor blades considering non-linear Goodman analysis combined with finite element analysis. In Proceedings of the EWEC, Warsaw, Poland, 20–23 April 2010. [Google Scholar]

- Mandell, J.F.; Samborsky, D.D. DOE/MSU Composite Material Fatigue Database: Test Methods, Materials and Analysis; Contractor Report SAND97-3002; Montana State University: Bozeman, Montana, 1997. [Google Scholar]

- Chen, X.; Eder, M.A. A critical Review of Damage and Failure of Composite Wind Turbine Blade Structures. IOP Conf. Ser. Mater. Sci. Eng. 2020, 942, 012001. [Google Scholar] [CrossRef]

- Marin, J.C.; Barroso, A.; Paris, F.; Canas, J. Study of fatigue damage in wind turbine blades. Eng. Fail. Anal. 2009, 16, 656–668. [Google Scholar] [CrossRef]

- Choi, S.-W.; Farinholt, K.M.; Taylor, S.G.; Light-Marquez, A.; Park, G. Damage Identification of Wind Turbine Blades Using Piezoelectric Transducers. Shock. Vib. 2014, 2014, 430854. [Google Scholar] [CrossRef] [Green Version]

- Jüngert, A. Damage Detection in Wind Turbine Blades Using two different Acoustic Techniques. e-J. Nondestruct. Test. 2008, 12, 1–10. [Google Scholar]

- Soerensen, B.F.; Joergensen, E.; Debel, C.P.; Jensen, F.M.; Jensen, H.M.; Jacobsen, T.; Halling, K.M. Improved Design of Large Wind Turbine Blade of Fibre Composites Based on Studies of Scale Effects (Phase 1)—Summary Report; Technical Report RISO-R-1390(EN); Risoe National Laboratory, Materials Research Department: Roskilde, Denmark, 2004. [Google Scholar]

- Karthikeyan, R.; Subbiah, R.; Ranganathan, N.; Bensingh, J.; Kader, A.; Nayak, S. A review on fatigue damages in the wind turbines: Challenges in determining and reducing fatigue failures in wind turbine blades. Wind. Eng. 2020, 44, 434–451. [Google Scholar]

- Castro, O. Fatigue Strength of Composite Wind Turbine Blade Structures. DTU Wind. Energy 2018. [Google Scholar] [CrossRef]

- Tate, J.S.; Akinola, A.T.; Espinoza, S.; Gaikwad, S.; Vasudevan, D.K.K.; Sprenger, S.; Kumar, K. Tension–tension fatigue performance and stiffness degradation of nanosilica-modified glass fiber-reinforced composites. J. Compos. Mater. 2018, 52, 823–834. [Google Scholar] [CrossRef]

- Rafiee, M.; Rad, S.H.; Nitzsche, F.; Laliberte, J.; Labrosse, M.R. Significant fatigue life enhancement in Mulitscale Doubly-Modified Fiber/Epoxy Nanocomposites with Graphene Nanoplatelets and Reduced-Graphene Oxide. Polymers 2020, 12, 2135. [Google Scholar] [CrossRef]

- Phong, N.T.; Gabr, M.H.; Anh, L.H.; Duc, V.M.; Betti, A.; Okubo, K.; Chuong, B.; Fujii, T. Improved fracture toughness and fatigue life of carbon fiber reinforced epoxy composite due to the incorporation of rubber nanoparticles. J. Mater. Sci. 2013, 48, 6039–6047. [Google Scholar] [CrossRef]

- Fenner, J.S.; Daniel, I.M. Hybrid nanoreinforced carbon/epoxy composites for enhanced damage tolerance and fatigue life. Compos. Part A 2014, 65, 47–56. [Google Scholar] [CrossRef]

- Makeev, A.; Bakis, C.; Strauch, E.; Chris, M.; Holemans, P.; Miller, G.; Nguyen, D.; Spencer, D.; Patz, N. Advanced Composite Materials Technology for Rotorcraft through the Use of Nanoadditives. J. Am. Helicopter Soc. 2015, 60, 32008. [Google Scholar] [CrossRef] [Green Version]

- Jagannathan, N.; Bojja, R.; Manjunatha, C.M.; Taylor, A.C.; Kinloch, A.J. Fatigue Behaviour of a Hybrid Particle Modified Fiberglass/Epoxy Composite under a Helicopter Spectrum Load Sequence. Adv. Compos. Lett. 2013, 22, 52–56. [Google Scholar] [CrossRef] [Green Version]

- Megahed, M.; El-Wafa Megahed, A.A.; Agwa, M.A. Mechanical properties of on/off-axis loading for hybrid glass fiber reinforced epoxy filled with silica and carbon black nanoparticles. Mater. Technol. 2018, 33, 398–405. [Google Scholar] [CrossRef]

- Manjunatha, C.M.; Taylor, A.C.; Kinloch, A.J.; Sprenger, S. The tensile fatigue behavior of a silica nanoparticle-modified glass fibre reinforced epoxy composite. Compos. Sci. Technol. 2010, 70, 193–199. [Google Scholar] [CrossRef] [Green Version]

- Manjunatha, C.M.; Sprenger, S.; Taylor, A.C.; Kinloch, A.J. The Tensile Fatigue Behavior of a Glass-fiber Reinforced Plastic Composite Using a Hybrid-toughened Epoxy Matrix. J. Compos. Mater. 2010, 44, 2095–2109. [Google Scholar] [CrossRef] [Green Version]

- Knoll, J.B.; Riecken, B.T.; Kosmann, N.; Chandrasekaran, S.; Schulte, K.; Fiedler, B. The effect of carbon nanoparticles on the fatigue performance of carbon fibre reinforced epoxy. Compos. Part A 2014, 67, 233–240. [Google Scholar] [CrossRef]

- Bourchak, M.; Algarni, A.; Khan, A.; Khashaba, U. Effect of SWCNTs and graphene on the fatigue behavior of antisymmetric GFRP laminate. Compos. Sci. Technol. 2018, 167, 164–173. [Google Scholar] [CrossRef]

- Manjunatha, C.M.; Bojja, R.; Jagannathan, N.; Kinloch, A.J.; Taylor, A.C. Enhanced fatigue behavior of a glass fiber reinforced hybrid particles modified epoxy nanocomposite under WISPERX spectrum load sequence. Int. J. Fatigue 2013, 54, 25–31. [Google Scholar] [CrossRef] [Green Version]

- Ngah, S.A.; Taylor, A.C. Fracture behavior of rubber- and silica nanoparticle-toughened glass fibre composites under static and fatigue loading. Compos. Part A 2018, 109, 239–256. [Google Scholar] [CrossRef]

- Fathy, A.; Shaker, A.; Abdel Hamid, M.; Megahed, A.A. The effects of nano-silica/nano-alumina on fatigue behavior of glass fiber-reinforced epoxy composites. J. Compos. Mater. 2017, 51, 1667–1679. [Google Scholar] [CrossRef]

- Kamble, M.; Lakhnot, A.S.; Bartolucci, S.F.; Littlefield, A.G.; Picu, C.R.; Koratkar, N. Improvement in fatigue life of carbon fibre reinforced polymer composites via a Nano-Silica Modified Matrix. Carbon 2020, 170, 220–224. [Google Scholar] [CrossRef]

- Jux, M.; Fankhänel, J.; Daum, B.; Mahrholz, T.; Sinapius, M.; Rolfes, R. Mechanical properties of epoxy/boehmite nanocomposites in dependency of mass fraction and surface modification—An experimental and numerical approach. Polymer 2018, 141, 34–45. [Google Scholar] [CrossRef]

- Jux, M.; Finke, B.; Mahrholz, T.; Sinapius, M.; Kwade, A.; Schilde, C. Effects of Al(OH)O nanoparticle agglomerate size in epoxy resin on tension, bending, and fracture properties. J. Nanoparticle Res. 2017, 19, 139. [Google Scholar] [CrossRef] [Green Version]

- Exner, W.; Arlt, C.; Mahrholz, T.; Riedel, U.; Sinapius, M. Nanoparticles with various surface modifications as functionalized crosslinking agents for composite resin materials. Compos. Sci. Technol. 2012, 72, 1153–1159. [Google Scholar] [CrossRef]

- Arlt, C.; Exner, W.; Riedel, U.; Sturm, H. Sinapius, J.M. Nanoscaled Boehmites’ Modes of Action in a Polymer and Its Carbon Fiber Reinforced Plastic. In Acting Principles of Nano-Scaled Matrix Additives for Composite Structures, 1st ed.; Sinapius, M., Ziegmann, G., Eds.; Springer: Cham, Switzerland, 2021; pp. 367–376. [Google Scholar]

- Jux, M. Einfluss der Grenzflächen Nanoskaliger Matrixadditive Auf das Schlagzähigkeitsverhalten von Faserverbunden, Dissertation; TU Braunschweig: Braunschweig, Germany, 2021. [Google Scholar]

- LaRosa, G.; Risitano, A. Thermographic methodology for rapid determination of the fatigue limit of materials and mechanical components. Int. J. Fatigue 2000, 22, 65–73. [Google Scholar] [CrossRef]

- Deutsches Institut für Normung. Kunststoffe—Bestimmung der Zugeigenschaften—Teil 4: Prüfbedingungen für Isotrop und Anisotrop Faserverstärkte Kunststoffverbundwerkstoffe/Plastics—Determination of Tensile Properties—Part 4: Test Conditions for Isotropic and Anisotropic Fibre-Reinforced Plastic Composites; DIN EN ISO 527-4:1997-07; Deutsches Institut für Normung: Berlin, Germany, 1997. [Google Scholar]

- Bryan, H. Fatigue Composite Materials; CRC Press: Boca Raton, FL, USA, 2003; pp. 201–202. [Google Scholar]

- Schneider, C.R.A.; Maddox, S.J. Best Practice Guide on Statistical Analysis of Fatigue Data; Tech. Rep. IIW-XIII-WG1-114–03; International Institute of Welding: Cambridge, UK, 2003. [Google Scholar]

- Luong, M.P. Fatigue Limit Evaluation of Metals using an Infrared Thermographic Technique. Mech. Mater. 1998, 28, 155–163. [Google Scholar] [CrossRef]

- Krapez, J.C.; Pacou, D. Thermography detection of damage initiation during fatigue tests. In Proceedings of the Thermosense XXIV, Proc. SPIE 4710, Orlando, FL, USA, 1–4 April 2002. [Google Scholar]

- Quaresimin, M. Fatigue of woven composite laminates under tensile and compressive loading. In Proceedings of the European Conference on Composite Materials, ECCM 10, Brugge, Belgium, 3–7 June 2002. [Google Scholar]

- Colombo, C.; Libonati, F.; Pezzani, F.; Salerno, A.; Vergani, L. Fatigue Behaviour of a GFRP laminate by thermographic measurements. Procedia Eng. 2011, 10, 3518–3527. [Google Scholar] [CrossRef] [Green Version]

- Gornet, L.; Westphal, O.; Burtin, C.; Bailleul, J.L.; Rozycki, P. Rapid Determination of the High Cycle Fatigue Limit Curve of Carbon Fiber Epoxy Matrix Composite Laminates by Thermography Methodology: Tests and Finite Element Simulations. Procedia Eng. 2013, 66, 697–704. [Google Scholar] [CrossRef]

- Jegou, L.; Marco, Y.; Le Saux, V.; Calloch, S. Fast prediction of the Wöhler curve from heat build-up measurements on Short Fiber Reinforced Plastic. Int. J. Fatigue 2013, 47, 259–267. [Google Scholar] [CrossRef]

- Montesano, J.; Fawaz, Z.; Bougherara, H. Use of infrared thermography to investigate the fatigue behavior of a carbon fiber reinforced polymer composite. Compos. Struct. 2013, 97, 76–83. [Google Scholar] [CrossRef]

- Tang, Y.; Ye, L.; Zhang, Z.; Friedrich, K. Interlaminar fracture toughness and CAI strength of fibre-reinforced composites with nanoparticles-A review. Compos. Sci. Technol. 2013, 86, 26–37. [Google Scholar] [CrossRef]

- ISO International Standard: ISO13003—Fibre-Reinforced Plastics—Determination of Fatigue Properties under Cyclic Loading Conditions, 1st ed.; ISO: Geneva, Switzerland, 2003.

- Reifsnider, K.L. Fatigue of Composite Materials; Elsevier Ltd.: Kidlington, UK, 1991. [Google Scholar]

- Talreja, R.; Singh, C.V. Damage and Failure of Composite Materials; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Adam, T.J.; Horst, P. Fatigue damage and fatigue limits of a GFRP angle-ply laminate tested under very high cycle fatigue loading. Int. J. Fatigue 2017, 99, 202–214. [Google Scholar] [CrossRef]

| Matrix Modification | Number of Specimens | E-Modulus | Rupture Strain | Tensile Strength | |||

|---|---|---|---|---|---|---|---|

| STD/MPa | STD/MPa | ||||||

| 0 wt.% (Ref.) | 7 | 13,021 | 236 | 3.20 | 0.26 | 94.8 | 2.14 |

| 5 wt.% (TM) | 6 | 13,240 | 200 | 2.73 | 0.30 | 93.8 | 2.43 |

| 10 wt.% | 6 | 14,846 | 103 | 2.67 | 0.20 | 99.6 | 3.45 |

| 10 wt.% (TM) | 6 | 14,137 | 127 | 2.81 | 0.35 | 105.1 | 3.12 |

| 15 wt.% (TM) | 6 | 15,099 | 119 | 2.84 | 0.32 | 107.2 | 1.94 |

| LL | Load | Cycles per Block | Frequency | Specimens | Fatigue Cycles | Matrix Modification | |||

|---|---|---|---|---|---|---|---|---|---|

| N | STD | ||||||||

| MPa | - | - | Hz | - | - | - | % | ||

| 1 | 70 | 0.74 | 10 | 1 | 3 | 137 | 19 | 14 | 0 wt.% (Ref.) |

| 0.65 | 3 | 368 | 70 | 19 | 15 wt.% | ||||

| 2 | 55 | 0.58 | 100 | 3 | 3 | 2454 | 296 | 12 | 0 wt.% (Ref.) |

| 0.51 | 3 | 6157 | 256 | 4 | 15 wt.% (TM) | ||||

| 3 | 47 | 0.5 | 1000 | 3 | 5 | 7844 | 1386 | 18 | 0 wt.% (Ref.) |

| - | 3 | 15,160 | 689 | 5 | 0 wt.% (Ref.) (P) | ||||

| 0.5 | 6 | 8305 | 734 | 9 | 5 wt.% (TM) | ||||

| 0.47 | 4 | 13,159 | 1454 | 11 | 10 wt.% | ||||

| 0.45 | 4 | 11,981 | 2157 | 18 | 10 wt.% (TM) | ||||

| 0.44 | 4 | 18,414 | 1403 | 8 | 15 wt.% (TM) | ||||

| - | 3 | 30,354 | 1795 | 6 | 15 wt.% (TM)(P) | ||||

| 4 | 40 | 0.42 | 5000 | 3 | 6 | 29,835 | 4490 | 15 | 0 wt.% (Ref.) |

| 0.37 | 4 | 66,054 | 10,445 | 16 | 15 wt.% (TM) | ||||

| 5 | 33 | 0.35 | 10,000 | 3 | 5 | 251,235 | 21,423 | 9 | 0 wt.% (Ref.) |

| - | 4 | 325,134 | 39,462 | 12 | 0 wt.% (Ref.) (P) | ||||

| 0.35 | 7 | 235,973 | 39,799 | 17 | 5 wt.% (TM) | ||||

| 0.33 | 4 | 295,235 | 55,958 | 19 | 10 wt.% | ||||

| 0.31 | 4 | 317,201 | 57,003 | 18 | 10 wt.% (TM) | ||||

| 0.31 | 4 | 529,167 | 67,316 | 13 | 15 wt.% (TM) | ||||

| - | 3 | 631,415 | 64,046 | 10 | 15 wt.% (TM) (P) | ||||

| 6 | 28 | 0.3 | 50,000 | 6 | 4 | 1,486,201 | 264,921 | 18 | 0 wt.% (Ref.) |

| 0.26 | 4 | 3,624,331 | 1,028,596 | 28 | 15 wt.% (TM) | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adam, T.J.; Exner, W.; Wierach, P. Taurine-Modified Boehmite Nanoparticles for GFRP Wind Turbine Rotor Blade Fatigue Life Enhancement. Materials 2021, 14, 6997. https://doi.org/10.3390/ma14226997

Adam TJ, Exner W, Wierach P. Taurine-Modified Boehmite Nanoparticles for GFRP Wind Turbine Rotor Blade Fatigue Life Enhancement. Materials. 2021; 14(22):6997. https://doi.org/10.3390/ma14226997

Chicago/Turabian StyleAdam, Till Julian, Wibke Exner, and Peter Wierach. 2021. "Taurine-Modified Boehmite Nanoparticles for GFRP Wind Turbine Rotor Blade Fatigue Life Enhancement" Materials 14, no. 22: 6997. https://doi.org/10.3390/ma14226997

APA StyleAdam, T. J., Exner, W., & Wierach, P. (2021). Taurine-Modified Boehmite Nanoparticles for GFRP Wind Turbine Rotor Blade Fatigue Life Enhancement. Materials, 14(22), 6997. https://doi.org/10.3390/ma14226997