The Behavior of Cement-Bonded Particleboard with Modified Composition under Static Load Stress

Abstract

1. Introduction

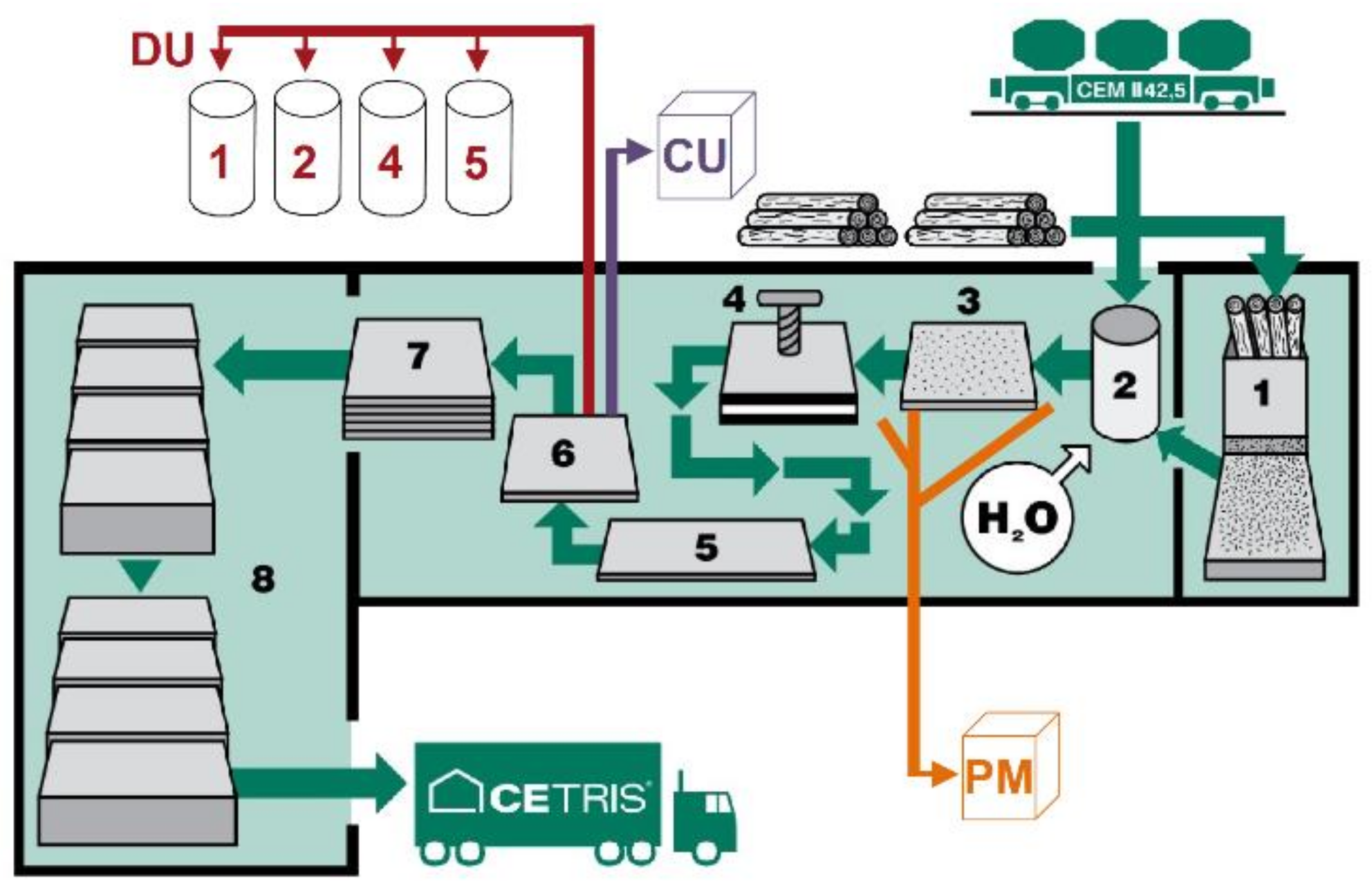

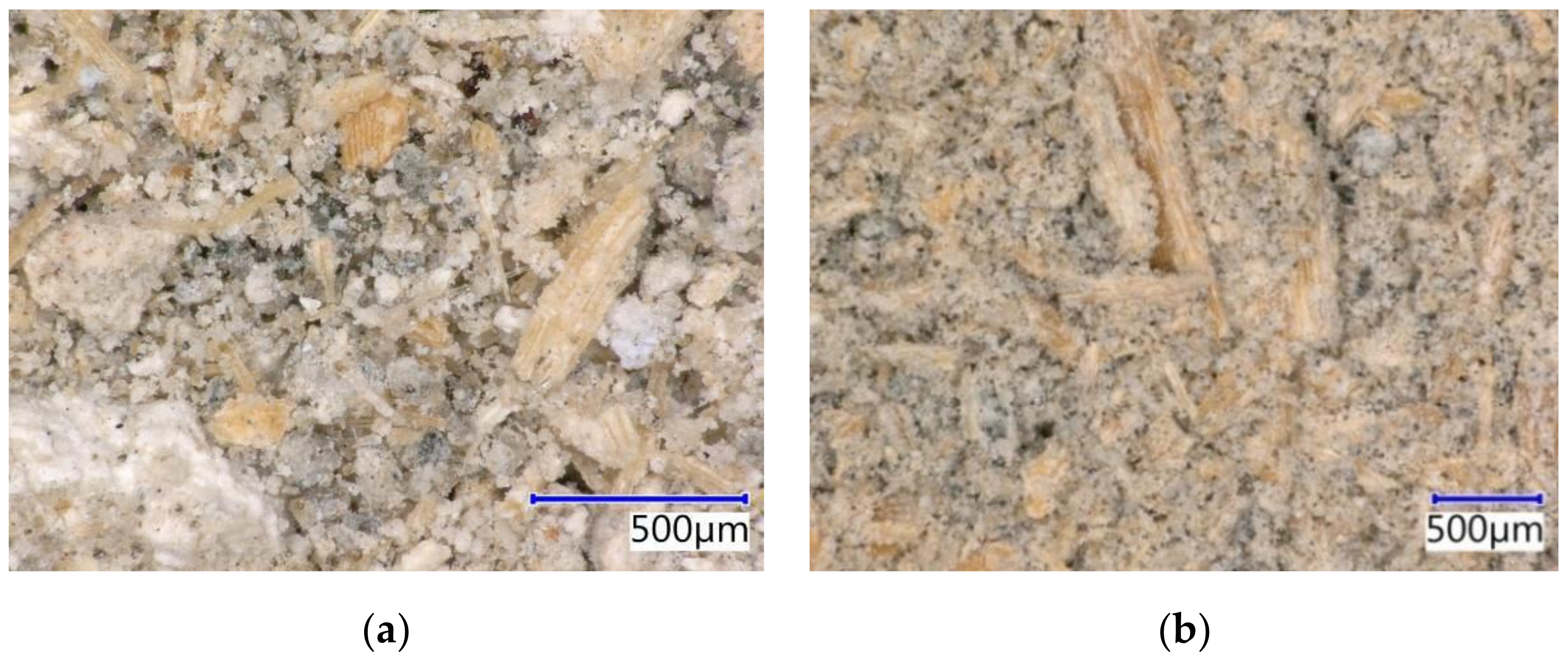

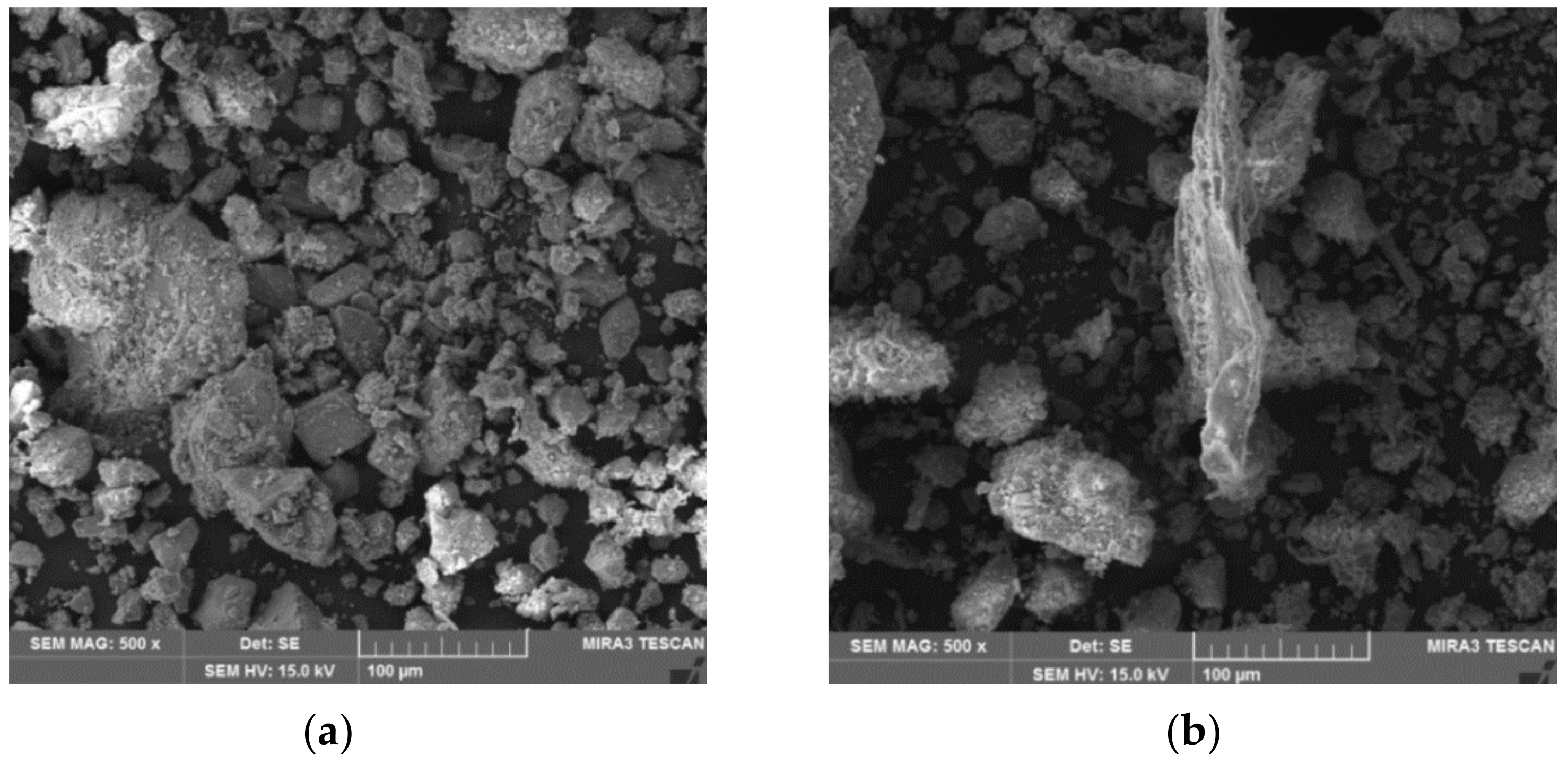

2. Materials

3. Methods

3.1. Curing of Test Specimens

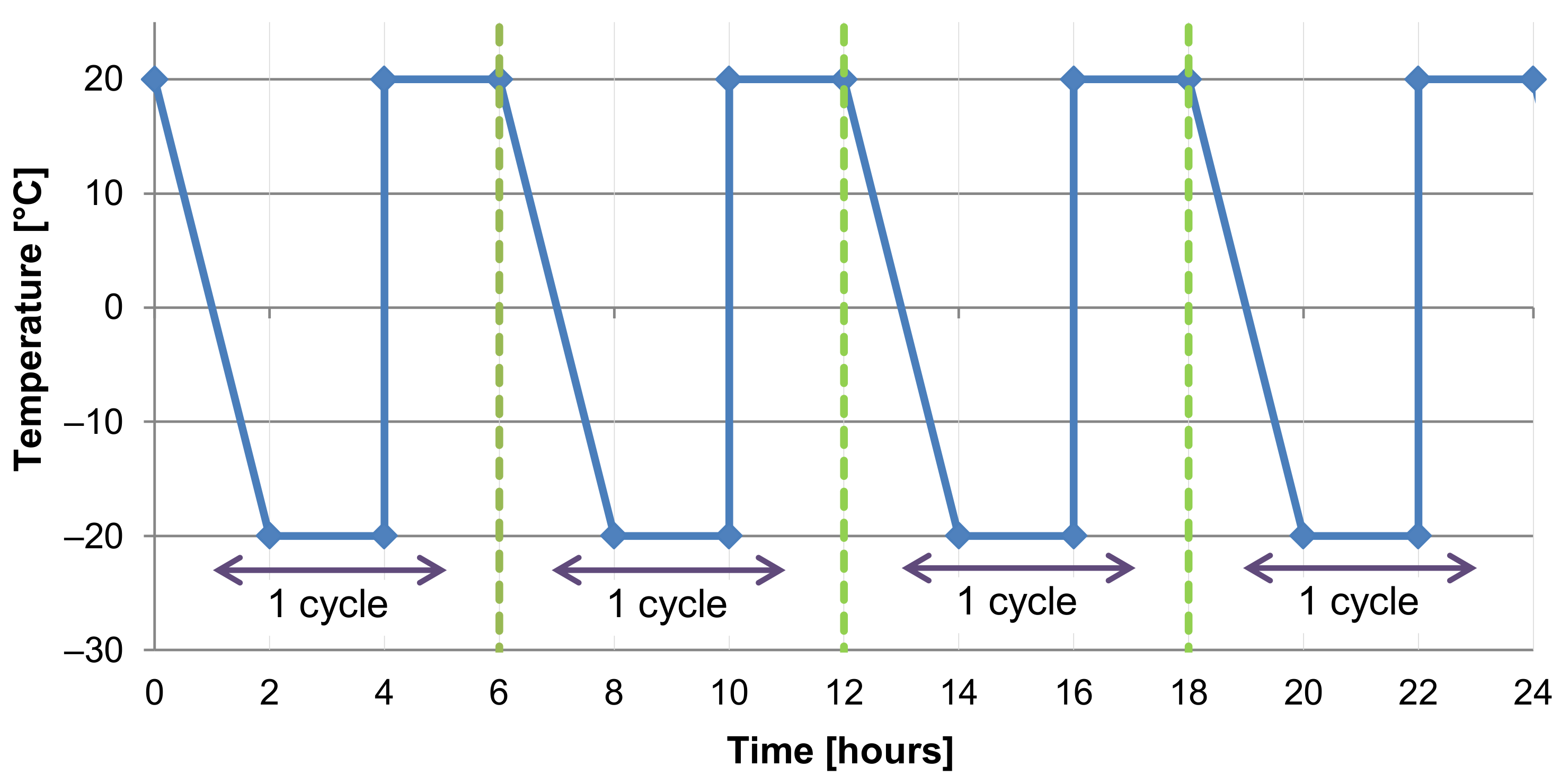

3.2. Adverse Environment—Frost/Defrost Cycles

- A set of reference specimens/Ref—stored under the conditions covered in Section 3.1;

- A set of specimens exposed to 100 frost/defrost cycles/M10;

- A set of specimens exposed to 150 frost/defrost cycles/M15;

- A set of specimens exposed to 200 frost/defrost cycles/M20;

- A set of specimens exposed to 250 frost/defrost cycles/M25.

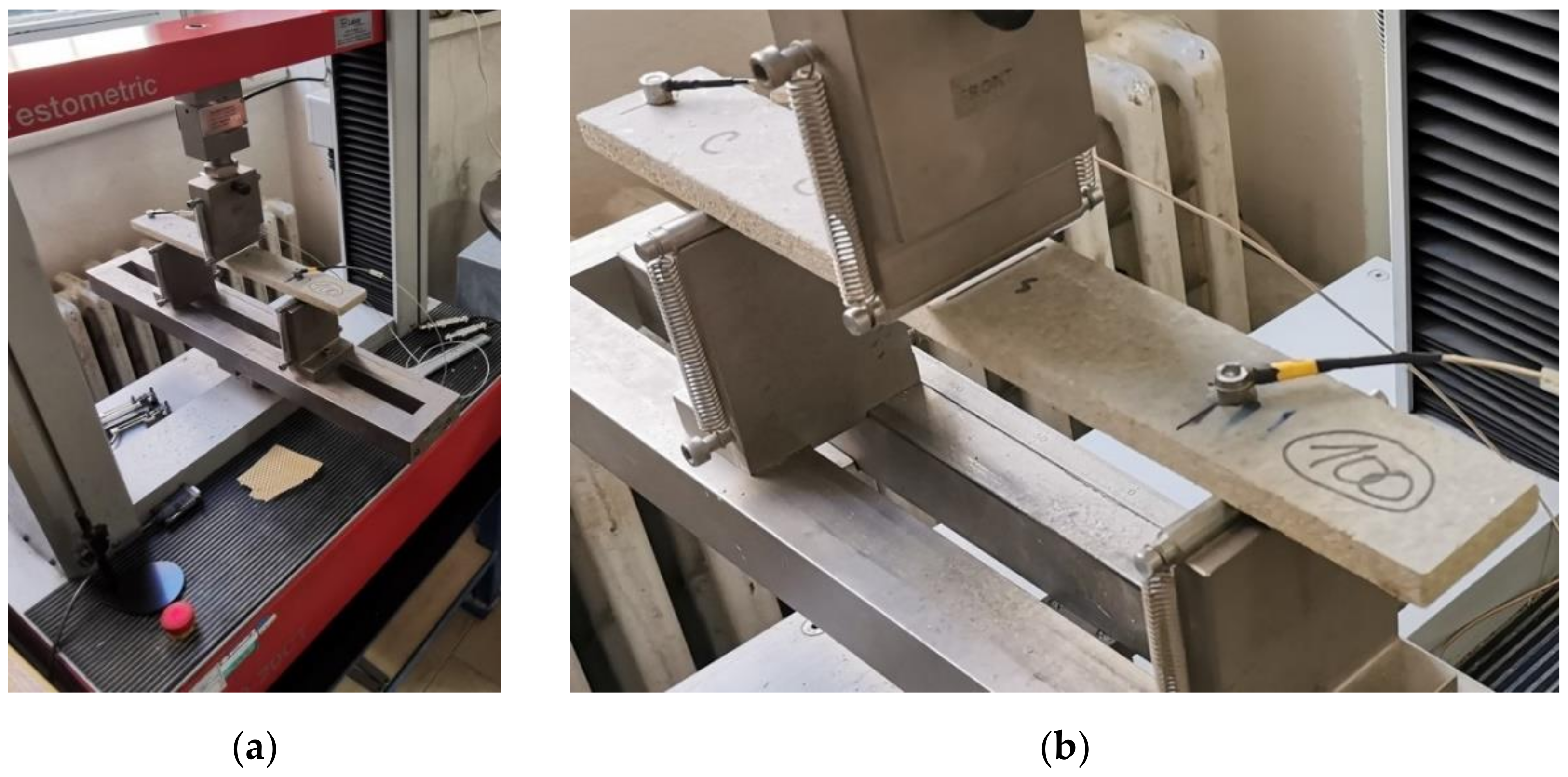

3.3. Physical and Mechanical Tests

3.3.1. Density

3.3.2. Bending Strength and Modulus of Elasticity in Bending

3.3.3. Transverse Tensile Strength Perpendicular to the Plane of the Board

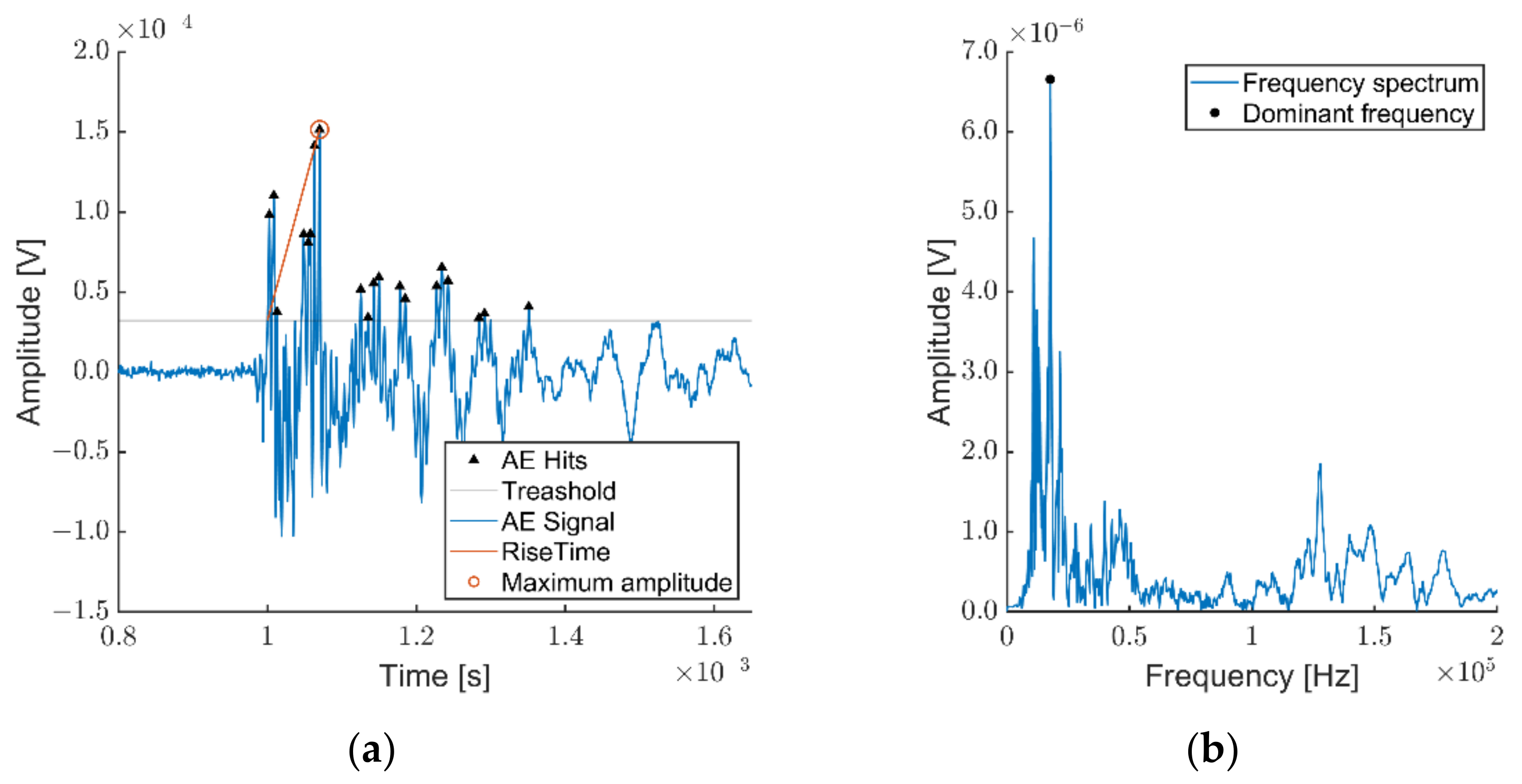

3.4. Localization of Defects—Acoustic Emission

3.5. Microstructural Analysis

4. Results and Discussion

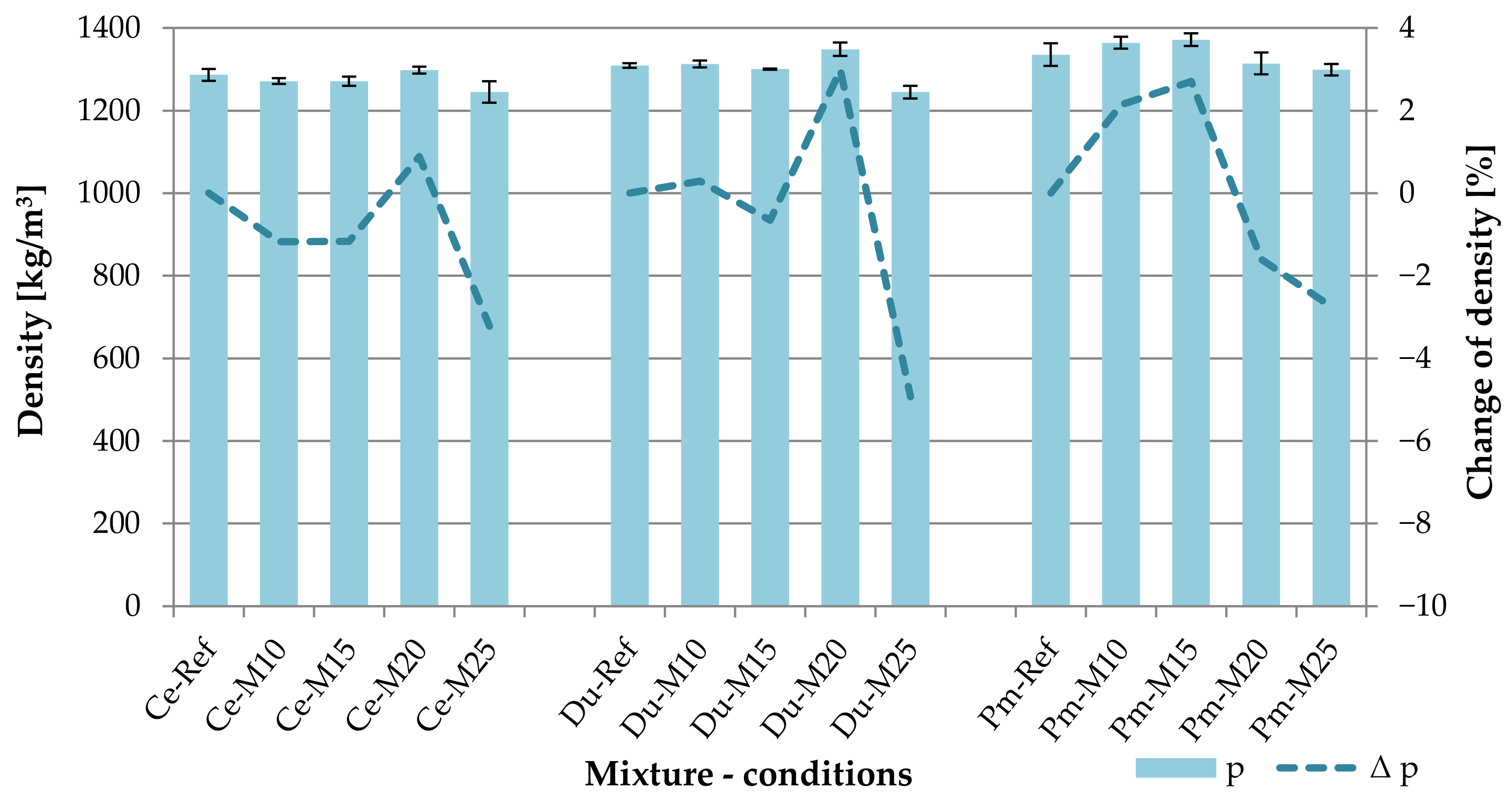

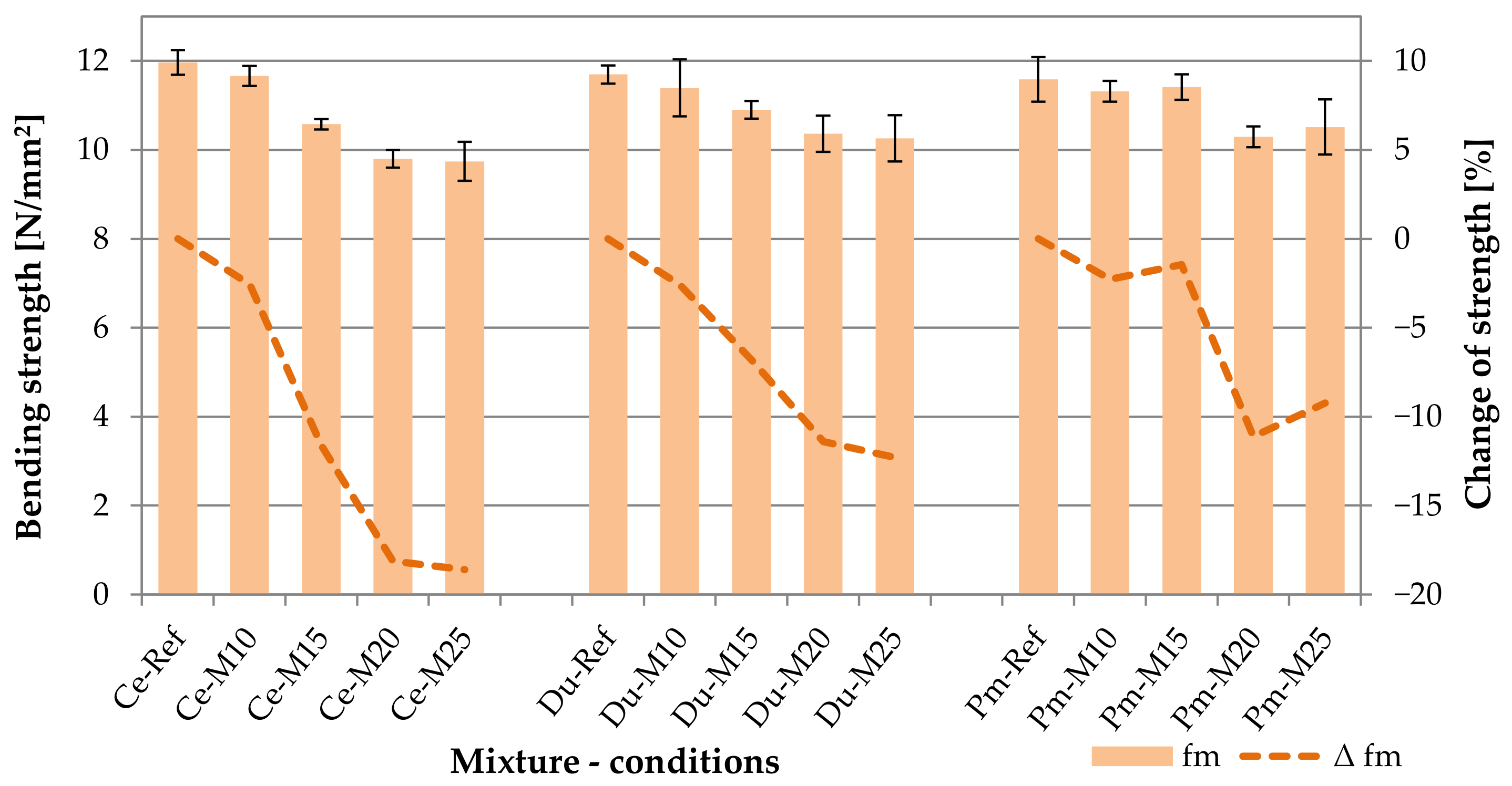

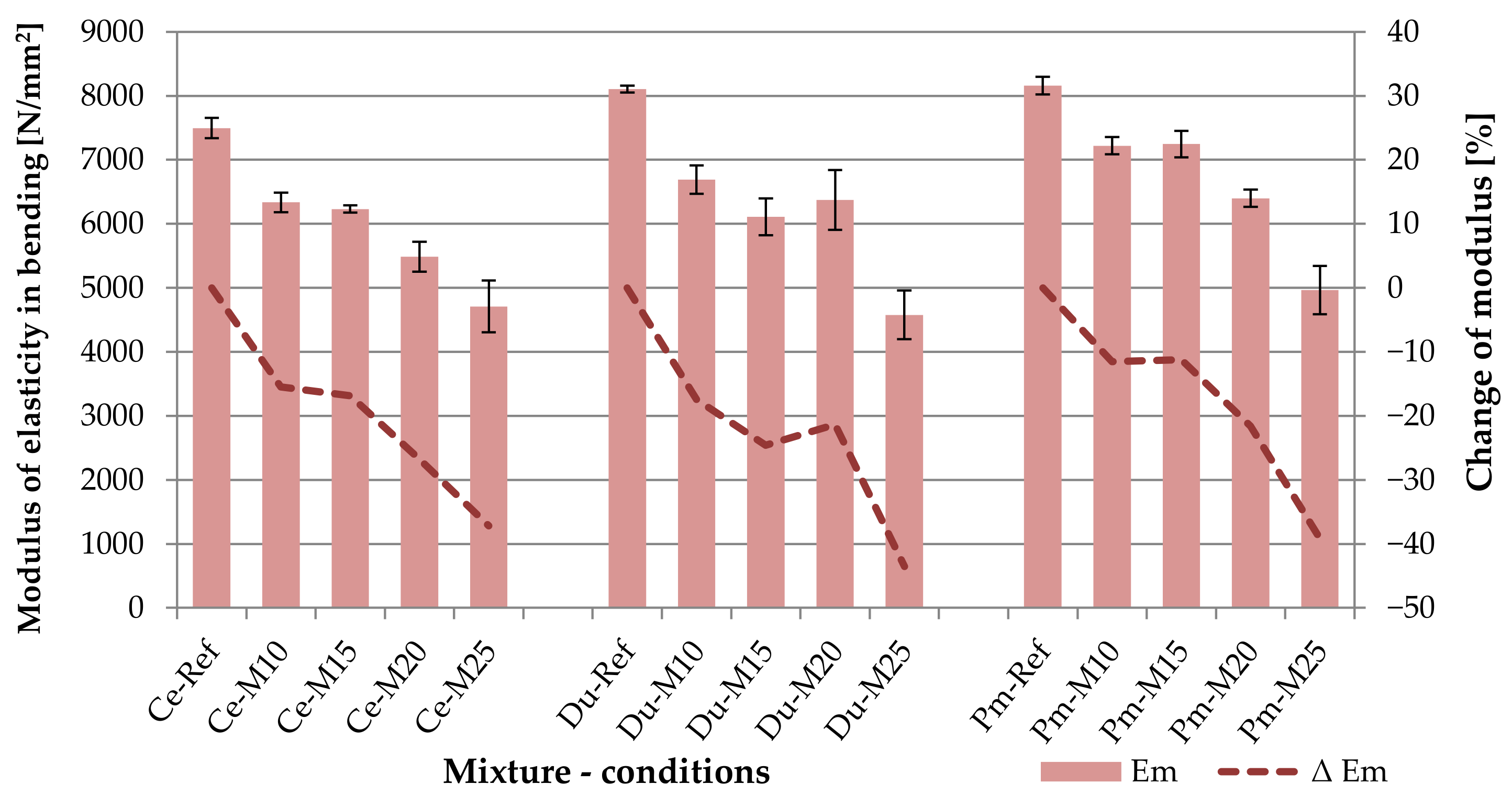

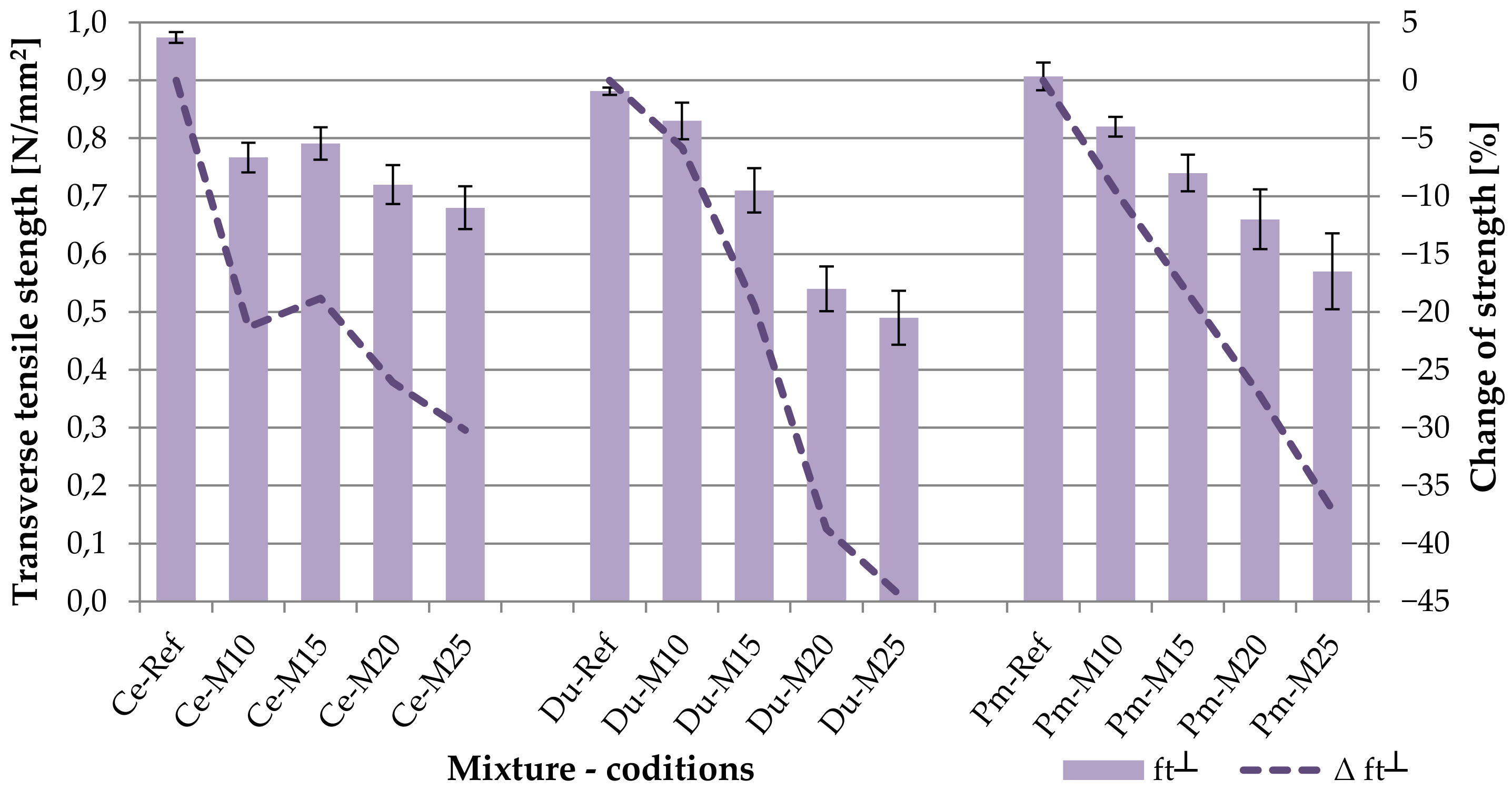

4.1. Physical and Mechanical Parameters

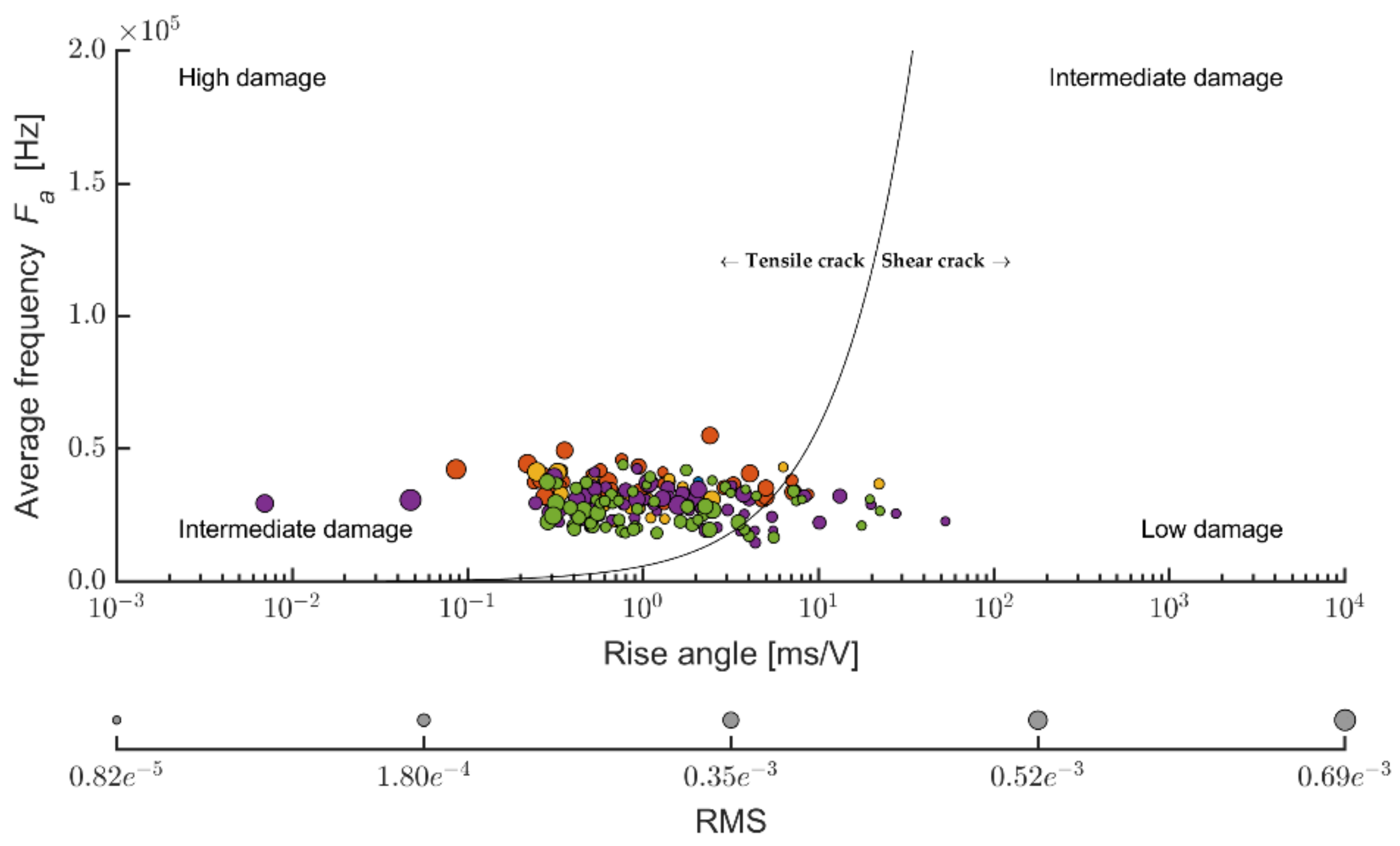

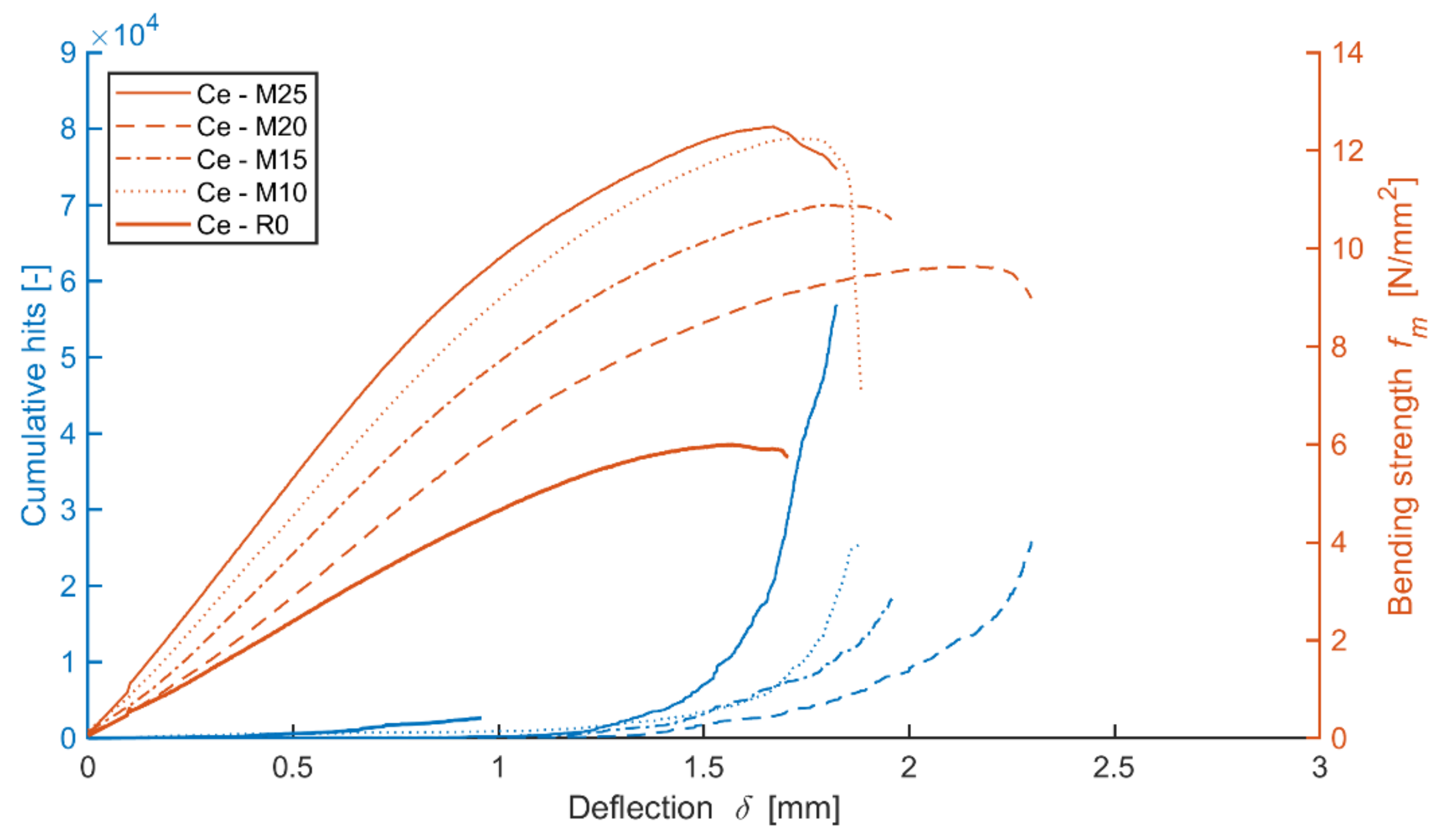

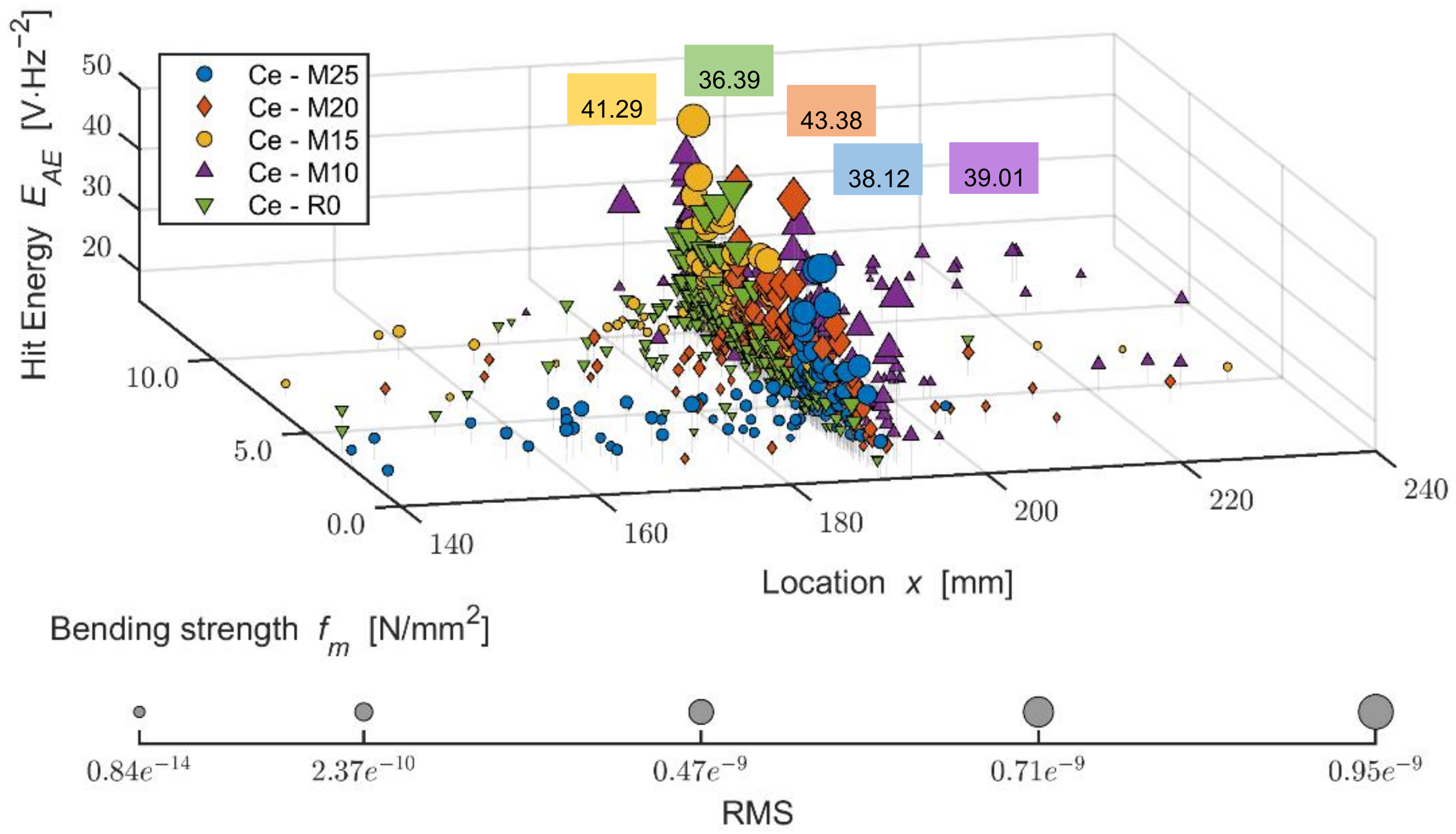

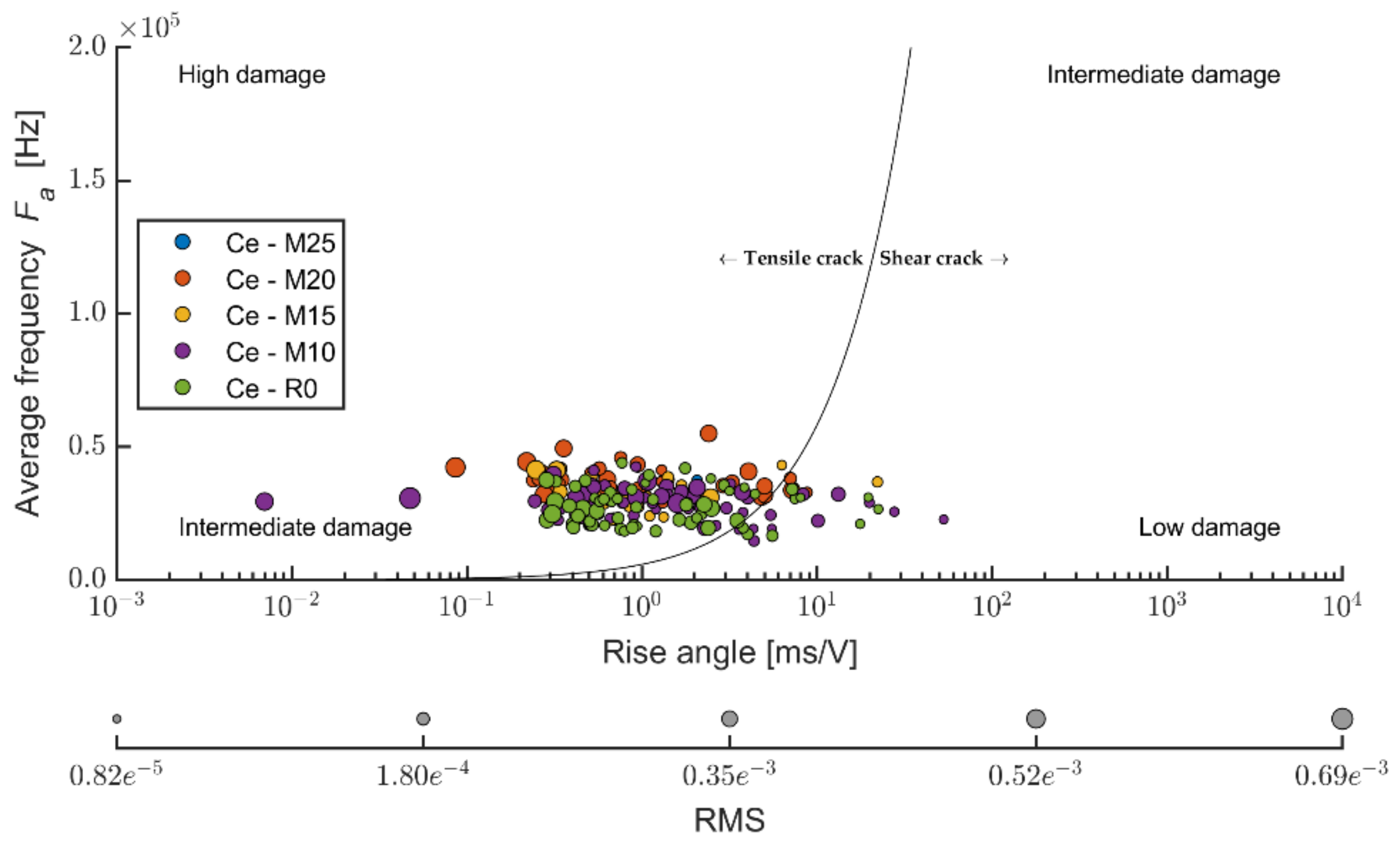

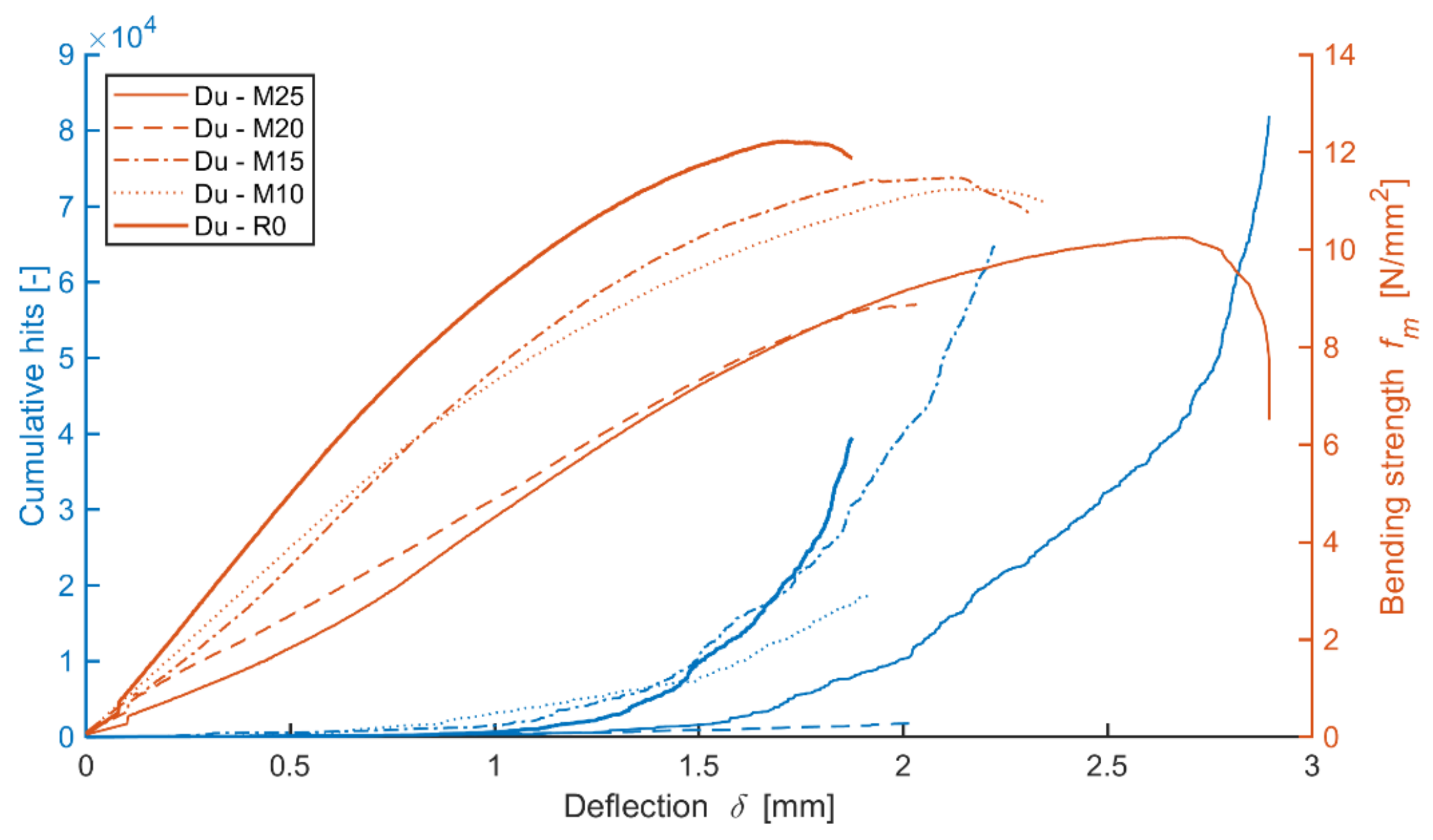

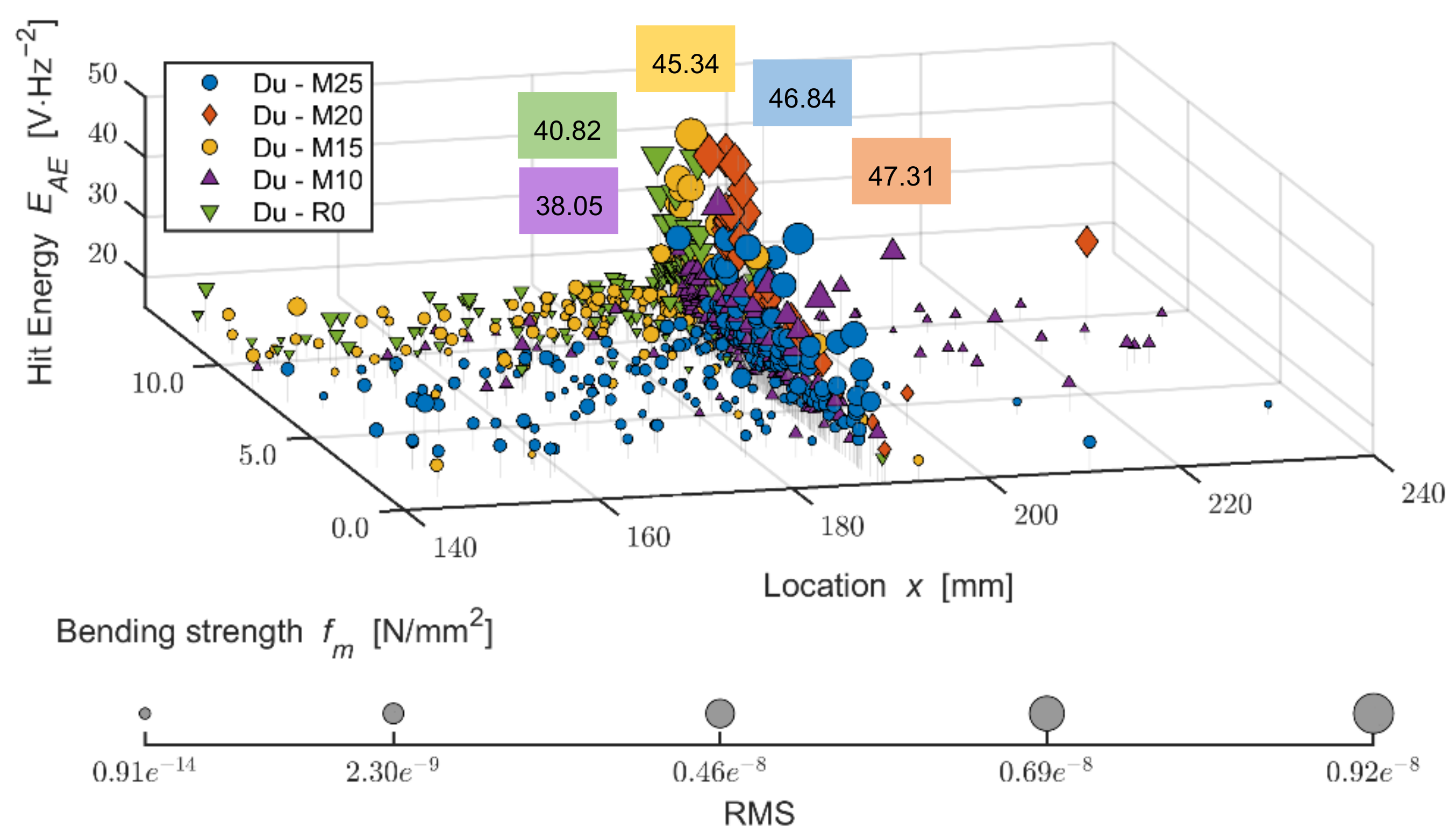

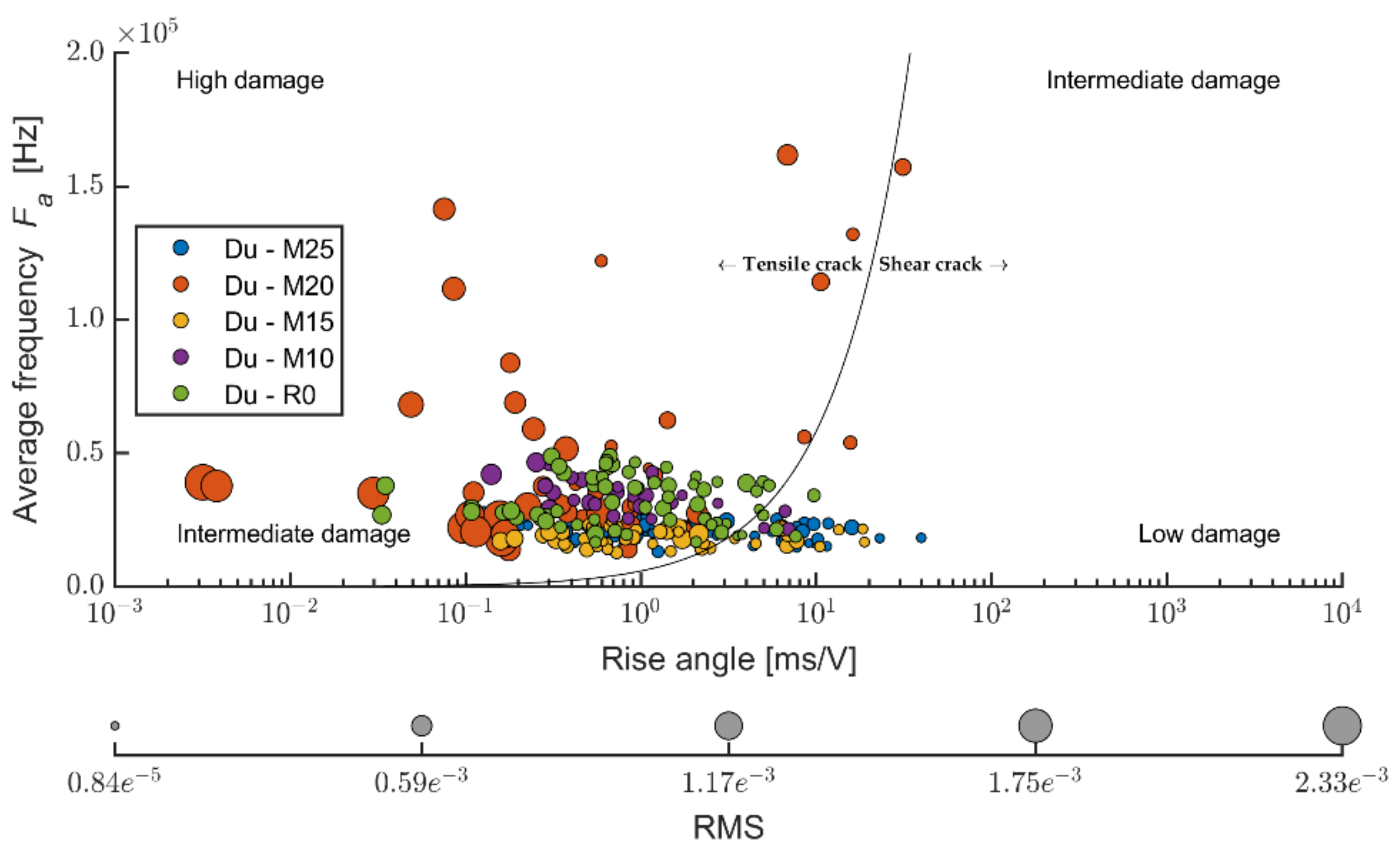

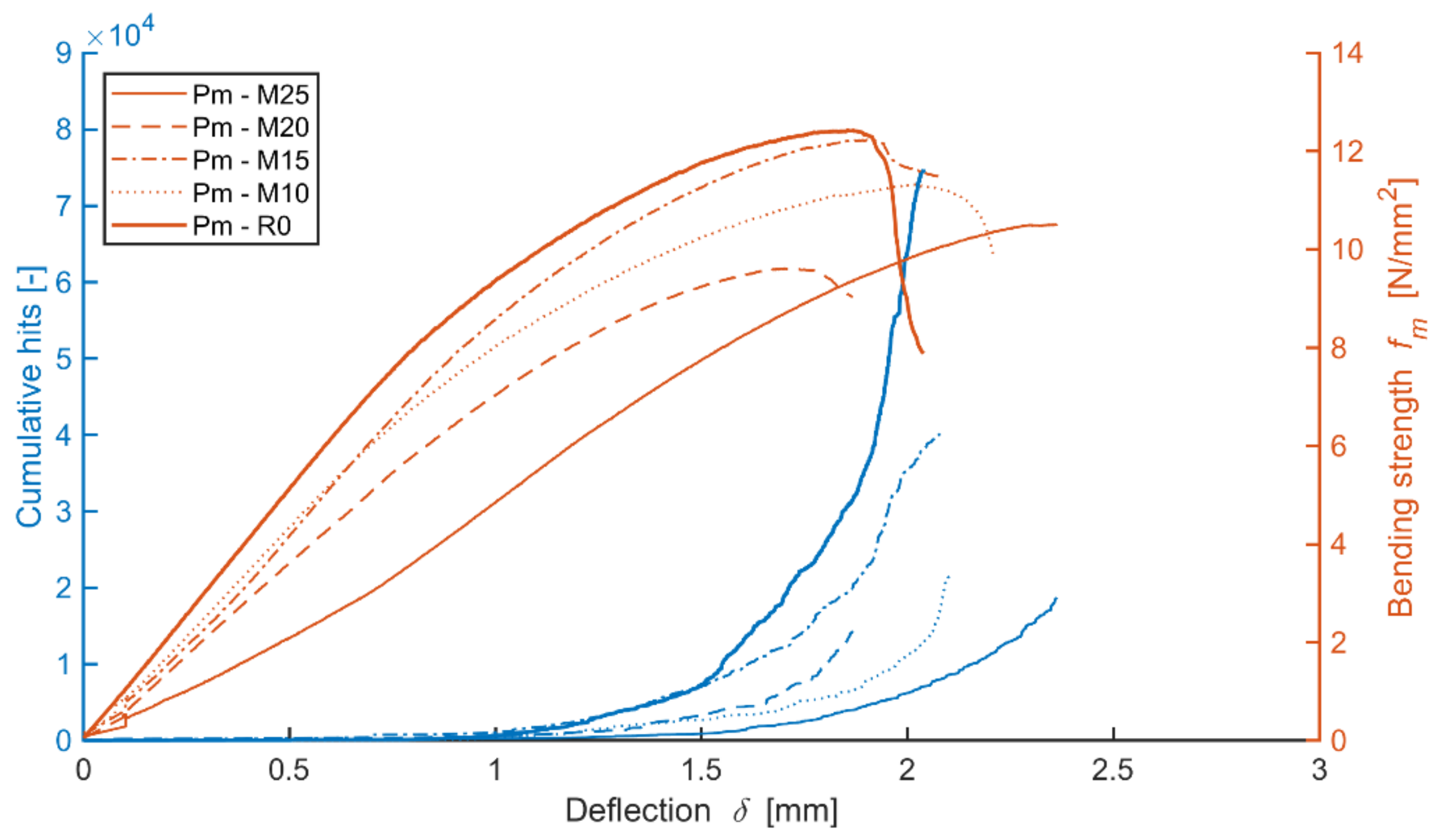

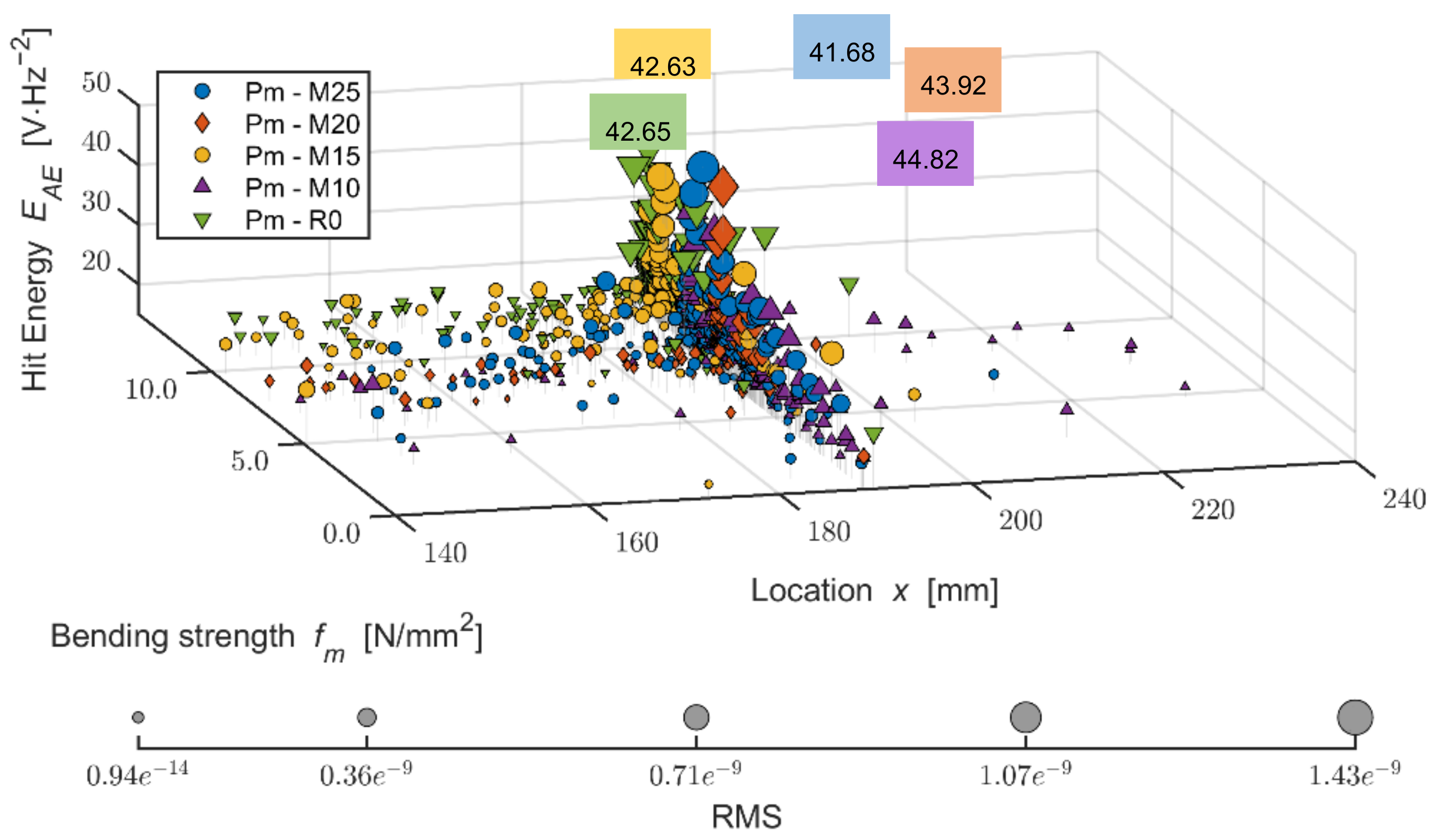

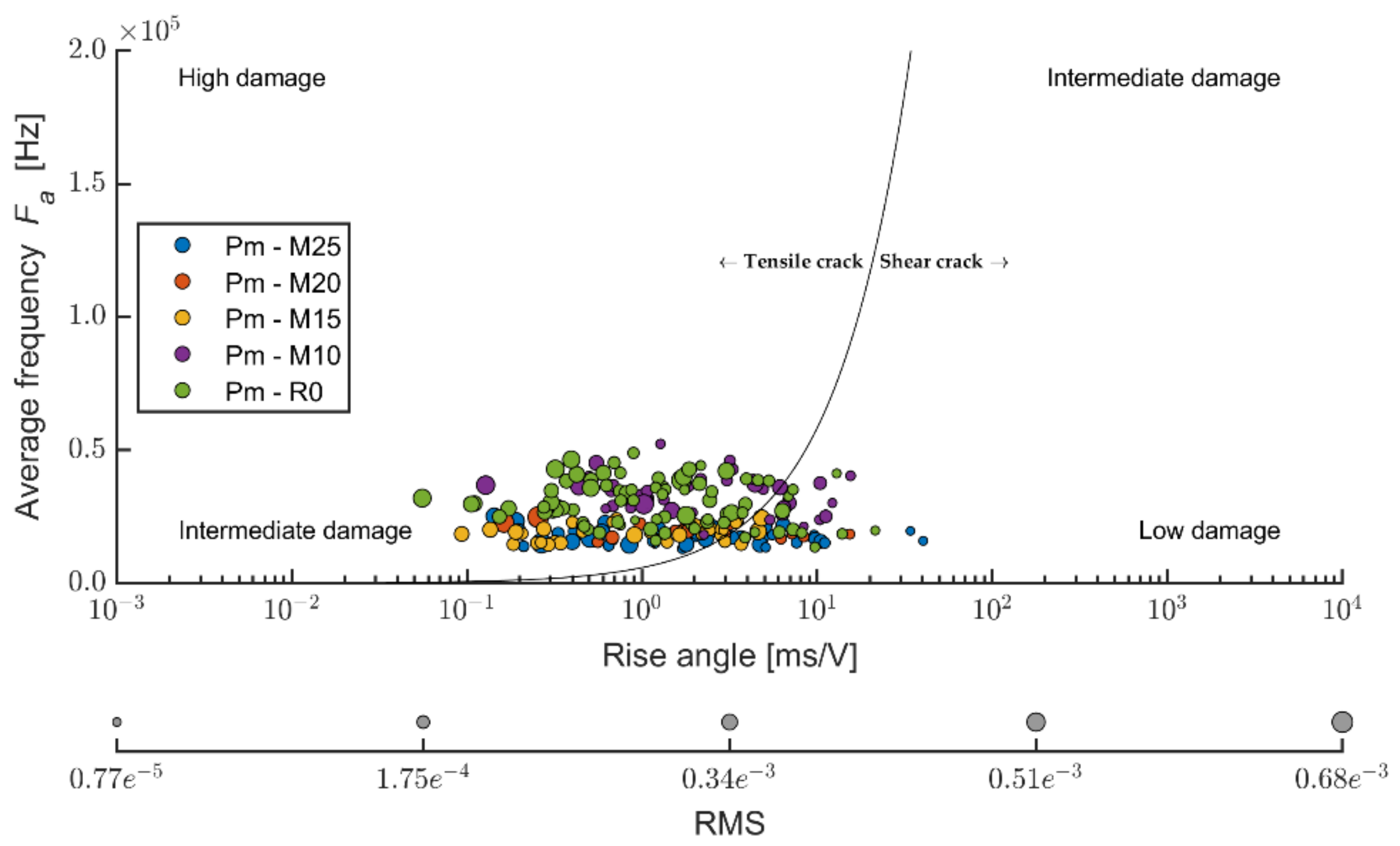

4.2. Acoustic Emission

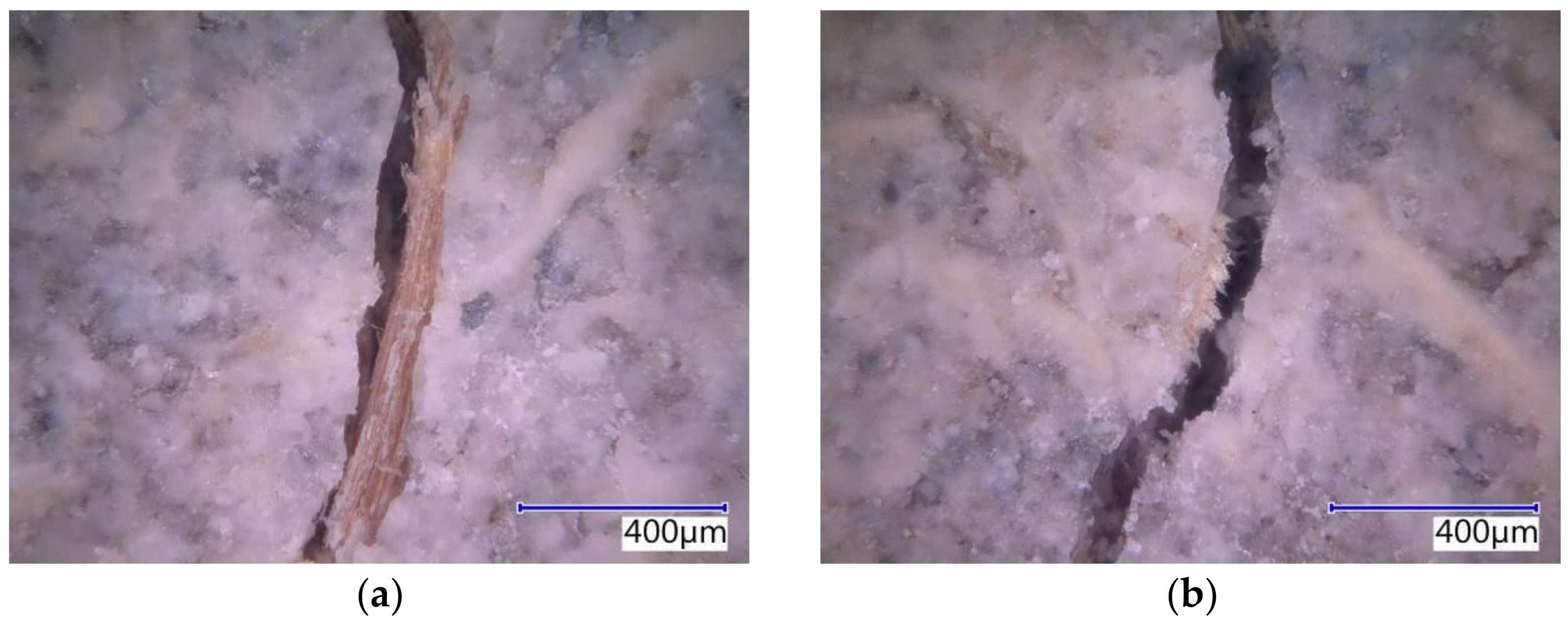

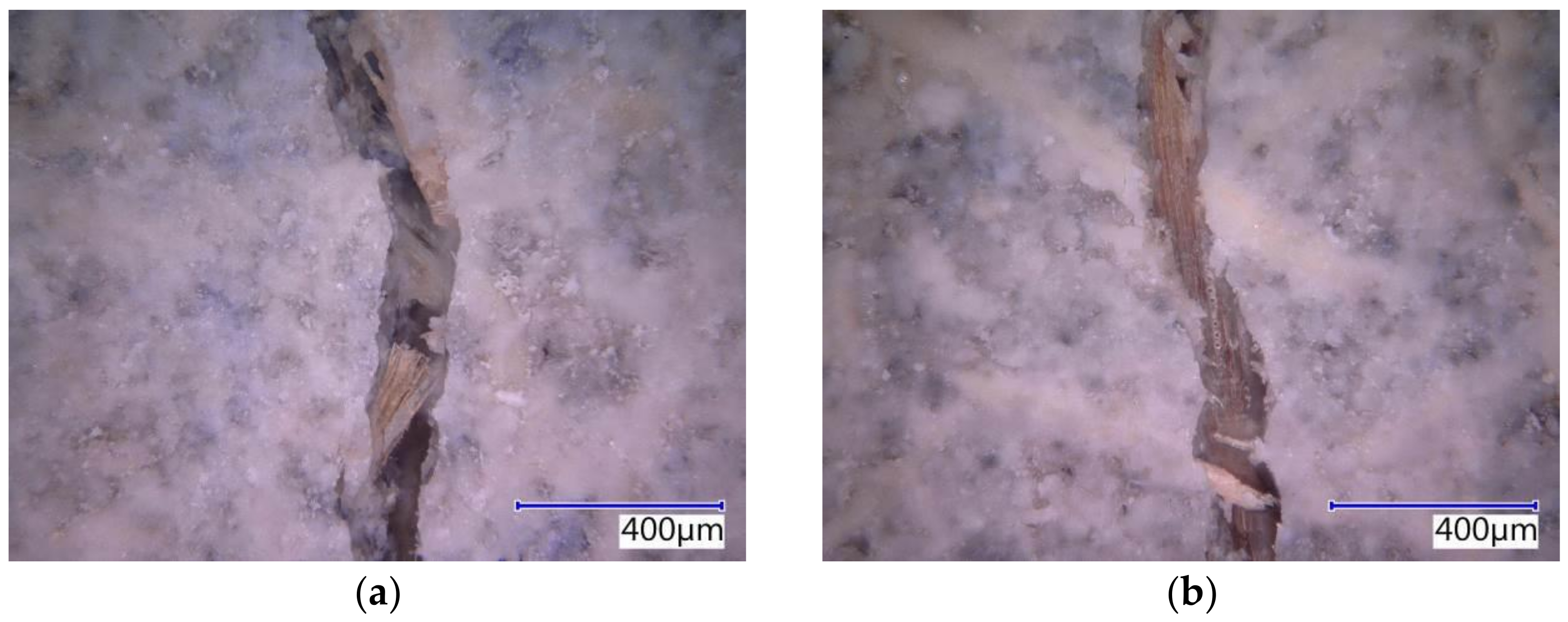

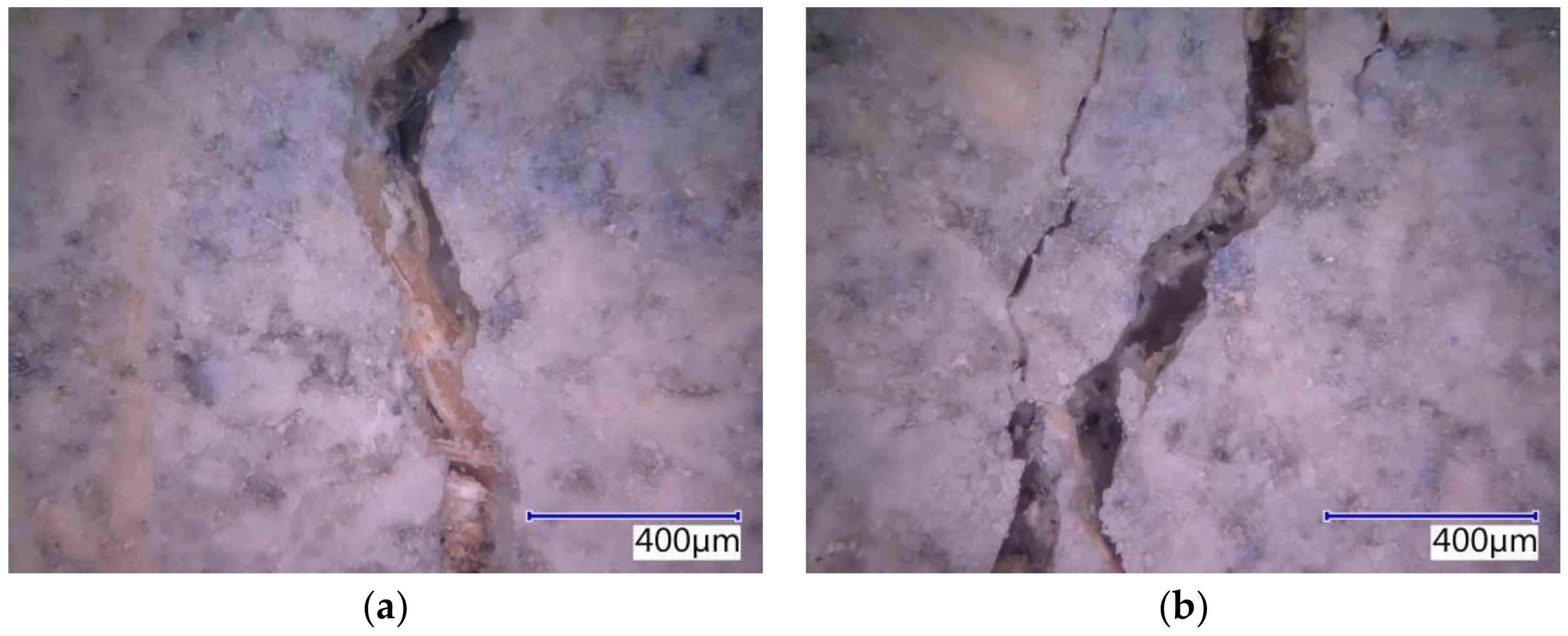

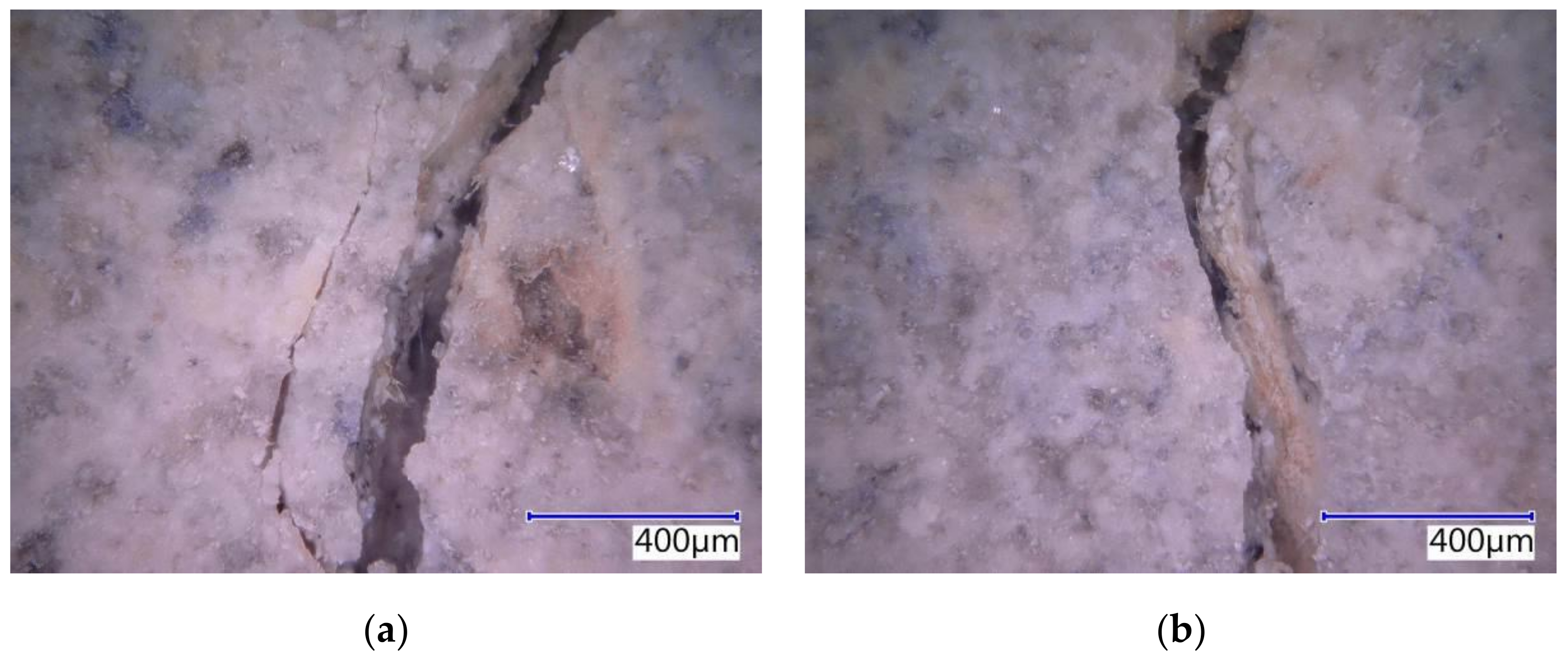

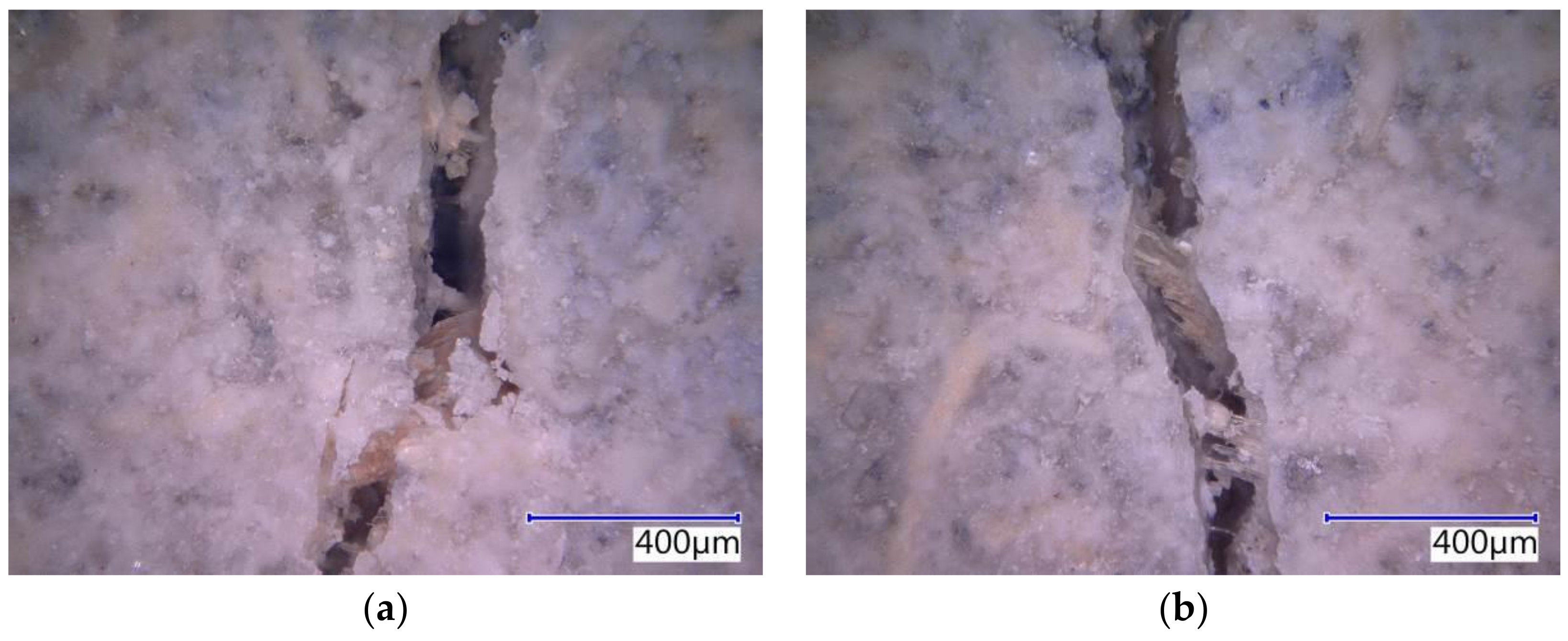

4.3. Microstructure

5. Conclusions

- The partial substitution of primary components of cement-bonded particleboards with dust DU or particle mixture PM in up to 8% is feasible and profitable;

- The alternative materials, DU and PM, show a slightly negative effect on the strength characteristics but, on the other hand, have a positive effect on the elasticity modulus in bending;

- The modified particleboards Du and Pm show better frost-resistance in the long-term horizon, meaning one year of age of the boards. A lower decrease in bending strength was recorded with the increased number of frost/defrost cycles in comparison with the control Ce boards;

- The acoustic emission proved different courses of damage, which enabled clarification of the different behavior of the mixtures from the perspective of bending properties;

- The location of active defects was executed during mechanical static bending load;

- The defects were found even in the case of lower tension, specifically in the flexible area (where they normally do not form) and are not notably concentrated in the area of the direct effect of the load;

- In the case of the board with the reference mixture Ce, active defects were concentrated mainly under the load head of the press. On the contrary, the modified mixtures at the tension on the limit of damage showed the broader distribution of defects that were also located further away from the load head of the press;

- Upon damage to the modified mixtures, meaning reaching bending strength, higher hit energy was detected;

- The acoustic emission was also used to analyze defects caused by traction and friction. Traction defects are more prevalent than friction defects. However, friction defects were identified in significant amounts and energy levels;

- The initial setting of the RM:Af ratio was established for a CETRIS type material to 1:100,000;

- The differences between the ratio of friction and traction defects due to bending load are evident in the case of the individual mixtures. The highest ratio of friction defects was found in the modified Pm boards.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Melichar, T.; Bydžovský, J.; Černý, V. Effect of modification of cement-bonded particle boards composition on their frost resistance. Adv. Mater. Res. 2014, 897, 184–187. [Google Scholar] [CrossRef]

- Odeyemi, S.O.; Abdulwahab, R.; Adeniyi, A.G.; Atoyebi, O.D. Physical and mechanical properties of cement-bonded particleboard produced from African balsam tree (Populous Balsamifera) and periwinkle shell residues. Results Eng. 2020, 6, 100–126. [Google Scholar] [CrossRef]

- Ohijeagbon, I.O.; Adeleke, A.A.; Mustapha, V.T.; Olorunmaiye, J.A.; Okokpujie, I.P.; Ikubanni, P.P. Development and characterization of wood-polypropylene plastic-cement composite board. Case Stud. Constr. Mater. 2020, 13, e00365. [Google Scholar] [CrossRef]

- Borysiuk, P.; Jenczyk-Tolloczko, I.; Auriga, R.; Kordzikowski, M. Sugar beet pulp as raw material for particleboard production. Ind. Crop. Prod. 2019, 141, 111829. [Google Scholar] [CrossRef]

- Taha, I.; Elkafafy, M.S.; Mously, H.E. Potential of utilizing tomato stalk as raw material for particleboards. Ain Shams Eng. J. 2018, 9, 1457–1464. [Google Scholar] [CrossRef]

- Hossain, M.U.; Wang, L.; Yu, I.K.M.; Tsang, D.C.W.; Poon, C.-S. Environmental and technical feasibility study of upcycling wood waste into cement-bonded particleboard. Constr. Build. Mater. 2018, 173, 474–480. [Google Scholar] [CrossRef]

- Cabral, M.R.; Nakanishi, E.Y.; Mármol, G.; Palacios, J.; Godbout, S.; Lagacé, R.; Savastano, H.; Fiorelli, J. Potential of Jerusalem Artichoke (Helianthus tuberosus L.) stalks to produce cement-bonded particleboards. Ind. Crop. Prod. 2018, 122, 214–222. [Google Scholar] [CrossRef]

- Wang, L.; Chen, S.S.; Tsang, D.C.W.; Poon, C.-S.; Shih, K. Value-added recycling of construction waste wood into noise and thermal insulating cement-bonded particleboards. Constr. Build. Mater. 2016, 125, 316–325. [Google Scholar] [CrossRef]

- Wang, L.; Chen, S.S.; Tsang, D.C.W.; Poon, C.-S.; Shih, K. Recycling contaminated wood into eco-friendly particleboard using green cement and carbon dioxide curing. J. Clean. Prod. 2016, 137, 861–870. [Google Scholar] [CrossRef]

- Taghiyari, H.R.; Bari, E.; Schmidt, O.; Ghanbary, M.A.T.; Karimi, A.; Tahir, P.M.D. Effects of nanowollastonite on biological resistance of particleboard made from wood chips and chicken feather against Antrodia vaillantii. Int. Biodeterior. Biodegrad. 2014, 90, 93–98. [Google Scholar] [CrossRef]

- Karade, S.R. Cement-bonded composites from lignocellulosic wastes. Constr. Build. Mater. 2010, 24, 1323–1330. [Google Scholar] [CrossRef]

- Sassoni, E.; Manzi, S.; Motori, A.; Montecchi, M.; Canti, M. Experimental study on the physical–mechanical durability of innovative hemp-based composites for the building industry. Energy Build. 2015, 104, 316–322. [Google Scholar] [CrossRef]

- Soroushian, P.; Won, J.-P.; Hassan, M. Durability and microstructure analysis of CO2-cured cement-bonded wood particleboard. Cem. Concr. Compos. 2013, 41, 34–44. [Google Scholar] [CrossRef]

- Fuwape, J.A.; Fabiyi, J.S.; Osuntuyi, E.O. Technical assessment of three layered cement-bonded boards produced from wastepaper and sawdust. Waste Manag. 2007, 27, 1611–1616. [Google Scholar] [CrossRef]

- Han, T.U.; Kim, Y.; Watanabe, C.; Teramae, N.; Park, Y.; Kim, S.; Lee, Y. Analytical pyrolysis properties of waste medium-density fiberboard and particle board. J. Ind. Eng. Chem. 2015, 32, 345–352. [Google Scholar] [CrossRef]

- Sotannde, O.A.; Oluwadare, A.O.; Ogedoh, O.; Adeogun, P.F. Evaluation of cement-bonded particle board produced from Afzelia Africana wood residues. J. Eng. Sci. Technol. 2012, 7, 732–743. [Google Scholar]

- Schwarzova, I.; Stevulova, N.; Melichar, T. Hemp fibre reinforced composites. In Proceedings of the 10th International Conference on Environmental Engineering, ICEE 2017, Vilnius, Lithuania, 27–28 April 2017. [Google Scholar]

- Schwarzova, I.; Stevulova, N.; Melichar, T. Lightweight composites based on technical hemp hurds in construction industry. Chem. Eng. Trans. 2017, 57, 1369–1374. [Google Scholar]

- Savastano, H.; Warden, P.G.; Coutts, R.S.P. Brazilian waste fibres as reinforcement for cement-based composites. Cem. Concr. Compos. 2000, 22, 379–384. [Google Scholar] [CrossRef]

- Okino, E.Y.A.; de Souza, M.R.; Santana, M.A.E.; Alves, M.V.S.; de Sousa, M.E.; Teixeira, D.E. Cement-bonded wood particleboard with a mixture of eucalypt and rubberwood. Cem. Concr. Compos. 2004, 26, 729–734. [Google Scholar] [CrossRef]

- Zhou, Y.; Kamdem, D.P. Effect of cement/wood ratio on the properties of cement-bonded particleboard using CCA-treated wood removed from service. For. Prod. J. 2002, 52, 77–81. [Google Scholar]

- Caprai, V.; Gauvin, F.; Schollbach, K.; Brouwers, H.J.H. MSWI bottom ash as binder replacement in wood cement composites. Constr. Build. Mater. 2019, 196, 672–680. [Google Scholar] [CrossRef]

- Ezerskiy, V.; Kuznetsova, N.V.; Seleznev, A.D. Evaluation of the use of the CBPB production waste products for cement composites. Constr. Build. Mater. 2018, 190, 1117–1123. [Google Scholar] [CrossRef]

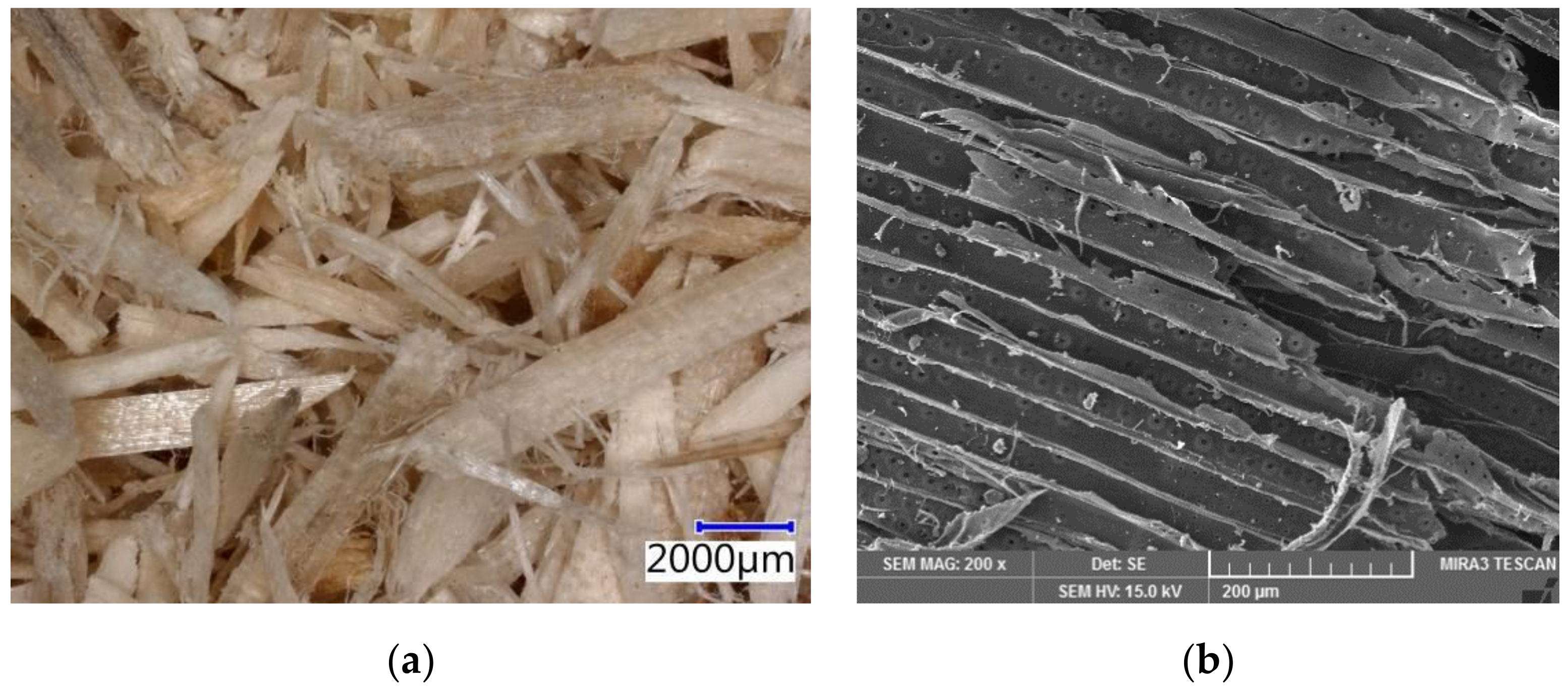

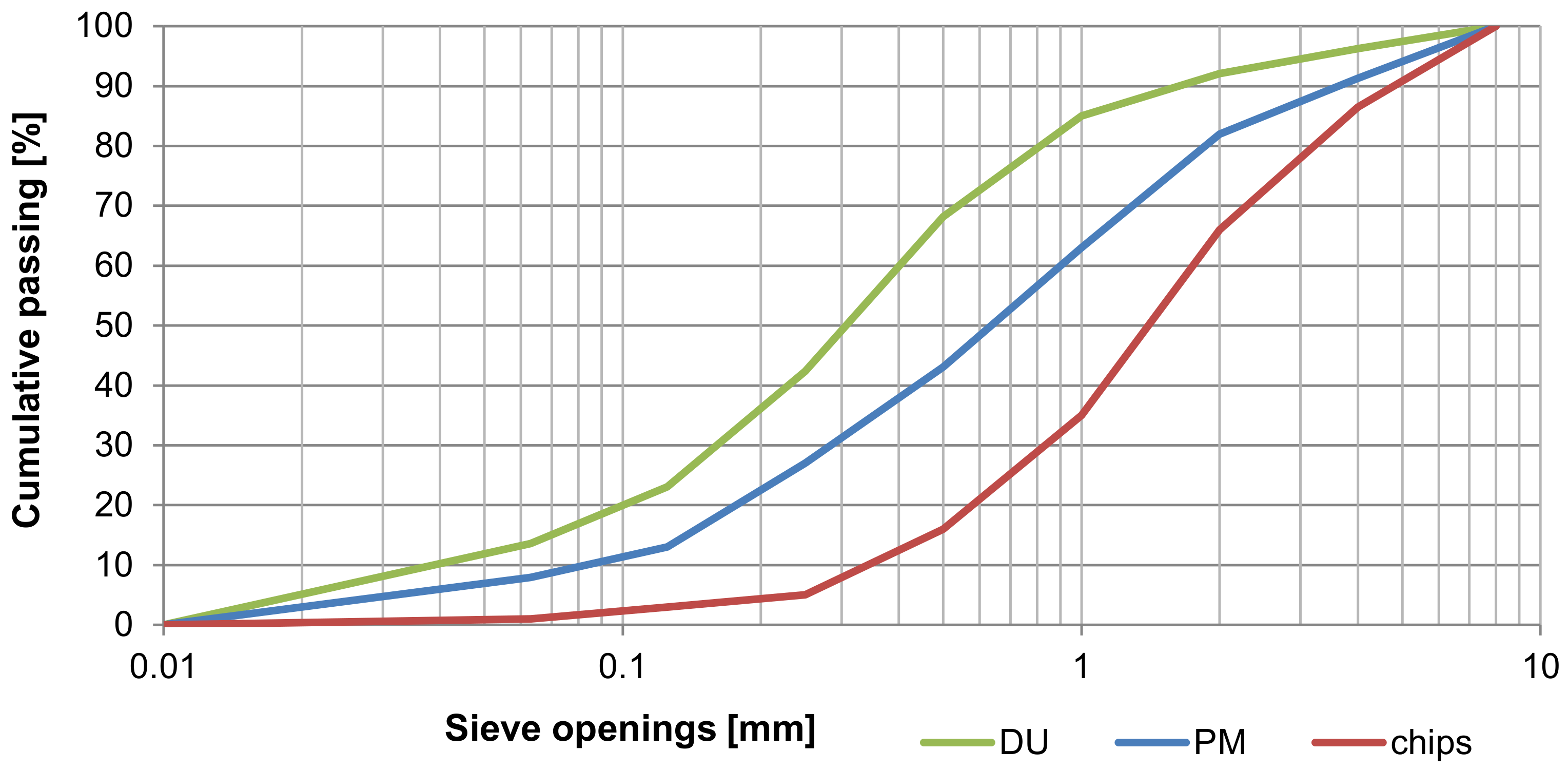

- Melichar, T.; Venhodová, E.; Bydžovský, J. Analyzing of alternative raw materials for production of cement-bonded particle boards. Adv. Mater. Res. 2014, 923, 108–111. [Google Scholar] [CrossRef]

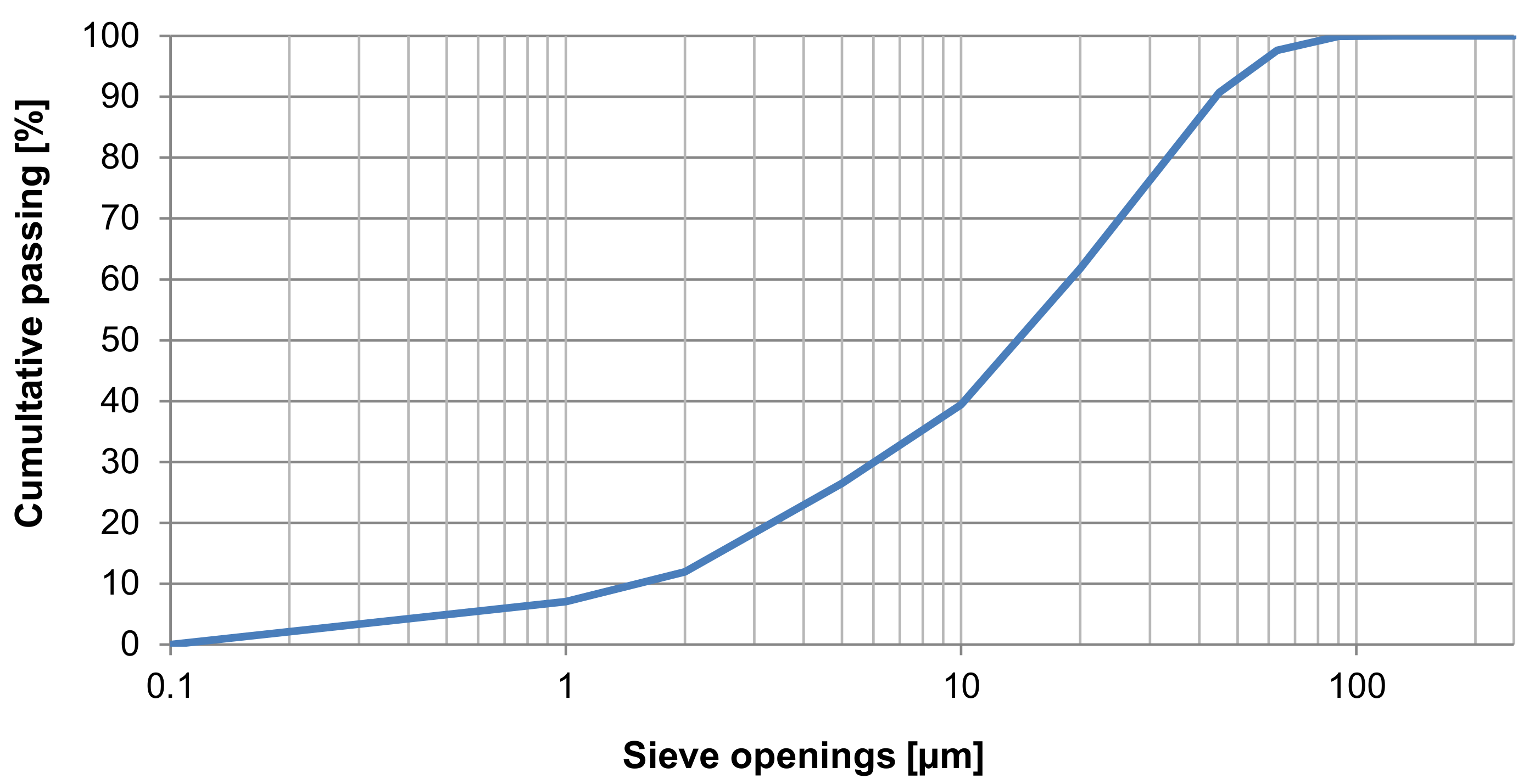

- Melichar, T.; Bydžovský, J.; Dufka, A. Detailed analysis of modified by-product from cement-bonded particle board fabrication. WSEAS Trans. Environ. Dev. 2018, 14, 408–417. [Google Scholar]

- Melichar, T.; Bydzovsky, J. Influence of dust waste containing a silicate matrix and organic filler on properties of cement composites [Vliv prachového odpadu s obsahem silikátové matrice a organického plniva na vlastnosti cementových kompozitů]. Waste Forum 2019, 4, 378–390. [Google Scholar]

- Melichar, T.; Bydzovsky, J.; Dufka, A. Seldom used by-product from trimming cement-bonded particleboard shows potential for modifying building materials composition. Waste Forum 2019, 4, 368–377. [Google Scholar]

- Nakamura, H. Roles and safety/health of technicians involved in non-destructive testing. In Practical Acoustic Emission Testing. The Japanese Society for Non-Destructive; Springer: Tokyo, Japan, 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Ohtsu, M.; Enoki, M.; Mizutani, Y.; Shigeishi, M. Principles of the acoustic emission (AE) method and signal processing. In Practical Acoustic Emission Testing; Springer: Tokyo, Japan, 2016; pp. 5–34. [Google Scholar] [CrossRef]

- Shamsudin, M.F.b. Structural Health Monitoring of Fatigue Cracks Using Acoustic Emission Technique. Ph.D. Thesis, Brunel University London, Uxbridge, UK, 2019. [Google Scholar]

- Grosse, C.U.; Ohtsu, M. (Eds.) Acoustic Emission Testing; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Debecker, B.; Vervoort, A. Localization by acoustic emission in transversely isotropic slate. Adv. Acoust. Vib. 2011, 2011, 735913. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, W.; Li, F. Acoustic emission source location using a distributed feedback fiber laser rosette. Sensors 2013, 13, 14041–14054. [Google Scholar] [CrossRef]

- Zhou, Z.; Rui, Y.; Zhou, J.; Dong, L.; Chen, L.; Cai, X.; Cheng, R. A New Closed-Form Solution for Acoustic Emission Source Location in the Presence of Outliers. Appl. Sci. 2018, 8, 949. [Google Scholar] [CrossRef]

- Beattie, A.G. Acoustic emission non-destructive testing of structures using source location techniques. Albuq. Livermore 2013. [Google Scholar] [CrossRef][Green Version]

- AE Measurement System DAKEL-ZEDO©. Available online: http://dakel.cz/index.php?pg=prod/dev/zedo_en (accessed on 1 November 2021).

- ČSN EN 13554 (015081). Non-Destructive Testing—Acoustic Emission Testing—General Principles; European Committee for Standardization: Bruxelles, Belgium, 2011. [Google Scholar]

- Quy, T.B.; Kim, J.-M. Crack detection and localization in a fluid pipeline based on acoustic emission signals. Mech. Syst. Signal Process. 2021, 150, 107254. [Google Scholar] [CrossRef]

- Peng, S.; Sbartaï, Z.M.; Parent, T. Mechanical damage evaluation of masonry under tensile loading by acoustic emission technique. Constr. Build. Mater. 2020, 258, 120336. [Google Scholar] [CrossRef]

- Friedrich, L.; Colpo, A.; Maggi, A.; Becker, T. Giuseppe Lacidogna, Ignacio Iturrioz, Damage Process in Glass Fiber Reinforced Polymer Specimens Using Acoustic Emission Technique with Low Frequency Acquisition. Compos. Struct. 2020, 256, 113105. [Google Scholar] [CrossRef]

- Verstrynge, E.; Lacidogna, G.; Accornero, F.; Tomor, A. A review on acoustic emission monitoring for damage detection in masonry structures. Constr. Build. Mater. 2020, 268, 121089. [Google Scholar] [CrossRef]

- Deák, F.; Kovács, L.; Mucsi, P.; Máthé, Z. Microscopic Identification of Progressive Fracturing in Granite Under Triaxial and Uniaxial Stress Conditions from Bátaapáti Radwaste Repository. Period. Polytech. Civ. Eng. 2020, 64, 231–240. [Google Scholar] [CrossRef]

- De Rosa, I.M.; Santulli, C.; Sarasini, F. Acoustic emission for monitoring the mechanical behaviour of naturel fibre composites: A literature review. Compos. Part A 2009, 40, 1456–1469. [Google Scholar] [CrossRef]

- CETRIS®. Available online: www.cetris.cz (accessed on 1 November 2021).

- ČSN EN 1328 Cement Bonded Particleboards—Determination of Frost Resistance; ÚNMZ: Prague, Czech Republic, 1998.

- ČSN EN 633 Cement-Bonded Particleboards. Definition and Classification; ÚNMZ: Prague, Czech Republic, 1996.

- ČSN EN 634-1 Cement-Bonded Particleboards—Specification—Part 1: General Requirements; ÚNMZ: Prague, Czech Republic, 1997.

- ČSN EN 634-2 Cement-Bonded Particleboards—Specifications—Part 2: Requirements for OPC Bonded Particleboards for Use in Dry, Humid and External Conditions; ÚNMZ: Prague, Czech Republic, 2007.

- ASTM D 1037 Standard Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials; ASTM: West Conshohocken, PA, USA, 2012.

- ČSN EN 323 Wood-Based Panels. Determination of Density; ÚNMZ: Prague, Czech Republic, 1994.

- ČSN EN 310 Wood Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength; ÚNMZ: Prague, Czech Republic, 1995.

- ČSN EN 319 Particleboards and Fibreboards. Determination of Transverse Tensile Strength Perpendicular to the Plane of the Board; ÚNMZ: Prague, Czech Republic, 1994.

- Suzuki, T.; Shimamoto, Y. Damage evaluation in concrete materials by acoustic emission. In Acoustic Emission and Related Non-Destructive Evaluation Techniques in the Fracture Mechanics of Concrete; Woodhead Publishing: Duxford, UK, 2015; pp. 1–17. [Google Scholar]

- Nor, N.M.; Ibrahim, A.; Bunnori, N.M.; Saman, H.M. Acoustic emission signal for fatigue crack classification on reinforced concrete beam. Constr. Build. Mater. 2013, 49, 583–590. [Google Scholar] [CrossRef]

- Ohno, K.; Ohtsu, M. Crack classification in concrete based on acoustic emission. Constr. Build. Mater. 2010, 24, 2339–2346. [Google Scholar] [CrossRef]

- JCMS-III B5706, Monitoring Method for Active Cracks in Concrete by Acoustic Emission; Federation of Construction Materials Industries: Tokyo, Japan, 2003.

- Ohno, K.; Uji, K.; Ueno, A.; Ohtsu, M. Fracture process zone in notched concrete beam under three-point bending by acoustic emission. Constr. Build. Mater. 2014, 67, 139–145. [Google Scholar] [CrossRef]

- Vidya Sagar, R.; Raghu Prasad, B.K.; Singh, R.K. Laboratory investigations on concrete fracture using acoustic emission techniques. In Acoustic Emission and Related Non-Destructive Evaluation Techniques in the Fracture Mechanics of Concrete; Woodhead Publishing: Duxford, UK, 2015; pp. 139–162. [Google Scholar]

- Jiang, Z.; Li, Q.; Hu, Q.; Liang, Y.; Xu, Y.; Liu, L.; Wu, X.; Li, X.; Wang, X.; Hu, L.; et al. Acoustic emission characteristics in hydraulic fracturing of stratified rocks: A laboratory study. Powder Technol. 2020, 371, 267–276. [Google Scholar] [CrossRef]

| Compound | Mixture–Number of Compounds [%] | ||

|---|---|---|---|

| Standard Ce | Modified (by DU) Du | Modified (by PM) Pm | |

| Cement | 50 | 44 | 46 |

| Spruce chips | 18 | 17 | 14 |

| Dust (from grinding and cutting cement-bonded particleboards) | 0 | 7 | 0 |

| Particle mixture (from production line of Cement-bonded particleboards) | 0 | 0 | 8 |

| Water | 30 | 30 | 30 |

| Hydration additives | 2 | 2 | 2 |

| Chemical Compound | Amount of Compound [Mass %] | ||

|---|---|---|---|

| Cement | DU | PM | |

| SiO2 | 19.3 | 10.6 | 15.2 |

| Fe2O3 | 3.1 | 3.7 | 4.3 |

| Al2O3 | 5.6 | 14.8 | 14.1 |

| CaO | 59.8 | 45.9 | 42.7 |

| SO3 | 3.27 | 0.36 | 0.73 |

| Na2O | 0.16 | 0.39 | 1.26 |

| K2O | 0.73 | 0.073 | 0.084 |

| MgO | 1.8 | 0.16 | 0.061 |

| MnO | 0.061 | 0.018 | 0.048 |

| Cl− | 0.065 | <0.01 | <0.01 |

| wood content—from TOC | --- | 25.8 | 20.3 |

| Mixture | Density [kg/m3] | Average Density [kg/m3] | Absolute Error [kg/m3] | Relative Error [%] |

|---|---|---|---|---|

| Ce-Ref | 1245–1317 | 1287 | 14.4 | 1.12 |

| Ce-M10 | 1252–1285 | 1272 | 6.8 | 0.53 |

| Ce-M15 | 1254–1305 | 1272 | 11.1 | 0.87 |

| Ce-M20 | 1274–1319 | 1298 | 8.7 | 0.67 |

| Ce-M25 | 1172–1303 | 1245 | 25.7 | 2.07 |

| Du-Ref | 1292–1318 | 1309 | 5.5 | 0.42 |

| Du-M10 | 1288–1328 | 1313 | 8.5 | 0.65 |

| Du-M15 | 1297–1305 | 1301 | 1.5 | 0.12 |

| Du-M20 | 1302–1385 | 1348 | 16.3 | 1.21 |

| Du-M25 | 1211–1288 | 1245 | 15.1 | 1.21 |

| Pm-Ref | 1274–1412 | 1336 | 27.0 | 2.02 |

| Pm-M10 | 1321–1389 | 1364 | 14.4 | 1.06 |

| Pm-M15 | 1331–1411 | 1372 | 15.4 | 1.12 |

| Pm-M20 | 1297–1392 | 1314 | 26.1 | 1.99 |

| Pm-M25 | 1259–1331 | 1299 | 14.1 | 1.09 |

| Mixture | Bending Strength [N/mm2] | Average Bending Strength [N/mm2] | Absolute Error [N/mm2] | Relative Error [%] |

|---|---|---|---|---|

| Ce-Ref | 11.2–12.5 | 12.0 | 0.3 | 2.30 |

| Ce-M10 | 11.1–12.2 | 11.7 | 0.2 | 1.92 |

| Ce-M15 | 10.3–10.9 | 10.6 | 0.1 | 1.11 |

| Ce-M20 | 8.9–10.4 | 9.8 | 0.3 | 3.12 |

| Ce-M25 | 8.6–10.9 | 9.7 | 0.4 | 4.51 |

| Du-Ref | 11.2–12.2 | 11.7 | 0.2 | 1.73 |

| Du-M10 | 9.8–13.1 | 11.4 | 0.6 | 5.63 |

| Du-M15 | 10.5–11.5 | 10.9 | 0.2 | 1.83 |

| Du-M20 | 9.3–11.4 | 10.4 | 0.4 | 3.95 |

| Du-M25 | 8.9–11.6 | 10.3 | 0.5 | 5.10 |

| Pm-Ref | 9.9–12.4 | 11.6 | 0.5 | 4.33 |

| Pm-M10 | 10.9–11.7 | 11.3 | 0.2 | 2.06 |

| Pm-M15 | 10.6–12.2 | 11.4 | 0.3 | 2.51 |

| Pm-M20 | 9.6–11.0 | 10.3 | 0.2 | 2.25 |

| Pm-M25 | 8.9–12.1 | 10.5 | 0.6 | 5.91 |

| Mixture | Modulus of Elasticity in Bending [N/mm2] | Average Modulus of Elasticity in Bending [N/mm2] | Absolute Error [N/mm2] | Relative Error [%] |

|---|---|---|---|---|

| Ce-Ref | 7054–7881 | 7496 | 160.3 | 2.14 |

| Ce-M10 | 5987–6774 | 6356 | 152.3 | 2.40 |

| Ce-M15 | 6080–6382 | 6231 | 58.2 | 0.93 |

| Ce-M20 | 5036–6174 | 5487 | 232.7 | 4.24 |

| Ce-M25 | 3757–5847 | 4710 | 406.9 | 8.64 |

| Du-Ref | 7960–8250 | 8105 | 55.9 | 0.69 |

| Du-M10 | 6119–7265 | 6692 | 220.5 | 3.30 |

| Du-M15 | 5389–6874 | 6111 | 286.2 | 4.68 |

| Du-M20 | 5032–7388 | 6374 | 466.3 | 7.32 |

| Du-M25 | 3694–5653 | 4578 | 382.4 | 8.35 |

| Pm-Ref | 7730–8413 | 8160 | 139.9 | 1.71 |

| Pm-M10 | 6870–7569 | 7220 | 134.5 | 1.86 |

| Pm-M15 | 6715–7776 | 7246 | 204.2 | 2.82 |

| Pm-M20 | 6045–6752 | 6399 | 136.0 | 2.13 |

| Pm-M25 | 4021–5981 | 4965 | 377.9 | 7.61 |

| Mixture | Transverse Tensile Strength [N/mm2] | Average Transverse Tensile Strength [N/mm2] | Absolute Error [N/mm2] | Relative Error [%] |

|---|---|---|---|---|

| Ce-Ref | 0.96–1.01 | 0.99 | 0.01 | 0.95 |

| Ce-M10 | 0.67–0.79 | 0.75 | 0.03 | 3.39 |

| Ce-M15 | 0.69–0.83 | 0.75 | 0.03 | 3.71 |

| Ce-M20 | 0.62–0.78 | 0.72 | 0.03 | 4.66 |

| Ce-M25 | 0.59–0.78 | 0.68 | 0.04 | 5.40 |

| Du-Ref | 0.86–0.89 | 0.88 | 0.01 | 0.73 |

| Du-M10 | 0.76–0.92 | 0.83 | 0.03 | 3.80 |

| Du-M15 | 0.61–0.81 | 0.71 | 0.04 | 5.42 |

| Du-M20 | 0.44–0.64 | 0.54 | 0.04 | 7.13 |

| Du-M25 | 0.35–0.57 | 0.49 | 0.05 | 9.56 |

| Pm-Ref | 0.84–0.97 | 0.91 | 0.02 | 2.63 |

| Pm-M10 | 0.77–0.85 | 0.82 | 0.02 | 2.05 |

| Pm-M15 | 0.65–0.81 | 0.74 | 0.03 | 4.26 |

| Pm-M20 | 0.55–0.81 | 0.66 | 0.05 | 7.85 |

| Pm-M25 | 0.38–0.71 | 0.57 | 0.07 | 11.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melichar, T.; Bydzovsky, J.; Dvorak, R.; Topolar, L.; Keprdova, S. The Behavior of Cement-Bonded Particleboard with Modified Composition under Static Load Stress. Materials 2021, 14, 6788. https://doi.org/10.3390/ma14226788

Melichar T, Bydzovsky J, Dvorak R, Topolar L, Keprdova S. The Behavior of Cement-Bonded Particleboard with Modified Composition under Static Load Stress. Materials. 2021; 14(22):6788. https://doi.org/10.3390/ma14226788

Chicago/Turabian StyleMelichar, Tomas, Jiri Bydzovsky, Richard Dvorak, Libor Topolar, and Sarka Keprdova. 2021. "The Behavior of Cement-Bonded Particleboard with Modified Composition under Static Load Stress" Materials 14, no. 22: 6788. https://doi.org/10.3390/ma14226788

APA StyleMelichar, T., Bydzovsky, J., Dvorak, R., Topolar, L., & Keprdova, S. (2021). The Behavior of Cement-Bonded Particleboard with Modified Composition under Static Load Stress. Materials, 14(22), 6788. https://doi.org/10.3390/ma14226788