Oxygen Plasma Treatment of Rear Multilayered Graphene: A Potential Top Electrode for Transparent Organic Light-Emitting Diodes

Abstract

:1. Introduction

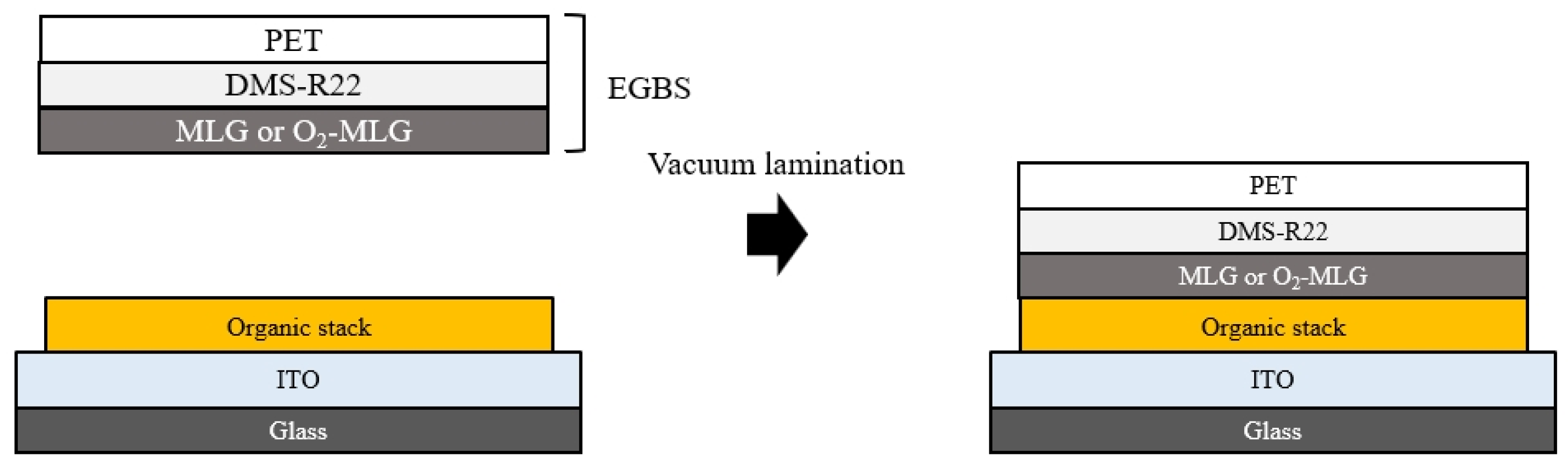

2. Materials and Methods

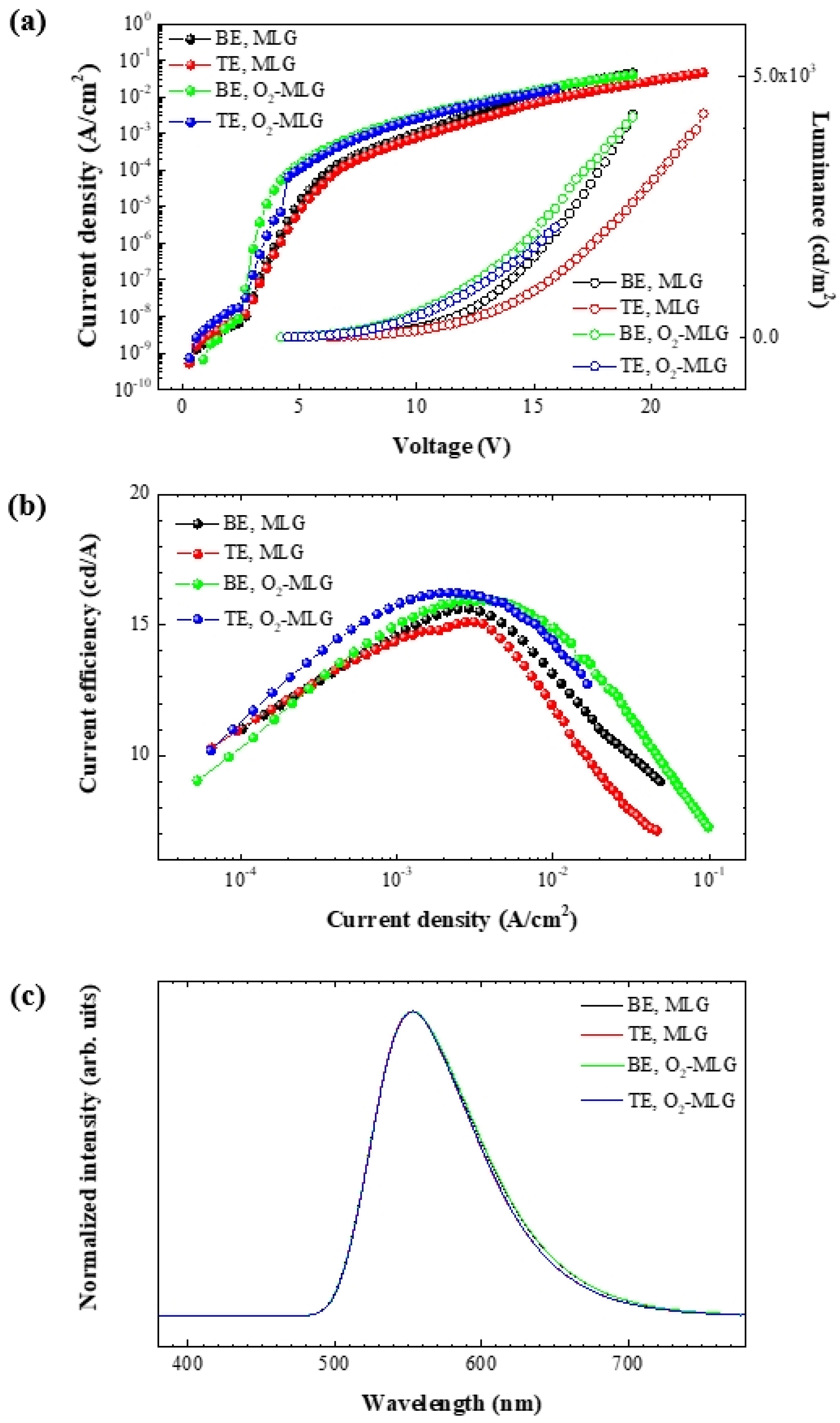

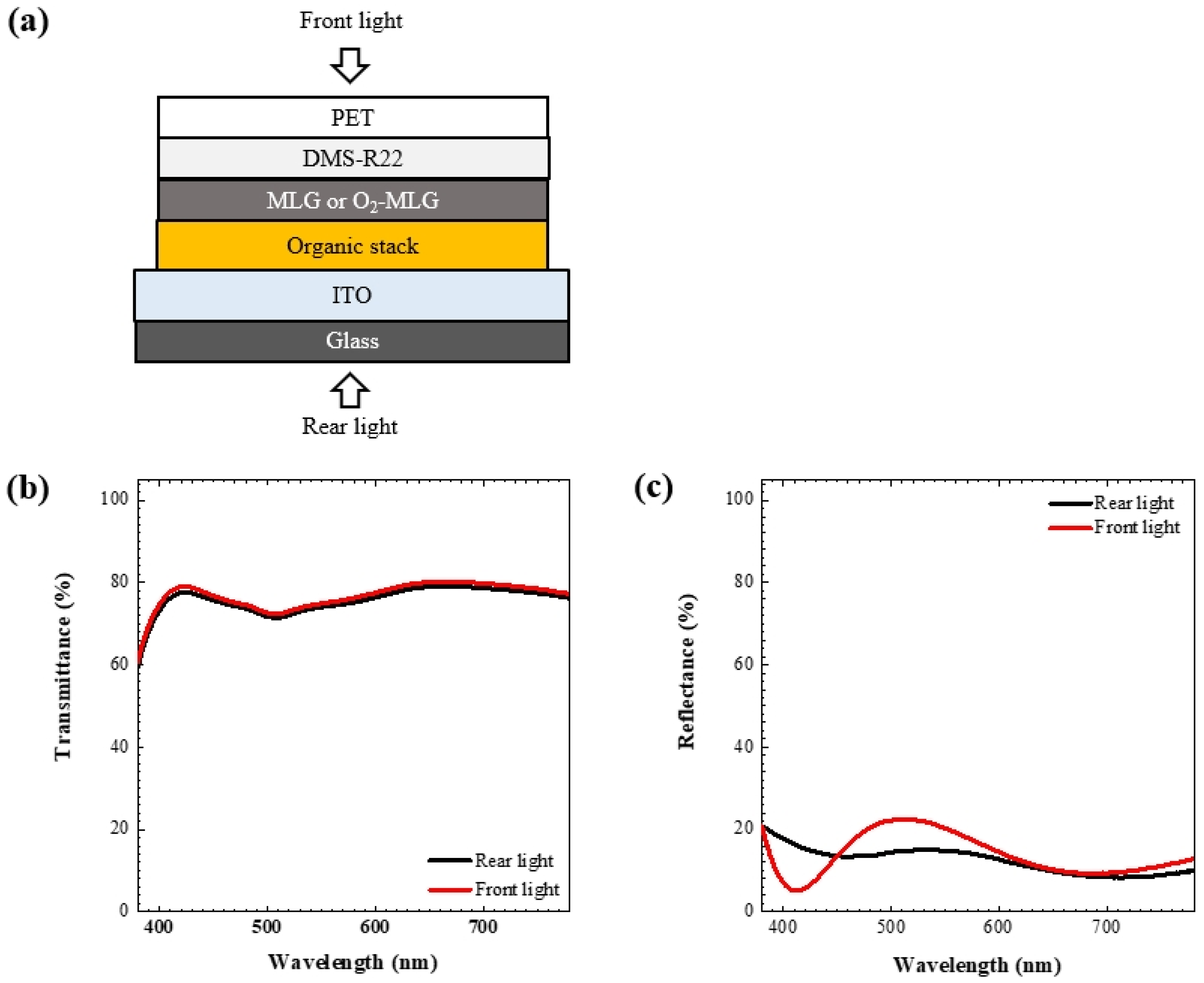

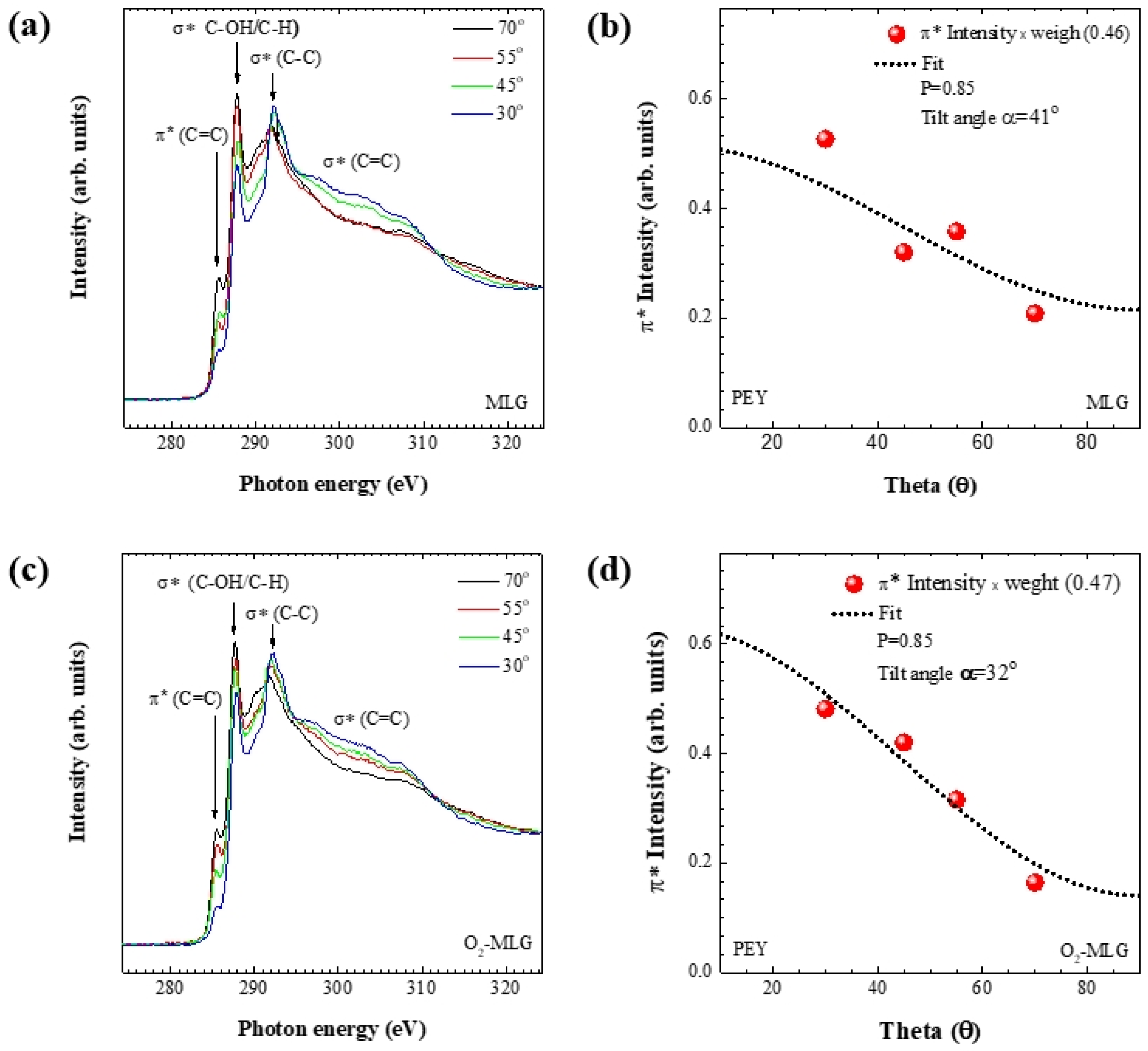

3. Results and Discussion

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tang, C.W.; VanSlyke, S.A. Organic electroluminescent didoes. Appl. Phys. Lett. 1987, 51, 913–915. [Google Scholar] [CrossRef]

- Jin, S.W.; Lee, Y.H.; Yeom, K.M.; Yun, J.; Park, H.; Jeong, Y.R.; Hong, S.Y.; Lee, G.; Oh, J.H.; Noh, J.H. Highly durable and flexible transparent electrode for flexible optoelectronic applications. ACS Appl. Mater. Interfaces 2018, 10, 30706–30715. [Google Scholar] [CrossRef]

- Kumar, A.; Zhou, C. The race to replace tin-doped indium oxide: Which materials will win? ACS Nano 2010, 4, 11–14. [Google Scholar] [CrossRef]

- Kim, G.S.; Zhao, Y.; Jang, H.; Lee, S.Y.; Kim, J.M.; Kim, K.S.; Ahn, J.H.; Kim, P.; Choi, J.-Y.; Hong, B.H. Large-scale pattern growth of graphene films for stretchable transparent electrodes. Nature 2009, 457, 706–710. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Oida, S.; Tulevski, G.S.; Han, S.-J.; Hannon, J.B.; Sadana, D.K.; Chen, T.-C. Efficient and bright organic light-emitting diodes on single-layer graphene electrodes. Nat. Commun. 2013, 4, 2294. [Google Scholar] [CrossRef]

- Han, T.-H.; Lee, Y.; Choi, M.-R.; Woo, S.-H.; Bae, S.-H.; Hong, B.H.; Ahn, J.-H.; Lee, T.-H. Extremely efficient flexible organic light-emitting diodes with modified graphene anode. Nat. Photonics 2012, 6, 105–110. [Google Scholar] [CrossRef]

- Kang, M.-G.; Guo, L.J. Nanoimpinted semitransparent metal electrodes and their application in organic light-emitting diodes. Adv. Mater. 2007, 19, 1391–1396. [Google Scholar] [CrossRef] [Green Version]

- Lim, J.T.; Yeom, G.Y.; Ihm, K.; Kang, T.-H. Electronic structures of Ba-on-Alq3 interfaces and device characteristics of organic light-emitting diodes based on these interfaces. J. Appl. Phys. 2009, 105, 083705. [Google Scholar] [CrossRef] [Green Version]

- Fehse, K.; Walzer, K.; Leo, K.; Lövenich, W.; Elschner, A. Highly conductive polymer anodes as replacements for inorganic materials in high-efficiency organic light-emitting diodes. Adv. Mater. 2007, 19, 441–444. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, Z.; Du, X.; Logan, J.M.; Sippel, J.; Nikolou, M.; Kamaras, K.; Reynolds, J.R.; Tanner, D.B.; Hebard, A.F.; et al. Transparent, conductive carbon nanotube films. Science 2004, 305, 1273–1276. [Google Scholar] [CrossRef]

- Kang, M.-G.; Kim, M.-S.; Kim, J.; Guo, L.J. Organic solar cells using nanoimprinted transparent metal electrodes. Adv. Mater. 2008, 20, 4408–4413. [Google Scholar] [CrossRef] [Green Version]

- De, S.; Higgins, T.M.; Lyons, P.E.; Doherty, E.M.; Nirmalraj, P.N.; Blau, W.J.; Boland, J.J.; Coleman, J.N. Silver nanowire networks as flexible, transparent, conducting films, extremely high DC to optical conductivity ratios. ACS Nano 2009, 3, 1767–1774. [Google Scholar] [CrossRef] [PubMed]

- Zeng, X.-Y.; Zhang, Q.-K.; Yu, R.-M.; Lu, C.-Z. A new transparent conductor: Silver nanowire film buried at the surface of a transparent polymer. Adv. Mater. 2010, 22, 4484–4488. [Google Scholar] [CrossRef] [PubMed]

- Jin, D.U.; Jeong, J.K.; Shin, H.S.; Kim, M.K.; Ahn, T.K.; Kwon, S.Y.; Kwack, J.H.; Kim, T.W.; Mo, Y.G.; Chung, H.K. 64.1: 5.6-inch Flexible Full Color Top Emission AMOLED Display on Stainless Steel Foil. In SID Symposium Digest of Technical Papers; Blackwell Publishing Ltd.: Oxford, UK, 2006. [Google Scholar]

- Ishii, H.; Sugiyama, K.; Ito, E.; Seki, K. Energy level alignment and interfacial electronic structures at organic/metal and organic/organic interfaces. Adv. Mater. 1999, 11, 605–625. [Google Scholar] [CrossRef]

- Lim, J.T.; Kim, J.; Lee, H.; Moon, J.; Kwon, B.-H.; Ahn, S.; Cho, N.S.; Ahn, B.-W.; Lee, J.-I.; Ihm, K.; et al. Unraveled face-dependent effects of multilayered graphene embedded in transparent organic light-emitting diodes. ACS Appl. Mater. Interfaces 2017, 9, 43105–43112. [Google Scholar] [CrossRef]

- Yuan, J.; Ma, L.-P.; Pei, S.; Du, J.; Su, Y.; Ren, W.; Cheng, H.-M. Tuning the electrical and optical properties of graphene by ozone treatment for patterning monolithic transparent electrodes. ACS Nano 2013, 7, 4233–4241. [Google Scholar] [CrossRef]

- Adetayo, A.E.; Ahmed, T.N.; Zakhidov, A.; Beall, G.W. Improvements of organic light-emitting diodes using graphene as an emerging and efficient transparent conducting electrode material. Adv. Opt. Mater. 2021, 9, 202102. [Google Scholar] [CrossRef]

- Hwang, J.; Choi, H.K.; Moon, J.; Kim, T.Y.; Shin, J.-W.; Joo, C.W.; Han, J.-H.; Cho, D.-H.; Huh, J.W.; Choi, S.-Y.; et al. Multilayered graphene anode for blue phosphorescent organic light emitting diodes. Appl. Phys. Lett. 2012, 100, 133304. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Singh, A.; Bayram, F.; Childress, A.S.; Rao, A.M.; Koley, G. Impact of oxygen plasma treatment on carrier transport and molecular adsorption in graphene. Nanoscale 2019, 11, 11145. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.W.; Ren, F.; Chi, G.-C.; Hung, S.-C.; Huang, Y.P.; Kim, J.; Kravchenko, I.I.; Pearton, S.J. UV ozone treatment for improving contact resistance on graphene. J. Vac. Sci. Technol. B 2012, 30, 060604. [Google Scholar] [CrossRef] [Green Version]

- Nair, R.R.; Blake, P.; Grigorenko, A.N.; Novoselov, K.S.; Booth, T.J.; Stauber, T.; Peres, N.M.R.; Geim, A.K. Fine structure constant defines visual transparency of graphene. Science 2008, 320, 1308. [Google Scholar] [CrossRef] [Green Version]

- Schumm, B.; Wisser, F.M.; Mondin, G.; Hippauf, F.; Fritsch, J.; Grothe, J.; Kaskel, S. Semi-transparent silver electrodes for flexible electronic devices prepared by nanoimprint lithography. J. Mater. Chem. C 2013, 1, 638–645. [Google Scholar] [CrossRef]

- Axelevitch, A.; Gorenstein, B.; Golan, G. Investigation of optical transmission in thin metal films. Phys. Procedia 2012, 32, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, Y.; Dubois, M.; Guérin, K.; Hamwi, A.; Fawal, Z.; Kharitonov, A.P.; Generalov, A.V.; Klyushin, A.Y.; Simonov, K.A.; Vinogradov, N.A.; et al. NMR and NEXAFS study of various graphite fluorides. J. Phys. Chem. C 2013, 117, 13564–13572. [Google Scholar] [CrossRef]

- Rojas, W.Y.; Winter, A.D.; Grote, J.; Kim, S.S.; Naik, R.R.; Williams, A.D.; Weiland, C.; Principe, E.; Fischer, D.A.; Banerjee, S.; et al. Strain and bond length dynamics upon growth and transfer of graphene by NEXAFS spectroscopy from first–principles and experiment. Langmuir 2018, 34, 1783–1794. [Google Scholar] [CrossRef] [Green Version]

- Milev, A.; Dissanayake, D.M.A.S.; Kannangara, G.S.K.; Kumarasinghe, A.R. Defect induced electronic states and magnetism in ball–milled graphite. Phys. Chem. Chem. Phys. 2013, 15, 16294–16302. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, J.; Hu, Y.; Regier, T. Chemical interaction and imaging of single Co3O4/graphene sheets studied by scanning transmission X-ray microscopy and X-ray absorption spectroscopy. Energy Environ. Sci. 2013, 6, 926–934. [Google Scholar] [CrossRef]

- Stöhr, J. NEXAFS Spectroscopy; Springer: Berlin, Germany, 1992. [Google Scholar]

- Jia, P.; Pan, F.; Chen, T. Effect of oxygen plasma etching on graphene’s mechanical and electrical properties. IOP Conf. Series Mater. Sci. Eng. 2017, 182, 012030. [Google Scholar] [CrossRef]

| Anode | Emission Direction | V1000 at L1000 (V) | ηLCE at L1000 (cd/A) | λmax at EL Spectra (nm) |

|---|---|---|---|---|

| MLG | BE | 13.8 | 13.9 | 554 |

| TE | 15.3 | 13.0 | 553 | |

| O2-MLG | BE | 12.0 | 15.7 | 554 |

| TE | 12.6 | 15.3 | 553 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, J.T. Oxygen Plasma Treatment of Rear Multilayered Graphene: A Potential Top Electrode for Transparent Organic Light-Emitting Diodes. Materials 2021, 14, 6652. https://doi.org/10.3390/ma14216652

Lim JT. Oxygen Plasma Treatment of Rear Multilayered Graphene: A Potential Top Electrode for Transparent Organic Light-Emitting Diodes. Materials. 2021; 14(21):6652. https://doi.org/10.3390/ma14216652

Chicago/Turabian StyleLim, Jong Tae. 2021. "Oxygen Plasma Treatment of Rear Multilayered Graphene: A Potential Top Electrode for Transparent Organic Light-Emitting Diodes" Materials 14, no. 21: 6652. https://doi.org/10.3390/ma14216652

APA StyleLim, J. T. (2021). Oxygen Plasma Treatment of Rear Multilayered Graphene: A Potential Top Electrode for Transparent Organic Light-Emitting Diodes. Materials, 14(21), 6652. https://doi.org/10.3390/ma14216652