Effect of Heat Treatment on the Physic-Mechanical Characteristics of Eucalyptusurophylla S.T. Blake

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Heat Treatment

2.3. Mass Losss (ML)

2.4. Moisture Adsorption

2.5. Density

2.6. Dimensional Stability

2.7. Bending Strength and Modulus of Elasticity

2.8. Colour Measurements

2.9. FTIR Spectroscopy

2.10. Statistical Analysis

3. Results and Discussion

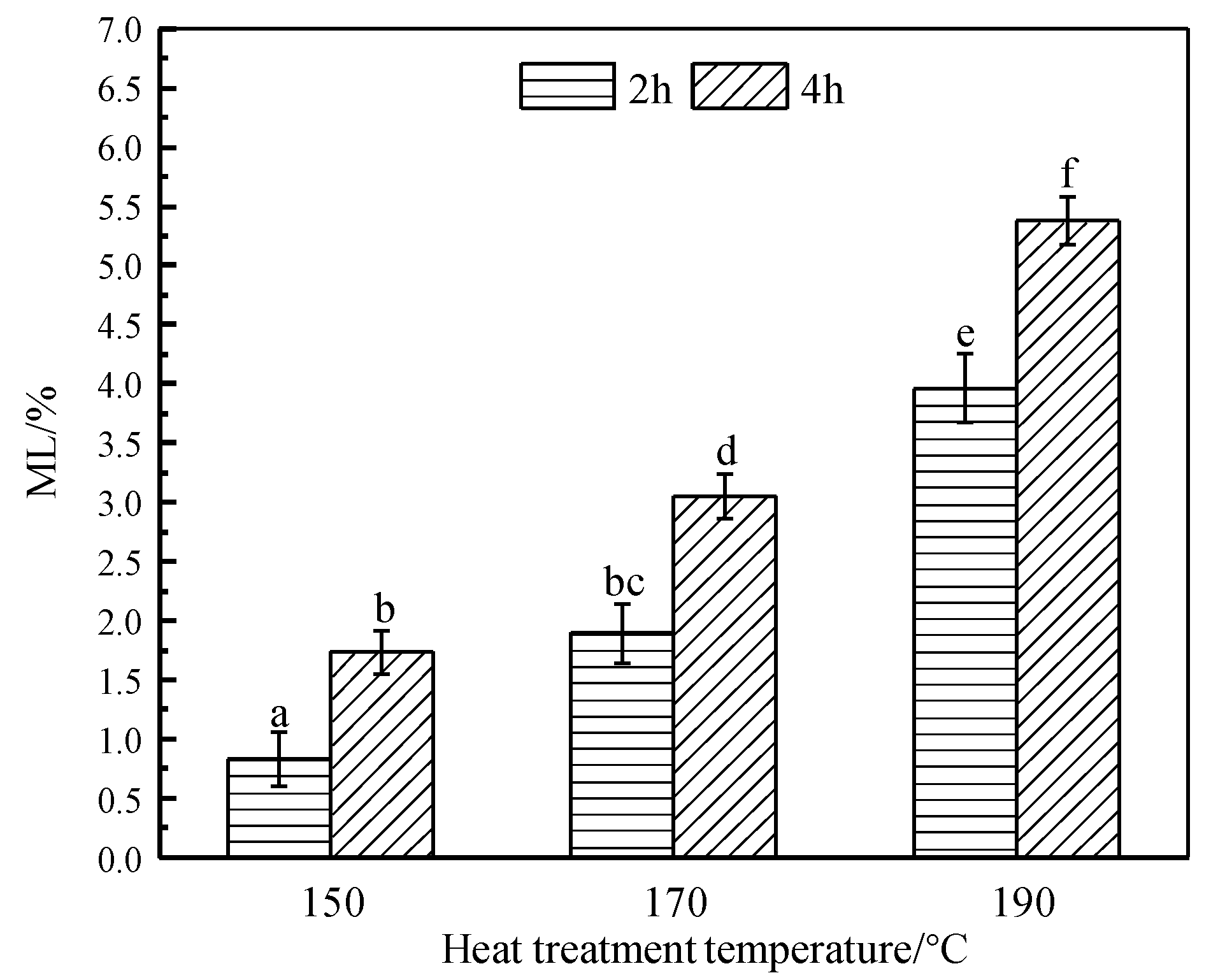

3.1. Mass Loss (ML)

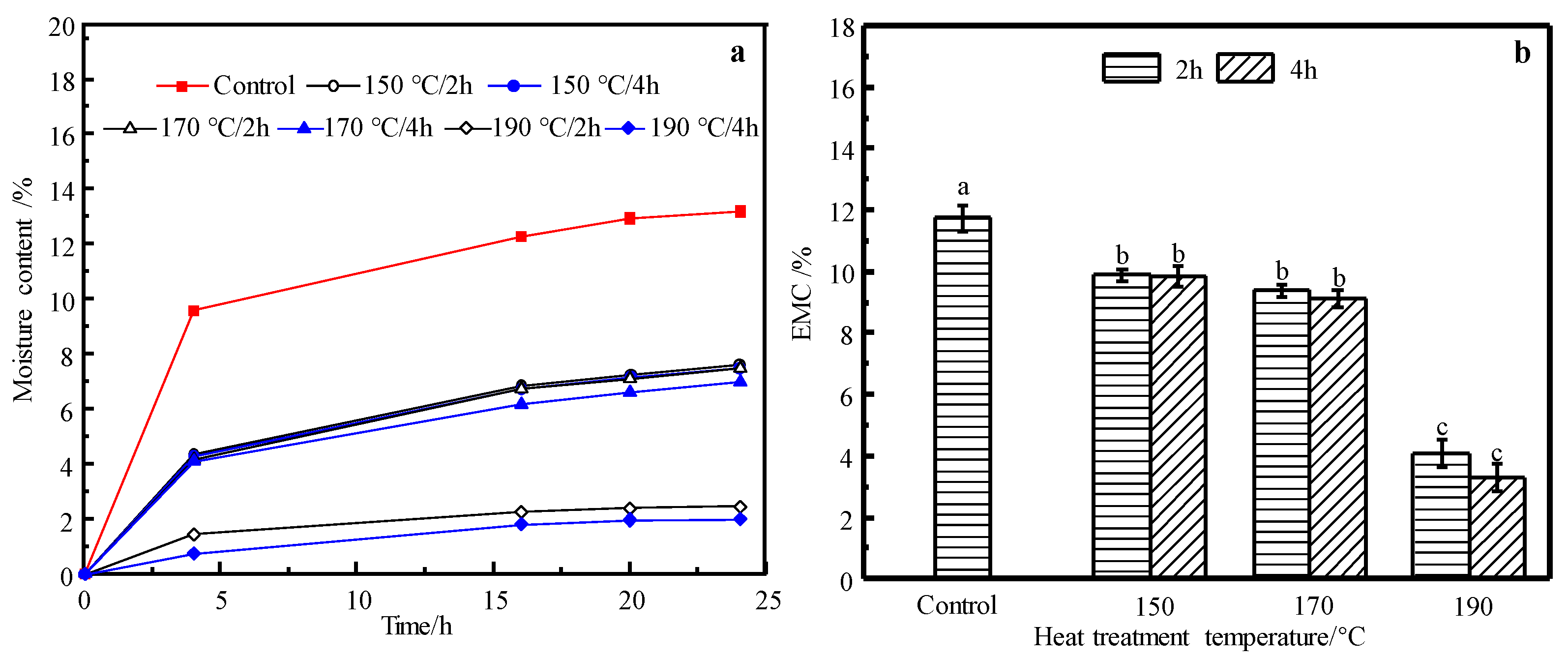

3.2. Moisture Adsorption

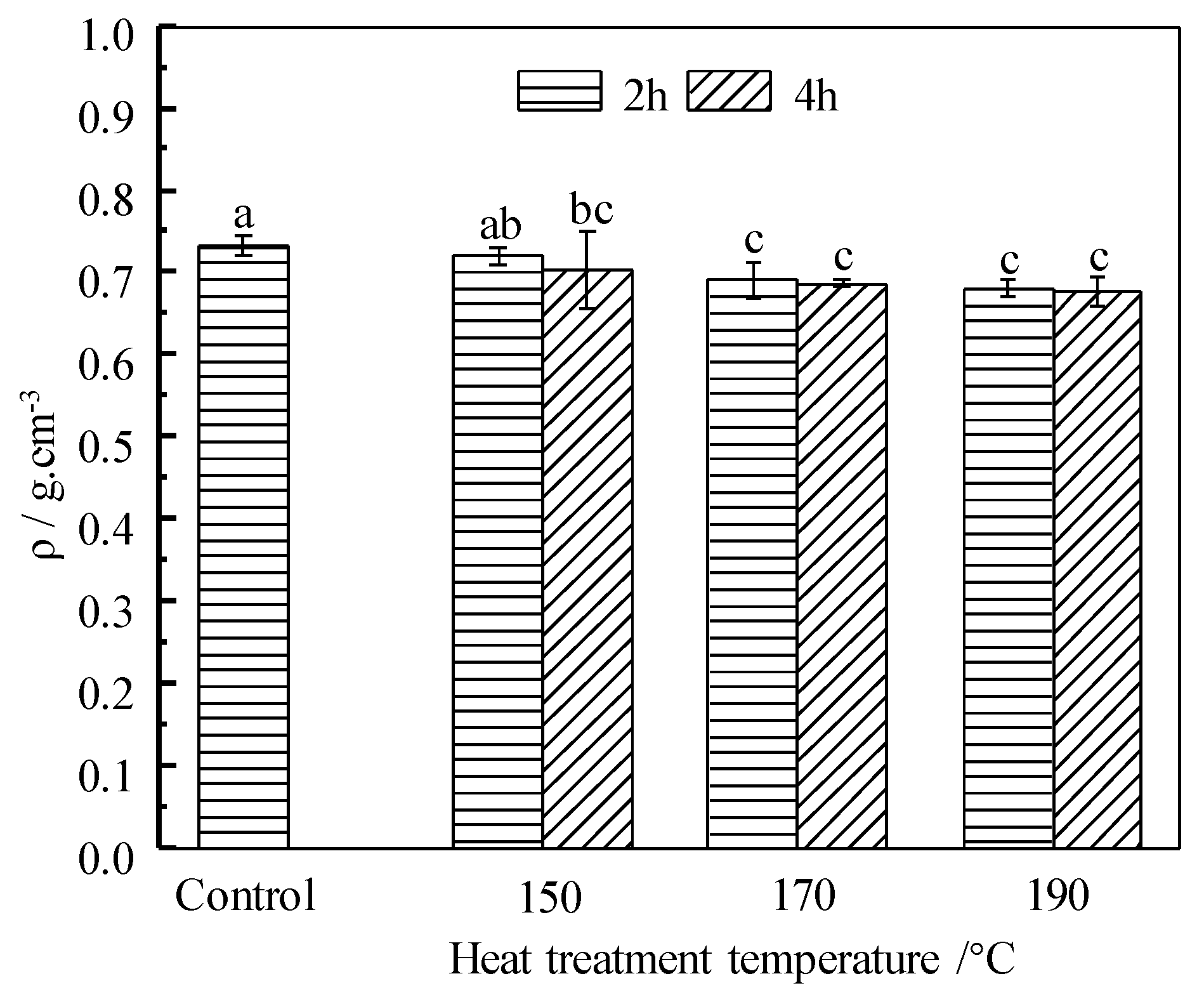

3.3. Density

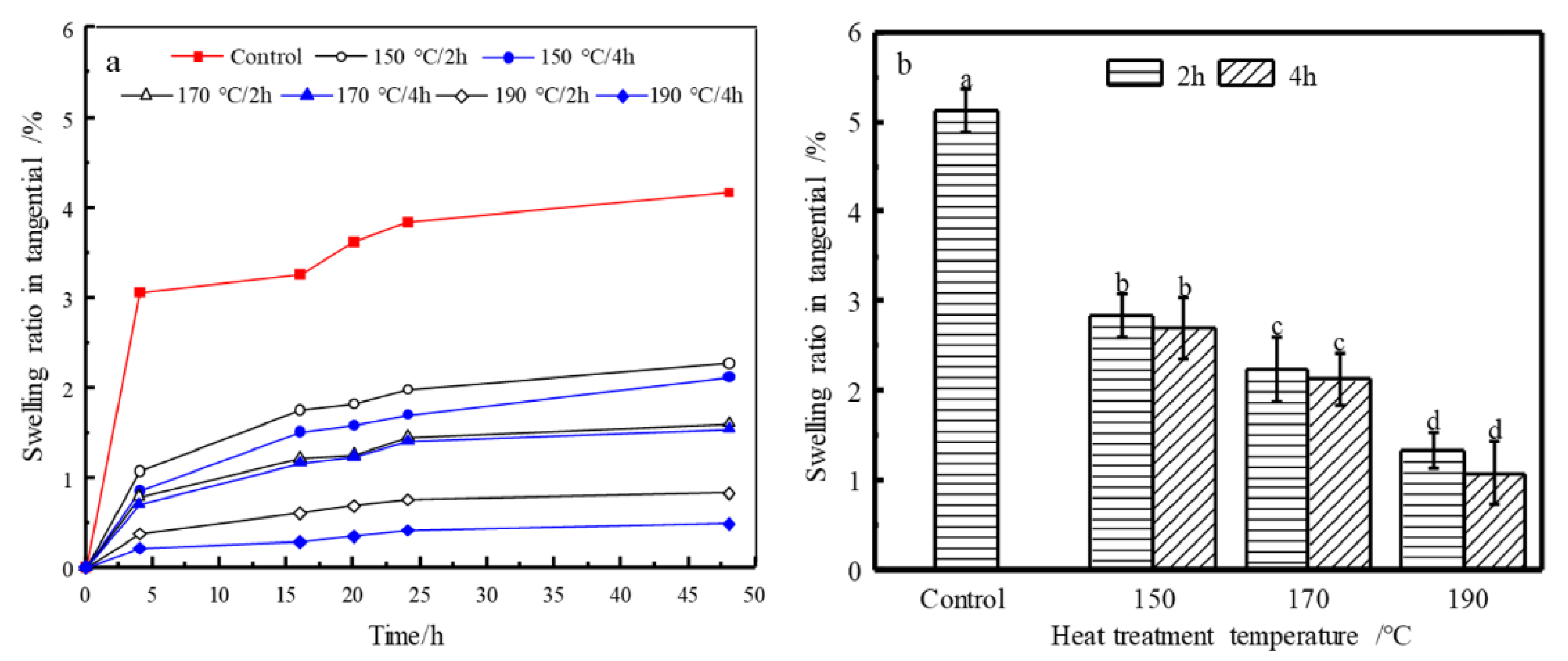

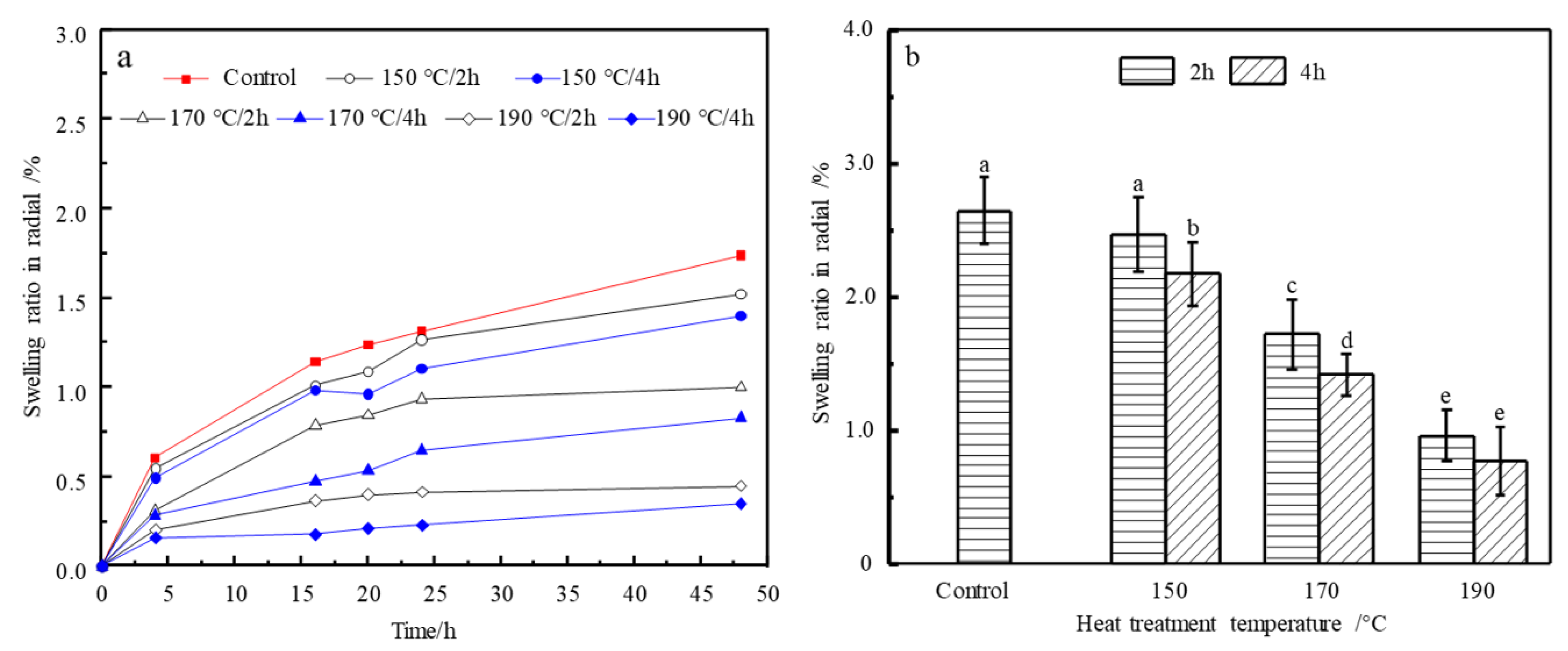

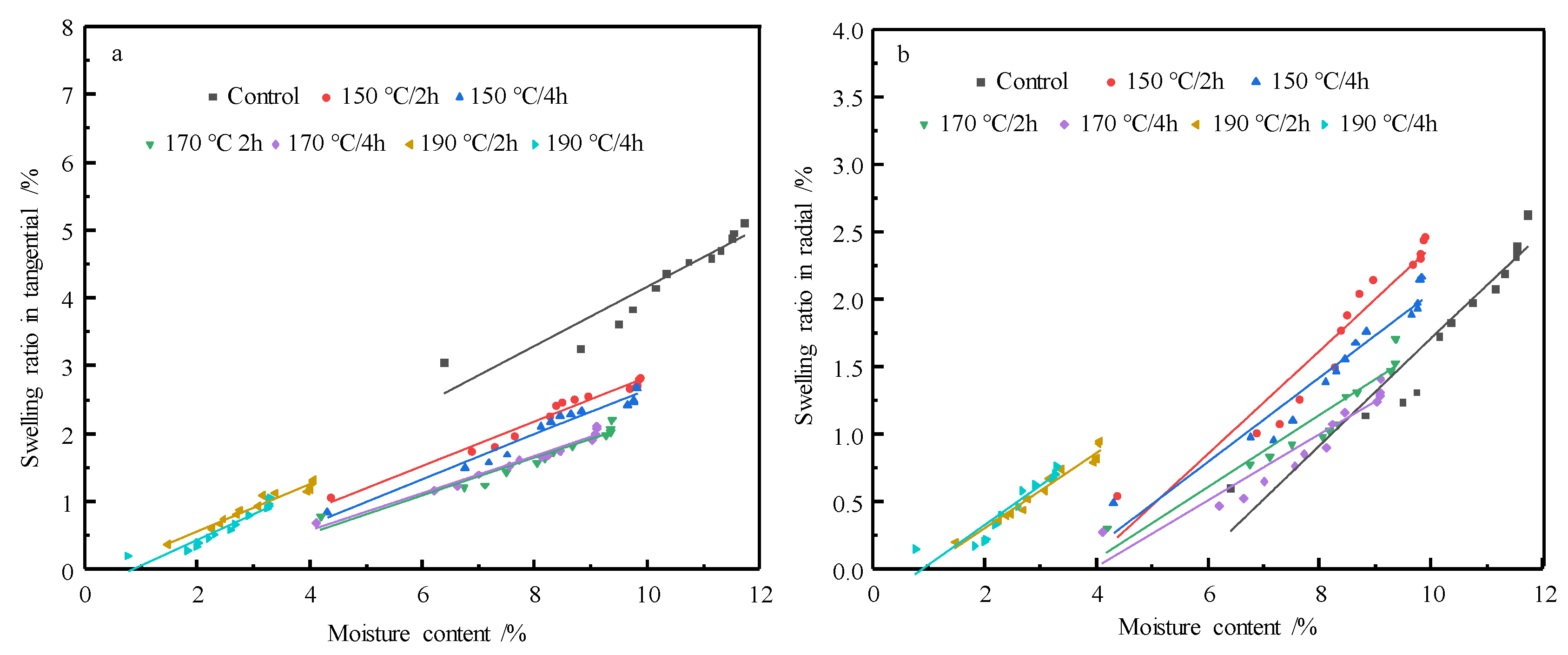

3.4. Dimensional Stability

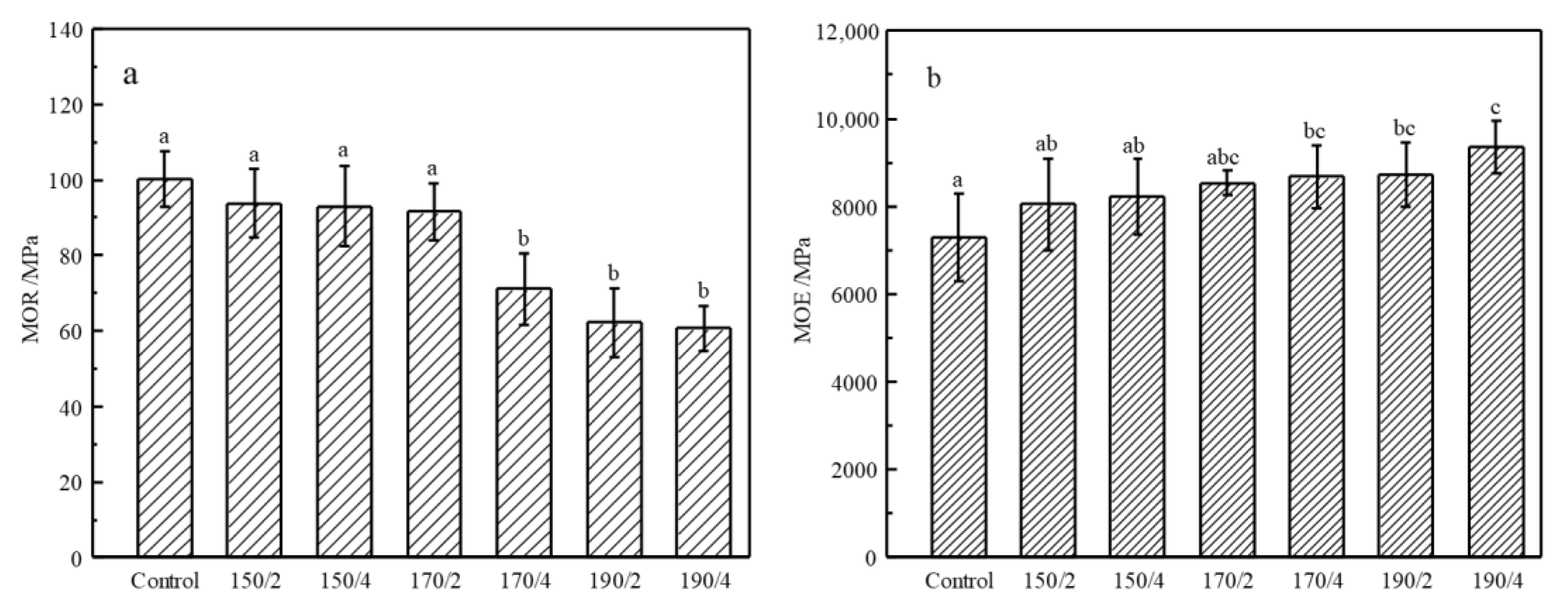

3.5. Modulus of Rupture and Modulus of Elasticity

3.6. Colour Change

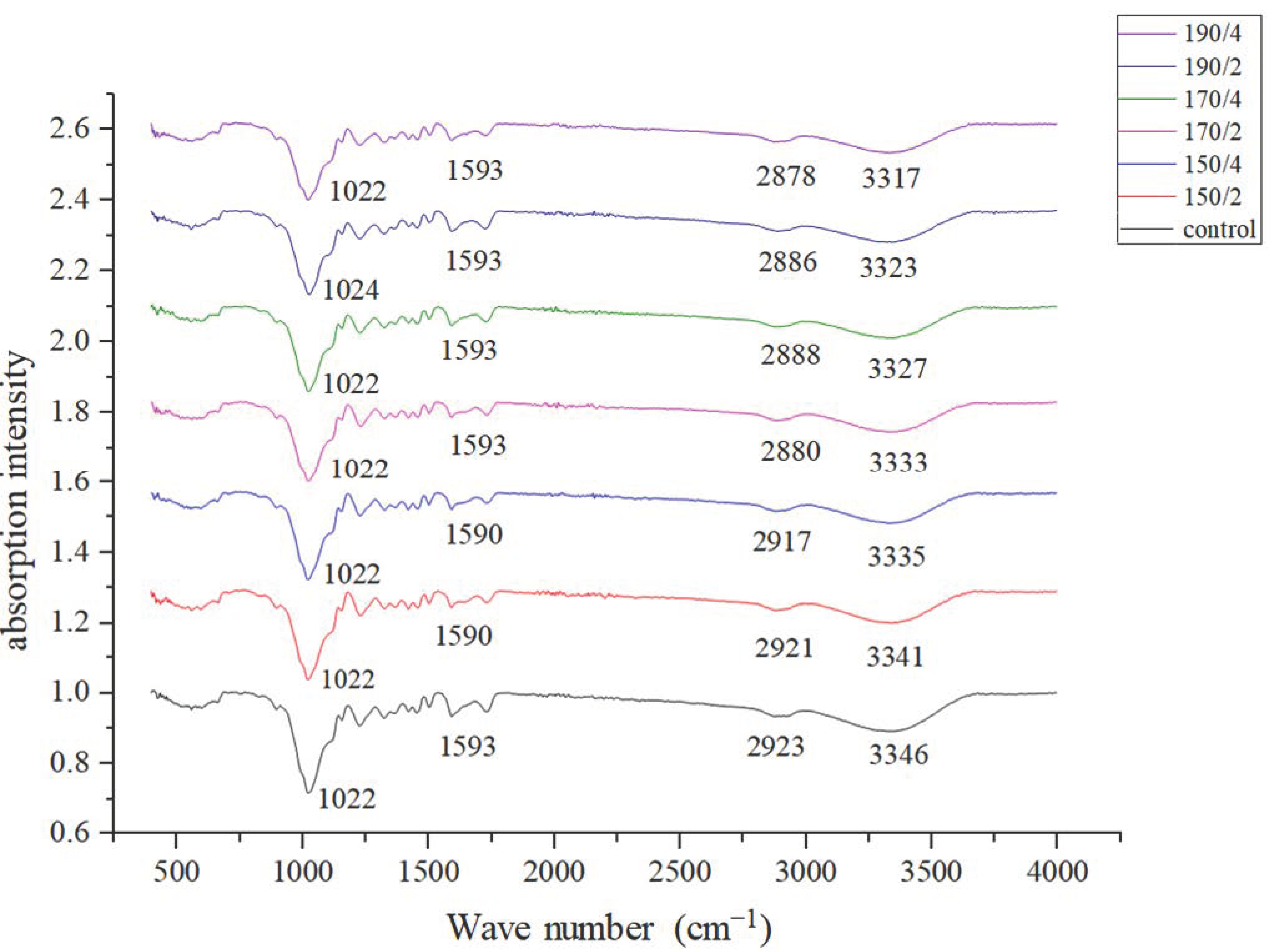

3.7. Changes in the Chemical Structure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Morales, P.; Gentina, J.C.; Aroca, G.; Mussatto, S.I. Development of an Acetic Acid Tolerant Spathaspora passalidarum Strain through Evolutionary Engineering with Resistance to Inhibitors Compounds of Autohydroly sate of Eucalyptus globulus. Ind. Crops Prod. 2017, 106, 5–11. [Google Scholar] [CrossRef]

- Carignato, A.; De Moraes, C.B.; Zimback, L.; Mori, E.S. Genetic Resistance to Rust of Eucalyptus urophylla Progenies. Flores. Ambi. 2018, 25, e00094014. [Google Scholar] [CrossRef] [Green Version]

- Stape, J.L.; Binkley, D.; Ryan, M.G.; Fonseca, S.; Loos, R.A.; Takahashi, E.N.; Silva, C.R.; Silva, S.R.; Hakamada, R.E.; De Ferreira, J.M.A.; et al. The Brazil Eucalyptus Potential Productivity Project: Influence of Water, Nutrient sand Stand Uniformity on Wood Production. For. Ecol. Manag. 2010, 259, 1684–1694. [Google Scholar] [CrossRef]

- Wu, S.S.; Tao, X.; Xu, W. Thermal conductivity of poplar wood veneer impregnated with graphene/polyvinyl alcohol. Forests 2021, 12, 777. [Google Scholar] [CrossRef]

- Yan, W.; Zhou, J.C.; Yang, F.; Wang, Y.J.; Wang, J.; Zhang, J.L. A strong multi-layered transparent wood with natural wood color and texture. J. Mater. Sci. 2021, 56, 8000–8013. [Google Scholar]

- Liu, Y.X.; Liu, H.H.; Shen, Z.R. Nanocellulose based filtration membrane in industrial waste water treatment: A Review. Materials 2021, 14, 5398. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Liu, H.H. A review of Eucalyptus wood collapse and its control during drying. BioResources 2018, 13, 2171–2181. [Google Scholar] [CrossRef]

- Honghai, L.; Yueting, Z.; Zhihui, W. Effects of Ultrasound Pretreatment on Microstructure and Drying Characteristics of Eucalyptus urophylla × E. grandis. BioResources 2018, 13, 5953–5964. [Google Scholar]

- Chen, Y.; Zhu, J. Study on bending characteristics of fast growing eucalyptus bookcase shelves by using burgers mode. Wood Res. 2019, 64, 137–144. [Google Scholar]

- Liu, H.H.; Zhang, J.W.; Jiang, W.J.; Cai, Y.C. Characteristics of commercial-scale Radio-frequency/vacuum (RF/V) drying for hardwood lumber. BioResources 2019, 14, 6923–6935. [Google Scholar] [CrossRef]

- Yin, Q.; Liu, H.H. Drying stress and strain of wood: A Review. Appl. Sci. 2021, 11, 5023. [Google Scholar] [CrossRef]

- Cai, C.Y.; Haapala, A.; Rahman, M.H.; Tiitta, M.; Tiitta, V.; Tomppo, L.; Lappalainen, R.; Heräjärvi, H. Effect of 2-year Natural Weathering on Chemical and Physical Properties of Thermally Modified Picea abies, Pinus sylvestris and Fraxinus Excelsior Wood. Can. J. Forest Res. 2020, 50, 1160–1171. [Google Scholar] [CrossRef]

- Esteves, B.M.; Domingos, I.J.; Pereira, H.M. Pine wood modification by heat treatment in air. BioResources 2007, 3, 1–5. [Google Scholar]

- Esteves, B.M.; Marques, A.V.; Domingos, I.; Pereira, H. Heat-induced colour changes of pine (Pinus pinaster) and eucalypt (Eucalyptus globulus) wood. Wood Sci. Technol. 2008, 42, 369–384. [Google Scholar] [CrossRef] [Green Version]

- Esteves, B.M.; Pereira, H.M. Wood modification by heat treatment: A review. BioResources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Kaygın, B.; Gunduz, G.; Aydemir, D. Some physical properties of heat treated Paulwnia (Paulownia elongate) wood. Dry Technol. 2009, 27, 89–93. [Google Scholar] [CrossRef]

- Gunduz, G.; Aydemir, D. Some physical properties of heat-treated Hornbeam (Carpinus betulus L.) wood. Dry Technol. 2009, 27, 714–720. [Google Scholar] [CrossRef]

- Da Moura, L.F.; Brito, J.O.; Da Silvam, J.F.G. Effect of thermal treatment on the chemical characteristics of wood from Eucalyptus grandis W. Hill ex Maiden under different atmospheric conditions. CERNE 2012, 18, 449–455. [Google Scholar] [CrossRef] [Green Version]

- Kang, C.W.; Jang, E.S.; Jang, S.S.; Cho, J.I.; Kim, N.H. Effect of Heat Treatment on the Gas Permeability, Sound Absorption Coefficient, and Sound Transmission Loss of Paulownia tomentosa Wood. J. Korean Wood Sci. Technol. 2019, 47, 644–654. [Google Scholar]

- Henrique, W.; Dalla, C.; Rodrigo, C.; Fernanda, R.; Andrade, M.G.; Ronan, C.; Darci, A.; Gatto, D.A.; André, L.M. Brittleness increase in Eucalyptus wood after thermal treatment. Int. Wood Prod. J. 2020, 11, 38–42. [Google Scholar]

- Nemeth, R.; Tolvaj, L.; Bak, M.; Alpar, T. Colour stability of oil-heat treated black locust and poplar wood during short-term UV radiation. J. Photoch. Photobiol. A 2016, 329, 287–292. [Google Scholar] [CrossRef] [Green Version]

- Feist, W.C.; Sell, J. Weathering Behavior of Dimensionally Stabilized Wood Treated by Heating under Pressure of Nitrogen Gas. Wood Fiber Sci. 1987, 19, 183–195. [Google Scholar]

- Giebeler, E. Dimensional Stabilization of Wood by Moisture-Heat-Pressure Treatment. Holz Roh. Werkstoff. 1983, 41, 87–94. [Google Scholar] [CrossRef]

- Araújo, S.O.; Vital, B.R.; Oliveira, B.; Carneiro, A.C.O.; Lourenço, A.; Pereira, H. Physical and mechanical properties of heat treated wood from Aspidosperma populifolium, Dipteryx odorata and Mimosa scabrella. Maderas-Cienc. Tecnol. 2016, 18, 143–156. [Google Scholar]

- Bekir, C.B.; İbrahim, B. The Effects of Heat Treatment on the Physical Properties of Juvenile Wood and Mature Wood of Eucalyptus grandis. BioResource 2012, 7, 5117–5127. [Google Scholar]

- Bekir, C.B.; İbrahim, B. The Effects of Heat Treatment on Some Mechanical Properties of Juvenile Wood and Mature Wood of Eucalyptus grandis. Dry Technol. 2013, 31, 479–485. [Google Scholar]

- Santos, J.A. Mechanical behavior of eucalyptus wood modified by heat. Wood Sci. Technol. 2000, 34, 39–43. [Google Scholar] [CrossRef]

- Calonego, F.W.; Severo, E.T.D.; Ballarin, A.W. Physical and mechanical properties of thermally modified wood from E. Grandis. Eur. J. Wood Wood Prod. 2011, 70, 453–460. [Google Scholar] [CrossRef]

- Zhang, N.N.; Xu, M. Effects of silicon dioxide combined heat treatment on properties of rubber wood. J. For. Eng. 2019, 4, 38–42. [Google Scholar]

- Korkut, S.; Budakc, M. Effect of high-temperature treatment on the mechanical properties of rowan (Sorbus aucuparia L.) wood. Dry Technol. 2009, 27, 1240–1247. [Google Scholar] [CrossRef]

- Unsal, O.; Korkut, S.; Atik, C. The effect of heat treatment on some properties and color in eucalyptus (Eucalyptus camaldulensis Dehn.) wood. Maderas Cienc. Tecnol. 2003, 5, 145–152. [Google Scholar]

- Guller, B. Effects of heat treatment on density, dimensional stability and color of Pinusnigra wood. Afr. J. Biotechnol. 2012, 11, 2204–2209. [Google Scholar]

- Zhang, J.Y.; Chesnokova, T.; Zhang, B.Y.; Zhan, J.F. Chromatic variability of larch wood impacted by high-temperature thermal treatment and oil-wax coating. J. For. Eng. 2020, 5, 64–75. [Google Scholar]

- Moura, L.F.; Brito, J.O. Efeito da termorretifcação sobre as propriedades colorimétricas das madeiras de Eucalyptus grandis e Pinus caribaea var. hondurensis. Sci. For. 2011, 39, 69–76. [Google Scholar]

- He, Z.; Wang, Z.; Qu, L.; Qian, J.; Yi, S. Modeling and simulation of heat-mass transfer and its application in wood thermal modification. Res. Phys. 2019, 13, 2213. [Google Scholar] [CrossRef]

- Batista, D.C.; Nisgoski, S.; Oliveira, J.T.S.; Muñiz, G.I.B.; Paes, J.B. Resistance of thermally modified Eucalyptus grandis W. Hill ex Maiden wood to deterioration by dry-wood termites (Cryptotermes sp.). Ciência Florest. 2016, 26, 671–678. [Google Scholar] [CrossRef]

- Zhao, Y.S.; Xue, X.M.; Song, X.J.; Nan, C.H.; Chen, R.K.; Wang, Y. Comparison and analysis of FT-IR spectra for six broad-leaved wood species. J. For. Eng. 2019, 4, 40–45. [Google Scholar]

- Cademartori, P.H.G.; Missio, A.L.; Mattos, B.D.; Schneid, E.; Gatto, D.A. Physical and mechanical properties and colour changes of fast growing Gympie messmate wood subjected to two-step steam-heat treatments. Wood Mater. Sci. Eng. 2014, 9, 40–48. [Google Scholar] [CrossRef]

- Hosseinaei, O.; Wang, S.; Rials, T.G.; Xing, C.; Zhang, Y. Effects of decreasing carbohydrate content on properties of wood strands. Cellulose 2011, 18, 841–850. [Google Scholar] [CrossRef]

- Wang, W.; Ran, Y.; Wang, J. Improved performance of thermally modified wood via impregnation with carnauba wax/organoclay emulsion. Constr. Build. Mater. 2020, 247, 118586. [Google Scholar] [CrossRef]

- Zhou, Y.Q.; Xue, Z.Q.; Huang, Q.T.; Yao, B.; Wang, X.H. Physical and mechanical properties of Aucoumea klaineana wood after vacuum heat treatment for furniture components. J. For. Eng. 2020, 5, 73–78. [Google Scholar]

- Cruz, N.; Bustos, C.A.; Aguayo, M.G.; Cloutier, A.; Castillo, R. Impact of the chemical composition of Pinus radiata wood on its physical and mechanical properties following thermo-hygromechanical densification. BioResources 2018, 13, 2268–2282. [Google Scholar] [CrossRef]

- Kamperidou, V.; Barmpoutis, P. Correlation between the changes of colour and mechanical properties of thermally-modified Scots pine (Pinus sylvestris L.) wood. Pro Ligno 2015, 11, 360–365. [Google Scholar]

- Kuo, M.L.; Mcclelland, J.F.; Luo, S.Q.; Chien, P.L.; Walked, R.D.; Hse, C.Y. Applications of infrared photoacoustic-spectroscopy for wood samples. Wood Fiber Sci. 1988, 20, 132–145. [Google Scholar]

- Ding, T.; Peng, W.W.; Li, T. Mechanism of color change of heat-treated white ash wood by means of FT-IR and XPS analyses. J. For. Eng. 2017, 2, 25–30. [Google Scholar]

| Treating Conditions | Tangential | Radial | |||

|---|---|---|---|---|---|

| Temperature (°C) | Time (h) | Regression Equations | Correlation Coefficient | Regression Equations | Correlation Coefficient |

| - | - | Y = 0.4354X − 0.1759 | 0.8949 | Y = 0.3963X − 2.2416 | 0.9169 |

| 150 | 2 | Y = 0.3249X − 0.407 | 0.9743 | Y = 0.3846X − 1.445 | 0.9226 |

| 4 | Y = 0.3312X − 0.6439 | 0.9621 | Y = 0.3139X − 1.0778 | 0.9394 | |

| 170 | 2 | Y = 0.28X − 0.5751 | 0.9327 | Y = 0.2664X − 0.9818 | 0.9012 |

| 4 | Y = 0.2763X − 0.5193 | 0.9742 | Y = 0.2454X − 0.9569 | 0.9018 | |

| 190 | 2 | Y = 0.3426X − 0.1015 | 0.9550 | Y = 0.2792X − 0.2493 | 0.9594 |

| 4 | Y = 0.3778X − 0.2898 | 0.8984 | Y = 0.2918X − 0.2489 | 0.8777 | |

| Treating Conditions | Δa* | Δb* | ΔL* | ΔE* | |

|---|---|---|---|---|---|

| Temperature/°C | Time/h | ||||

| 150 | 2 | −1.17 | 1.45 | −3.98 | 4.4 |

| 4 | −0.66 | 0.68 | −4.89 | 5.0 | |

| 170 | 2 | −2.30 | 2.17 | −8.39 | 9.0 |

| 4 | −1.34 | 1.85 | −10.59 | 10.8 | |

| 190 | 2 | −3.20 | 6.71 | −16.67 | 18.3 |

| 4 | −3.08 | 5.27 | −22.53 | 23.3 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Jin, H. Effect of Heat Treatment on the Physic-Mechanical Characteristics of Eucalyptusurophylla S.T. Blake. Materials 2021, 14, 6643. https://doi.org/10.3390/ma14216643

Yang L, Jin H. Effect of Heat Treatment on the Physic-Mechanical Characteristics of Eucalyptusurophylla S.T. Blake. Materials. 2021; 14(21):6643. https://doi.org/10.3390/ma14216643

Chicago/Turabian StyleYang, Lin, and Honghui Jin. 2021. "Effect of Heat Treatment on the Physic-Mechanical Characteristics of Eucalyptusurophylla S.T. Blake" Materials 14, no. 21: 6643. https://doi.org/10.3390/ma14216643

APA StyleYang, L., & Jin, H. (2021). Effect of Heat Treatment on the Physic-Mechanical Characteristics of Eucalyptusurophylla S.T. Blake. Materials, 14(21), 6643. https://doi.org/10.3390/ma14216643