Fatigue Crack Growth Behavior and Fracture Toughness of EH36 TMCP Steel

Abstract

:1. Introduction

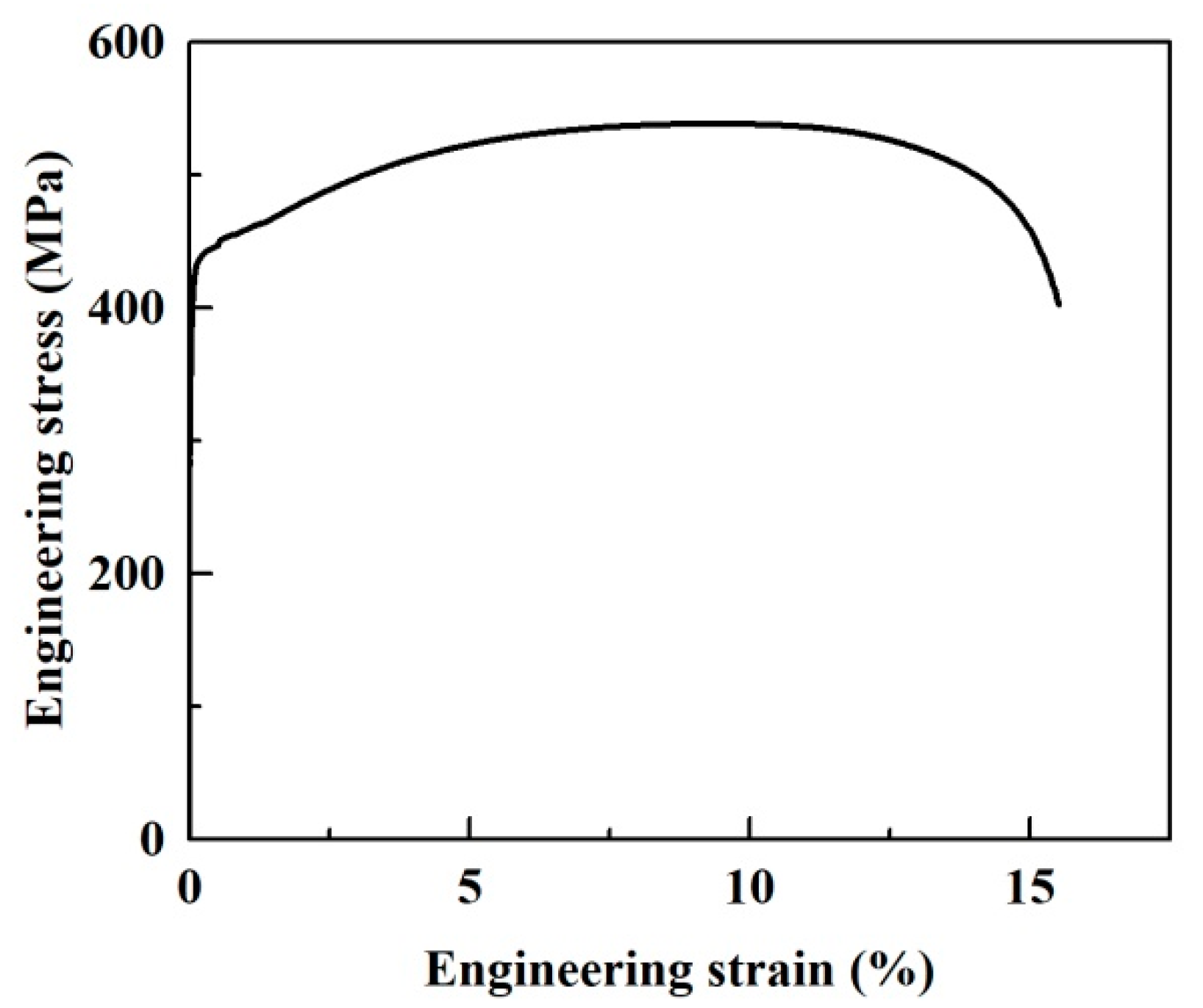

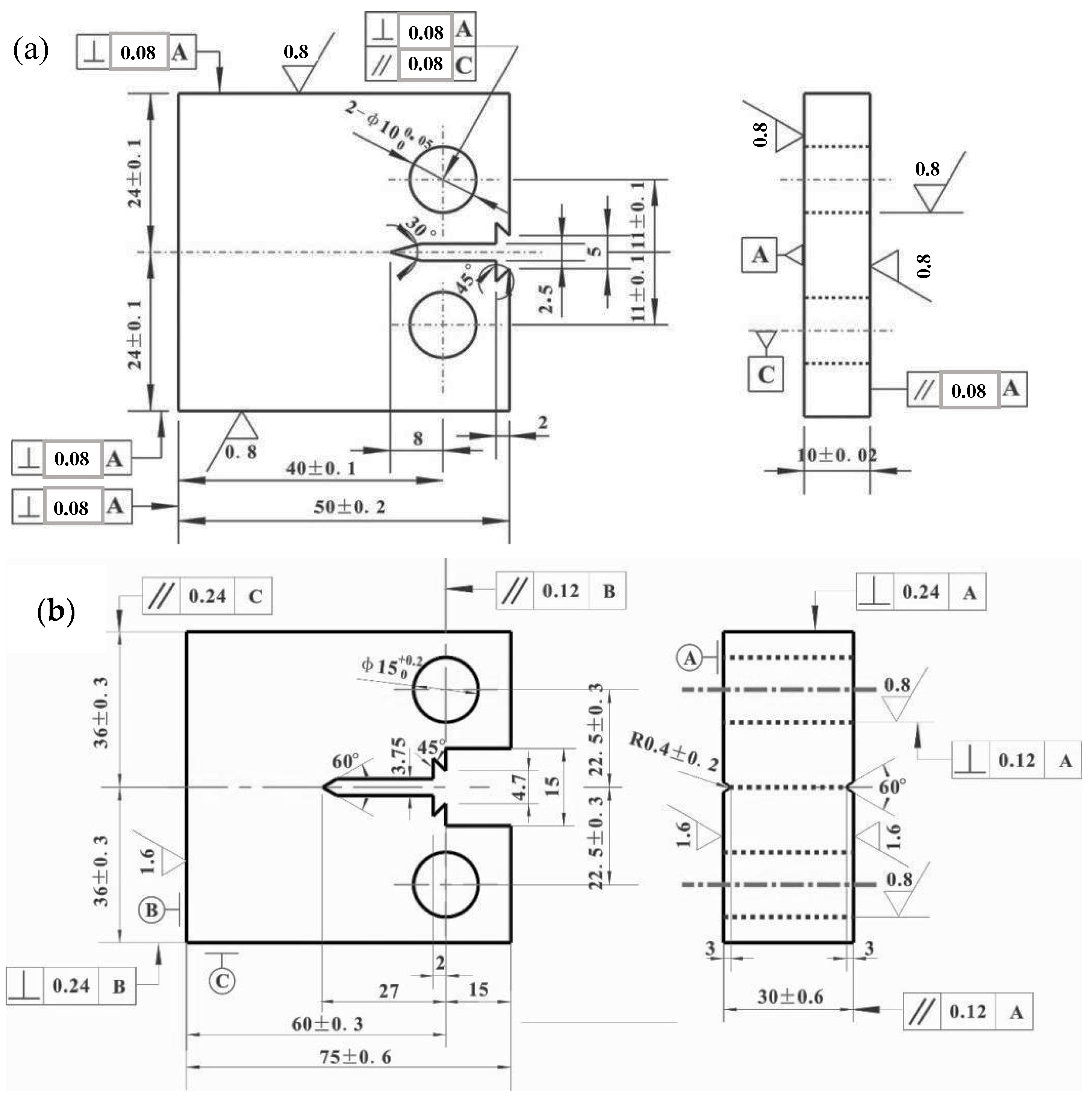

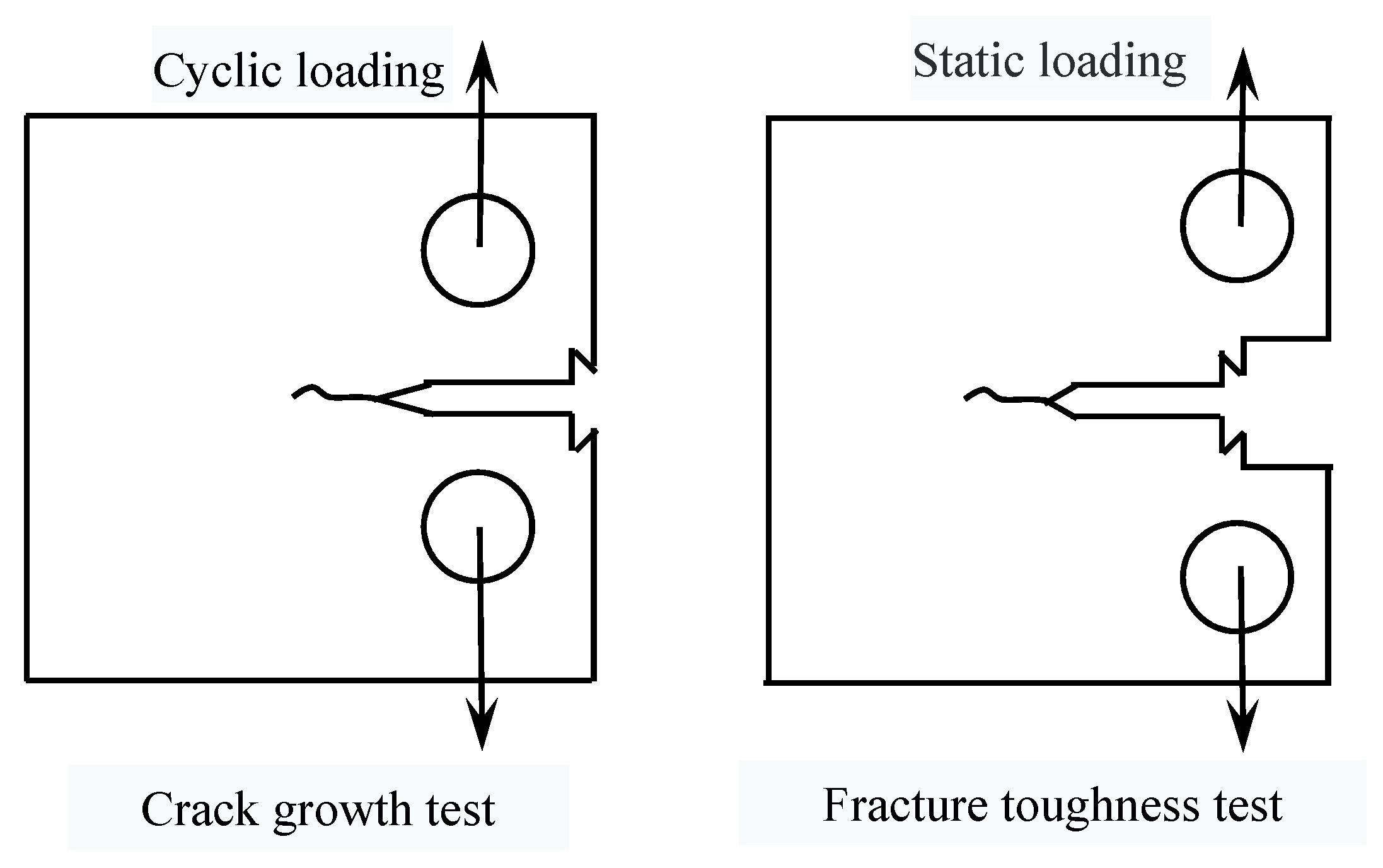

2. Materials and Methods

3. Results and Discussion

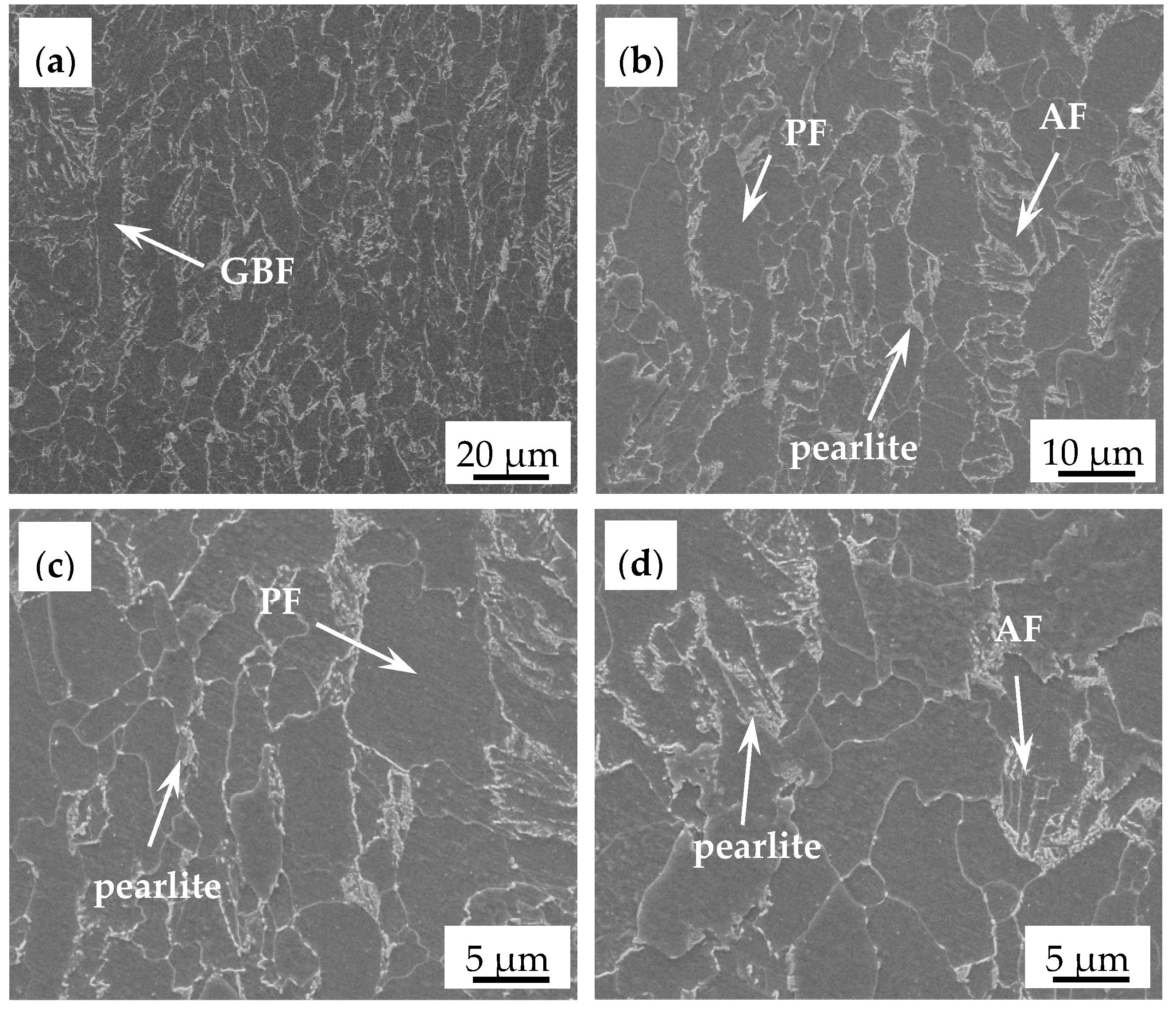

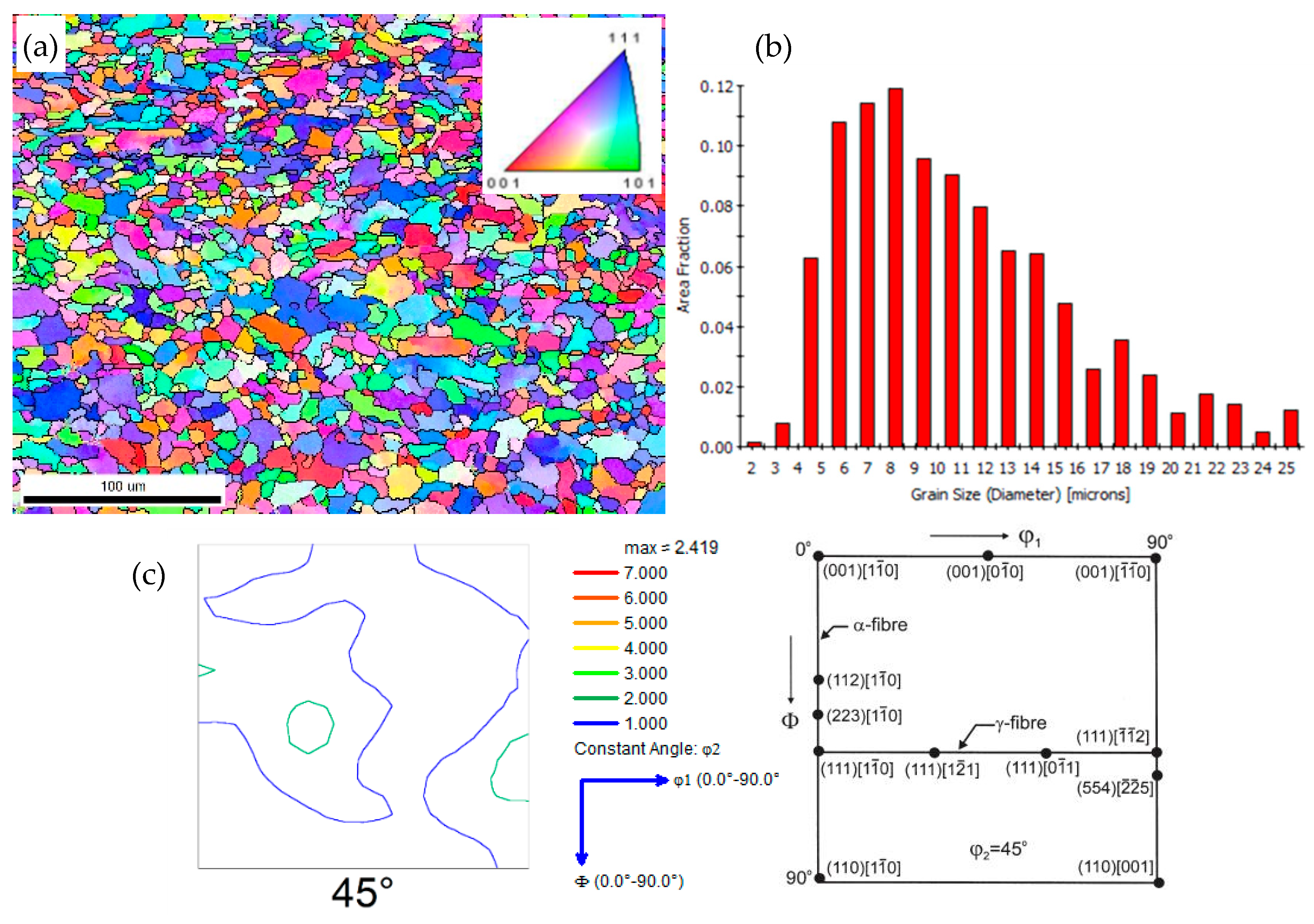

3.1. Microstructural Observation

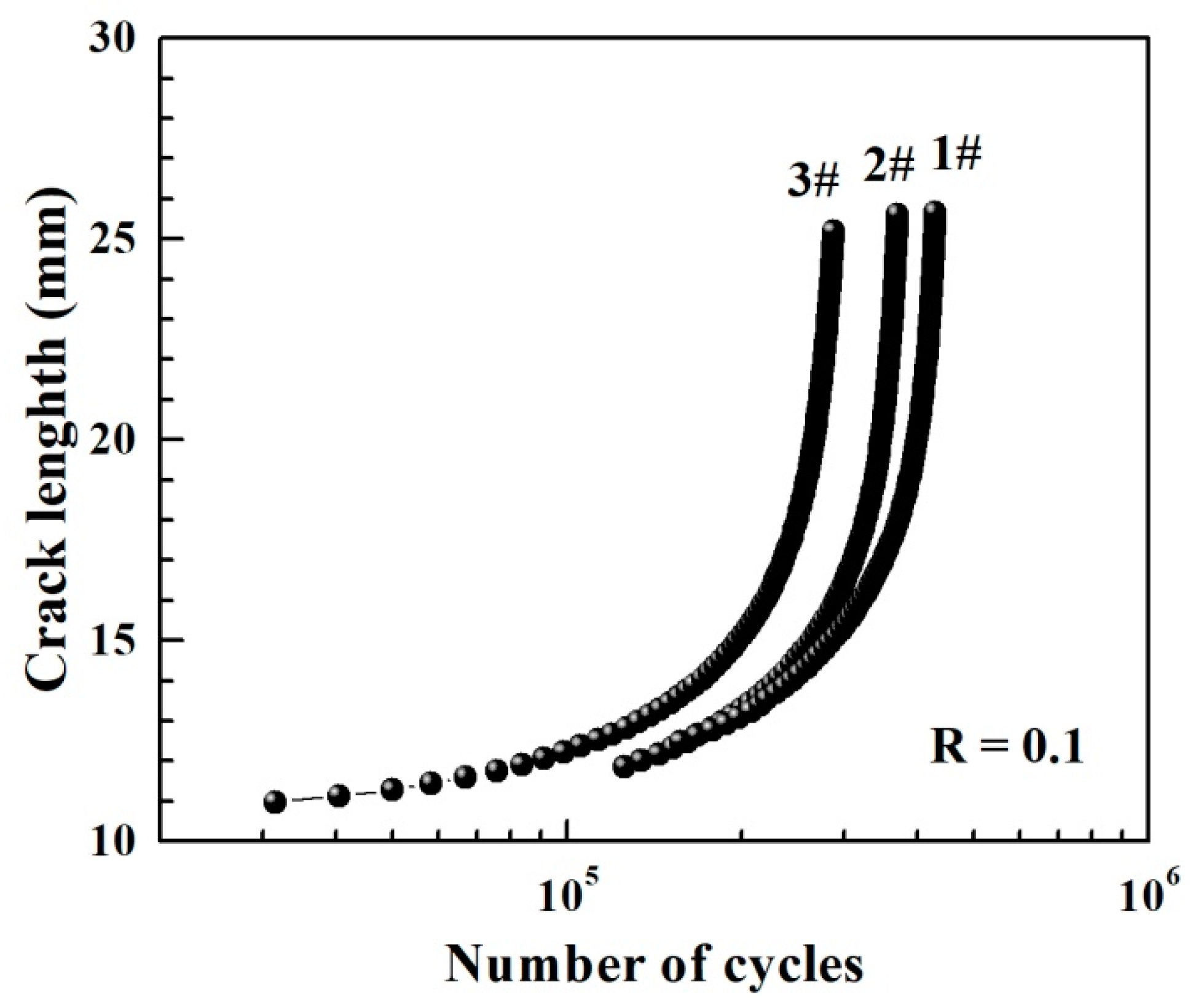

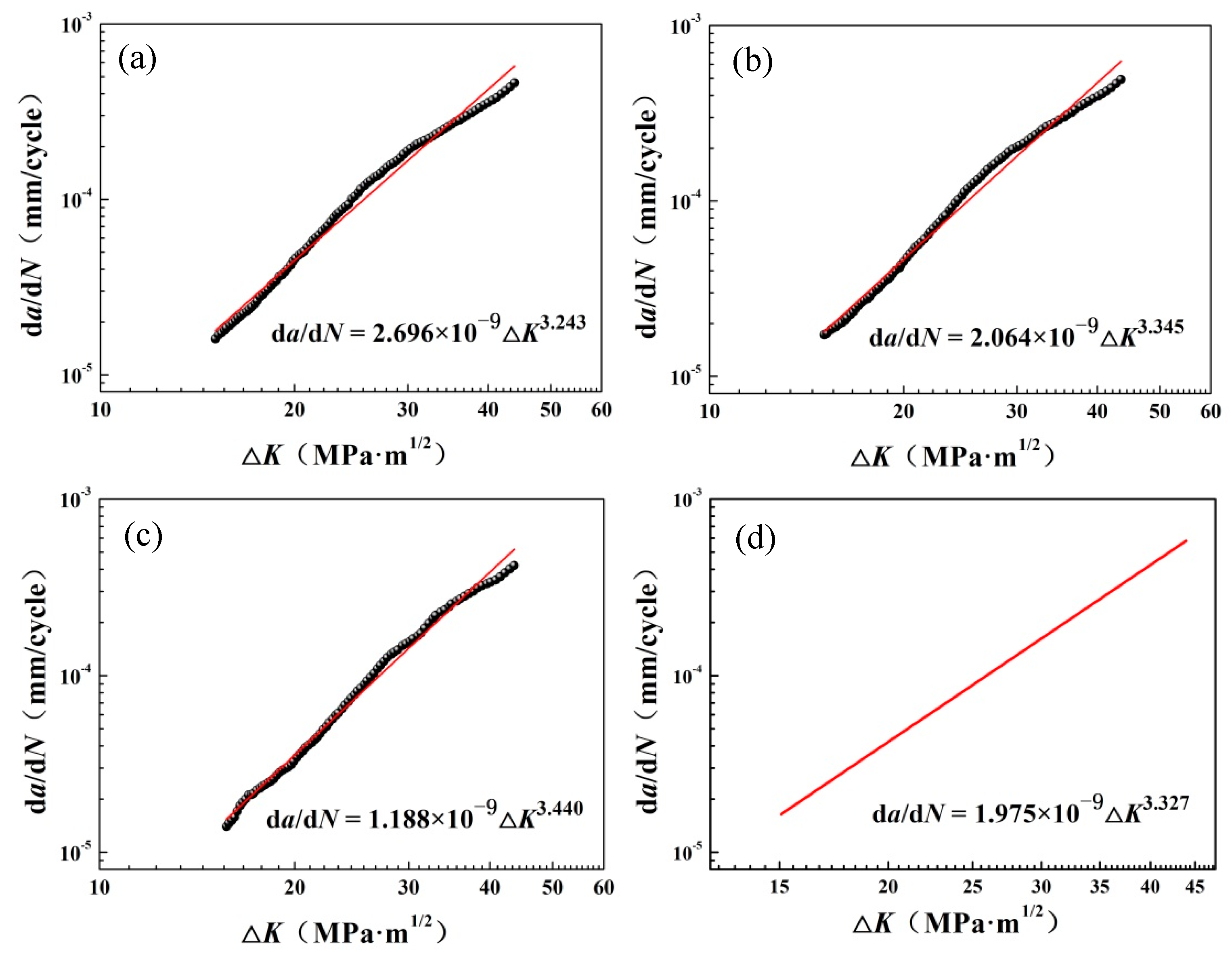

3.2. Fatigue Properties and Fracture Toughness

3.3. Morphological Features of Fracture Surface

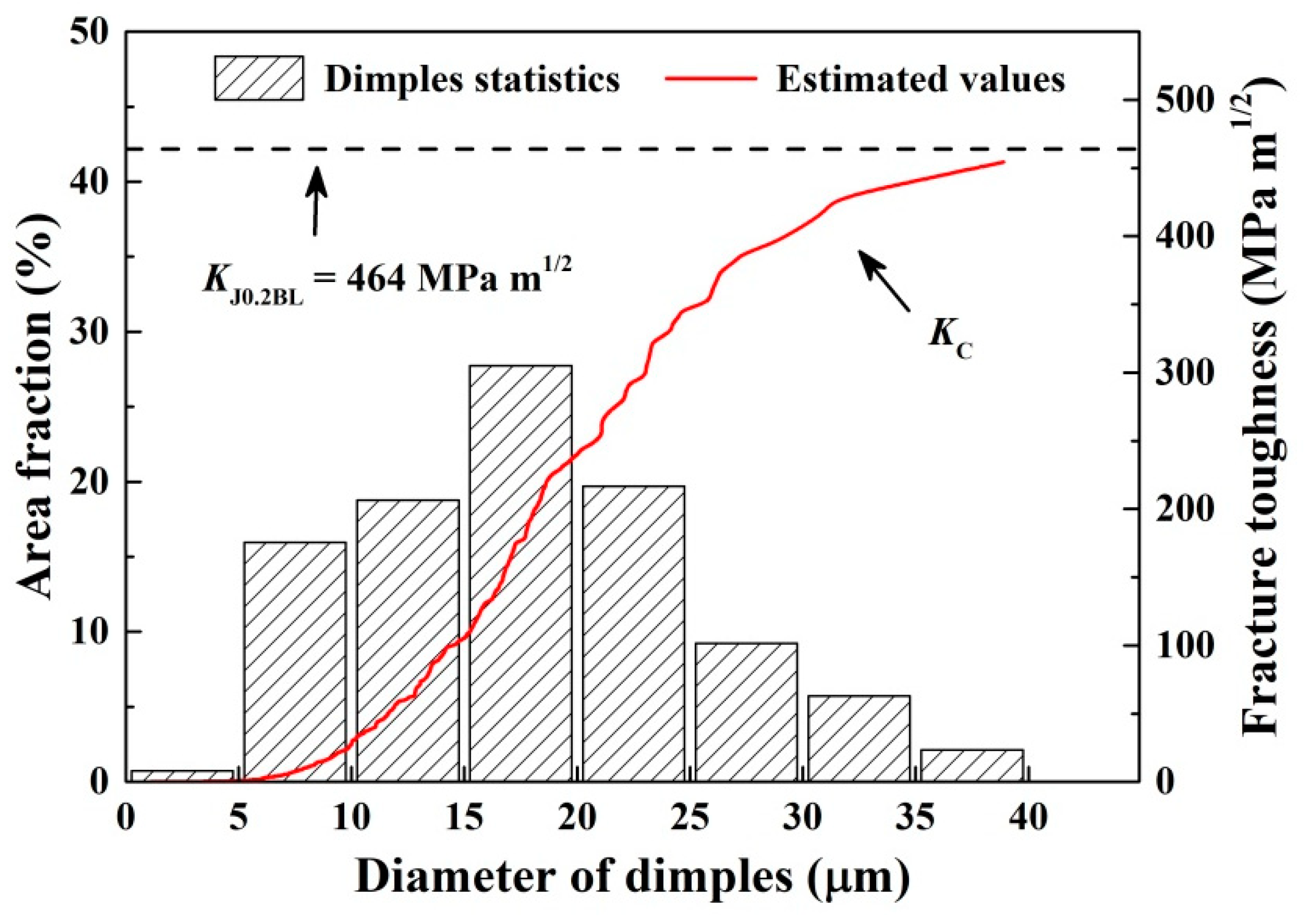

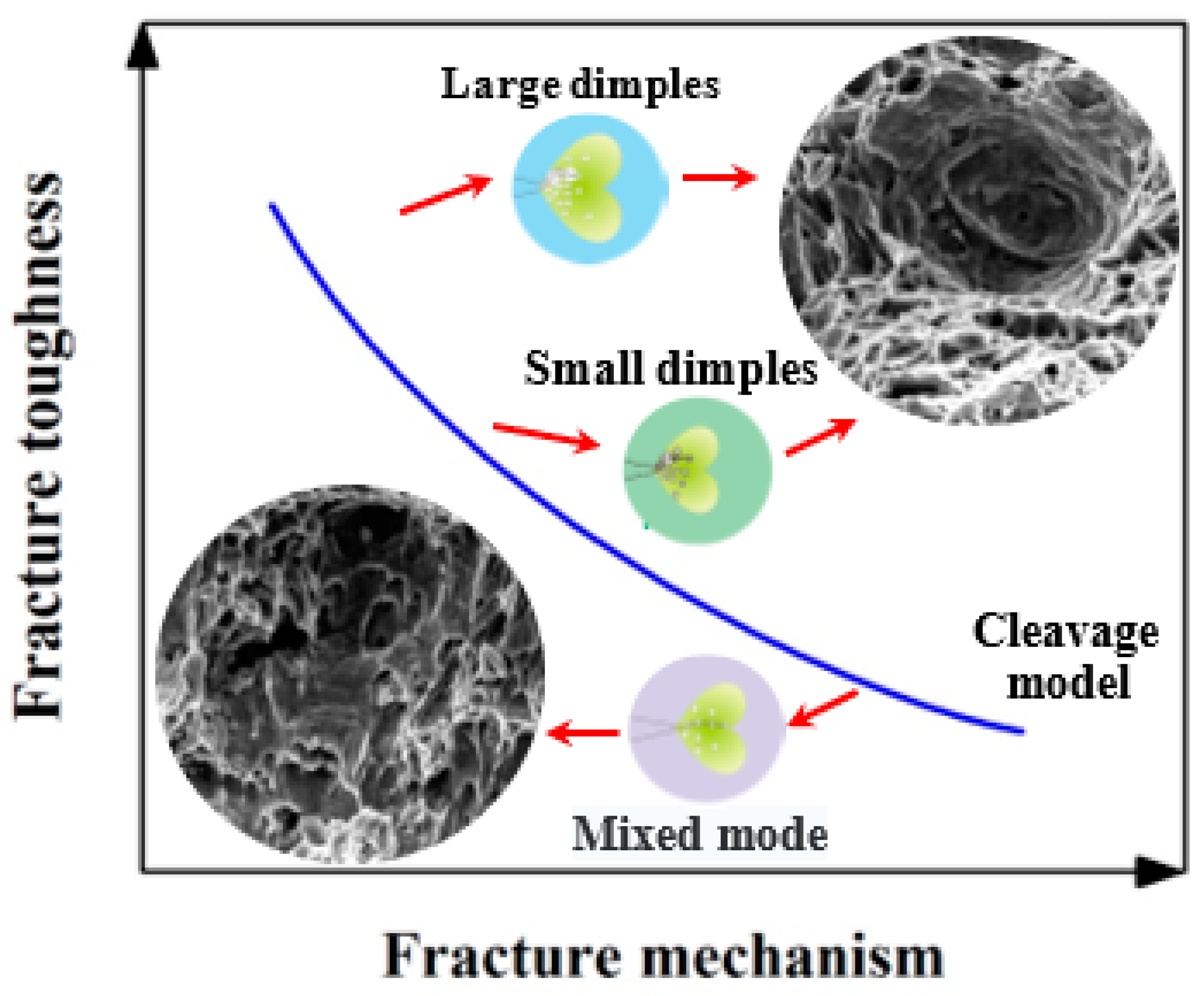

3.4. Analysis of Fracture Morphology and Fracture Toughness

4. Conclusions

- (1)

- The microstructure of EH36 steel was composed of fine ferrite and pearlite, with an average grain size of about 7.3 μm. The Paris formula was obtained by means of linear fitting, and the corresponding average values of C and m were equal to 1.975 × 10−9 and 3.327, respectively. The fracture toughness of the EH36 steel was also calculated using the J-integral method, and the value of KJ0.2BL was 464 MPa·m1/2.

- (2)

- The fatigue fracture surfaces of the EH36 steel exhibited typical transcrystalline fracture characteristics, accompanied by fatigue striations, secondary cracks and tearing ridges. There were many dimples with different sizes in the static loading process zone of the fracture toughness tests, which indicated that EH36 steel has good toughness and presents the characteristics of ductile fracture under static loading conditions.

- (3)

- Based on the energy consumption analysis of the fracture morphology, the relationship between the micro-fracture surface morphology and the fracture toughness of EH36 steel was established, and the fracture toughness obtained was close to that calculated using the J-integral method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbols | Description | Unit |

| Rp0.2 | Yield strength | MPa |

| Rm | Ultimate tensile strength | MPa |

| E | Elastic modulus | GPa |

| ν | Poisson’s ratio | |

| B | Thickness of specimen | mm |

| W | Width of specimen | mm |

| L | Length of specimen | mm |

| N | Number of cycles | |

| a | Length of propagation crack | mm |

| Δa | Crack propagation quantity | mm |

| K | Stress intensity factor | MPa·m1/2 |

| ΔK | Stress intensity factor range | MPa·m1/2 |

| Kmax | Maximum stress intensity factor | MPa·m1/2 |

| KIC | Plane strain fracture toughness | MPa·m1/2 |

| KJ0.2BL | Value of fracture toughness calculated by the J-integral method | MPa·m1/2 |

| KC | Value of fracture toughness calculated by dimple size | MPa·m1/2 |

| J | The experimental equivalent of the J integral | kJ/m2 |

| J0.2BL | Intersection point of the J-Δa resistance curve and the 0.2 mm passivation line | kJ/m2 |

| h | Height of dimple | µm |

| hl | Height of large dimple | µm |

| hs | Height of small dimple | µm |

| d | Diameter of dimple | µm |

| dl | Diameter of large dimple | µm |

| ds | Diameter of small dimple | µm |

| S | Area fraction of dimple | |

| Sl | Area fraction of large dimple | |

| Ss | Area fraction of small dimple |

References

- Wu, B.B.; Huang, S.; Wang, Z.Q.; Zhao, J.X.; Wang, C.S.; Shang, C.J.; Misra, R.D.K. Crystallography analysis of toughness in high strength ultra-heavy plate steel. Mater. Lett. 2019, 250, 55–59. [Google Scholar] [CrossRef]

- Zou, X.; Sun, J.; Matsuura, H.; Wang, C. Profiling microstructure evolution roadmap in heat-affected zones of EH36 shipbuilding steel under controlled thermal simulation. Metall. Mater. Trans. A 2020, 51, 3392–3397. [Google Scholar] [CrossRef]

- Shao, C.W.; Zhang, P.; Zhang, Z.J.; Liu, R.; Zhang, Z.F. Forecasting low-cycle fatigue performance of twinning-induced plasticity steels: Difficulty and attempt. Metall. Mater. Trans. A 2017, 48, 5833–5848. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, M.; Tan, X.; Liu, T.; Bi, G.; Li, H.; Tor, S.B.; Liu, E. Fatigue behavior of ASTM A131 EH36 steel samples additively manufactured with selective laser melting. Mater. Sci. Eng. A 2020, 777, 139049. [Google Scholar] [CrossRef]

- Wang, X.L.; Wang, Z.Q.; Ma, X.P.; Subramanian, S.V.; Xie, Z.J.; Shang, C.J.; Li, X.C. Analysis of impact toughness scatter in simulated coarse-grained HAZ of E550 grade offshore engineering steel from the aspect of crystallographic structure. Mater. Charact. 2018, 140, 312–319. [Google Scholar] [CrossRef]

- Li, H.F.; Duan, Q.Q.; Zhang, P.; Qu, R.T.; Zhang, Z.F. A new method to estimate the plane strain fracture toughness of materials. Fatigue Fract. Eng. Mater. 2019, 42, 415–424. [Google Scholar] [CrossRef]

- Ning, A.; Wang, S.; Luo, Y.; Liu, Y. Characterization of precipitated phases and carbides’ coarsening in DH36 shipbuilding steel during tempering process. Mater. Trans. 2019, 60, 429–436. [Google Scholar] [CrossRef]

- Jorge, J.C.F.; Bott, I.S.; Souza, L.F.G.; Mendes, M.C.; Araújo, L.S.; Evans, G.M. Mechanical and microstructural behavior of C-Mn steel weld deposits with varying titanium contents. J. Mater. Res. Technol. 2019, 8, 4659–4671. [Google Scholar] [CrossRef]

- Bejinariu, C.; Burduhos-Nergis, D.P.; Cimpoesu, N. Immersion behavior of carbon steel, phosphate carbon steel and phosphate and painted carbon steel in saltwater. Materials 2021, 14, 188. [Google Scholar] [CrossRef]

- Bosch, J.; Martin, U.; Aperador, W.; Bastidas, J.M.; Ress, J.; Bastidas, D.M. Corrosion behavior of high-Mn austenitic Fe-Mn-Al-Cr-C steels in NaCl and NaOH solutions. Materials 2021, 14, 425. [Google Scholar] [CrossRef]

- Sarkar, P.P.; De, P.S.; Dhua, S.K.; Chakraborti, P.C. Strain energy based low cycle fatigue damage analysis in a plain C-Mn rail steel. Mater. Sci. Eng. A 2017, 707, 125–135. [Google Scholar] [CrossRef]

- Li, C.; Cai, N.; Liu, C.; Qi, Q.; Qiu, Y. Optical in-situ analysis method for fatigue cracks and its application in fatigue initiation and growth study on steels with different microstructures. Mater. Res. Express 2019, 6, 1265b6. [Google Scholar]

- Toumpis, A.; Galloway, A.; Molter, L.; Polezhayeva, H. Systematic investigation of the fatigue performance of a friction stir welded low alloy steel. Mater. Des. 2015, 80, 116–128. [Google Scholar] [CrossRef] [Green Version]

- Barbosa, L.H.S.; Modenesi, P.J.; Godefroid, L.B.; Arias, A.R. Fatigue crack growth rates on the weld metal of high heat input submerged arc welding. Int. J. Fatigue 2019, 119, 43–51. [Google Scholar] [CrossRef]

- Aeran, A.; Acosta, R.; Siriwardane, S.C.; Starke, P.; Mikkelsen, O.; Langen, I.; Walther, F. A nonlinear fatigue damage model: Comparison with experimental damage evolution of S355 (SAE 1020) structural steel and application to offshore jacket structures. Int. J. Fatigue 2020, 135, 105568. [Google Scholar] [CrossRef]

- Shikimoto, K.; Ishida, S.; Jinnouchi, W.; Ogawa, Y.; Akebono, H.; Sugeta, A. Effect of laser patterning preprocessing on fatigue strength of adhesive bonded joints using thin steel plate. Mater. Trans. 2019, 61, 469–474. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Liu, J.; Hu, J.; Garbatov, Y.; Guedes-Soares, C. Fatigue strength of EH36 steel welded joints and base material at low-temperature. Int. J. Fatigue 2021, 142, 105896. [Google Scholar] [CrossRef]

- Molaei, R.; Fatemi, A. Fatigue design with additive manufactured metals: Issues to consider and perspective for future research. Procedia Eng. 2018, 213, 5–16. [Google Scholar] [CrossRef]

- Paul, S.K. A critical review of experimental aspects in ratcheting fatigue: Microstructure to specimen to component. J. Mater. Res. Technol. 2019, 8, 4894–4914. [Google Scholar] [CrossRef]

- Yong, L.; Liu, Z.Y.; Endian, F.; Cui, Z. The effect of crack tip environment on crack growth behaviour of a low alloy steel at cathodic potentials in artificial seawater. J. Mater. Sci. Technol. 2020, 54, 121–133. [Google Scholar]

- Wang, H.; Liu, X.; Ni, G.X.; Jiang, J. Research on corrosion fatigue crack growth of marine engineering equipment material E690 high-strength steel. Sci. Adv. Mater. 2019, 11, 862–865. [Google Scholar] [CrossRef]

- Wang, Y.; Baidoo, P.; Xu, Z.; Wu, J. Study on fatigue crack growth performance of EH36 weldments by laser shock processing. Surf Interfaces 2019, 15, 199–204. [Google Scholar]

- Gao, J.Y.; Liu, X.B.; Zhou, H.F.; Zhang, X.F. Modification of corrosion resistance of the plain carbon steels by pulsed electric current. Acta Metall. Sin. (Engl. Lett.) 2018, 31, 5–11. [Google Scholar] [CrossRef] [Green Version]

- Sharma, T.; Bonagani, S.K.; Kumar, N.N.; Samajdar, I.; Kain, V. Detection of intergranular embrittlement of reactor pressure vessel steel by electrochemical method. Mater. Sci. Eng. A 2018, 725, 88–97. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, J.; Hu, C.; Luo, Z.; Zhang, Y.; Song, C.; Zhai, Q. Structures and properties of Fe-(8-16)Mn-9Al-0.8 C low density steel made by a centrifugal casting in near-rapid solidification. Mater. Sci. Eng. A 2019, 748, 74–84. [Google Scholar] [CrossRef]

- Ogawa, K.; Maeda, R.; Kobayashi, T.; Yokoi, E.; Furusawa, T.; Takada, K.; Omiya, M. Investigation on simplified equation for estimating J-integral of adhesive joint and its application to galvannealed steel plate. Mater. Trans. 2019, 60, 1928–1935. [Google Scholar] [CrossRef]

- Zhu, Z.; Han, J.; Li, H. Effect of alloy design on improving toughness for X70 steel during welding. Mater. Des. 2015, 88, 1326–1333. [Google Scholar] [CrossRef]

- Qi, X.; Du, L.; Dong, Y.; Misra, R.D.K.; Du, Y.; Wu, H.; Gao, X. Fracture toughness behavior of low-C medium-Mn high-strength steel with submicron- scale laminated microstructure of tempered martensite and reversed austenite. J. Mater. Sci. 2019, 54, 12095–12105. [Google Scholar] [CrossRef]

- Hohenwarter, A.; Pippan, R. A comprehensive study on the damage tolerance of ultrafine-grained copper. Mater. Sci. Eng. A 2012, 540, 89–96. [Google Scholar] [CrossRef]

- Fang, X.; Xue, H.; Yang, F. Anomalous mechanical behavior in stationary small crack tips about EAC for nickel-base alloy. Rare Metal Mat. Eng. 2016, 45, 321–325. [Google Scholar]

- Zhang, Z.; Hu, Z.; Schmauder, S.; Mlikota, M.; Fan, K. Low-cycle fatigue properties of P92 ferritic-martensitic steel at elevated temperature. J. Mater. Eng. Perform. 2016, 25, 1650–1662. [Google Scholar] [CrossRef]

- Liu, T.L.; Chen, L.J.; Bi, H.Y.; Che, X. High-temperature fatigue behavior of 15CrNbTi ferritic stainless steel. J. Iron Steel Res. Int. 2019, 26, 285–291. [Google Scholar] [CrossRef]

- Guo, C.; Hao, L.; Li, S.; Kang, Y.; An, Y. Effect of microstructure quenched around Ac3 point on the damage behavior in 0.087C-1.35Mn steel. J. Mater. Res. Technol. 2019, 8, 5103–5113. [Google Scholar] [CrossRef]

- Chen, J.; Pan, Q.L.; Yu, X.H.; Li, M.J.; Zou, H.; Xiang, H.; Huang, Z.Q.; Hu, Q. Effect of annealing treatment on microstructure and fatigue crack growth behavior of Al-Zn-Mg-Sc-Zr alloy. J. Cent. South Univ. 2018, 25, 961–975. [Google Scholar] [CrossRef]

- Qu, R.T.; Wang, S.G.; Wang, X.D.; Liu, Z.Q.; Zhang, Z.F. Revealing the shear band cracking mechanism in metallic glass by X-ray tomography. Scripta Mater. 2017, 133, 24–28. [Google Scholar] [CrossRef]

- Zhang, P.; Qu, S.; Yang, M.X.; Yang, G.; Wu, S.D.; Li, S.X.; Zhang, Z.F. Varying tensile fracture mechanisms of Cu and Cu-Zn alloys with reduced grain size: From necking to shearing instability. Mater. Sci. Eng. A 2014, 594, 309–320. [Google Scholar] [CrossRef]

- Lubarda, V.A.; Schneider, M.S.; Kalantar, D.H.; Remington, B.A.; Meyers, M.A. Void growth by dislocation emission. Acta Mater. 2004, 52, 1397–1408. [Google Scholar] [CrossRef]

- Li, H.F.; Wang, S.G.; Zhang, P.; Qu, R.T.; Zhang, Z.F. Crack propagation mechanisms of AISI 4340 steels with different strength and toughness. Mater. Sci. Eng. A 2018, 729, 130–140. [Google Scholar] [CrossRef]

- Qin, E.W.; Lu, L.; Tao, N.R.; Tan, J.; Lu, K. Enhanced fracture toughness and strength in bulk nanocrystalline Cu with nanoscale twin bundles. Acta Mater. 2009, 57, 6215–6225. [Google Scholar] [CrossRef]

- Frómeta, D.; Parareda, S.; Lara, A.; Molas, S.; Casellas, D.; Jonsén, P.; Calvo, J. Identification of fracture toughness parameters to understand the fracture resistance of advanced high strength sheet steels. Eng. Frac. Mech. 2020, 229, 106949. [Google Scholar] [CrossRef]

| C | Si | Mn | Ni | V | Nb | Ti | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0.10 | 0.15 | 1.55 | 0.25 | 0.05 | 0.04 | 0.012 | 0.002 | 0.003 | Bal. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Q.; Zhang, P.; Peng, X.; Yan, L.; Li, G. Fatigue Crack Growth Behavior and Fracture Toughness of EH36 TMCP Steel. Materials 2021, 14, 6621. https://doi.org/10.3390/ma14216621

Zhu Q, Zhang P, Peng X, Yan L, Li G. Fatigue Crack Growth Behavior and Fracture Toughness of EH36 TMCP Steel. Materials. 2021; 14(21):6621. https://doi.org/10.3390/ma14216621

Chicago/Turabian StyleZhu, Qingyan, Peng Zhang, Xingdong Peng, Ling Yan, and Guanglong Li. 2021. "Fatigue Crack Growth Behavior and Fracture Toughness of EH36 TMCP Steel" Materials 14, no. 21: 6621. https://doi.org/10.3390/ma14216621

APA StyleZhu, Q., Zhang, P., Peng, X., Yan, L., & Li, G. (2021). Fatigue Crack Growth Behavior and Fracture Toughness of EH36 TMCP Steel. Materials, 14(21), 6621. https://doi.org/10.3390/ma14216621