Lightweight Structural Materials in Open Access: Latest Trends

Abstract

:1. Introduction

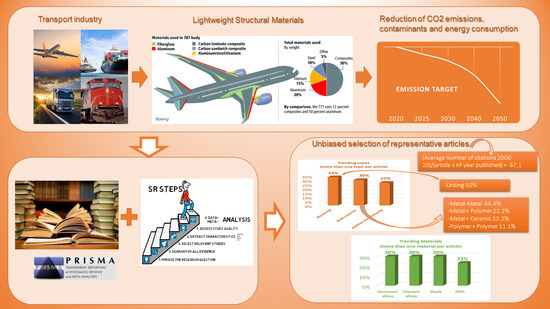

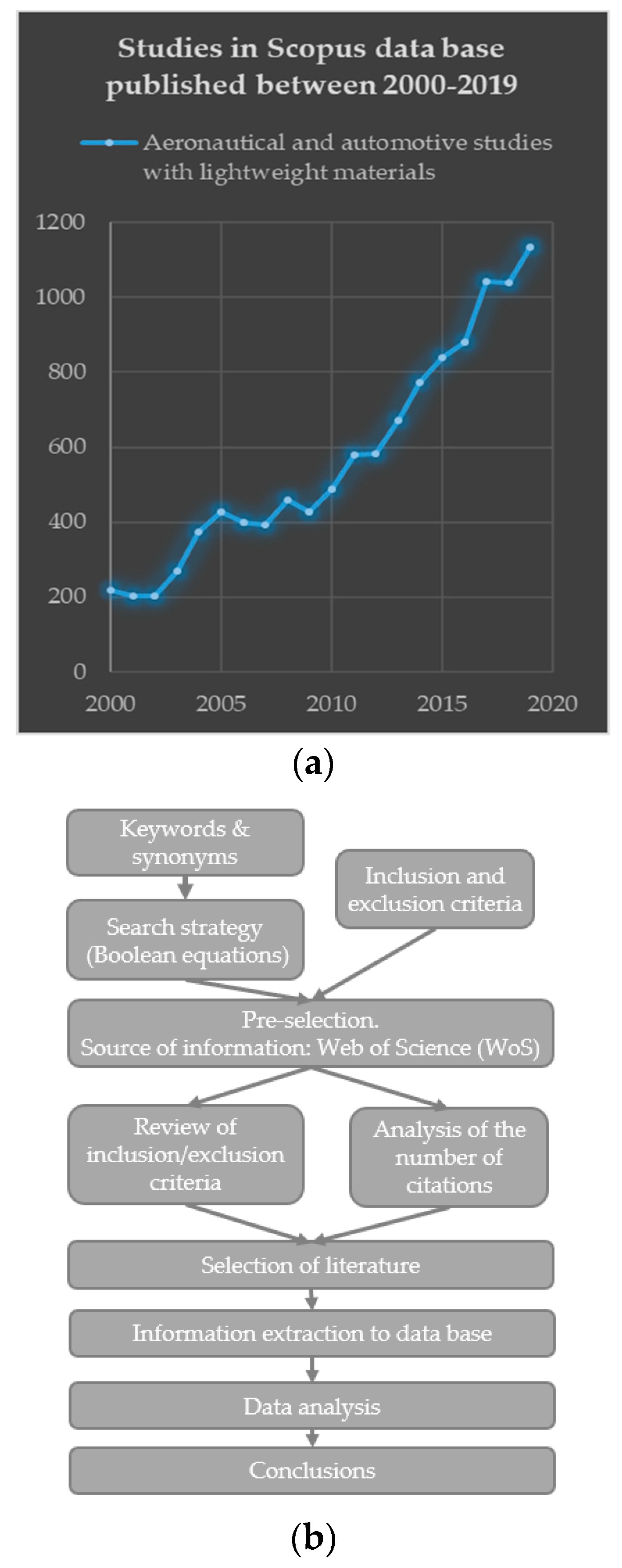

2. Methodology: Trend Analysis in Structural Lightweight Materials

2.1. Methodology for Article Selection and Analysis

automotive *) AND (drilling OR turning OR cutting OR machinability OR machining) AND (hybrid compo * OR

hybrid material * OR hybrid structure * OR multi-material * OR multimaterial * OR lightweight * OR light-weight *

OR light allo * OR light material * OR structural material *) NOT (nano *) AND (magnesium OR aluminum OR

titanium OR steel OR FRP OR GFRP OR CFRP OR Metal OR Polymer OR Ceramic OR Polymer OR textile)).

TS * searches for topic terms in the fields title, abstract, and author keywords within a record.

2.2. Origin of Research

3. Trend Analysis in Structural Lightweight Materials

3.1. Materials

3.1.1. Aluminum Alloys

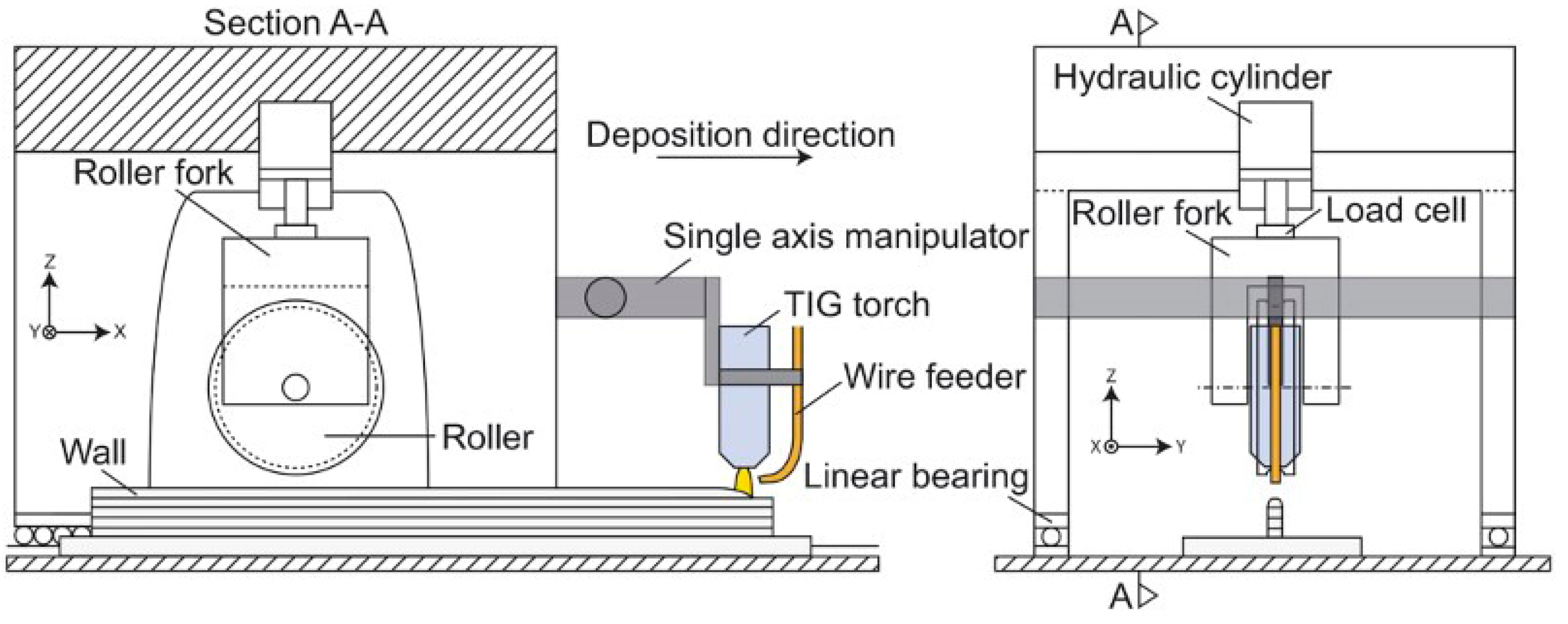

3.1.2. Titanium Alloys

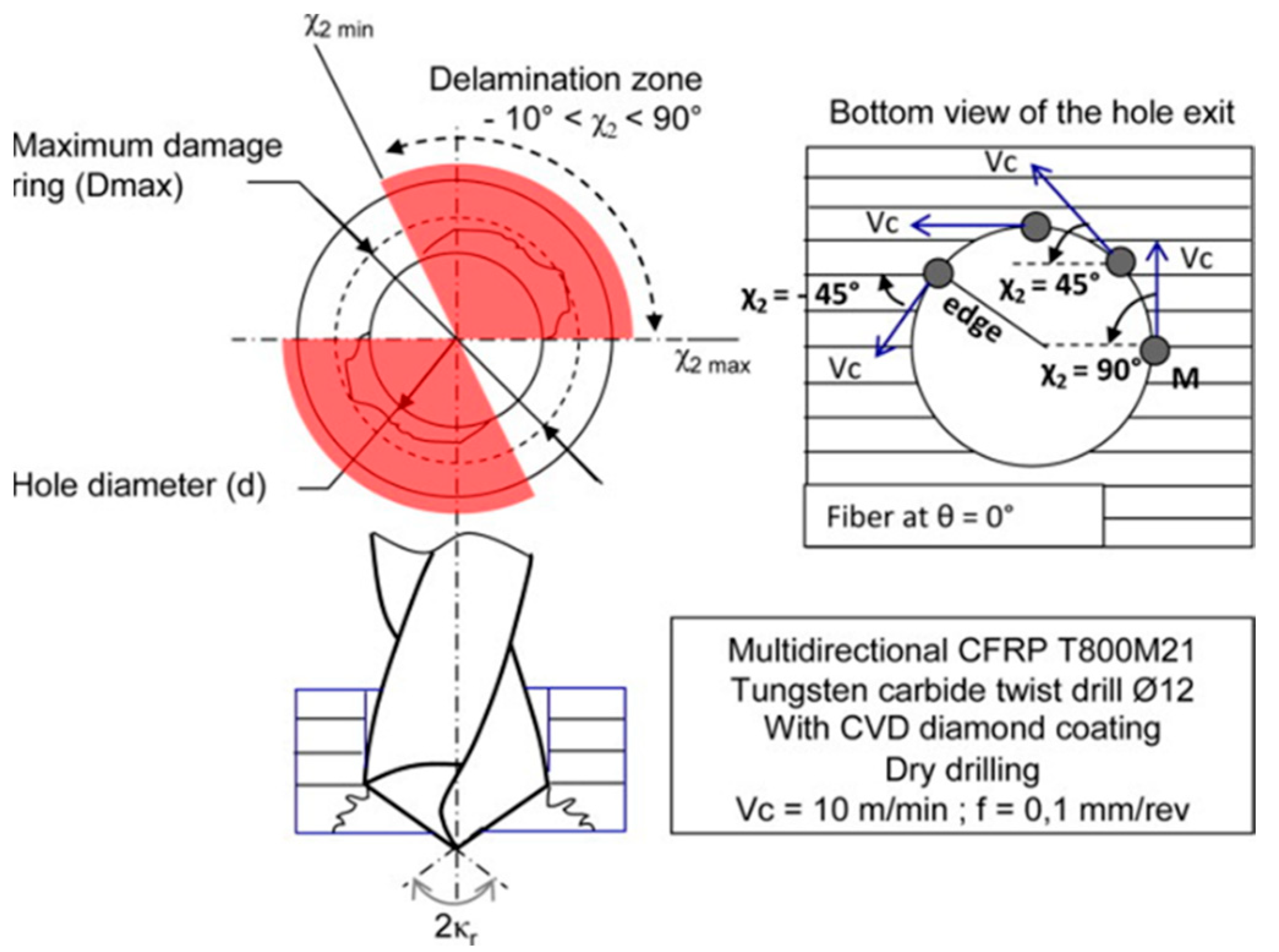

3.1.3. Fiber Reinforced Polymers

3.1.4. Special Alloys

3.1.5. Magnesium

3.2. Topics of Interest

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Intergovernmental Panel on Climate Change (IPCC): Summary for Policymakers. Available online: https://www.ipcc.ch/site/assets/uploads/sites/2/2019/05/SR15_SPM_version_report_LR.pdf (accessed on 19 March 2021).

- Advisory Council for Aeronautics Research in Europe (ACARE). Available online: https://www.acare4europe.org/sria/flightpath-2050-goals/protecting-environment-and-energy-supply-0 (accessed on 19 March 2021).

- Airbus Environment. Available online: https://www.airbus.com/content/dam/corporate-topics/corporate-social-responsibility/environment/Environment-matters-for-the-future-of-aerospace.pdf (accessed on 19 March 2021).

- Boeing. Boeing Environment Report. 2020. Available online: http://www.boeing.com/resources/boeingdotcom/principles/environment/pdf/er-companion-summary-092820.pdf (accessed on 19 March 2021).

- ICAO. Effects of COVID-19 on Civil Aviation: Economic Impact. Analysis. Available online: https://www.icao.int/sustainability/Documents/COVID-19/ICAO_Coronavirus_Econ_Impact.pdf (accessed on 19 March 2021).

- ICAO. Economic Impacts of COVID-19 on Civil Aviation. Available online: https://www.icao.int/sustainability/Pages/Economic-Impacts-of-COVID-19.aspx (accessed on 25 May 2021).

- International Council on Clean Transportation (ICCT). Available online: https://theicct.org/clean-air (accessed on 25 October 2021).

- Energy Efficiency Design Index (EEDI) from International Council on Clean Transportation (ICCT). Available online: https://theicct.org/sites/default/files/publications/ICCTpolicyupdate15_EEDI_final.pdf (accessed on 19 March 2021).

- Wong, V.W.; Tung, S.C. Overview of automotive engine friction and reduction trends-Effects of surface, material, and lubricant-additive technologies. Friction 2016, 4, 1–28. [Google Scholar] [CrossRef] [Green Version]

- Mavhungu, S.T.; Akinlabi, E.T.; Onitiri, M.A.; Varachia, F.M. Aluminum Matrix Composites for Industrial Use: Advances and Trends. In Proceedings of the International Conference On Sustainable Materials Processing and Manufacturing (SMPM), Kruger, South Africa, 23–25 January 2017; Volume 7, pp. 178–182. [Google Scholar]

- Nassirnia, M.; Heidarpour, A.; Zhao, X.L.; Minkkinen, J. Innovative hollow columns comprising corrugated plates and ultra high-strength steel tubes. Thin-Walled Struct. 2016, 101, 6–8. [Google Scholar] [CrossRef]

- Gullino, A.; Matteis, P.; D’Aiuto, F. Review of Aluminum-To-Steel Welding Technologies for Car-Body Applications. Metals 2019, 9, 315. [Google Scholar] [CrossRef] [Green Version]

- Talla, G.; Sahoo, D.K.; Gangopadhyay, S.; Biswas, C.K. Modeling and multi-objective optimization of powder mixed electric discharge machining process of aluminum/alumina metal matrix composite. Eng. Sci. Technol. Int. J. JESTECH 2015, 18, 369–373. [Google Scholar] [CrossRef] [Green Version]

- Prime, M.B.; Newborn, M.A.; Balog, J.A. Quenching and cold-work residual stresses in aluminum hand forgings: Contour method measurement and FEM prediction. Mater. Sci. Forum 2003, 426–432, 435–440. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.Y.; Liu, F.; Yang, N.; Zhai, X.B.; Zhang, L.; Yang, Y.; Li, B.; Li, J.; Ma, E.; Nie, J.F.; et al. Large plasticity in magnesium mediated by pyramidal dislocations. Science (80) 2019, 365, 73–75. [Google Scholar] [CrossRef]

- Xu, J.; Mkaddem, A.; El Mansori, M. Recent advances in drilling hybrid FRP/Ti composite: A state-of-the-art review. Compos. Struct. 2016, 135, 316–338. [Google Scholar] [CrossRef] [Green Version]

- Salama, A.; Li, L.; Mativenga, P.; Whitehead, D. TEA CO2 laser machining of CFRP composite. Appl. Phys. A Mater. Sci. Process. 2016, 122, 497. [Google Scholar] [CrossRef] [Green Version]

- Airbus Sustainability. Decarbonisation. Available online: https://www.airbus.com/company/sustainability/environment/climate-change/decarbonisation.html (accessed on 12 May 2021).

- Suresh, S.; Moorthi, N.S.V. Aluminium- Titanium diboride (Al-TiB2) metal matrix composites: Challenges and opportunities. Procedia Eng. 2012, 38, 89–97. [Google Scholar] [CrossRef] [Green Version]

- Pecat, O.; Rentsch, R.; Brinksmeier, E. Influence of milling process parameters on the surface integrity of CFRP. Procedia CIRP 2012, 1, 466–470. [Google Scholar] [CrossRef] [Green Version]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire plus Arc Additive Manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; El Mansori, M. Wear characteristics of polycrystalline diamond tools in orthogonal cutting of CFRP/Ti stacks. Wear 2017, 376, 91–106. [Google Scholar] [CrossRef] [Green Version]

- Sun, Y.; Huang, B.; Puleo, D.A.; Jawahir, I.S. Enhanced Machinability of Ti-5553 Alloy from Cryogenic Machining: Comparison with MQL and Flood-cooled Machining and Modeling. Procedia CIRP 2015, 31, 477–482. [Google Scholar] [CrossRef] [Green Version]

- Blanco, D.; Rubio, E.M.; de Pipaón, J.M.S.; Marín, M.M. Thicknesses/roughness relationship in mg-al-mg and mg-ti-mg hybrid component plates for drilled aeronautical lightweight parts. Appl. Sci. 2020, 10, 8208. [Google Scholar] [CrossRef]

- Kim, Y.-W.; Kim, S.-L. Advances in Gammalloy Materials-Processes-Application Technology: Successes, Dilemmas, and Future. JOM 2018, 70, 553–560. [Google Scholar] [CrossRef] [Green Version]

- Elahinia, M.; Moghaddam, N.S.; Andani, M.T.; Amerinatanzi, A.; Bimber, B.A.; Hamilton, R.F. Fabrication of NiTi through additive manufacturing: A review. Prog. Mater. Sci. 2016, 83, 630–663. [Google Scholar] [CrossRef] [Green Version]

- Tian, Y.; Robson, J.D.; Riekehr, S.; Kashaev, N.; Wang, L.; Lowe, T.; Karanika, A. Process Optimization of Dual-Laser Beam Welding of Advanced Al-Li Alloys Through Hot Cracking Susceptibility Modeling. Phys. Metall. Mater. Sci. 2016, 47A, 3533–3544. [Google Scholar] [CrossRef]

- Ezugwu, E.O. High speed machining of aero-engine alloys. J. Brazilian Soc. Mech. Sci. Eng. 2004, 26, 1–11. [Google Scholar] [CrossRef] [Green Version]

- SenthilKumar, M.; Prabukarthi, A.; Krishnaraj, V. Study on Tool Wear and Chip Formation During Drilling Carbon Fiber Reinforced Polymer (CFRP)/Titanium Alloy (Ti6Al4V) Stacks. Procedia Eng. 2013, 64, 582–592. [Google Scholar] [CrossRef] [Green Version]

- Tabernero, I.; Paskual, A.; Alvarez, P.; Suarez, A. Study on Arc Welding processes for High Deposition Rate Additive Manufacturing. In Proceedings of the 19th CIRP Conference On Electro Physical and Chemical Machining, Bilbao, Spain, 23–27 April 2017; Elsevier Procedia: Amsterdam, The Netherlands, 2018; Volume 68, pp. 358–362. [Google Scholar]

- Lockett, H.; Ding, J.; Williams, S.; Martina, F. Design for Wire plus Arc Additive Manufacture: Design rules and build orientation selection. J. Eng. Des. 2017, 28, 568–598. [Google Scholar] [CrossRef] [Green Version]

- Uhlmann, E.; Kersting, R.; Klein, T.B.; Cruz, M.F.; Borille, A.V. Additive Manufacturing of Titanium Alloy for Aircraft Components. Procedia CIRP 2015, 35, 55–60. [Google Scholar] [CrossRef]

- Kalentics, N.; Boillat, E.; Peyre, P.; Gorny, C.; Kenel, C.; Leinenbach, C.; Jhabvala, J.; Loge, R.E. 3D Laser Shock Peening—A new method for the 3D control of residual stresses in Selective Laser Melting. Mater. Des. 2017, 130, 350–356. [Google Scholar] [CrossRef] [Green Version]

- Wycisk, E.; Siddique, S.; Herzog, D.; Walther, F.; Emmelmann, C. Fatigue performance of laser additive manufactured Ti–6Al–4V in very high cycle fatigue regime up to 10 9 cycles. Front. Mater. 2015, 2, 72. [Google Scholar] [CrossRef]

- Agius, D.; Kourousis, K.I.; Wallbrink, C. A Review of the As-Built SLM Ti-6Al-4V Mechanical Properties towards Achieving Fatigue Resistant Designs. Metals 2018, 8, 75. [Google Scholar] [CrossRef] [Green Version]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Altman, D.; Antes, G.; Atkins, D.; Barbour, V.; Barrowman, N.; Berlin, J.A.; et al. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Baraniuk, R.G.; Burrus, C.S.; Thierstein, E.J. IEEE-SPS and connexions—An open access education collaboration. IEEE Signal. Process. Mag. 2007, 24, 6–8. [Google Scholar] [CrossRef]

- Guédon, J.-C. Open Access: Toward the Internet of the Mind. Bp. Open Access Initiat. 2017, 23, 38. [Google Scholar]

- Inefuku, H.W. Globalization, Open Access, and the Democratization of Knowledge. Educ. Rev. 2017, 52, 62. [Google Scholar]

- Budapest Open Access Initiative. Available online: https://www.budapestopenaccessinitiative.org/ (accessed on 29 June 2021).

- Woolston, C. Impact factor abandoned by Dutch university in hiring and promotion decisions. Nature 2021, 595, 462. [Google Scholar] [CrossRef]

- Koler-Povh, T.; Južnič, P.; Turk, G. Impact of open access on citation of scholarly publications in the field of civil engineering. Scientometrics 2014, 98, 1033–1045. [Google Scholar] [CrossRef] [Green Version]

- Montgomery, S.L. English and Science: Realities and issues for translation in the age of an expanding lingua franca. J. Spec. Transl. 2009, 11, 6–16. [Google Scholar]

- Hamel, R.E. The dominance of English in the international scientific periodical literature and the future of language use in science. AILA Rev. 2007, 20, 53–71. [Google Scholar] [CrossRef]

- Shukla, A.K.; Janmaijaya, M.; Abraham, A.; Muhuri, P.K. Engineering applications of artificial intelligence: A bibliometric analysis of 30 years (1988–2018). Eng. Appl. Artif. Intell. 2019, 85, 517–532. [Google Scholar] [CrossRef]

- Cancino, C.; Merigó, J.M.; Coronado, F.; Dessouky, Y.; Dessouky, M. Forty years of Computers & Industrial Engineering: A bibliometric analysis. Comput. Ind. Eng. 2017, 113, 614–629. [Google Scholar] [CrossRef]

- Martín-Martín, A.; Orduna-Malea, E.; Thelwall, M.; Delgado López-Cózar, E. Google Scholar, Web of Science, and Scopus: A systematic comparison of citations in 252 subject categories. J. Informetr. 2018, 12, 1160–1177. [Google Scholar] [CrossRef] [Green Version]

- Li, K.; Rollins, J.; Yan, E. Web of Science use in published research and review papers 1997–2017: A selective, dynamic, cross-domain, content-based analysis. Scientometrics 2018, 115, 1–20. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Baldan, A. Adhesion phenomena in bonded joints. Int. J. Adhes. Adhes. 2012, 38, 95–116. [Google Scholar] [CrossRef]

- Budhe, S.; Banea, M.D.; de Barros, S.; da Silva, L.F.M. An updated review of adhesively bonded joints in composite materials. Int. J. Adhes. Adhes. 2017, 72, 30–42. [Google Scholar] [CrossRef]

- Banea, M.D.; Rosioara, M.; Carbas, R.J.C.; da Silva, L.F.M. Multi-material adhesive joints for automotive industry. Compos. Part B Eng. 2018, 151, 71–77. [Google Scholar] [CrossRef]

- Caminero, M.A.; Lopez-Pedrosa, M.; Pinna, C.; Soutis, C. Damage monitoring and analysis of composite laminates with an open hole and adhesively bonded repairs using digital image correlation. Compos. Part B Eng. 2013, 53, 76–91. [Google Scholar] [CrossRef]

- Saleema, N.; Sarkar, D.K.; Paynter, R.W.; Gallant, D.; Eskandarian, M. A simple surface treatment and characterization of AA 6061 aluminum alloy surface for adhesive bonding applications. Appl. Surf. Sci. 2012, 261, 742–748. [Google Scholar] [CrossRef] [Green Version]

- Caminero, M.A.; Pavlopoulou, S.; Lopez-Pedrosa, M.; Nicolaisson, B.G.; Pinna, C.; Soutis, C. Analysis of adhesively bonded repairs in composites: Damage detection and prognosis. Compos. Struct. 2013, 95, 500–517. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M.; Carbas, R.J.C.; de Barros, S. Debonding on command of multi-material adhesive joints. J. Adhes. 2017, 93, 756–770. [Google Scholar] [CrossRef]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.A.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA statement for reporting systematic reviews and meta-analyses of studies that evaluate health care interventions: Explanation and elaboration. PLoS Med. 2009, 6, e1–e34. [Google Scholar] [CrossRef] [PubMed]

- Scopus. Available online: https://service.elsevier.com/app/home/supporthub/scopus/ (accessed on 19 March 2021).

- Web of Science. Available online: https://clarivate.com/webofsciencegroup/solutions/web-of-science/ (accessed on 19 March 2021).

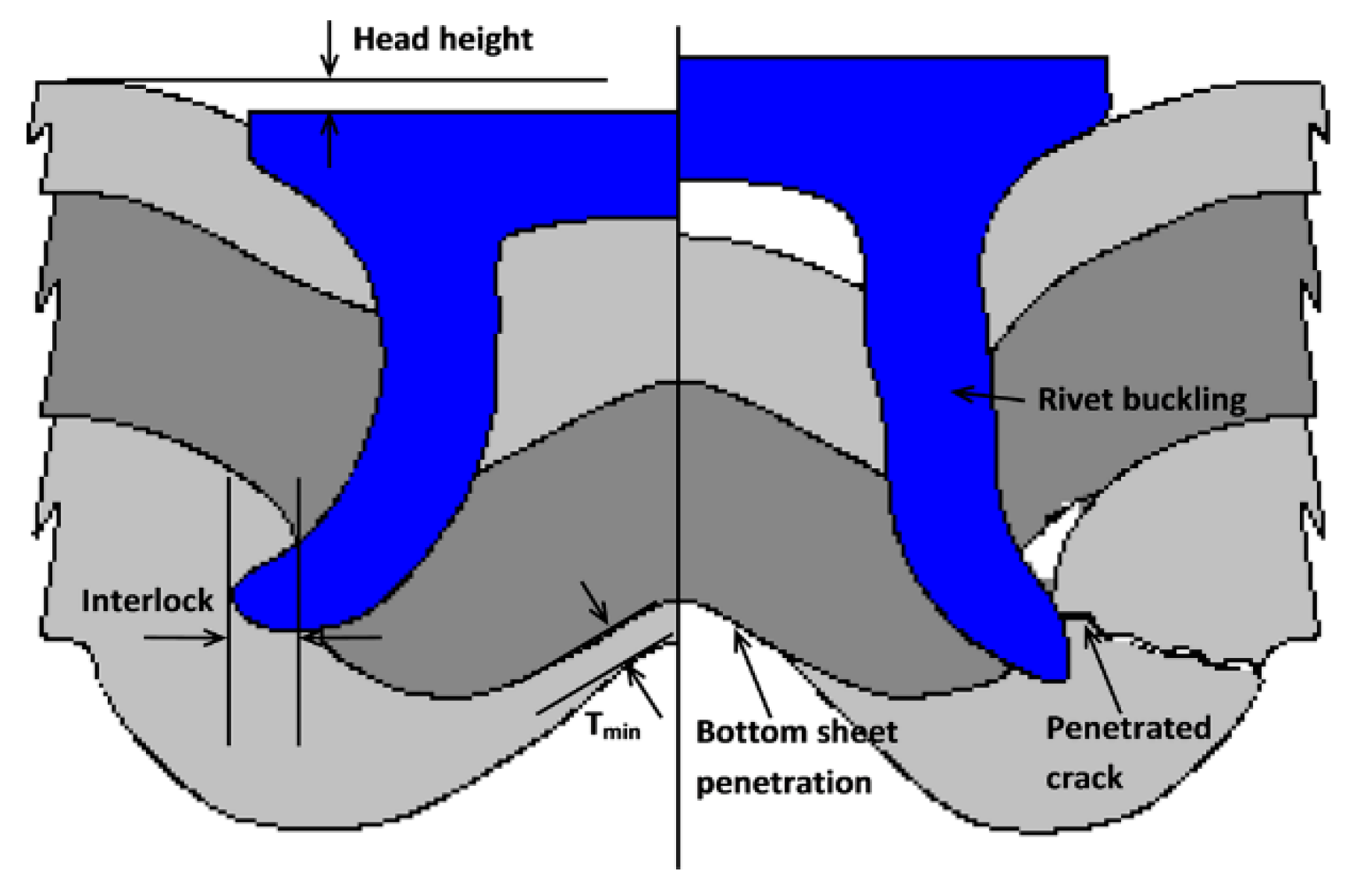

- Li, D.; Chrysanthou, A.; Patel, I.; Williams, G. Self-piercing riveting-a review. Int. J. Adv. Manuf. Technol. 2017, 92, 1777–1824. [Google Scholar] [CrossRef] [Green Version]

- Haghshenas, M.; Gerlich, A.P. Joining of automotive sheet materials by friction-based welding methods: A review. Eng. Sci. Technol. Int. J. Jestech 2018, 21, 130–148. [Google Scholar] [CrossRef]

- Chan, H.; Masserey, B.; Fromme, P. High frequency guided ultrasonic waves for hidden fatigue crack growth monitoring in multi-layer model aerospace structures. Smart Mater. Struct. 2015, 24, 025037. [Google Scholar] [CrossRef] [Green Version]

- Denkena, B.; Schmidt, C.; Weber, P. Automated Fiber Placement Head for Manufacturing of Innovative Aerospace Stiffening Structures. In Proceedings of the 16TH Machining Innovations Conference for Aerospace Industry—MIC, Garbsen, Germany, 23–24 November 2016; Volome 6, pp. 96–104. [Google Scholar]

- Li, X.; Zhao, W.; Li, L.; He, N.; Chi, S. Modeling and Application of Process Damping in Milling of Thin-Walled Workpiece Made of Titanium Alloy. Shock Vib. 2015, 2015, 431476. [Google Scholar] [CrossRef]

- Wei, W.; Di, Z.; Allen, D.M.; Almond, H.J.A. Non-traditional machining techniques for fabricating metal aerospace filters. Chin. J. Aeronaut. 2008, 21, 441–447. [Google Scholar] [CrossRef] [Green Version]

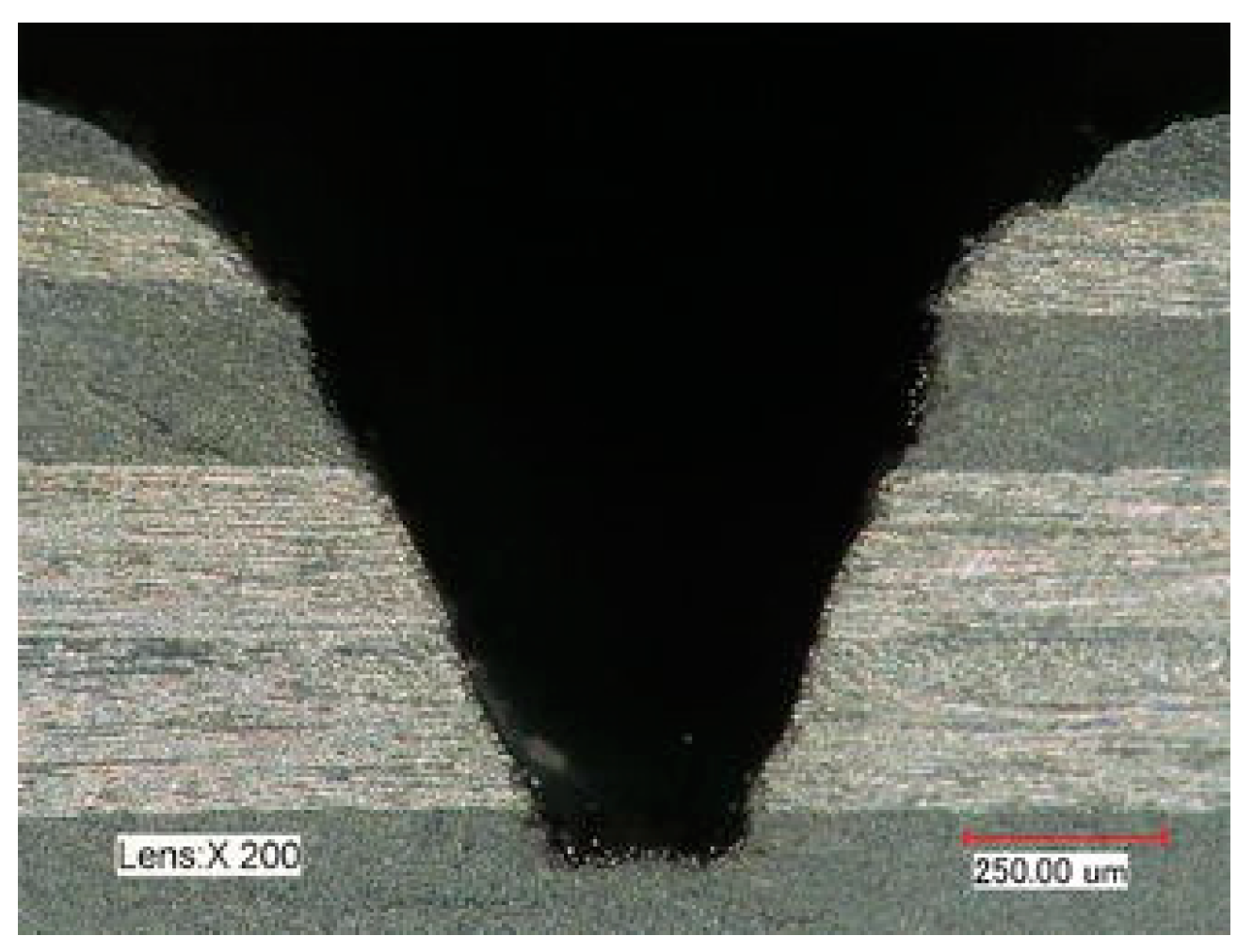

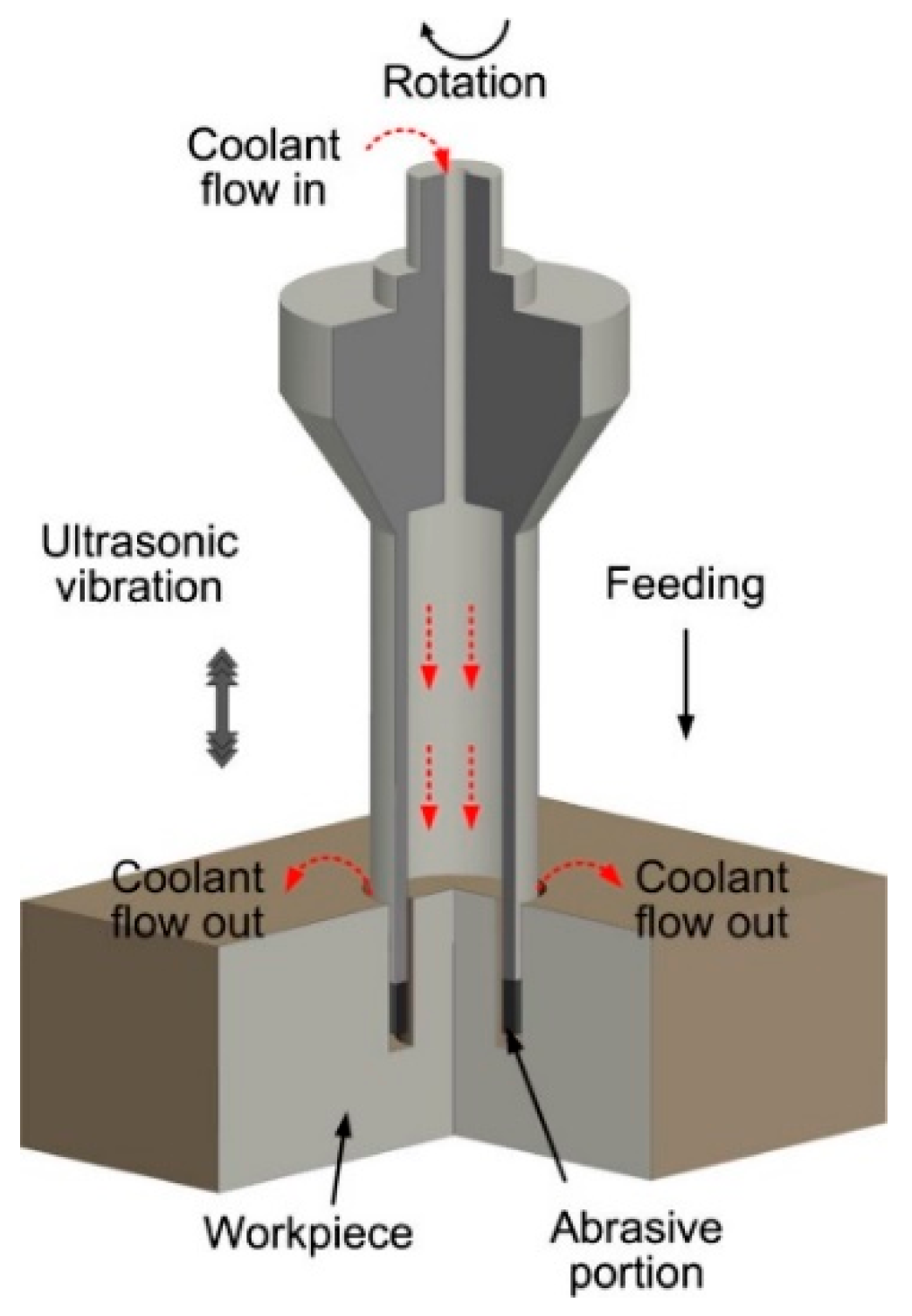

- Ning, F.D.; Cong, W.L.; Pei, Z.J.; Treadwell, C. Rotary ultrasonic machining of CFRP: A comparison with grinding. Ultrasonics 2016, 66, 125–132. [Google Scholar] [CrossRef] [Green Version]

- Composites: Airbus Continues to Shape the Future. Available online: https://www.airbus.com/newsroom/news/en/2017/08/composites--airbus-continues-to-shape-the-future.html (accessed on 19 March 2021).

- Bonnet, C.; Poulachon, G.; Rech, J.; Girard, Y.; Costes, J.P. CFRP drilling: Fundamental study of local feed force and consequences on hole exit damage. Int. J. Mach. Tools Manuf. 2015, 94, 57–64. [Google Scholar] [CrossRef] [Green Version]

- Ojo, S.O.; Ismail, S.O.; Paggi, M.; Dhakal, H.N. A new analytical critical thrust force model for delamination analysis of laminated composites during drilling operation. Compos. Part B Eng. 2017, 124, 207–217. [Google Scholar] [CrossRef] [Green Version]

- Karpat, Y.; Deger, B.; Bahtiyar, O. Drilling thick fabric woven CFRP laminates with double point angle drills. J. Mater. Process. Technol. 2012, 212, 2117–2127. [Google Scholar] [CrossRef] [Green Version]

- Zeng, Z.; Nie, J.F.; Xu, S.W.; Davies, C.H.J.; Birbilis, N. Super-formable pure magnesium at room temperature. Nat. Commun. 2017, 8, 1–6. [Google Scholar] [CrossRef]

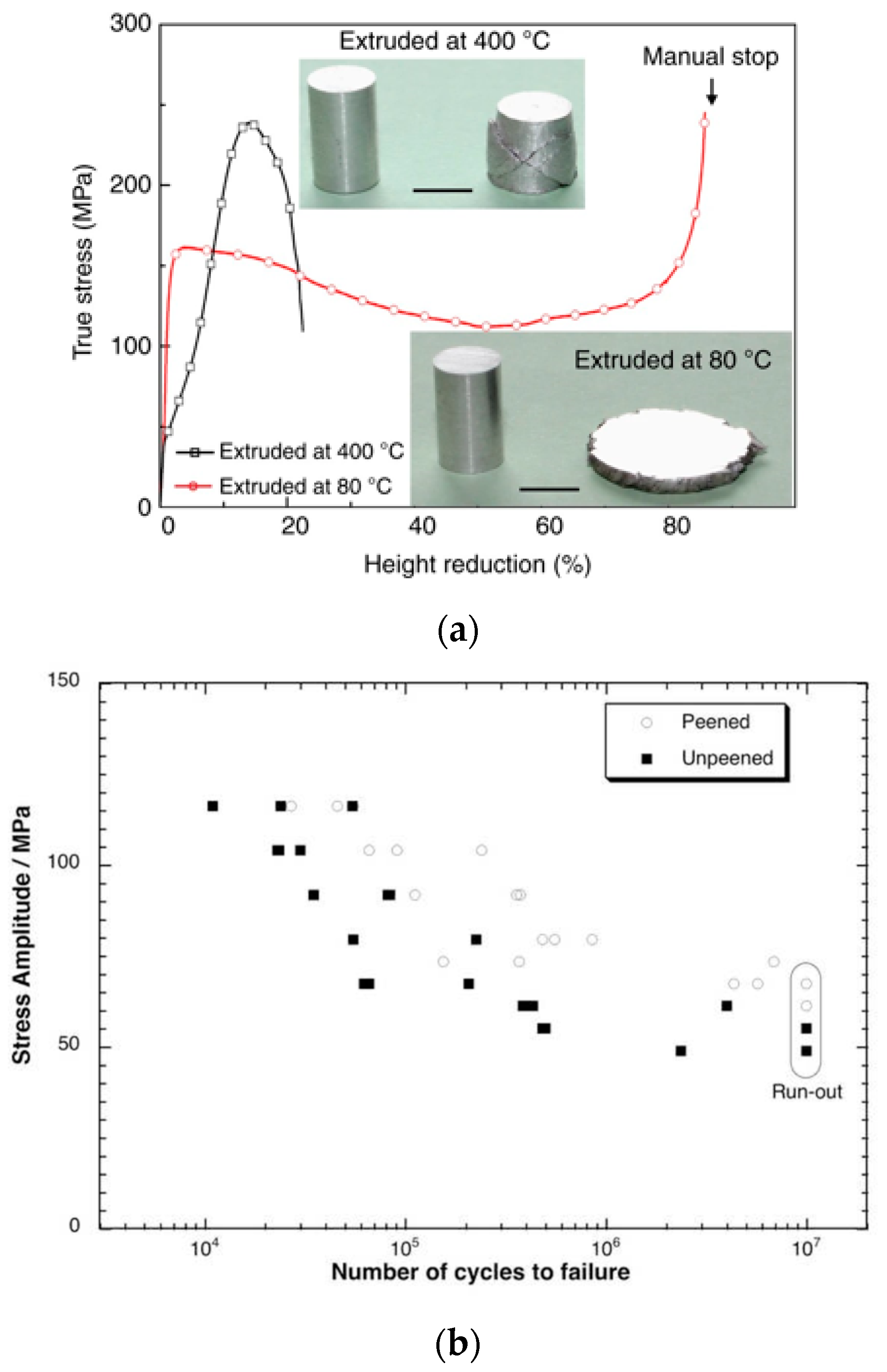

- Barry, N.; Hainsworth, S.V.; Fitzpatrick, M.E. Effect of shot peening on the fatigue behaviour of cast magnesium A8. Mater. Sci. Eng. A 2009, 8, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Muralidhar, A.; Narendranath, S.; Shivananda Nayaka, H. Effect of equal channel angular pressing on AZ31 wrought magnesium alloys. J. Magnes. Alloy. 2013, 1, 336–340. [Google Scholar] [CrossRef] [Green Version]

- Yamazaki, T. Development of A Hybrid Multi-tasking Machine Tool: Integration of Additive Manufacturing Technology with CNC Machining. In Proceedings of the 18th CIRP Conference On Electro Physical and Chemical Machining, Tokyo, Japan, 19–22 April 2016; Volume 42, pp. 81–86. [Google Scholar]

- Qu, N.S.; Zhang, Q.L.; Fang, X.L.; Ye, E.K.; Zhu, D. Experimental Investigation on Electrochemical Grinding of Inconel 718. In Proceedings of the MIC2015—15th Machining Innovations Conference for Aerospace Industry, Hannover, Germany, 18–19 November 2015. [Google Scholar]

- Nan, L.; He, Y.; Heng, L.; Siliang, Y. Plastic wrinkling prediction in thin-walled part forming process: A review. Chin. J. Aeronaut. 2016, 29, 1–14. [Google Scholar] [CrossRef] [Green Version]

| Period | 2000–2020 | 2015–2020 | 2000–2014 |

|---|---|---|---|

| (Average number of citations)/(article x N° year published) | 67.1 | 72.9 | 42.0 |

| Period | 2000–2020 | 2015–2020 | 2000–2014 | |||

|---|---|---|---|---|---|---|

| Articles selected | N° | % | N° | % | N° | % |

| Final selection | 37 | 30 | 81.1% | 7 | 18.9% | |

| Proceedings Paper | 11 | 30% | 8 | 27% | 3 | 43% |

| Q1 | 23 | 62% | 19 | 63% | 4 | 57% |

| Q2 | 3 | 8% | 3 | 10% | 0 | 0% |

| Criteria | Features |

|---|---|

| Publication period | 6 years/2015–2020/30 articles most cited |

| 15 years/2000–2014/7 articles most cited | |

| Date of last search | 7 March 2021 |

| Type of studies | Articles: Scientific journals Q1–Q2 and conference proceedings |

| Search strategy | Equation (1) |

| Bibliography sources | Only databases included in Web of Science |

| Language | English |

| Type of publication | Only Open Access |

| Ref. | Citations Averaged | Publication Type | Year | Material(s) | Key Topics Addressed | Origin |

|---|---|---|---|---|---|---|

| [21] | 75.8 | Q1 | 2016 | Al/Ti/Steel | 1 AM | United Kingdom |

| [59] | 12.75 | Q1 | 2017 | Al/Steel | 3 SoA/2 HC | United Kingdom |

| [60] | 11.67 | * PP | 2018 | Al/Steel | 3 SoA/2 HC/WT | USA |

| [10] | 11.60 | * PP | 2016 | Al/Ceramics | 3 SoA/2 HC | South Africa |

| [12] | 11.00 | Q1 | 2019 | Al/Steel | 3 SoA/2 HC/4 WT | Italy |

| [61] | 6.67 | Q1 | 2015 | Al/Polymer | 2 HC | United Kingdom |

| [13] | 6.00 | Q1 | 2015 | Al/Ceramics | 2 HC/5 M | India |

| [31] | 5.50 | Q1 | 2017 | Al/Ti/Steel | 1 AM/4 WT | United Kingdom |

| [62] | 5.00 | * PP | 2016 | Al/FRP | Other(s) | Germany |

| [19] | 4.75 | * PP | 2012 | Al/Ceramics | 1 AM | India |

| Ref. | Citations Averaged | Publication Type | Year | Material(s) | Key Topics Addressed | Origin |

|---|---|---|---|---|---|---|

| [21] | 75.80 | Q1 | 2016 | Ti/Al/steel | 1 AM | United Kingdom |

| [63] | 50.67 | Q2 | 2015 | Ti | 5 M | China |

| [16] | 21.00 | Q1 | 2016 | Ti/FRP | 5 M | France |

| [32] | 16.00 | * PP | 2015 | Ti | 1 AM/3 SoA | Germany |

| [35] | 16.00 | Q2 | 2018 | Ti | 1 AM/3 SoA | Australia |

| [30] | 8.67 | * PP | 2018 | Ti/steel | 1 AM/4 * WT | Spain |

| [23] | 8.33 | * PP | 2015 | Ti | 5 M | USA |

| [22] | 5.5 | Q1 | 2017 | Ti/FRP | 2 HC/5 M | China |

| [31] | 5.5 | Q1 | 2017 | Ti/Al/steel | 1 AM/3 SoA | USA |

| [29] | 4.23 | * PP | 2013 | Ti/FRP | 5 M | India |

| [64] | 1.88 | Q1 | 2008 | Ti/Ni | 5 M/3 SoA | China |

| Ref. | Citations Averaged | Publication Type | Year | Material(s) | Key Topics Addressed | Origin |

|---|---|---|---|---|---|---|

| [16] | 21.00 | Q1 | 2016 | FRP/Ti | 2 SoA/1 HC/3 M | France |

| [16] | 14.80 | Q1 | 2016 | FRP | 3 M | USA |

| [65] | 9.33 | Q1 | 2015 | FRP | 3 M | France |

| [17] | 7.20 | Q2 | 2016 | FRP | 3 M | United Kingdom |

| [68] | 6.00 | Q1 | 2017 | FRP | 3 M | Italy |

| [22] | 5.50 | Q1 | 2017 | FRP/Ti | 1 HC/3 M | China |

| [69] | 5.42 | Q1 | 2012 | FRP | 3 M | Turkey |

| [62] | 5.00 | * PP | 2016 | FRP/Al | Al/Ceramics | Germany |

| [20] | 4.33 | * PP | 2012 | FRP | 3 M | Germany |

| [29] | 4.23 | * PP | 2013 | FRP/Ti | 3 M | India |

| Ref. | Citations Averaged | Publication Type | Year | Material(s) | Key Topics Addressed | Origin |

|---|---|---|---|---|---|---|

| [26] | 37.2 | Q1 | 2016 | NiTi | 1 AM/2 SoA | USA |

| [25] | 32.33 | Q1 | 2018 | Gamma alloy | 2 SoA | USA |

| [15] | 22.50 | Q1 | 2019 | Mg | Ductility enhancement | China |

| [70] | 17.00 | Q1 | 2017 | Mg | Ductility enhancement | Australia |

| [71] | 2.78 | Q1 | 2009 | Mg | Fatigue | United Kingdom |

| [72] | 1.92 | Q1 | 2013 | Mg | Ductility enhancement | United Kingdom |

| Ref. | Citations Averaged | Type | Year | Hybrid Combination Type | Material(s) | Key Topics Addressed | Origin |

|---|---|---|---|---|---|---|---|

| [16] | 21.00 | Q1 | 2016 | Metal + Polymer | FRP/Ti | 2 SoA/4 M | France |

| [59] | 12.75 | Q1 | 2017 | Metal + Metal | Al/Steel | 2 SoA/4 M | United Kingdom |

| [60] | 11.67 | * PP | 2018 | Metal + Metal | Al/Steel | 2 SoA/3 * WT/1 JDM | USA |

| [10] | 11.60 | * PP | 2016 | Metal + Ceramic | Al/Ceramics | 2 SoA | South Africa |

| [12] | 11.00 | Q1 | 2019 | Metal + Metal | Al/Steel | 3 WT/5 JDM | Italy |

| [73] | 8.40 | * PP | 2016 | Metal + Metal | Ni/Steel | 1 AM/5 JDM | Japan |

| [61] | 6.67 | Q1 | 2015 | Metal + Polymer | Al/Polymer | Al/Ceramics | United Kingdom |

| [13] | 6.00 | Q1 | 2015 | Metal + Ceramic | Al/Ceramics | 4 M | India |

| [22] | 5.50 | Q1 | 2017 | Polymer + Polymer | Ti/FRP | 4 M | China |

| [19] | 4.75 | * PP | 2012 | Metal + Ceramic | Al/Ceramics | 4 M | India |

| Ref. | Citations Averaged | Publication Type | Year | Material(s) | Additive Technology | Key Topics Addressed | Origin |

|---|---|---|---|---|---|---|---|

| [21] | 75.80 | Q1 | 2016 | Al/Ti/Steel | 4 WAAM | 2 WT | United Kingdom |

| [26] | 37.20 | Q1 | 2016 | NiTi | 3 SLM | 1 SoA/Fatigue | USA |

| [32] | 16.00 | * PP | 2015 | Ti | 3 SLM | Fatigue | Germany |

| [35] | 16.00 | Q2 | 2018 | Ti | 3 SLM | 1 SoA | Australia |

| [33] | 13.75 | Q1 | 2017 | Steel | 3 SLM | Fatigue | Switzerland |

| [30] | 8.67 | * PP | 2018 | Ti/Steel | 4 WAAM | Mechanical properties | Spain |

| [73] | 8.40 | * PP | 2016 | Ni/Steel | 3 SLM | Hybrid manufacturing | Japan |

| [31] | 5.50 | Q1 | 2017 | Al/Steel | 4 WAAM | Design guide | United Kingdom |

| Ref. | Citations Averaged | Publication Type | Year | Material(s) | Key Topics Addressed | Origin |

|---|---|---|---|---|---|---|

| [16] | 21.00 | Q1 | 2016 | FRP/Ti | 1 D/2 CTF | France |

| [65] | 14.80 | Q1 | 2016 | FRP | 3 RUM | USA |

| [67] | 9.33 | Q1 | 2015 | FRP | 1 D/4 A | France |

| [68] | 6.00 | Q1 | 2017 | FRP | 1 D/CTF | Italy |

| [22] | 5.50 | Q1 | 2017 | FRP/Ti | 4 A | China |

| [69] | 5.42 | Q1 | 2012 | FRP | 1 D | Turkey |

| [29] | 4.23 | * PP | 2013 | FRP/Ti | Metal + Polymer | India |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blanco, D.; Rubio, E.M.; Lorente-Pedreille, R.M.; Sáenz-Nuño, M.A. Lightweight Structural Materials in Open Access: Latest Trends. Materials 2021, 14, 6577. https://doi.org/10.3390/ma14216577

Blanco D, Rubio EM, Lorente-Pedreille RM, Sáenz-Nuño MA. Lightweight Structural Materials in Open Access: Latest Trends. Materials. 2021; 14(21):6577. https://doi.org/10.3390/ma14216577

Chicago/Turabian StyleBlanco, David, Eva María Rubio, Raquel María Lorente-Pedreille, and María Ana Sáenz-Nuño. 2021. "Lightweight Structural Materials in Open Access: Latest Trends" Materials 14, no. 21: 6577. https://doi.org/10.3390/ma14216577

APA StyleBlanco, D., Rubio, E. M., Lorente-Pedreille, R. M., & Sáenz-Nuño, M. A. (2021). Lightweight Structural Materials in Open Access: Latest Trends. Materials, 14(21), 6577. https://doi.org/10.3390/ma14216577