2.1. Full Scale Fatigue Test and Load Monitoring System of Su-22 Aircraft

Su-22 is a variable wing sweep angle fighter–bomber aircraft which was introduced into operation in Polish Armed Forces (PLAF) in mid-1980’s. There are two versions of the aircraft: single-seated combat version M4 and a two-seated trainer version UM3K. Based on the PLAF decision, a service life extension program was launched in 2014 in order to prolong the designed operation period guaranteed by the manufacturer. As some of the aircraft were close to the original limits, the actual service life, adequate to the flight profile in Polish Air Force, had to be validated. Full-Scale Fatigue Tests (FSFTs) have been carried out in order to verify that the required service life is available with respect to adequate load spectrum [

22]. Furthermore, for two-seated Su22UM3K aircraft, the development of an OLM system providing reliable and detailed data for Individual Aircraft Tracking (IAT) program was required, due to their increased usage compared to M4 version, in particular an increased number of standard and Touch-And-Go landings [

14].

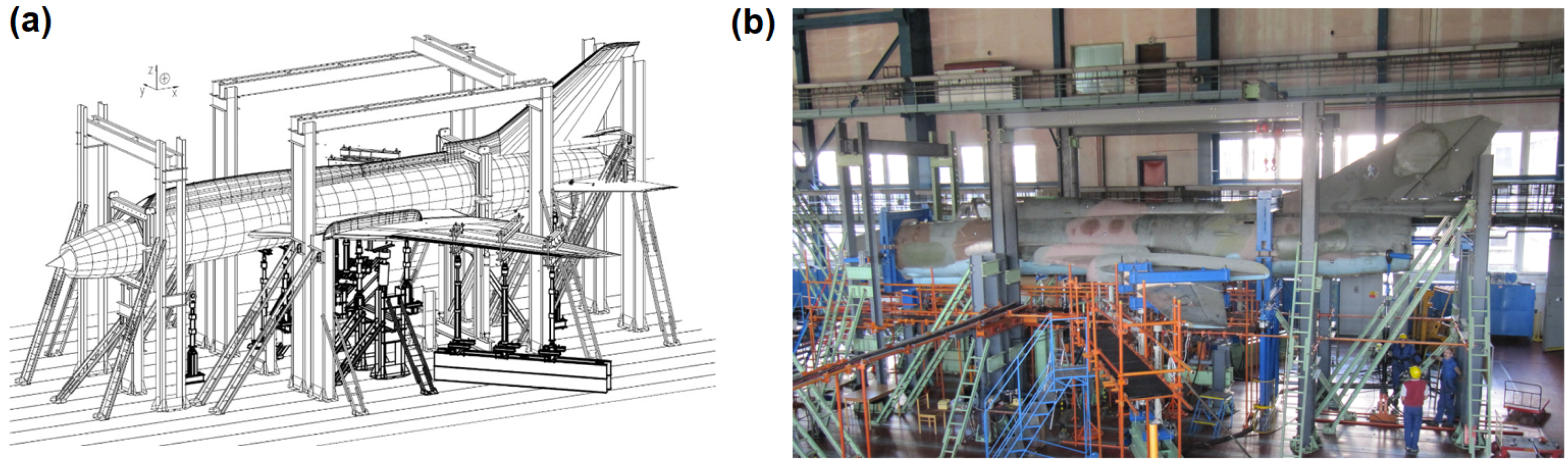

FSFT was designed to be a four-stage test due to the variable sweep angle of the aircraft wings [

22]. This was decided in order to minimize the laborious and time consuming wing sweep changes and actuator reconfigurations. Different wing sweep angles are used for takeoff and landing (30

), subsonic flights (45

) and supersonic flights (63

). The final goal of the FSFT was determination of the total durability of the structure in order to reach 3200 flight hours and 6000 landings. Based on analysis of flight profiles of Polish Su-22, four aircraft configurations for subsequent stages were determined (

Table 1). Landing loads and loads for flight with extended flaps were represented in separate stages due to different hydraulic actuators arrangement under wings. The final stage was designed to represent flights with the highest vertical overloads from Stage 2 until appearance of critical damage of the structure. In order to represent the load distribution in each stage, an array of hydraulic actuators was designed for each stage (

Figure 1) taking into account load and displacement range for each considered load node as well as wing sweep angle and aircraft configuration.

This article is devoted to the development of a methodology for fatigue estimation of Main Landing Gear (MLG) attachment frame due to aircraft landing; therefore, we will focus on Stage I of the test while more detailed description of the approach to FSFT of Su-22 aircraft and other test Stages can be found in [

22,

23]. For Stage I, the wing sweep was set to 30° and the structure was fixed with clamps on the fourth and thirty-fourth fuselage frame as well as by two rods mounted in the engine bay (highlighted in blue in

Figure 2). Loads were exerted on the structure by means of 16 hydraulic actuators. Six actuators (highlighted in red in

Figure 2) were used in order to represent front (1 actuator acting in the vertical direction) and main landing gear loads (2 actuator on each side representing vertical and longitudinal landing forces and 1 actuator in the middle representing transverse taxing forces), whereas 4 actuators were acting on the variable sweep wing part (2 each side) corresponding to lift and inertia forces during landing. The remaining 6 actuators were distributed along the fuselage in order to represent inertial forces. In this study, fatigue wear of the attachment frame due to it being carried by MLG is considered as one of the key factors determining remaining service life of an aircraft. Those forces were represented by actuators denoted as no. 6 in

Figure 2 (one actuator on each side). Different types of full stop landings were represented during Stage I with the same landing mass of the aircraft but different vertical load levels during touchdown. Simulated vertical load sequences on the actuators in terms of the equivalent weight carried by main landing gear node is shown in

Figure 3, and the number of different type of landings represented in FSFT load spectrum is provided in

Table 2 below. Each full stop landing was represented by 14 load levels exerted on the frame of the aircraft in linear sequences (

Figure 3).

Load envelope and landing statistics were estimated based on dedicated flight tests program and historical flight data. The information about stress level occurring in various areas of interest during flight was collected with use of a network of strain gauges installed on a test aircraft. After sensor installation, a dedicated flight test program was performed in order to acquire sufficient data about load distribution during flight for the purpose of FSFT load spectra preparation for different test stages. In total, 40 strain gauges were installed on the test aircraft selected for in flight measurements (

Figure 4):

The same installation was used for test structure monitoring during FSFT.

The strain gauge measurement array was designed to monitor the following loads:

bending momentum in the wing fuselage joint (one section each side);

bending momentum in the main pivot joint (one section each side);

bending momentum in the fuselage (5 sections);

main landing gear loads:

- -

vertical force along z axis;

- -

bending momentum along y axis;

- -

bending momentum along x axis.

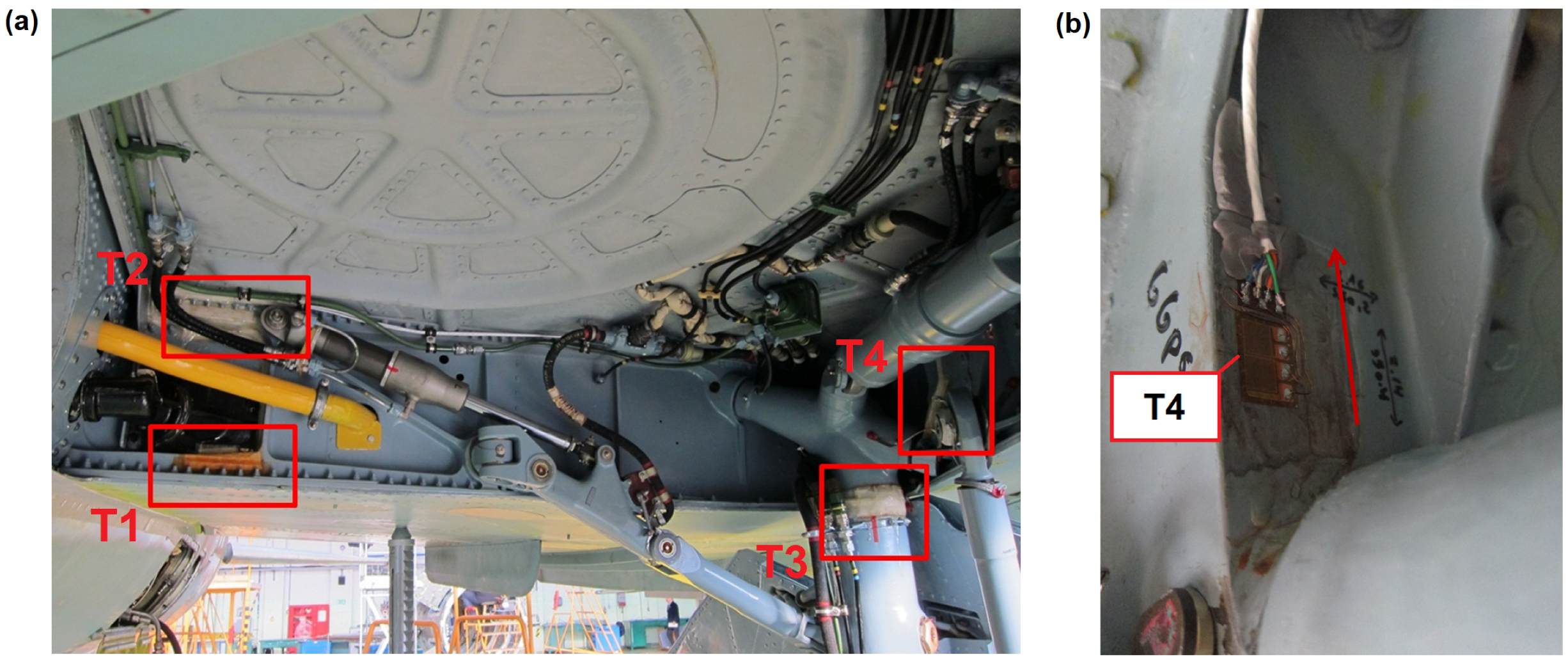

All of the strain gauges were in the form of tee rosette configuration (

Figure 5b), which allowed for strain measurements in the primary direction with temperature compensation due to the secondary perpendicular strain gauge. In

Figure 5a, localization of strain gauges installed in the main landing gear compartment is presented.

In addition, a load monitoring system with a reduced number of strain gauges was installed on six selected Su-22UM3K aircraft, in order to track their individual usage and remaining service life. In particular, as aircraft selected to be equipped with a Operational Load Monitoring (OLM) system are used for pilot training and certification, it was necessary to develop a methodology for main landing gear attachment node fatigue wear monitoring, as those aircraft perform more landings (especially Touch-And-Go landings) than combat one-seat aircraft. There exist many approaches to Individual Aircraft Tracking [

10] depending on the type of data available for load estimation in critical locations. A through revision of different methods for fatigue assessment and comparison of different monitoring techniques is provided in [

24]. One of the most common approaches is to use the vertical overload parameter recorded by Flight Data Recorder (FDR) in order to determine stress levels at critical locations. This parameter, in particular in combination with some other flight parameters, e.g., angle of attack and aircraft mass distribution, is especially efficient for fatigue assessment of wing spars or wing to fuselage attachment nodes, as vertical acceleration is the key parameter determining fatigue wear of such structural elements. Based on acceleration measurements, it is moreover possible to define many useful damage sensitive signal features for the purpose of Structural Health Monitoring [

25]. However, the bandwidth and sensitivity of accelerometers used in FDR are sometimes not sufficient for proper determination of fatigue due to landings, in particular it can be hard to detect and properly assess touchdown of an aircraft based on that parameter. Furthermore, accelerometers cannot be used for determination of takeoff weight which in the case of landing gear attachment node can significantly contribute to Ground-Air-Ground cycle, therefore strain gauges were used for OLM purposes.

The sensor network of the system developed for the IAT program is reduced with respect to the system installed on the test aircraft (

Figure 4). It contains eight strain gauges which are installed symmetrically in the most relevant structural elements of the aircraft on both wings and main landing gear frame. In

Figure 6 general location of strain gauges of the reduced system is presented. The limitation to eight strain gauges was due to the hardware requirements of the FDR used. Four sensors are placed on the main wing spar, on lower (sensors denoted as T1 and T5) and upper (sensors denoted as T2 and T6) flanges. For main landing gear monitoring, the sensor denoted as GGPZ1 in

Figure 5a was selected to measure backward bending moment of the landing gear (denoted as T3 and T7 in the reduced system), and sensor GGPS2 (

Figure 5a) is used for estimation of vertical force during landing (denoted as T4 and T8 in the reduced system). Strain gauge selection was determined based on signal-to-noise ratio measured during flight tests as well as the results of sensors calibration on test specimen during FSFT. All the selected strain gauges depended linearly on the corresponding relevant forces. In particular, sensor T4 (

Figure 6b) was linearly dependent on vertical force applied to main landing gear in full range of the load spectrum while it was barely sensitive to force applied in perpendicular direction. Therefore, for the purpose of fatigue wear estimation of the MLG attachment node due to vertical landing forces, the strain values

measured by sensors T4 (left node) and T8 (right node) were used.

2.2. Methodology of Signal Analysis for Landing Operations Extraction

In order to determine fatigue of landing gear attachment node, it is necessary to extract signals corresponding to on-ground operations from full record of a given flight. For the detection of on-ground segments recorded by the system, it was assumed that the threshold

for detection of significant deformations originating from landing gear loads corresponding to landings is 20% of the base deformation, which is determined before the takeoff of the plane, using the loads at full stop. In

Figure 7, an example of signal acquired during landing with multiple touchdowns preceding final touchdown and deceleration is presented. As can be seen, signal can exceed the estimated threshold during before final deceleration and load transfer to landing gear node; therefore, for a proper determination of signal corresponding to landings, an additional algorithm is required.

In the presented algorithm, the first step of on-ground operations detection and classification is to select all the signal samples

below the determined threshold

, i.e., satisfying the condition

where

t is time of a given sample acquisition. Then, starting from the first signal sample satisfying this condition, consecutive disjoints sets of data are determined:

such that the difference between the acquisition time

of the initial signal value

from a given set

and acquisition time

of the final signal value

from the preceding set

is not less than 3 s. For proper on-ground connected signal segments detection, datasets

lasting no longer than 2 s, i.e., for which

are disregarded, in order to remove eventual artificial events due to natural signal disturbances, e.g., due to short power outages or drops of pressure in hydraulic blocks during flight. In the next step, for every segment

, all the signal samples

satisfying

are added to a given set

in order to analyze full data records corresponding to subsequent on-ground operations, i.e., each part of the signal corresponding to such operation is extended by additional 3 s time offset of signal before and after the operation, in order to track all load cycles exerted on landing gear node. The first of such extended sets,

, contains signal acquired during aircraft takeoff and taxiing before takeoff, and the last set

corresponds to full stop landing and taxiing after landing, whereas all sets in between are classified as Touch-And-Go (T&G) landings.

In

Figure 8, the outcome of the proposed algorithm for landing presented in

Figure 7 is delivered. The signal corresponding to full stop landing was extracted from raw signal with use of the proposed algorithm. In particular, all the aircraft touchdowns are included in the extracted signal, and an additional 3 s time offset provides data corresponding to no load condition on landing gear node; therefore, based on such data, it is possible to capture all relevant load cycles exerted on the node due to landing.

All the parameters, e.g., threshold and offset levels, were decided based on algorithm results on database of reference signals, where signals corresponding to on-ground operations were manually determined, so the number and duration of landings was compared between expert and automated analysis for different adjustments of the parameters. Furthermore, the performance of the algorithm is periodically verified, i.e., number of landings is compared with maintenance data, but also validity and performance of the algorithm is evaluated by the experts based on randomly selected flights from a given period.

In

Figure 9a, an example of an OLM system record with indication of subsequent on-ground operations is presented. The approach is efficient in detection of on-ground operations, in particular for Touch-And-Go landings (

Figure 9b). Detection of such events based on flight parameters acquired by a standard flight data recorder was very inaccurate, as many simulated landing approaches, but without touchdown, are performed during pilot training process. In

Figure 10, an example of system records for a flight with three simulated attempts to landing is presented. For every such maneuver, low pass flight over runway was performed (

Figure 10b) with released landing gear, which caused a slight change of strain values recorded on the node (

Figure 10a); however, no actual touchdown occurred. This is correctly recognized by the proposed algorithm, as only takeoff and full stop landing were detected in that flight (

Figure 10a). As both records—the altitude parameter as well as indicator of landing gear release command—were similar as for proper Touch-And-Go landings, such events were often misclassified with use of algorithms based on only flight parameters records, as sensitivity and signal sampling rate of the standard g-load sensor used on this type of aircraft are not sufficient for such events detection.

An interesting example of algorithm output is presented in

Figure 11. The recorded strain signal shows a clear example of a bounced landing. In this case, after the first touchdown, the plane took off from the ground for about two seconds, and full stop landing was performed afterwards. The algorithm detected a Touch-And-Go landing event and subsequent proper landing. Such events, when detected by the system with high confidence, can provide an automated tool for human error assessment, which could be beneficial for pilot training programs.

In

Figure 12, an example of a strain gauge signal recorded during full stop landing is shown, with indication of the characteristic stages of this process. One of the parameters used to assess the stress level of the main landing gear node structure during full stop and Touch-And-Go landings is the amplitude of the maximum deformation cycle recorded during the touchdown (

Figure 12). A characteristic feature of the touchdown is the rapid deformation change related to the slowing down of the descent speed of the aircraft and the dissipation of energy on the elements of the landing gear node [

26]. Two warning levels were defined for the strain signals characterizing hard landings, which are presented in

Table 3. In addition to structural load monitoring purposes, the distribution of landings corresponding to different warning levels can also be used for the assessment of pilot training advancements. The warning levels were determined based on landing statistics determined for a certain period of time. Another approach could be based on relevant material data and depend on the stress values at the critical point for the main landing gear attachment node, yet the adopted statistical approach is better suited for pilot training purposes.

2.3. Methodology of Landing Gear Node Fatigue Estimation

In this paragraph, a method for fatigue estimation of Main Landing Gear (MLG) attachment frame due to vertical landing forces based on OLM system records is delivered. The classic approach to fatigue estimation is based on the S–N fatigue curve of a given material and linear cumulative Palmgren–Miner hypothesis. The S–N curve determines the relationship between the equivalent stress amplitude

of the zero-to-tension load cycle and the number of cycles

N needed to fracture of an element, subjected to load cycles of this amplitude. The S–N curve is usually described by the relationship [

27]

Cumulative fatigue

D of a set of load cycles

is given by the expression

where

C is a constant dependent on material constants

A and

B.

Based on classic S–N and cumulative fatigue equations presented above, an approach to fatigue wear estimation of main landing gear attachment frame can be defined as follows. In order to determine the fatigue wear of a given structural element, a linear relation between stress level

at critical point of the element and some physical parameter

p can be assumed:

As the parameter

p, records of strain gauge

installed in a point of the structure where stress level is linearly proportional to

can be used, or

p can be a function of flight parameters determining load values of a given structural element, e.g., weight and

g-load factor in the case of fuselage wing attachment. Equation (

6) can be rewritten as follows:

where

and

is value of physical parameter corresponding to equivalent zero-to-tension stress amplitude of the

i-th load cycle.

The material constant

C and proportionality parameter

can be omitted if reference fatigue for a given set of cycles is known, for instance, if data from Full Scale Fatigue Test are available. In that case,

where summation is carried over load cycles

exerted on the structure during Full-Scale Fatigue Test (FSFT) and

is number of load cycles during FSFT. Therefore,

can be calculated if material constant

B and reference data from FSFT is known.

There exist several conditions which need to be satisfied in order to apply the presented approach based on Miner’s law. First, if only laboratory material data are available with no reference fatigue exerted on a real test structure, then the correspondence between stress level in the critical location of the structure and the parameter used for fatigue evaluation must be known in exact form and Miner’s Equation (

6) needs to be used directly instead of the Equation (

10). Another requirement is a linear relation between the physical parameter used for fatigue assessment and stress level

in the critical location. As mentioned in

Section 2.1, strain gauge readings used in the study are linearly dependent on vertical landing force in full range of admissible loads of the aircraft, as confirmed during FSFT rig calibration. Furthermore, in the case of Su-22 aircraft, it is assumed in load spectra design that the aircraft will be operated within the linear elastic regime of the materials, as if high overloads during flight or very harsh landings occur, special procedures are introduced in order to evaluate aircraft condition (e.g., plastic deformations) and its airworthiness. In addition, no looseness in highly loaded joints is allowed, therefore linearity between vertical force and stress level in critical location is legitimate assumption in our case. Finally, fatigue limit [

1] of the material needs to be considered for fatigue estimation based on Equation (

10), as load cycles below the fatigue threshold in a given point can be above fatigue limit in critical location. In our case, all strain data corresponding to physical load cycles exerted on main landing gear attachment are taken into account for the purpose of fatigue assessment, therefore all the load cycles in critical location are considered as well.

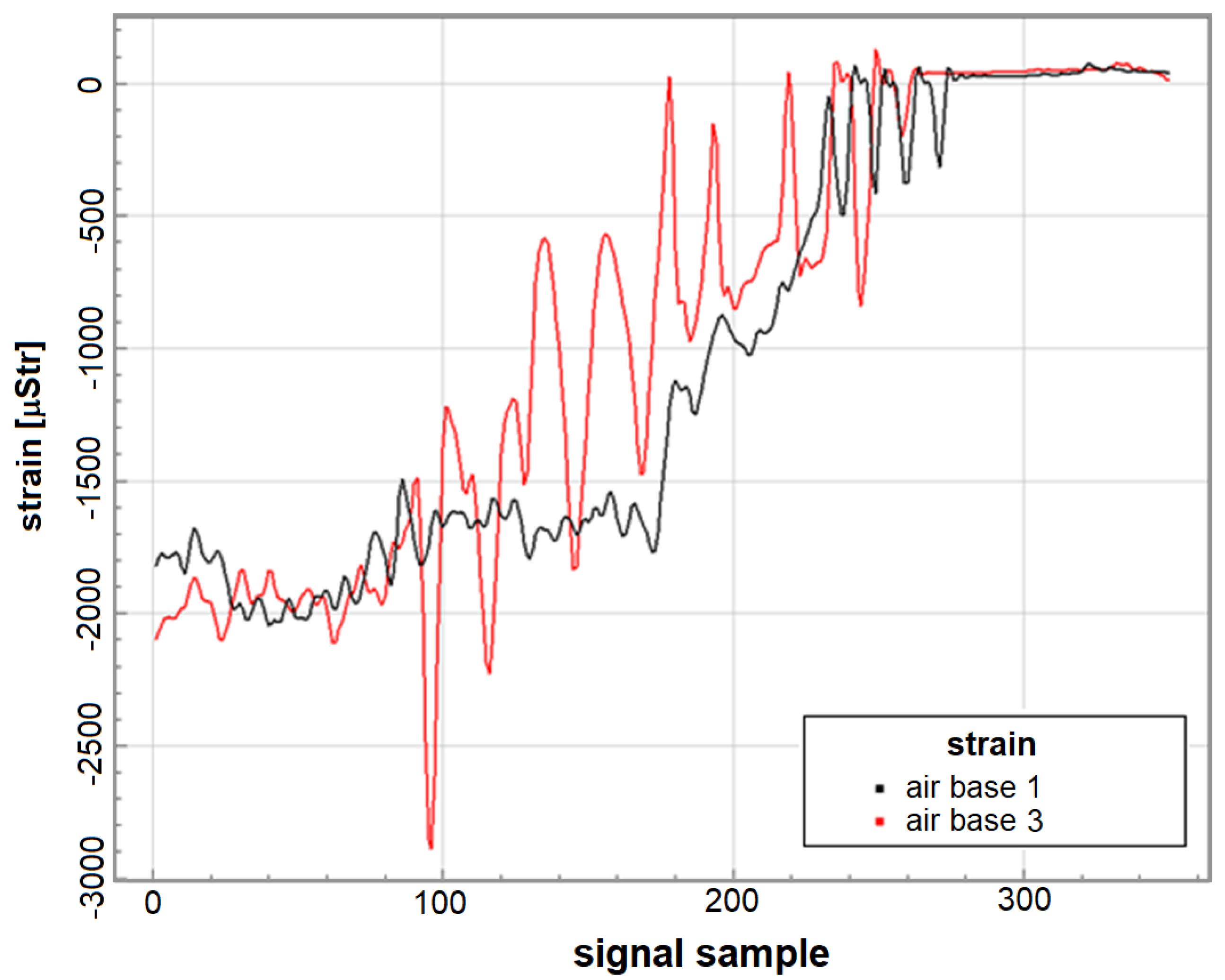

For the purpose of this study, the equivalent weight

w carried by landing gear node was adopted as a physical parameter needed for fatigue wear calculation in accordance with the Equation (

8). Equivalent weight was assessed by strain gauge reading and results of linear physical scaling, i.e., values of strain for lifted aircraft with released landing gear were related to no load condition and values of strain readings for aircraft on-ground were related to its measured weight carried by a given landing gear node. Furthermore, data from actuators used for the Full-Scale Fatigue Test were rescaled in those units and used in the denominator of the Equation (

10) for fatigue calculation. The parameter

B was estimated based on laboratory fatigue tests of material used for landing gear attachment node manufacturing.

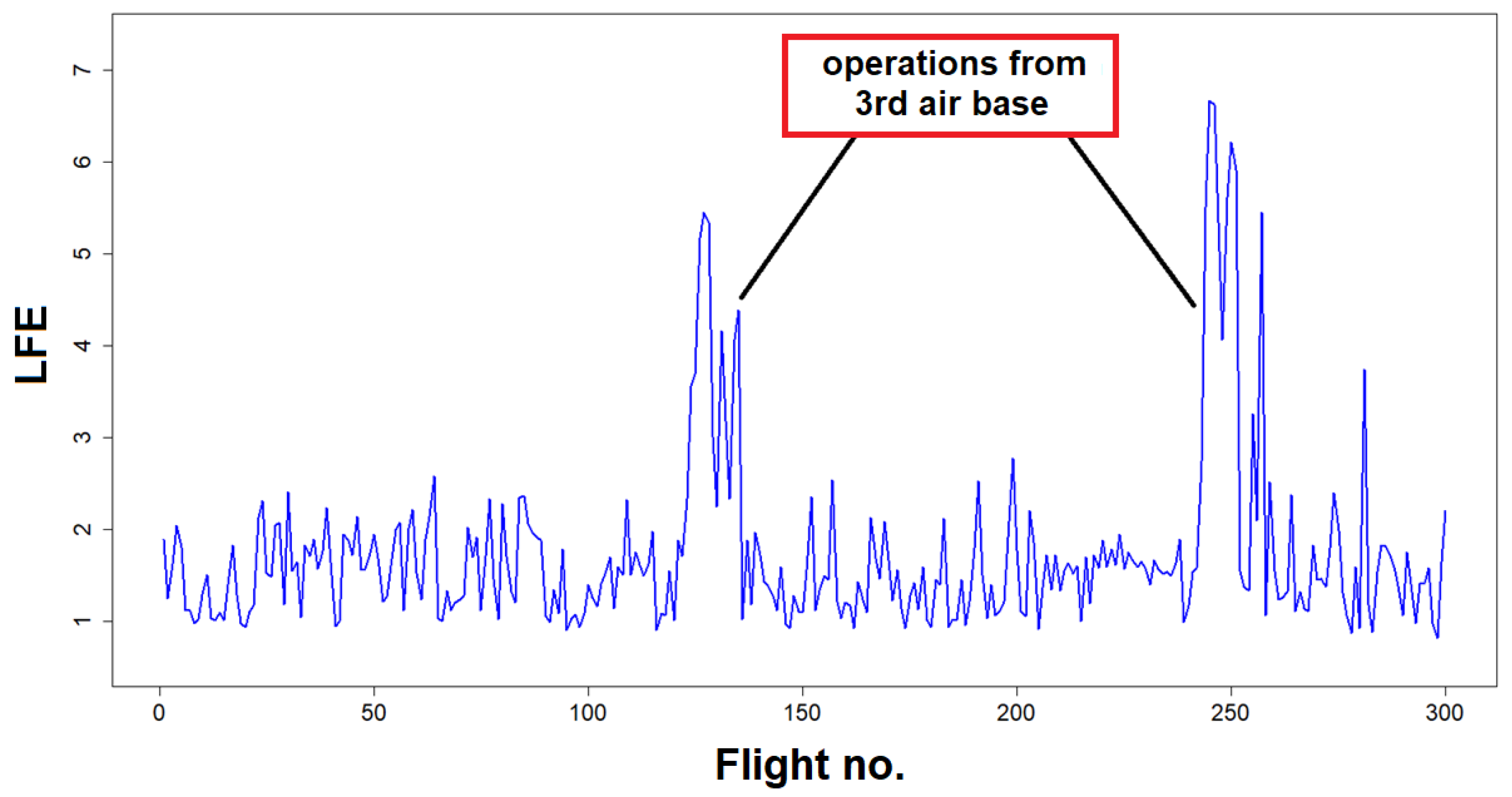

For easier interpretation of the obtained results, a notion of Landing Fatigue Equivalent (

LFE) can be introduced.

LFE represents the relative fatigue of landing gear node due to loads exerted during a given landing

with respect to mean fatigue due to simulated landings during FSFT:

where:

denotes amplitude of equivalent zero-to-tension load cycles exerted on landing gear node during landing (in terms of equivalent weight carried by the node as measured by strain gauge),

denotes number of load cycles recorded during landing,

denotes amplitude of equivalent zero-to-tension load cycles exerted on landing gear node during FSFT (in terms of equivalent weight carried by the node) and

N denotes number of simulated landings during FSFT.

In order to account properly Ground–Air–Ground cycle when calculating

LFE for full stop landing, the records of strain gauge obtained for takeoff and landing are joined (

Figure 13) prior to determination of load cycles with use of Range-Pair Counting algorithm [

28]. Furthermore, the noise level of the recorded signal during on-ground operations was estimated, and for

LFE calculation, only relevant recorded cycles, i.e., corresponding to physical load of the structure and higher than the level of noise, were considered.

LFE provides a direct measure to estimate the fatigue wear of the landing gear attachment node for a given flight if:

then loads exerted on landing gear attachment node during a given landing was less severe than mean landing profile during FSFT; or

then loads exerted on landing gear attachment node during a given landing was more severe than mean landing profile during FSFT.

Cumulative LFE obtained for a given aircraft can be considered as a limiting condition for possibility of further aircraft operation instead of total estimated fatigue for landing gear attachment.

For Touch-And-Go landings, all the load cycles are due to aircraft touchdown. For full stop landing, additional information about this process can be obtained by distinction of load cycles occurring during different stages of landing (

Figure 12) and calculation of the corresponding fatigue. An algorithm for the classification of structure load cycles recorded by strain gauges during the normal landings and other ground loads during take-off and full stop landing was developed. It was assumed that the cycles are classified into the following categories:

cycles recorded during touchdown—P;

Ground–Air–Ground cycle—GAG;

cycles recorded during braking—W;

cycles recorded during taxing before take-off—KSR;

cycles recorded during taxing after landing—DKL;

other cycles recorded during takeoff—OS;

other cycles (not classified elsewhere)—O.

In

Figure 13, the general concept of division of a single take-off and landing operation into above defined cycles is shown—the height of the shown color boxes correspond the assumed minimum and maximum values of certain types of cycles for a given flight.

Since:

where

c denotes cycles corresponding to different types, also fatigue equivalent obtained for full stop landing can be factored accordingly:

Based on investigation of the defined contributions to fatigue equivalent, additional conclusions can be drawn, e.g., with respect to pilot training program or with respect to condition of the runway, as will be shown further in the text.