Cyclic Crack Growth in Chemically Tailored Isotropic Austenitic Steel Processed by Electron Beam Powder Bed Fusion

Abstract

:1. Introduction

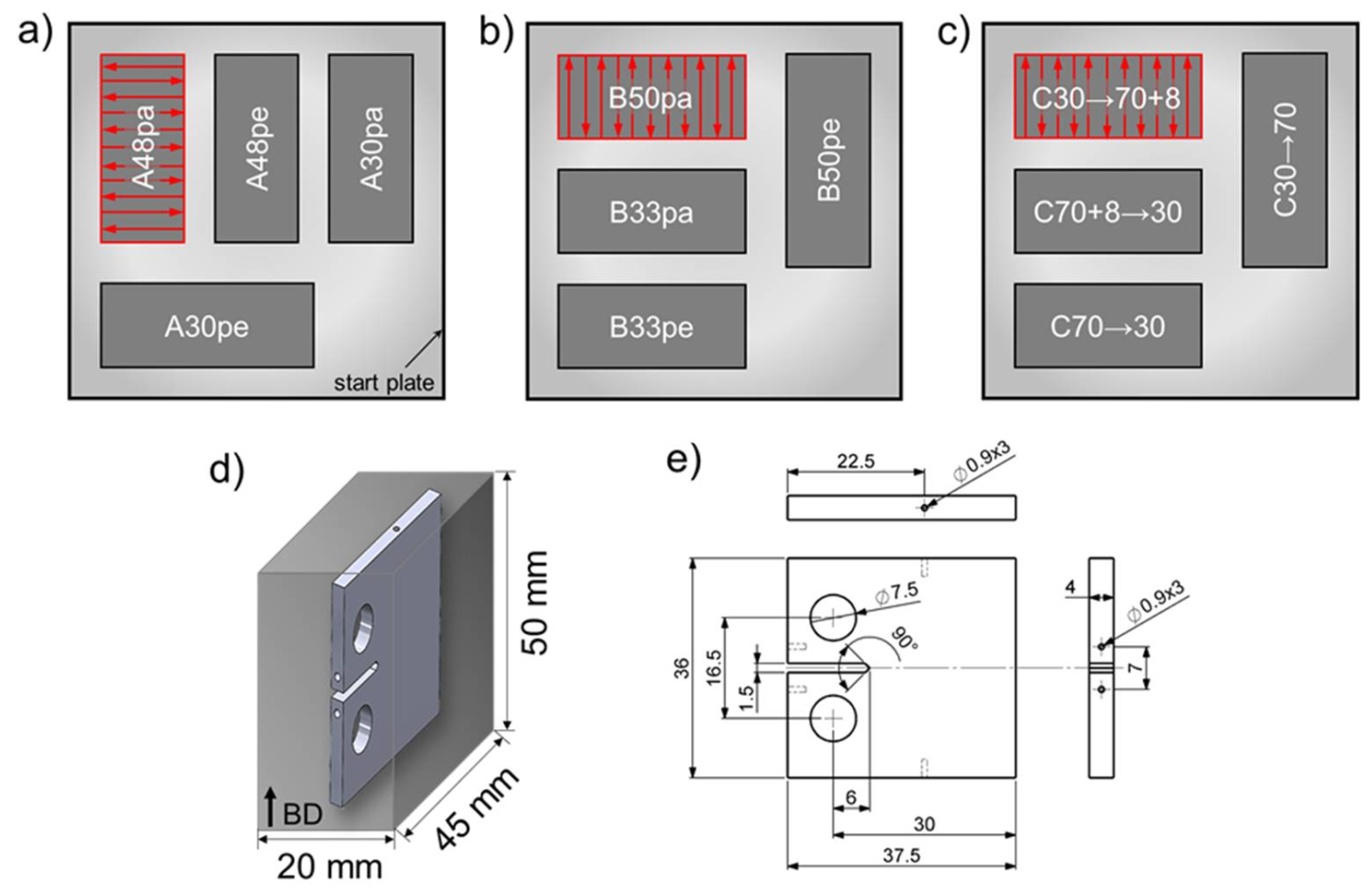

2. Materials and Methods

3. Results and Discussion

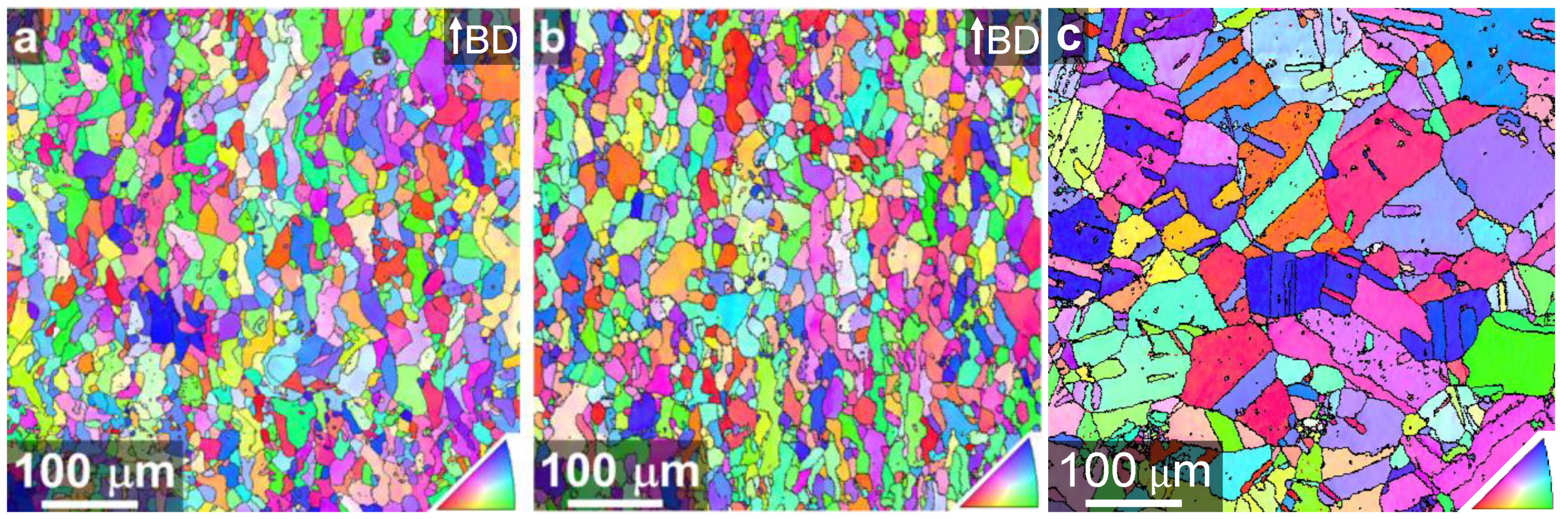

3.1. Microstructures after Electron Beam Powder Bed Fusion

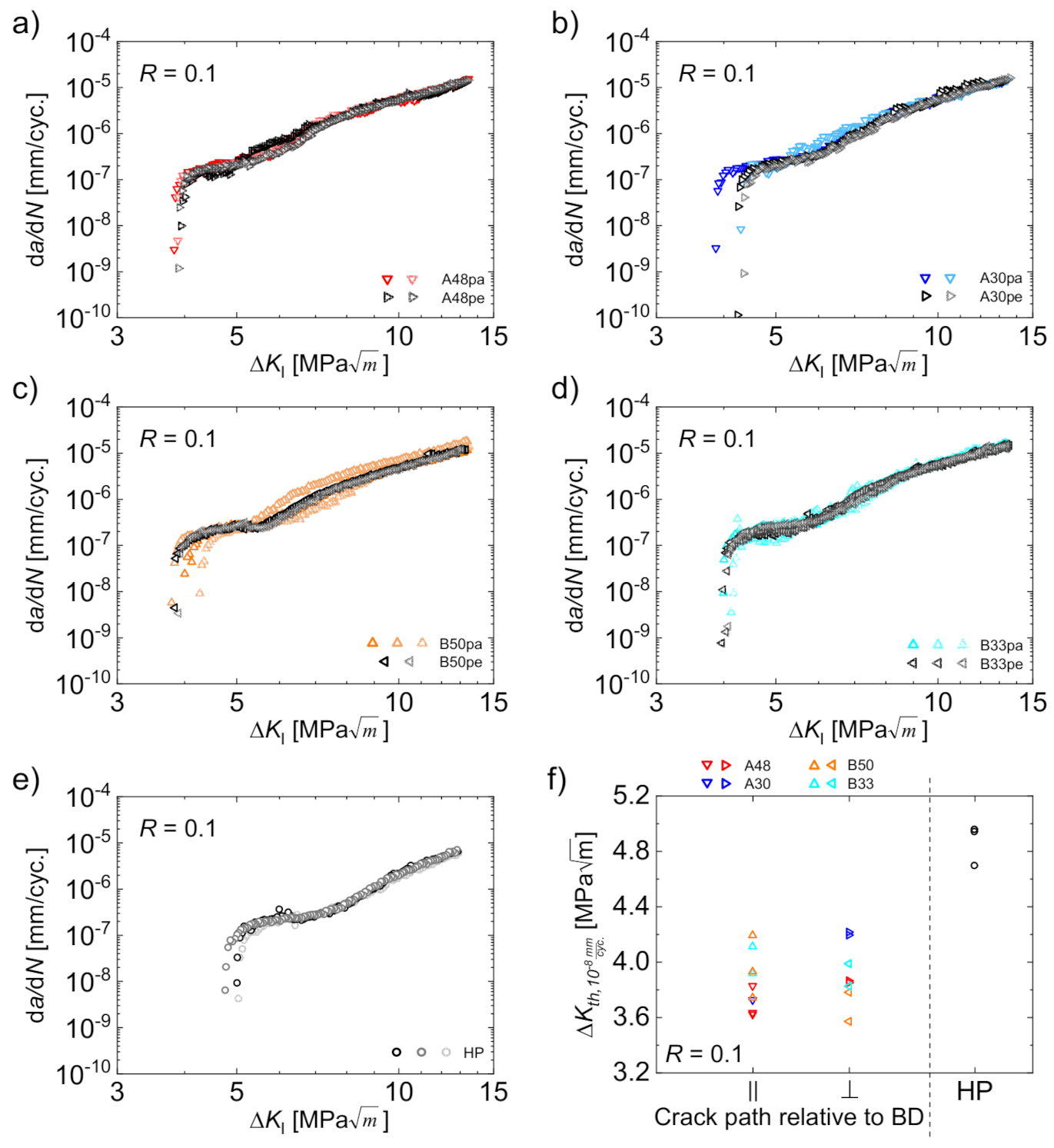

3.2. Influence of Building Direction

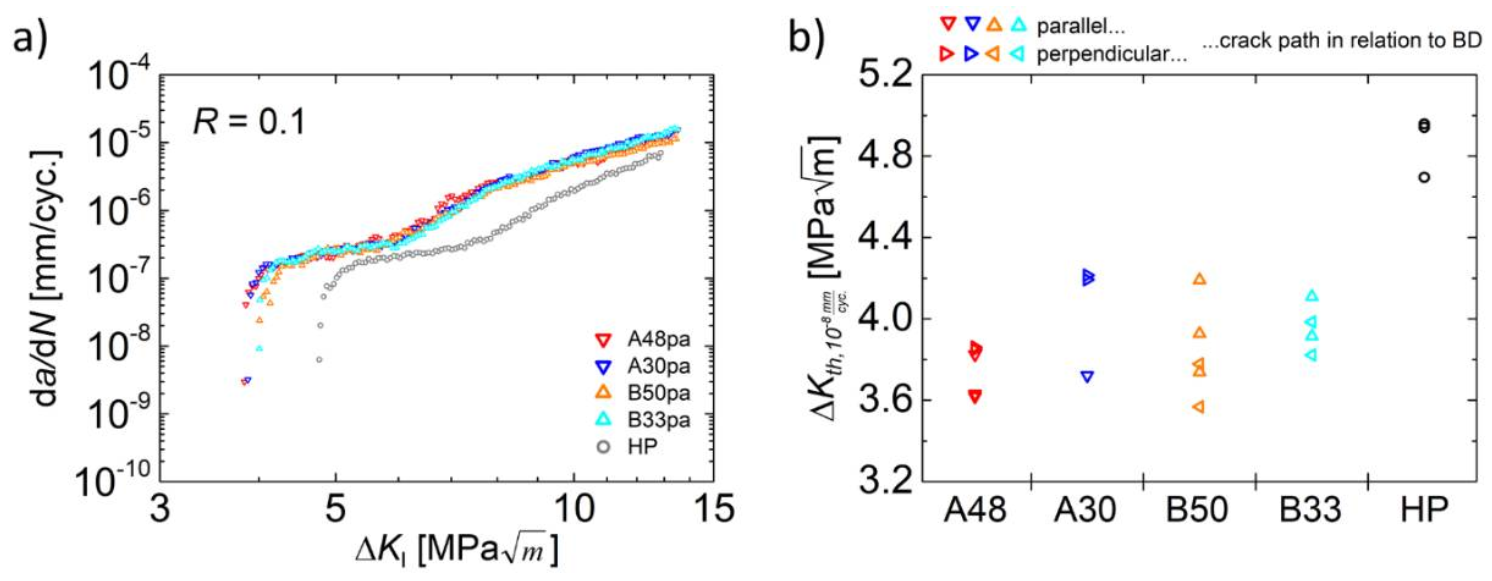

3.3. Influence of Building Parameters

3.4. Influence of Gradation

4. Summary

- The cyclic crack growth is not affected by the building direction of the PBF-EB process; i.e., crack propagation parallel and perpendicular to the building direction were similar due to the almost isotropic microstructure.

- The crack growth rates were not affected by different PBF-EB process parameters and, eventually, different manganese fractions.

- A compositional gradation within the same specimen did not effectively influence the crack growth rate at a cyclic stress intensity factor of 12 MPa. Despite some local crack growth rate changes in the direct vicinity of the interface, the crack propagation behavior was not affected in the long run.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhong, Y.; Rännar, L.-E.; Liu, L.; Koptyug, A.; Wikman, S.; Olsen, J.; Cui, D.; Shen, Z. Additive manufacturing of 316 L stainless steel by electron beam melting for nuclear fusion applications. J. Nucl. Mater. 2017, 486, 234–245. [Google Scholar] [CrossRef]

- Olsén, J.; Shen, Z.; Liu, L.; Koptyug, A.; Rännar, L.-E. Micro- and macro-structural heterogeneities in 316 L stainless steel prepared by electron-beam melting. Mater. Charact. 2018, 141, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Niendorf, T.; Leuders, S.; Riemer, A.; Richard, H.A.; Tröster, T.; Schwarze, D. Highly Anisotropic Steel Processed by Selective Laser Melting. Metall. Mater. Trans. B 2013, 44, 794–796. [Google Scholar] [CrossRef] [Green Version]

- Niendorf, T.; Brenne, F. Steel showing twinning-induced plasticity processed by selective laser melting—An additively manufactured high performance material. Mater. Charact. 2013, 85, 57–63. [Google Scholar] [CrossRef]

- Segura, I.A.; Mireles, J.; Bermudez, D.; Terrazas, C.A.; Murr, L.E.; Li, K.; Injeti, V.; Misra, R.; Wicker, R.B. Characterization and mechanical properties of cladded stainless steel 316 L with nuclear applications fabricated using electron beam melting. J. Nucl. Mater. 2018, 507, 164–176. [Google Scholar] [CrossRef]

- Bajaj, P.; Hariharan, A.; Kini, A.; Kürnsteiner, P.; Raabe, D.; Jägle, E.A. Steels in additive manufacturing: A review of their microstructure and properties. Mater. Sci. Eng. A 2020, 772, 138633. [Google Scholar] [CrossRef]

- Riemer, A.; Leuders, S.; Thöne, M.; Richard, H.A.; Tröster, T.; Niendorf, T. On the fatigue crack growth behavior in 316 L stainless steel manufactured by selective laser melting. Eng. Fract. Mech. 2014, 120, 15–25. [Google Scholar] [CrossRef]

- Leicht, A.; Rashidi, M.; Klement, U.; Hryha, E. Effect of process parameters on the microstructure, tensile strength and productivity of 316 L parts produced by laser powder bed fusion. Mater. Charact. 2020, 159, 110016. [Google Scholar] [CrossRef]

- Andreau, O.; Koutiri, I.; Peyre, P.; Penot, J.-D.; Saintier, N.; Pessard, E.; de Terris, T.; Dupuy, C.; Baudin, T. Texture control of 316 L parts by modulation of the melt pool morphology in selective laser melting. J. Mater. Process. Technol. 2019, 264, 21–31. [Google Scholar] [CrossRef] [Green Version]

- Günther, J.; Brenne, F.; Droste, M.; Wendler, M.; Volkova, O.; Biermann, H.; Niendorf, T. Design of novel materials for additive manufacturing—Isotropic microstructure and high defect tolerance. Sci. Rep. 2018, 8, 1298. [Google Scholar] [CrossRef] [Green Version]

- Weidner, A.; Biermann, H. Combination of Different In Situ Characterization Techniques and Scanning Electron Microscopy Investigations for a Comprehensive Description of the Tensile Deformation Behavior of a CrMnNi TRIP/TWIP Steel. JOM 2015, 67, 1729–1747. [Google Scholar] [CrossRef]

- Ullrich, C.; Martin, S.; Schimpf, C.; Stark, A.; Schell, N.; Rafaja, D. Deformation Mechanisms in Metastable Austenitic TRIP/TWIP Steels under Compressive Load Studied by in situ Synchrotron Radiation Diffraction. Adv. Eng. Mater. 2019, 21, 1801101. [Google Scholar] [CrossRef] [Green Version]

- Martin, S.; Wolf, S.; Martin, U.; Krüger, L.; Rafaja, D. Deformation Mechanisms in Austenitic TRIP/TWIP Steel as a Function of Temperature. Metall. Mater. Trans. A 2016, 47, 49–58. [Google Scholar] [CrossRef] [Green Version]

- Weidner, A.; Hangen, U.D.; Biermann, H. Nanoindentation measurements on deformation-induced α’-martensite in a metastable austenitic high-alloy CrMnNi steel. Philos. Mag. Lett. 2014, 94, 522–530. [Google Scholar] [CrossRef]

- Biermann, H.; Glage, A.; Droste, M. Influence of Temperature on Fatigue-Induced Martensitic Phase Transformation in a Metastable CrMnNi-Steel. Metall. Mater. Trans. A 2016, 47, 84–94. [Google Scholar] [CrossRef]

- Droste, M.; Järvenpää, A.; Jaskari, M.; Motylenko, M.; Weidner, A.; Karjalainen, P.; Biermann, H. The role of grain size in static and cyclic deformation behaviour of a laser reversion annealed metastable austenitic steel. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 43–62. [Google Scholar] [CrossRef]

- Ackermann, S.; Kulawinski, D.; Henkel, S.; Biermann, H. Biaxial in-phase and out-of-phase cyclic deformation and fatigue behavior of an austenitic TRIP steel. Int. J. Fatigue 2014, 67, 123–133. [Google Scholar] [CrossRef]

- Weidner, A. Deformation Processes in TRIP/TWIP Steels: In-Situ Characterization Techniques; Springer Nature: Cham, Switzerland; ISBN 978-3-030-37148-7.

- Günther, J.; Lehnert, R.; Wagner, R.; Burkhardt, C.; Wendler, M.; Volkova, O.; Biermann, H.; Niendorf, T. Effect of Compositional Variation Induced by EBM Processing on Deformation Behavior and Phase Stability of Austenitic Cr-Mn-Ni TRIP Steel. JOM 2020, 72, 1052–1064. [Google Scholar] [CrossRef] [Green Version]

- Droste, M.; Günther, J.; Kotzem, D.; Walther, F.; Niendorf, T.; Biermann, H. Cyclic deformation behavior of a damage tolerant CrMnNi TRIP steel produced by electron beam melting. Int. J. Fatigue 2018, 114, 262–271. [Google Scholar] [CrossRef]

- Burkhardt, C.; Wagner, R.; Baumgart, C.; Günther, J.; Krüger, L.; Biermann, H. Microstructural and Mechanical Characterization of Square-Celled TRIP Steel Honeycomb Structures Produced by Electron Beam Melting. Adv. Eng. Mater. 2020, 15, 2000037. [Google Scholar] [CrossRef] [Green Version]

- Decker, S.; Baumgart, C.; Krüger, L.; Schumacher, A. Electron Beam Melting of various structures and their quasi-static compression behavior. Mater. Sci. Eng. A 2020, 793, 139849. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Ramamurty, U. Mechanical behavior of selective laser melted 316 L stainless steel. Mater. Sci. Eng. A 2017, 696, 113–121. [Google Scholar] [CrossRef]

- Afkhami, S.; Dabiri, M.; Alavi, S.H.; Björk, T.; Salminen, A. Fatigue characteristics of steels manufactured by selective laser melting. Int. J. Fatigue 2019, 122, 72–83. [Google Scholar] [CrossRef]

- Zerbst, U.; Bruno, G.; Buffiere, J.-Y.; Wegener, T.; Niendorf, T.; Wu, T.; Zhang, X.; Kashaev, N.; Meneghetti, G.; Hrabe, N.; et al. Damage tolerant design of additively manufactured metallic components subjected to cyclic loading: State of the art and challenges. Prog. Mater. Sci. 2021, 121. [Google Scholar] [CrossRef]

- Brenne, F.; Niendorf, T. Damage tolerant design by microstructural gradation—Influence of processing parameters and build orientation on crack growth within additively processed 316 L. Mater. Sci. Eng. A 2019, 764, 138186. [Google Scholar] [CrossRef]

- Henkel, S.; Biermann, H. Kennwertermittlung bei zyklischem Langrisswachstum. In Moderne Methoden der WerkstoffprüFung; Biermann, H., Krüger, L., Eds.; Wiley-VCH: Weinheim, Germany, 2015; pp. 53–81. ISBN 9783527334131. [Google Scholar]

- Zerbst, U.; Vormwald, M.; Pippan, R.; Gänser, H.-P.; Sarrazin-Baudoux, C.; Madia, M. About the fatigue crack propagation threshold of metals as a design criterion—A review. Eng. Fract. Mech. 2016, 153, 190–243. [Google Scholar] [CrossRef]

- Klassen, A.; Scharowsky, T.; Körner, C. Evaporation model for beam based additive manufacturing using free surface lattice Boltzmann methods. J. Phys. D Appl. Phys. 2014, 47, 275303. [Google Scholar] [CrossRef]

- Dubberstein, T.; Hötzel, M.; Hagemann, R.; Heller, P.; Scheller, P.R. Some thermophysical properties of liquid Cr-Mn-Ni-steels. Steel Res. Int. 2011, 82, 1122–1128. [Google Scholar] [CrossRef]

- Das, S. Physical aspects of process control in selective laser sintering of metals. Adv. Eng. Mater. 2003, 5, 701–711. [Google Scholar] [CrossRef]

- Plekhov, O.; Paggi, M.; Naimark, O.; Carpinteri, A. A dimensional analysis interpretation to grain size and loading frequency dependencies of the Paris and Wöhler curves. Int. J. Fatigue 2011, 33, 477–483. [Google Scholar] [CrossRef]

- Ma, P.; Qian, L.; Meng, J.; Liu, S.; Zhang, F. Fatigue crack growth behavior of a coarse- and a fine-grained high manganese austenitic twin-induced plasticity steel. Mater. Sci. Eng. A 2014, 605, 160–166. [Google Scholar] [CrossRef]

- Jambor, M.; Vojtek, T.; Pokorný, P.; Šmíd, M. Effect of Solution Annealing on Fatigue Crack Propagation in the AISI 304L TRIP Steel. Materials 2021, 14, 1331. [Google Scholar] [CrossRef]

- Deng, R.; Yu, G.; Li, H. Effect of grain size on slow fatigue crack propagation and plastic deformation near crack tip. Theor. Appl. Fract. Mech. 1987, 7, 37–40. [Google Scholar] [CrossRef] [Green Version]

- Robin, C.; Pluvinage, G. Fatigue threshold in a 2618A aluminium alloy. Fatigue Fract. Eng. Mater. Struct. 1980, 3, 147–157. [Google Scholar] [CrossRef]

- McEvily, A.J.; Gonzalez Velazquez, J.L. Fatigue crack tip deformation. MTA 1992, 23, 2211–2221. [Google Scholar] [CrossRef]

- McEvily, A.J.; Gonzalez, J.L.; Hallen, J.M. Dislocation substructures at fatigue crack tips of 304 stainless steel cycled in air or vaccum. Scr. Mater. 1996, 35, 761–765. [Google Scholar] [CrossRef]

- Petit, J.; Hénaff, C.; Sarrazin-Baudoux, C. Environmentally assisted fatigue in the gaseous atmosphere. In Comprehensive Structural Integrity: Fracture of Materials from Nano to Macro; Milne, I., Ed.; Elsevier Pergamon: Amsterdam, The Netherlands, 2003; pp. 211–280. ISBN 0-08-043749-4. [Google Scholar]

- Carter, R.D.; Lee, E.W.; Starke, E.A.; Beevers, C.J. The effect of microstructure and environment on fatigue crack closure of 7475 aluminum alloy. Metall. Mater. Trans. A 1984, 15, 555–563. [Google Scholar] [CrossRef]

- Gudladt, H.-J.; Petit, J. Stage II crack propagation of Al-Zn-Mg-single crystals in dry and wet atmospheres. Scr. Metall. Mater. 1991, 25, 2507–2512. [Google Scholar] [CrossRef]

- Stanzl-Tschegg, S.; Schönbauer, B. Near-threshold fatigue crack propagation and internal cracks in steel. Procedia Eng. 2010, 2, 1547–1555. [Google Scholar] [CrossRef] [Green Version]

- Suresh, S.; Ritchie, R.O. On the influence of environment on the load ratio dependence of fatigue thresholds in pressure vessel steel. Eng. Fract. Mech. 1983, 18, 785–800. [Google Scholar] [CrossRef]

- Kelestemur, M.; Chaki, T. The effect of various atmospheres on the threshold fatigue crack growth behavior of AISI 304 stainless steel. Int. J. Fatigue 2001, 23, 169–174. [Google Scholar] [CrossRef]

- Vichytil, C.; Mori, G.; Pippan, R.; Panzenböck, M.; Fluch, R. Crack Growth Rates and Corrosion Fatigue of Austenitic Stainless Steels in High Chloride Solutions. KEM 2011, 488-489, 97–100. [Google Scholar] [CrossRef]

- Wendler, M.; Weiß, A.; Krüger, L.; Mola, J.; Franke, A.; Kovalev, A.; Wolf, S. Effect of manganese on microstructure and mechanical properties of cast high alloyed CrMnNi-N steels. Adv. Eng. Mater. 2013, 15, 558–565. [Google Scholar] [CrossRef]

| Manufacturing Technology | Cr (wt.%) | Mn (wt.%) | Ni (wt.%) | C (wt.%) | N (wt.%) | Si (wt.%) | d10 (µm) | d50 (µm) | d90 (µm) |

|---|---|---|---|---|---|---|---|---|---|

| PBF-EB | 15.8 | 6.4 | 5.9 | 0.05 | 0.04 | 0.9 | 47.8 | 72.5 | 118.8 |

| HP | 16.4 | 7.1 | 6.3 | 0.02 | 0.06 | 0.1 | 12.4 | 25.9 | 46.6 |

| Batch | Type | CGD↔BD (↑ BD) | Evol (J/mm3) | vs (mm/s) | l (µm) | IB (mA) | Mn (wt.%) |

|---|---|---|---|---|---|---|---|

| A48pa | homogenous |  | 48 | 2500 | 75 | 7.5 | 4.4 |

| A48pe |  | 48 | 2500 | 75 | 7.5 | ||

| A30pa |  | 30 | 4000 | 75 | 7.5 | 4.0 | |

| A30pe |  | 30 | 4000 | 75 | 7.5 | ||

| B50pa |  | 50 | 2000 | 90 | 7.5 | 4.5 | |

| B50pe |  | 50 | 2000 | 90 | 7.5 | ||

| B33pa |  | 33.3 | 3000 | 90 | 7.5 | 5.2 | |

| B33pe |  | 33.3 | 3000 | 90 | 7.5 | ||

| C30 → 70 | graded |  | 70.6 | 1700 | 75 | 7.5 | 2.9 |

| 30 | 4000 | 75 | 7.5 | 5.1 | |||

| C70 → 30 |  | 70.6 | 1700 | 75 | 7.5 | 4.0 | |

| 30 | 4000 | 75 | 7.5 | 5.2 | |||

| C30 → 70 + 8 |  | 1st exp.: 70.6 2nd exp.: 8 | 1700 5000 | 75 15 | 7.5 5 | 3.1 | |

| 30 | 4000 | 75 | 7.5 | 5.2 | |||

| C70 + 8 → 30 |  | 1st exp.: 70.6 2nd exp.: 8 | 1700 5000 | 75 15 | 7.5 5 | 3.8 | |

| 30 | 4000 | 75 | 7.5 | 5.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Droste, M.; Wagner, R.; Günther, J.; Burkhardt, C.; Henkel, S.; Niendorf, T.; Biermann, H. Cyclic Crack Growth in Chemically Tailored Isotropic Austenitic Steel Processed by Electron Beam Powder Bed Fusion. Materials 2021, 14, 6544. https://doi.org/10.3390/ma14216544

Droste M, Wagner R, Günther J, Burkhardt C, Henkel S, Niendorf T, Biermann H. Cyclic Crack Growth in Chemically Tailored Isotropic Austenitic Steel Processed by Electron Beam Powder Bed Fusion. Materials. 2021; 14(21):6544. https://doi.org/10.3390/ma14216544

Chicago/Turabian StyleDroste, Matthias, Ruben Wagner, Johannes Günther, Christina Burkhardt, Sebastian Henkel, Thomas Niendorf, and Horst Biermann. 2021. "Cyclic Crack Growth in Chemically Tailored Isotropic Austenitic Steel Processed by Electron Beam Powder Bed Fusion" Materials 14, no. 21: 6544. https://doi.org/10.3390/ma14216544

APA StyleDroste, M., Wagner, R., Günther, J., Burkhardt, C., Henkel, S., Niendorf, T., & Biermann, H. (2021). Cyclic Crack Growth in Chemically Tailored Isotropic Austenitic Steel Processed by Electron Beam Powder Bed Fusion. Materials, 14(21), 6544. https://doi.org/10.3390/ma14216544