Abstract

Diatomite-based X zeolite was obtained and its crystallinity, morphology, and interface properties were investigated by XRD, BET, SEM, EDS, and XRF. The obtained X zeolite possessed a unique meso-microporous structure and showed good ion exchange properties for Cu2+ and Zn2+. The pseudo-second-order model and Langmuir isotherm model can best describe the adsorption kinetics and isotherms of Cu2+ and Zn2+, respectively. The maximal adsorption capacities of X zeolite for Cu2+ and Zn2+ were 146 and 195 mg/g at 323 K, respectively. Meanwhile, the adsorption process for Cu2+ and Zn2+ were chemical adsorption and ion exchange, respectively. Furthermore, the adsorption data turned out to be an endothermic and spontaneous process. Compared with other reported materials, the adsorption capacity of X zeolite synthesized from diatomite was among the highest. Therefore, it could be a promising adsorbent for the disposal of wastewater that contains metal ions.

1. Introduction

Nowadays, Water pollution has turned out to be more and more serious in the world and especially in developing countries. Heavy metal pollution [1] usually occurred from many industries, such as electroplating, metal mining operations, battery manufacturing, tanneries, fertilizer industries, and leather industries. Furthermore, the US Environmental Protection Agency designated heavy metals as “priority pollutants”, because they are unbiodegradable and tend to accumulate in living organisms [2]. Among these heavy metals, Cu2+ and Zn2+ are special, because they played an important role in living organisms and act as micronutrients with trace amounts. However, intake of excess Cu2+ might cause vomiting, shock, liver and kidney failure, or even death. Excessive intake of Zn2+ can also cause serious health problems, such as diarrhea, fever, or even acute gastrointestinal disturbances accompanied by nausea. Therefore, we must regulate the maximum allowed concentrations of Cu2+ and Zn2+ before releasing them into surface waters. To meet the strict environmental regulations and the rising demands for water quality, the safe disposal of heavy metal pollution has become more and more important and urgent.

Currently, the disposal methods of heavy metals from the aqueous system are usually chemical precipitation [3], coagulation [4,5,6,7], membrane separation [8], photocatalytic degradation [9], extraction [10], chemical oxidation, and reduction [11], biological treatment [12] and adsorption technologies [13,14]. Among all these methods, adsorption is highly effective and economical. In addition, the great advantages of adsorption over others are the low generation of residues, the possibility of large-scale processing, easy metal recovery, and the possibility of the reuse of the adsorbents [15]. Therefore, different types of materials have been developed as adsorbents for the removal of heavy metals, such as modified natural minerals [16,17], activated carbon [18], polymer [19,20], modified metal oxides [21,22,23] and zeolite [24,25].

Zeolites are well-known adsorbents as they can easily absorb and exchange metal ions with positive charges in their framework because they possess the net negative charges generated from the isomorphic substitution of Si4+ by Al3+ due to the compensation by alkali and alkaline-earth metal ions. Meanwhile, the greatest advantage of zeolites over other adsorbents is that they also show ion exchange selectivity. Because they have a three-dimensional framework constructed by tetrahedral units and then linked by shared oxygen atoms to create cavities and channels of different dimensions to control ion selectivity in zeolite structures. In addition, they are highly porous aluminosilicates with different cavity structures that offer large internal and external surface areas, which are beneficial for adsorption [26,27].

Here, we synthesized X zeolite from diatomite. And systematically characterized their physicochemical properties via various techniques. Then we evaluated the adsorption performance of the obtained sample via the removal of Cu2+ and Zn2+. To the best of our knowledge, the removal of Cu2+ and Zn2+ by X zeolite synthesized from diatomite has not been investigated. This work demonstrates the potential performance of X zeolite for the removal of Cu2+ and Zn2+ in industrial effluent. Moreover, we systematically studied the adsorption kinetics, isotherms, thermodynamics, and the adsorption mechanisms of X zeolite for Cu2+ and Zn2+.

2. Experiments

2.1. Materials

Diatomite (Linjiang, China), copper(II) chloride dehydrate (CuCl2·2H2O), sodium hydroxide (NaOH), zinc sulfate heptahydrate (ZnSO4·7H2O), aluminum hydroxide (Al(OH)3), hydrochloric acid (HCl). The whole reagents were analytical reagent grade, and distilled water was used in all the experiments.

2.2. Batch Adsorption Experiments

We synthesized X zeolite as reported in our previous work [26,28]. And then we investigated its adsorption behaviors via bath experiments. First, forty milligrams of X zeolite was added into 40 mL of Cu2+ or Zn2+ solution of different initial concentrations and different temperatures. Then the concentration of Cu2+ or Zn2+ solution was measured at adsorption equilibrium and the amount of the adsorbed Cu2+ and Zn2+ was determined as follows.

where qe (mg/g) is the adsorption capacity at equilibrium, v (mL) is the volume of aqueous solution, m (g) is the dosage of the adsorbent, ci (mg/L) is the initial concentration of Cu2+ or Zn2+ solution, ce (mg/L) is the equilibrium concentration of Cu2+ or Zn2+ solution.

Similarly, the effects of initial solution pH on the adsorption of Cu2+ or Zn2+ were studied by adjusting the pH value. First, we studied the adsorption kinetics and added 40 mg of X zeolite into 40 mL of Cu2+ or Zn2+ solutions with an initial concentration of 200 mg/L, 250 mg/L, 300 mg/L, and 350 mg/L in order to determine the minimum time needed for equilibrium. Furthermore, we measured the concentrations of Cu2+ or Zn2+solution at fixed intervals. Then we studied the thermodynamic properties and added 40 mg of X zeolite into 40 mL of Cu2+ or Zn2+ solution with different initial concentrations at temperatures of 303, 313, and 323 K. All adsorption experiments here were carried out using three replicates and the average values were displayed.

3. Results and Discussion

3.1. Adsorption Experiments

3.1.1. Kinetic Models

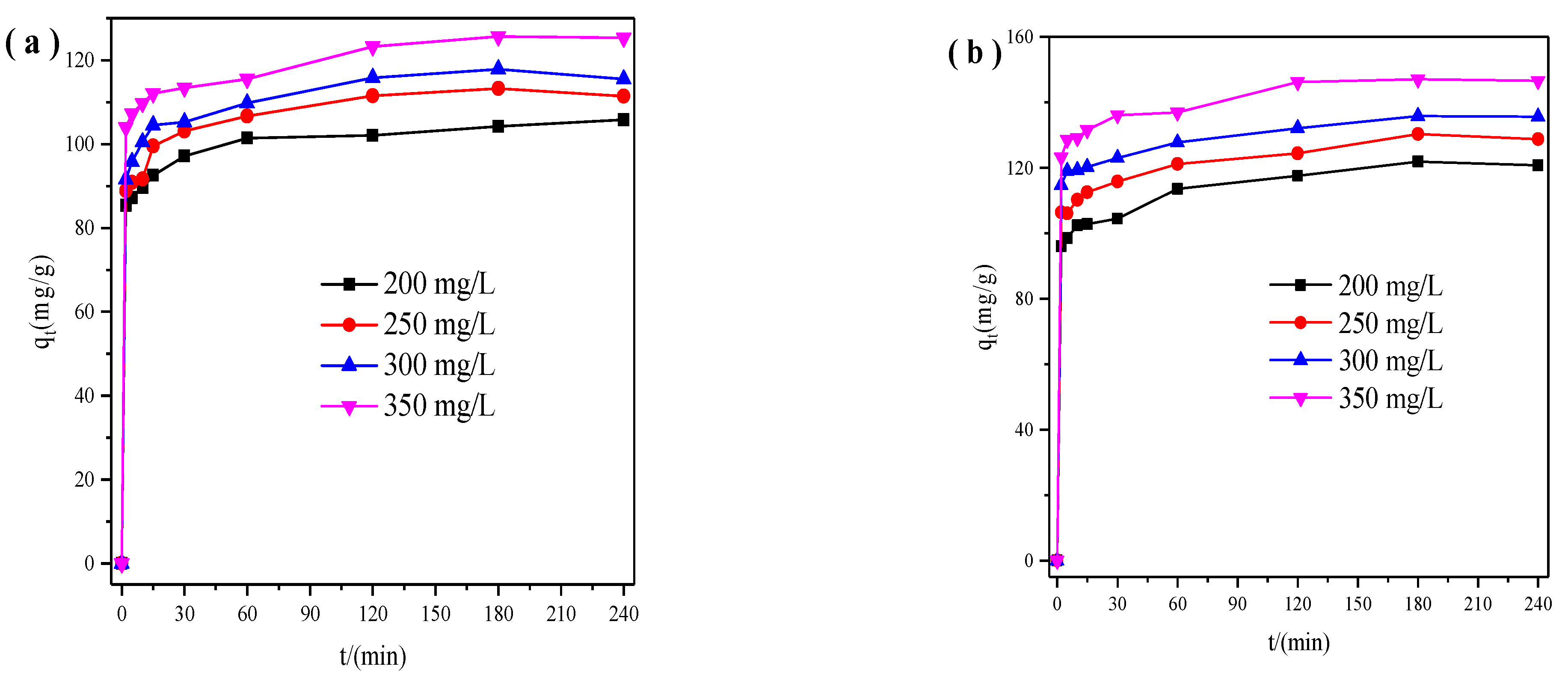

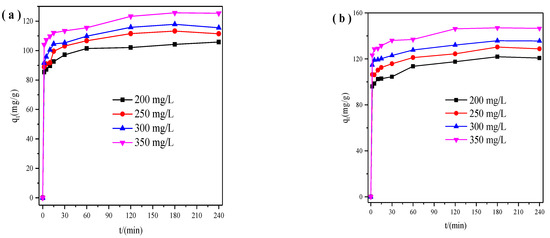

First, we studied the adsorption behavior of X zeolite for Cu2+ and Zn2+ and then got the relationship between time and adsorption capacity (Figure 1). The adsorption capacity of X zeolite for Cu2+ and Zn2+ grew fast within 15 min, and then slowly reached up to adsorption equilibrium within 2 h. The easily accessible sorption sites and high surface area of the adsorbent contributed to the rapid adsorption. Meanwhile, the equilibrium adsorption capacities of X zeolite for Cu2+ or Zn2+ went up at higher concentrations. The equilibrium adsorption capacities for Cu2+ and Zn2+ increased from 104 and 122 mg/g to 126 and 147 mg/g when Cu2+ and Zn2+ concentration increased from 200 to 350 mg/L, respectively. The adsorption capacities of Cu2+ and Zn2+ increased with their initial concentration raising, due to the higher driving force produced by the concentration gradient [29].

Figure 1.

Relationship between time and adsorption capacity of X zeolite for Cu2+ (a) and Zn2+ (b) with different concentrations.

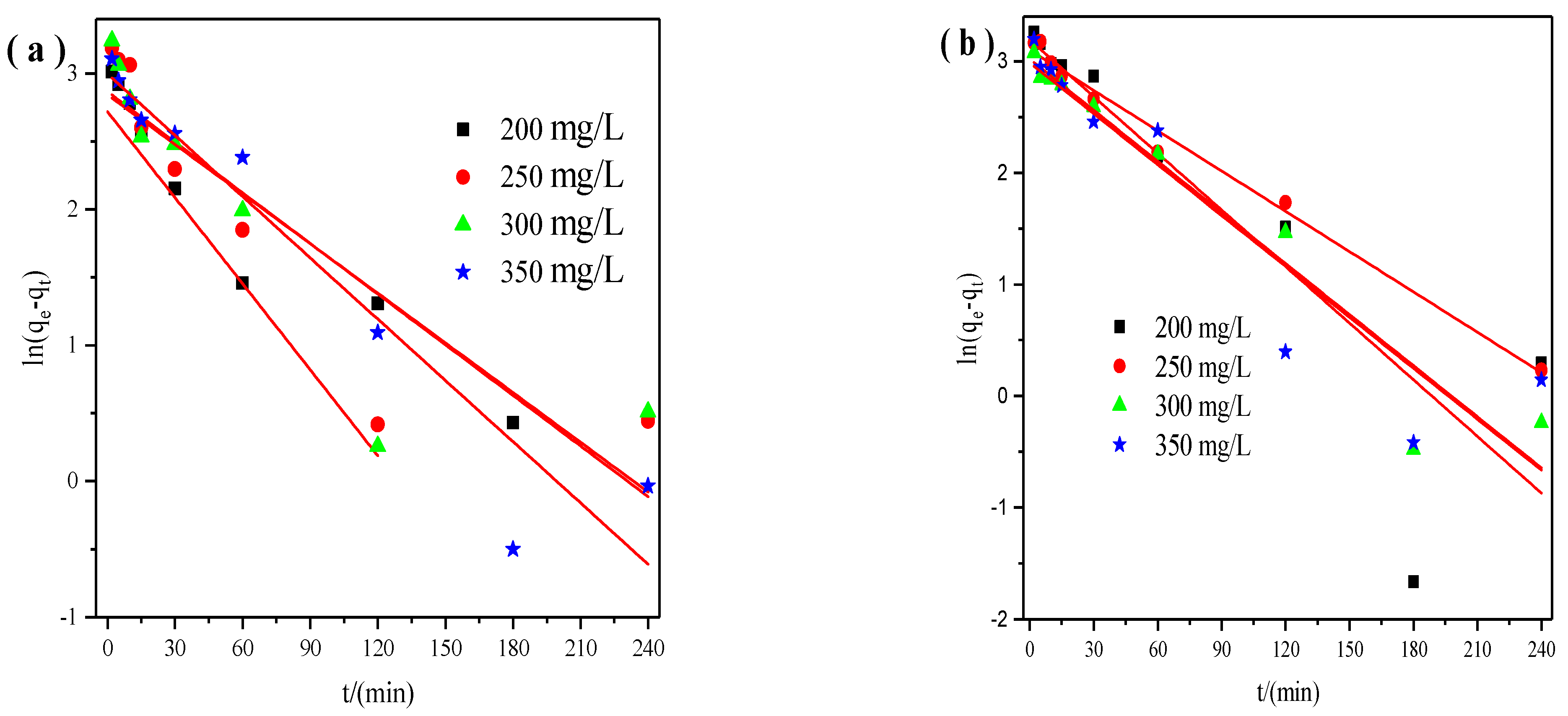

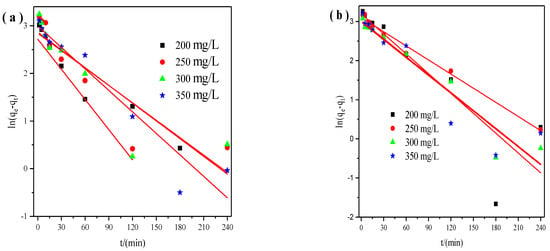

Then we utilized the pseudo-first and pseudo-second-order model to evaluate the adsorption mechanism of X zeolite for Cu2+ and Zn2+ during the adsorption process. The pseudo-first-order model was shown in the following form [30]:

where k1 (min−1) is the rate constant of pseudo-first-order reaction, qe (mg/g) is the equilibrium adsorption capacity of X zeolite for Cu2+ or Zn2+, qt (mg/g) is the adsorption capacity of X zeolite for Cu2+ or Zn2+ at any time t. From the linear plot of ln(qe − qt) versus t (Figure 2), both qe and k1 can be obtained.

ln(qe − qt) = lnqe − k1t

Figure 2.

Pseudo−first order model of X zeolite for Cu2+ (a) and Zn2+ (b).

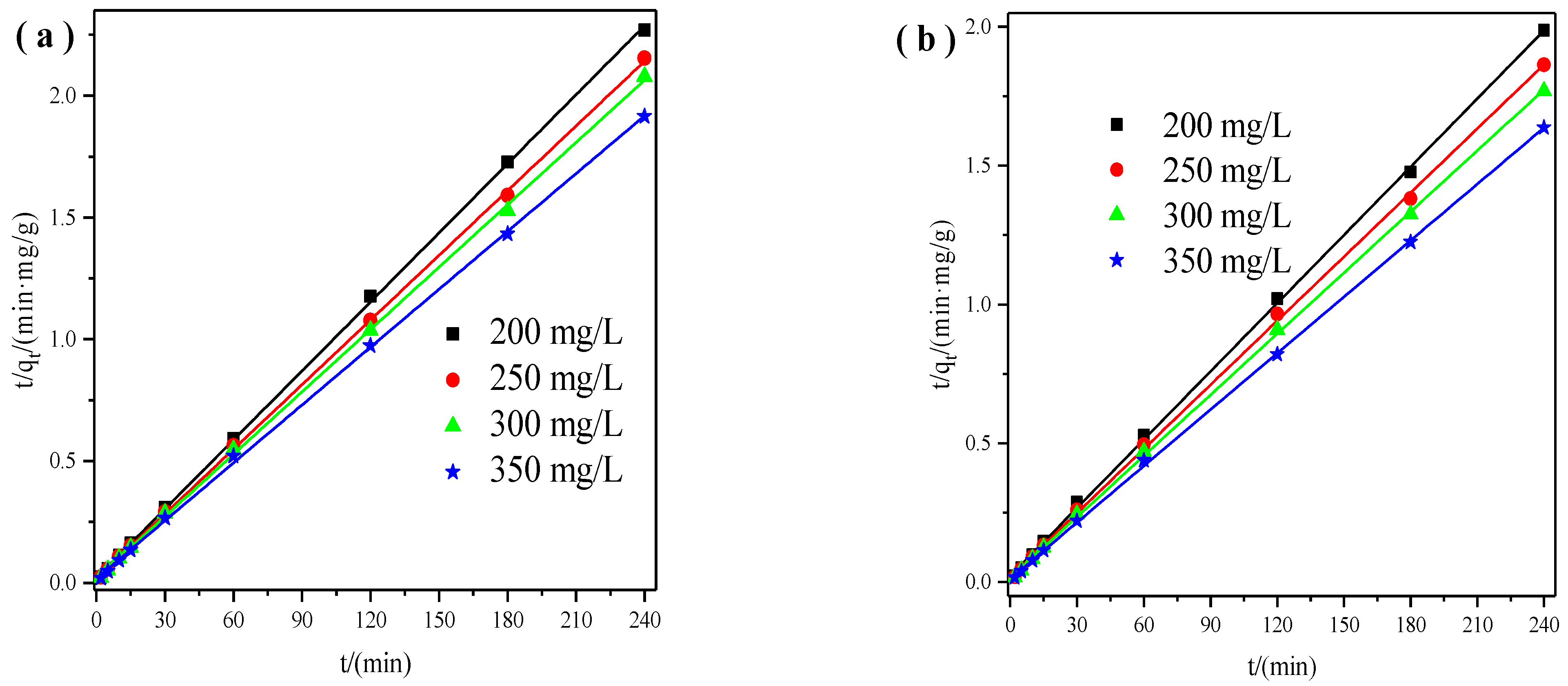

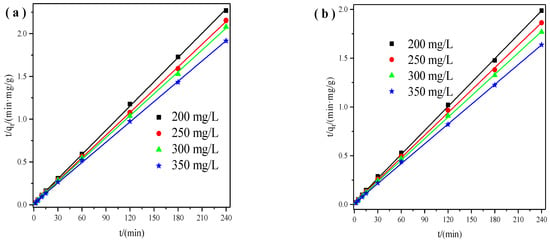

The pseudo−second order model was displayed in the following format [31]:

where k2 (min−1) is the rate constant of pseudo-second-order reaction and h [mg/(g·min)] is the initial sorption rate. The rate constants can be determined via the linear plot t/qt against t (Figure 3).

h = k2qe2

Figure 3.

Pseudo−second order model of X zeolite for Cu2+ (a) and Zn2+ (b).

Table 1 and Table 2 summarized the calculated parameters of the pseudo-first and pseudo-second-order model. The correlation coefficients (R2) of the pseudo-second-order model ranged from 0.9995 to 0.9997, and the pseudo-second-order model ranged from 0.7519 to 0.0.9867. The correlation coefficients suggested that the adsorption kinetics can best fit the pseudo-second-order model, which indicates that chemical sorption played an important effect during its adsorption process. It may be owing to the exchange of electrons between X zeolite and Cu2+ or Zn2+ metal ions [32]. Meanwhile, it found that the values of initial sorption rate (h) increased at a higher initial concentration, which indicated that a higher driving force produced by the concentration gradient can promote the adsorption process [22]. Furthermore, the maximum adsorption capacities for Cu2+ and Zn2+ could reach 126 and 148 mg/g, respectively.

Table 1.

Parameters of the pseudo−second order model.

Table 2.

Parameters of pseudo−first order model.

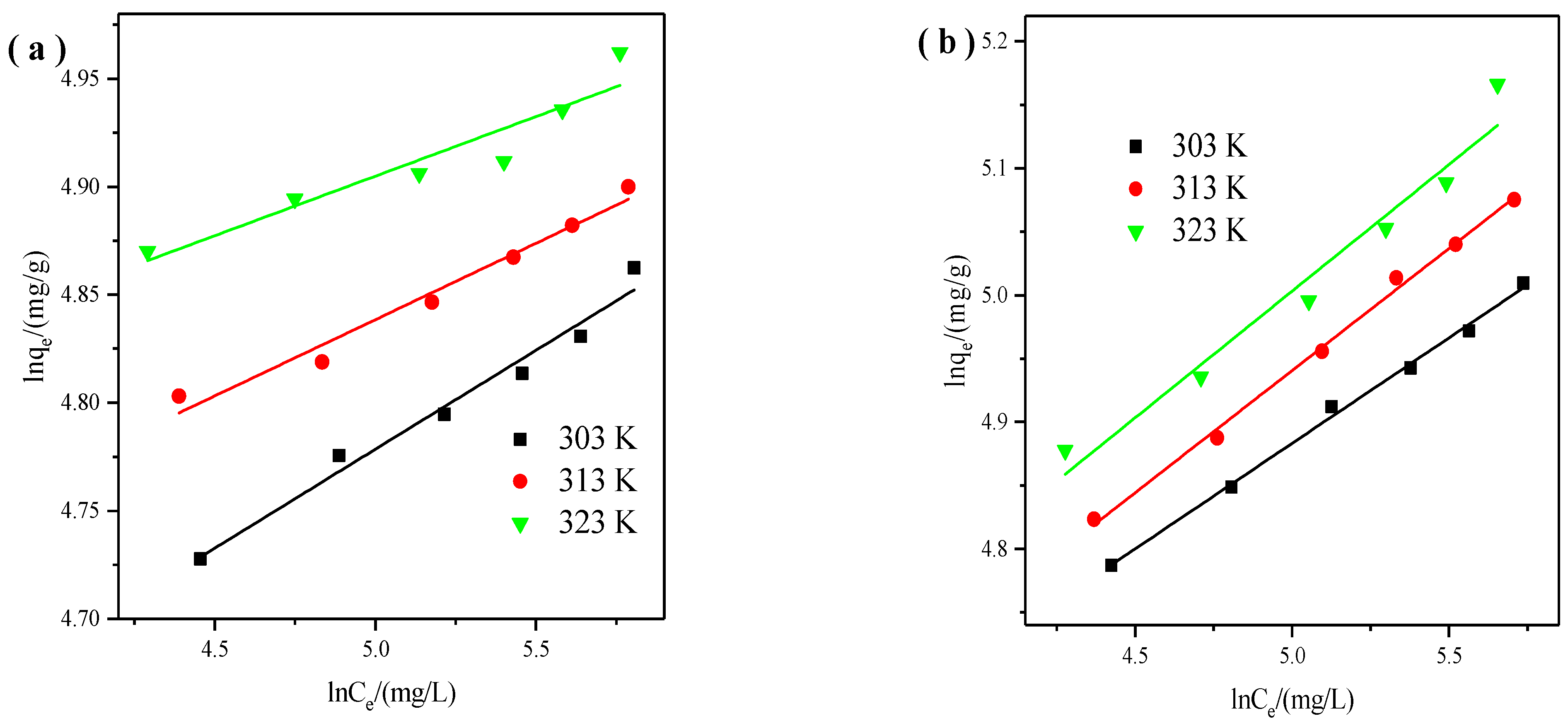

3.1.2. Isotherm Models

To get a deep understanding of the surface property of X zeolite and maximum adsorption capacity, three classic physical isotherm models [32] were utilized to describe the adsorption mechanism of Cu2+ or Zn2+ by X zeolite.

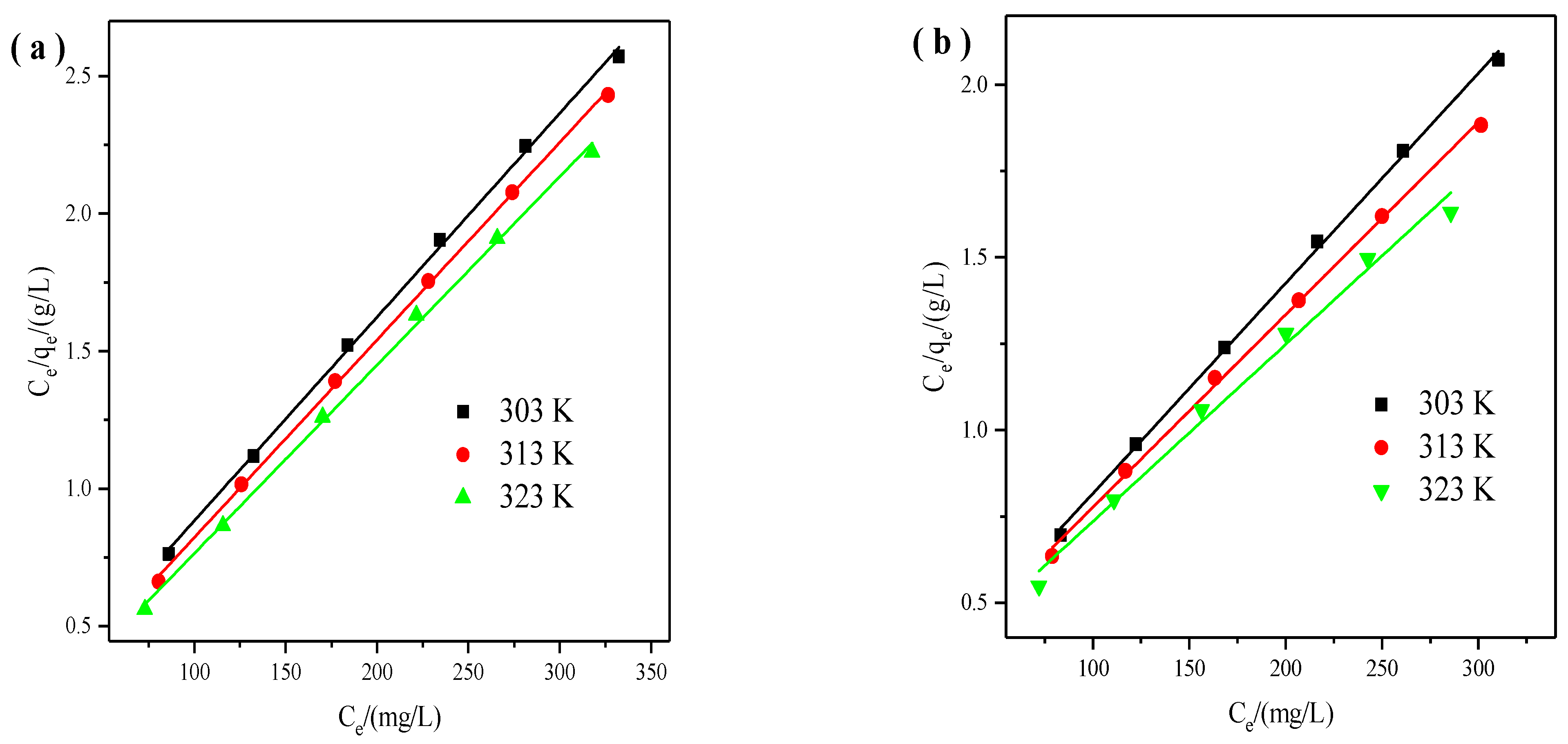

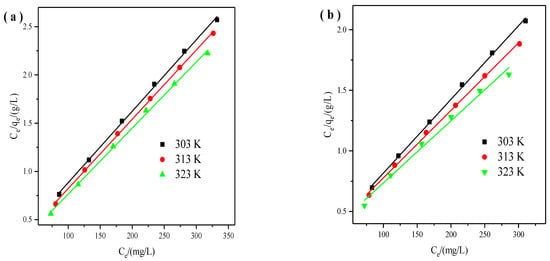

We used the Langmuir isotherm model to describe the relationship between Cu2+ or Zn2+ solution and the surface of X zeolite. And the Langmuir isotherm model was expressed in the following format [33]:

where KL (L/mg) is the Langmuir constant related to the adsorption energy, qm (mg/g) is the maximum adsorption capacity of X zeolite. From the linear plot of Ce/qe against Ce (Figure 4), Both qm and KL can be determined.

Figure 4.

Langmuir isotherms of X zeolite for Cu2+ (a) and Zn2+ (b).

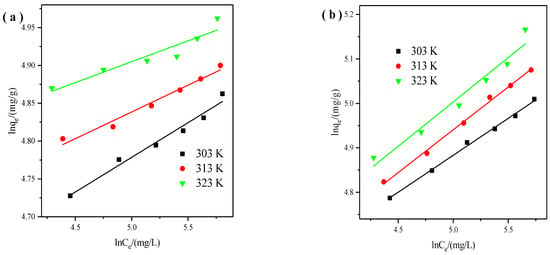

Meanwhile, We used the Freundlich isotherm model to describe the heterogeneous systems [31]. The equation is described in the following format:

where KF is related to the adsorption capacity, n is related to the adsorption intensity. From data correlation (Figure 5), both n and KF can be determined.

Figure 5.

Freundlich isotherms of X zeolite for Cu2+ (a) and Zn2+ (b).

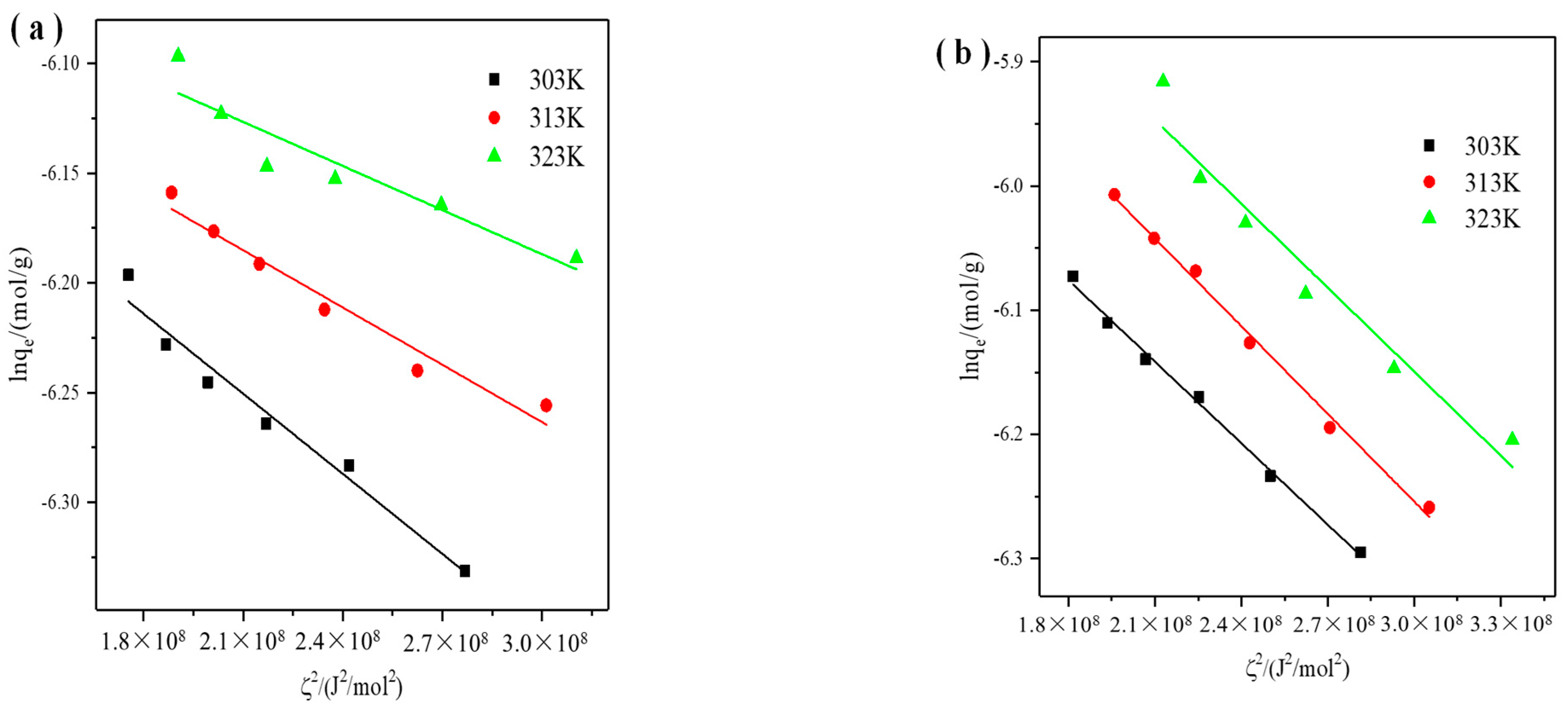

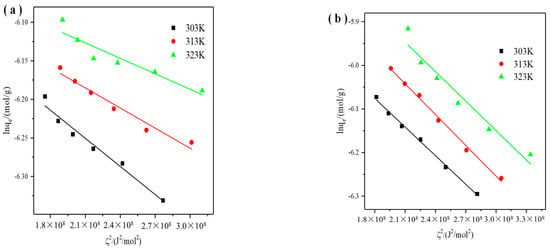

The Dubinin-Radushkevich (D−R) isotherm model is generally used to estimate the adsorption mechanism (physical or chemical adsorption) of microporous adsorbents, which was based on the adsorption potential theory. The adsorption potential theory reflected the change in the Gibbs free energy of an adsorbent after adsorbing a unit molar mass of adsorbate. The equation is expressed as follows:

where qe (mol/g) is the quantity of adsorbate adsorbed by the adsorbent, qmax (mol/g) is the quantity of maximum adsorption capacity of the adsorbent (mol/g). R (8.314/(mol·K)) is the universal gas constant, T (K) is the absolute solution temperature. β (mol2/J2) and ζ (J/mol) are the constants related to adsorption energy and Polanyi adsorption potential, respectively. Ce is the equilibrium concentration (mol/L). From the linear plot of lnqe against ζ2 (Figure 6), both qm and β can be determined. E is the mean free energy of adsorption, which is applied to distinguish the adsorption type. When the magnitude of E is below 8 KJ/mol, the adsorption process is physical adsorption. When the magnitude of E is between 8 and 16 KJ/mol, the adsorption process is ion exchange. When the magnitude of E is above 16 KJ/mol, the adsorption process is chemical adsorption.

Figure 6.

D-R isotherms of X zeolite for Cu2+ (a) and Zn2+ (b).

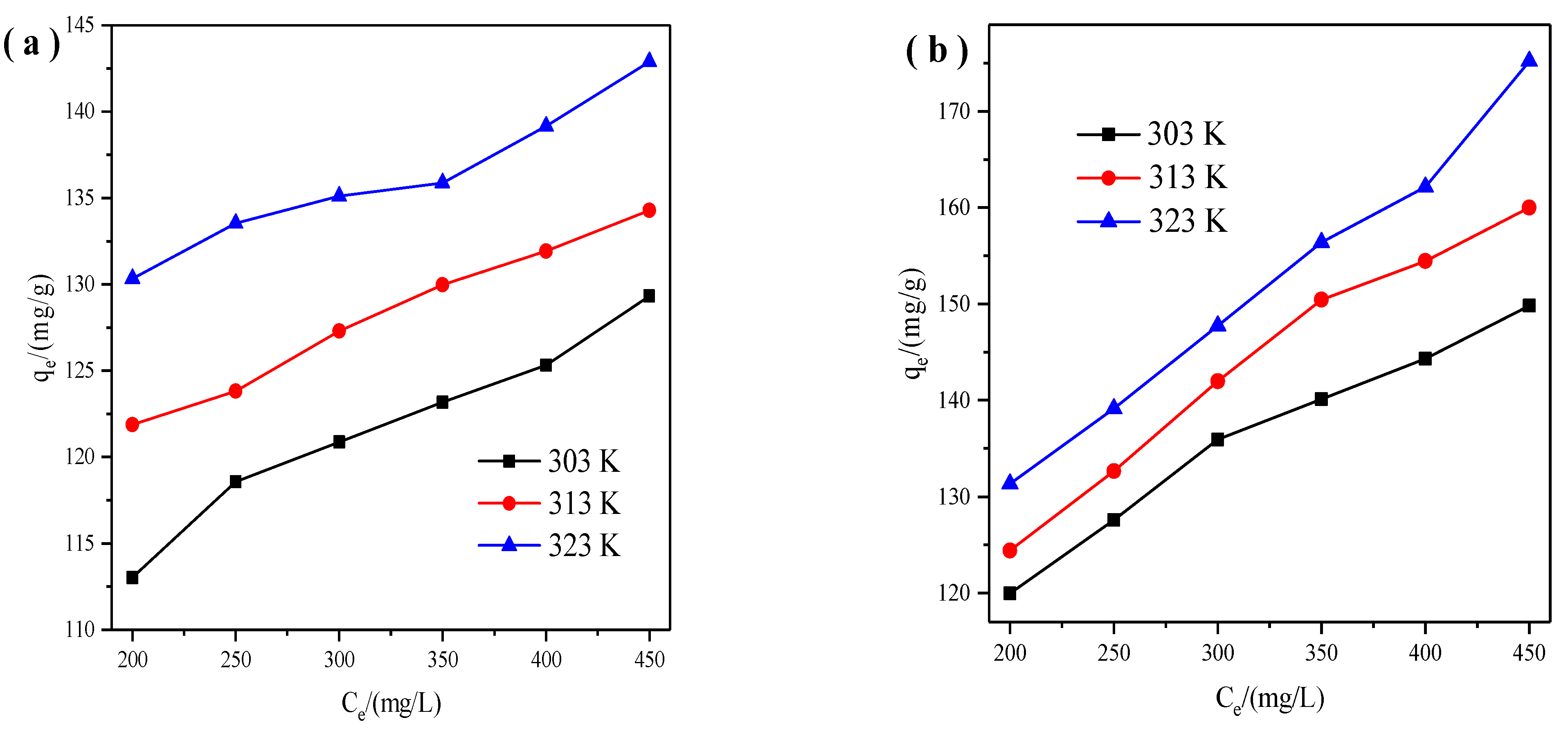

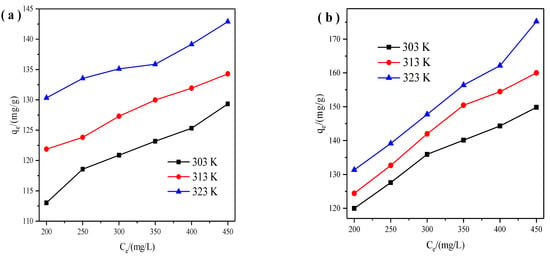

We handled the experiments at 303 K, 313 K, and 323 K, and the results are displayed in Figure 7. It can be found that the adsorption capacities of X zeolite for Cu2+ and Zn2+ reached as the temperature went up, which indicated the endothermic process.

Figure 7.

Adsorption isotherms of X zeolite for Cu2+ (a) and Zn2+ (b).

Table 3, Table 4 and Table 5 summarized the calculated parameters of Langmuir, Freundlich, and D-R isotherms. All the correlation coefficient values (R2) of the Langmuir, Freundlich, and D-R models are high. However, the Langmuir model correlation coefficient (R2) values of Cu2+ and Zn2+ were a little higher demonstrating that the adsorption data followed well with the Langmuir isotherm. These results indicated that Cu2+ and Zn2+ were unevenly adsorbed in the form of monolayer coverage. The KL constant of the Langmuir parameters demonstrated the binding affinity between X zeolite and Cu2+ or Zn2+ [34]. The KL values of Cu2+ range from 0.0521 to 0.0865, and the KL values range from 0.0230 to 0.0293. The KL values suggested that X zeolite possesses stronger adsorption of Cu2+ than those of Zn2+. The n values of Freundlich isotherms for Cu2+ and Zn2+ were all more than 1 at 303, 313, 323 K demonstrating the facile adsorption between X zeolite and Cu2+ or Zn2+ [35]. Meanwhile, higher adsorption capacities were obtained at higher temperatures suggesting the endothermic nature. In addition, the theoretical maximum adsorption capacities for Cu2+ and Zn2+ by the D-R isotherm model are higher. It may be due to that there are still many active adsorption sites in the micropore when the surface adsorption of X zeolite reaches saturation. And the internal diffusion rate of heavy metals is slow, which decreased the binding chance between heavy metals and adsorption sites in X zeolites, thus resulting in a smaller adsorption capacity. The values of E for Cu2+ are above 16 kJ/mol suggesting that the adsorption process is chemical adsorption. The values of E for Zn2+ are between 8 and 16 kJ/mol demonstrating that the adsorption process is ion exchange. The values of E for Cu2+ range from 20.27 to 27.32 kJ/mol, and the values of E for Zn2+ range from 14.58 to 15.13 kJ/mol. The values of E suggested that X zeolite possesses stronger adsorption of Cu2+ than those of Zn2+, which is consistent with the characteristics of Cu2+ and Zn2+. Therefore, the prepared X zeolite probably possessed selective adsorption towards Cu2+ [27]. Moreover, the maximum adsorption capacities of X zeolite for Cu2+ and Zn2+ can reach 146 and 195 mg/g, respectively.

Table 3.

Parameters of Langmuir and Freundlich isotherms for the adsorption of Cu2+.

Table 4.

Parameters of Langmuir and Freundlich isotherms for the adsorption of Zn2+.

Table 5.

Parameters of D-R isotherms for the adsorption of Cu2+ and Zn2+.

In addition, we compared the adsorption capacities of X zeolite for Cu2+ and Zn2+ with some other reported materials. As shown in Table 6 and Table 7, the prepared X zeolite possessed higher adsorption capacities for Cu2+ and Zn2+ than those of other reported adsorbents. Meanwhile, the present synthetic method of X zeolite is environmentally friendly and perhaps low-cost compared with other methods. Therefore, X zeolite prepared from diatomite could be a candidate for removing Cu2+ and Zn2+ from wastewater.

Table 6.

Comparison of adsorption capacities of various adsorbents for Cu2+.

Table 7.

Comparison of adsorption capacities of various adsorbents for Zn2+.

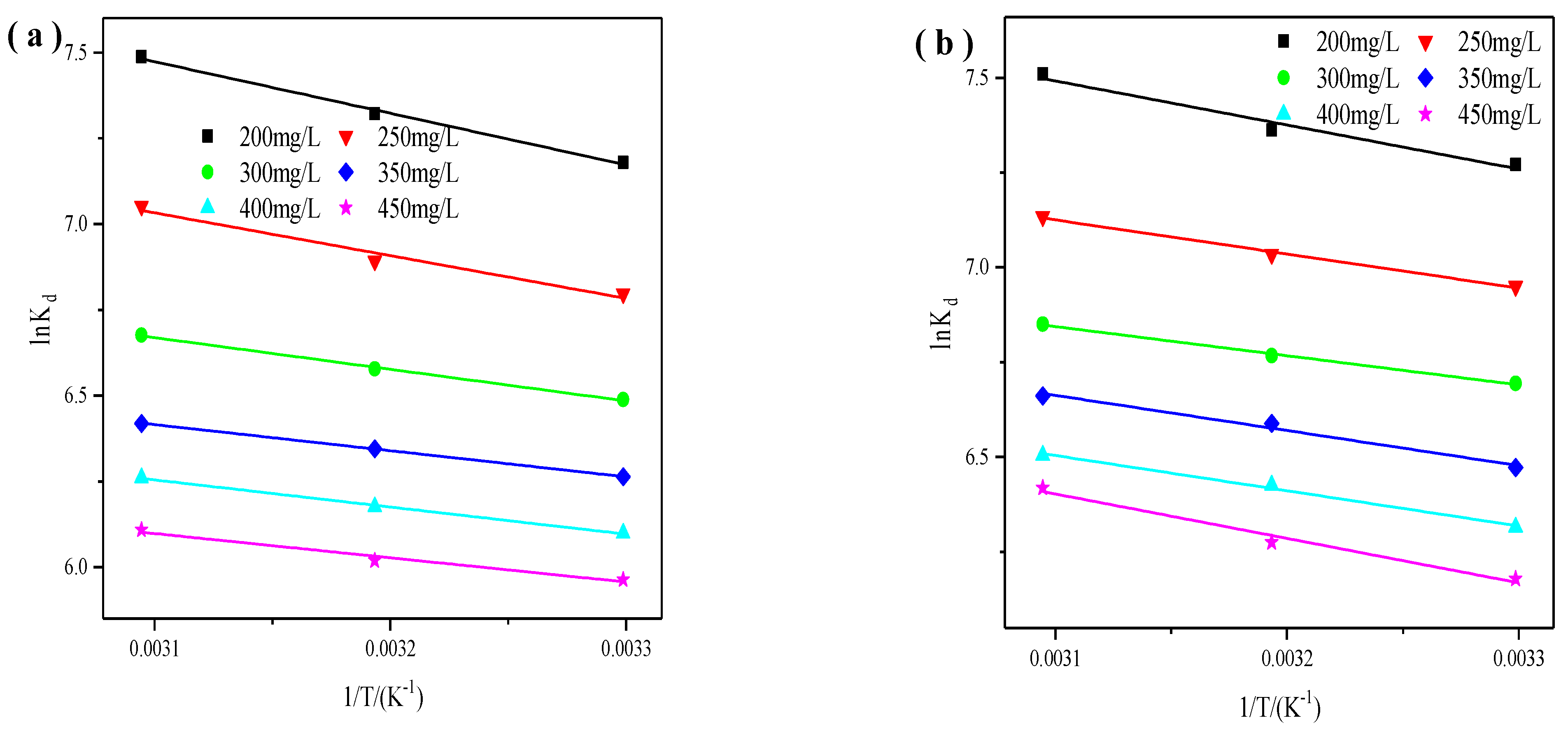

3.1.3. Adsorption thermodynamics

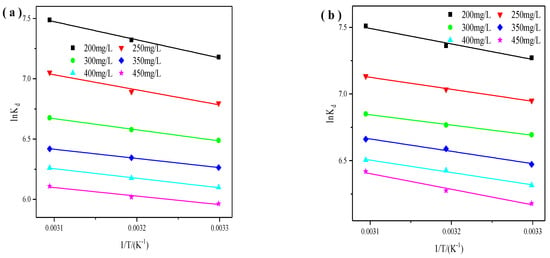

Generally, we can get more detailed data of internal energy within the adsorption process through the study of thermodynamics. And the thermodynamic parameters for the adsorption of Cu2+ and Zn2+ can be described in the following format [41].

where ΔG0 (kJ/mol) is the standard free energy, ΔS0 (J/K) is the standard entropy, ΔH0 (kJ/mol) is the standard enthalpy, R (8.314/(molK)) is the universal gas constant, T (K) is the absolute solution temperature, Kd is the distribution coefficient. Finally, we can get the ΔG0, ΔH0, and ΔS0, and they are presented in Figure 8.

Figure 8.

Plot of LnKd versus 1/T at various initial concentrations of Cu2+ (a) and Zn2+ (b).

The calculated thermodynamic parameters of Cu2+ and Zn2+ were listed in Table 8 and Table 9, respectively. The values of ΔH0 for Cu2+ and Zn2+ range from 5.88 to 12.52 KJ/mol, and the values of ΔS0 for Cu2+ and Zn2+ range from 68.92 to 100.92 J/mol. They demonstrated the endothermic nature and good affinity of X zeolite for Cu2+ and Zn2+ metal ions, respectively. And positive ΔS0 values of Cu2+ and Zn2+ suggested the increased randomness between the interface of X zeolite and Cu2+ or Zn2+. However, ΔS0 for Cu2+ and Zn2+ went down as their initial concentration went up, which is consistent with the previous literature [42]. The values of ΔG0 for Cu2+ and Zn2+ at three temperatures are all negative indicating the feasible and spontaneous nature. Moreover, ΔG0 for Cu2+ and Zn2+ all went down with temperature went up indicating the spontaneous nature with high affinity [43]. The ΔG0 for Cu2+ and Zn2+ went up as their initial concentration increased, which is also in accordance with the previous work [32].

Table 8.

Thermodynamic parameters for Cu2+ adsorption.

Table 9.

Thermodynamic parameters for Zn2+ adsorption.

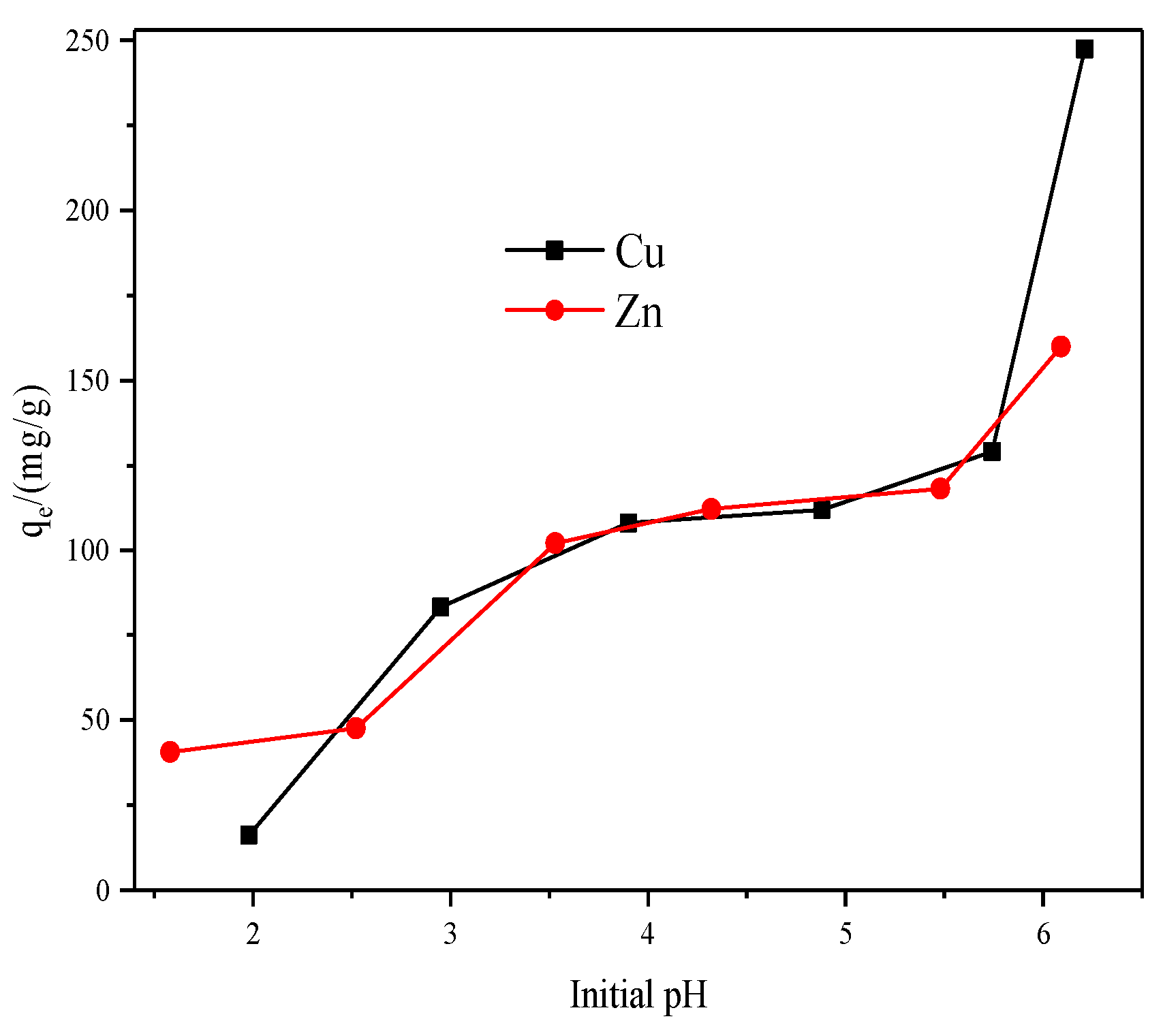

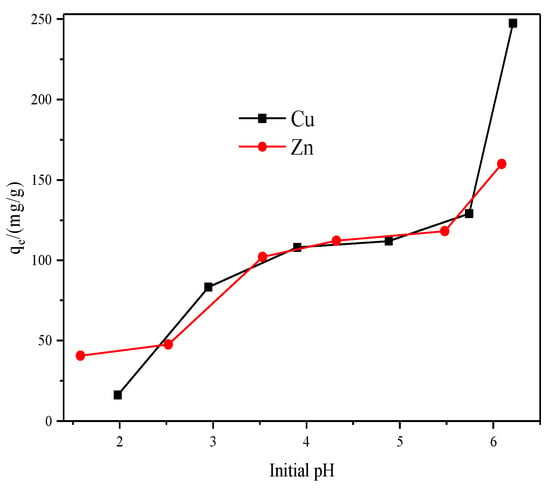

3.1.4. Effect of Initial pH

Because the solution pH is one of the critical factors that directly influence the solubility of metals, the effect of initial pH on the adsorption capacity of X zeolite was studied in the pH range of 1.0–6.0. Generally, the increase in pH results in a decrease in solubility of metals due to the formation of metal hydroxides of low solubility. Therefore, making metals soluble in solution is critical for adsorption. As shown in Figure 9, the adsorption capacity of X zeolite increased as the pH value increased. According to the experimental data, the initial pH values of Cu(II) and Zn(II) solutions were 4.88 and 5.48, respectively with the concentration of 250 ppm. Some blue and white flocs appeared with increasing the pH value of Cu(II) and Zn(II) solution due to hydrolysis and the higher adsorption capacity at high pH value was due to the hydroxide precipitation [44]. However, the lower adsorption capacity at lower solution pH was owing to the excessive H+, which will compete with the heavy metals for adsorption sites.

Figure 9.

Effect of initial pH on the adsorption capacity of X zeolite for Cu2+ and Zn2+.

3.2. Characterization of X Zeolite

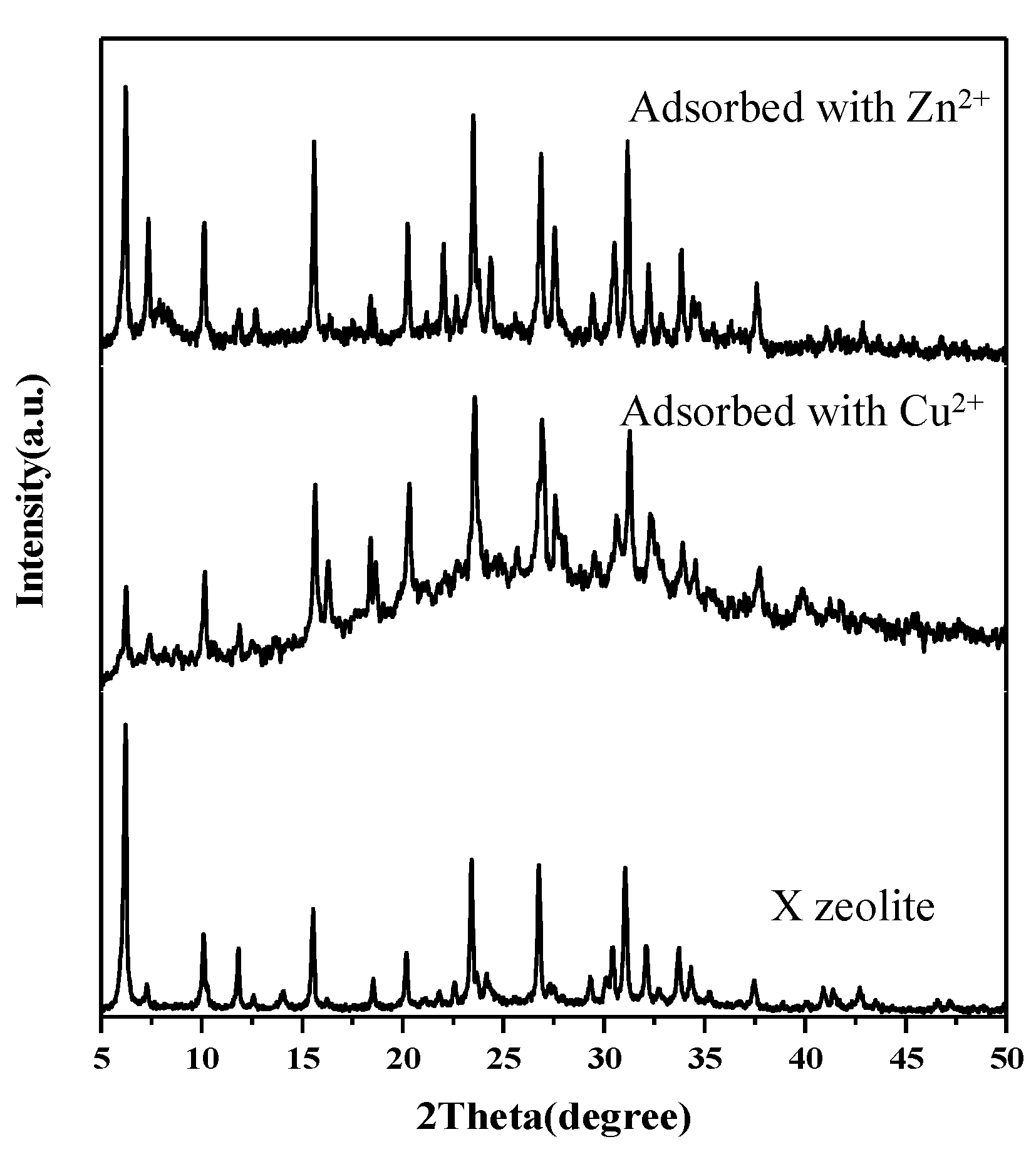

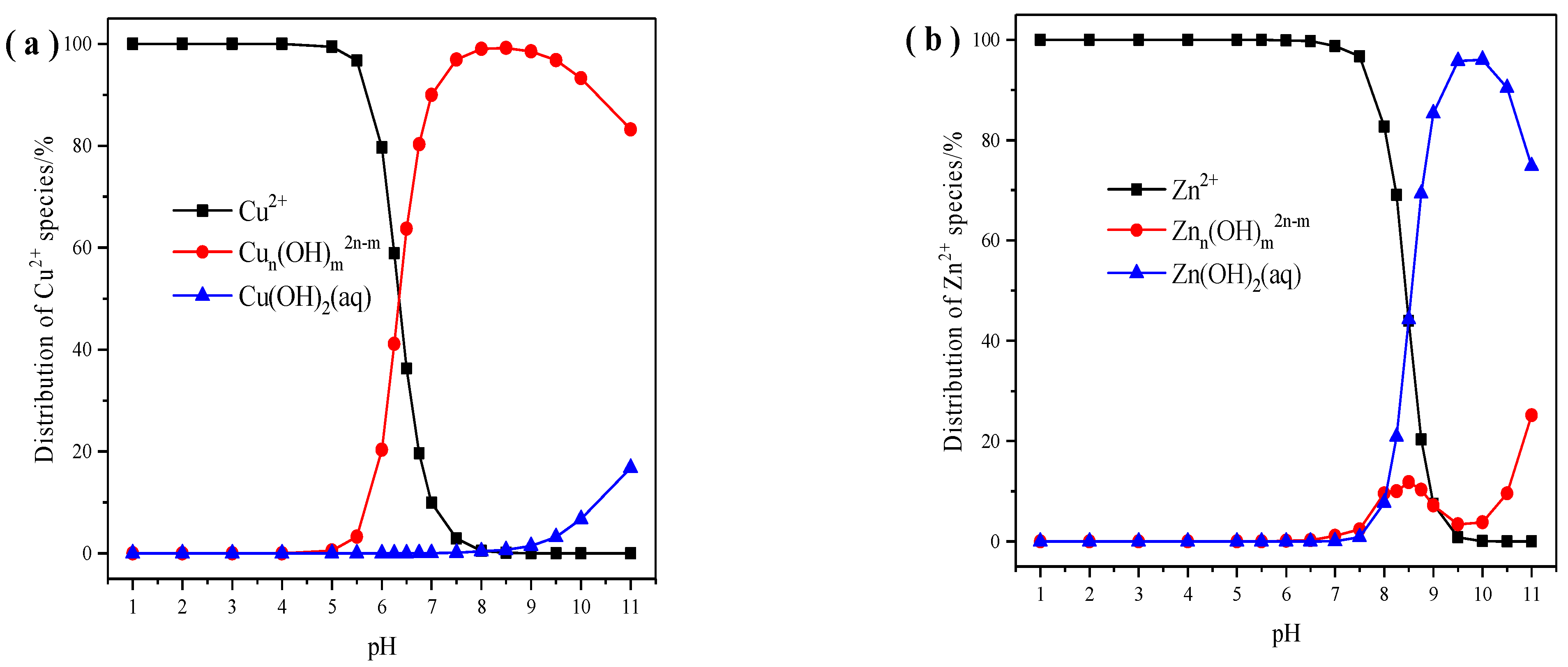

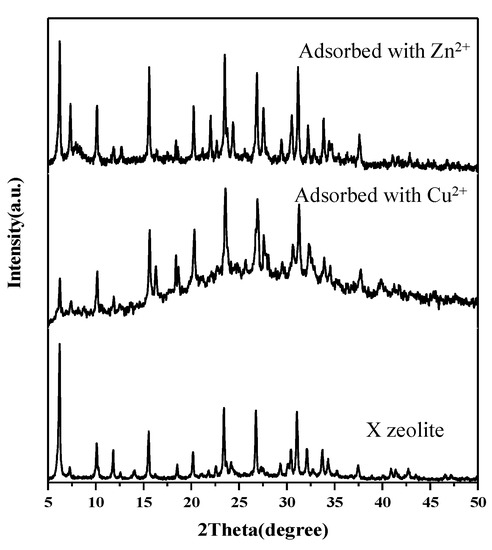

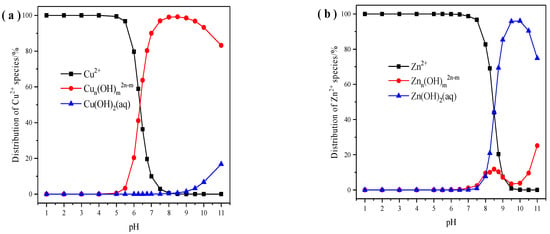

3.2.1. XRD

XRD patterns of X zeolite and samples after adsorption with Cu2+ and Zn2+ are shown in Figure 10. After adsorption of Cu2+ and Zn2+, we can still observe the mineral structure of X zeolite. and the intensity of X zeolite at 2θ = 6.10°, 9.97°, 15.39°, 23.24°, 26.58°, and 30.86° decreased in intensity and samples after adsorption with Cu2+ appears to show some amorphous background possibly due to Cu hydroxide precipitation. Moreover, the software Visual MINTEQ was applied to get the state distribution of Cu2+ and Zn2+ as pH values range from 1–11. When the pH of the Cu2+ solution is lower than 5.0, the copper existed in the Cu2+ state (Figure 11a). The pH of the Cu2+ solution became 5.28 after adsorption with Cu2+. When the pH of the Zn2+ solution is lower than 7.5, the zinc existed in the Zn2+ state (Figure 11b). The pH of the Zn2+ solution became 6.25 after adsorption with Zn2+. Based on the above analysis, the state of copper and zinc after adsorption of Cu2+ and Zn2+ are Zn2+, Cu2+, and a small amount of Cu hydroxide precipitation, respectively. The pH analysis is in agreement with the XRD data.

Figure 10.

XRD patterns of X zeolite and samples after adsorption with Cu2+ and Zn2+.

Figure 11.

The state distribution of Cu2+ (a) and Zn2+ (b) at different pH values.

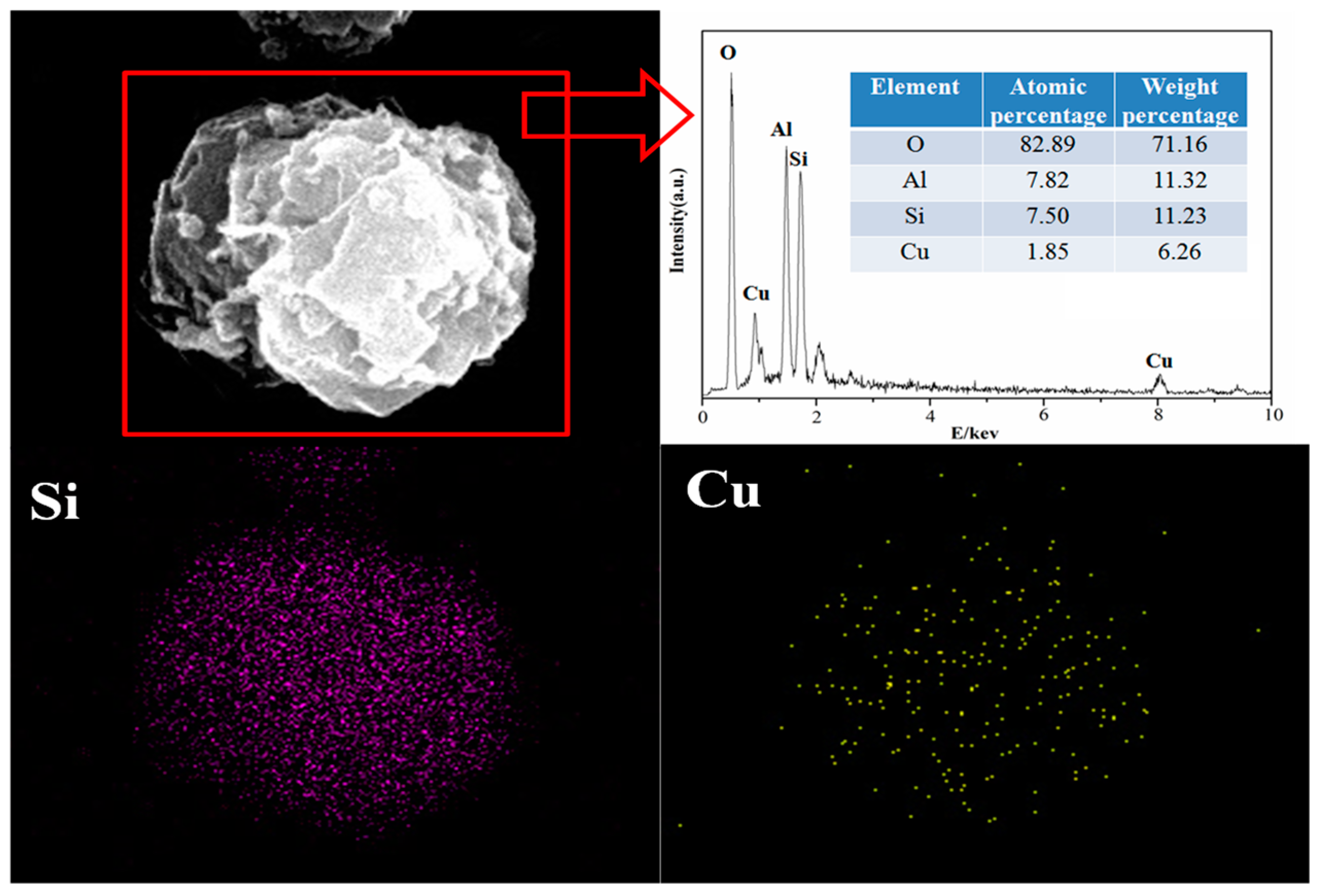

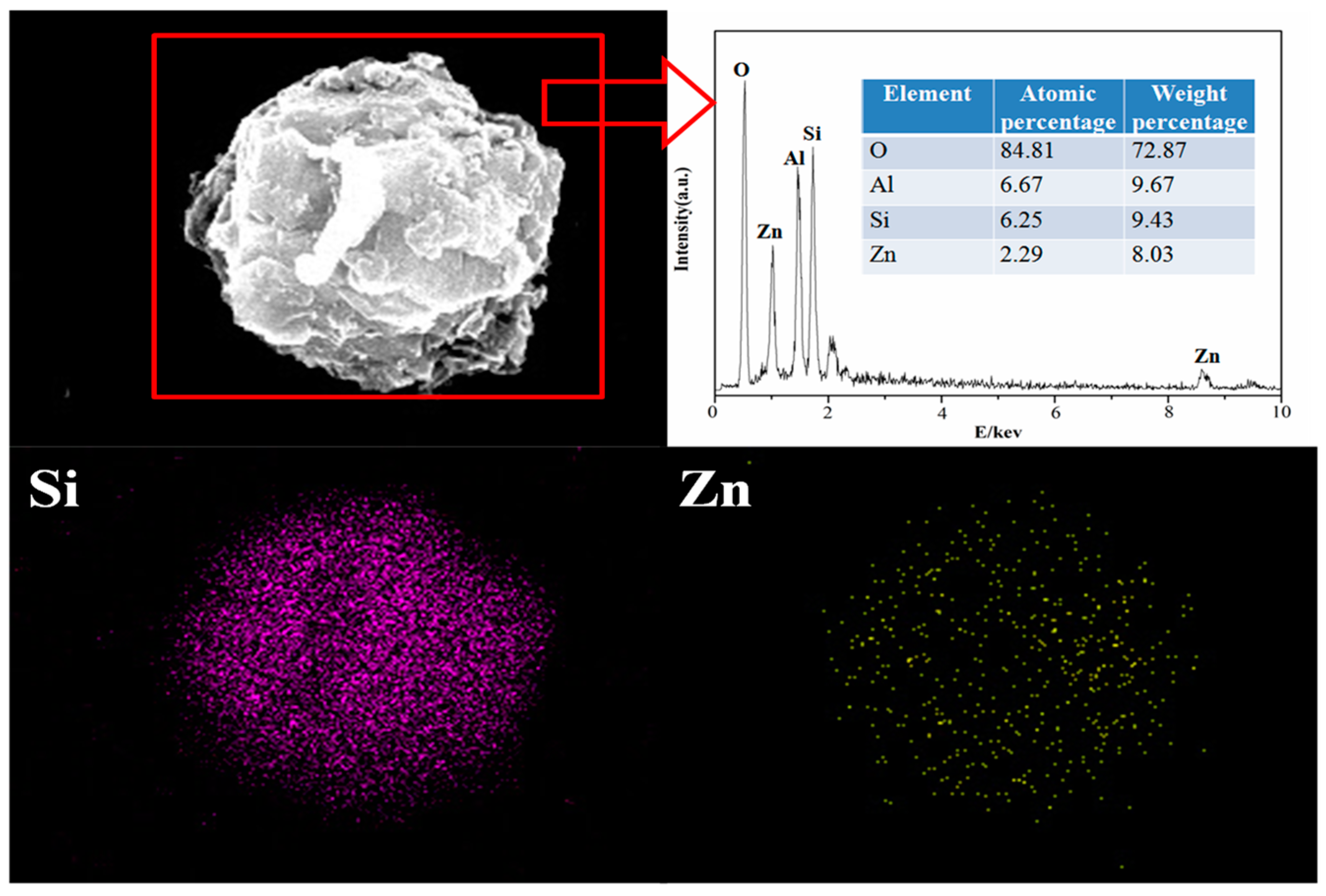

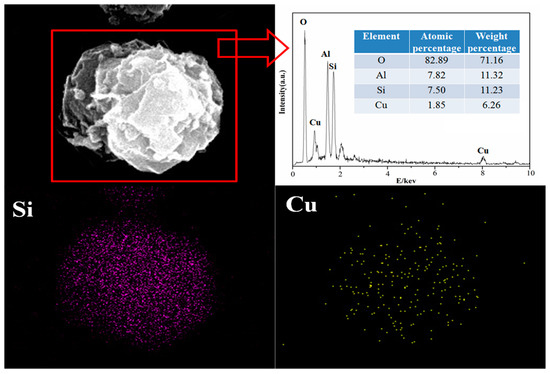

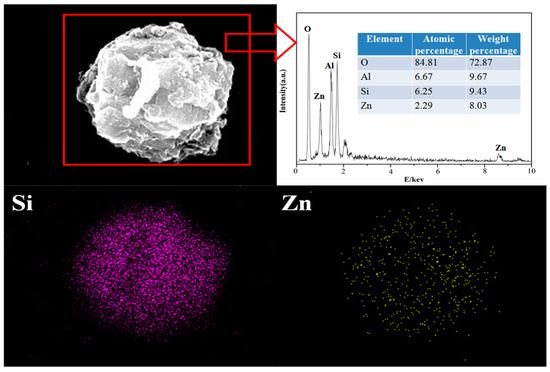

3.2.2. SEM

The morphology of X zeolite and samples after adsorption with Cu2+ and Zn2+ are shown in Figure 12 and Figure 13, respectively. The SEM images of X zeolite are an aggregation of small particles in spherical shape according to our previous work [45]. The morphology of X zeolite was almost unchanged with Cu2+ and Zn2+ dispersed well on X zeolite after adsorption of Cu2+ and Zn2+, respectively. The compositions of X zeolite and samples after adsorption of Cu2+ or Zn2+ are presented in Table 10. After adsorption, the composition of sodium greatly decreased. These chemical analyses suggest that Na ions were exchanged with Cu2+ or Zn2+ by the ion-exchange process.

Figure 12.

SEM images and EDS analysis of X zeolite adsorbed with Cu2+.

Figure 13.

SEM images and EDS analysis of X zeolite adsorbed with Zn2+.

Table 10.

The composition of X zeolite and samples of X zeolite after adsorption with Cu2+ or Zn2+.

3.2.3. BET

According to our previous work [27], the obtained X zeolite from diatomite possessed a unique meso-microporous structure with a high BET surface of 453 m2/g, which can improve the mass diffusion and transport of Cu2+ and Zn2+ by utilizing its large cavity volumes and mesopore channels. And then it will increase the effective meso-microporous contact area, which is beneficial for the adsorption process [46]. The adsorption mechanism of X zeolite for Cu2+ and Zn2+ can be described as follows: first, metal ions diffused to the surface of X zeolite through its liquid membrane; then metal ions diffused from the surface to the interior of X zeolite; finally, metal ions exchanged with cations at the active sites in the X zeolite.

4. Conclusions

The X zeolite was synthesized from diatomite displayed a unique meso-microporous structure. The Langmuir isotherm model can best describe the isotherms of Cu2+ and Zn2+ with the maximum adsorption capacities of 146 and 195 mg/g, respectively. The pseudo-second-order model can best describe the kinetic of Cu2+ and Zn2+. The adsorption process for Cu2+ and Zn2+ is chemical adsorption and ion exchange, respectively. Therefore, the prepared X zeolite probably possessed selective adsorption towards Cu2+. Moreover, the Langmuir model can best describe the isotherm of Cu2+ and Zn2+ indicating that Cu2+ and Zn2+ were unevenly adsorbed in the form of monolayer coverage. In addition, the adsorption processes of Cu2+ and Zn2+ are both endothermic and spontaneous. The excellent adsorption performance of X zeolite could be attributed to the meso-microporous structure, which improved its mass diffusion and transport of Cu2+ and Zn2+ by its large cavity volumes and mesopore channels with effective meso-microporous contact area. Therefore, the X zeolite is a promising and potentially cost-effective adsorbent for the efficient disposal of wastewater that contains more metal ions.

Author Contributions

G.Y.: Conceptualization; funding acquisition; investigation; methodology; resources; writing-review and editing; Y.L.: Funding acquisition; supervision; resources; S.Z.: Funding acquisition; supervision; resources; Y.X.: Investigation; methodology; writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

National Key Research and Development Plan (2018YFC1800902), China Scholarship Council (CSC).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data sets supporting the results of this article are included within the article.

Acknowledgments

The authors gratefully acknowledge the financial support provided by the National Key Research and Development Plan (2018YFC1800902). The first author also thanks the China Scholarship Council (CSC) for financial support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Fu, F.; Wang, Q. Removal of heavy metal ions from wastewaters: A review. J. Environ. Manag. 2011, 92, 407–418. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, R.; Zhao, J.; Zhang, Y.; Wong, P.K.; Ma, F. Biosorption of zinc from aqueous solution using chemically treated rice husk. BioMed Res. Int. 2013, 2013, 365163. [Google Scholar] [CrossRef]

- Taty-Costodes, V.C.; Fauduet, H.; Porte, C.; Delacroix, A. Removal of Cd(II) and Pb(II) ions, from aqueous solutions, by adsorption onto sawdust of Pinus sylvestris. J. Hazard. Mater. 2003, 105, 121–142. [Google Scholar] [CrossRef]

- Kulik, N.; Panova, Y.; Trapido, M. The Fenton Chemistry and Its Combination with Coagulation for Treatment of Dye Solutions. Sep. Sci. Technol. 2007, 42, 1521–1534. [Google Scholar] [CrossRef]

- López-Maldonado, E.A.; Oropeza-Guzmán, M.T. Nejayote biopolyelectrolytes multifunctionality (glucurono ferulauted arabinoxylans) in the separation of hazardous metal ions from industrial wastewater. Chem. Eng. J. 2021, 423, 130210. [Google Scholar] [CrossRef]

- Xiao, X.; Yu, Y.; Sun, Y.; Zheng, X.; Chen, A. Heavy metal removal from aqueous solutions by chitosan-based magnetic composite flocculants. J. Environ. Sci. 2021, 108, 22–32. [Google Scholar] [CrossRef] [PubMed]

- Macczak, P.; Kaczmarek, H.; Ziegler-Borowska, M. Recent Achievements in Polymer Bio-Based Flocculants for Water Treatment. Materials 2020, 13, 3951. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Zhao, Y.-H.; Bai, R. Development of a multifunctional membrane for chromatic warning and enhanced adsorptive removal of heavy metal ions: Application to cadmium. J. Membr. Sci. 2011, 379, 69–79. [Google Scholar] [CrossRef]

- Sun, Z.; Zheng, L.; Zheng, S.; Frost, R.L. Preparation and characterization of TiO2/acid leached serpentinite tailings composites and their photocatalytic reduction of chromium(VI). J. Colloid Interface Sci. 2013, 404, 102–109. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luo, J.; Li, J.; Yang, Z.; Liu, X. Removal of chromium(III) from aqueous waste solution by predispersed solvent extraction. Trans. Nonferr. Met. Soc. China 2013, 23, 524–529. [Google Scholar] [CrossRef]

- Ölmez, T.; Kabdaşlı, I.; Tünay, O. The effect of the textile industry dye bath additive EDTMPA on colour removal characteristics by ozone oxidation. Water Sci. Technol. 2007, 55, 145. [Google Scholar] [CrossRef]

- Allègre, C.; Moulin, P.; Maisseu, M.; Charbit, F. Treatment and reuse of reactive dyeing effluents. J. Membr. Sci. 2006, 269, 15–34. [Google Scholar] [CrossRef]

- Feng, Y.; Gong, J.-L.; Zeng, G.-M.; Niu, Q.-Y.; Zhang, H.-Y.; Niu, C.-G.; Deng, J.-H.; Yan, M. Adsorption of Cd (II) and Zn (II) from aqueous solutions using magnetic hydroxyapatite nanoparticles as adsorbents. Chem. Eng. J. 2010, 162, 487–494. [Google Scholar] [CrossRef]

- Banerjee, S.S.; Chen, D.H. Fast removal of copper ions by gum arabic modified magnetic nano-adsorbent. J. Hazard. Mater. 2007, 147, 792–799. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, Y.; Ding, J.; Zhang, Z.; Gao, C.; Halimi, M.; Demey, H.; Yang, Z.; Yang, W. High phosphate removal using La(OH)3 loaded chitosan based composites and mechanistic study. J. Environ. Sci 2021, 106, 105–115. [Google Scholar] [CrossRef] [PubMed]

- Ivanets, A.I.; Kitikova, N.V.; Shashkova, I.L.; Oleksiienko, O.V.; Levchuk, I.; Sillanpää, M. Removal of Zn2+, Fe2+, Cu2+, Pb2+, Cd2+, Ni2+ and Co2+ ions from aqueous solutions using modified phosphate dolomite. J. Environ. Chem. Eng. 2014, 2, 981–987. [Google Scholar] [CrossRef]

- Abu-Zurayk, R.A.; al Bakain, R.Z.; Hamadneh, I.; Al-Dujaili, A.H. Adsorption of Pb(II), Cr(III) and Cr(VI) from aqueous solution by surfactant-modified diatomaceous earth: Equilibrium, kinetic and thermodynamic modeling studies. Int. J. Miner. Process. 2015, 140, 79–87. [Google Scholar] [CrossRef]

- Terdkiatburana, T.; Wang, S.; Tadé, M.O. Competition and complexation of heavy metal ions and humic acid on zeolitic MCM-22 and activated carbon. Chem. Eng. J. 2008, 139, 437–444. [Google Scholar] [CrossRef]

- Tao, P.; Shao, M.; Song, C.; Wu, S.; Cheng, M.; Cui, Z. Preparation of porous and hollow Mn2O3 microspheres and their adsorption studies on heavy metal ions from aqueous solutions. J. Ind. Eng. Chem. 2014, 20, 3128–3133. [Google Scholar] [CrossRef]

- Wang, W.; Ding, Z.; Cai, M.; Jian, H.; Zeng, Z.; Li, F.; Liu, J.P. Synthesis and high-efficiency methylene blue adsorption of magnetic PAA/MnFe2O4 nanocomposites. Appl. Surf. Sci. 2015, 346, 348–353. [Google Scholar] [CrossRef]

- Ge, F.; Li, M.M.; Ye, H.; Zhao, B.X. Effective removal of heavy metal ions Cd2+, Zn2+, Pb2+, Cu2+ from aqueous solution by polymer-modified magnetic nanoparticles. J. Hazard. Mater. 2012, 211–212, 366–372. [Google Scholar] [CrossRef] [PubMed]

- Han, R.; Zou, W.; Zhang, Z.; Shi, J.; Yang, J. Removal of copper(II) and lead(II) from aqueous solution by manganese oxide coated sand I. Characterization and kinetic study. J. Hazard. Mater. 2006, 137, 384–395. [Google Scholar] [CrossRef]

- Hua, M.; Zhang, S.; Pan, B.; Zhang, W.; Lv, L.; Zhang, Q. Heavy metal removal from water/wastewater by nanosized metal oxides: A review. J. Hazard. Mater. 2012, 211–212, 317–331. [Google Scholar] [CrossRef] [PubMed]

- Nibou, D.; Mekatel, H.; Amokrane, S.; Barkat, M.; Trari, M. Adsorption of Zn2+ ions onto NaA and NaX zeolites: Kinetic, equilibrium and thermodynamic studies. J. Hazard. Mater. 2010, 173, 637–646. [Google Scholar] [CrossRef] [PubMed]

- Zanin, E.; Scapinello, J.; de Oliveira, M.; Rambo, C.L.; Franscescon, F.; Freitas, L.; de Mello, J.M.M.; Fiori, M.A.; Oliveira, J.V.; Magro, J.D. Adsorption of heavy metals from wastewater graphic industry using clinoptilolite zeolite as adsorbent. Process Saf. Environ. Prot. 2017, 105, 194–200. [Google Scholar] [CrossRef]

- Yao, G.; Lei, J.; Zhang, X.; Sun, Z.; Zheng, S.; Komarneni, S. Mechanism of zeolite X crystallization from diatomite. Mater. Res. Bull. 2018, 107, 132–138. [Google Scholar] [CrossRef]

- Yao, G.; Zhang, X.; Sun, Z.; Zheng, S. High adsorption selectivity of zeolite X in the binary ionic system of Cu(II) and Zn(II). J. Porous Mater. 2019, 26, 1197–1207. [Google Scholar] [CrossRef]

- Yao, G.; Lei, J.; Zhang, X.; Sun, Z.; Zheng, S. One-Step Hydrothermal Synthesis of Zeolite X Powder from Natural Low-Grade Diatomite. Materials 2018, 11, 906. [Google Scholar] [CrossRef] [Green Version]

- Zou, W.; Han, R.; Chen, Z.; Jinghua, Z.; Shi, J. Kinetic study of adsorption of Cu(II) and Pb(II) from aqueous solutions using manganese oxide coated zeolite in batch mode. Colloids Surf. A Physicochem. Eng. Asp. 2006, 279, 238–246. [Google Scholar] [CrossRef]

- Park, Y.; Sun, Z.; Ayoko, G.A.; Frost, R.L. Bisphenol A sorption by organo-montmorillonite: Implications for the removal of organic contaminants from water. Chemosphere 2014, 107, 249–256. [Google Scholar] [CrossRef] [Green Version]

- Park, Y.; Ayoko, G.A.; Horvath, E.; Kurdi, R.; Kristof, J.; Frost, R.L. Structural characterisation and environmental application of organoclays for the removal of phenolic compounds. J. Colloid Interface Sci. 2013, 393, 319–334. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, Z.; Yao, G.; Liu, M.; Zheng, S. In situ synthesis of magnetic MnFe2O4/diatomite nanocomposite adsorbent and its efficient removal of cationic dyes. J. Taiwan Inst. Chem. Eng. 2017, 71, 501–509. [Google Scholar] [CrossRef]

- Zheng, S.; Sun, Z.; Park, Y.; Ayoko, G.A.; Frost, R.L. Removal of bisphenol A from wastewater by Ca-montmorillonite modified with selected surfactants. Chem. Eng. J. 2013, 234, 416–422. [Google Scholar] [CrossRef] [Green Version]

- Ates, A. Role of modification of natural zeolite in removal of manganese from aqueous solutions. Powder Technol. 2014, 264, 86–95. [Google Scholar] [CrossRef]

- Cui, L.; Hu, L.; Guo, X.; Zhang, Y.; Wang, Y.; Wei, Q.; Du, B. Kinetic, isotherm and thermodynamic investigations of Cu2+ adsorption onto magnesium hydroxyapatite/ferroferric oxide nano-composites with easy magnetic separation assistance. J. Mol. Liq. 2014, 198, 157–163. [Google Scholar] [CrossRef]

- Wang, S.; Soudi, M.; Li, L.; Zhu, Z.H. Coal ash conversion into effective adsorbents for removal of heavy metals and dyes from wastewater. J. Hazard. Mater. 2006, 133, 243–251. [Google Scholar] [CrossRef]

- Hui, K.S.; Chao, C.Y.; Kot, S.C. Removal of mixed heavy metal ions in wastewater by zeolite 4A and residual products from recycled coal fly ash. J. Hazard. Mater. 2005, 127, 89–101. [Google Scholar] [CrossRef]

- Chen, Y.H.; Li, F.A. Kinetic study on removal of copper(II) using goethite and hematite nano-photocatalysts. J. Colloid Interface Sci. 2010, 347, 277–281. [Google Scholar] [CrossRef] [PubMed]

- Koivula, R.; Pakarinen, J.; Sivenius, M.; Sirola, K.; Harjula, R.; Paatero, E. Use of hydrometallurgical wastewater as a precursor for the synthesis of cryptomelane-type manganese dioxide ion exchange material. Sep. Purif. Technol. 2009, 70, 53–57. [Google Scholar] [CrossRef]

- Su, Q.; Pan, B.; Wan, S.; Zhang, W.; Lv, L. Use of hydrous manganese dioxide as a potential sorbent for selective removal of lead, cadmium, and zinc ions from water. J. Colloid Interface Sci. 2010, 349, 607–612. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, Y.; Wang, J.; Qiao, W.; Long, D.; Ling, L. Effective removal of hexavalent chromium from aqueous solutions by adsorption on mesoporous carbon microspheres. J. Colloid Interface Sci. 2016, 462, 200–207. [Google Scholar] [CrossRef]

- Al-Qodah, Z.; Lafi, W.K.; Al-Anber, Z.; Al-Shannag, M.; Harahsheh, A. Adsorption of methylene blue by acid and heat treated diatomaceous silica. Desalination 2007, 217, 212–224. [Google Scholar] [CrossRef]

- Ballav, N.; Choi, H.J.; Mishra, S.B.; Maity, A. Polypyrrole-coated halloysite nanotube clay nanocomposite: Synthesis, characterization and Cr(VI) adsorption behavior. Appl. Clay Sci. 2014, 102, 60–70. [Google Scholar] [CrossRef]

- Kocaoba, S.; Orhan, Y.; Akyüz, T. Kinetics and equilibrium studies of heavy metal ions removalby use of natural zeolite. Desalination 2007, 214, 1–10. [Google Scholar] [CrossRef]

- Yao, G.; Lei, J.; Zhang, W.; Yu, C.; Sun, Z.; Zheng, S.; Komarneni, S. Antimicrobial activity of X zeolite exchanged with Cu(2+) and Zn(2+) on Escherichia coli and Staphylococcus aureus. Environ. Sci. Pollut. Res. Int. 2019, 26, 2782–2793. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Xu, W.; He, C.; Huang, Y.; Zhang, Z.; Wang, Y.; Hu, L.; Xia, D.; Shu, D. One-step synthesis of silicon carbide foams supported hierarchical porous sludge-derived activated carbon as efficient odor gas adsorbent. J. Hazard. Mater. 2017, 344, 33–41. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).