Effect of Rejuvenators on the Workability and Performances of Reclaimed Asphalt Mixtures

Abstract

:1. Introduction

2. Materials Preparation

2.1. Raw Materials

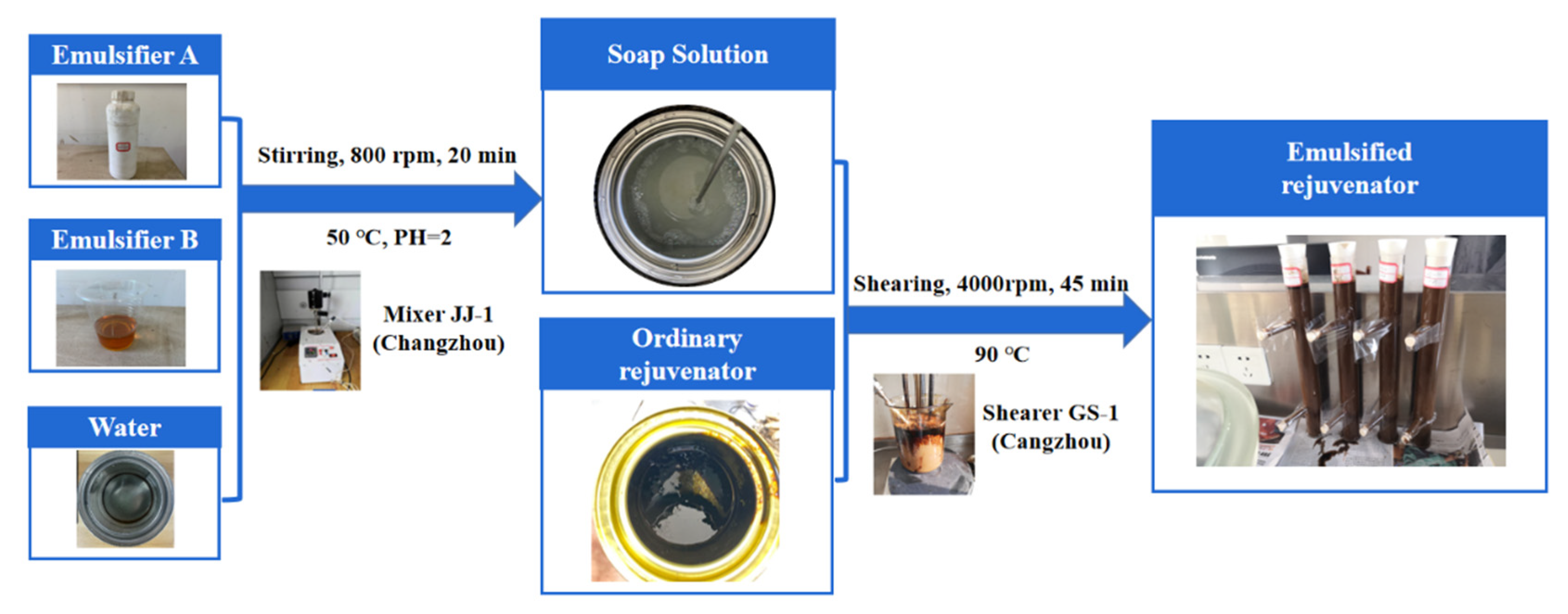

2.2. Preparation of Recycled Asphalt Binders

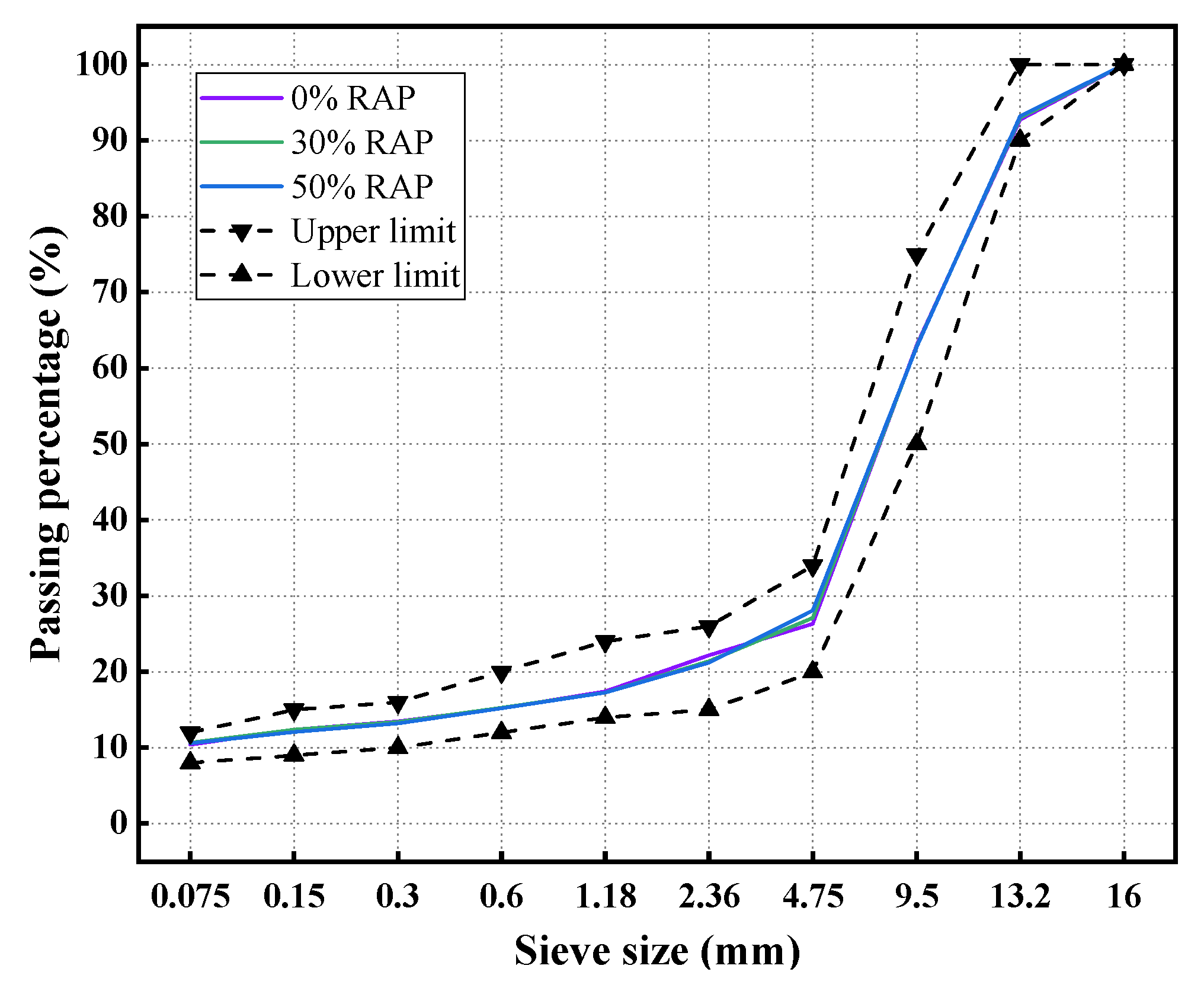

2.3. Mix Design of Reclaimed Asphalt Mixtures

3. Evaluation Methods

3.1. Workability Evaluation Methods

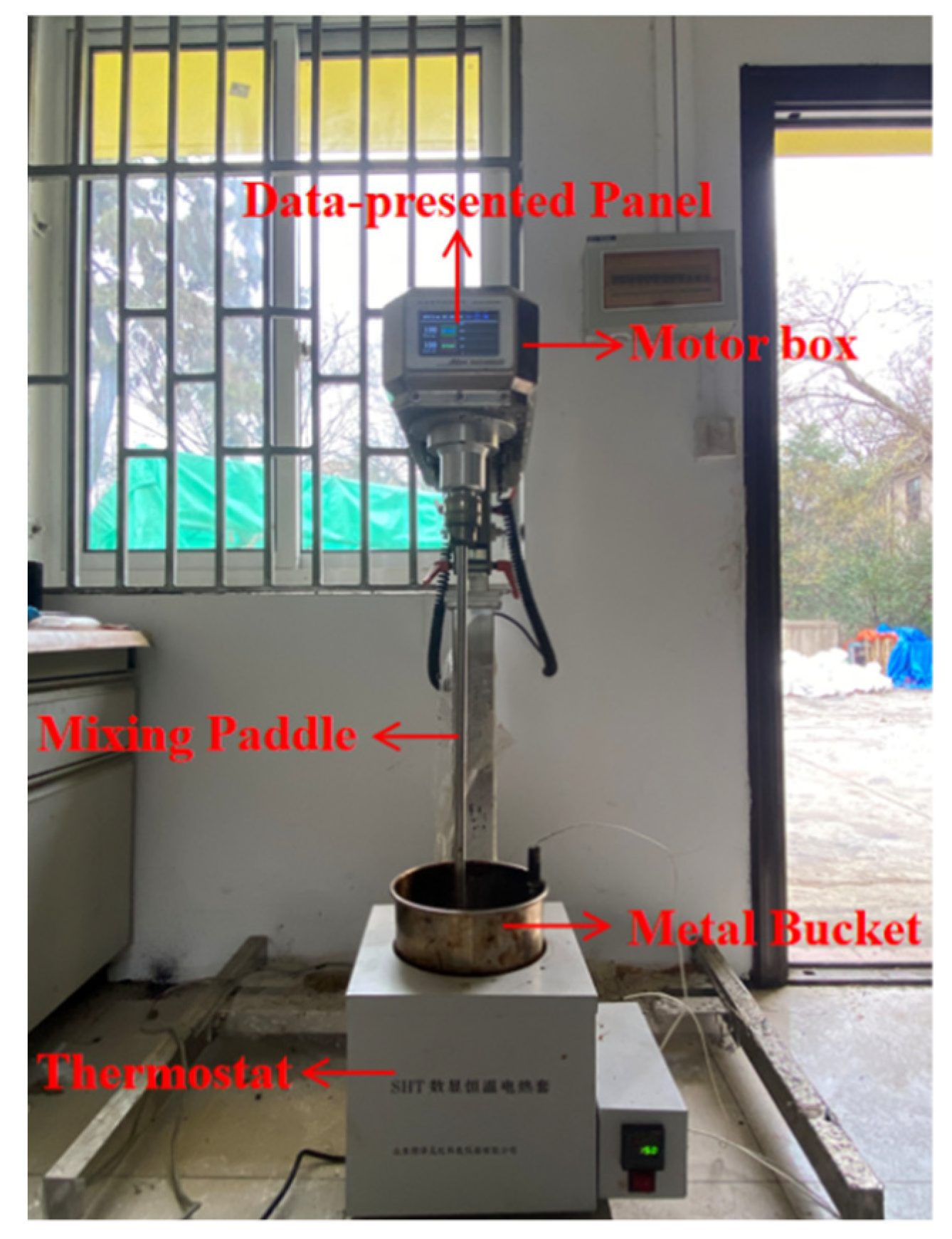

3.1.1. Measurements of Mixing Torque

3.1.2. Determination of Air Void Content

- The RAP, virgin aggregates and virgin asphalt were heated at 140 °C, 180 °C and 170 °C for 2 h, respectively. The CR was heated to 110 °C, while the CR was used at room temperature without heating;

- The RAP was premixed with rejuvenator in a laboratory mixer (model F-20, Changji, Shanghai, China). The virgin aggregates, virgin asphalt and powder were successively added into the mixer for mixing. Each mixing duration was 60 s;

- After mixing, the loose reclaimed mixtures were subjected to heat preservation in an oven. The preserved temperature was 160 °C and preserved time was 1 h;

- Marshall specimens were prepared with 75 blows per side following the Chinese specification JTG-E20 T0702. Lastly, surface-dry method was used to measure the air void content.

3.2. Performances Evaluation Methods

3.2.1. Three Indexes Tests

3.2.2. Rutting Test

3.2.3. Freeze-Thaw Splitting Tests

4. Results and Discussions

4.1. Effect of Rejuvenators on the Workability of Reclaimed Mixtures

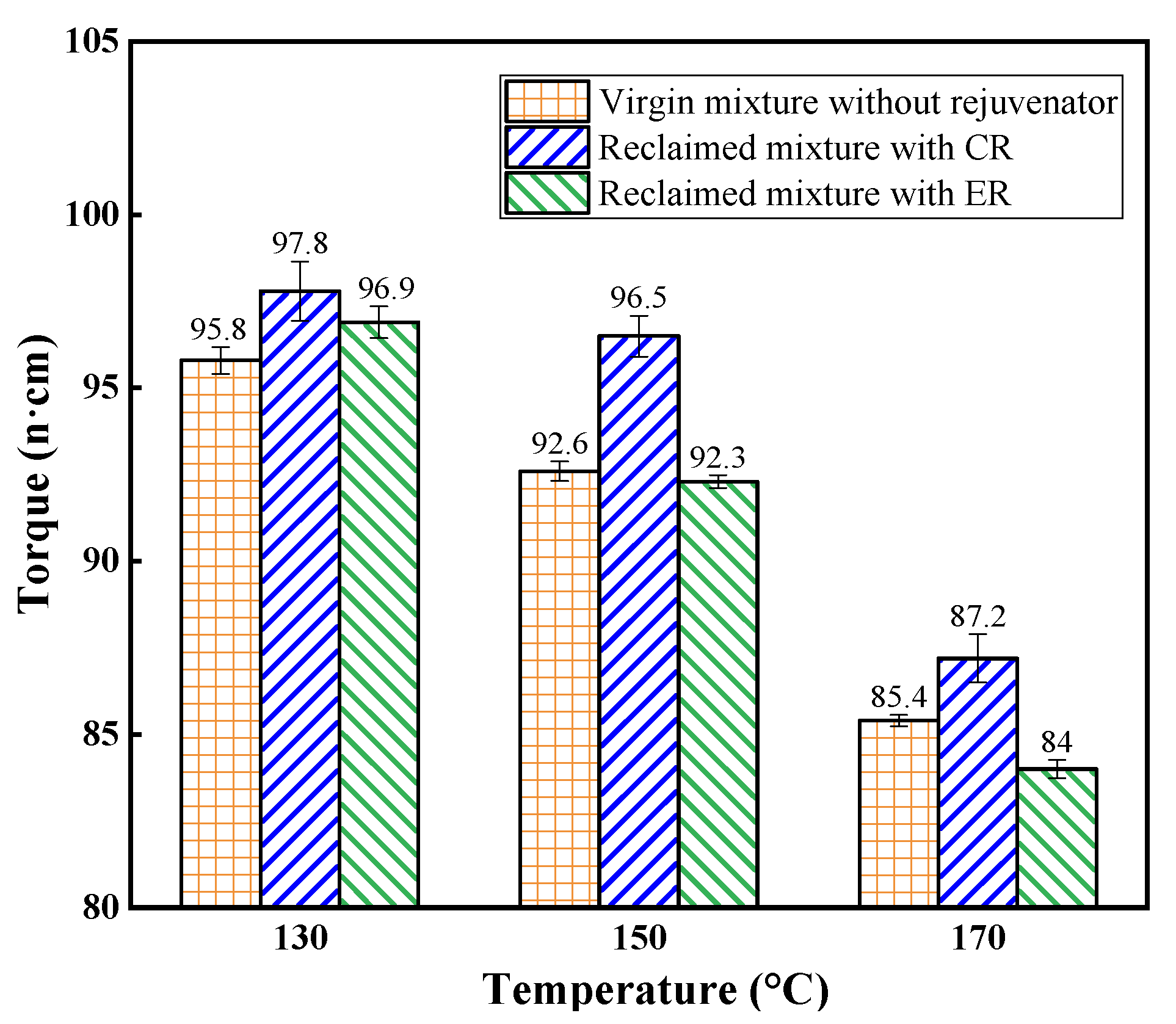

4.1.1. Mixing Torque

4.1.2. Air Void Content

4.2. Effect of Rejuvenators on the Performances of Reclaimed Mixtures

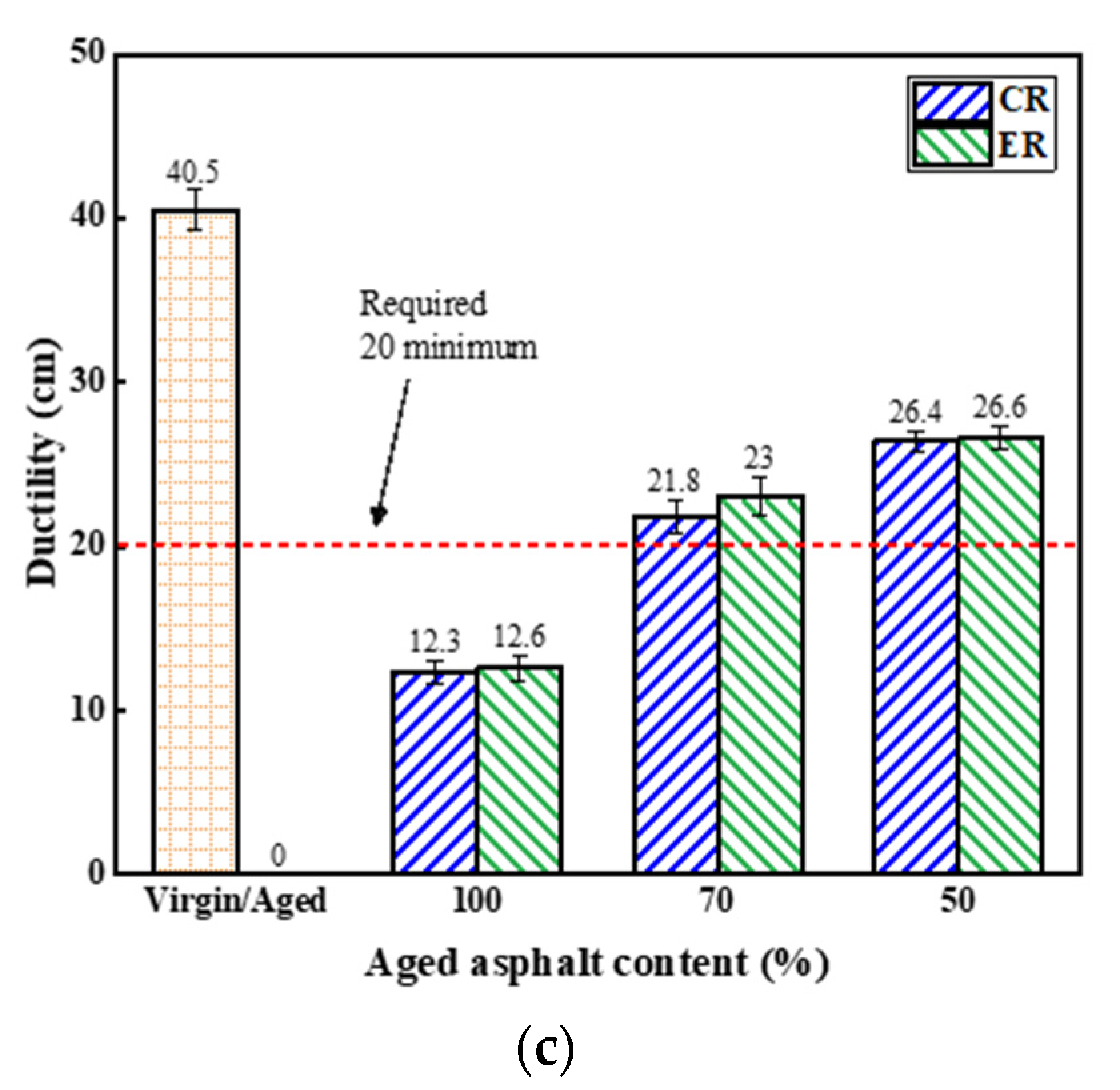

4.2.1. Three Indexes of Recycled Asphalt Binders

4.2.2. High-Temperature Stability

4.2.3. Moisture Susceptibility

5. Conclusions

- i.

- The emulsified rejuvenator can be used without heating in engineering practice owing to its low viscosity, while the ordinary rejuvenator has to be heated.

- ii.

- The addition of RAP into asphalt mixtures has an adverse effect on the workability. Compared to using an ordinary rejuvenator, reclaimed mixtures prepared using the emulsified rejuvenator exhibit lower torques and air void contents. This can be attributed to that using oil-water emulsified medium shows better lubricating effect during the mixing and compaction process.

- iii.

- Reclaimed mixtures with the emulsified rejuvenator show similar moisture susceptibility to that with the ordinary rejuvenator. At least 20% higher high-temperature stability is obtained for reclaimed mixtures by using the emulsified rejuvenator than an ordinary rejuvenator. This can be attributed to better workability when using the emulsified rejuvenator, which results in lower air voids content in the reclaimed mixtures.

- iv.

- The emulsified rejuvenator improves the workability and high-temperature stability of reclaimed mixtures, while not affecting the moisture susceptibility of mixtures. Therefore, rejuvenators are recommended to be emulsified for use in practice.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ding, Y.J.; Huang, B.S.; Shu, X. Blending efficiency evaluation of plant asphalt mixtures using fluorescence microscopy. Constr. Build. Mater. 2018, 161, 461–467. [Google Scholar] [CrossRef]

- Ding, Y.J.; Huang, B.S.; Shu, X. Characterizing blending efficiency of plant produced asphalt paving mixtures containing high RAP. Constr. Build. Mater. 2016, 126, 172–178. [Google Scholar] [CrossRef]

- Li, N.; Zhan, H.; Yu, X.; Tang, W.; Xue, Q.L. Investigation of the aging behavior of cellulose fiber in reclaimed asphalt pavement. Constr. Build. Mater. 2021, 271, 121559. [Google Scholar] [CrossRef]

- Gao, J.; Yang, J.G.; Di, Y.; Jiang, Y.; Ruan, K.G.; Tao, W.J.; Sun, C.; Luo, L.H. Reducing the variability of multi-source reclaimed asphalt pavement materials: A practice in China. Constr. Build. Mater. 2021, 278, 122389. [Google Scholar] [CrossRef]

- Rafiq, W.; Napiah, M.; Habib, N.Z.; Sutanto, M.H.; Alaloul, W.S.; Khan, M.I.; Musarat, M.A.; Memon, A.M. Modeling and design optimization of reclaimed asphalt pavement containing crude palm oil using response surface methodology. Constr. Build. Mater. 2020, 291, 123288. [Google Scholar] [CrossRef]

- Sreeram, A.; Leng, Z.; Zhang, Y.; Rabindra, K.P. Evaluation of RAP binder mobilisation and blending efficiency in bituminous mixtures: An approach using ATR-FTIR and artificial aggregate. Constr. Build. Mater. 2018, 179, 245–253. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Baaj, H. The use of rejuvenating agents in production of recycled hot mix asphalt: A systematic review. Constr. Build. Mater. 2016, 114, 805816. [Google Scholar] [CrossRef]

- Yu, J.M.; Guo, Y.F.; Peng, L.; Guo, F.; Yu, H.Y. Rejuvenating effect of soft bitumen, liquid surfactant and bio-rejuvenator on artificial aged asphalt. Constr. Build. Mater. 2020, 254, 119336. [Google Scholar]

- Ekblad, J.; Lundstroam, R. Soft bitumen asphalt produced using RAP. Mater. Struct. 2017, 50, 13. [Google Scholar] [CrossRef] [Green Version]

- Ma, H.; Mao, Q.; Li, N. Influence factors of RAP content in plant-mixed hot recycling asphalt pavement. J. Chongqing Jiaotong Univ. Nat. Sci. 2020, 39, 97–104. (In Chinese) [Google Scholar]

- Ech, M.; Tintillier, P.; Baaj, H.; Richard, N. Asphalt Mixture without Virgin Bitumen Based on Recycled Materials. U.S. Patent Publication Number 20140033951, 6 February 2014. [Google Scholar]

- Zaumanis, M.; Mallick, R.B.; Robert, F. Evaluation of rejuvenator′s effectiveness with conventional mix testing for 100% reclaimed asphalt pavement mixtures. Transp. Res. Rec. 2013, 2370, 17–25. [Google Scholar] [CrossRef] [Green Version]

- Zaumanis, M.; Mallick, R.B.; Poulikakos, L.; Robert, F. Influence of six rejuvenators on the performance properties of reclaimed asphalt pavement (RAP) binder and 100% recycled asphalt mixtures. Constr. Build. Mater. 2014, 71, 538–550. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. Evaluation of different recycling agents for restoring aged asphalt binder and performance of 100% recycled asphalt. Mater. Struct. 2015, 48, 2475–2488. [Google Scholar] [CrossRef]

- El-Shorbagy, A.M.; El-Badawy, S.M.; Gabr, A.R. Investigation of waste oils as rejuvenators of aged bitumen for sustainable pavement. Constr. Build. Mater. 2019, 220, 228–237. [Google Scholar] [CrossRef]

- Woszuk, A.; Wróbel, M.; Franus, W. Influence of waste engine oil addition on the properties of zeolite-foamed asphalt. Materials 2019, 12, 2265. [Google Scholar] [CrossRef] [Green Version]

- Daryaee, D.; Ameri, M.; Mansourkhaki, A. Utilizing of waste polymer modified bitumen in combination with rejuvenator in high reclaimed asphalt pavement mixtures. Constr. Build. Mater. 2020, 235, 117516. [Google Scholar] [CrossRef]

- Kuang, D.L.; Jiao, Y.; Ye, Z.; Lu, Z.H.; Chen, H.Y.; Yu, J.Y.; Liu, N. Diffusibility enhancement of rejuvenator by epoxidized soybean oil and its influence on the performance of recycled hot mix asphalt mixtures. Materials 2018, 11, 833. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kuang, D.L.; Feng, Z.G.; Yu, J.Y.; Chen, X.; Zhou, B. A new approach for evaluating rejuvenator diffusing into aged bitumen. J. Wuhan Univ. Technol. 2011, 26, 43–46. [Google Scholar] [CrossRef]

- Jain, M.A.; Sharma, A.; Sharma, D.K. Use of edible oil as rejuvenator in reclaimed asphalt pavement. In Proceedings of the a National Conference on Roads and Transport (NCORT-2017), Roorkee, India, 14–15 October 2017. [Google Scholar]

- Ahmad, K.A.; Abdullah, M.E.; Hassan, N.A.; Usman, N.; Hassan, R.M.; Bilema, M.A.; Saeed, S.M.; Batari, A. Effect of bio based rejuvenator on mix design, energy consumption and GHG emission of high RAP mixture. In Proceedings of the 4th International Conference on Civil and Environmental Engineering for Sustainability (IConCEES 2017), Langkawi, Malaysia, 4–5 December 2017. [Google Scholar]

- Gong, M.H.; Yang, J.; Zhang, J.Y.; Zhu, H.R.; Tong, T.Z. Physical–chemical properties of aged asphalt rejuvenated by bio-oil derived from biodiesel residue. Constr. Build. Mater. 2016, 105, 35–45. [Google Scholar] [CrossRef]

- Qian, Y.; Guo, F.; Leng, Z.; Zhang, Y.; Yu, H.Y. Simulation of the field aging of asphalt binders in different reclaimed asphalt pavement (RAP) materials in Hong Kong through laboratory tests. Constr. Build. Mater. 2020, 265, 120651. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. JTG E20-2011-Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- Thomas, M.; Gerald, R.; Walaa, M.; Karissa, M. Assessment of workability and compactability of warm-mix asphalt. Transp. Res. Rec. 2010, 2180, 36–47. [Google Scholar]

- Tao, M.J.; Mallick, R.B.; Robert, F. Effects of warm-mix asphalt additives on workability and mechanical properties of reclaimed asphalt pavement material. Transp. Res. Rec. 2009, 2126, 151–160. [Google Scholar] [CrossRef]

- Wang, C.; Hao, P.W.; Ruan, F.; Zhang, X.Y.; Adhikari, S. Determination of the production temperature of warm mix asphalt by workability test. Constr. Build. Mater. 2013, 48, 1165–1170. [Google Scholar] [CrossRef]

- Ali, A.; Abbas, A.; Nazzal, M.; Alhasan, A.; Roy, A.; Powers, D. Workability evaluation of foamed warm-mix asphalt. J. Mater. Civ. Eng. 2014, 26, 93–101. [Google Scholar] [CrossRef]

- Kowalska, A.C.; Gardziejczyk, W.; Iwanski, M.M. Moisture resistance and compactibility of asphalt concrete produced in half-warm mix asphalt technology with foamed bitumen. Constr. Build. Mater. 2016, 126, 108–118. [Google Scholar] [CrossRef] [Green Version]

- Ministry of Transport of the People’s Republic of China. JTG T55-2019-Technical Specifications for Highway Asphalt Pavements Recycling; Ministry of Transport of the People’s Republic of China: Beijing, China, 2019.

- Ren, P. Study on the Fretting Corrosion Behavior of Steels. Ph.D. Thesis, Southwest Jiaotong University, Xi’an, China, 2019. [Google Scholar]

- Ministry of Transport of the People’s Republic of China. JTG F40–2004-Technical Specification for Construction of Highway Asphalt Pavement; Ministry of Transport of the People’s Republic of China: Beijing, China, 2004.

- Li, N.; Tang, W.; Yu, X.; Zhan, H.; Ma, H.; Ding, G.Y. Investigation of moisture dissipation of water-foamed asphalt and its influence on the viscosity. Materials 2020, 13, 5235. [Google Scholar] [CrossRef]

- Ghabchi, R.; Singh, D.; Zaman, M. Evaluation of moisture susceptibility of asphalt mixes containing RAP and different types of aggregates and asphalt binders using the surface free energy method. Constr. Build. Mater. 2014, 73, 479–489. [Google Scholar] [CrossRef]

- Nahar, S.; Mohajeri, M.; Schmets, A.; Scarpas, A.; van de Ven, M.; Schitter, G. First observation of blending-zone morphology at interface of reclaimed asphalt binder and virgin bitumen. Transp. Res. Rec. 2013, 2370, 1–9. [Google Scholar] [CrossRef] [Green Version]

| Properties | Test Results | Requirements (RA-25) | Specification Method |

|---|---|---|---|

| Viscosity, mm2/s (60 °C) | 2080 | 901~4500 | ASTM D2171 |

| Flash point, °C | 240 | >219 | ASTM D92 |

| Saturates, % (wt) | 22.3 | <30 | ASTM D2007 |

| Wt change, % (After TFOT, 163 °C) | 0.5 | <3 | ASTM D1754 |

| Specific gravity | 0.99 | Report | ASTM D70 |

| Properties | Emulsifier A | Emulsifier B |

|---|---|---|

| Appearance | viscous liquid | yellow liquid |

| Electric charge | + | + |

| Blend stability | quick-set | quick-set |

| PH of aqueous solution | 10 | 11.3 |

| Amine value (mg/g) | - | 360–410 |

| RAP Size (mm) | Passing Percentage of Different Sieve Size/% | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |

| 10~16 | 100 | 89.3 | 32.8 | 10.5 | 9.1 | 7.6 | 6.4 | 4.8 | 3.9 | 3.4 |

| 5~10 | 100 | 100 | 91.2 | 18.6 | 11.0 | 8.8 | 7.5 | 6.2 | 5.4 | 4.8 |

| 0~5 | 100 | 100 | 100 | 90.9 | 62.4 | 41.0 | 29.6 | 19.6 | 15.8 | 13.7 |

| RAP (%) | Virgin Mineral Materials (%) | AC (%) | Rejuvenator 1 (%) | |||

|---|---|---|---|---|---|---|

| 10~15 mm | 5~10 mm | 0~3 mm | Filler | |||

| 0 | 39.8 | 31.8 | 12.1 | 10.3 | 6.0 | 0 |

| 30 | 34.0 | 18.0 | 4.3 | 8.8 | 6.0 | 4/6.67 |

| 50 | 30.1 | 8.3 | 0 | 7.3 | 6.0 | 4/6.67 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, W.; Yu, X.; Li, N.; Dong, F.; Wang, Z.; Zhang, Y. Effect of Rejuvenators on the Workability and Performances of Reclaimed Asphalt Mixtures. Materials 2021, 14, 6385. https://doi.org/10.3390/ma14216385

Tang W, Yu X, Li N, Dong F, Wang Z, Zhang Y. Effect of Rejuvenators on the Workability and Performances of Reclaimed Asphalt Mixtures. Materials. 2021; 14(21):6385. https://doi.org/10.3390/ma14216385

Chicago/Turabian StyleTang, Wei, Xin Yu, Ning Li, Fuqiang Dong, Zhongyuan Wang, and Yu Zhang. 2021. "Effect of Rejuvenators on the Workability and Performances of Reclaimed Asphalt Mixtures" Materials 14, no. 21: 6385. https://doi.org/10.3390/ma14216385

APA StyleTang, W., Yu, X., Li, N., Dong, F., Wang, Z., & Zhang, Y. (2021). Effect of Rejuvenators on the Workability and Performances of Reclaimed Asphalt Mixtures. Materials, 14(21), 6385. https://doi.org/10.3390/ma14216385