Statistical Analysis of Uniform Switching Characteristics of Ta2O5-Based Memristors by Embedding In-Situ Grown 2D-MoS2 Buffer Layers

Abstract

:1. Introduction

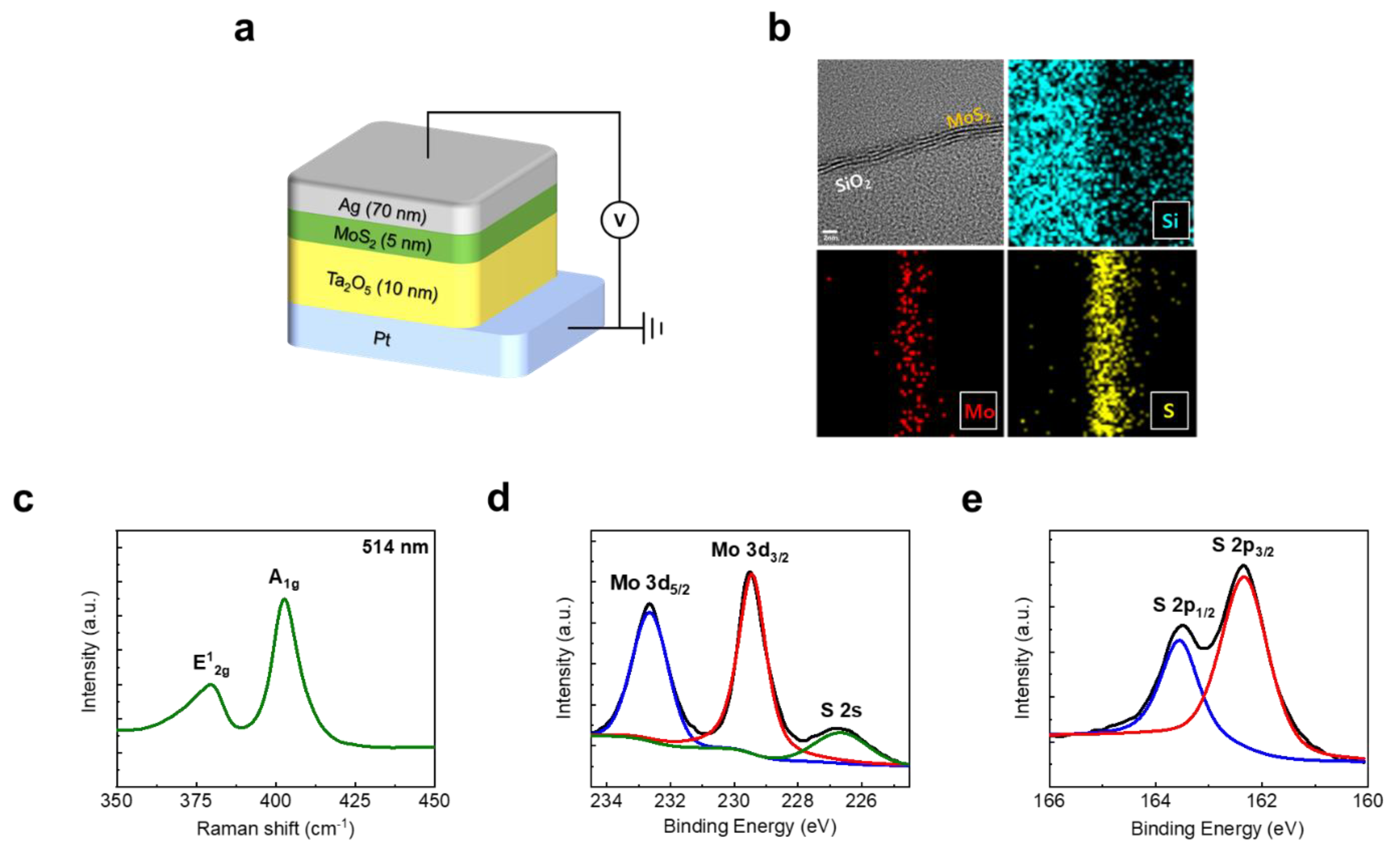

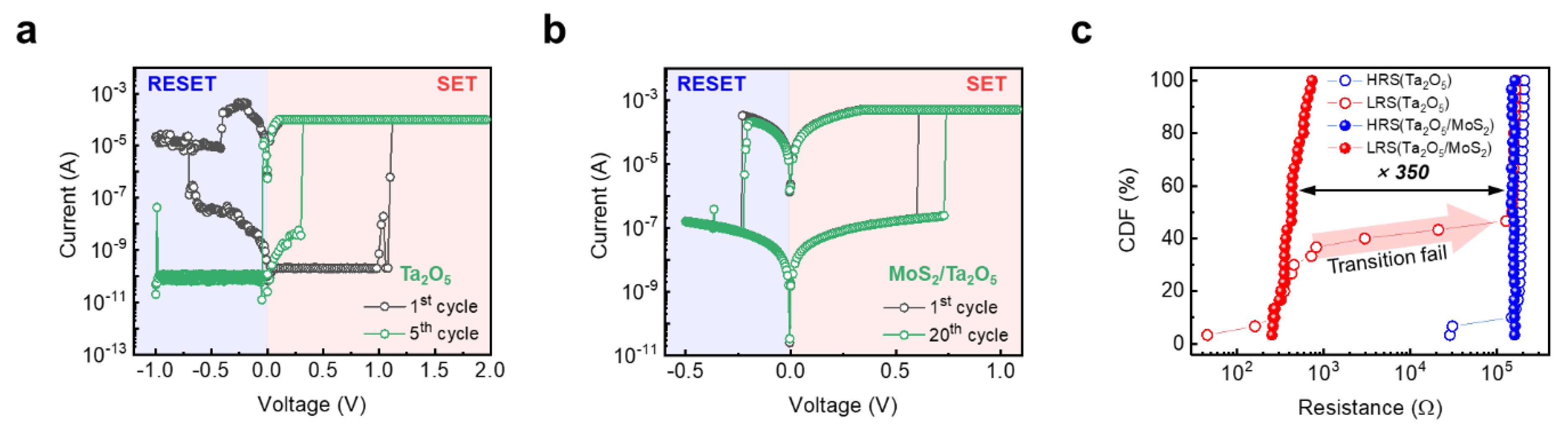

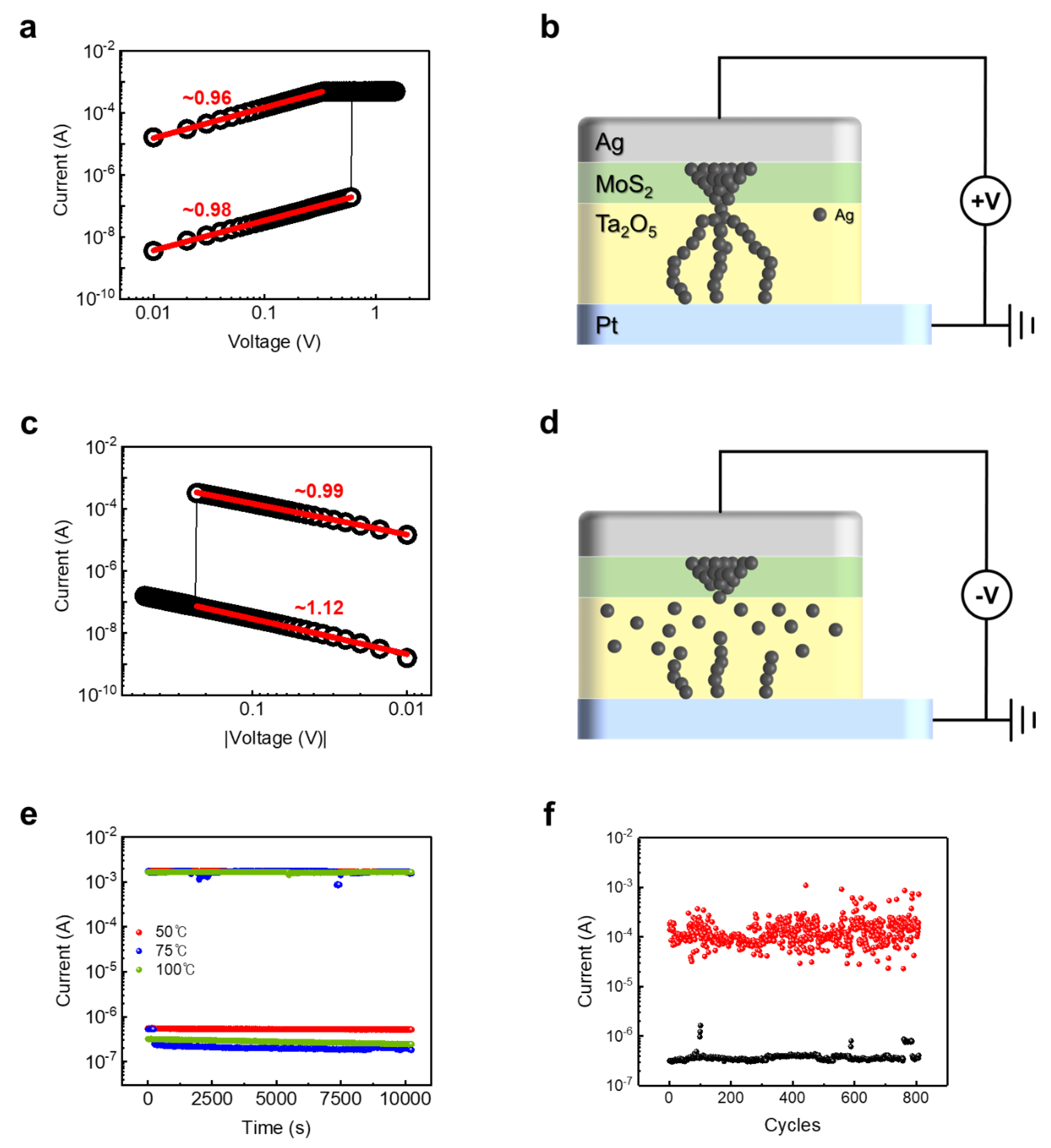

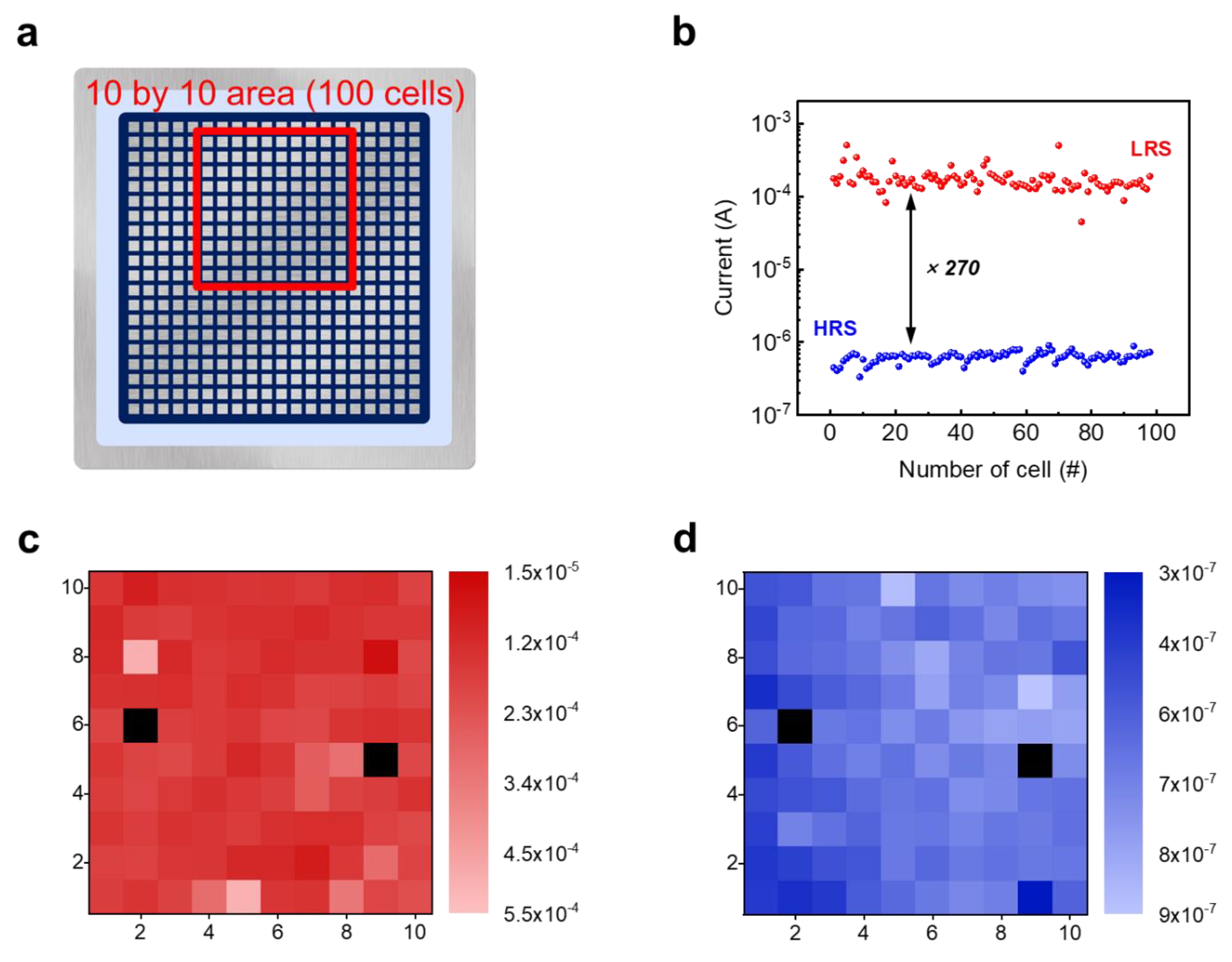

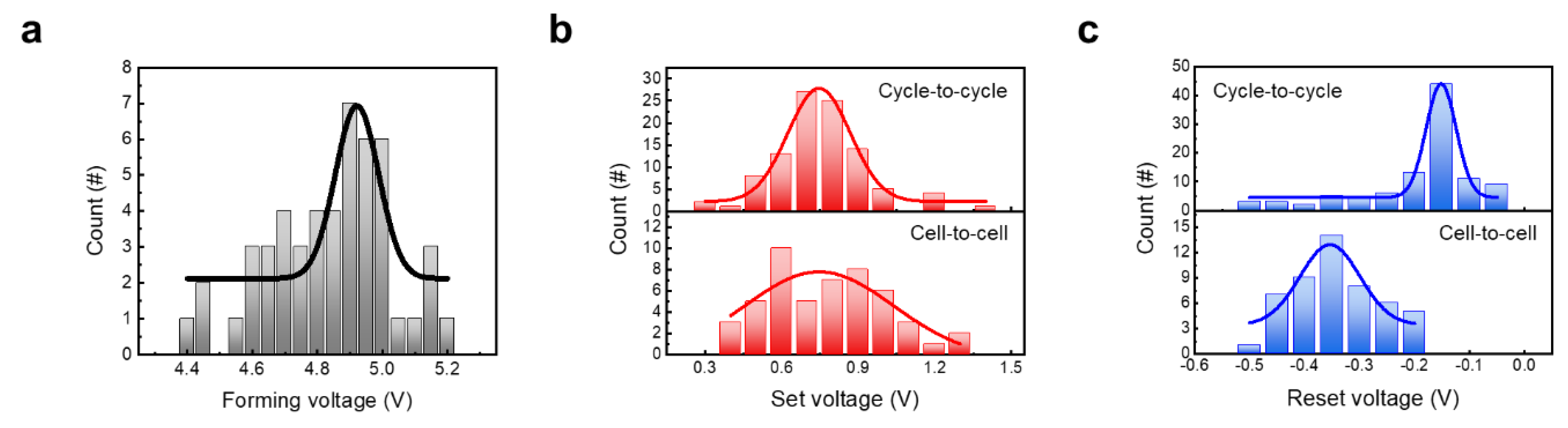

2. Results and Discussion

3. Conclusions

4. Experimental Section

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liang, F.; Yu, W.; An, D.; Yang, Q.; Fu, X.; Zhao, W. A Survey on Big Data Market: Pricing, Trading and Protection. IEEE Access 2018, 6, 15132–15154. [Google Scholar] [CrossRef]

- Indiveri, G.; Liu, S. Memory and Information Processing in Neuromorphic Systems. Proc. IEEE 2015, 103, 1379–1397. [Google Scholar] [CrossRef] [Green Version]

- Fuller, E.J.; Keene, S.T.; Melianas, A.; Wang, Z.; Agarwal, S.; Li, Y.; Tuchman, Y.; James, C.D.; Marinella, M.J.; Yang, J.J.; et al. Parallel Programming of an Ionic Floating-Gate Memory Array for Scalable Neuromorphic Computing. Science 2019, 364, 570–574. [Google Scholar] [CrossRef] [PubMed]

- Sebastian, A.; Le Gallo, M.; Khaddam-Aljameh, R.; Eleftheriou, E. Memory devices and applications for in-memory computing. Nat. Nanotechnol. 2020, 15, 529–544. [Google Scholar] [CrossRef] [PubMed]

- Yao, P.; Wu, H.; Gao, B.; Tang, J.; Zhang, Q.; Zhang, W.; Yang, J.J.; Qian, H. Fully hardware-implemented memristor convolutional neural network. Nature 2020, 577, 641–646. [Google Scholar] [CrossRef]

- Prezioso, M.; Bayat, F.M.; Hoskins, B.D.; Adam, G.C.; Likharev, K.K.; Strukov, D.B. Tranining and operation of an integrated neuromorphic network based on metal-oxide memristors. Nature 2015, 521, 61–64. [Google Scholar] [CrossRef] [Green Version]

- Sheridan, P.M.; Cai, F.; Du, C.; Ma, W.; Zhang, Z.; Lu, W.D. Spare coding with memristor networks. Nat. Nanotechnol. 2017, 12, 784–789. [Google Scholar] [CrossRef]

- Oh, S.; Shi, Y.; Liu, X.; Song, J.; Kuzum, D. Drift-enhanced unsupervised learning of handwritten digits in spiking neural network with pcm syanapses. IEEE Electron Device Lett. 2018, 39, 1768–1771. [Google Scholar] [CrossRef]

- Lim, D.-H.; Wu, S.; Zhao, R.; Lee, J.-H.; Jeong, H.; Shi, L. Spontaneous sparse learning for PCM-based memristor neural networks. Nat. Commun. 2021, 12, 1–14. [Google Scholar] [CrossRef]

- Pan, Y.; Ouyang, P.; Zhao, Y.; Kang, W.; Yin, S.; Zhang, Y.; Zhao, W.; Wei, S. A mulilevel cell STT-MRAM-based computing in-memory accelerator for binary convolutional neural network. IEEE Trans. Mag. 2018, 54, 9401305. [Google Scholar] [CrossRef]

- Khvalkovskiy, A.V.; Apalkov, D.; Watts, S.; Chepulskii, R.; Beach, R.S.; Ong, A.; Tang, X.; Smith, A.D.; Butler, W.H.; Visscher, P.B.; et al. Basic principles of STT-MRAM cell operation in memory arrays. J. Phys. D Appl. Phys. 2013, 46, 139601. [Google Scholar] [CrossRef]

- Guo, X.; Bayat, F.M.; Bavandpour, M.; Klachko, M.; Mahmoodi, M.R.; Prezioso, M.; Likharev, K.K.; Strukov, D.B. Fast, energy-efficient, robust, and reproducible mixed-signal neuromorphic classifier based on embedded NOR flash memory technology. In Proceedings of the IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 2–6 December 2017; p. 17524788. [Google Scholar]

- Burr, G.W.; Shelby, R.M.; Sebastian, A.; Kim, S.; Kim, S.; Sidler, S.; Virwani, K.; Ishii, M.; Narayanan, P.; Fumarola, A.; et al. Neuromorphic Computing Using Non-Volatile Memory. Adv. Phys. X 2017, 2, 89–124. [Google Scholar] [CrossRef]

- Kim, K.-H.; Gaba, S.; Wheeler, D.; Cruz-Albrecht, J.M.; Hussain, T.; Srinivasa, N.; Lu, W. A Functional Hybrid Memristor Crossbar-Array/CMOS System for Data Storage and Neuromorphic Applications. Nano Lett. 2012, 12, 389–395. [Google Scholar] [CrossRef]

- Yan, B.; Li, B.; Qiao, X.; Xue, C.-X.; Chang, M.-F.; Chen, Y.; Li, H. Resistive Memory-Based In-Memory Computing: From Device and Large-Scale Integration System Perspectives. Adv. Intell. Syst. 2019, 1, 1900068. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.J.; Strukov, D.B.; Stewart, D.R. Memristive Devices for Computing. Nat. Nanotechnol. 2013, 8, 13–24. [Google Scholar] [CrossRef]

- Cavallini, M.; Hemmatian, Z.; Riminucci, A.; Prezioso, M.; Morandi, V.; Murgia, M. Regenerable Resistive Switching in Silicon Oxide Based Nanojunctions. Adv. Mater. 2012, 24, 1197–1201. [Google Scholar] [CrossRef]

- Wong, H.-P.; Lee, H.; Yu, S.; Chen, Y.; Wu, Y.; Chen, P.; Lee, B.; Chen, F.T.; Tsai, M. Metal–Oxide RRAM. Proc. IEEE 2012, 100, 1951–1970. [Google Scholar] [CrossRef]

- Gupta, V.; Kapur, S.; Saurabh, S.; Grover, A. Resistive Random Access Memory: A Review of Device Challenges. IETE Tech. Rev. 2020, 37, 377–390. [Google Scholar] [CrossRef]

- Zahoor, F.; Azni Zulkifli, T.Z.; Khanday, F.A. Resistive Random Access Memory (RRAM): An Overview of Materials, Switching Mechanism, Performance, Multilevel Cell (MLC) Storage, Modeling, and Applications. Nanoscale Res. Lett. 2020, 15, 1–26. [Google Scholar] [CrossRef]

- Yao, J.D.; Yang, G.W. All-2D Architectures toward Advanced Electronic and Optoelectronic Devices. Nano Today 2021, 36, 101026. [Google Scholar] [CrossRef]

- Gong, C.; Zhang, Y.; Chen, W.; Chu, J.; Lei, T.; Pu, J.; Dai, L.; Wu, C.; Cheng, Y.; Zhai, T.; et al. Electronic and Optoelectronic Applications Based on 2D Novel Anisotropic Transition Metal Dichalcogenides. Adv. Sci. 2017, 4, 1700231. [Google Scholar] [CrossRef] [PubMed]

- Radisavljevic, B.; Radenovic, A.; Brivio, J.; Giacometti, V.; Kis, A. Single-Layer MoS2 Transistors. Nat. Nanotechnol. 2011, 6, 147–150. [Google Scholar] [CrossRef] [PubMed]

- Singh, E.; Singh, P.; Kim, K.S.; Yeom, G.Y.; Nalwa, H.S. Flexible Molybdenum Disulfide (MoS2) Atomic Layers for Wearable Electronics and Optoelectronics. ACS Appl. Mater. Interfaces 2019, 11, 11061–11105. [Google Scholar] [CrossRef] [PubMed]

- Nipane, A.; Karmakar, D.; Kaushik, N.; Karande, S.; Lodha, S. Few-Layer MoS2 p-Type Devices Enabled by Selective Doping Using Low Energy Phosphorus Implantation. ACS Nano 2016, 10, 2128–2137. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharjee, S.; Caruso, E.; McEvoy, N.; Coileáin, C.Ó.; O’Neill, K.; Ansari, L.; Duesberg, G.S.; Nagle, R.; Cherkaoui, K.; Gity, F.; et al. Insights into Multilevel Resistive Switching in Monolayer MoS2. ACS Appl. Mater. Interfaces 2020, 12, 6022–6029. [Google Scholar] [CrossRef]

- He, H.-K.; Yang, R.; Zhou, W.; Huang, H.-M.; Xiong, J.; Gan, L.; Zhai, T.-Y.; Guo, X. Photonic Potentiation and Electric Habituation in Ultrathin Memristive Synapses Based on Monolayer MoS2. Small 2018, 14, 1800079. [Google Scholar] [CrossRef]

- Feng, X.; Li, Y.; Wang, L.; Chen, S.; Yu, Z.G.; Tan, W.C.; Macadam, N.; Hu, G.; Huang, L.; Chen, L.; et al. A Fully Printed Flexible MoS2 Memristive Artificial Synapse with Femtojoule Switching Energy. Adv. Electron. Mater. 2019, 5, 1900740. [Google Scholar] [CrossRef] [Green Version]

- Jeon, Y.-R.; Choi, J.; Kwon, J.-D.; Park, M.H.; Kim, Y.; Choi, C. Suppressed stochastic switching behavior and improved synaptic functions in an atomic swtich embedded with a 2D NbSe2 Materials. ACS Appl. Mater. Interfaces 2021, 13, 10161–10170. [Google Scholar] [CrossRef]

- Pan, F.; Gao, S.; Chen, C.; Song, C.; Zeng, F. Recent Progress in Resistive Random Access Memories: Materials, Switching Mechanisms, and Performance. Mater. Sci. Eng. R. Rep. 2014, 83, 1–59. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, S.; Kwon, J.-D.; Kim, Y. Statistical Analysis of Uniform Switching Characteristics of Ta2O5-Based Memristors by Embedding In-Situ Grown 2D-MoS2 Buffer Layers. Materials 2021, 14, 6275. https://doi.org/10.3390/ma14216275

Jin S, Kwon J-D, Kim Y. Statistical Analysis of Uniform Switching Characteristics of Ta2O5-Based Memristors by Embedding In-Situ Grown 2D-MoS2 Buffer Layers. Materials. 2021; 14(21):6275. https://doi.org/10.3390/ma14216275

Chicago/Turabian StyleJin, Soeun, Jung-Dae Kwon, and Yonghun Kim. 2021. "Statistical Analysis of Uniform Switching Characteristics of Ta2O5-Based Memristors by Embedding In-Situ Grown 2D-MoS2 Buffer Layers" Materials 14, no. 21: 6275. https://doi.org/10.3390/ma14216275

APA StyleJin, S., Kwon, J.-D., & Kim, Y. (2021). Statistical Analysis of Uniform Switching Characteristics of Ta2O5-Based Memristors by Embedding In-Situ Grown 2D-MoS2 Buffer Layers. Materials, 14(21), 6275. https://doi.org/10.3390/ma14216275