Annealing Effect on the Characteristics of Co40Fe40W10B10 Thin Films on Si(100) Substrate

Abstract

:1. Introduction

2. Materials and Methods

3. Results

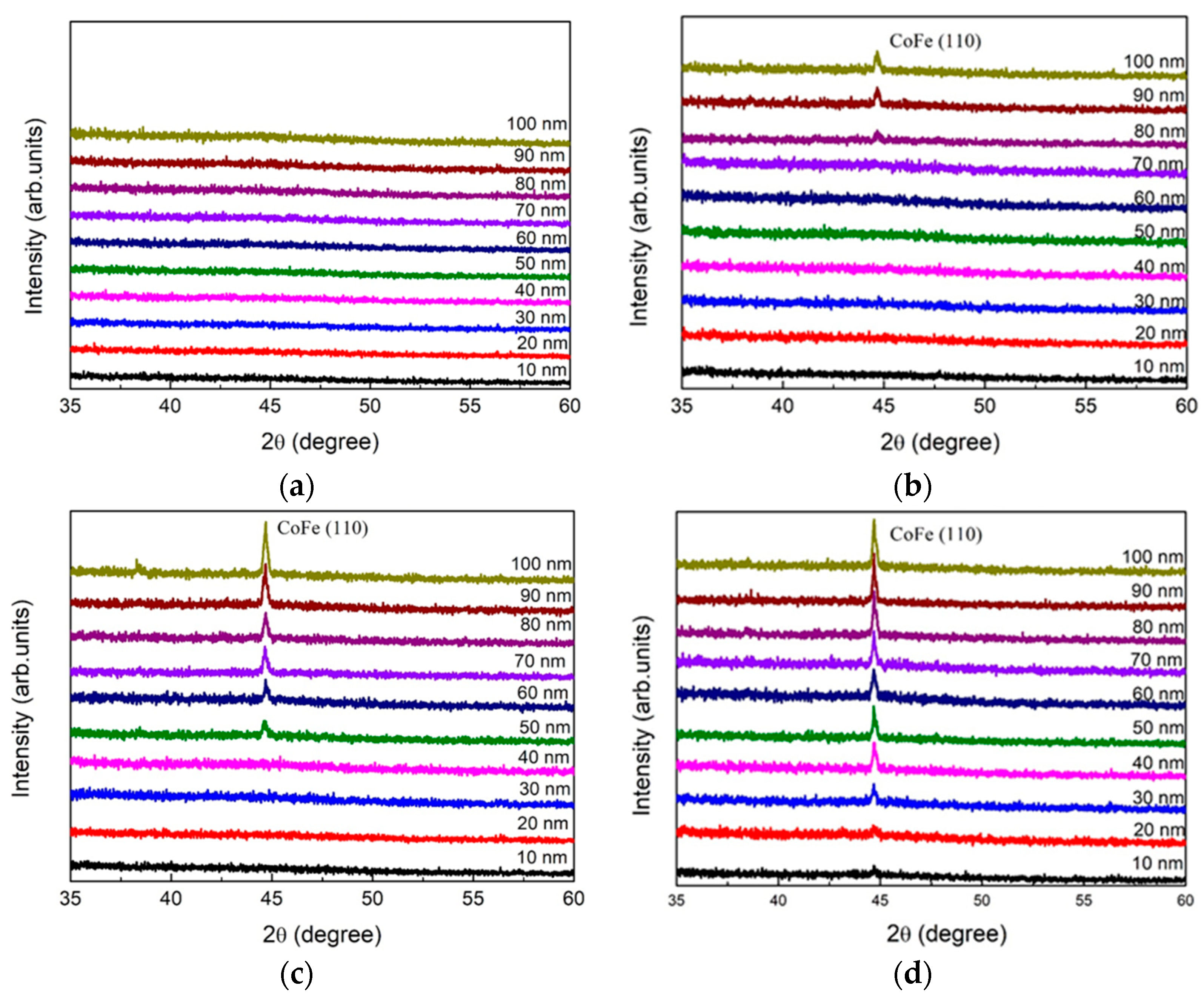

3.1. X-ray Diffraction

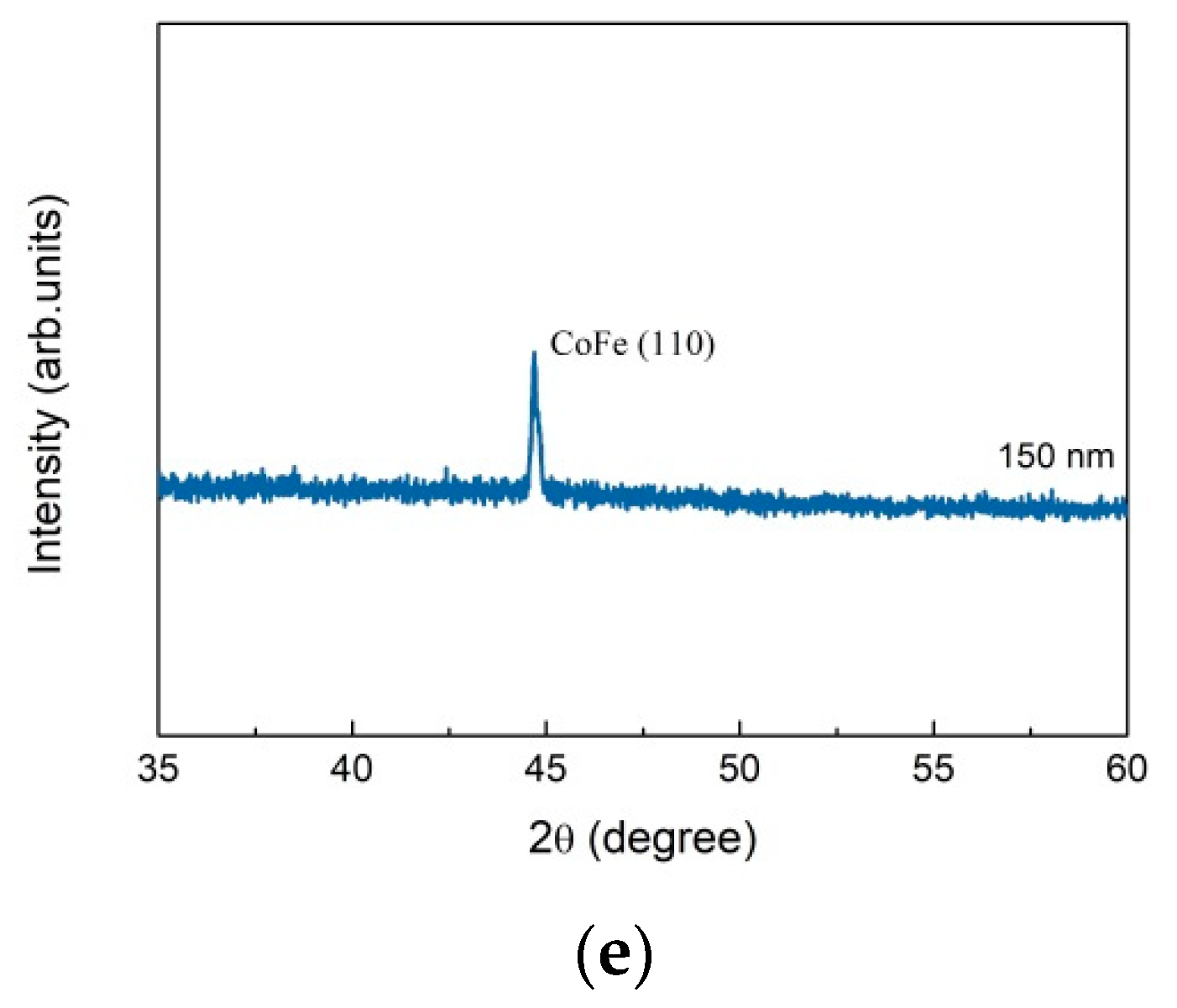

3.2. Full-Width at Half Maximum (FWHM) and Grain Size Distribution

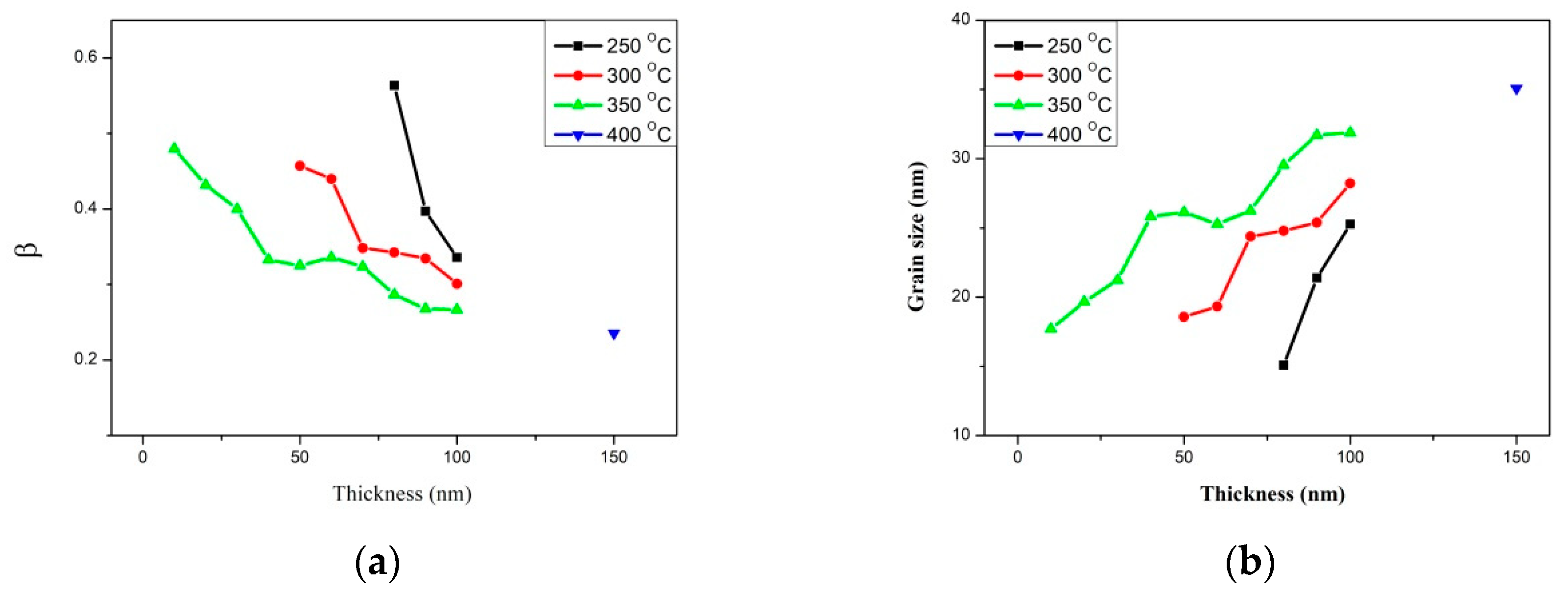

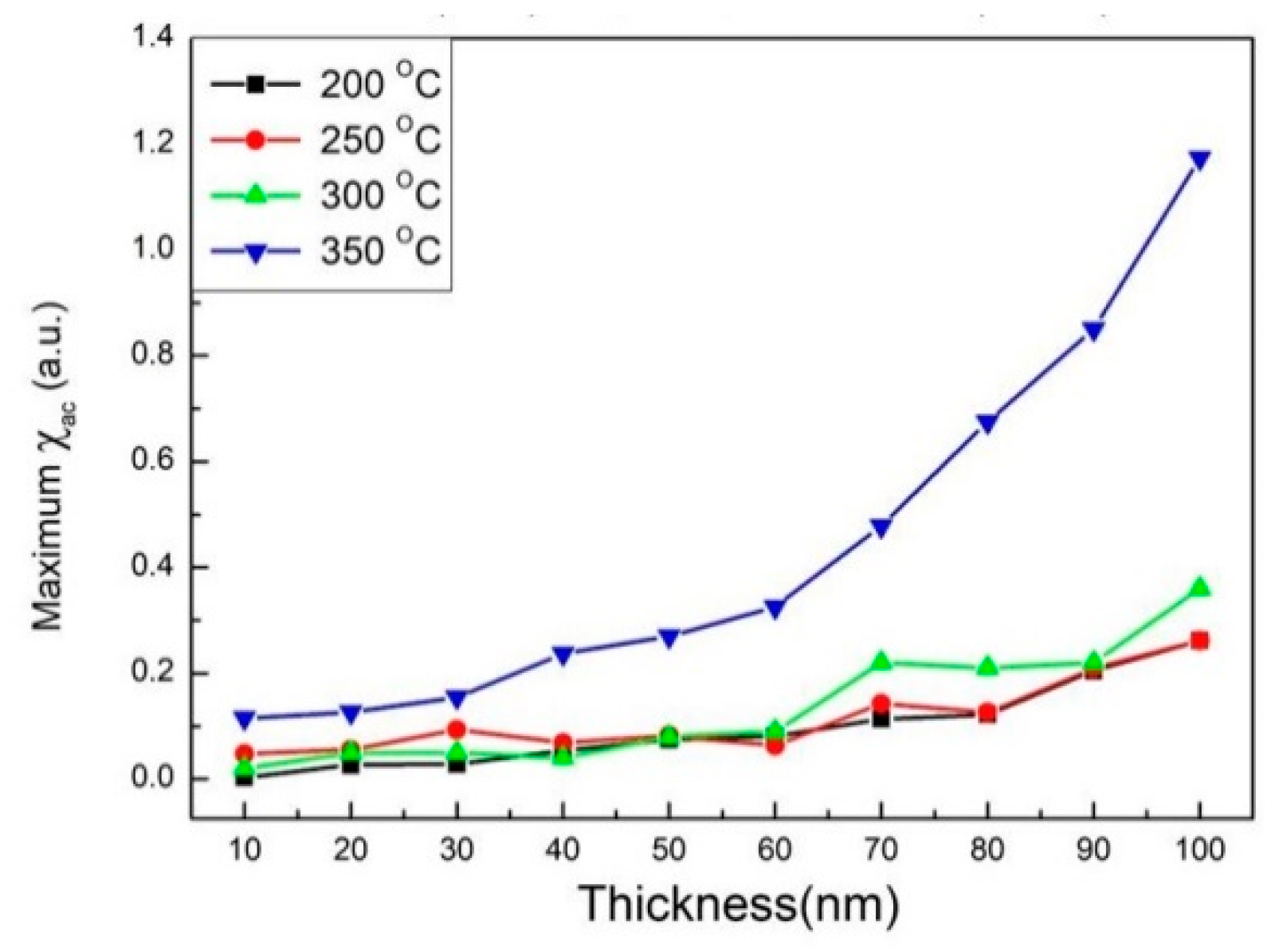

3.3. Magnetic Analysis

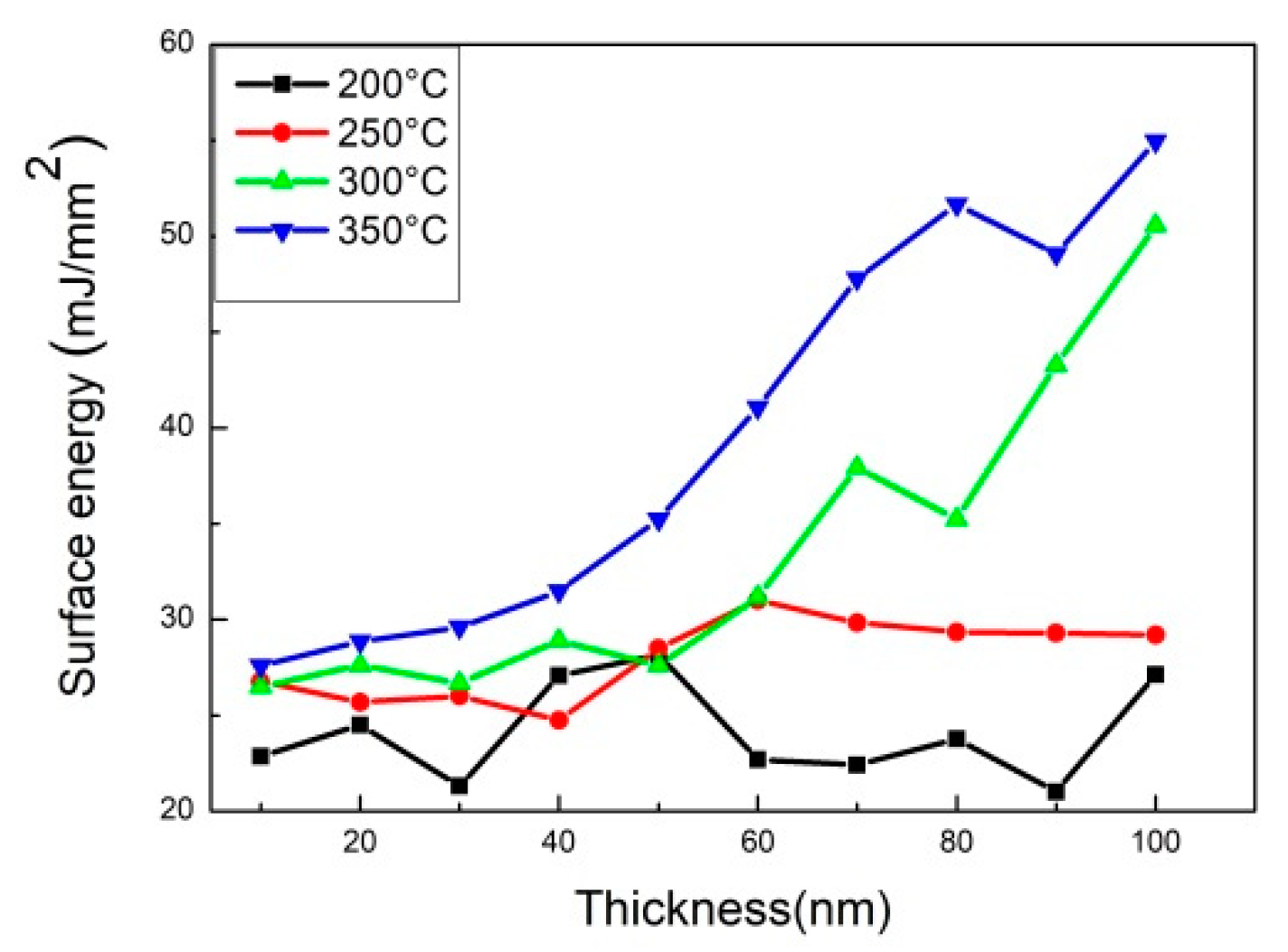

3.4. Contact Angle and Surface Energy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rozlin, N.M.N.; Alfantazi, A.M. Nanocrystalline cobalt-iron alloy: Synthesis and characterization. Mater. Sci. Eng. A 2012, 550, 388–394. [Google Scholar] [CrossRef]

- Gibbs, M.R.J.; Hill, E.W.; Wright, P.J. Magnetic materials for MEMS applications. J. Phys. D 2004, 37, R237–R244. [Google Scholar] [CrossRef]

- Chen, C.; Xiong, D.; Gu, M.; Lu, C.; Yi, F.Y.; Ma, X. MOF-Derived Bimetallic CoFe-PBA Composites as Highly Selective and Sensitive Electrochemical Sensors for Hydrogen Peroxide and Nonenzymatic Glucose in Human Serum. ACS Appl. Mater. Interfaces 2020, 12, 35365–35374. [Google Scholar] [CrossRef] [PubMed]

- Takemura, Y.; Inoue, T.; Nishimoto, M.; Yamada, T. Fabrication of zero-speed sensor using weakly coupled NiFe/CoFe multilayer films. IEEE Trans. Magn. 2004, 40, 2667–2669. [Google Scholar] [CrossRef]

- Takemura, Y.; Yamada, T. Output properties of zero-speed sensors using FeCoV wire and NiFe/CoFe multilayer thin film. IEEE Sens. J. 2006, 6, 1186–1190. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Feng, Y.C.; Clinton, T.; Badran, G.; Yeh, N.H.; Tarnopolsky, G.; Girt, E.; Munteanu, M.; Harkness, S.; Richter, H.; et al. Magnetic Recording Demonstration Over 100 Gb/in2. IEEE Trans. Magn. 2002, 38, 1861–1866. [Google Scholar] [CrossRef]

- Li, M.; Shi, H.; Yu, G.; Lu, J.; Chen, X.; Han, G.; Yu, G.; Amiri, P.K.; Wang, K.L. Effects of annealing on the magnetic properties and microstructures of Ta/Mo/CoFeB/MgO/Ta films. J. Alloys Compd. 2017, 692, 243–248. [Google Scholar] [CrossRef] [Green Version]

- Almasi, H.; Hickey, D.R.; Newhouse-Illige, T.; Xu, M.; Rosales, M.R.; Nahar, S.; Held, J.T.; Mkhoyan, K.A.; Wang, W.G. Enhanced tunneling magnetoresistance and perpendicular magnetic anisotropy in Mo/CoFeB/MgO magnetic tunnel junctions. Appl. Phys. Lett. 2015, 106, 182406. [Google Scholar] [CrossRef]

- Huang, S.X.; Chen, T.Y.; Chien, C.L. Spin polarization of amorphous CoFeB detemined by point-contact Andreev reflection. Appl. Phys. Lett. 2008, 92, 242509. [Google Scholar] [CrossRef]

- Paluskar, P.V.; Attema, J.J.; de Wijs, G.A.; Fiddy, S.; Snoeck, E.; Kohlhepp, J.T.; Swagten, H.J.M.; de Groot, R.A.; Koopmans, B. Spin tunneling in junctions with disordered ferromagnets. Phys. Rev. Lett. 2008, 100, 057205. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Wang, S.; Zhang, S.; Fang, S.; Yu, G. The perpendicular magnetic anisotropies of CoFeB/MgO films with Nb buffer layers. J. Magn. Magn. Mater. 2019, 485, 187–192. [Google Scholar] [CrossRef]

- Meng, H.; Lum, W.H.; Sbiaa, R.; Lua, S.Y.H.; Tan, H.K. Annealing effects on CoFeB-MgO magnetic tunnel junctions with perpendicular anisotropy. J. Appl. Phys. 2011, 110, 033904. [Google Scholar] [CrossRef]

- Pai, C.F.; Liu, L.; Li, Y.; Tseng, H.W.; Ralph, D.C.; Buhrman, R.A. Spin transfer torque devices utilizing the giant spin Hall effect of tungsten. Appl. Phys. Lett. 2012, 101, 122404. [Google Scholar] [CrossRef]

- An, G.G.; Lee, J.B.; Yang, S.M.; Kim, J.H.; Chung, W.S.; Hong, J.P. Highly stable perpendicular magnetic anisotropies of CoFeB/MgO frames employing W buffer and capping layers. Acta Mater. 2015, 87, 259–265. [Google Scholar] [CrossRef]

- Ghaferi, Z.; Sharafi, S.; Bahrololoom, M.E. The role of electrolyte pH on phase evolution and magnetic properties of CoFeW codeposited films. Appl. Surf. Sci. 2016, 375, 35–41. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, T.; Zhu, Z.; Zhong, H.; Khamis, K.M.; Zhu, K. High thermal stability in W/MgO/CoFeB/W/CoFeB/W stacks via ultrathin W insertion with perpendicular magnetic anisotropy. J. Magn. Magn. Mater. 2016, 410, 123–127. [Google Scholar] [CrossRef]

- Wang, H.; Kou, X.; Wang, S.; Zhou, J.; Zhang, X.; Li, J. Structures, magnetic properties and thermal stability of CoFeB/MgO films. Phys. Procedia 2011, 18, 267–273. [Google Scholar] [CrossRef] [Green Version]

- Ma, K.; Chung, T.S.; Good, R.J. Surface energy of thermotropic liquid crystalline polyesters and polyesteramide. J. Polym. Sci. 1998, 36, 2327–2337. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Kaelble, D.H.; Uy, K.C. A Reinterpretation of Organic Liquid-Polytetrafluoroethylene Surface Interactions. J. Adhens. 1970, 2, 50–60. [Google Scholar] [CrossRef]

- Cullity, B.D. Elements of X-ray Diffraction, 2nd ed.; Addison-Wesley: Reading, MA, USA, 1978. [Google Scholar]

- Patterson, A.L. The Scherrer formula for X-Ray particle size determination. Phys. Rev. 1939, 56, 978–982. [Google Scholar] [CrossRef]

- Jin, Y.; Lin, B.; Bernacki, M.; Rohrer, G.S.; Rollett, A.D.; Bozzolo, N. Annealing twin development during recrystallization and grain growth in pure nickel. Mater. Sci. Eng. A 2014, 597, 295–303. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.; Duan, F.; Pan, J.; Li, Y. High-throughput screening of critical size of grain growth in gradient structured nickel. J. Mater. Sci. Technol. 2021, 82, 33–39. [Google Scholar] [CrossRef]

- Mouhib, F.Z.; Sheng, F.; Mandia, R.; Pei, R.; Korte-Kerzel, S. Texture selection mechanisms during recrystallization and grain growth of a magnesium-erbium-zinc alloy. Metals 2021, 11, 171. [Google Scholar] [CrossRef]

- Budde, T.; Gatzen, H.H. Magnetic properties of an SmCo/NiFe system for magnetic microactuators. J. Magn. Magn. Mater. 2004, 272–276, 2027–2028. [Google Scholar] [CrossRef]

- Wen, D.; Li, J.; Gan, G.; Yang, Y.; Zhang, H.; Liu, Y. Double peaks of the permeability spectra of obliquely sputtered CoFeB amorphous films. Mater. Res. Bull. 2019, 110, 107–111. [Google Scholar] [CrossRef]

- Iihama, S.; Mizukami, S.; Naganuma, H.; Oogane, M.; Ando, Y.; Miyazaki, T. Gilbert damping constants of Ta/CoFeB/MgO(Ta) thin films measured by optical detection of precessional magnetization dynamics. Phys. Rev. B 2014, 89, 174416. [Google Scholar] [CrossRef]

- Li, M.; Wang, S.; Zhang, S.; Fang, S.; Feng, G.; Cao, X.; Zhang, P.; Wang, B.; Yu, G. The effect of interfacial oxygen migration on the PMA and thermal stability in MTJ with double MgO layers. Appl. Sur. Sci. 2019, 488, 30–35. [Google Scholar] [CrossRef]

- Miyakawa, N.; Worledge, D.C.; Kita, K. Impact of Ta diffusion on the perpendicular magnetic anisotropy of Ta/CoFeB/MgO. IEEE Magn. Lett. 2013, 4, 100104. [Google Scholar] [CrossRef]

- Yang, S.Y.; Chien, J.J.; Wang, W.C.; Yu, C.Y.; Hing, N.S.; Hong, H.E.; Hong, C.Y.; Yang, H.C.; Chang, C.F.; Lin, H.Y. Magnetic nanoparticles for high-sensitivity detection on nucleic acids via superconducting-quantum-interference-device-based immunomagnetic reduction assay. J. Magn. Magn. Mater. 2011, 323, 681–685. [Google Scholar] [CrossRef]

- Chen, Y.T.; Xie, S.M.; Jheng, H.Y. The low-frequency alternative-current magnetic susceptibility and electrical properties of Si(100)/Fe40Pd40B20(X Å)/ZnO(500 Å) and Si(100)/ZnO(500 Å)/Fe40Pd40B20(Y Å) systems. J. Appl. Phys. 2013, 113, 17B303. [Google Scholar] [CrossRef]

- Porter, D.A.; Easterling, K.E. Phase Transformations in Metals and Alloy, 2nd ed.; CRC: London, UK, 1992. [Google Scholar]

- Ou, S.L.; Liu, W.J.; Chang, Y.H.; Chen, Y.T.; Wang, Y.T.; Li, W.S.; Tseng, J.Y.; Wu, T.H.; Chi, P.W.; Chu, C.L. Structure, magnetic property, surface morphology, and surface energy of Co40Fe40V10B10 films on Si(100) substrate. Appl. Sci. 2020, 10, 449. [Google Scholar] [CrossRef] [Green Version]

| Thickness (nm) | After Annealing at 200 °C (Hz) | After Annealing at 250 °C (Hz) | After Annealing at 300 °C (Hz) | After Annealing at 350 °C (Hz) |

|---|---|---|---|---|

| 10 | 500 | 250 | 500 | 250 |

| 20 | 500 | 250 | 100 | 250 |

| 30 | 100 | 500 | 200 | 250 |

| 40 | 50 | 50 | 100 | 50 |

| 50 | 50 | 250 | 250 | 500 |

| 60 | 250 | 500 | 100 | 100 |

| 70 | 250 | 1000 | 250 | 250 |

| 80 | 250 | 50 | 250 | 50 |

| 90 | 250 | 100 | 500 | 250 |

| 100 | 250 | 50 | 250 | 250 |

| Process | Thickness | Contact Angle with DI Water (θ) | Contact Angle with Glycerol (θ) | Surface Energy (mJ/mm2) |

|---|---|---|---|---|

| Post-annealing 200 °C | 10 nm | 90.0° | 73.2° | 22.87 |

| 20 nm | 80.7° | 65.7° | 24.50 | |

| 30 nm | 85.8° | 81.4° | 21.31 | |

| 40 nm | 84.3° | 72.6° | 27.09 | |

| 50 nm | 80.5° | 71.5° | 28.15 | |

| Post-annealing 200 °C | 60 nm | 83.7° | 79.4° | 22.69 |

| 70 nm | 84.9° | 84.0° | 22.43 | |

| 80 nm | 87.4° | 81.7° | 23.77 | |

| 90 nm | 87.4° | 83.0° | 21.02 | |

| 100 nm | 84.4° | 72.7° | 27.13 | |

| Post-annealing 250 °C | 10 nm | 82.5° | 80.7° | 26.77 |

| 20 nm | 85.6° | 76.0° | 25.69 | |

| 30 nm | 86.5° | 83.2° | 26.01 | |

| 40 nm | 80.7° | 80.0° | 24.75 | |

| 50 nm | 84.2° | 61.9° | 28.49 | |

| Post-annealing 250 °C | 60 nm | 80.3° | 77.3° | 31.01 |

| 70 nm | 73.7° | 70.0° | 29.84 | |

| 80 nm | 80.0° | 71.4° | 29.35 | |

| 90 nm | 75.5° | 70.6° | 29.30 | |

| 100 nm | 77.2° | 75.2° | 29.19 | |

| Post-annealing 300 °C | 10 nm | 82.2° | 78.0° | 26.49 |

| 20 nm | 77.2° | 77.2° | 27.62 | |

| 30 nm | 80.5° | 51.0° | 26.68 | |

| 40 nm | 77.8° | 74.9° | 28.90 | |

| 50 nm | 83.4° | 81.9° | 27.61 | |

| Post-annealing 300 °C | 60 nm | 80.8° | 78.2° | 31.18 |

| 70 nm | 79.6° | 65.9° | 37.93 | |

| 80 nm | 76.5° | 72.4° | 35.24 | |

| 90 nm | 77.7° | 76.6° | 43.26 | |

| 100 nm | 83.7° | 73.0° | 50.56 | |

| Post-annealing 350 °C | 10 nm | 78.3° | 73.6° | 27.60 |

| 20 nm | 75.6° | 75.4° | 28.85 | |

| 30 nm | 76.9° | 71.7° | 29.61 | |

| 40 nm | 71.6° | 68.5° | 31.48 | |

| 50 nm | 81.1° | 79.6° | 35.24 | |

| Post-annealing 350 °C | 60 nm | 80.0° | 78.0° | 41.06 |

| 70 nm | 80.9° | 77.2° | 47.79 | |

| 80 nm | 81.8° | 79.7° | 51.65 | |

| 90 nm | 80.7° | 73.9° | 49.08 | |

| 100 nm | 81.7° | 75.6° | 54.95 |

| Material | Maximum χac (a.u.) | Optimal Resonance Frequency, fres (Hz) | Surface Energy (mJ/mm2) | Crystallinity |

|---|---|---|---|---|

| Si(100)/Co40Fe40V10B10 [34] 10–50 nm at RT | 0.013–0.019 | 50–200 | 34.2–51.5 | Weak |

| Si(100)/Co40Fe40W10B10 [*] 10–100 nm at annealed conditions[*]: Current research | 0.24–1.17 | 50–1000 | 21.0–54.9 | Strong |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.-J.; Chang, Y.-H.; Chen, Y.-T.; Chang, C.-Y.; Lai, J.-X.; Lin, S.-H.; Wu, T.-H.; Chi, P.-W. Annealing Effect on the Characteristics of Co40Fe40W10B10 Thin Films on Si(100) Substrate. Materials 2021, 14, 6017. https://doi.org/10.3390/ma14206017

Liu W-J, Chang Y-H, Chen Y-T, Chang C-Y, Lai J-X, Lin S-H, Wu T-H, Chi P-W. Annealing Effect on the Characteristics of Co40Fe40W10B10 Thin Films on Si(100) Substrate. Materials. 2021; 14(20):6017. https://doi.org/10.3390/ma14206017

Chicago/Turabian StyleLiu, Wen-Jen, Yung-Huang Chang, Yuan-Tsung Chen, Chun-Yu Chang, Jian-Xin Lai, Shih-Hung Lin, Te-Ho Wu, and Po-Wei Chi. 2021. "Annealing Effect on the Characteristics of Co40Fe40W10B10 Thin Films on Si(100) Substrate" Materials 14, no. 20: 6017. https://doi.org/10.3390/ma14206017

APA StyleLiu, W.-J., Chang, Y.-H., Chen, Y.-T., Chang, C.-Y., Lai, J.-X., Lin, S.-H., Wu, T.-H., & Chi, P.-W. (2021). Annealing Effect on the Characteristics of Co40Fe40W10B10 Thin Films on Si(100) Substrate. Materials, 14(20), 6017. https://doi.org/10.3390/ma14206017