Effect of High Rotational-Speed Friction-Stir Welding on Microstructure and Properties of Welded Joints of 6061-T6 Al Alloy Ultrathin Plate

Abstract

1. Introduction

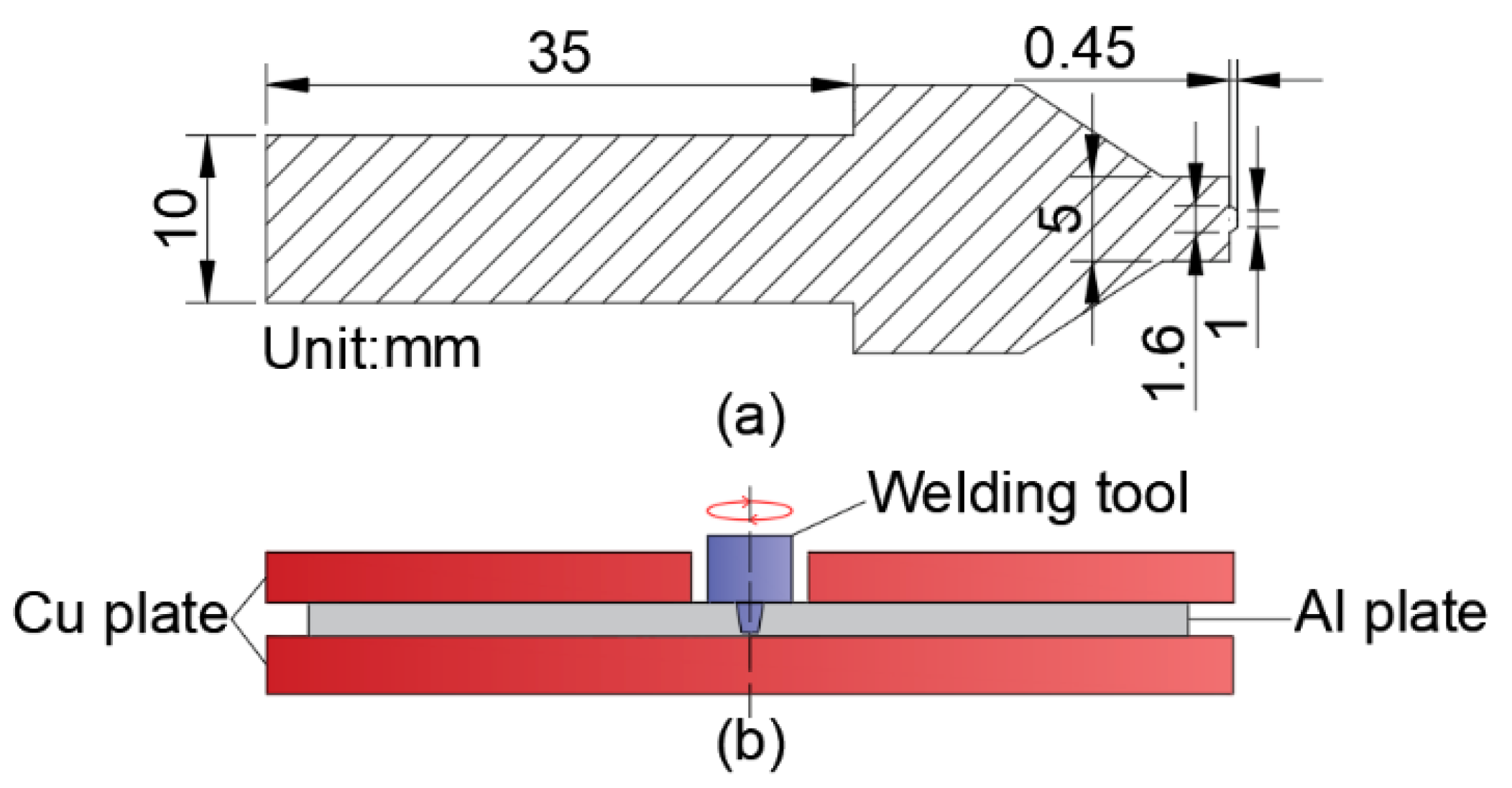

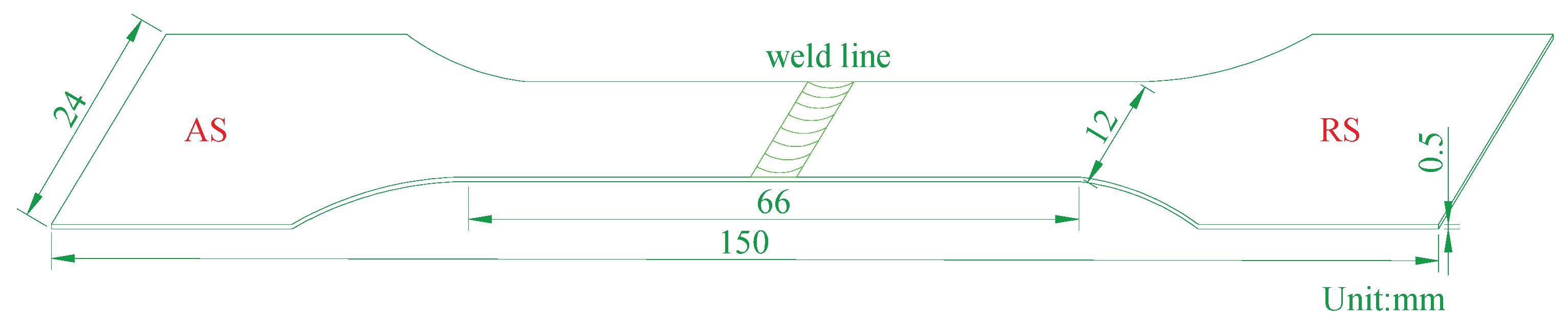

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Result and Discussion

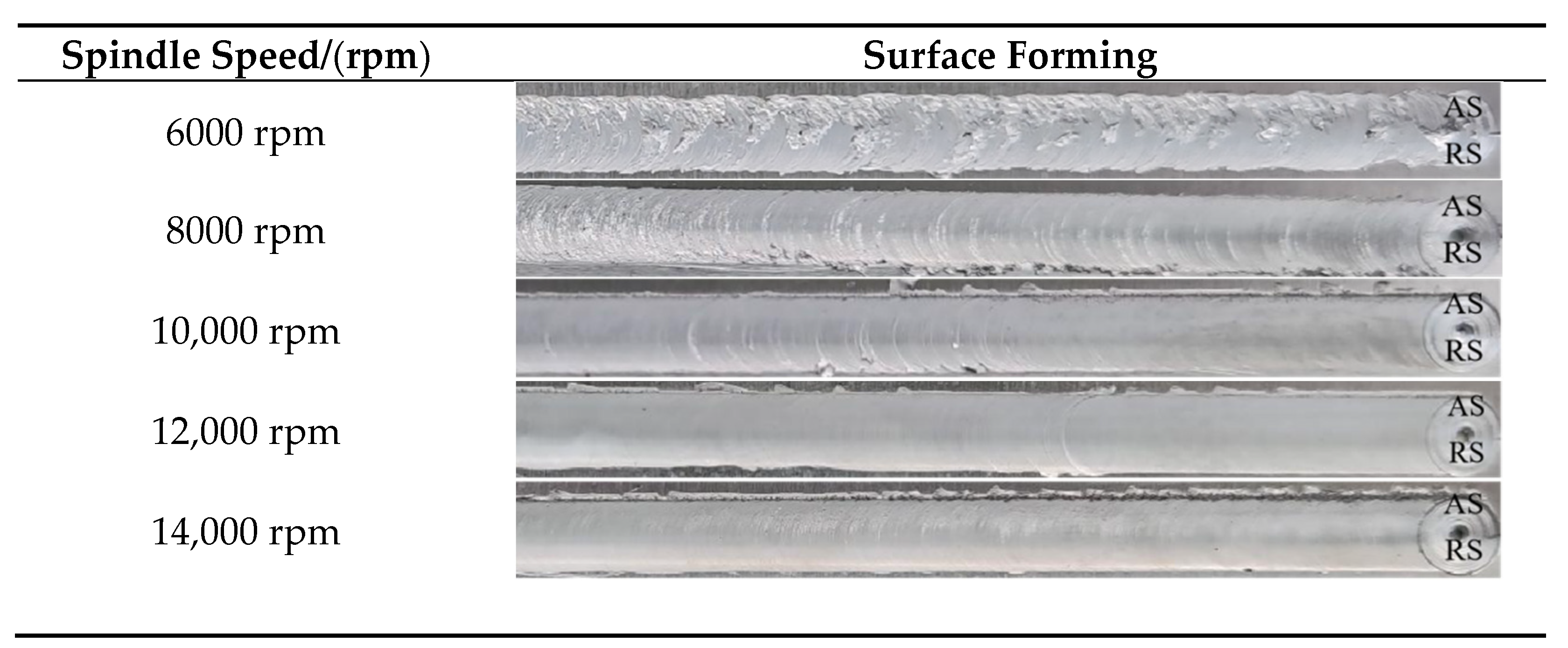

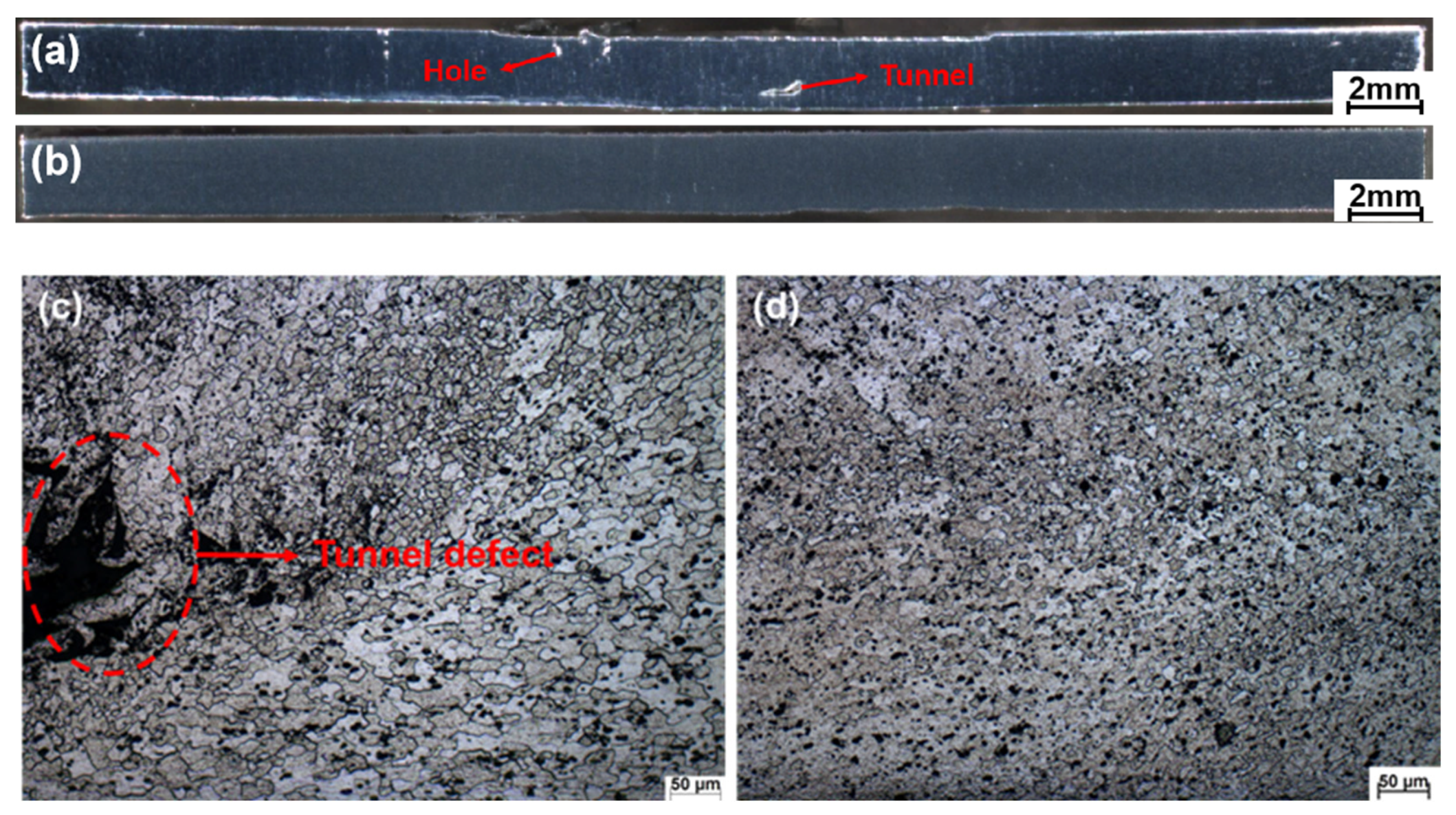

3.1. Macro Forming Analysis

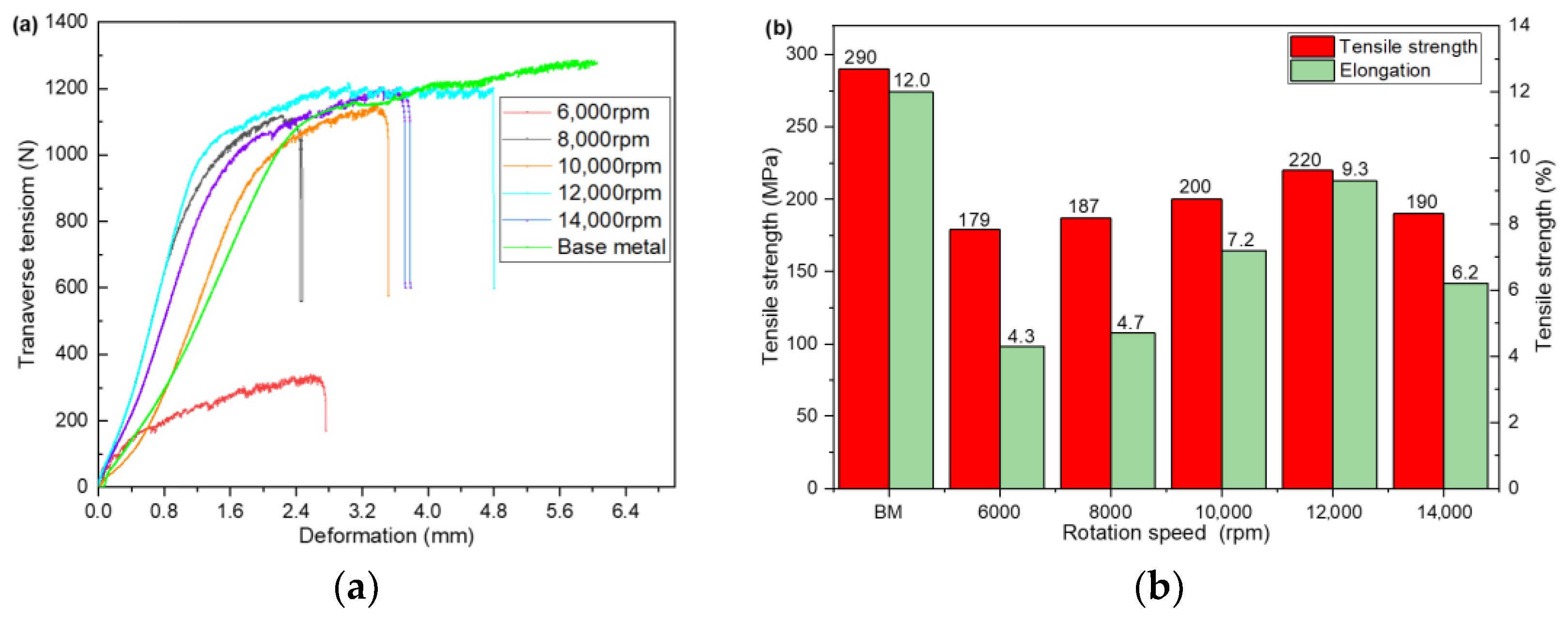

3.2. Mechanical Property Analysis

3.3. Precipitation Phase Analysis

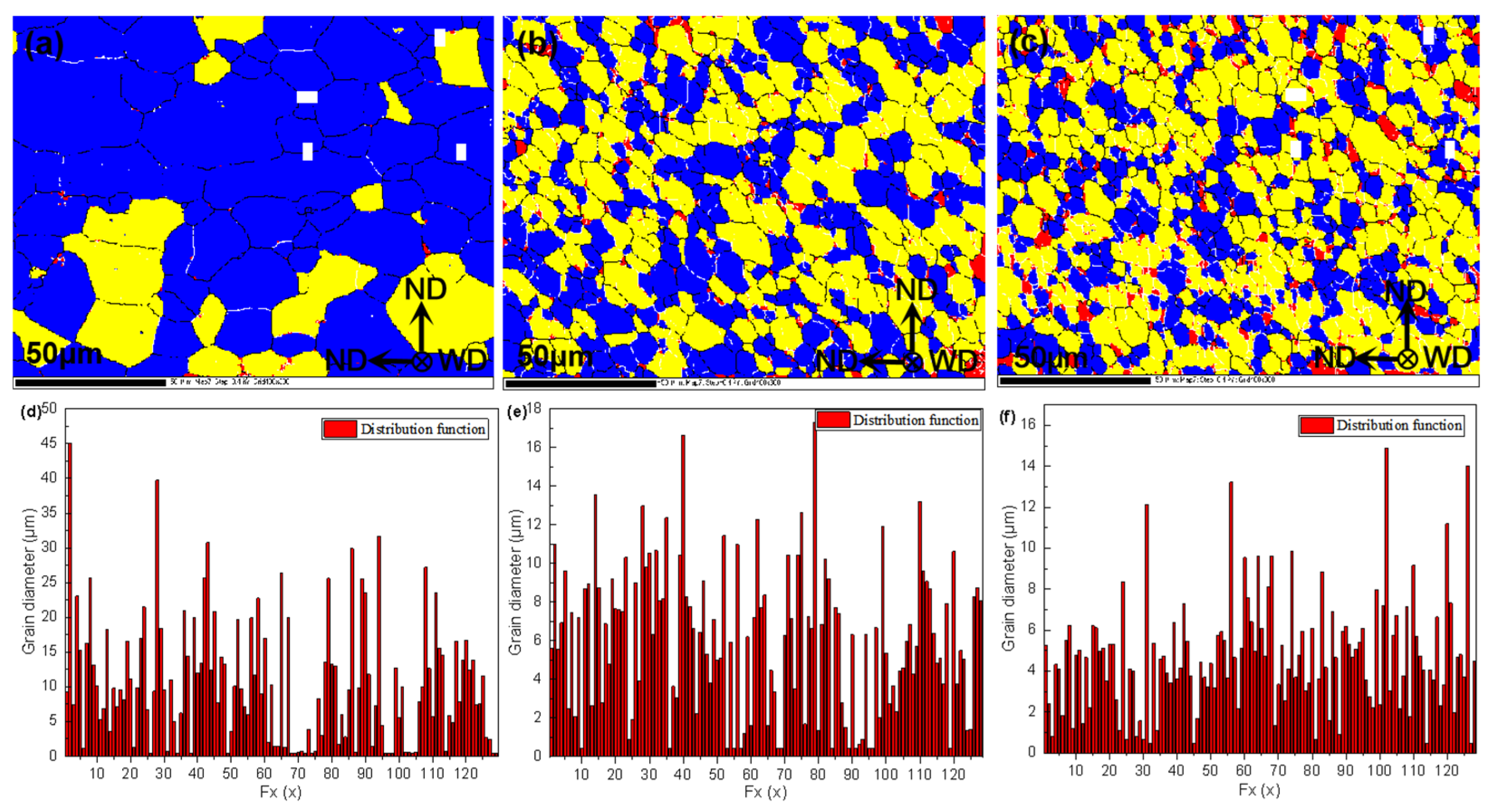

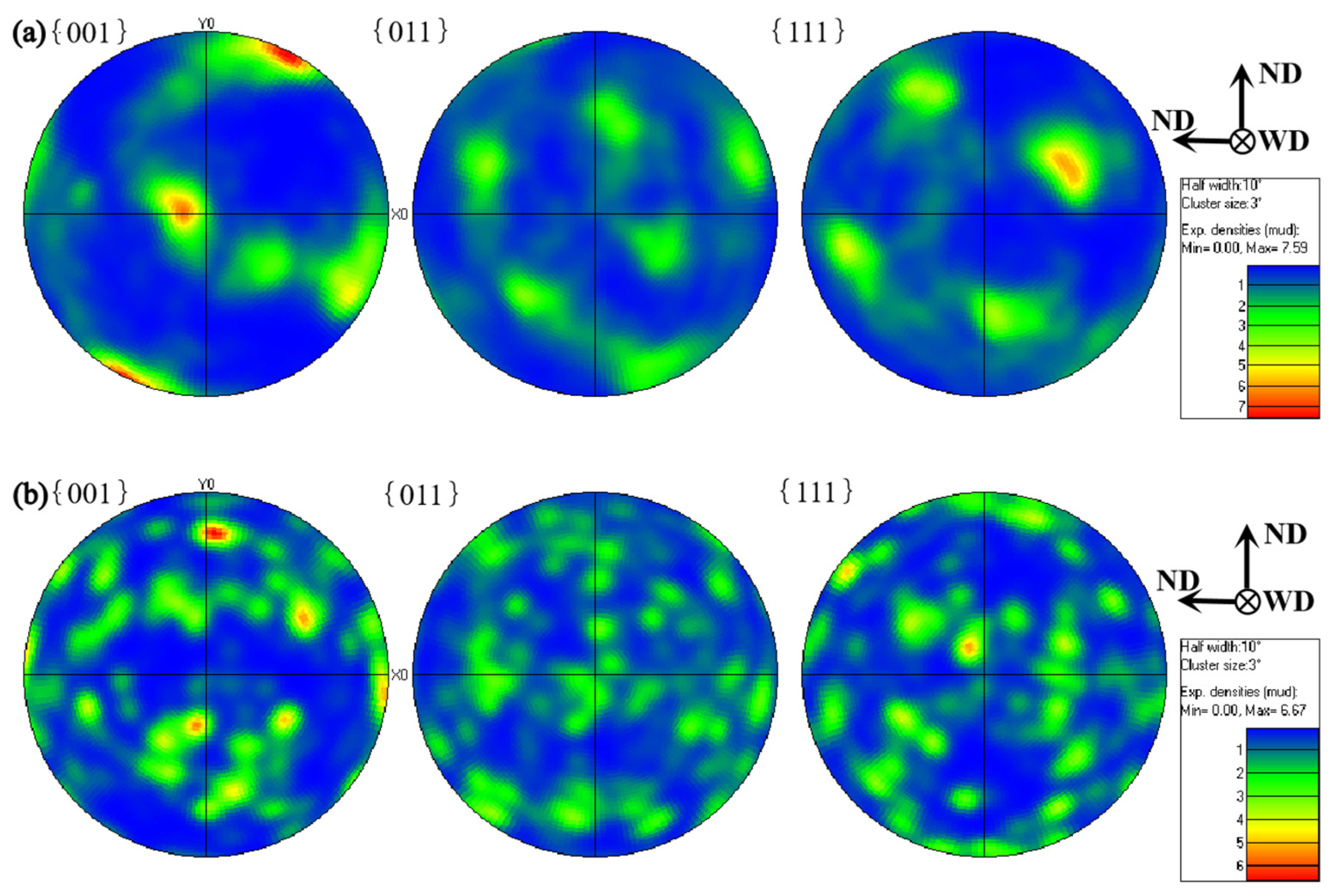

3.4. Microstructural Analysis

3.5. Tensile Fracture Analysis

4. Conclusions

- Low rotational-speed welding of a 0.5 mm-thick Al alloy ultrathin plate will have welding defects such as holes, tunnels, and weak bonding. HRFSW can obtain high-quality welded joints. When the spindle speed is 12,000 rpm and the welding speed is 300 mm/min, a joint with a good weld surface and no obvious welding defects is obtained.

- The mechanical properties of the welded joints obtained by HRFSW are significantly improved compared with those obtained at low rotational speeds. The tensile strength is about 76% of the BM. The average microhardness of the NZ is approximately 88.42% of the BM. The plastic deformation of the joint is the largest, the joint has good plasticity, and the elongation after fracture is about 77.5% of the BM.

- Under a high rotational-speed process, the grain size of the joint welding area decreases significantly after mechanical stirring with a microwelding tool. The microstructure is mainly composed of fine recovery recrystallization grains and subgrain structures, which plays the role of fine-grain weld strengthening. The grain texture grows randomly during the growth process, and the texture strength is relatively uniform, indicating that the high rotational-speed microwelding tool can stir more fully and evenly in the NZ. Due to the thin plate thickness, fast heat dissipation, and large temperature gradient in the NZ, there is a small amount of insoluble brittle phase in the weld area in addition to the dispersed Mg2Si. The precipitation of the brittle phase is the main factor causing the joint strength to be lower than the BM.

- The welded joint obtained by HRFSW has large deformation and high elongation. The dimples on the fracture surface are dispersed and higher in number, which are typical of plastic fractures with better mechanical properties; at low rotational speed, the elongation and strength of the joint are low, and the fracture is brittle.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sunde, J.K.; Christiansen, E.; Thronsen, E.; Wenner, S.; Marioara, C.D.; Van Helvoort, A.T.J.; Holmestad, R. Scanning Precession Electron Diffraction to aid Aluminum Alloy Development. Microsc. Microanal. 2019, 25, 1920–1921. [Google Scholar] [CrossRef][Green Version]

- Robin, W.; Avio Cast Inc. X-Ray Image Interpretation Guide for Aviation Aluminum Alloy Castings. J. Mech. Eng. Autom. 2021, 11, 46–53. [Google Scholar]

- Shinde, G.; Jadhav, G.; Jamadar, V.; Mulani, S.; Arakerimath, R. Optimization of Process Parameters for Peak Temperature during Friction Stir Welding of Aluminum Alloy. Mater. Sci. Eng. 2021, 1123, 012025. [Google Scholar]

- Su, H.; Xue, L.; Wu, C. Optimizing the tool pin with three flats in friction stir welding of aluminum alloy. Int. J. Adv. Manuf. Technol. 2020, 108, 721–733. [Google Scholar] [CrossRef]

- Ogunsemi, B.T.; Abioye, T.E.; Ogedengbe, T.I.; Zuhailawati, H. A review of various improvement strategies for joint quality of AA 6061-T6 friction stir weldments. J. Mater. Res. Technol. 2021, 11, 1061–1089. [Google Scholar] [CrossRef]

- Nie, L.; Wu, Y.X.; Gong, H. Prediction of temperature and residual stress distributions in friction stir welding of aluminum alloy. Int. J. Adv. Manuf. Technol. 2020, 106, 3301–3310. [Google Scholar] [CrossRef]

- Huang, Y.; Xiangchen, M.; Meng, X.; Lv, Z.; Huang, T.; Zhang, Y.; Cao, J.; Zhou, L.; Feng, J. Microstructures and mechanical properties of micro friction stir welding (μFSW) of 6061-T4 aluminum alloy. J. Mater. Res. Technol. 2019, 8, 1084–1091. [Google Scholar] [CrossRef]

- Mehta, K.P.; Badheka, V.J. A review on dissimilar friction stir welding of copper to aluminum: Process, properties, and variants (Review). Mater. Manuf. Process. 2016, 31, 233–254. [Google Scholar] [CrossRef]

- Neto, F.C.; Pereira, M.; dos Santos Paes, L.E.; Fredel, M.C. Assessment of power modulation formats on penetration depth for laser welding. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 1–12. [Google Scholar]

- Ou, Y.; Qinghua, L.; Li, C.; Yan, H.; Zhang, P.; Jin, J. Correction to Effect of Vibration Frequency on Microstructure and Properties of Laser-Welded Inconel 718 Nickel-Base Superalloy. J. Mater. Eng. Perform. 2021, 30, 2408. [Google Scholar]

- Lin, L.; Yang, L.Y.; Yu, J.Q. Summary of 6 series aluminum alloy for automobile and its welding methods. Weld. Technol. 2020, 49, 1–4. [Google Scholar]

- Anlian, X. Properties of High-Speed Friction Stir Welded 6063-T6 Aluminum Alloy. J. Phys. Conf. Ser. 2020, 1676, 012107. [Google Scholar]

- Raja, S.; Ridha, M.M.; Fadzil, J.M.; Farazila, Y. A review on nanomaterials reinforcement in friction stir welding. J. Mater. Res. Technol. 2020, 9, 16459–16487. [Google Scholar] [CrossRef]

- Xu, W.F.; Wu, X.K.; Ma, J.; Lu, H.J.; Luo, Y.X. Abnormal fracture of 7085 high strength aluminum alloy thick plate joint via friction stir welding. J. Mater. Res. Technol. 2019, 8, 6029–6040. [Google Scholar] [CrossRef]

- Li, G.; Zhou, L.; Zhang, J.; Luo, S.; Guo, N. Macrostructure, microstructure and mechanical properties of bobbin tool friction stir welded ZK60 Mg alloy joints. J. Mater. Res. Technol. 2020, 9, 9348–9361. [Google Scholar] [CrossRef]

- Bernard, D.; Hattingh, D.G.; Goosen, W.E.; James, M.N. High Speed Friction Stir Welding of 5182-H111 Alloy: Temperature and Microstructural Insights into Deformation Mechanisms. Met. Mater. Int. 2021, 27, 2821–2836. [Google Scholar] [CrossRef]

- Fenjun, L.; Li, F.; Haiyan, C. High speed friction stir welding of ultra-thin AA6061-T6 sheets using different backing plates. J. Manuf. Process. 2018, 33, 219–227. [Google Scholar]

- Chen, S.J.; Zhou, Y.; Xue, J.R.; Ni, R.Y.; Guo, Y.; Dong, J.H. High Rotation Speed Friction Stir Welding for 2014 Aluminum Alloy Thin. Sheets. J. Mater. Eng. Perform. 2017, 26, 1337–1345. [Google Scholar] [CrossRef]

- Zhang, H.J.; Wang, M.; Qi, R.L.; Zhu, Z.; Zhang, X.; Yu, T.; Wu, Z.Q. Effect of rotation speed on nugget structure and property of high rotation speed friction stir welded Al-Mn aluminum alloy. Int. J. Adv. Manuf. Technol. 2017, 92, 2401–2410. [Google Scholar] [CrossRef]

- Athanasios, T.; Galloway, A.; Cater, S. Development of a process envelope for friction stir welding of DH36 steel—A step change. Mater. Des. 2014, 62, 64–75. [Google Scholar]

- Mohan, R.; Jayadeep, U.B.; Manu, R. CFD modeling of ultra-high rotational speed micro friction stir welding. J. Manuf. Process. 2021, 64, 1377–1386. [Google Scholar] [CrossRef]

- Ahmed, S.; Verma, M.; Saha, P. Process responses during μ-FSW of AA6061-T6 under the influence of triple-spiral micro-grooves on shoulder end-surface. J. Mater. Process. Technol. 2021, 290, 116984. [Google Scholar] [CrossRef]

- Mao, Y.; Ni, Y.; Xiao, X.; Qin, D.; Fu, L. Microstructural characterization and mechanical properties of micro friction stir welded dissimilar Al/Cu ultra-thin sheets. J. Manuf. Process. 2020, 60, 356–365. [Google Scholar] [CrossRef]

- Changqing, Z.; Zhuo, Q.; Chen, R. The Preliminary Exploration of Micro-Friction Stir Welding Process and Material Flow of Copper and Brass Ultra-Thin Sheets. Materials 2020, 13, 2401. [Google Scholar]

- Khajeh, R.; Jafarian, H.R.; Seyedein, S.H.; Jabraeili, R.; Eivani, A.R.; Park, N.; Kim, Y.; Heidarzadeh, A. Microstructure, mechanical and electrical properties of dissimilar friction stir welded 2024 aluminum alloy and copper joints. J. Mater. Res. Technol. 2021, 14, 1945–1957. [Google Scholar] [CrossRef]

- Mehta, K.; Astarita, A.; Carlone, P.; della Gatta, R.; Vyas, H.; Vilaça, P.; Tucci, F. Investigation of exit-hole repairing on dissimilar aluminum-copper friction stir welded joints. J. Mater. Res. Technol. 2021, 13, 2180–2193. [Google Scholar] [CrossRef]

- Yusof, F.; Firdaus, A.; Fadzil, M.; Hamdi, M. Ultra-thin Friction Stir Welding (FSW) between aluminum alloy and copper. In Proceedings of the 1st International Joint Symposium on Joining and Welding, Osaka, Japan, 6–8 November 2013; pp. 219–224. [Google Scholar]

- Scialpi, A.; De Filippis, L.A.C.; Cuomo, P.; Di Summa, P. Micro friction stir welding of 2024–6082 aluminum alloys. Riv. Ital. Della Saldatura 2007, 59, 93–200. [Google Scholar]

- Cerri, E.; Leo, P.; Wang, X.; Embury, D. A study of mechanical properties and microstructure in friction stir welded thin sheet aluminum alloys. Metall. Ital. 2011, 5, 5–12. [Google Scholar]

- Galvao, I.; Leitao, C.; Loureiro, A.; Rodrigues, D. Friction stir welding of very thin plates. Rev. Soldag. E Insp. 2012, 17, 02–10. [Google Scholar] [CrossRef]

- Panchal, M.; Patel, D.; Vyas, H.; Mehta, K. Ultra-thin friction stir welding on Aluminum alloy. Mater. Today Proc. 2020, 26, 2888–2894. [Google Scholar] [CrossRef]

- Du, C.; Pan, Q.; Chen, S.; Tian, S. Effect of rolling on the microstructure and mechanical properties of 6061-T6 DS-FSW plate. Mater. Sci. Eng. A 2020, 772, 138692. [Google Scholar] [CrossRef]

- Kalinenko, A.; Vysotskii, I.; Malopheyev, S.S.; Mironov, S.Y.; Rustam, A. Relationship between welding conditions, abnormal grain growth and mechanical performance in friction-stir welded 6061-T6 aluminum alloy. Mater. Sci. Eng. A 2021, 817, 141409. [Google Scholar] [CrossRef]

- Liu, Z.-K.; Wang, Y.; Chen, L.-Q. First-principles calculations of β″-Mg5Si6/α-Al interfaces. Acta Mater 2007, 55, 5934–5947. [Google Scholar]

- Du, C.C.; Wang, X.; Pan, Q.H.; Xue, K.L.; Ni, M.S.; Liu, J.J. Correlation between microstructure and mechanical properties of 6061-T6 double-side FSW joint. Manuf. Process 2019, 38, 122–134. [Google Scholar] [CrossRef]

- Abdulstaar, M.A.; Al-Fadhalah, K.J.; Wagner, L. Microstructural variation through weld thickness and mechanical properties of peened friction stir welded 6061 aluminum alloy joints. Mater. Charact. 2017, 126, 64–73. [Google Scholar] [CrossRef]

- Silva-Magalhães, A.; de Backer, J.; Martin, J.; Bolmsjö, G. In-situ temperature measurement in friction stir welding of thick section aluminum alloys. Manuf. Process 2019, 3, 12–17. [Google Scholar] [CrossRef]

- Hamilton, C.; Dymek, S.; Blicharski, M. A model of material flow during friction stir welding. Mater. Charact. 2008, 59, 1206–1214. [Google Scholar] [CrossRef]

- Scialpi, A.; Filippis, L.A.C.D.; Cavaliere, P. Influence of shoulder geometry on microstructure and mechanical properties of friction stir welded 6082 aluminum alloy. Mater. Des. 2007, 28, 1124–1129. [Google Scholar] [CrossRef]

- Sashank, J.S.; Sampath, P.; Krishna, P.S.; Sagar, R.; Venukumar, S.; Muthukumaran, S. Effects of friction stir welding on microstructure and mechanical properties of 6063 aluminum alloy. Mater. Today Proc. 2018, 5, 8348–8353. [Google Scholar] [CrossRef]

- Zhang, L.; Zhong, H.; Li, S.; Zhao, H.; Chen, J.; Qi, L. Microstructure, mechanical properties and fatigue crack growth behavior of friction stir welded joint of 6061-T6 aluminum alloy. Int. J. Fatigue 2020, 135, 105556. [Google Scholar] [CrossRef]

- Oosterkamp, A.; Oosterkamp, L.D.; Nordeide, A. ‘Kissing bond’ phenomena in solid-state welds of aluminum alloys. Welding 2004, 83, 225–231. [Google Scholar]

- Chen, H.B.; Yan, K.; Lin, T.; Chen, S.B.; Jiang, C.Y.; Zhao, Y. The investigation of typical welding defects for 5456 aluminum alloy friction stir welds. Mater. Sci. Eng. A 2006, 433, 64–69. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiao, B.L.; Ma, Z.Y. Effect of segregation of secondary phase particles and “S” line on tensile fracture behavior of friction stir-welded 2024 Al-T351 joints. Met. Mater. Trans. A 2013, 44, 4081–4097. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 0.40–0.8 | 0.7 | 0.15–0.04 | 0.15 | 0.8–1.2 | 0.04–0.35 | 0.25 | 0.15 | allowance |

| Factors | Spindle Speed (rpm) | Welding Speed (mm/min) | Plunge Depth (mm) |

|---|---|---|---|

| 1 | 6000 | 300 | 0.03 |

| 2 | 8000 | 300 | 0.03 |

| 3 | 10,000 | 300 | 0.03 |

| 4 | 12,000 | 300 | 0.03 |

| 5 | 14,000 | 300 | 0.03 |

| Serial Number | Spindle Speed (rpm) | Elongation (%) | Fracture Location |

|---|---|---|---|

| 1 | 6000 | 4.3 | Weld center |

| 2 | 8000 | 4.7 | Weld center |

| 3 | 10,000 | 7.2 | RS |

| 4 | 12,000 | 9.3 | RS |

| 5 | 14,000 | 6.2 | Weld center |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Chen, S.; Zhang, Y.; Chen, X.; Li, Z.; Yang, Z. Effect of High Rotational-Speed Friction-Stir Welding on Microstructure and Properties of Welded Joints of 6061-T6 Al Alloy Ultrathin Plate. Materials 2021, 14, 6012. https://doi.org/10.3390/ma14206012

Zhang H, Chen S, Zhang Y, Chen X, Li Z, Yang Z. Effect of High Rotational-Speed Friction-Stir Welding on Microstructure and Properties of Welded Joints of 6061-T6 Al Alloy Ultrathin Plate. Materials. 2021; 14(20):6012. https://doi.org/10.3390/ma14206012

Chicago/Turabian StyleZhang, Hao, Shujin Chen, Yuye Zhang, Xinyi Chen, Zhipeng Li, and Zhidong Yang. 2021. "Effect of High Rotational-Speed Friction-Stir Welding on Microstructure and Properties of Welded Joints of 6061-T6 Al Alloy Ultrathin Plate" Materials 14, no. 20: 6012. https://doi.org/10.3390/ma14206012

APA StyleZhang, H., Chen, S., Zhang, Y., Chen, X., Li, Z., & Yang, Z. (2021). Effect of High Rotational-Speed Friction-Stir Welding on Microstructure and Properties of Welded Joints of 6061-T6 Al Alloy Ultrathin Plate. Materials, 14(20), 6012. https://doi.org/10.3390/ma14206012