1. Introduction

Polyvinyl alcohol (PVA) fibers were found to significantly improve the ductility, fracture toughness and impact resistance of lightweight concrete [

1,

2]. They strengthen the surface bonds between the aggregate, matrix and reinforcement and also reduce the formation of flocculated structures by cement particles and the bleeding effect of cement paste, improves workability [

1,

2,

3]. The enhanced ductility of cement composite depends on the characteristics of the matrix and the fibers as well as on the appropriate amount of reinforcement, so that the load originally carried by the matrix would be transferred to the bridging fibers [

4]. The paper [

5] reported that 0.5–0.75% of polymer microfibers is the most effective content for improving the properties of cement-based concrete. According to the literature review, fibers must have a much higher modulus of elasticity in order to increase the strength of concrete; however, this property is often difficult to achieve because the modulus of elasticity of cement-based matrices ranges from 15 GPa to 30 GPa.

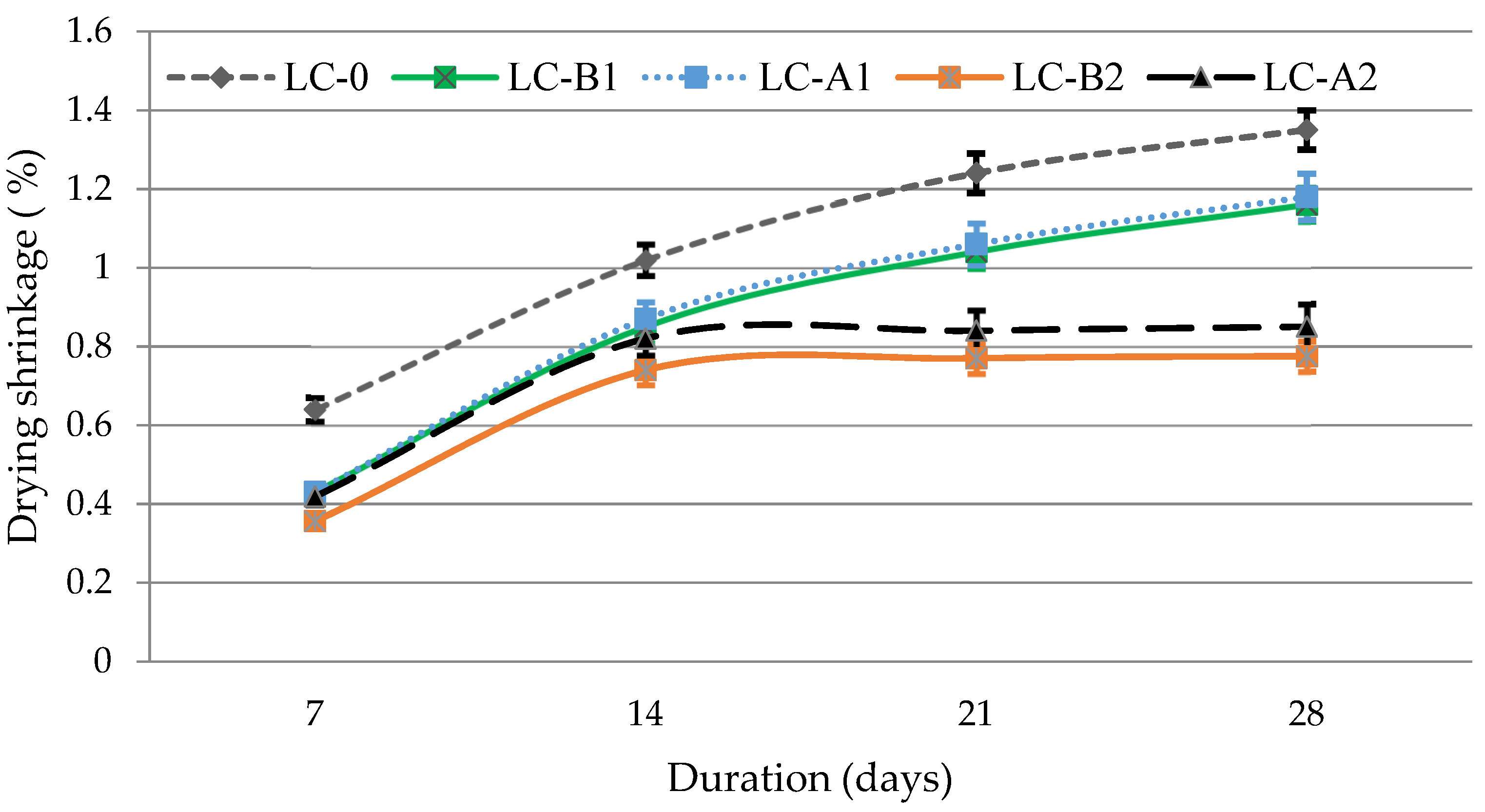

PVA fibers with a high modulus of elasticity can reduce the crack width and thus are the most suitable for reducing the drying shrinkage, which is one of the most important characteristics of lightweight composites [

6,

7]. The shrinkage of the composite is limited physically by a strong adhesion between the fibre and the cement matrix [

8,

9]; besides, the fibres increase the tensile strength of the composite, which also reduces shrinkage and potential cracking.

PVA fibers can change the pattern of water movement in the cementitious matrix by attracting more water to the surface of the fibers [

10]. An extremely strong bond between the fibers and the cement matrix in the conventional cement mix is formed due to the hydrophilic character of PVA fibers. It was determined that a denser CSH layer is formed around PVA fibers of a certain size. The denser is this layer, the stronger is the connection between PVA fibers and cement matrix [

11,

12,

13,

14,

15]. It was established [

15] that pozzolanic additives (especially nano SiO

2) accelerated cement hydration and contributed to the formation of additional CSH, which covered the surface of the PVA fibers. The CSH layer improved the bonding between PVA fibers and cement-based matrix and resulted in an efficient load-transfer by fibre bridging. Researchers [

16,

17,

18,

19,

20,

21] have found that a higher amount of CSH produced in the pozzolanic reaction reduces the porosity of the cement composite and at the same time reduces the drying shrinkage. Spent fluid catalytic cracking catalyst waste (FCCCW) from oil refineries, containing silica and alumina, accelerate cement hydration while the pozzolanic reactions have a positive effect on the mechanical characteristics of hardened cement paste [

22,

23,

24,

25]. Metakaolin waste MW generated in the manufacture of granulated expanded glass [

26] consists of metakaolin and glass waste. It has pozzolanic activity and also improves the mechanical properties of the material [

27]. Our previous research work [

10] revealed that cement hydration can be controlled and mechanical properties of lightweight composite materials can be improved through the combined use of FCCCW, which accelerates the hydration of Portland cement, and MW addition, which has a retarding effect. On the other hand, an excessively strong a chemical bond between PVA and cementitious hydrates can reduce the elasticity of the composite, cause the formation of cracks, and premature breakage of the fibers [

13,

14].

Agglomeration of the fibers may also reduce it positive effect. The strength decreases at the higher content of fibers [

28] because the fibers entrap air voids during mixing and increase the porosity. The increase in porosity depends on the amount, shape and length of the fibers. Besides the addition of fibers deteriorates the workability of the cement paste, make its harder to compact and increase porosity.

Taking into account the above aspects it is very important to choose the appropriate amount and type of PVA fibers. The quality of the cementitious binder, which is greatly influenced by pozzolanic additives, and its interaction with PVA fiber reinforcement, can have a significant impact on the properties of lightweight aggregate composite. Granulated expanded glass (GEG) used in combination with pozzolanic additives in cement-based materials is expected not only to improve their mechanical properties but also to mitigate alkali aggregate reactions, increase their durability [

29,

30]. Lightweight plaster with GEG can replace dangerous asbestos in the masonry structures of energy units or can be used in fire resistance refractory mortars applied to protect metal structures in chemical plants. GEG can be also used in refractory mortar for the insulation of the interior of energy units because light composite materials containing GEG retain heat, sustain mechanical impact and resist deformation in the temperature up to 600 °C. The basis for the development of such a composite is low density and good mechanical characteristics of GEG [

31]. It also has good frost resistance properties, because the porous structure contributes to decreasing the microdamage caused by the crystallization of ice [

31]. It should also be noted that glass-based filler is sufficiently resistant to alkaline corrosion because the gel formed during the alkali-aggregate reaction penetrates into the granules without creating high stresses [

31,

32,

33].

The aim of this study was to determine the effect of PVA fibers of different types (Type A: Ø40 µm, L = 8 mm and Type B: Ø200 µm, L = 12 mm) on the hydration and structure of the cement matrix modified with combined pozzolanic additive and physical-mechanical properties of the lightweight composite containing GEG.

2. Materials and Methods

The chemical analysis of raw materials was determined with a ZSX Primus IV wavelength dispersive X-ray fluorescence spectrometer (XRF, Rigaku, Tokyo, Japan) (X-ray tube, Rh-anode, 4 kW, 60 kV, specimen size 37 mm (diameter)). The tablets of powders (<50 µm) were prepared by using a 20 t force hydraulic press.

Portland cement (PC) CEM I 42.5 R (Rocket cement M-600, Heidelberg Cement, Skovde, Sweden) was used for the tests. The chemical composition of the cement is presented in

Table 1. Mineral composition of the cement used: C

3S—56.6%, C

2S—16.7%, C

3A—9.0%, C

4AF—10.6% and 7.2% of other substances (alkaline sulphates and CaO).

The chemical composition of spent fluidized bed catalytic cracking catalyst waste (AB Orlen Lietuva oil refinery, Mazeikiai, Lithuania) and metakaolin based waste MW (UAB Stikloporas, Druskininkai, Lithuania) is presented in

Table 2. FCCCW particles are spherical, with an average diameter of ~40 μm [

34].

MW is generated in the manufacturing of granulated expanded glass. It is a mix of metakaolin and residues of granules. GEG of three different fractions (1.0–2.0 mm, 0.5–1.0 mm and 0.25–0.5 mm) were used as lightweight composite aggregates. GEG characteristics are presented in

Table 3.

PVA fibers are superficially treated to have an optimal adhesion with the interfacing cement matrix. The fibers have a specific weight of 1300 kg/m

3, other characteristics are presented in

Table 4.

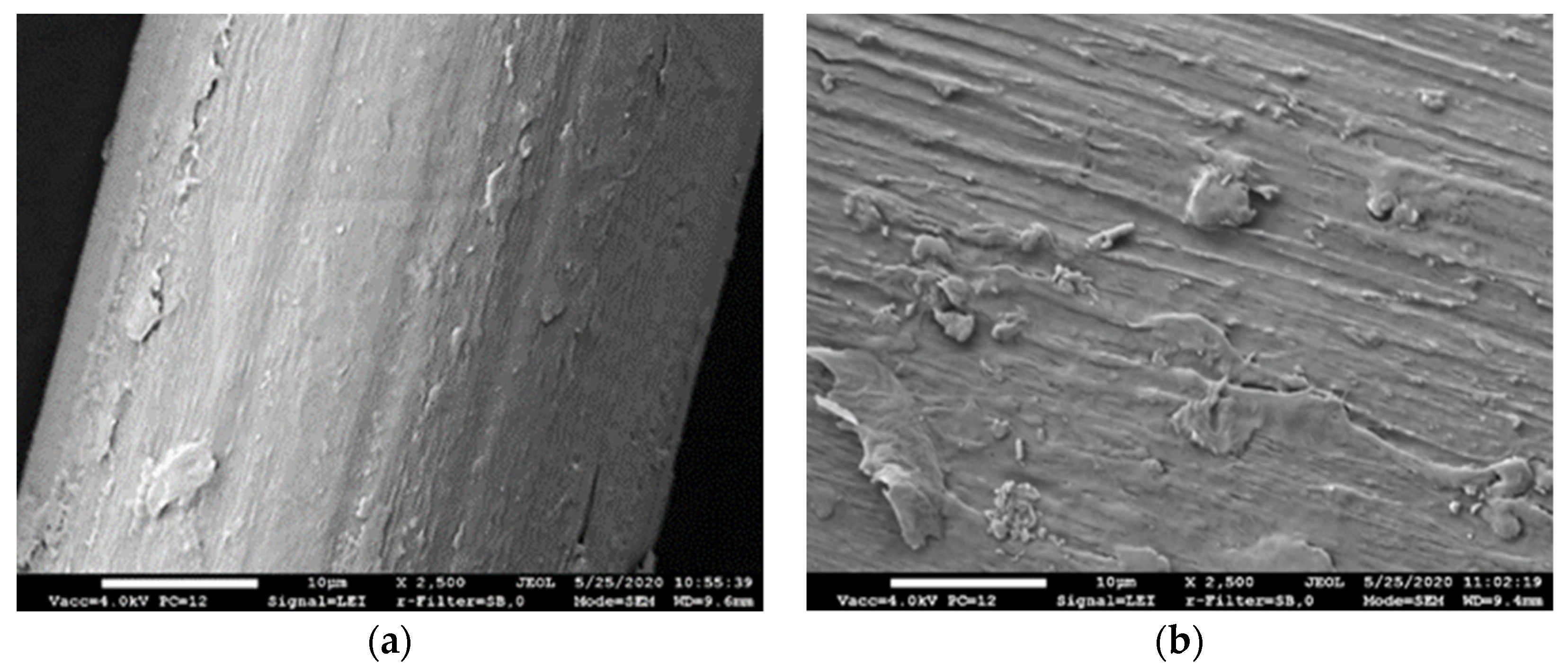

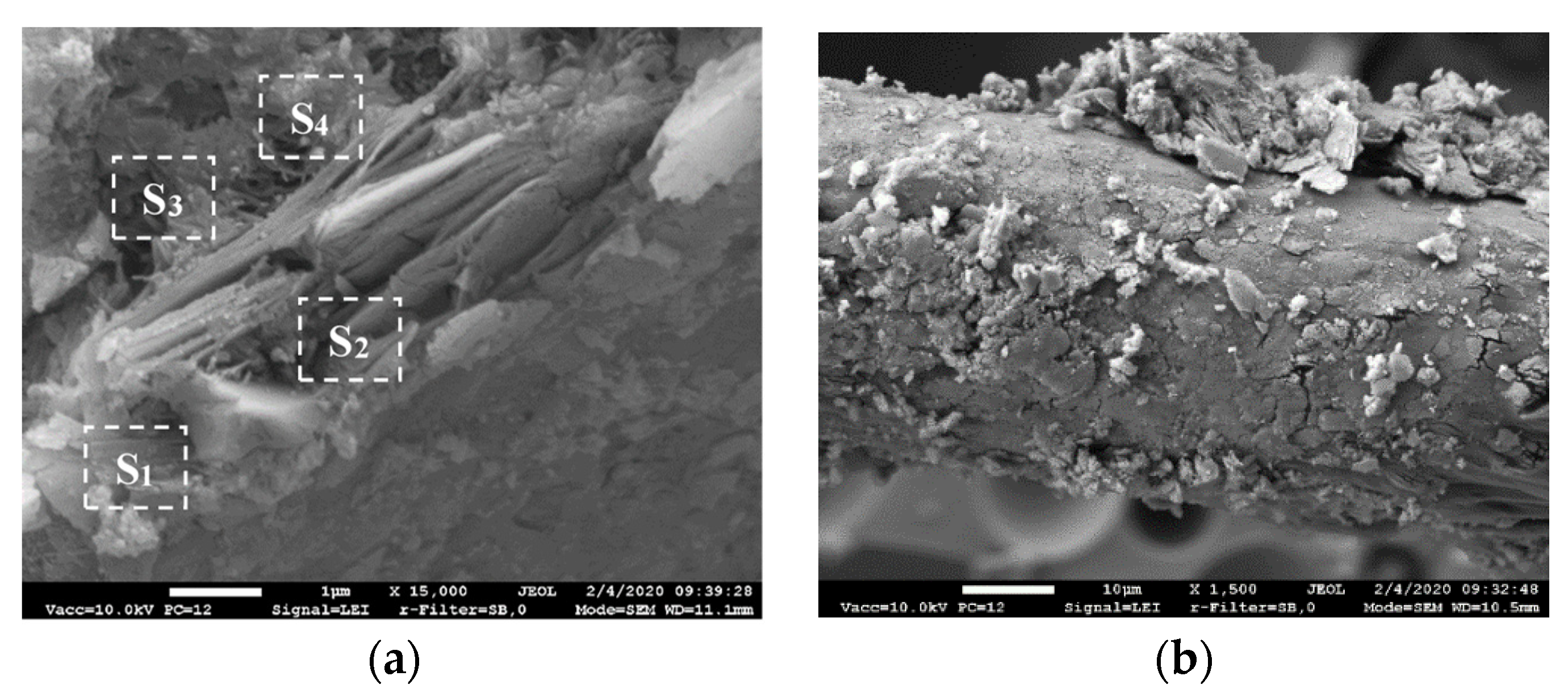

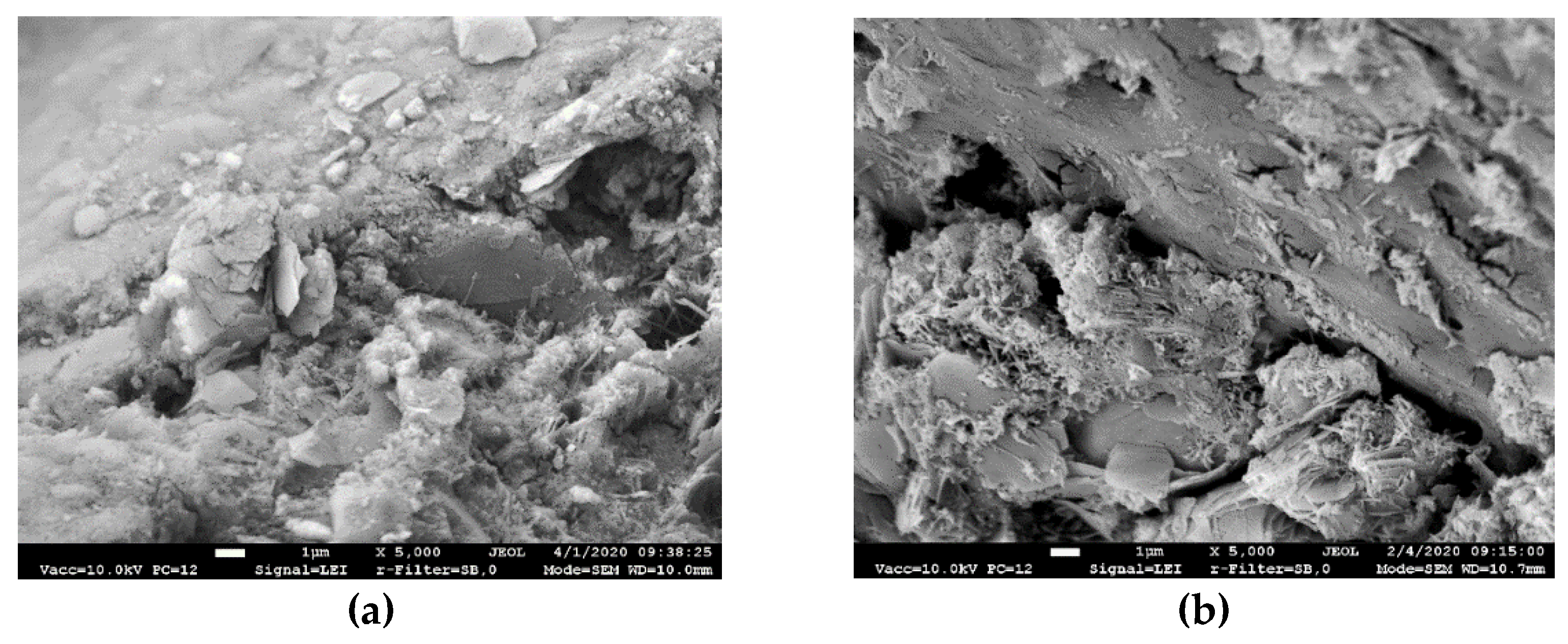

SEM images of Type A and Type B fibers used are presented in

Figure 1. The images show that the fibers of both types have uneven rough surfaces with visible grooves with a width of 1–3 µm.

The superplasticizer Melment F10 (SP) (BASF Construction Polymers GmbH, Trotsberg, Germany) used for the mixtures is a free-flowing spray dried powder of a sulphonated polycondensation product based on melamine. It has a pH value of 9.4 at 20 °C temperature in 20% solution. Tap water was used for the mixtures.

Compositions of cement paste for XRD, DTG, MIP analysis and lightweight composite used in the tests described in this paper are presented in

Table 5.

Specimens of blended cement paste and lightweight cement-based composition were mixed in a Hobart Type mixer for 2 min in dry stirring and for two more minutes after adding water. Specimens of 160 × 40 × 40 mm size were formed on the vibration table. The drying shrinkage deformation of lightweight composite was measured from the second day of curing until the 28th day. The specimens were cured for 24 h in moulds at 20 ± 2 °C and at least 90% relative humidity. On the second day they were demoulded and cured for 27 days at 20 ± 2 °C temperature and 65 ± 5% relative humidity.

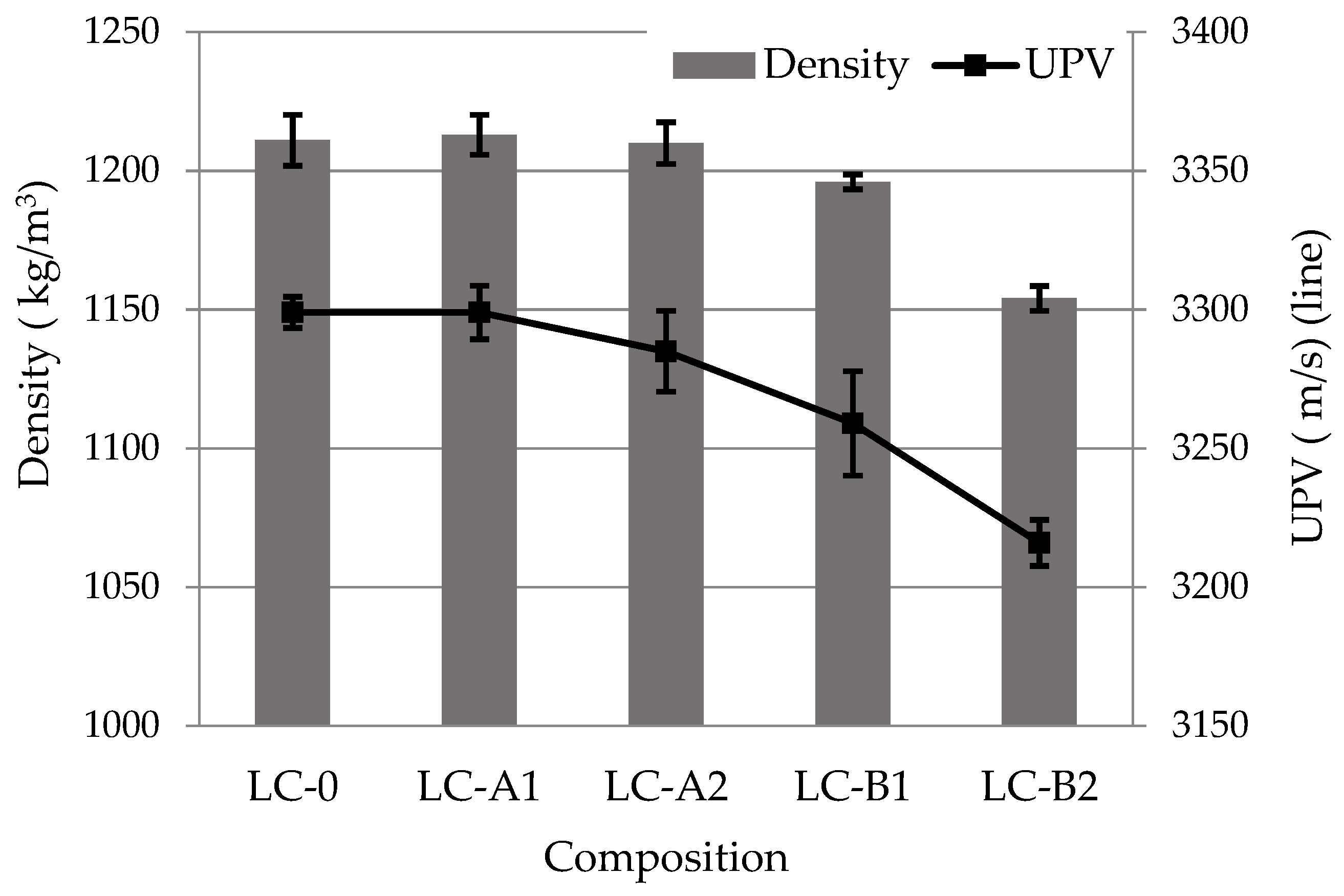

The density was calculated according to specimen weight (accuracy 0.01 g) and the volume was determined by dimensions (accuracy 0.01 mm).

Ultrasonic pulse velocity (UPV) was measured by direct transmission method using a Pundit 7 device equipped with two 54 kHz transducers (transmitter and receiver) firmly coupled to the farthest opposite ends of the paste prims using petroleum jelly as the couplant between the transducers and the specimens. The UPV was calculated using Equation (1) (UPV, m/s):

where: l is the length of ultrasonic pulse path through the specimen, m/s i.e., the distance between the two transducers (0.16 m); τ is signal propagation time provided by the test equipment, s.

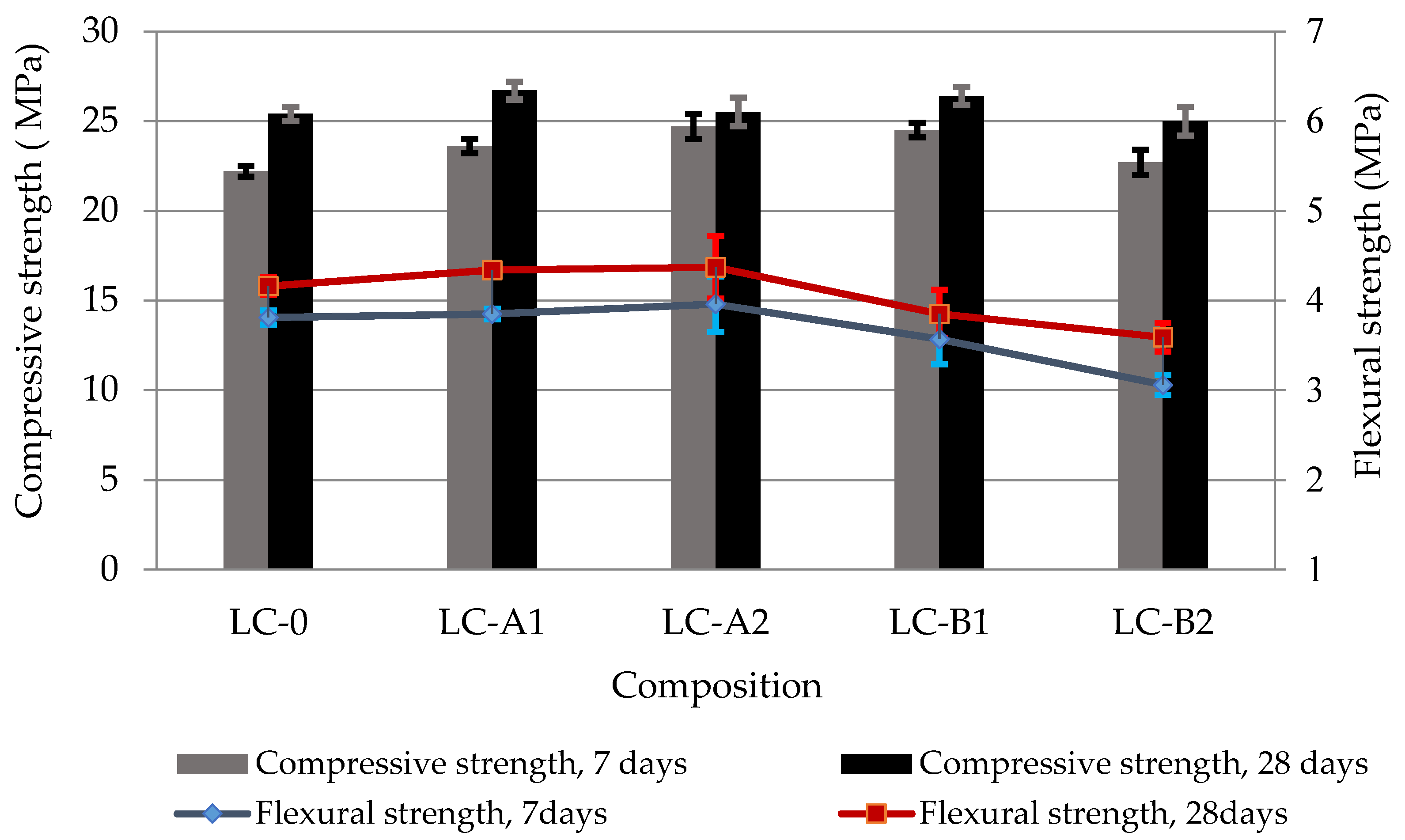

6 specimens of each batch of lightweight composite were used to determine the physical-mechanical properties: 3 of them were used to determine the mechanical properties at 7 days of curing and 3 at 28 days. The specimens were moulded, cured and hardened according to the standard LST EN 1015-11:2007. The flexural and compressive strength of the specimens was measured by an ALPHA3-3000S hydraulic press (Form+Test Seidner Co. GmbH, Riedlingen, Germany).

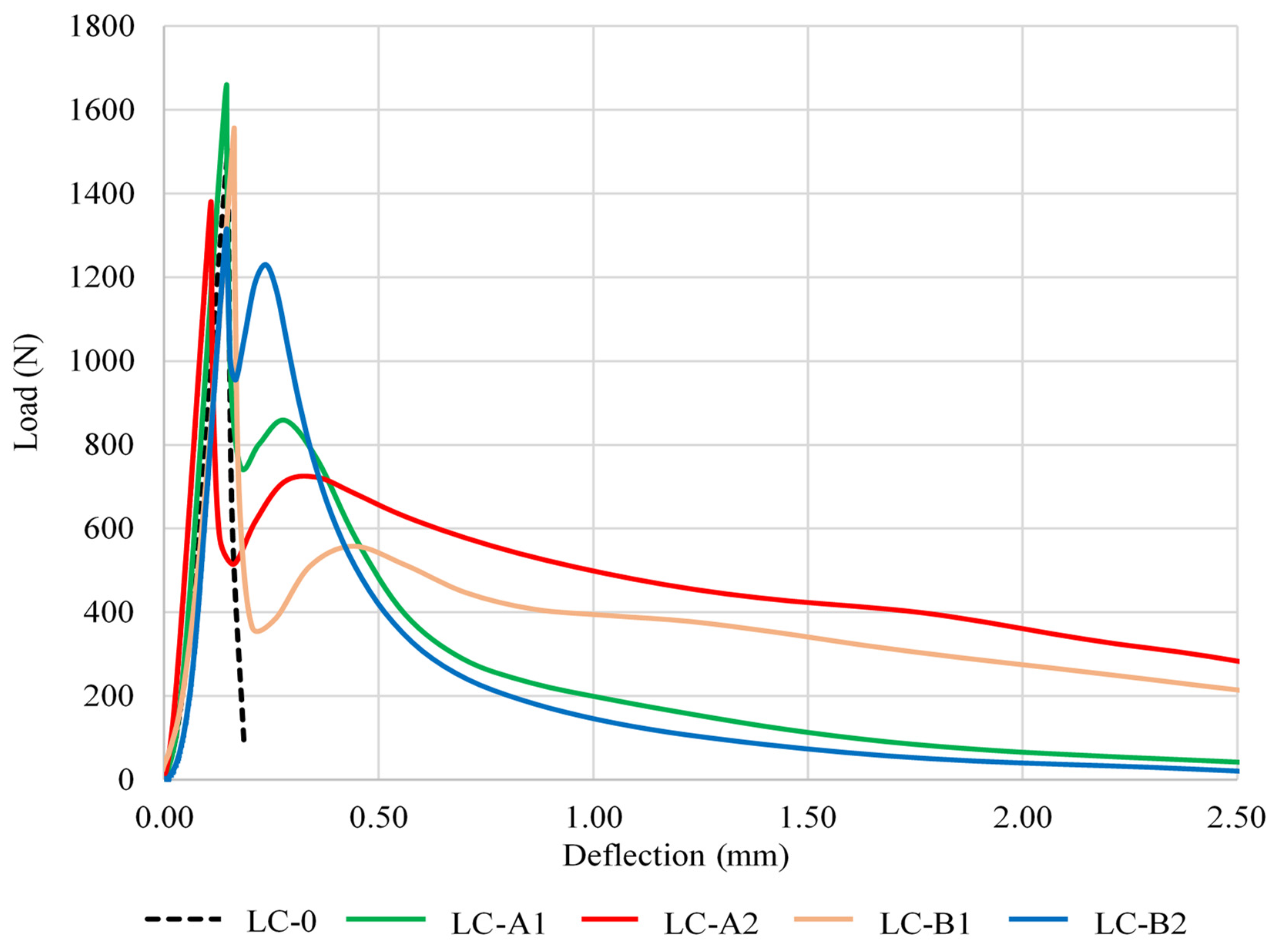

The specimens (160 × 40 × 40 mm prisms) were tested for bending according to a three-point scheme with a distance between the supports of Lo = 130 mm. Flexural strength fb was determined according to the known formula as the ratio between the bending moment and the moment of resistance of the cross-section. The flexural strength was determined according to the peak fracture load Fmax. In the case of fiber cement composites, the parameter of flexural strength is insufficient for the full assessment of the effect of dispersed reinforcement. The fibers continue working in the material after the crack has opened. Therefore, in this study the mid-span deflection of prisms was measured during the bending test in order to calculate the fracture work of the material.

The fracture work energy was determined according to the RILEM TC-50 FMC method. It includes elastic deformation energy and the effect of post-cracking work. Different from the requirements of the RILEM standard, no notch was made at the bottom of the specimen, since it better matches the purpose of the fibers in the material of the protective coating. The fracture energy (GF) is calculated by referring to the method recommended by RILEM in Equation (2):

where:

GF—is the fracture energy, N/m (or Nm/m

2);

W0—is the work done by specimen bending machine measured by the load-deflection curve (area under the curve), Nm;

mg—is the specimen weight, N;

δmax—is the deflection when the residual load is 20% of the maximum load, m;

Alig—is the fracture area of specimens, m

2. It should be noted that in this case the effect of the weight of the specimens (

mgδmax) has a very insignificant effect, therefore this parameter can be ignored in fractural energy calculations.

The drying shrinkage of lightweight composite was measured by a digital micrometre of 0.001 mm precision.

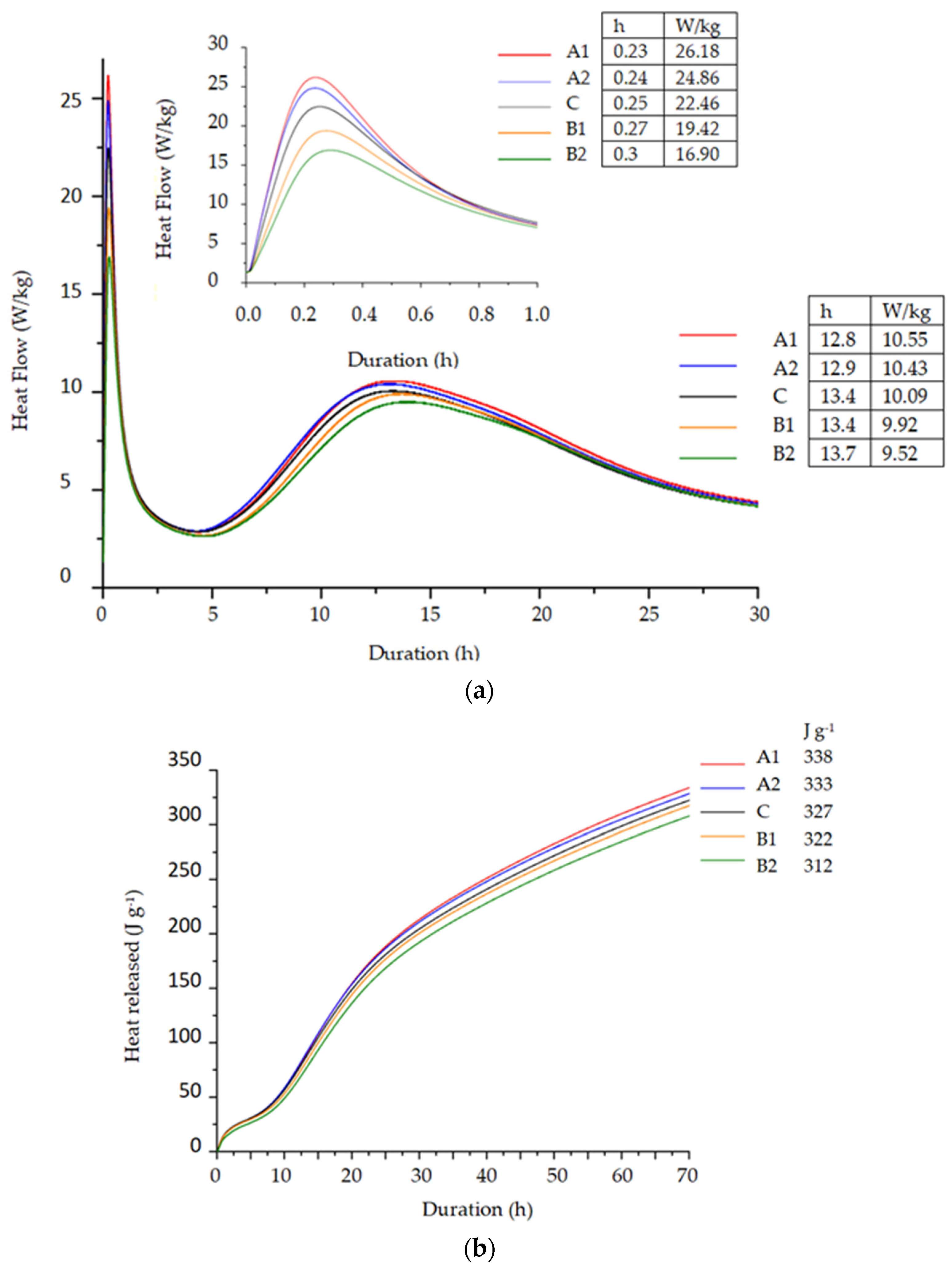

The amount of heat released during the hydration, and the heat release rate were measured by the calorimeter TONICAL III (Toni Technik GmbH, Berlin, Germany). The measurements were done at 20 °C temperature, the measurement duration was 48 h.

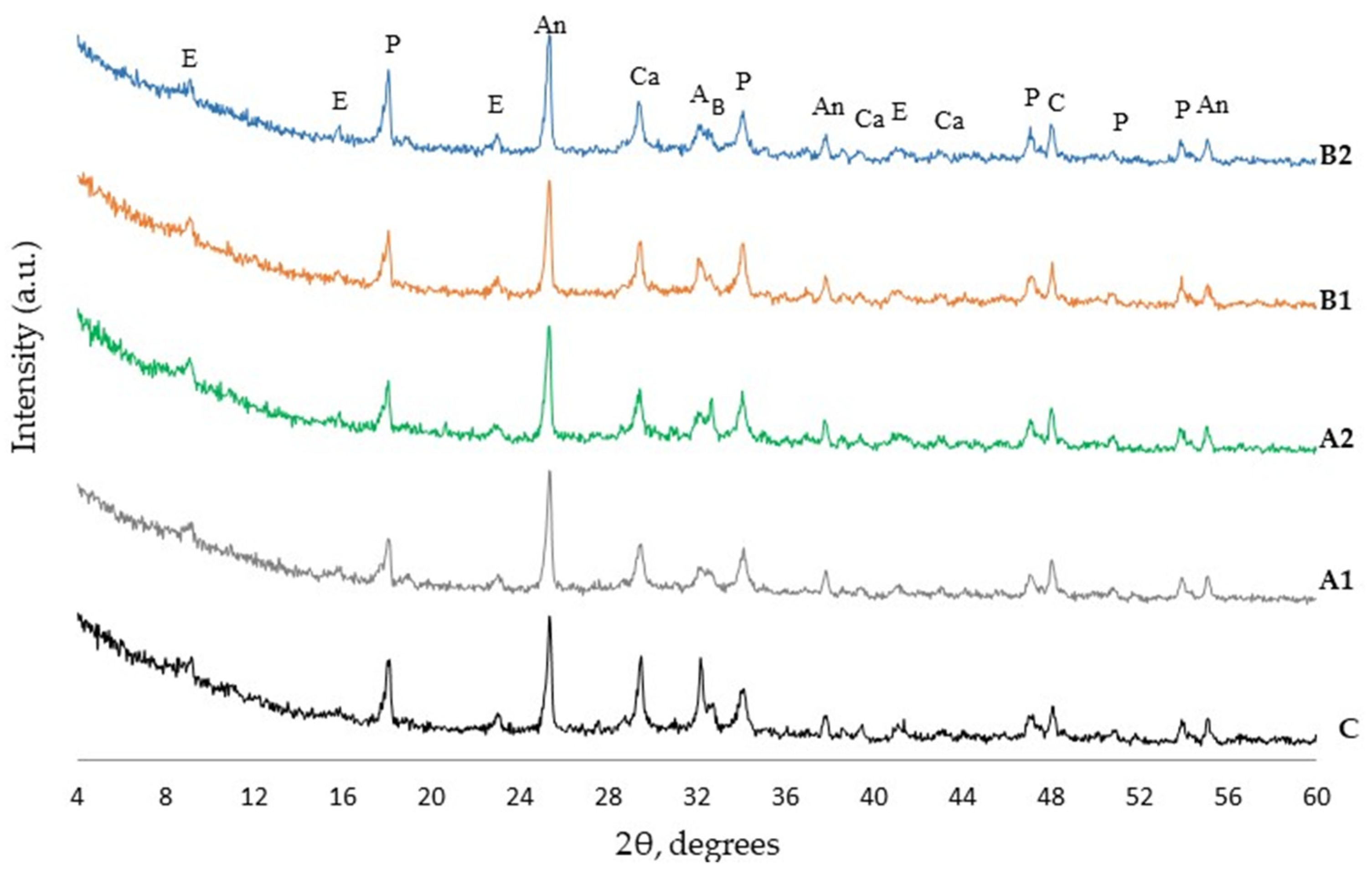

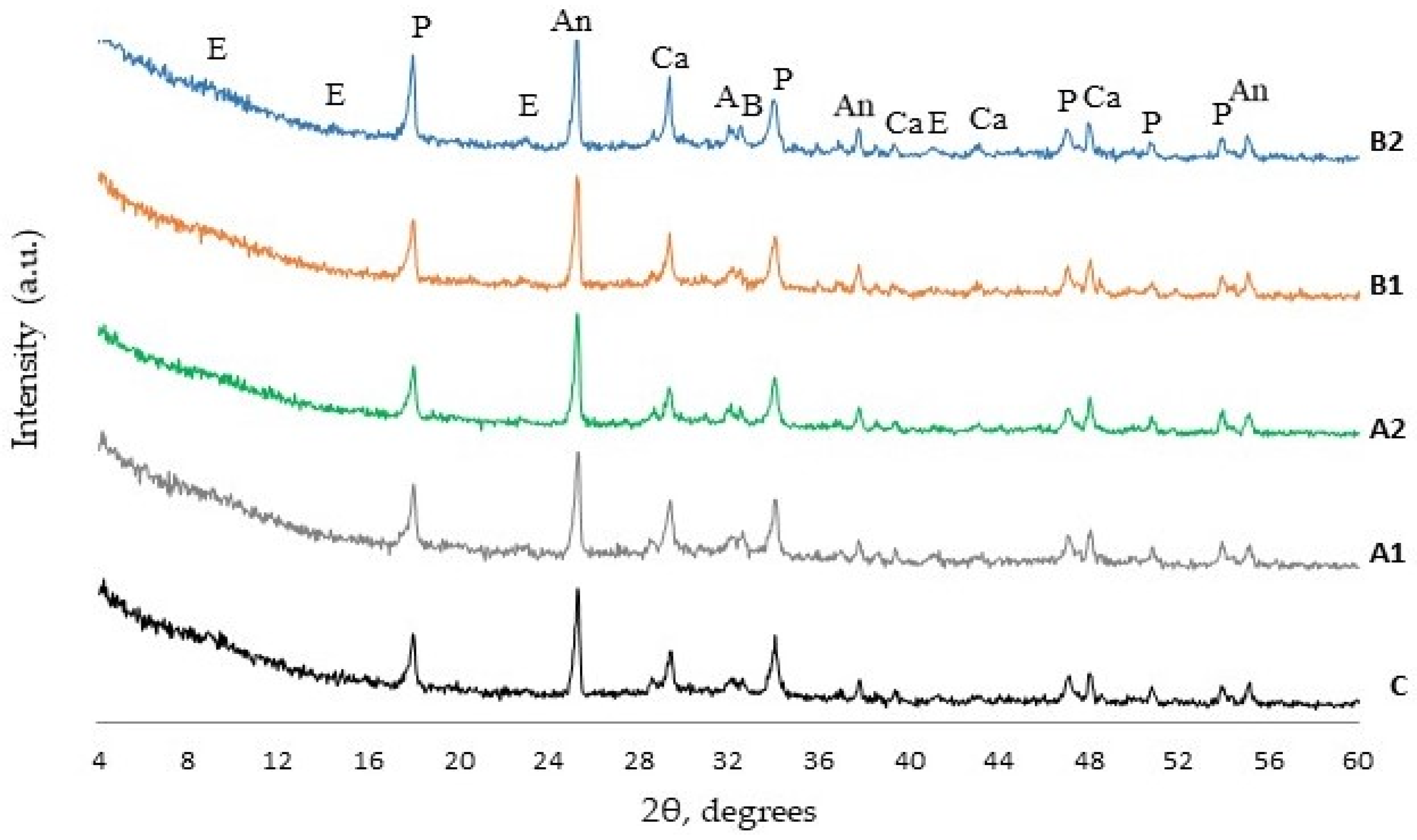

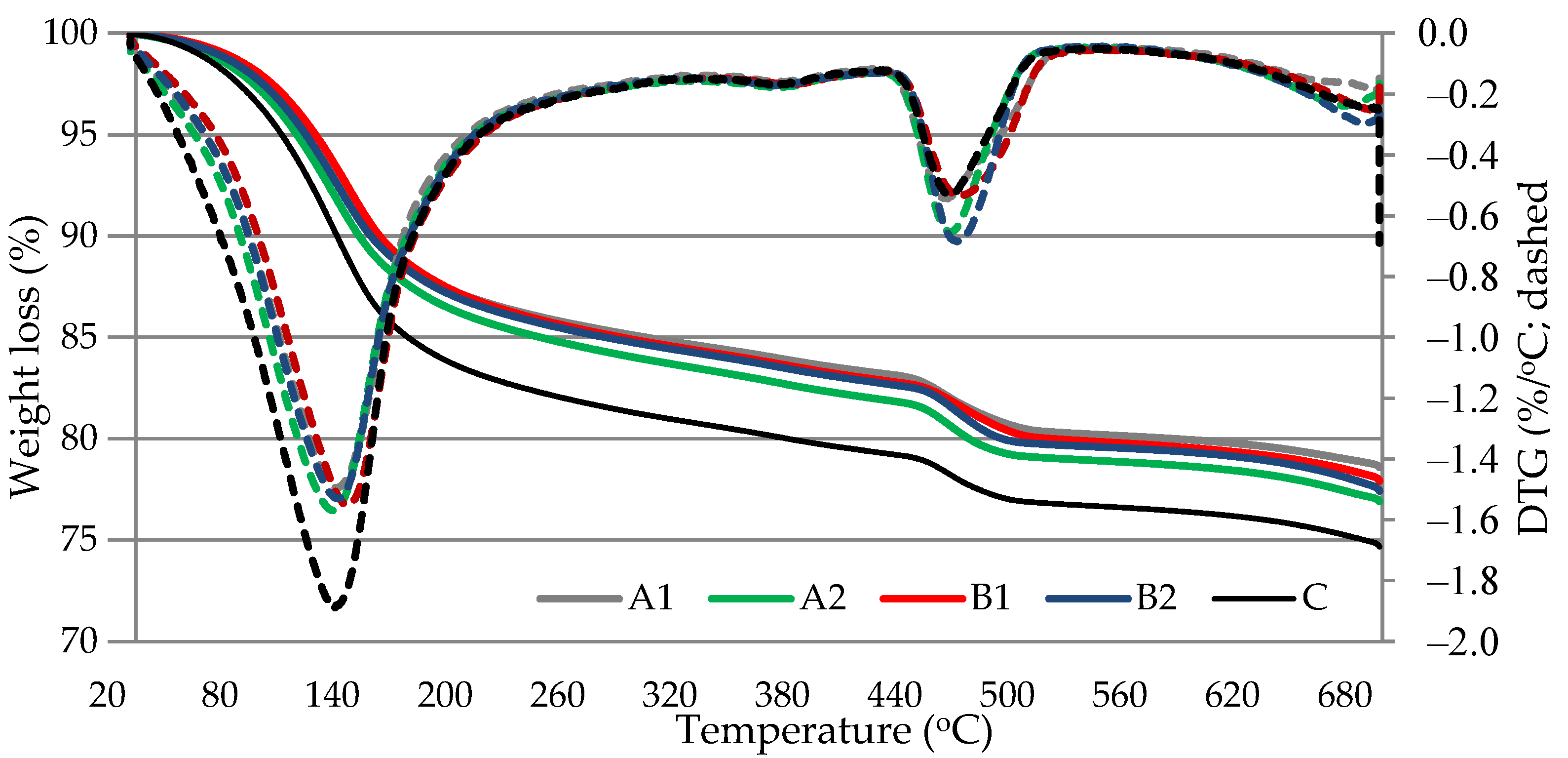

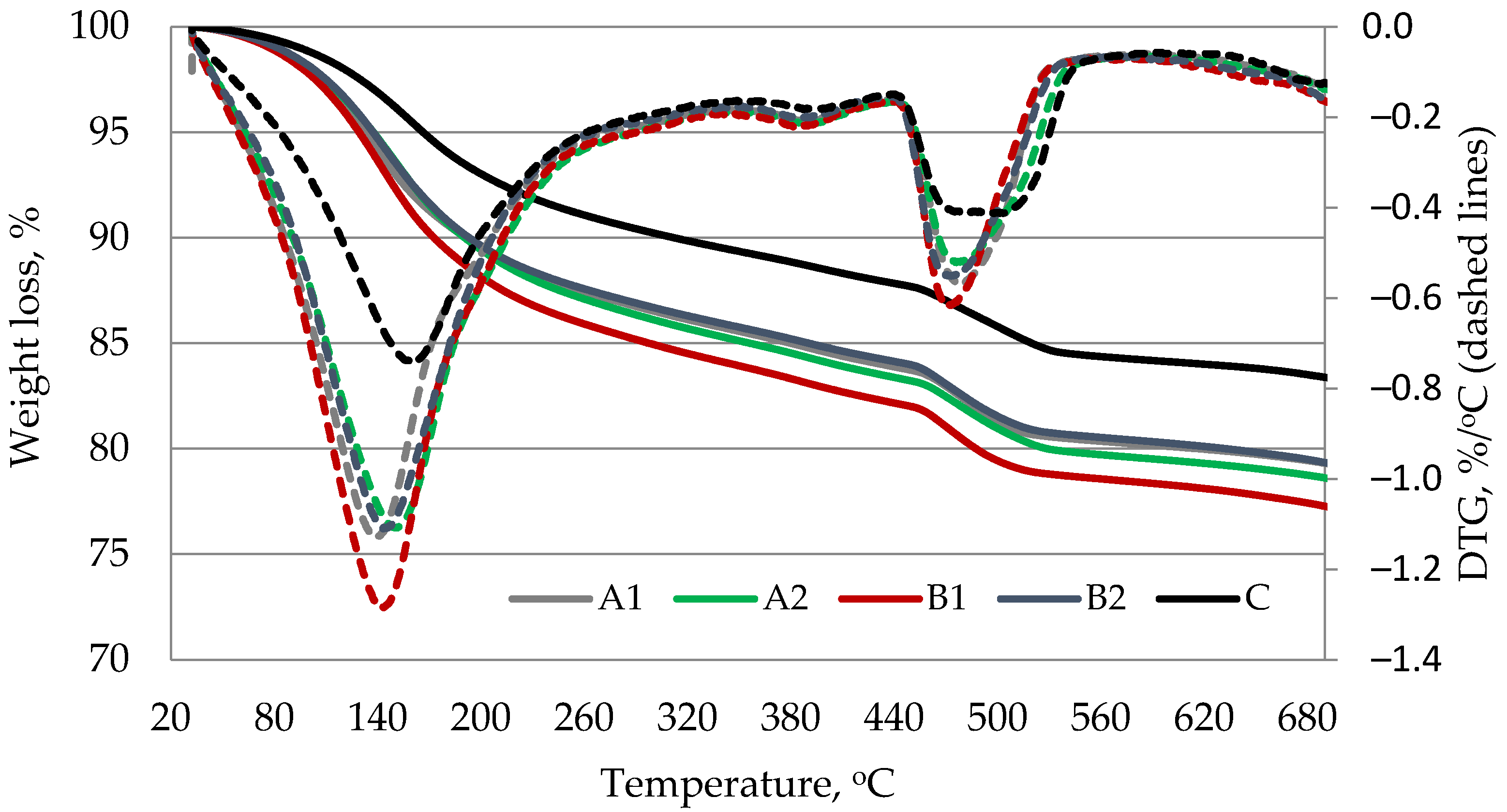

X-ray diffraction (XRD), thermal (DTG) and calorimetric analyses were done with cement paste specimens without GEG (

Table 5).

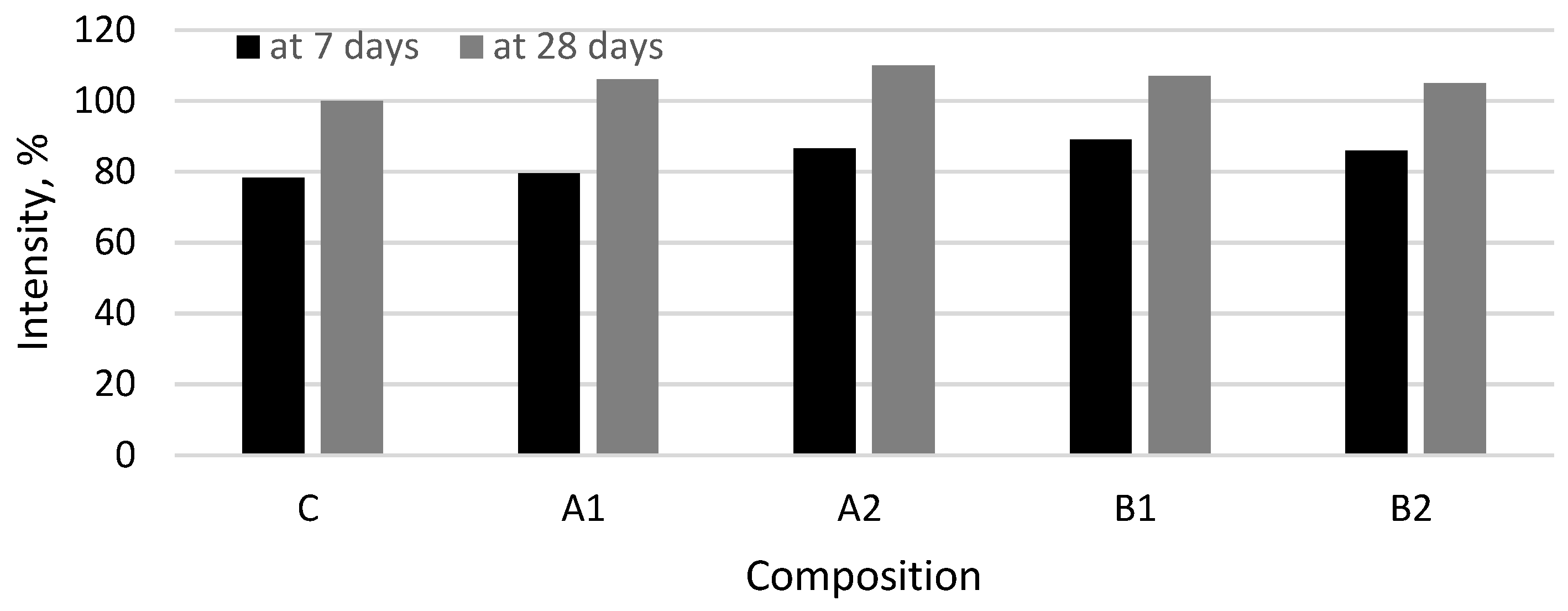

The XRD analysis was performed using a DRON-7 diffractometer (Bourevestnik SJC, St. Petersburg, Russia) (with Cu-Kα (λ = 0.1541837 nm) radiation. The following test parameters were used: 30 kV voltage; 12 mA current; 2θ diffraction angle range from 4° to 60° with increment of 0.02° measured each 0.5 s. The phases present were identified comparing the XRD diffractograms with standard diffraction patterns provided by the International Centre for Diffraction Data (ICDD). The internal standard anatase was used. 9:1 (binder:anatase) specimens were prepared. The amount of compounds was valued according the intensity of the main peaks.

Thermal analysis (DTG/TG) was performed with a TGA 4000 thermal analyser (Perkin-Elmer, Waltham, MA, USA). Specimens with a mass of 50–60 mg were placed in a platinum crucible and heated at 10 °C/min in the nitrogen environment up to 700 °C. The amount of portlandite was calculated according to literature [

34].

The microstructure of materials was tested with the scanning electron microscopy (SEM) device SEM JSM-7600F, JEOL, Tokyo, Japan). The following electron microscopy parameters were used: power 10 kW, distance to specimen surface from 7 to 11 mm. Characteristics of the microstructure was identified by testing the specimen splitting surface. Before testing, the splitting surface was coated with a thin electrically conductive layer of gold by evaporating the gold electrode in the vacuum using the instrument QUORUMQ150R ES (Quorum Technologies, Laughton, UK). X-ray microanalysis was performed by the energy dispersion spectrometer (EDX) Inca Energy 350 (Oxford Instruments, Abingdon, UK) using Silicon Drift Type detector X-Max20. The INCA software package (Oxford Instruments) was used.