Surface Reformation of Medical Devices with DLC Coating

Abstract

:1. Introduction

2. Materials and Methods

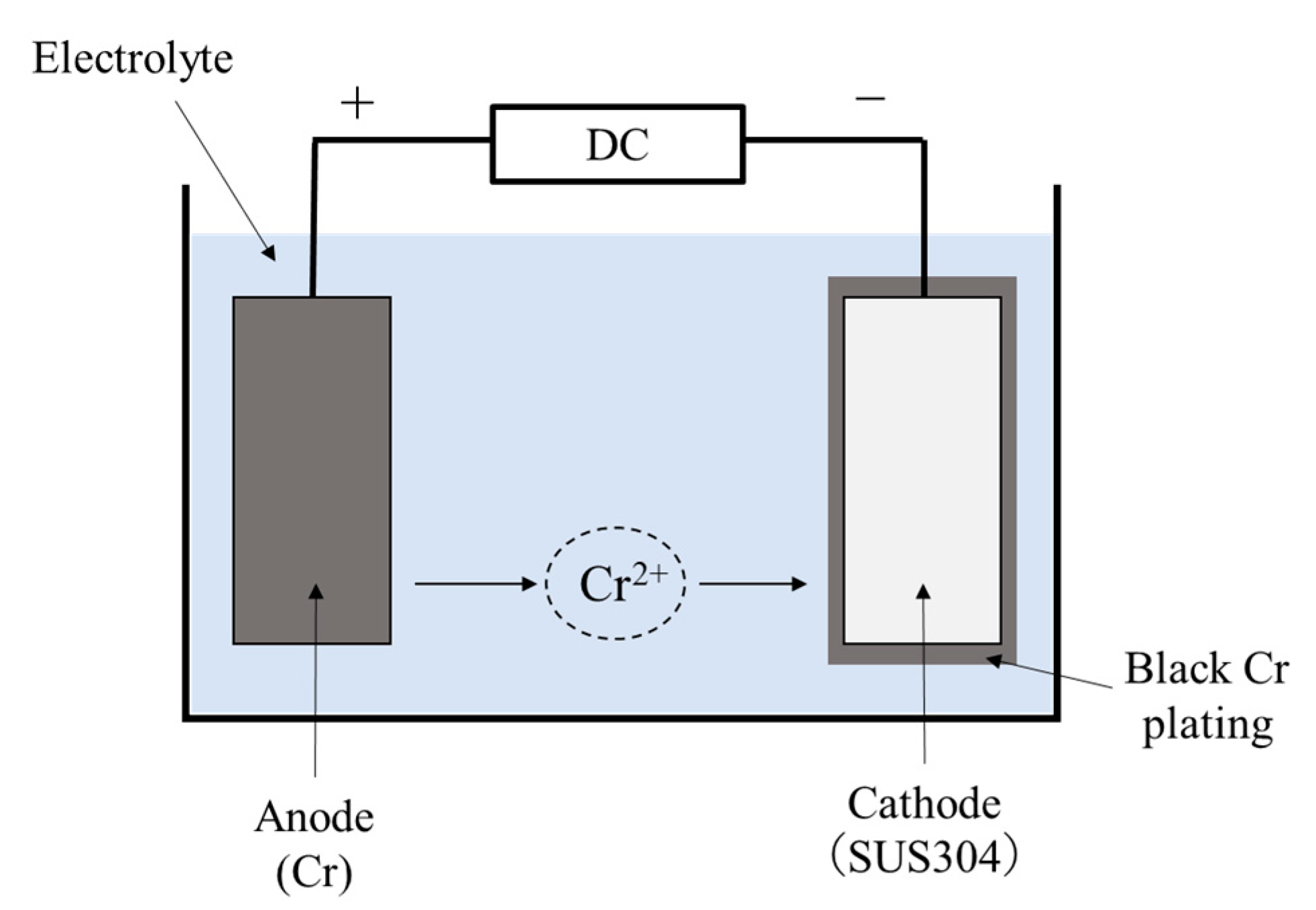

2.1. Sample Preparation and Surface Treatment

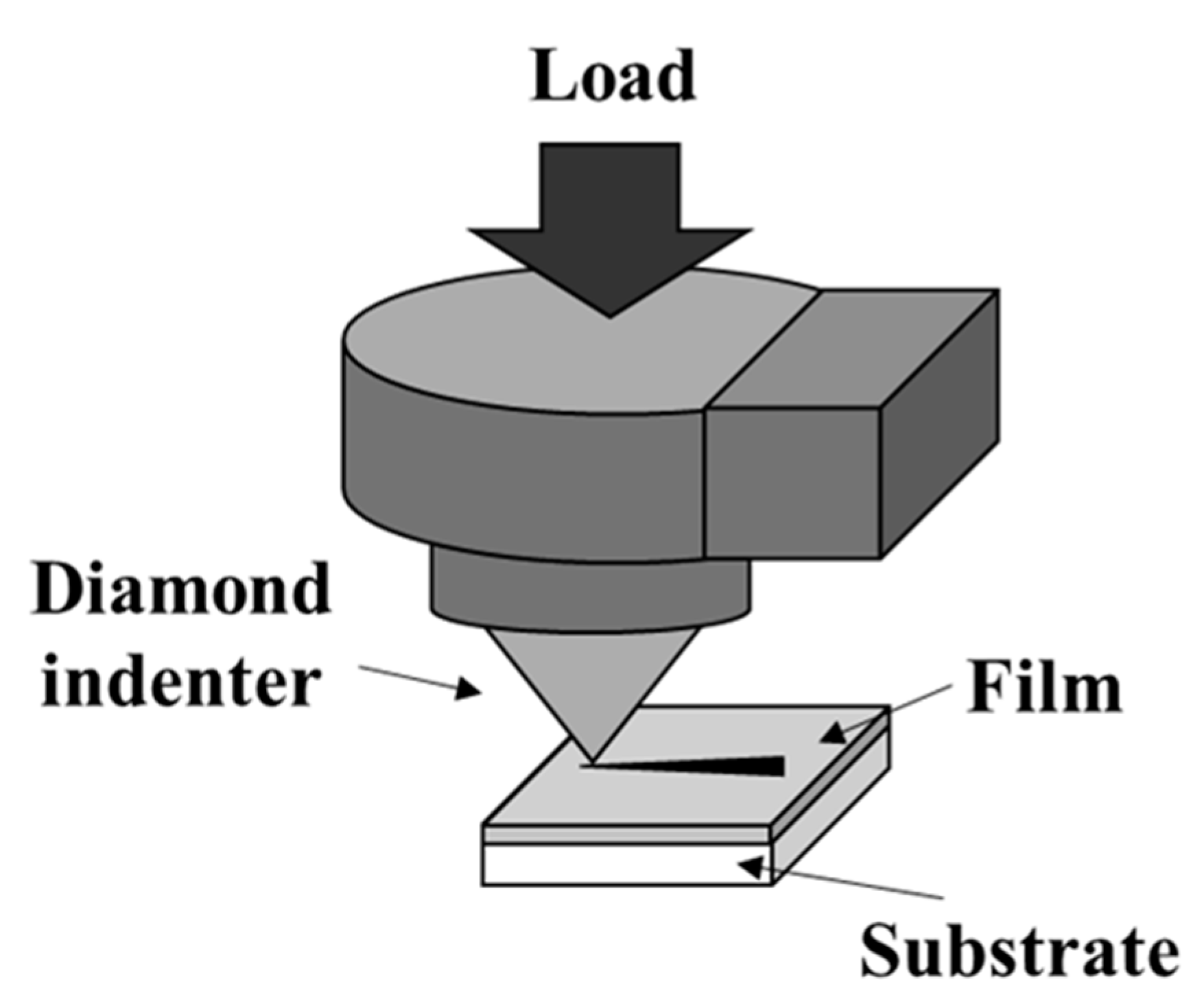

2.2. Evaluation of Film Adhesion by Scratch Testing

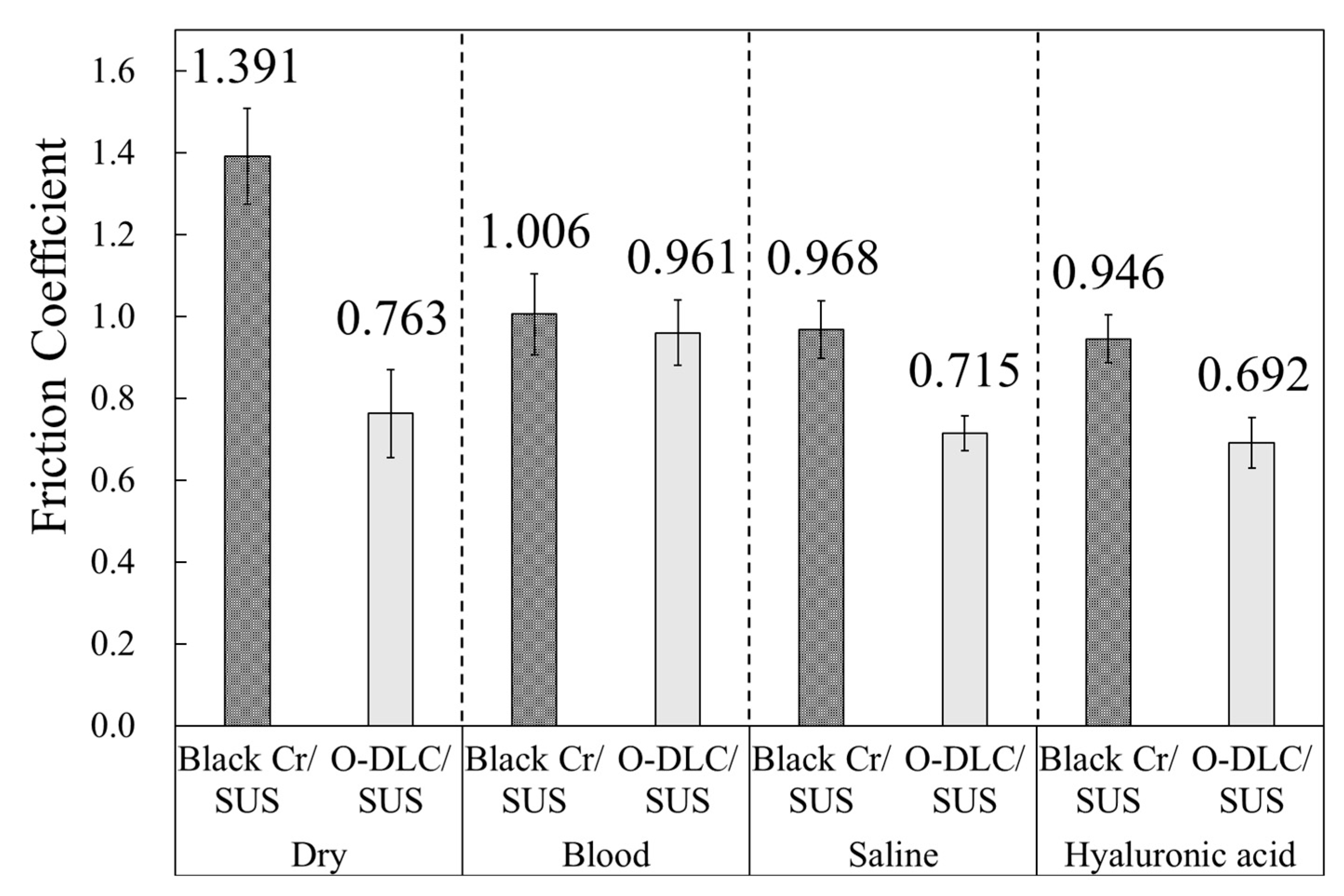

2.3. Measurement of the Coefficient of Friction in a Simulated Body Environment

2.4. Immersion and Sterilization Tests with Hydrochloric Acid

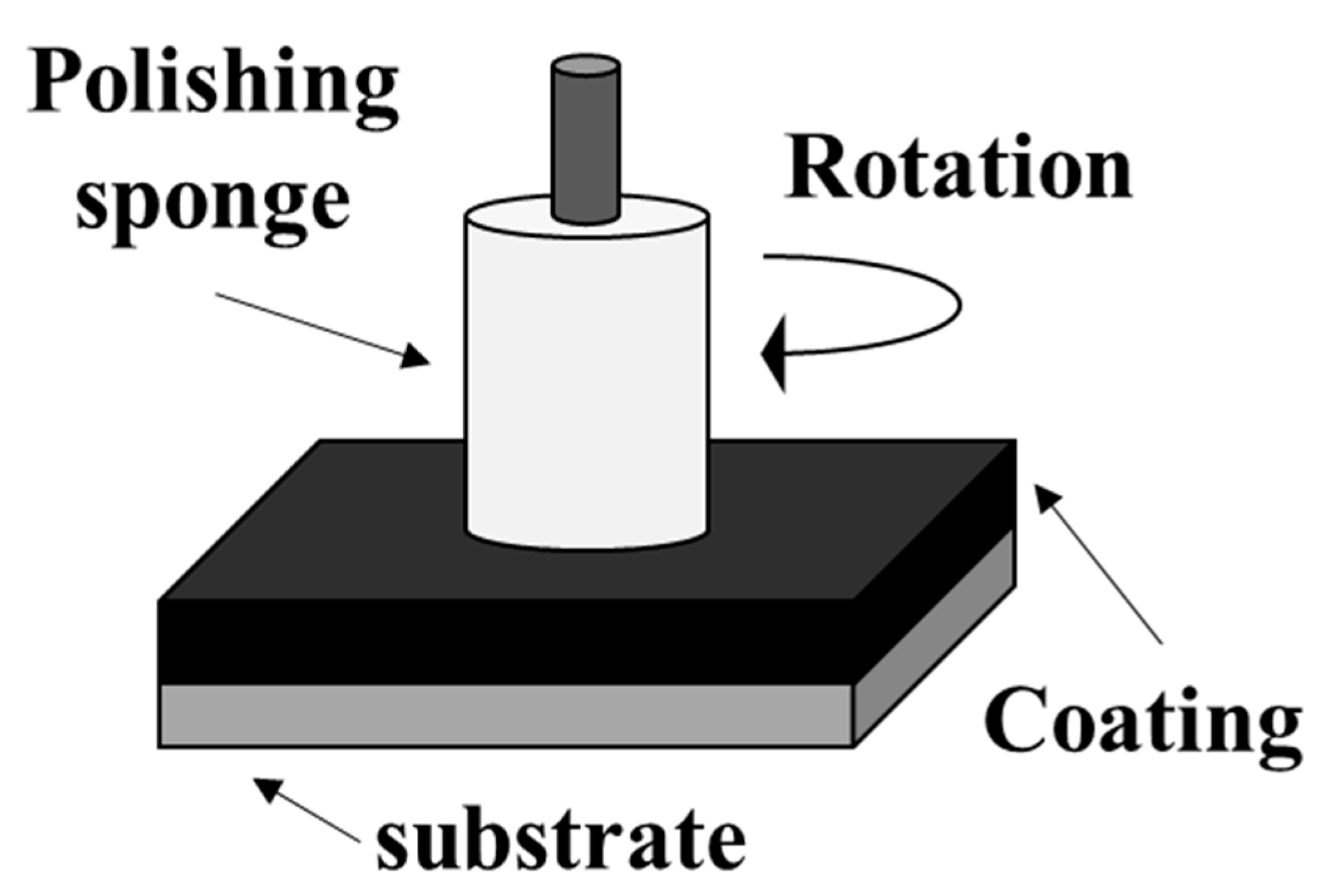

2.5. Light Reflection Evaluation before and after the Cleaning Test

- (1)

- Each substrate was fixed to a drill press (MECANIX Co., Ltd. Shop-Ace M18A) (MECANIX Co., Ltd., Japan).

- (2)

- The sponge attached to the drill press was slid at a constant load.

- (3)

- The reflection characteristics of each sample after sliding were measured using a gloss meter.

3. Results and Discussion

3.1. Film Adhesion Evaluation by Scratch Testing

3.2. Simulated Body Coefficient of Friction Measurement in Each Lubricating Liquid Environment

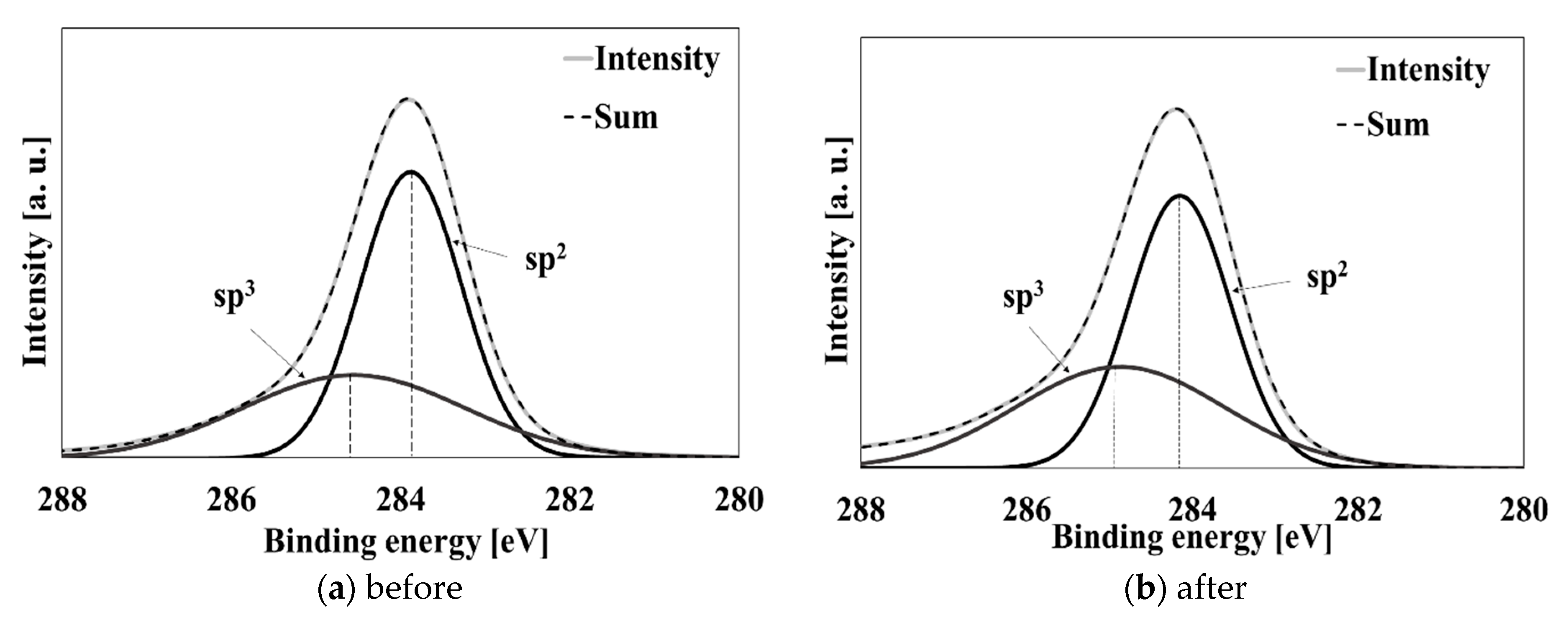

3.3. Immersion and High-Pressure Steam Sterilization Tests with Hydrochloric Acid

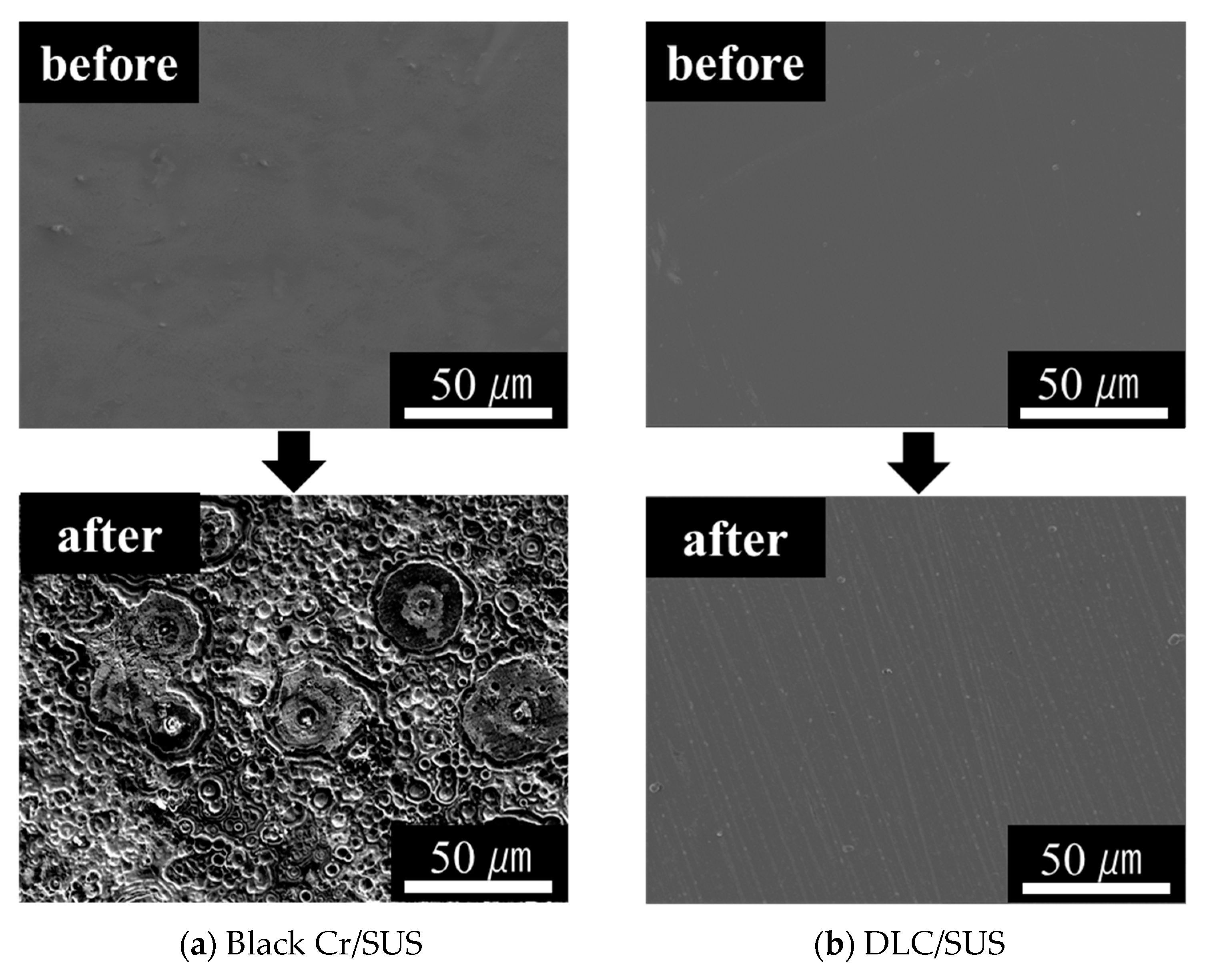

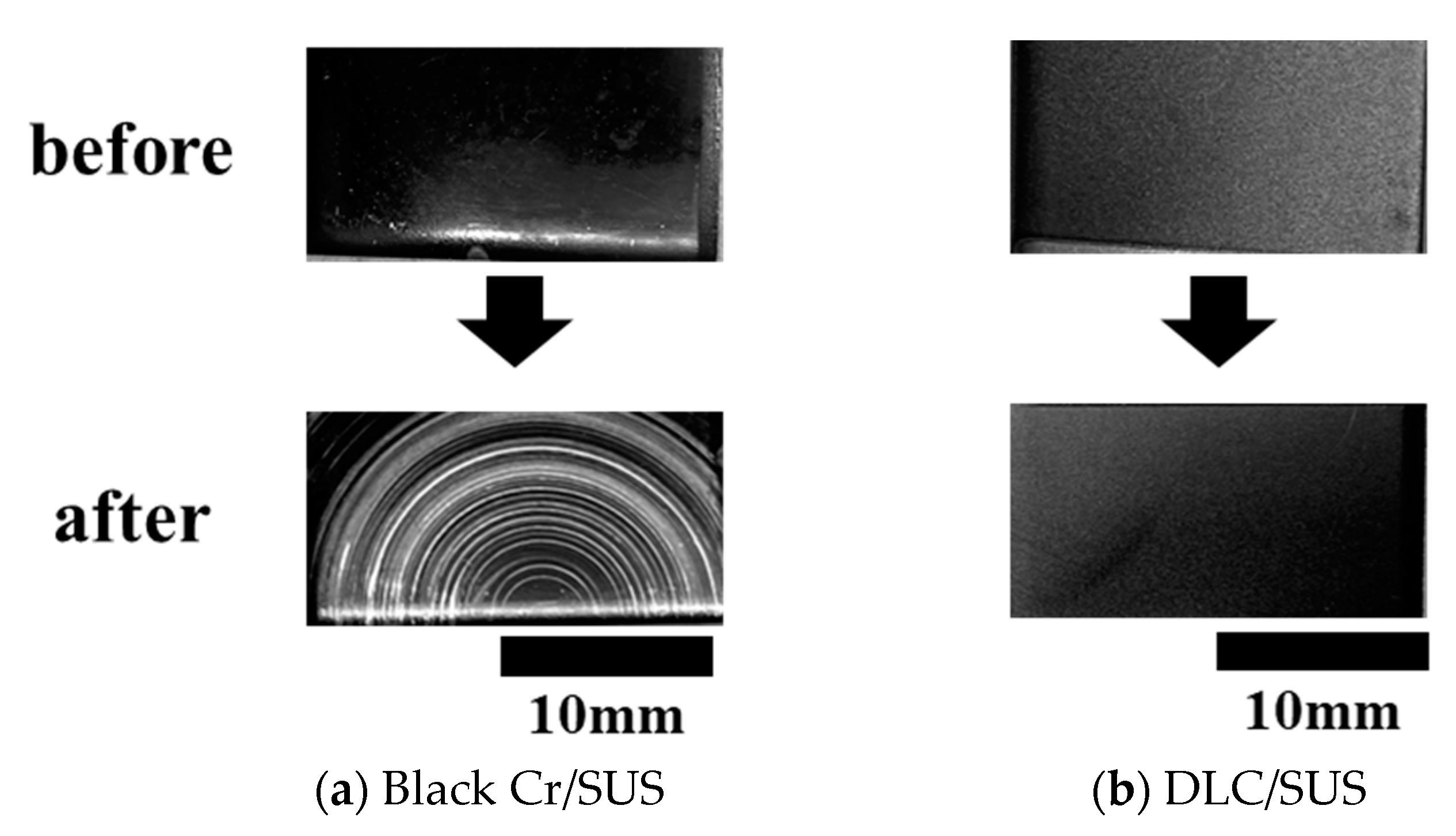

3.4. Light Reflection Characteristic Evaluation before and after the Cleaning Test

4. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Curtis, C.C.; Lugauer, S.; Mark, N.C. Demographics and aggregate household saving in Japan, China, and India. J. Macroecon. 2017, 51, 175–191. [Google Scholar] [CrossRef]

- Merali, N.; Singh, S. Abdominal access techniques (including laparoscopic access). Surgeons (Oxford) 2018, 36, 220–227. [Google Scholar] [CrossRef]

- Li, C.; Liu, Y.; Xue, D.; Chan, W.H. Effects of nurse-led interventions on early detection of cancer: A systematic re-view and meta-analysis. Int. J. Nur. Stud. 2020, 110, 103684. [Google Scholar] [CrossRef] [PubMed]

- Perez, R. Medical Speculum and Procedure. U.S. Patent 4597382A, 1 July 1986. [Google Scholar]

- Pan, C.; Chen, Y.; Yang, T.; Lin, P.-H.; Huang, J.C.; Lin, P.-H. Study of reflection-typed LED surgical shadowless lamp with thin film Ag-based metallic glass. Optic 2016, 127, 2193–2196. [Google Scholar] [CrossRef]

- Usui, T.; Iwata, T.; Miyake, S.; Otsuka, T.; Koizumi, S.; Shirakawa, N.; Kawata, T. Mechanical and frictional proper-ties of aesthetic orthodontic wires obtained by hard chrome carbide plating. J. Dent. Sci. 2018, 13, 151–159. [Google Scholar] [CrossRef]

- Karthik, C.; Ramkumar, V.S.; Pugazhendhi, A.; Gopalakrishnan, K.; Arulselvi, P.I. Biosorption and biotrans-formation of Cr (VI) by novel Cellulosimicrobium funkei strain AR6. J. Taiwan Inst. Chem. Eng. 2017, 70, 282–290. [Google Scholar] [CrossRef]

- Moradi, L.; Jobania, B.M.; Jafarnezhad-Ansariha, F.; Ghorbani, F.; Esmaeil-Pour, R.; Zolbina, M.M.; Kajbafzadeh, A.-M. Evaluation of different sterilization methods for decellularized kidney tissue. Tissue Cell 2020, 66, 101396. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Shamohammadi, M.; Moradi, M.; Hormozi, E.; Rakhshan, V. Effects of cold chemical (glutaraldehyde) versus autoclaving sterilization on the rate of coating loss of aesthetic archwires: A double-blind randomized clinical trial Comparaison des effets de la stérilisation à froid (glutaraldéhyde) et à l’autoclave sur le taux de perte de revêtement des arcs esthétiques: Essai clinique randomisé, contrôlé, en double-aveugle. Int. Orthod. 2020, 18, 380–388. [Google Scholar]

- Fontaine, J.; Donnet, C.; Erdemir, A. Fundamentals and Application of DLC Films, Tribology of Diamond-Like Carbon Films; Springer: Berlin, Germany, 2008; pp. 139–154. [Google Scholar]

- Mabuchi, Y.; Higuchi, T.; Weihnacht, V. Effect of sp2 /sp3 bonding ratio and nitrogen content on friction proper-ties of hydrogen-free DLC coatings. Tribol. Int. 2013, 62, 130–140. [Google Scholar] [CrossRef]

- Tashiro, H.; Nakaya, M.; Hotta, A. Enhancement of the gas barrier property of polymers by DLC coating with orga-nosilane interlayer. Diam. Relat. Mater. 2013, 35, 7–13. [Google Scholar] [CrossRef]

- Kumar, C.S.; Majumder, H.; Khan, A.; Patel, S.K. Applicability of DLC and WC/C low friction coatings on Al2O3/TiCN mixed ceramic cutting tools for dry machining of hardened 52100 steel. Ceram. Int. 2020, 46, 11889–11897. [Google Scholar] [CrossRef]

- Hauert, R. A review of modified DLC coatings for biological applications. Diam. Relat. Mater. 2003, 12, 583–589. [Google Scholar] [CrossRef]

- Dearnaley, G.; Arps, J.H. Biomedical applications of diamond-like carbon (DLC) coatings: A review. Surf. Coatings Technol. 2005, 200, 2518–2524. [Google Scholar] [CrossRef]

- Kobayashi, S.; Ohgoe, Y.; Ozeki, K.; Sato, K.; Sumiya, T.; Hirakuri, K.K.; Aoki, H. Diamond-like carbon coatings on or-thodontic archwires. Diam. Relat. Mater. 2005, 14, 1094–1097. [Google Scholar] [CrossRef]

- Banghard, M.; Hartmann, R.; Silmy, K.; Nisch, W.; Von Metzen, R.; Stett, A.; Bucher, V. High voltage insulation properties of DLC-Parylene multilayer films for microsurgery instruments. Microelectron. Eng. 2016, 153, 126–131. [Google Scholar] [CrossRef]

- Mano, T. Improvement of adhesion of diamond-like carbon films and its medical application. J. Surf. Finish. Soc. Jpn. 2007, 58, 18–22. [Google Scholar] [CrossRef]

- Ho, C. New device for Pentax-Airway Scope in pediatric intubation. Acta Anaesthesiol. Taiwanica 2010, 48, 178–179. [Google Scholar] [CrossRef]

- Lim, D.; Ku, B.; Seo, D.; Lim, C.; Oh, E.; Shim, S.E.; Baeck, S.-H. Pulse-reverse electroplating of chromium from Sargent baths: Influence of anodic time on physical and electrochemical properties of electroplated Cr. Int. J. Refract. Met. Hard Mater. 2020, 89, 105213. [Google Scholar] [CrossRef]

- Mayama, T.; Hiratsuka, M.; Nakamori, H.; Homma, A.; Hirakuri, K.; Ohgoe, Y. Effect of oxygen plasma treatment for different types of DLC films. In Proceedings of the 79th JSAP Autumn Meeting, Nagoya, Japan, 18–21 September 2016. [Google Scholar]

- Rahaman, M.L.; Zhang, L.; Liu, M.; Liu, W. Surface roughness effect on the friction and wear of bulk metallic glasses. Wear 2015, 332–333, 1231–1237. [Google Scholar] [CrossRef]

- Menezes, P.L.; Kishore; Kailas, S.V. Influence of surface texture and roughness parameters on friction and transfer layer formation during sliding of aluminium pin on steel plate. Wear 2009, 267, 1534–1549. [Google Scholar] [CrossRef]

- Tian, S.F.; Jiang, L.T.; Guo, Q.; Wu, G.H. Effect of surface roughness on tribological properties of TiB2/Al composites. Mater. Design 2014, 53, 129–136. [Google Scholar] [CrossRef]

- Lee, J.; He, M.; Yeo, C.-D.; Kumar, G.; Hu, Z.; Quitevis, E.L.; Thalangamaarachchige, V.D. Friction and wear of Pd-rich amorphous alloy (Pd43Cu27Ni10P20) under dry and ionic liquid (IL) lubricated conditions. Wear 2018, 190–199. [Google Scholar] [CrossRef]

- Sakurai, K.; Hiratsuka, M.; Nakamori, H.; Namiki, K.; Hirakuri, K. Evaluation of sliding properties and durability of DLC coating for medical devices. Diam. Relat. Mater. 2019, 96, 97–103. [Google Scholar] [CrossRef]

- Onodera, S.; Fujii, S.; Moriguchi, H.; Tsujioka, M.; Hirakuri, K. Antibacterial property of F doped DLC film with plasma treatment. Diam. Relat. Mater. 2020, 107, 107835. [Google Scholar] [CrossRef]

- International Organization for Standardization 20502:2005. Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Determination of Adhesion of Ceramic Coatings by Scratch Testing; ISO: Geneva, Switzerland, 2005. [Google Scholar]

- Wang, J.; Ma, L.; Li, W.; Zhou, Z. Influence of different lubricating fluids on friction trauma of small intestine during enteroscopy. Tribol. Int. 2018, 126, 29–38. [Google Scholar] [CrossRef]

- Xu, P.; Wang, Y.; Cao, X.; Nie, X.; Yue, W.; Zhang, G. The tribological properties of DLC/SiC and DLC/Si3N4 under different relative humidity: The transition from abrasive wear to tribo-chemical reaction. Ceram. Int. 2021, 47, 3901–3910. [Google Scholar] [CrossRef]

- Sander, T.; Tremmel, S.; Wartzack, S. A modified scratch test for the mechanical characterization of scratch re-sistance and adhesion of thin hard coating on soft substrates. Surf. Coatings Technol. 2011, 206, 1873–1878. [Google Scholar] [CrossRef]

- Kato, M.; Sakaki, T. Corrosion behavior of metallic chromium in aqueous hydrochloric acid solution. J. Surf. Finish. Soc. Jpn. 1991, 55, 1108–1114. [Google Scholar]

- Kato, M.; Sakaki, T. Effect of alloying elements on corrosion behavior of Cr in HCl solutions. J. Surf. Finish. Soc. Jpn. 1992, 56, 74–80. [Google Scholar]

- Uribe-Padilla, J.; Graells, M.; Salgado-Valle, J.; Serrano, J.L. A viscosity-mediated model for relating gross and film thickness of coatings. Prog. Org. Coating 2019, 136, 105195. [Google Scholar] [CrossRef]

| Samples | Black Cr/SUS, DLC/SUS |

|---|---|

| Scratch speed (mm/min) | 10 |

| Applied load increase rate (N/min) | 100 |

| Initial load (N) | 0.9 |

| End load (N) | 60 |

| Temperature (°C) | 24 |

| Humidity (%) | 48 |

| Substrate | Black Cr/SUS, DLC/SUS |

|---|---|

| Diameter of polishing sponge (mm) | 50 |

| Load (N) | 10 |

| Rotation speed (rpm) | 1290 |

| Time (s) | 20 |

| Sample | Delamination Load (N) | ||||

|---|---|---|---|---|---|

| N1 | N2 | N3 | Average | Standard Deviation | |

| Black Cr/SUS | 2.85 | 3.63 | 2.64 | 3.04 | 0.43 |

| DLC/SUS | 21.81 | 23.98 | 26.25 | 24.01 | 1.81 |

| wt.% | Black Cr/SUS | DLC/SUS | ||

|---|---|---|---|---|

| Before | After | Before | After | |

| C | 2.5 ± 0.21 | 2.3 ± 0.56 | 98.1 ± 0.31 | 98.7 ± 0.28 |

| O | 32.2 ± 0.47 | 47.2 ± 0.43 | 1.9 ± 0.12 | 1.3 ± 0.34 |

| Fe | 1.2 ± 0.46 | 0.3 ± 0.20 | ND | ND |

| Cr | 63.9 ± 0.38 | 50.3 ± 0.64 | ND | ND |

| Ni | 0.2 ± 0.27 | ND | ND | ND |

| Sample | Glossiness (%) | |

|---|---|---|

| before | after | |

| SUS | 75.4 (standard) | |

| Black Cr/SUS | 6.8 | 63.8 |

| DLC/SUS | 15.8 | 15.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaneko, M.; Hiratsuka, M.; Alanazi, A.; Nakamori, H.; Namiki, K.; Hirakuri, K. Surface Reformation of Medical Devices with DLC Coating. Materials 2021, 14, 376. https://doi.org/10.3390/ma14020376

Kaneko M, Hiratsuka M, Alanazi A, Nakamori H, Namiki K, Hirakuri K. Surface Reformation of Medical Devices with DLC Coating. Materials. 2021; 14(2):376. https://doi.org/10.3390/ma14020376

Chicago/Turabian StyleKaneko, Mao, Masanori Hiratsuka, Ali Alanazi, Hideki Nakamori, Kazushige Namiki, and Kenji Hirakuri. 2021. "Surface Reformation of Medical Devices with DLC Coating" Materials 14, no. 2: 376. https://doi.org/10.3390/ma14020376

APA StyleKaneko, M., Hiratsuka, M., Alanazi, A., Nakamori, H., Namiki, K., & Hirakuri, K. (2021). Surface Reformation of Medical Devices with DLC Coating. Materials, 14(2), 376. https://doi.org/10.3390/ma14020376