Synergistic Effect of F–T Synthetic Wax and Surface-Active Agent Content on the Properties and Foaming Characteristics of Bitumen 50/70

Abstract

1. Introduction

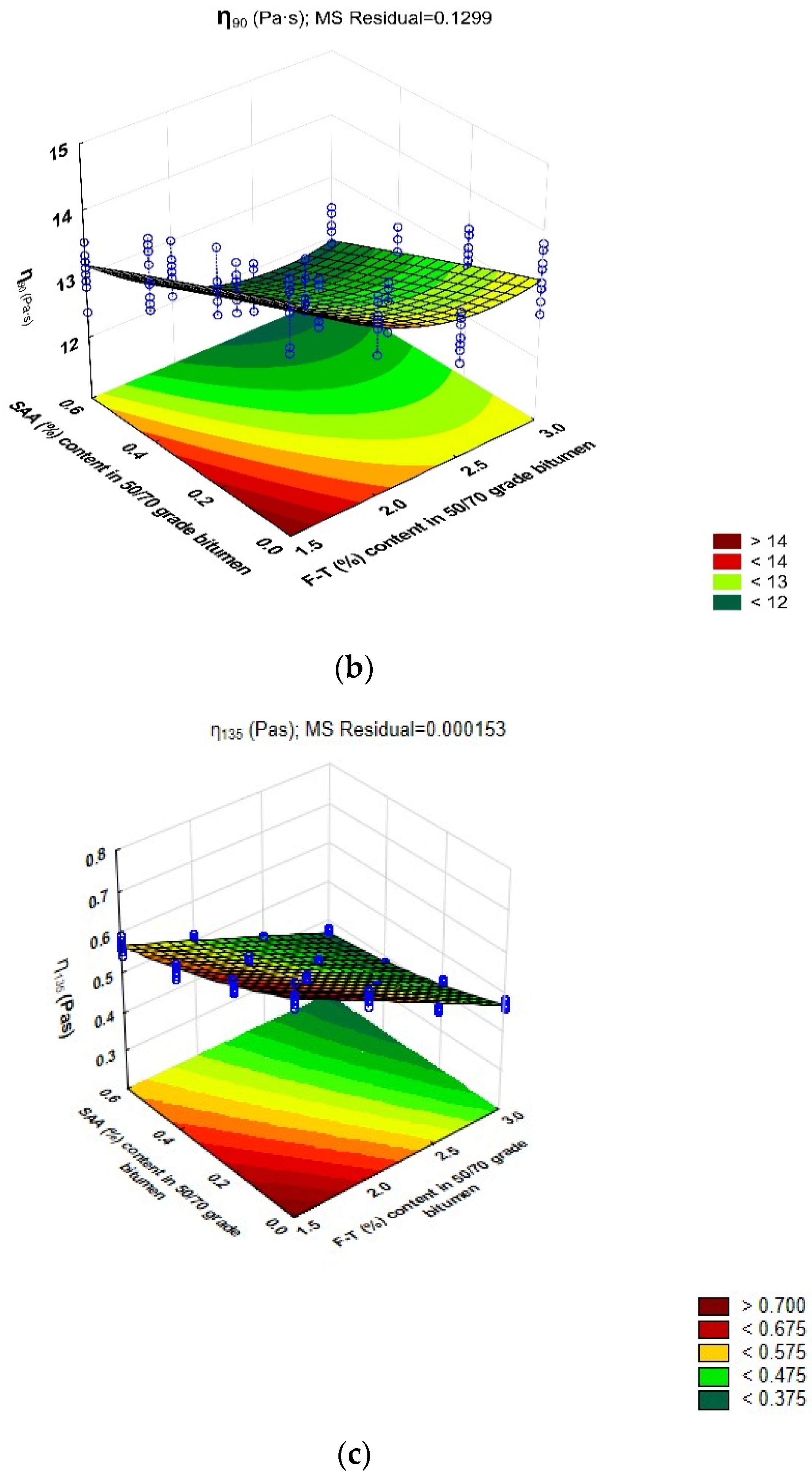

2. Materials and Methods

2.1. Material

- -

- -

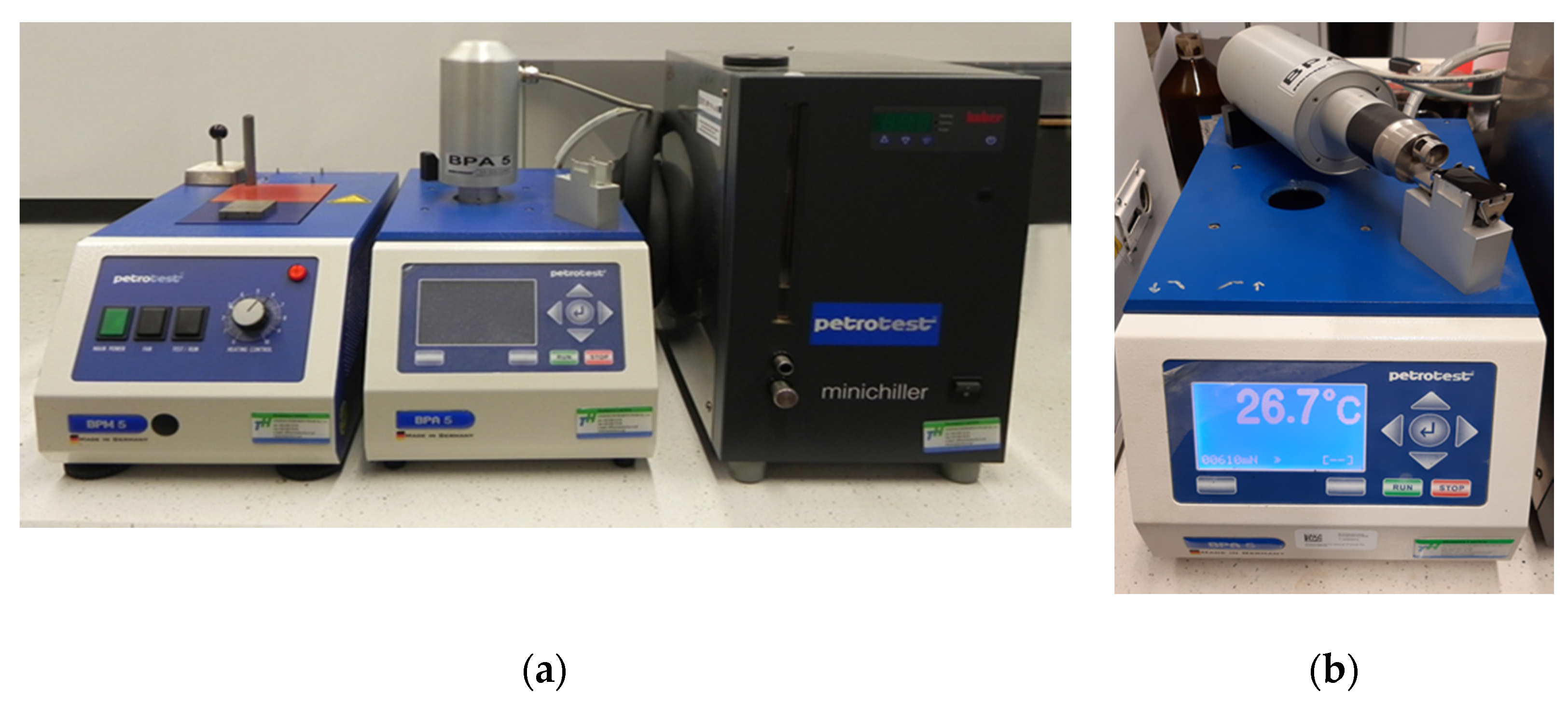

2.2. Experimental Program

- -

- y—analysed bitumen parameter

- -

- x1—synthetic wax FT (F–T) content in bitumen (%),

- -

- x2—surface active agent (SAA) content in bitumen (%),

- -

- b0–b5—regression coefficients.

3. Results and Discussion

- -

- Penetration at 25 °C (Pen, EN 1426:2015-08) [46], which is a measure of binder consistency;

- -

- Softening point (TR&B, EN 1427:2015-08) [47];

- -

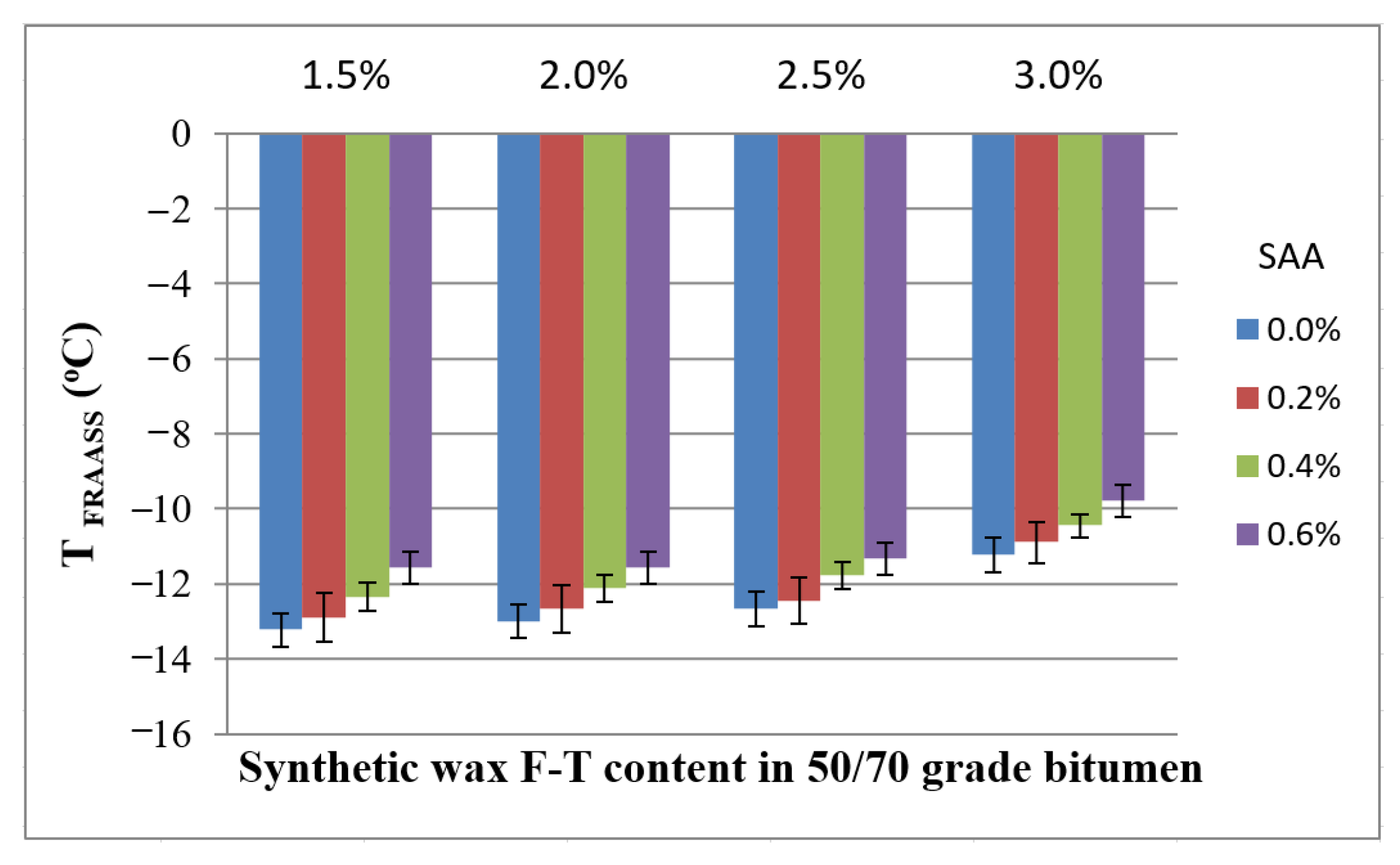

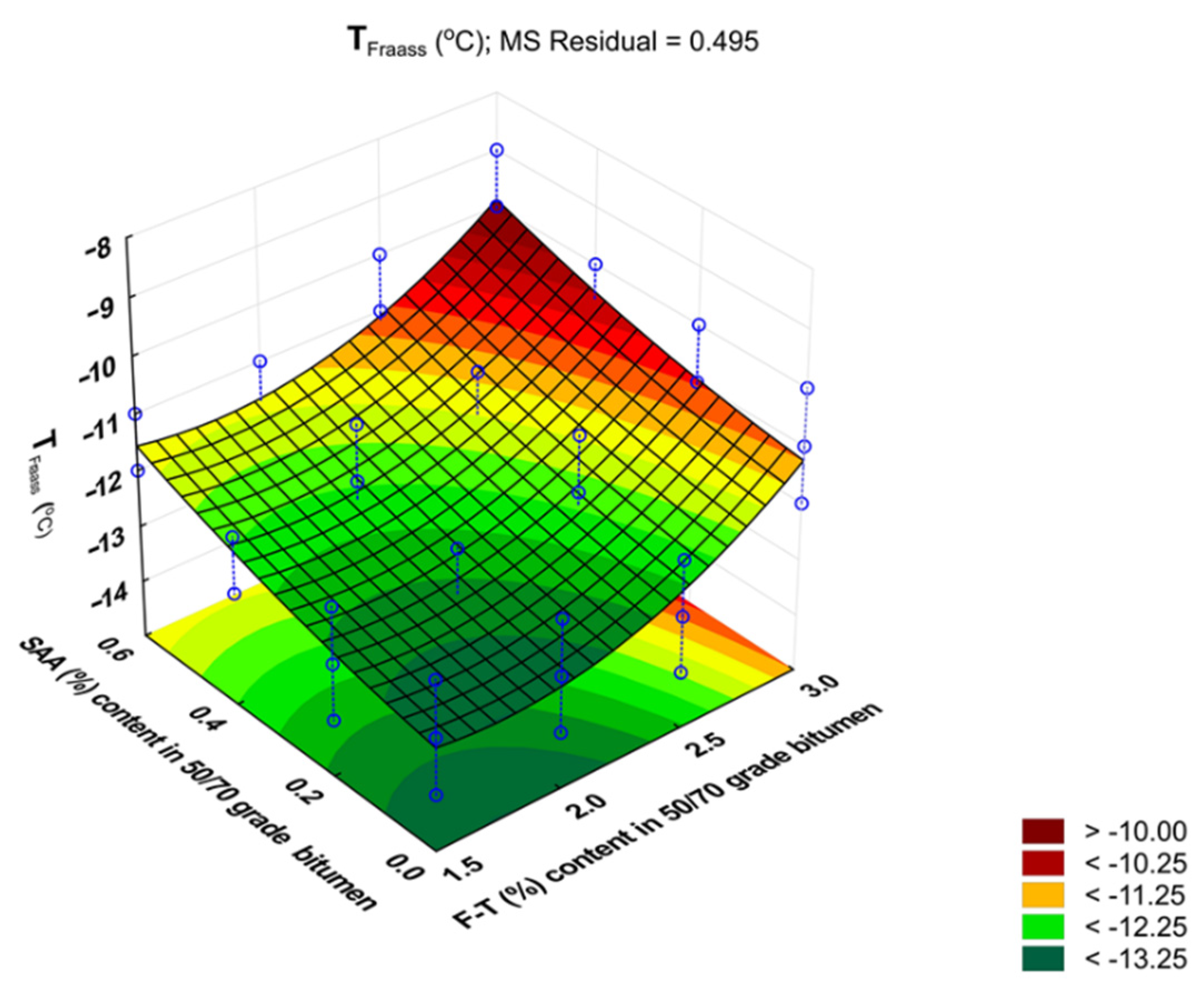

- Fraass breaking point (TFraass, EN 12593:2015-08) [48];

- -

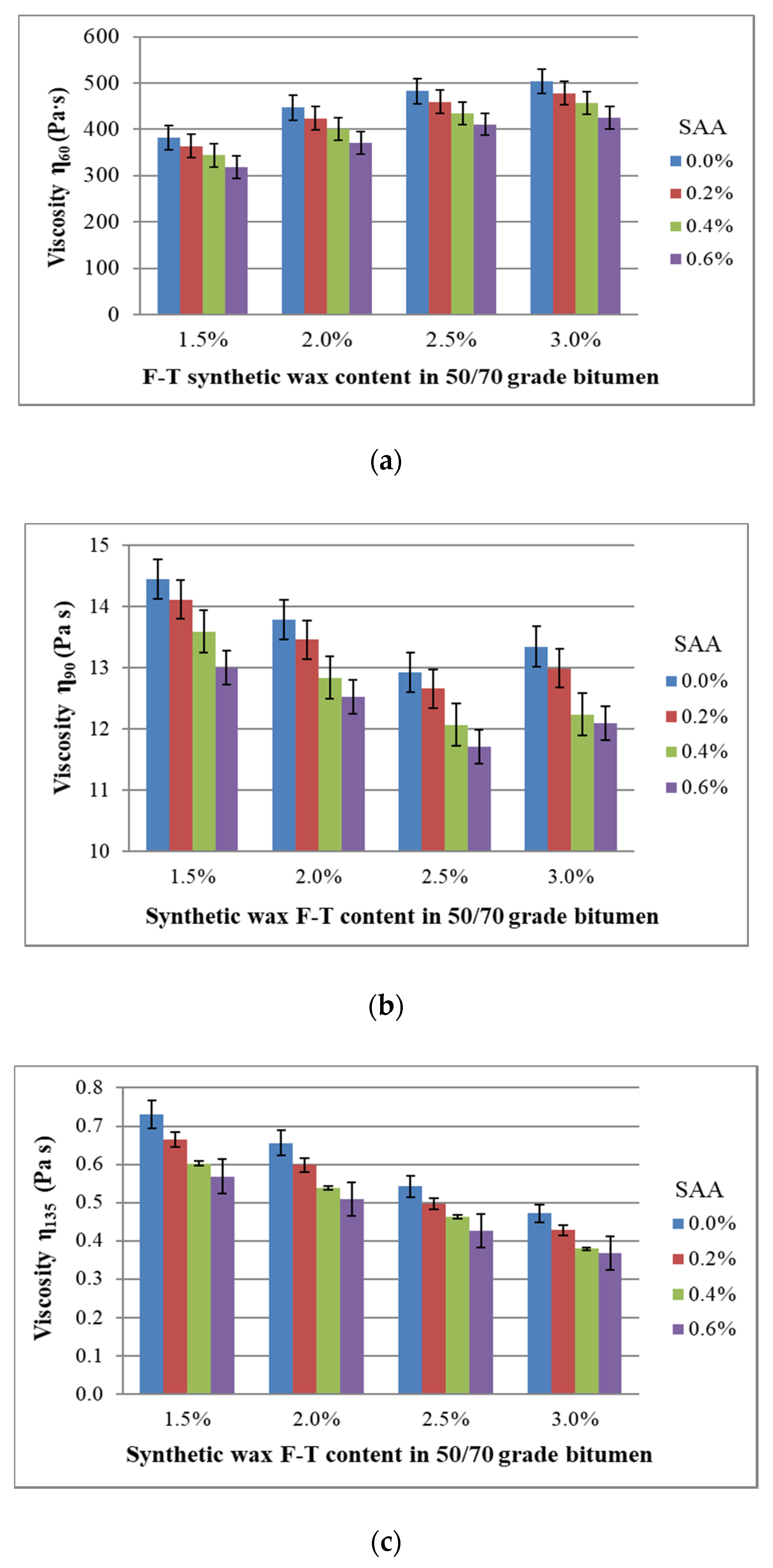

- Dynamic viscosity at 60 °C, 90 °C and 135 °C (η60, η90, η135, EN 13302:2018) [49];

- -

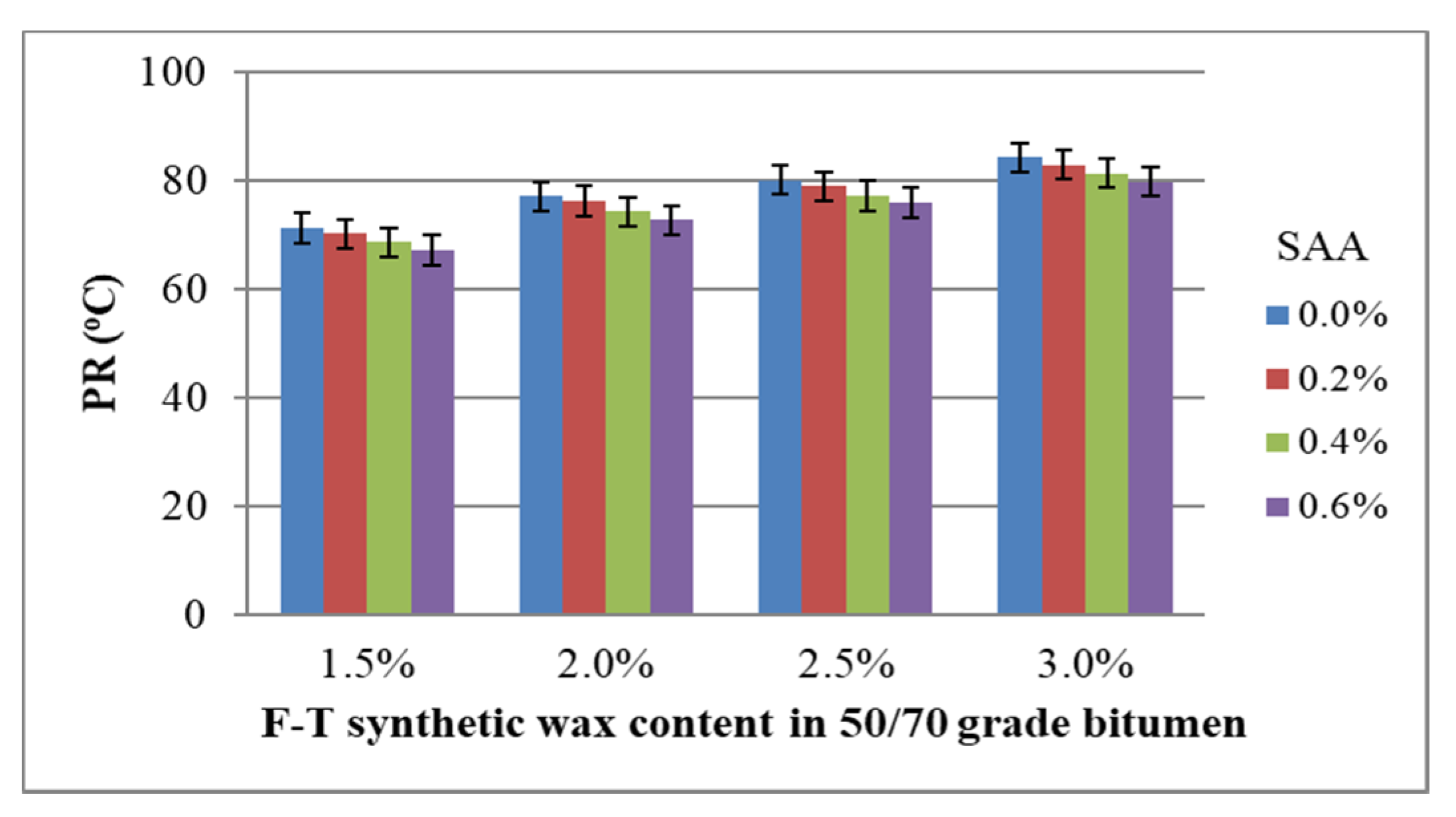

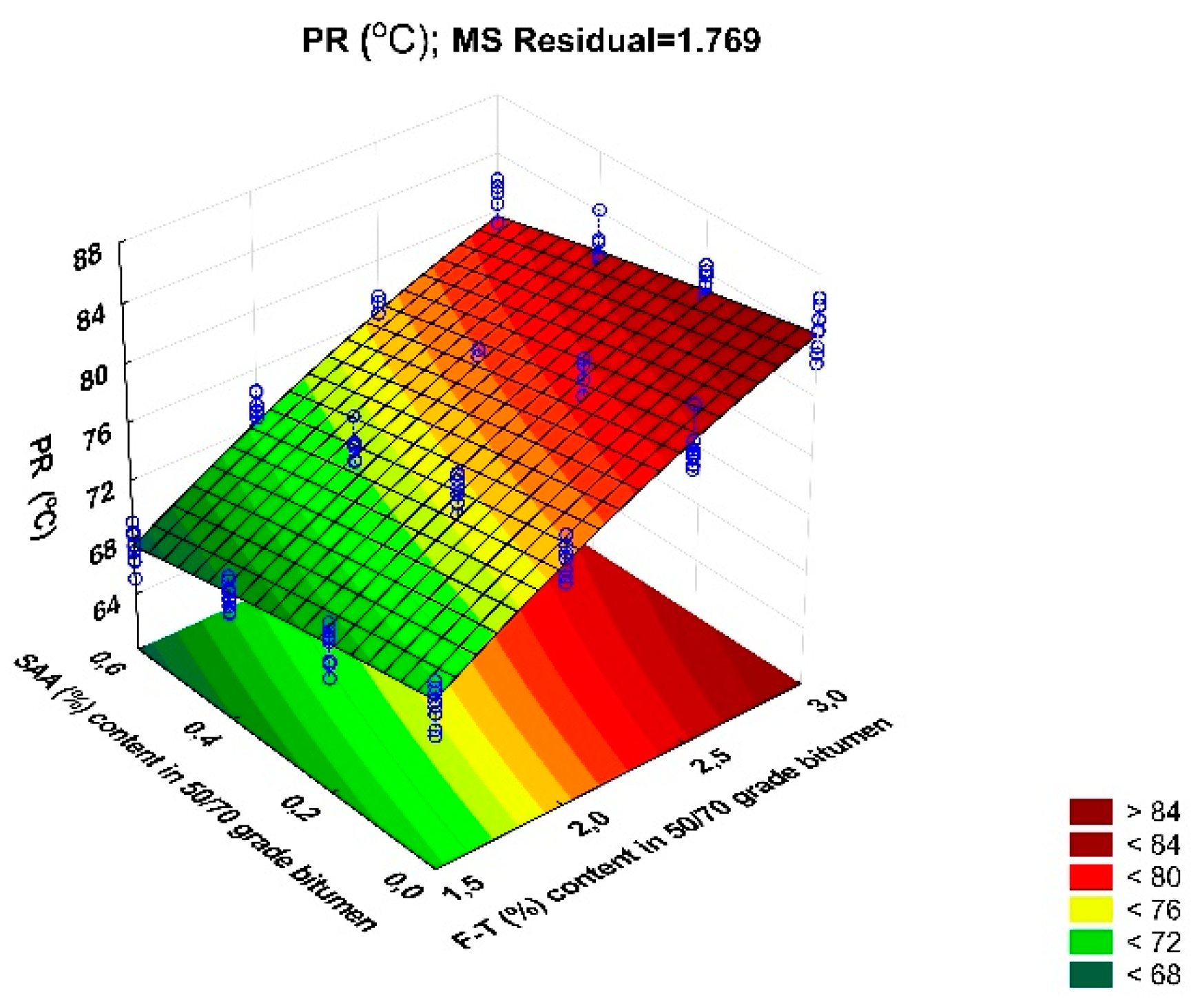

- Plasticity range PR;

- -

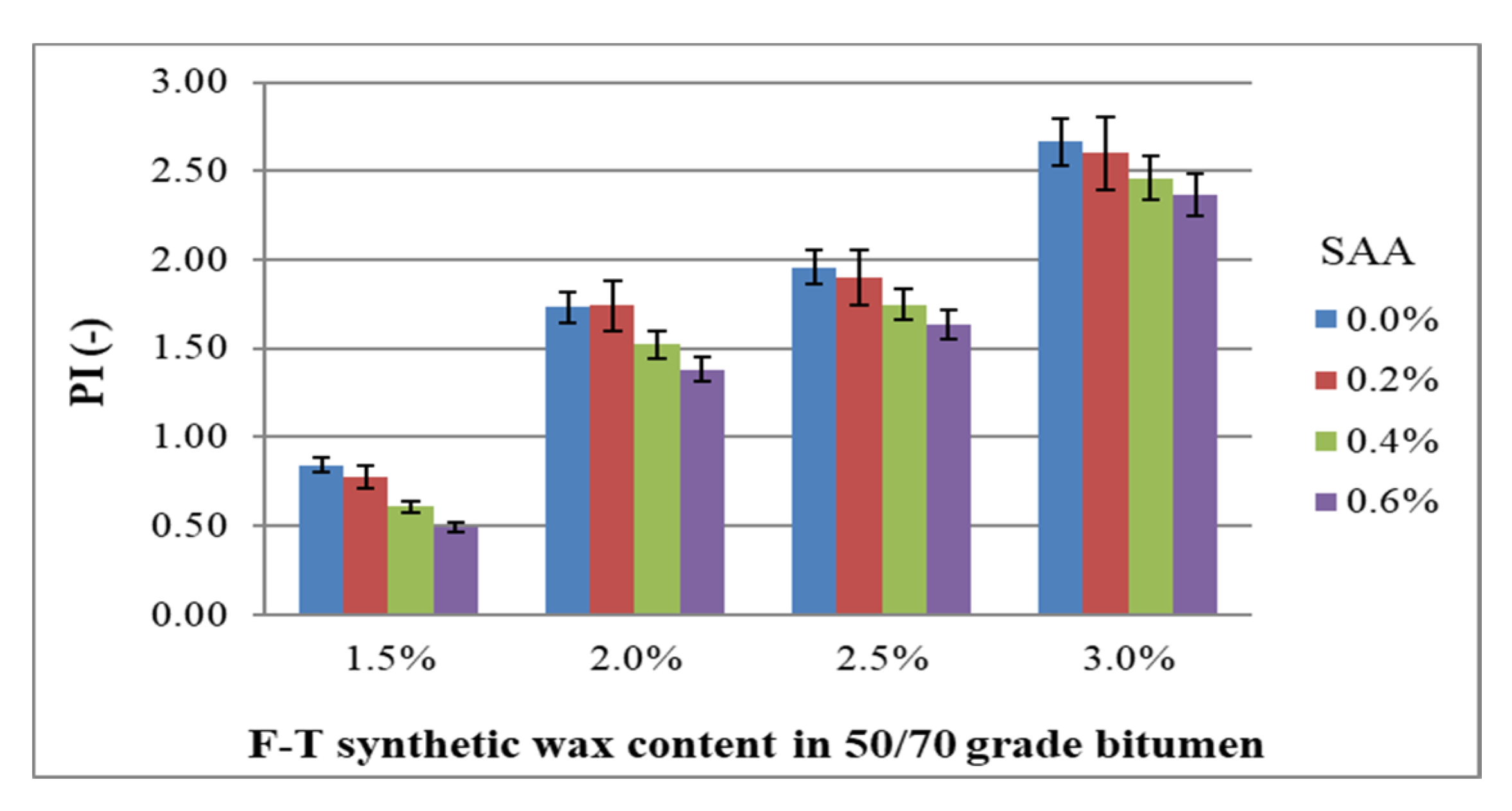

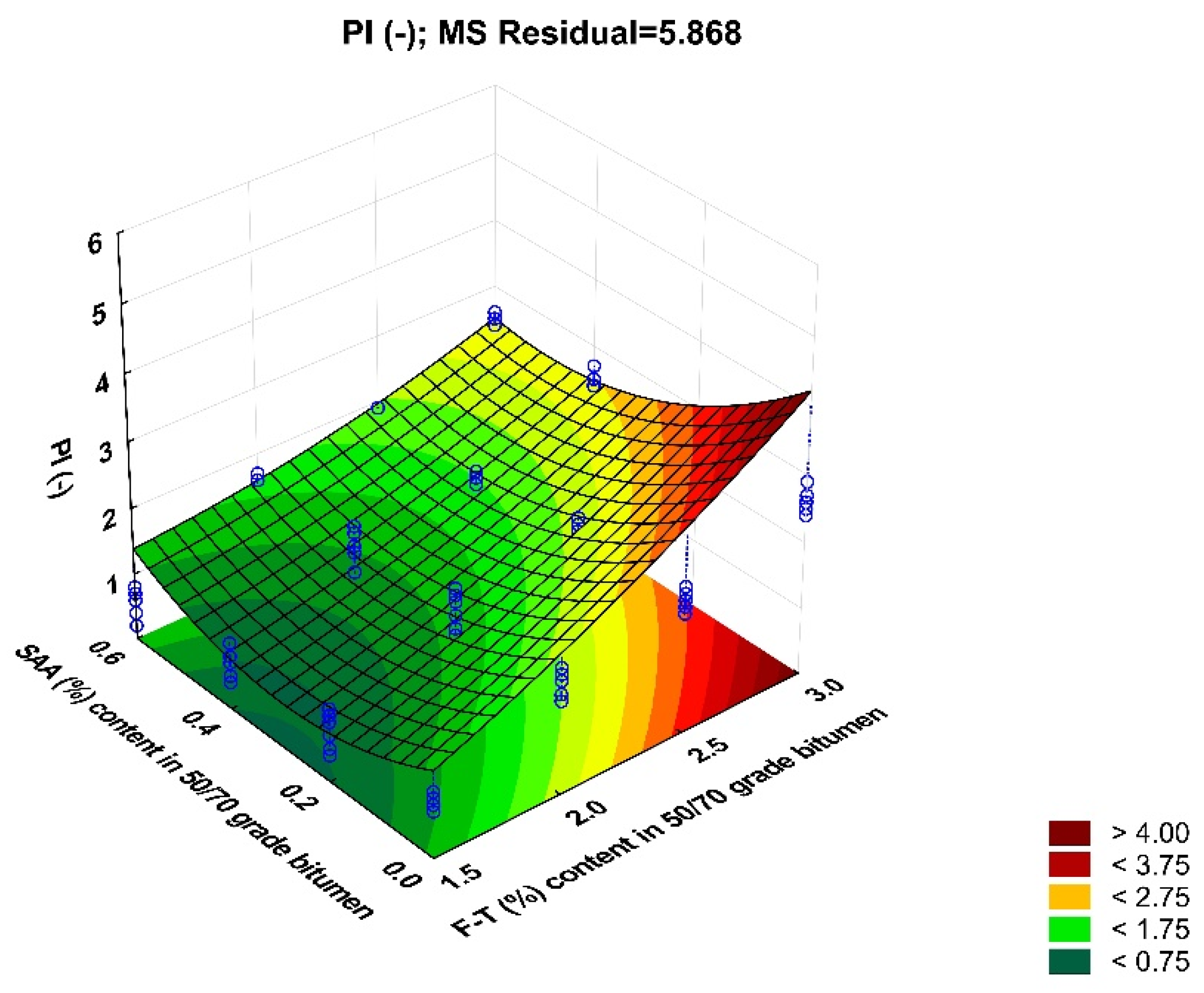

- Penetration index PI;

- -

- -

- -

- Foam index FI [16].

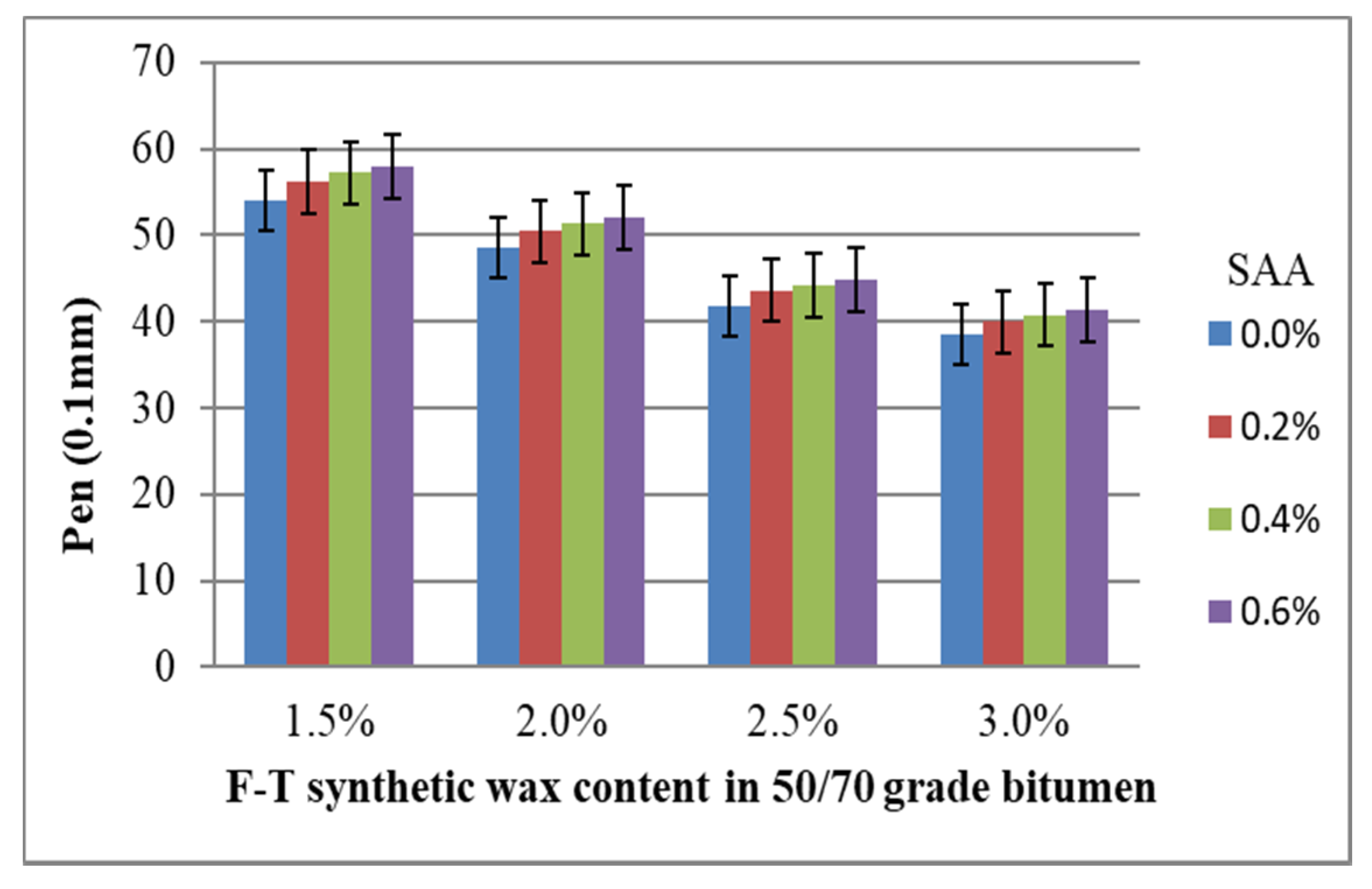

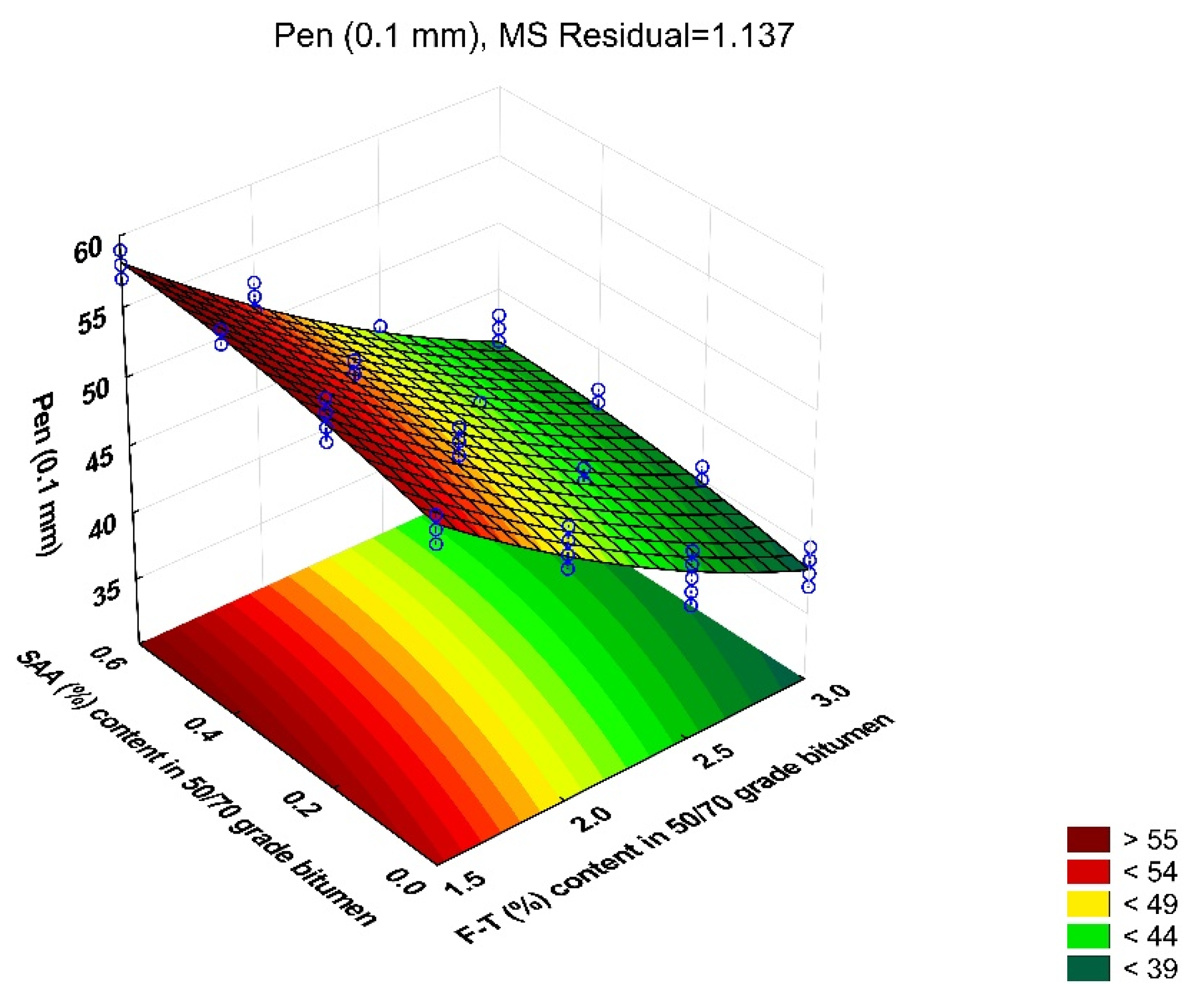

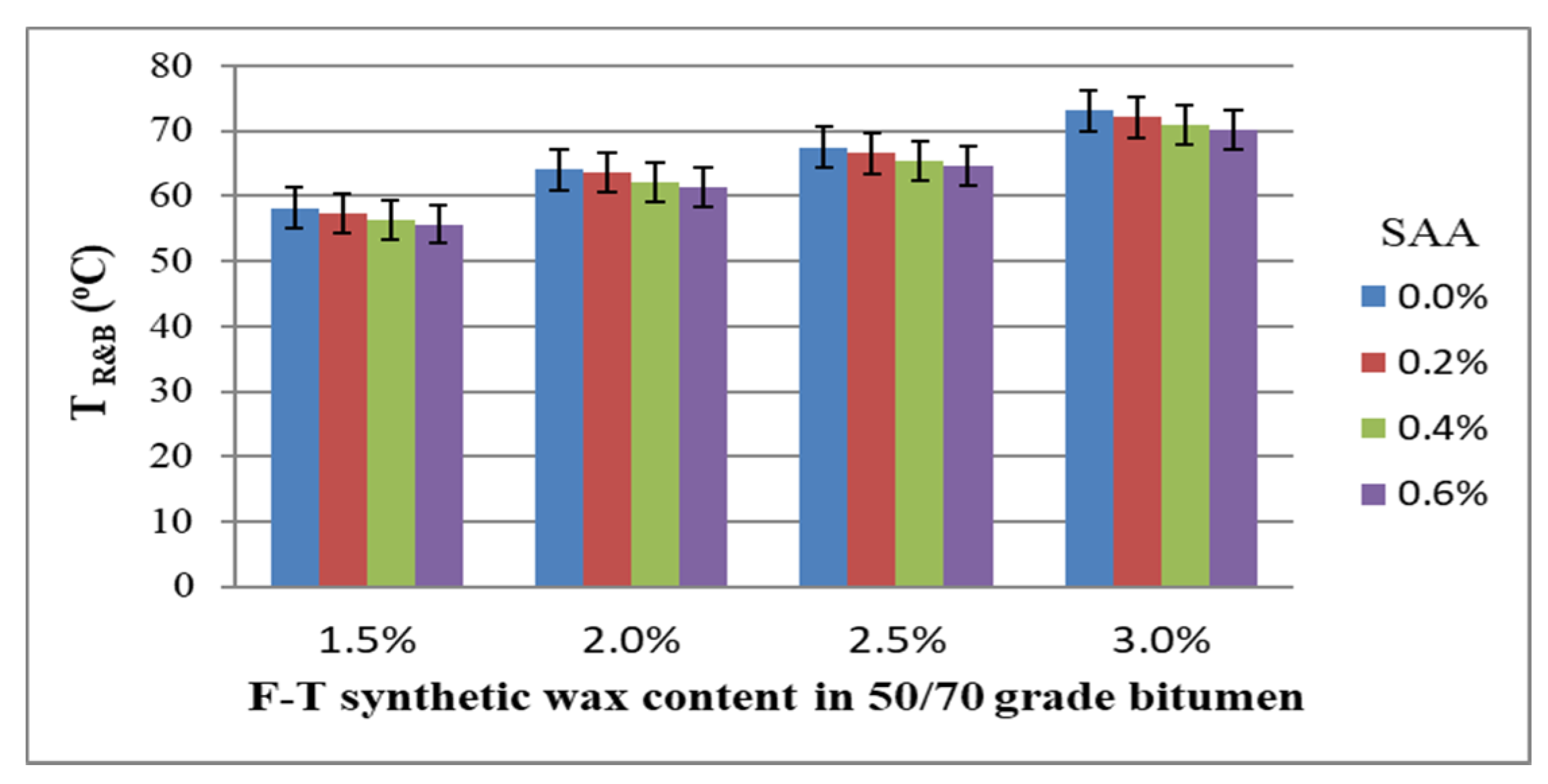

3.1. The Effects of the Synthetic Wax F–T and SAA Content on Basic Bitumen Properties

3.2. Determining Dynamic Viscosity of the Binder Containing SAA and Synthetic Wax F–T

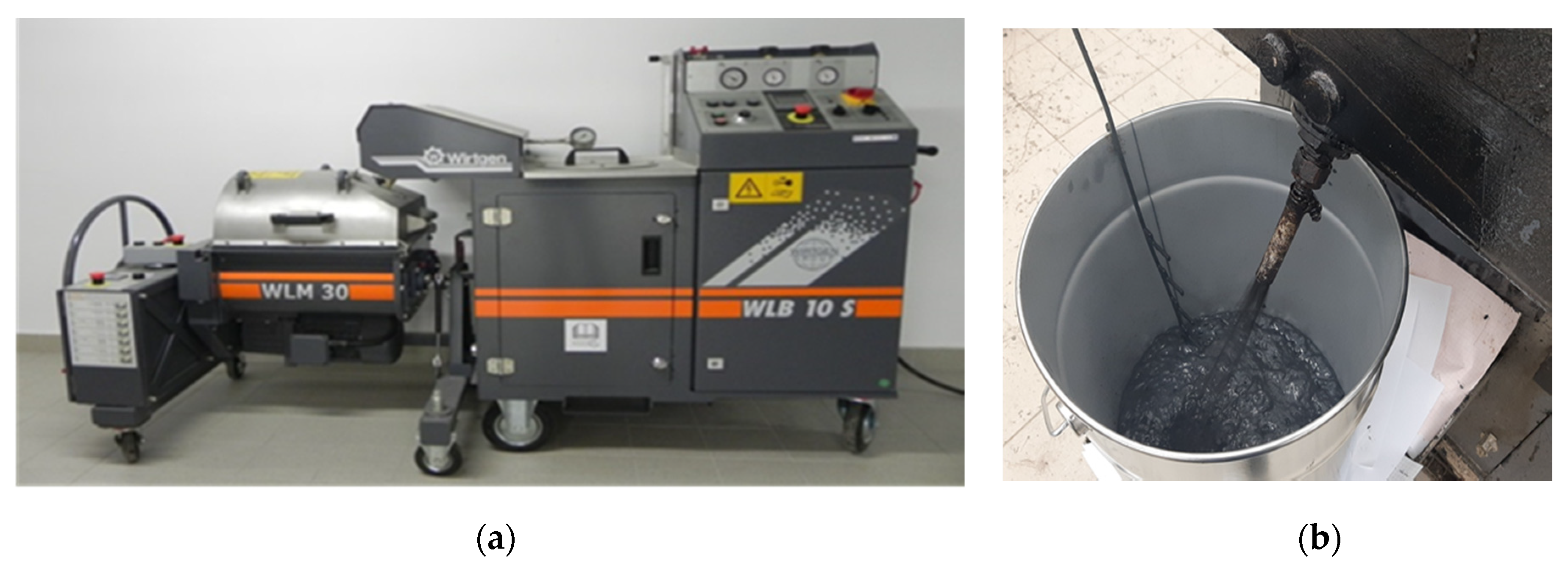

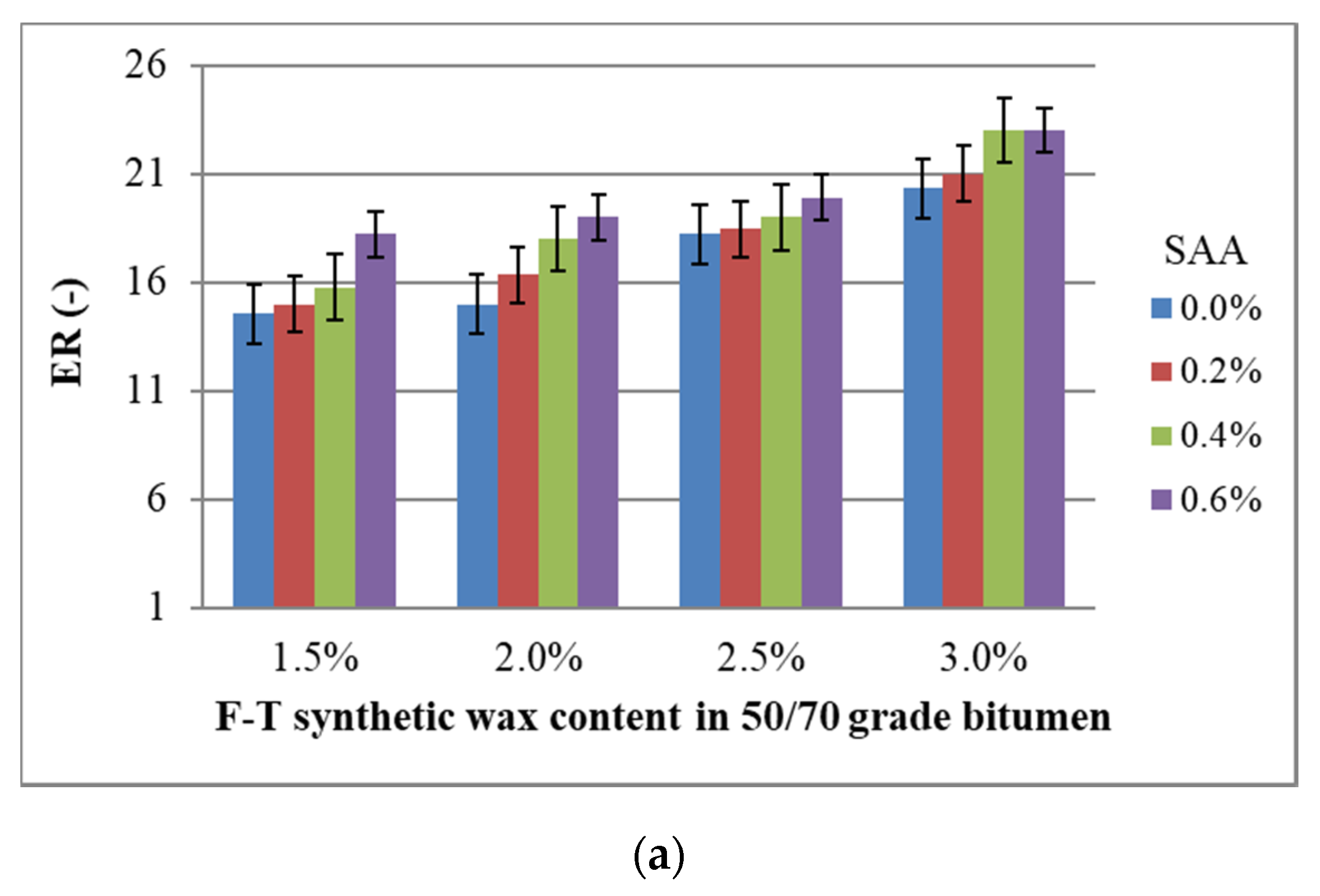

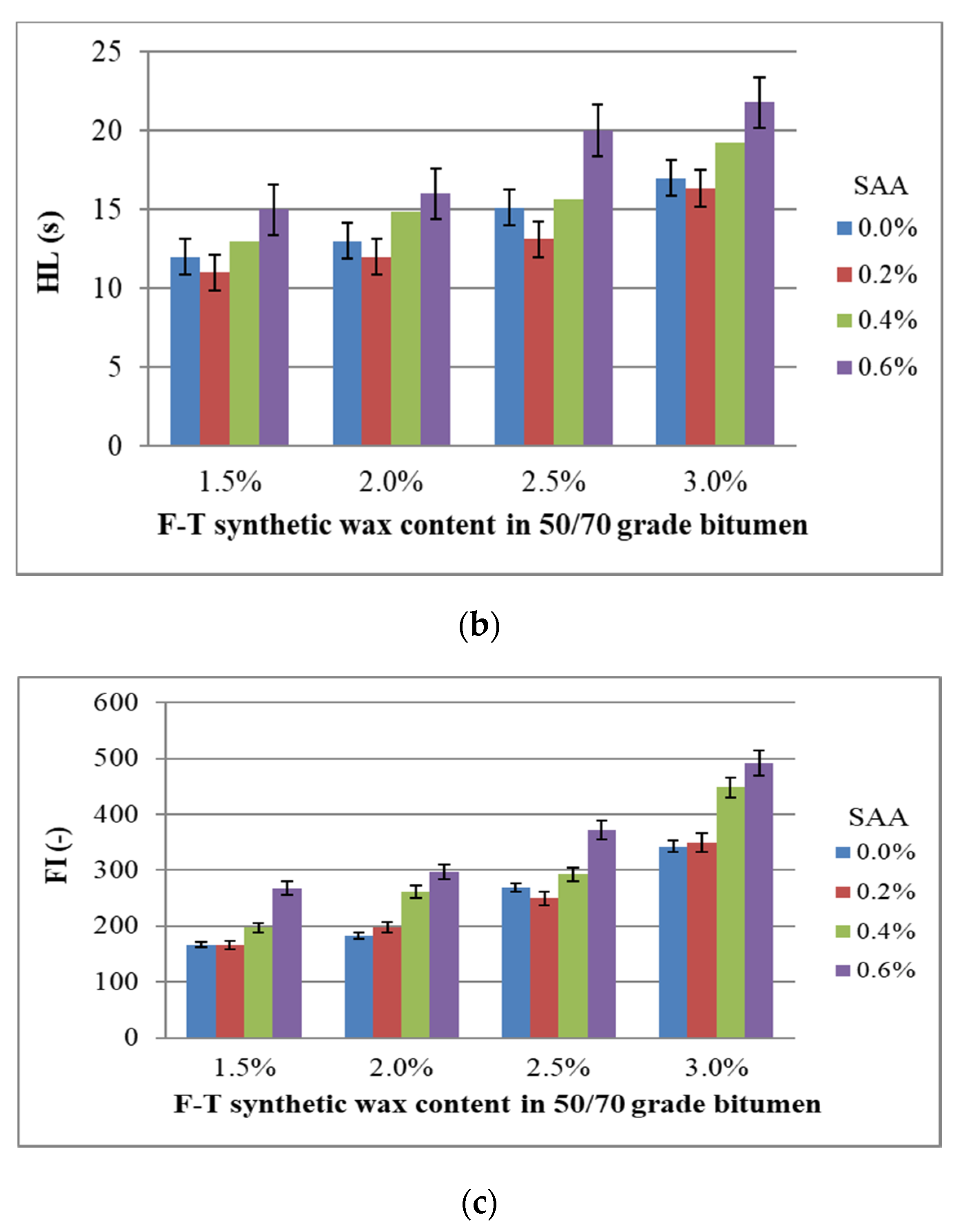

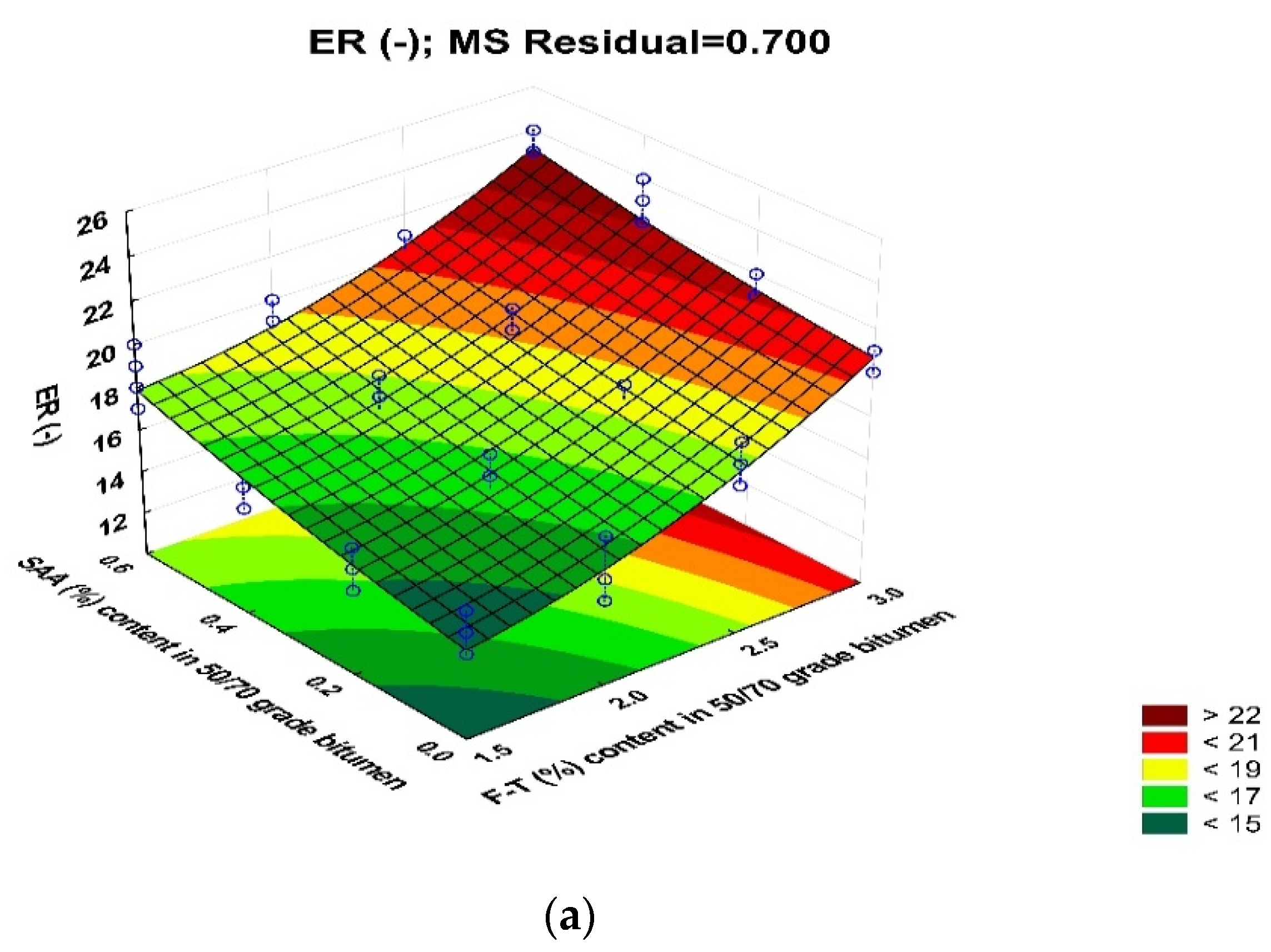

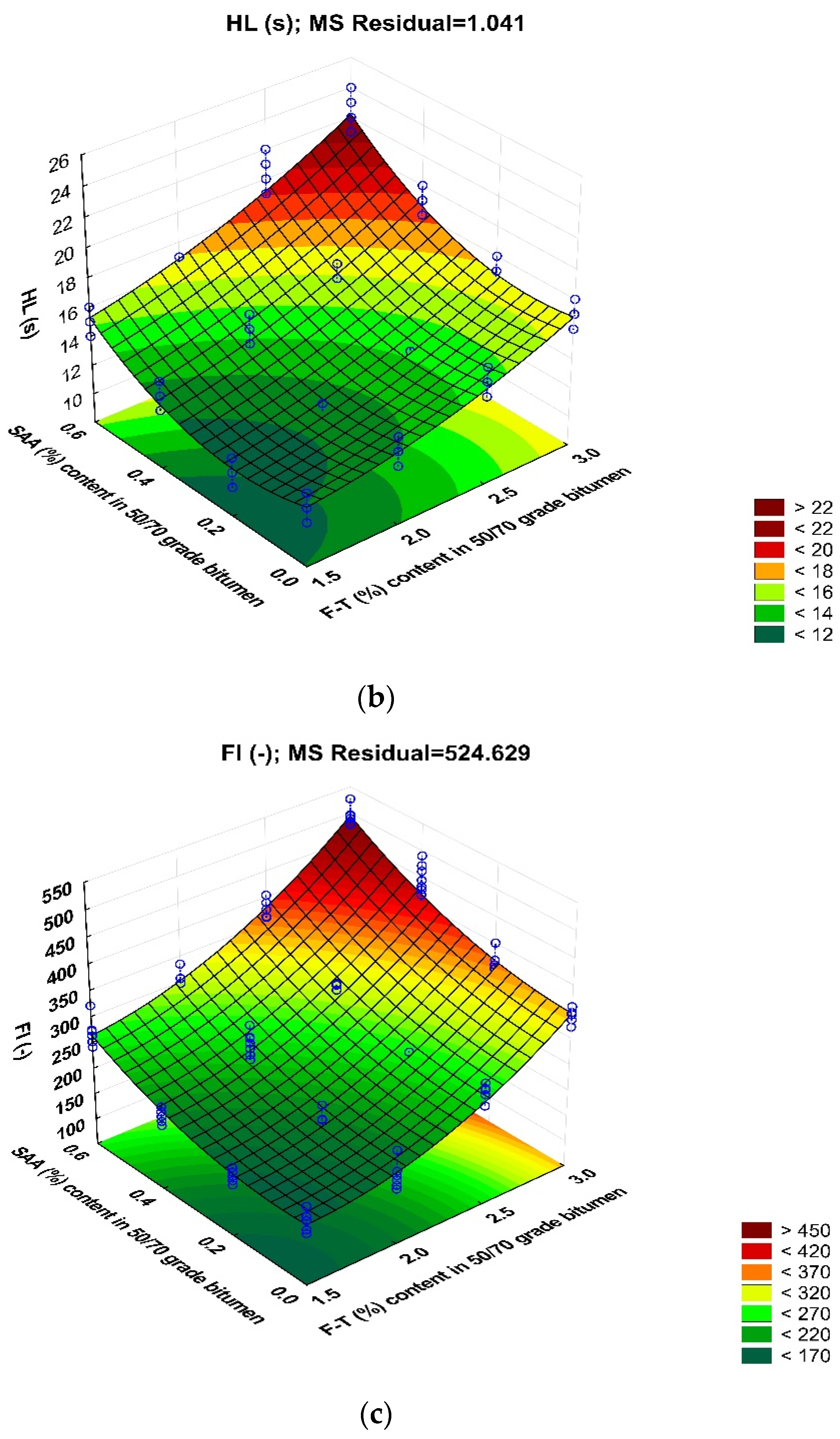

3.3. Foamed Bitumen Properties

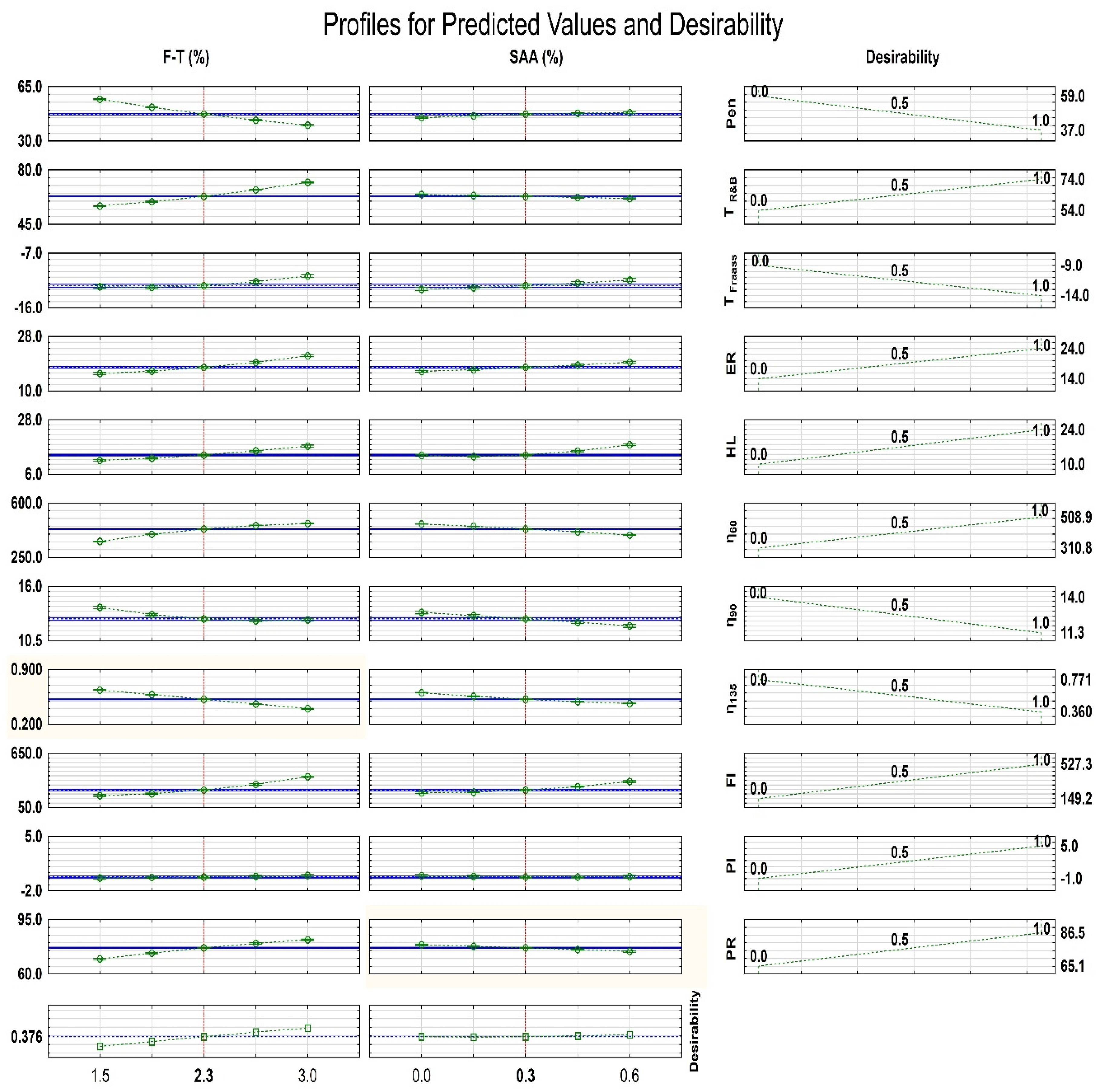

3.4. SAA and F–T Synthetic Wax Contents for Optimized Bitumen Properties

- -

- Penetration at 25 °C (Pen),

- -

- Softening point (TPiK);

- -

- Fraass braking point (TFraass);

- -

- Penetration index (PI);

- -

- Dynamic viscosity at 60 °C (η60), 90 °C (η90) and 135 °C (η135);

- -

- Maximum expansion ratio of bitumen foam (ER);

- -

- Half-life of bitumen foam (HL);

- -

- Foam index (FI).

- -

- Penetration at 25 °C (max—0, min—1);

- -

- Softening point TR&B (max—1, min—0);

- -

- Fraass breaking point TFraass (max—0, min—1);

- -

- Penetration index PI (max—1, min—0);

- -

- Dynamic viscosity at a temperature of η60 (max—1, min—0);

- -

- Dynamic viscosity at temperatures of η90 and η135 (max—0, min—1);

- -

- Maximum expansion ratio of the foam ER (max—1, min—0);

- -

- Half-life of the foam HL (max—1, min—0);

- -

- Foam index FI (max—1, min—0);

- -

- Plasticity range PR (max—1, min—0).

4. Conclusions

- The use of F–T synthetic wax increases the value of basic characteristics of 50/70 bitumen such as penetration at 25 °C and softening point. However, the SAA addition shows the opposite trend.

- F–T synthetic wax and SAA at the test temperature of 135 °C and 90 °C has a beneficial effect on dynamic viscosity; the binder with the lowered value of dynamic viscosity can be applied to mixtures produced at lower temperatures than the conventional temperature. At 60 °C, the synthetic wax increases the viscosity of bitumen 50/70, whereas the use of SAA decreases the value of this parameter.

- Increasing the content of F–T synthetic wax and SAA leads to higher values of bitumen 50/70 foam characteristics owing to the synergy that occurs between these two additives.

- The models of bitumen 50/70 foam characteristics as a function of F–T wax and SAA contents allow the selection of adequate binder composition for dedicated applications or technologies (the type of works, temperature range).

- The optimum content of the additives was found to be 2.3% for F–T synthetic wax and 0.3% for SAA as determined through the bitumen 50/70 optimization process. The binder containing these quantities of the additives ensures the most beneficial foam characteristics and the required level of standard parameters.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leng, Z.; Gamez, A.; Al-Qadi, I.L. Mechanical property characterization of warm-mix asphalt prepared with chemical additives. J. Mater. Civ. Eng. 2014, 26, 304–311. [Google Scholar] [CrossRef]

- Wing-gun, W.; Gang, L. Analysis of the effect of wax content on bitumen under performance grade classification. Constr. Build. Mater. 2009, 23, 2504–2510. [Google Scholar] [CrossRef]

- Iwański, M.; Mazurek, G. The influence of the low-viscosity modifier on viscoelasticity behavior of the bitumen at high operational temperature. In Proceedings of the 8th International Conference Environmental Engineering, Vilnius, Lithuania, 19–20 May 2011; Volume 1–3, pp. 1097–1102. [Google Scholar]

- Król, J.; Kowalski, K.; Radziszewski, P. Rheological behavior of n-alkane modified bitumen in aspect of Warm Mix Asphalt technology. Constr. Build. Mater. 2015, 93, 703–710. [Google Scholar] [CrossRef]

- Ai, C.; Li, O.J.; Qiu, Y. Testing and assessing the performance of a new warm mix asphalt with SMC. J. Traffic Transp. Eng. 2015, 2, 399–405. [Google Scholar] [CrossRef]

- Hurley, G.; Prowell, B. Evaluation of Sasobit for Use in Warm Mix Asphalt; NCAT report 05–06; Auburn University: Auburn, AL, USA, 2005. [Google Scholar]

- Sengoz, B.; Topa, A.; Gorkem, C. Evaluation of natural zeolite as warm mix asphalt additive and its comparison with other warm mix additives. Constr. Build. Mater. 2013, 43, 242–252. [Google Scholar] [CrossRef]

- Woszuk, A.; Franus, W. Properties of the Warm Mix Asphalt involving clinoptilolite and Na-P1 zeolite additives. Constr. Build. Mater. 2016, 114, 556–563. [Google Scholar] [CrossRef]

- Chomicz-Kowalska, A.; Maciejewski, K.; Iwański, M.M. Study of the Simultaneous Utilization of Mechanical Water Foaming and Zeolites and Their Effects on the Properties of Warm Mix Asphalt Concrete. Materials 2020, 13, 357. [Google Scholar] [CrossRef]

- Jenkins, K.J.; de Groot, J.L.A.; Van de Ven, M.F.C.; Molenaar, A. Half-warm foamed bitumen treatment, a new process. In Proceedings of the 7th Conference on Asphalt Pavements for Southern Africa, Victoria Falls, Zimbabwe, 29 August–2 September 1999. [Google Scholar]

- Yu, X.; Wang, Y.; Luo, T. Impacts of water content on rheological properties and performance-related behaviours of foamed war-mix asphalt. Constr. Build. Mater. 2013, 48, 203–209. [Google Scholar] [CrossRef]

- Woszuk, A.; Zofka, A.; Bandura, L.; Franus, W. Effect of zeolite properties on asphalt foaming. Constr. Build. Mater. 2017, 139, 247–255. [Google Scholar] [CrossRef]

- Barthel, W.; Marchand, J.; Von Devivere, M. Warm Mix Asphalt by adding a synthetic zeolite. In Proceedings of the Third Eurasphalt and Eurobitume Conference, Vienna, Austria, 12–14 May 2004; Foundation Eurasphalt: Breukelen, The Netherlands, 2004; pp. 1241–1249. [Google Scholar]

- Van De Ven, M.F.C.; Jenkins, K.J.; Voskuilen, J.L.M.; Van De Beemt, R. Development of (half-) warm foamed bitumen mixes: State of the art. Int. J. Pavement Eng. 2007, 8, 163–175. [Google Scholar] [CrossRef]

- Muthen, K.M. Foamed Asphalt Mixes. Mix Design Procedure; Contract Report CR 98/077; SABITA Ltd. & CSIR Transportek: Pretoria, South Africa, September 2009. [Google Scholar]

- Jenkins, K.J. Mix Design Considerations for Cold and Half-Warm Bituminous Mixes with Emphasis on Foamed Bitumen. Ph.D. Thesis, Department of Civil Engineering, Faculty of Engineering, University of Stellenbosch, Stellebosch, South Africa, 2000. [Google Scholar]

- Wirtgen. Wirtgen Cold Recycling Technology, 1st ed.; Wirtgen GmbH: Windhagen, Germany, 2012. [Google Scholar]

- Iwański, M.; Chomicz-Kowalska, A. Evaluation of the effect of using foamed bitumen and bitumen emulsion in cold recycling technology. In Proceedings of the 3rd International Conference on Transportation Infrastructure (ICTI), Sustainability, Eco-Efficiency and Conservation in Transportation Infrastructure Asset Management, Pisa, Italy, 22–25 April 2014; Taylor and Francis: Abington, Oxfordshire, UK, 2014; Volume 8, pp. 69–76. [Google Scholar]

- Buczyński, P.; Iwański, M. Inactive Mineral Filler as a Stiffness Modulus Regulator in Foamed Bitumen-Modified Recycled Base Layers. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 032042. [Google Scholar] [CrossRef]

- Iwański, M.; Chomicz-Kowalska, A.; Maciejewski, K. Application of synthetic wax for improvement of foamed bitumen parameters. Constr. Build. Mater. 2015, 83, 62–69. [Google Scholar] [CrossRef]

- Saleh, M. Characterization of Foam Bitumen Quality and the Mechanical Properties of Foam Stabilized Mixes; University of Canterbury Research Repository: Christchurch, New Zealand, 2006. [Google Scholar]

- Mallick, R.B.; Hendrix, G. Use of foamed asphalt in recycling incinerator ash for construction of stabilized base course. Resour. Conserv. Recycl. 2004, 42, 239–248. [Google Scholar] [CrossRef]

- Iwański, M.; Cholewińska, M. Application of the foamed bitumen and bitumen emulsion to the road base mixes in the deep cold recycling technology. Balt. J. Road Bridge Eng. 2014, 11, 291–301. [Google Scholar] [CrossRef]

- Iwański, M.; Buczyński, P.; Mazurek, G. The use of gabbro dust in the cold recycling of asphalt paving mixes with foamed bitumen. Bull. Pol. Acad. Sci. Tech. Sci. 2016, 64, 763–773. [Google Scholar] [CrossRef]

- Yan, J.; Ni, F.; Yang, M.; Li, J. An experimental study on fatigue properties of emulsion and foam cold recycled mixes. Constr. Build. Mater. 2010, 24, 2151–2156. [Google Scholar] [CrossRef]

- Mrugała, J.; Iwański, M. Resistance to permanent deformation of asphalt concrete with F-T wax modified foamed bitumen. 7th Scientific-Technical Conference Material Problems in Civil Engineering (MATBUD’2015). Procedia Eng. 2015, 108, 459–466. [Google Scholar] [CrossRef]

- Chomicz-Kowalska, A.; Iwański, M.M.; Mrugała, J. Basic Performance of Fibre Reinforced Asphalt Concrete with Reclaimed Asphalt Pavement Produced in Low Temperatures with Foamed Bitumen. WMCAUS. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 032092. [Google Scholar] [CrossRef]

- Hugo Silva, M.R.D.; Oliveira, J.R.M.; Peralta, J.; Zooro, S.E. Optimization of warm mix asphalt using different blends of binders and synthetic paraffin wax contents. Constr. Build. Mater. 2010, 24, 1621–1631. [Google Scholar] [CrossRef]

- Vaitkus, A.; Čygas, D.; Laurinavičius, A.; Perveneckas, Z. Analysis and Evaluation of Possibilities for the Use of Warm Mix Asphalt in Lithuana. Balt. J. Road Bridge Eng. 2009, 4, 80–86. [Google Scholar] [CrossRef]

- Chomicz-Kowalska, A.; Gardziejczyk, W.; Iwański, M.M. Analysis of IT-CY Stiffness Modulus of Foamed Bitumen Asphalt Concrete Compacted at 95 °C. Modern Building Materials, Structures and Techniques, MBMST 2016. Procedia Eng. 2017, 172, 550–559. [Google Scholar] [CrossRef]

- Sanchez-Alonso, E.; Vega-Zamanillo, A.; Castro-Fresno, D.; Del Rio-Prat, M. Evaluation of compactability and mechanical properties of bituminous mixes with warm additives. Constr. Build. Mater. 2011, 25, 2304–2311. [Google Scholar] [CrossRef]

- Iwański, M.; Mazurek, G. Optimization on the Syntetic Wax Content on Example of Bitumen 35/50. Procedia Eng. 2012, 57, 414–423. [Google Scholar] [CrossRef]

- Pszczola, M.; Jaczewski, M.; Rys, D.; Jaskula, P.; Szydlowski, C. Evaluation of Asphalt Mixture Low-Temperature Performance in Bending Beam Creep Test. Materials 2018, 11, 100. [Google Scholar] [CrossRef]

- Iwański, M.M.; Chomicz-Kowalska, A.; Maciejewski, K. Resistance to Moisture-Induced Damage of Half-Warm-Mix Asphalt Concrete with Foamed Bitumen. Materials 2020, 13, 654. [Google Scholar] [CrossRef]

- Stefańczyk, B.; Mieczkowski, P. Mieszanki Mineralno-Asfaltowe: Wykonawstwo i Badania. (Bituminous Mixtures: Performance and Research); WKiŁ: Warszawa, Poland, 2008; p. 322. (In Polisch) [Google Scholar]

- Iwański, M.M.; Chomicz-Kowalska, A.; Maciejewski, K. Effect of Surface Active Agent (SAA) on 50/70 Bitumen Foaming Characteristics. Materials 2019, 12, 3514. [Google Scholar] [CrossRef]

- Piłat, J.; Radziszewski, P. Nawierzchnie Asfaltowe: Podręcznik Akademicki. (Asphalt Pavements Academic handbook); WKiŁ: Warszawa, Poland, 2010. (In Polish) [Google Scholar]

- Luxemburk, F. Lime Hydrate as an Additive to Improve the Adhesion of Bitumen to the Aggregates. In Proceedings of the II International Conference Durable and Save Road Pavements, Kielce, Poland, 15–16 May 1996; pp. 296–302. [Google Scholar]

- Zou, J.; Isola, M.; Roque, R.; Chun, S.; Koh, C.; Lopp, G. Effect of hydrated lime on fracture performance of asphalt mixture. Constr. Build. Mater. 2013, 44, 302–308. [Google Scholar] [CrossRef]

- Blazek, J.; Debor, G.; Maxa, D.; Ajib, M.; Paniagua, H. Effect of hydrated lime addition on properties of asphalt. Pet. Coal 2000, 42, 41–45. [Google Scholar]

- Jamshidi, A.; Hamzah, M.O.; You, Z. Performance of Warm Mix Asphalt containing Sasobit®: State-of-the-art. Constr. Build. Mater. 2013, 38, 530–553. [Google Scholar] [CrossRef]

- Iwański, M.; Mazurek, G. Effect of Fischer-Tropsch synthetic wax additive on the functional properties of bitumen. Polimery 2015, 60, 272–278. [Google Scholar] [CrossRef]

- Butz, T.; Rahimian, I.; Hildebrand, G. Modification of road bitumens with the Fischer-Tropsch Paraffin Sasobit. J. Appl. Asph. Bind. Technol. 2001, 1, 70–86. [Google Scholar]

- WT-2. Technical Guidelines 2: Asphalt Pavements for National Roads; Part I: Asphaltmixes; General Directorate for National Roads and Motorways: Warsaw, Poland, 2014; p. 48. [Google Scholar]

- Judycki, J.; Jaskuła, P.; Pszczoła, M.; Alenowicz, J.; Dołżycki, B.; Jaczewski, M.; Ryś, D.; Stienss, M. Katalog Typowych Konstrukcji Nawierzchni Podatnych i Półsztywnych (Catalogue of Typical Flexible and Semi-Rigid Pavement Constructions); GDDKiA: Warsaw, Poland, 2014; p. 112. (In Polish) [Google Scholar]

- EN 1426:2015-08. Bitumen and Bituminous Binders—Determination of Needle Penetration.

- EN 1427:2015-08. Bitumen and Bituminous Binders—Determination of Softening Point—Ring and Ball Method.

- EN 12593:2015-08. Bitumen and Bituminous Binders—Determination of the Fraass Breaking Point.

- EN 13302-2018. Bitumen and Bituminous Binders - Determination of dynamic viscosity of bituminous binder using a rotating spindle apparatus.

- Mazurek, G. Optymalizacja składu betonu asfaltowego modyfikowanego woskiem syntetycznym w zakresie odkształceń plastycznych. [Optimization of the asphalt concrete aggregate modified with synthetic wax in the field of plastic deformation]. Ph.D. Thesis, Department of Civil and Environmental Engineering, Kielce University of Technology, Kielce, Poland, 2012; p. 303. [Google Scholar]

- Mazurek, G.; Iwański, M. Analysis of selected properties of asphalt concrete with synthetic wax. Bull. Pol. Acad. Sci. Tech. Sci. 2016, 66, 217–228. [Google Scholar] [CrossRef]

- Technical recommendation IBDiM No. RT/2009-03-0012/1. In Adhesion Promoters Wetfix BE and Wetfix AP17 for Use in Traffic Engineering; Road and Bridge Research Institute: Warszawa, Poland, 2014; p. 29.

- WETFIX BE. Thermally Stable Liquid Adhesion Promoter for Asphalt Binders; Minova Ekochem, S.A.: Siemianowice Śląskie, Poland, 2010. [Google Scholar]

- EN 12594:2014-12. Bitumen and Bituminous Binders—Preparation of Test Samples.

- EN 12591:2009. Bitumen and Bituminous Binders—Specifications for Paving Grade.

- STATISTICA 13.3. Statsoft. Available online: www.statsoft.com (accessed on 20 August 2019).

- Piasta, Z.; Lenarcik, A. Methods of statistical multi-criteria optimization. In Optimization Methods for Material Design of Cement-based Composites; E & FN Spon: London, UK; New York, NY, USA, 1998; pp. 45–59. [Google Scholar]

- Koronacki, J.; Mielniczuk, J. Statystyka dla Studentów Kierunków Technicznych i Przyrodniczych. (Statistics for Technical and Natural Sciences Students); Wydawnictwa Naukowo-Techniczne: Warszawa, Poland, 2004. (In Polish) [Google Scholar]

- Asphalt Academy. Technical Guideline TG2: Bitumen Stabilised Materials, a Guideline for the Design and Construction of Bitumen Emulsion and Foamed Bitumen Stabilised Materials, 2nd ed.; Asphalt Academy: Pretoria, South Africa, 2009. [Google Scholar]

- Chomicz-Kowalska, A.; Maciejewski, K. Multivariate optimization of recycled road base cold mixtures with foamed bitumen. Procedia Eng. 2015, 108, 436–444. [Google Scholar] [CrossRef]

| Property | Test Method | Unit of Measure | Result |

|---|---|---|---|

| Penetration at 25 °C | EN 1426 [46] | 0.1 mm | 65.9 |

| Softening point TR&B | EN 1427 [47] | °C | 50.4 |

| Fraass breaking point | EN 12593 [48] | °C | −15.1 |

| Dynamic viscosity at: 60 °C 90 °C 135 °C | EN 13302 [49] | Pa∙s | 372.9 14.0 0.649 |

| Property | Unit of Measure | Value |

|---|---|---|

| Colour | - | white, yellowish |

| Flash point | °C | 285 |

| Congening point | °C | 95 |

| Density at 25 °C | Mg/m3 | 0.9 |

| Viscosity at 135 °C | cSt | 12 |

| Molecular mass | g/mol | about 1000 |

| Property | Unit of Measure | Value |

|---|---|---|

| Appearance | - | Brown viscous liquid |

| Density at 20 °C | Mg/m3 | 0.98 |

| Pour point | °C | <0 |

| Viscosity at 20 °C | mP | 3000 |

| Viscosity at 50 °C | mP | 400 |

| Amine index | mg HCl/g | 159–185 |

| Acid index | mg KOH/g | <10 |

| Freezing point | °C | <0 |

| Flash point (open flame) | °C | >218 |

| Effect | Regresion Coefficients | Std. Error | pvalue |

|---|---|---|---|

| Variable: Pen (0,1 mm); R2 = 0.974; R2 adj:0.972; MS Residual = 1.136 | |||

| Intercept | 80.873 | 1.799 | <0.001 |

| (1) F–T (%) (L) | −21.112 | 1.621 | <0.001 |

| F–T (%) (Q) | 2.305 | 0.355 | <0.001 |

| (2) SAA (%) (L) | 12.529 | 2.119 | <0.001 |

| SAA (%) (Q) | −7.465 | 2.21 | <0.001 |

| 1L × 2L | −1.188 | 0.710 | 0.097 |

| Effect | Regresion Coefficients | Std. Error | pvalue |

|---|---|---|---|

| Variable: TR&B (°C); R2 = 0.9746; R2 adj:0.973; MS = 0.913 | |||

| Intercept | 54,005 | 1.613 | <0.001 |

| (1) F–T (%)(L) | −1.063 | 1.453 | 0.466 |

| F–T (%)(Q) | 2.500 | 0.318 | <0.001 |

| (2) SAA (%)(L) | −3.766 | 1.899 | <0.001 |

| SAA (%)(Q) | −0.694 | 1.991 | 0.728 |

| 1L × 2L | −0.066 | 0.637 | 0.917 |

| Effect | Regresion Coefficients | Std. Error | pvalue |

|---|---|---|---|

| Variable: TFraass (°C); R2 = 0.64902; R2Adj: 0.636; MS Residual = 0.494 | |||

| Intercept | −9.221 | 1.186 | <0.001 |

| (1) F–T (%) (L) | −4.592 | 1.069 | <0.001 |

| F–T (%) (Q) | 1.305 | 0.234 | <0.001 |

| (2) SAA (%) (L) | 1.915 | 1.398 | 0.173 |

| SAA (%) (Q) | 1.909 | 1.465 | 0.195 |

| 1L × 2L | −0.255 | 0.468 | 0.587 |

| Effect | Regresion Coefficients | Std. Error | pvalue |

|---|---|---|---|

| Variable: PR; R2 = 0.934; R2Adj: = 0.931 MS Residual = 1.769 | |||

| Intercept | 76.833 | 0.225 | <0.001 |

| (1) F–T (%) (L) | 12.373 | 0.297 | <0.001 |

| F–T (%) (Q) | −1.922 | 0.498 | <0.001 |

| (2) SAA (%) (L) | −4.337 | 0.297 | <0.001 |

| SAA (%) (Q) | −0.347 | 0.498 | 0.486 |

| 1L × 2L | −0.129 | 0.399 | 0.745 |

| Effect | Regresion Coefficients | Std. Error | pvalue |

|---|---|---|---|

| Variable: PI; R2 = 0.127; R2Adj: = 0.095; MS Residual = 5.868 | |||

| Intercept | 1.487 | 0.410 | <0.001 |

| (1) F–T (%) (L) | 2.019 | 0.541 | <0.001 |

| F–T (%) (Q) | 0.378 | 0.908 | 0.677 |

| (2) SAA (%) (L) | −0.817 | 0.541 | 0.133 |

| SAA (%) (Q) | 1.365 | 0.908 | 0.135 |

| 1L × 2L | −0.894 | 0.726 | 0.220 |

| Effect | Regresion Coefficient | Std. Error | pvalue |

|---|---|---|---|

| Variable: η60 (Pas); R2 = 0.991; R2Adj: 0.991; MS Residual = 23.316 | |||

| Intercept | 84.557 | 8.149 | <0.001 |

| (1) F–T (%) (L) | 259.376 | 7.342 | <0.001 |

| F–T (%) (Q) | −39.916 | 1.609 | <0.001 |

| (2) SAA (%) (L) | −71.099 | 9.599 | <0.001 |

| SAA (%)(Q) | −31.944 | 10.059 | <0.001 |

| 1L × 2L | −12.975 | 3.219 | <0.001 |

| Variable: η90 (Pas); R2 = 0.809; R2Adj: 0.802; MS Residual = 0.129 | |||

| Intercept | 20.186 | 0.608 | <0.001 |

| (1) F–T (%) (L) | −5.207 | 0.548 | <0.001 |

| F–T (%) (Q) | 0.963 | 0.120 | <0.001 |

| (2) SAA (%) (L) | −2.396 | 0.716 | <0.001 |

| SAA (%) (Q) | −0.190 | 0.750 | 0.799 |

| 1L × 2L | 0.116 | 0.240 | 0.628 |

| Variable: η135 (Pas); R2 = 0.985; R2Adj: 0.985; MS Residual=0.001 | |||

| Intercept | 0.520 | 0.002 | <0.001 |

| (1) F–T (%) (L) | −0.235 | 0.003 | <0.001 |

| F–T (%) (Q) | −0.003 | 0.004 | 0.405 |

| (2) SAA (%) (L) | −0.134 | 0.003 | <0.001 |

| SAA (%) (Q) | 0.029 | 0.005 | <0.001 |

| 1L × 2L | 0.031 | 0.004 | <0.001 |

| Response | Effect | Regression Coefficient | Std. Error | pvalue |

|---|---|---|---|---|

| ER (-) R2 = 0.905 R2Adj: 0.901 MS Res. = 0.700 | Intercept | 17.746 | 0.141 | <0.001 |

| (1) F–T (%) (L) | 5.891 | 0.187 | <0.001 | |

| F–T (%) (Q) | 1.968 | 0.313 | <0.001 | |

| (2) SAA (%) (L) | 3.075 | 0.187 | <0.001 | |

| SAA (%) (Q) | 0.468 | 0.313 | 0.137 | |

| L × 2L | −0.605 | 0.251 | 0.017 | |

| HL (s) R2 = 0.893 R2Adj: 0.889; MS Res. = 1.041 | Intercept | 13.739 | 0.172 | <0.001 |

| (1) F–T (%) (L) | 5.850 | 0.228 | <0.001 | |

| F–T (%) (Q) | 1.562 | 0.382 | <0.001 | |

| (2) SAA (%) (L) | 4.300 | 0.228 | <0.001 | |

| SAA (%) (Q) | 4.125 | 0.382 | <0.001 | |

| 1L × 2L | 1.080 | 0.306 | <0.001 | |

| FI (%) R2 = 0.945; R2Adj: 943; MS Res. = 524.628 | Intercept | 242.699 | 3.876 | <0.001 |

| (1) F–T (%) (L) | 206.231 | 5.121 | <0.001 | |

| F–T (%) (Q) | 86.097 | 8.589 | <0.001 | |

| (2) SAA (%) (L) | 123.335 | 5.121 | <0.001 | |

| SAA (%) (Q) | 64.360 | 8.589 | <0.001 | |

| 1L × 2L | 25.998 | 6.871 | <0.001 |

| Parameter | Temperature of Mineral Material | |

|---|---|---|

| 10 °C to 15 °C | Above 15 °C | |

| Expansion ratio ER (-) | 10 | 8 |

| Half-life HL (s) | 6 | 6 |

| Type of Mixture with Foamed Bitumen | Required Minimum Values | ||

|---|---|---|---|

| ER | HL (s) | FI (s) | |

| Surface dressing | 10 | 30 | 131 |

| CMA | 15 | 15 | 164 |

| Surface recycling | 17 | 13 | 180 |

| WMA | |||

| Dependent Variable | SS Test for the Full Fodel with Respect to SS for Residual | |||||

|---|---|---|---|---|---|---|

| Multicrit. R | Multicrit. R2 | Adjusted R2 | SS Model | MS Model | pvalue | |

| Pen (0.1 mm) | 0.986 | 0.973 | 0.972 | 5810.8 | 1162.15 | <0.001 |

| TR&B (°C) | 0.987 | 0.974 | 0.973 | 4842.8 | 968.56 | <0.001 |

| TFraass (°C) | 0.805 | 0.649 | 0.636 | 126.2 | 25.25 | <0.001 |

| ER (-) | 0.951 | 0.904 | 0.901 | 916.5 | 183.31 | <0.001 |

| HL (s) | 0.945 | 0.893 | 0.889 | 1205.6 | 241.11 | <0.001 |

| η60 (Pas) | 0.995 | 0.991 | 0.991 | 376,660 | 75,332.12 | <0.001 |

| η90 (Pas) | 0.899 | 0.809 | 0.802 | 76.2 | 15.24 | <0.001 |

| η135 (Pas) | 0.992 | 0.985 | 0.985 | 1.5 | 0.30 | <0.001 |

| FI (-) | 0.972 | 0.945 | 0.943 | 1,244,535 | 248,907 | <0.001 |

| PI (-) | 0.356 | 0.127 | 0.095 | 118.0 | 23.6 | <0.001 |

| PR (°C) | 0.966 | 0.934 | 0.931 | 3466.0 | 693.2 | <0.001 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iwański, M.M. Synergistic Effect of F–T Synthetic Wax and Surface-Active Agent Content on the Properties and Foaming Characteristics of Bitumen 50/70. Materials 2021, 14, 300. https://doi.org/10.3390/ma14020300

Iwański MM. Synergistic Effect of F–T Synthetic Wax and Surface-Active Agent Content on the Properties and Foaming Characteristics of Bitumen 50/70. Materials. 2021; 14(2):300. https://doi.org/10.3390/ma14020300

Chicago/Turabian StyleIwański, Mateusz M. 2021. "Synergistic Effect of F–T Synthetic Wax and Surface-Active Agent Content on the Properties and Foaming Characteristics of Bitumen 50/70" Materials 14, no. 2: 300. https://doi.org/10.3390/ma14020300

APA StyleIwański, M. M. (2021). Synergistic Effect of F–T Synthetic Wax and Surface-Active Agent Content on the Properties and Foaming Characteristics of Bitumen 50/70. Materials, 14(2), 300. https://doi.org/10.3390/ma14020300