Effect of Addition of Rubber Granulate and Type of Modified Binder on the Viscoelastic Properties of Stone Mastic Asphalt Reducing Tire/Road Noise (SMA LA)

Abstract

1. Introduction

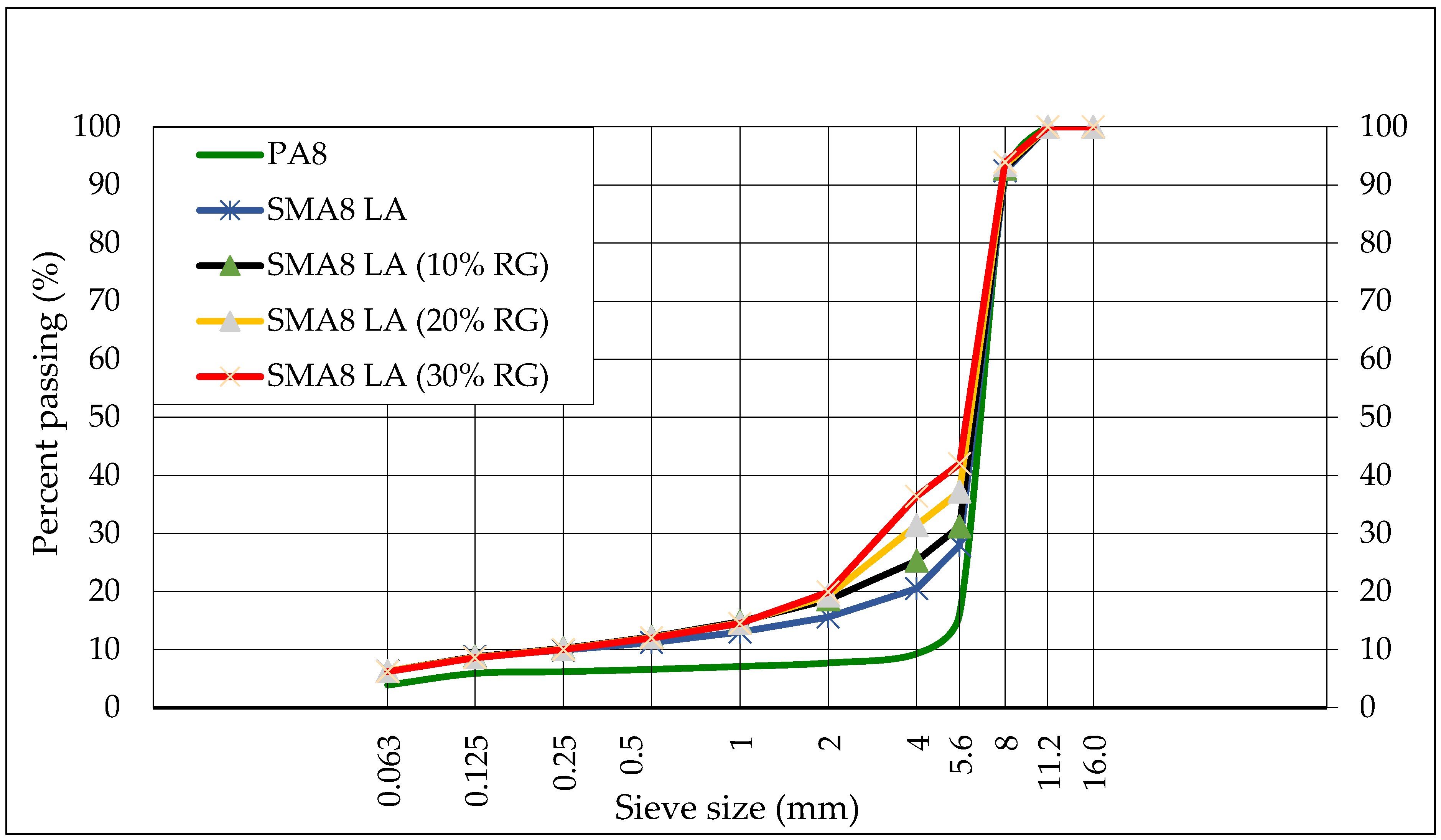

2. Materials

- penetration at temperatures: 5 °C, 15 °C and 25 °C;

- softening point with ring and ball method (R & B);

- dynamic viscosity at 90 °C, 110 °C and 135 °C;

- strain energy along with the determination of the maximum tensile force at temperatures of 5 °C, 15 °C and 25 °C;

- elastic recovery at temperatures of 15 °C and 25 °C.

3. Methods and Experimental Results

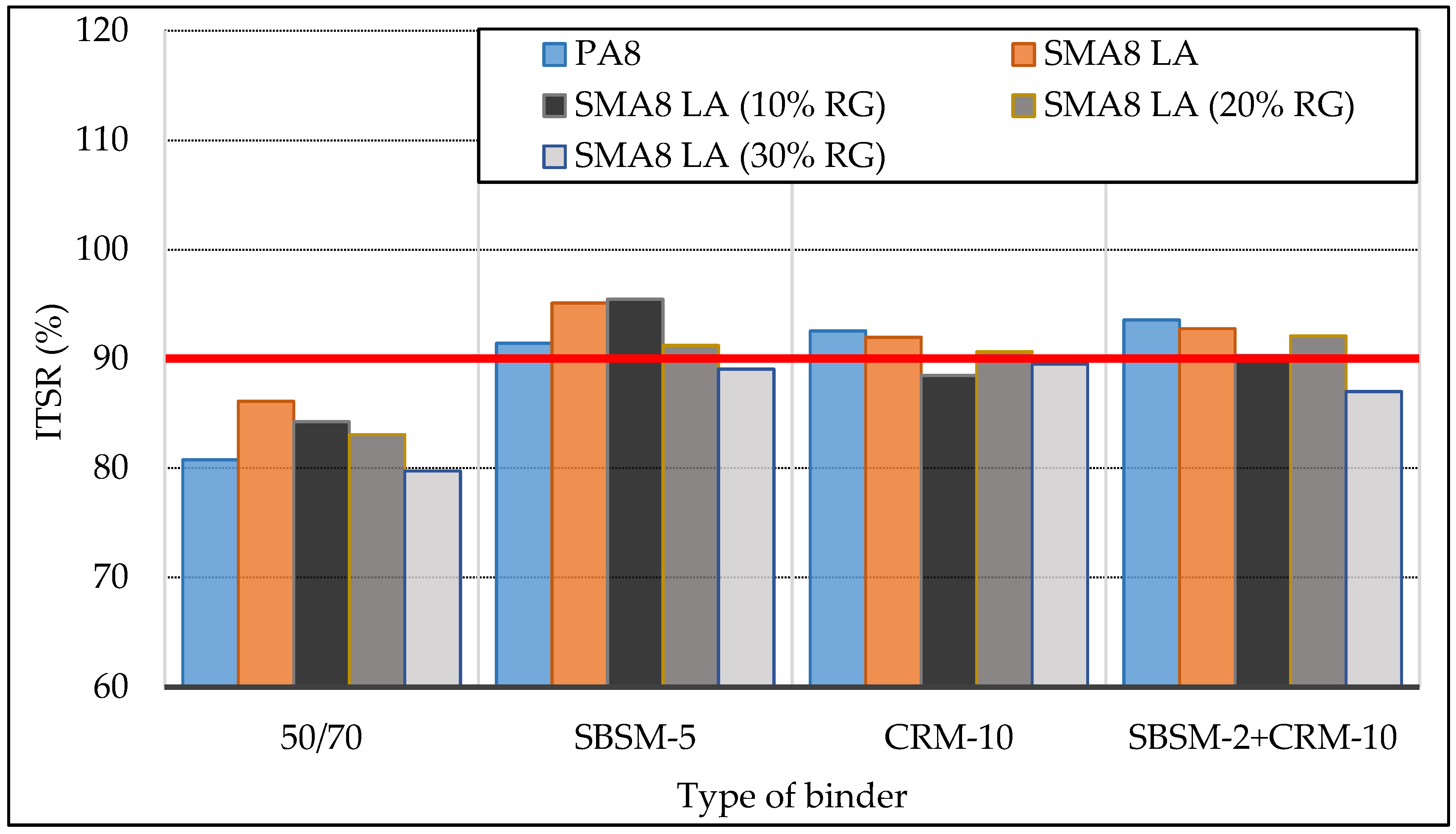

3.1. Water Damage Resistance

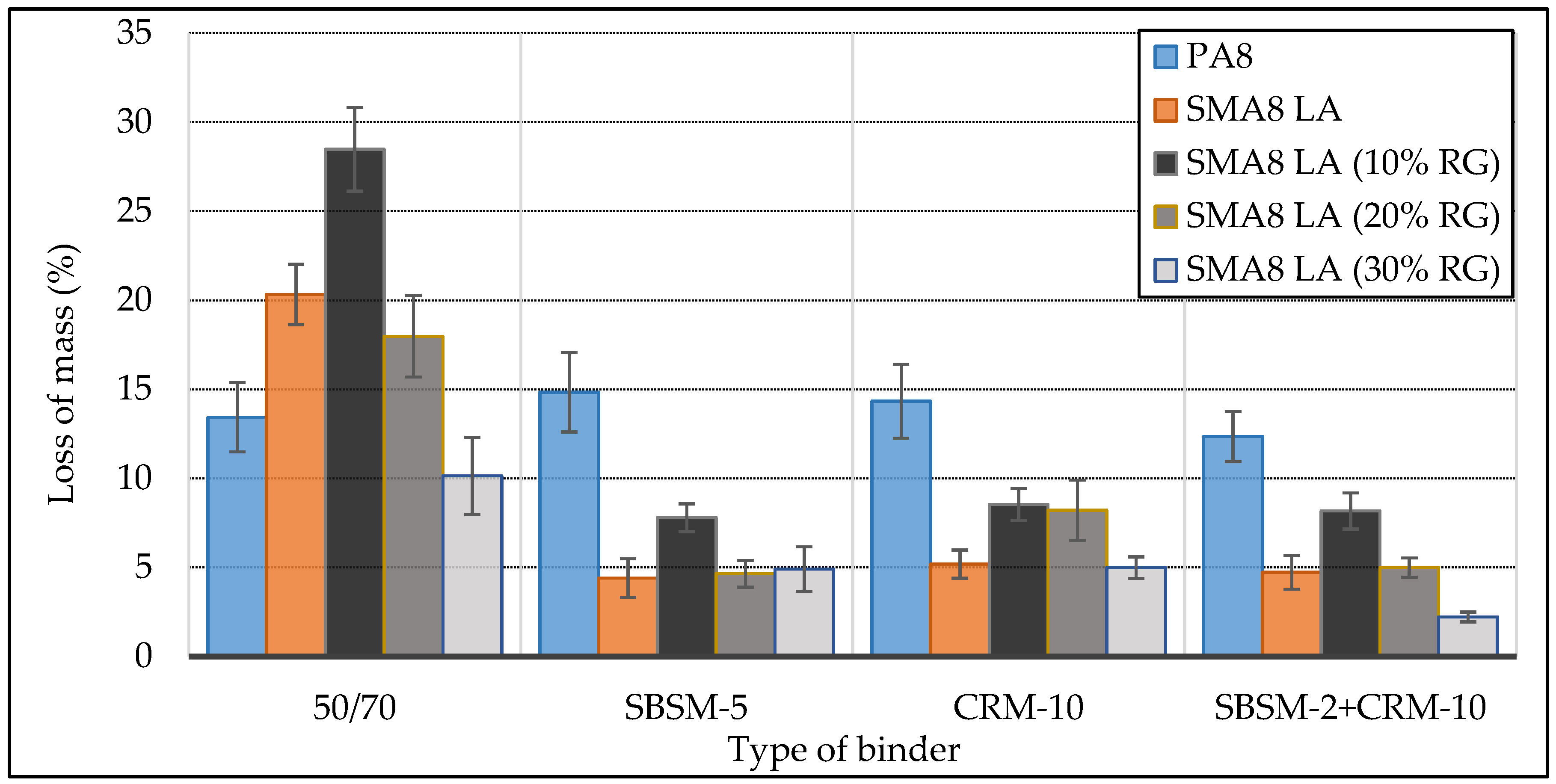

3.2. Cantabro Abrasion Loss Test

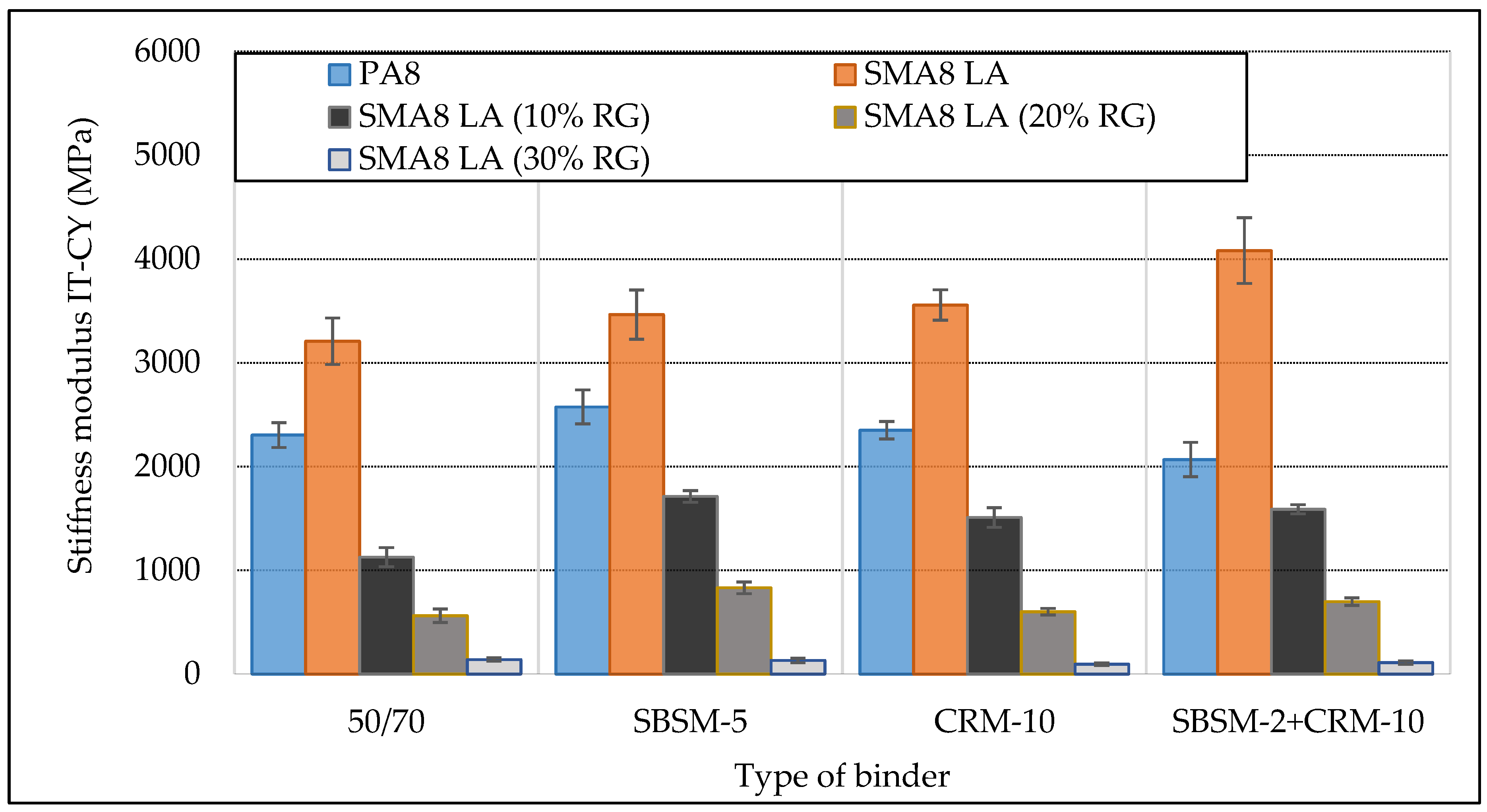

3.3. Stiffness Modulus According to the Indirect Tensile Method (IT-CY)

3.4. Modified Uniaxial Cyclic Compression Test

4. Analysis of Results and Discussion

4.1. Water Damage Resistance ITSR

4.2. Cantabro Abrasion Loss Test

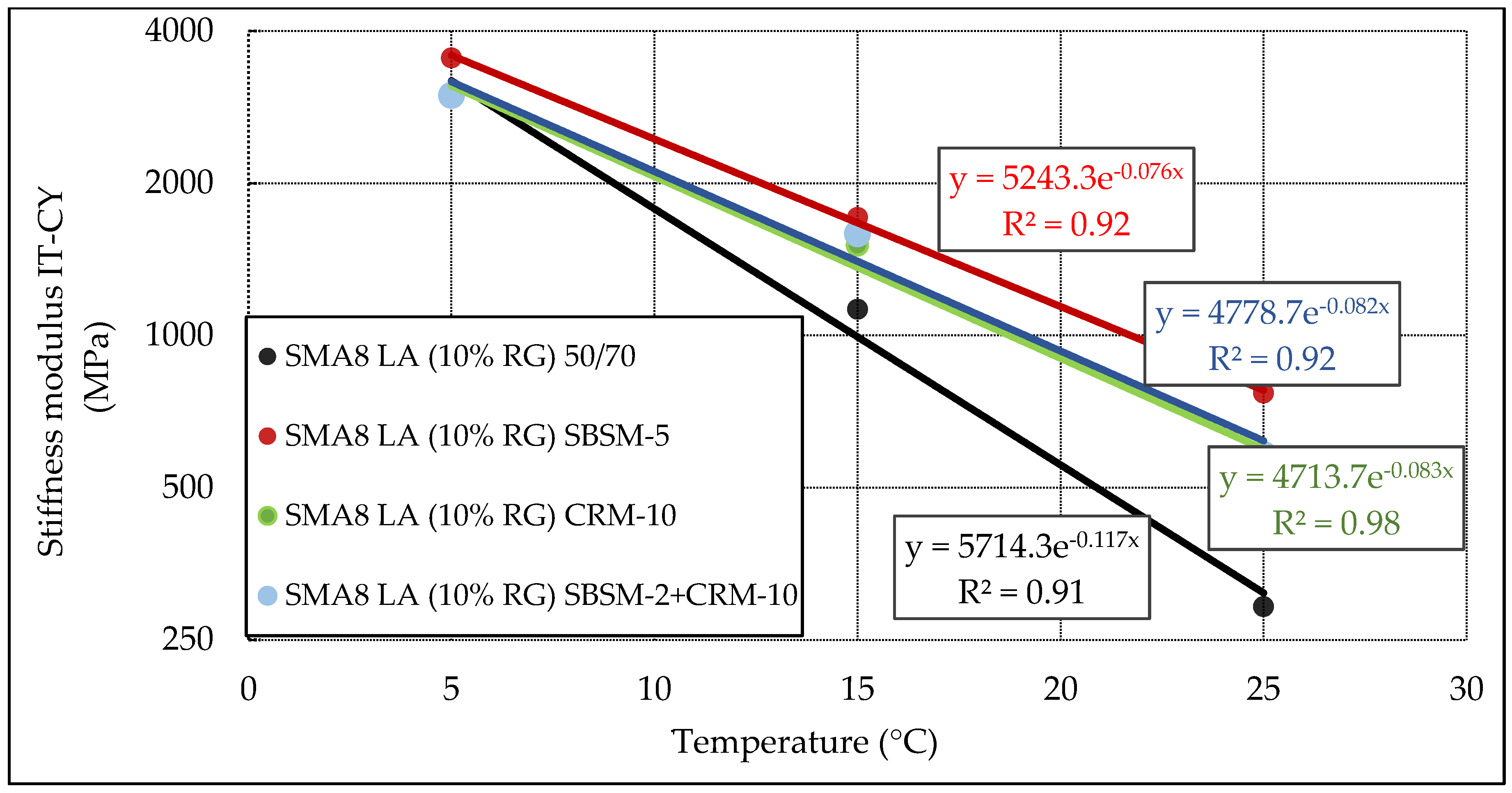

4.3. Stiffness Modulus (IT-CY)

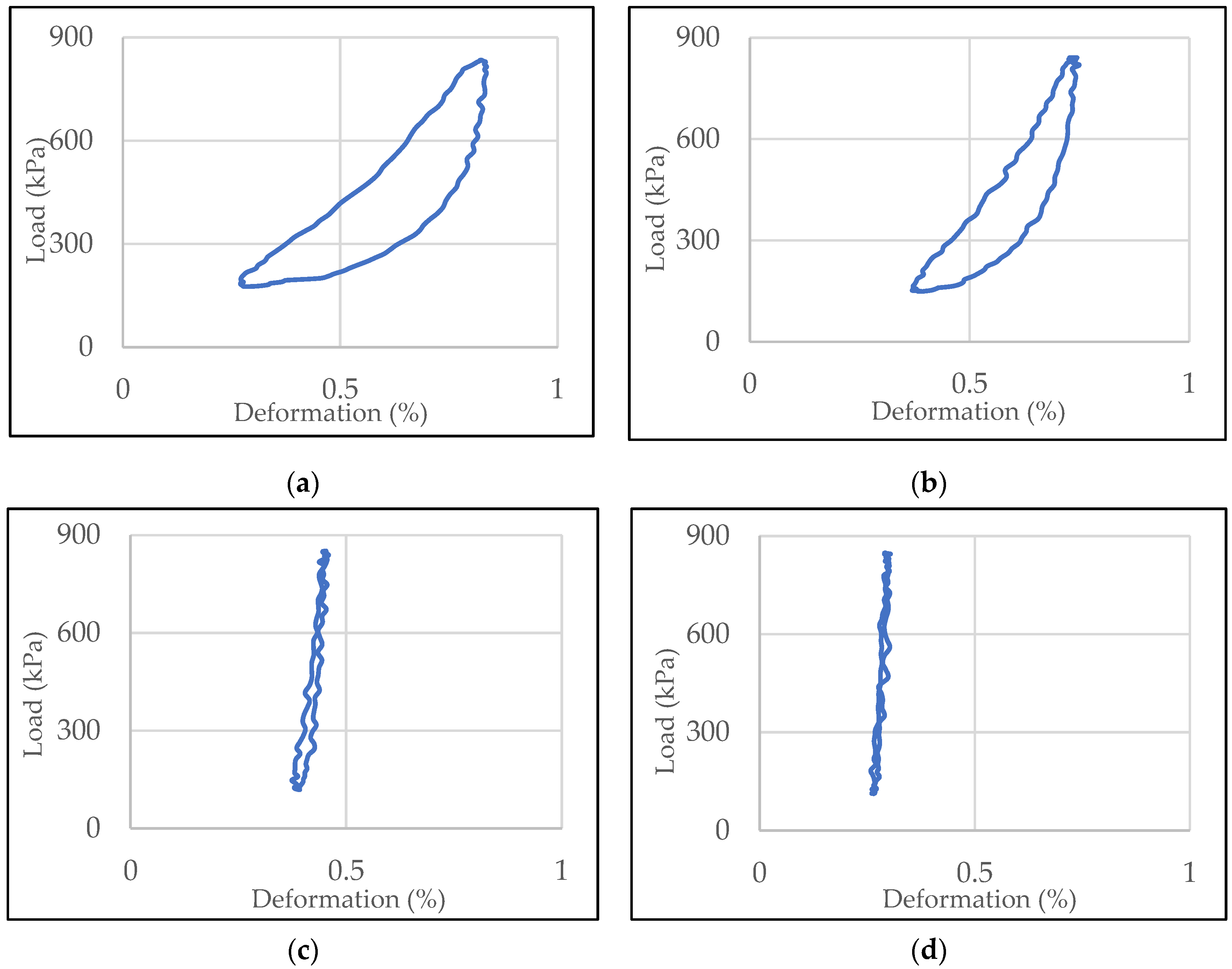

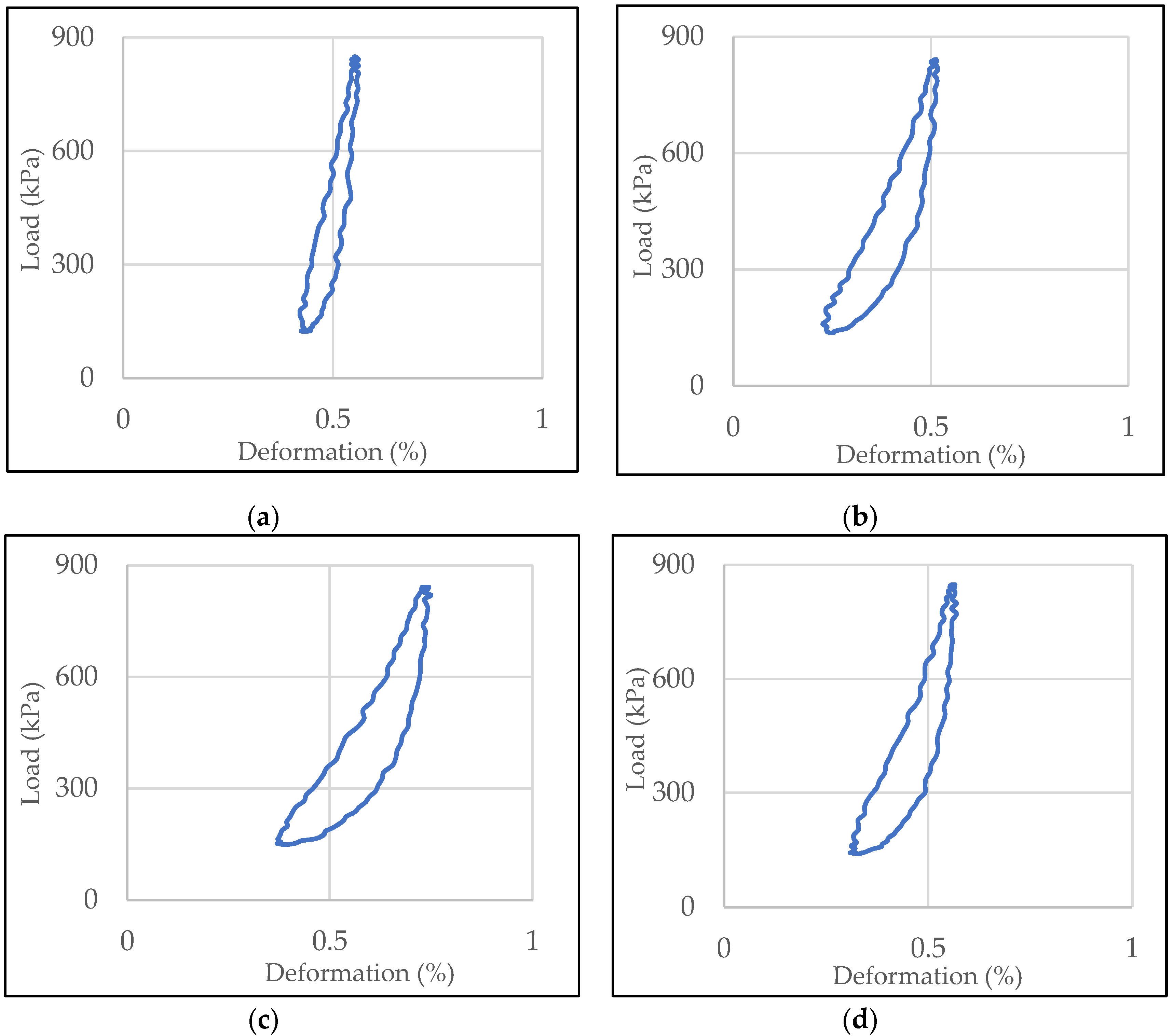

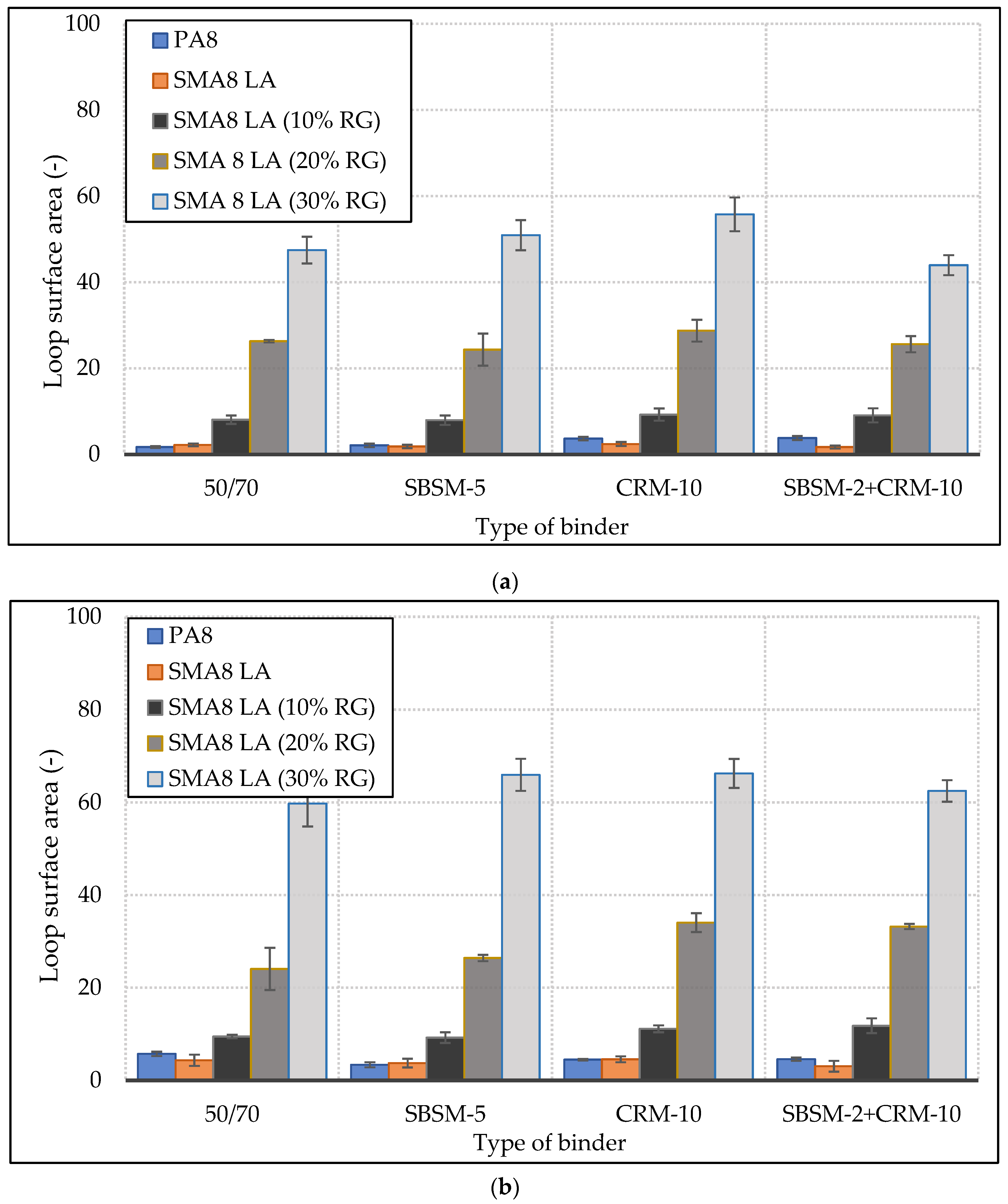

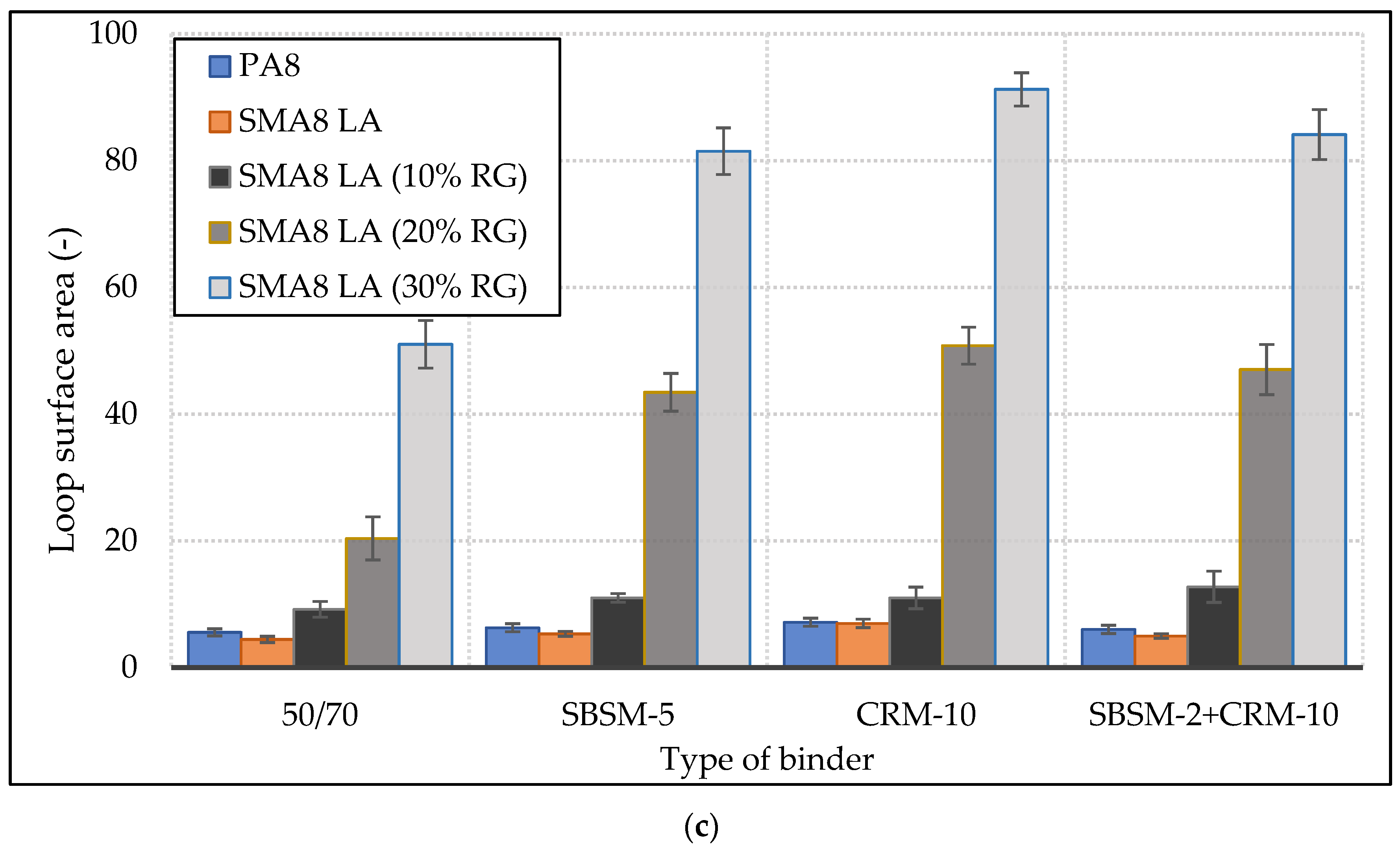

4.4. Elastic Hysteresis Loops

5. Conclusions

- The type of binder affects the water damage resistance (ITSR) of SMA8 LA mixtures. Modified binders contribute to the increase of ITSR by about 10% compared to mixtures with bitumen 50/70. The replacement of mineral aggregate by rubber granulate slightly reduces the water damage resistance of SMA8 LA mixtures.

- The increase in the addition of rubber granulate in SMA8 LA mixtures improves their resistance to degradation in the Cantabro abrasion loss test. The highest degradation resistance achieved SMA8 LA (30% RG) mixtures with copolymer modified bitumen and crumb rubber (SBSM-2 + CRM-10). SMA8 LA mixtures with modified binders are characterized by greater resistance to degradation compared to SMA8 LA with bitumen 50/70. The application of modified binders improves the degradation resistance of SMA LA mixtures by 3–4 times.

- SMA8 LA, SMA8 LA (10% RG) and SMA8 LA (20% RG) mixtures with modified binders are characterized by higher stiffness modulus values compared to those mixtures with bitumen 50/70. SMA8 LA mixture with modified bitumen with simultaneous copolymer and rubber modification (SBSM-2 + CRM-10) achieved the highest value of stiffness modulus—4082 MPa. This is a 25% increase in modulus value compared to the mixtures with bitumen 50/70. The addition of rubber granulate replacing mineral aggregate reduces the values of stiffness modules of SMA8 LA mixtures.

- SMA8 LA mixtures with modified bitumen have much higher resistance to temperature changes compared to mixtures with bitumen 50/70. It can be expected that they will be more resistant to rutting in the summer.

- The addition of rubber granulate to SMA8 LA mixtures has a very significant impact on the elasticity of the mixtures. Increasing the addition of granulate causes an increase in the hysteresis loop area. The highest loop area values were obtained for SMA8 LA (30% RG) mixture with binder modified by rubber (CRM-10). This value is higher by 44% in relation to SMA8 LA (30% RG) with bitumen 50/70, by about 40%- in relation to the mixture with SBSM-2 + CRM-10 and by 37%—in relation to the mixture with SBSM-5.

- The type of binder significantly affects the values of the hysteresis loop area of SMA8 LA (20% RG) and SMA8 LA (30% RG) mixtures, especially at 35 °C. This means that these mixtures will have a higher capability to suppress vibrations and tire/road noise.

- As the test temperature increases, the modified binders give the mixtures better elasticity in relation to the mixtures with the reference bitumen 50/70. SMA8 LA mixtures with rubber granulate and bitumen 50/70 show lower hysteresis loop areas at 35 °C compared to 25 °C. This indicates that bitumen 50/70 loses its elastic properties in the temperature range between 25 °C and 35 °C.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sandberg, U.; Ejsmont, J.A. Tyre/Road Noise. Reference Book; Informex: Kisa, Sweden, 2002; pp. 1–640. [Google Scholar]

- Praticò, F.G.; Anfosso-Lédée, F. Trends and issues in mitigating traffic noise through quiet pavements. Procedia-Soc. Behav. Sci. 2012, 53, 203–212. [Google Scholar] [CrossRef]

- Gardziejczyk, W. Influence of road pavement macrotexture on tyre/road noise of vehicles. Balt. J. Road Bridge Eng. 2014, 9, 180–190. [Google Scholar] [CrossRef]

- Gardziejczyk, W. The effect of time on acoustic durability of low noise pavements—The case studies in Poland. Transp. Res. Part D Transp. Environ. 2016, 44, 93–104. [Google Scholar] [CrossRef]

- Mioduszewski, P.; Gardziejczyk, W. Inhomogeneity of low-noise wearing courses evaluated by tire/road noise measurements using the close-proximity method. Appl. Acoust. 2016, 111, 58–66. [Google Scholar] [CrossRef]

- Bendtsen, H.; Gspan, K. State of the Art in Managing Road Traffic Noise: Noise-Reducing Pavements; Technical Report 2017-01; CEDR: London, UK, January 2017; ISBN 979-10-93321-26-4. [Google Scholar]

- Gӓrtner, K. Lärmreduzierung im Kommunalen BereichDie neuen Merkblätter der FGSV; DAV-Informationsveranstaltung München: München, Germany, 2014; Available online: https://www.asphalt.de/fileadmin/user_upload/asphaltberatung/downloads/m_lrm.pdf (accessed on 9 July 2020).

- Paje, S.E.; Bueno, M.; Terán, F.; Miró, R.; Pérez-Jiménez, F.; Martínez, A.H. Acoustic field evaluation of asphalt mixtures with crumb rubber. Appl. Acoust. 2010, 71, 578–582. [Google Scholar] [CrossRef]

- Vázquez, V.F.; Paje, S.E. Study of the road surface properties that control the acoustic performance of a rubberised asphalt mixture. Appl. Acoust. 2016, 102, 33–39. [Google Scholar] [CrossRef]

- Paje, S.E.; Luong, J.; Vázquez, V.F.; Bueno, M.; Miro, R. Road pavement rehabilitation using a binder with a high content of crumb rubber: Influence on noise reduction. Constr. Build. Mater. 2013, 47, 789–798. [Google Scholar] [CrossRef]

- Bendtsen, H.; Andersen, B.; Kalman, B.; Cesbron, J. The first poroelastic test section in PERSUADE. In Proceeding of the 42nd International Congress and Exposition on Noise Control Engineering, Innsbruck, Austria, 15–18 September 2013. [Google Scholar]

- Ejsmont, J.A.; Goubert, L.; Ronowski, G.; Świeczko-Żurek, B. Ultra low noise poroelastic road surfaces. Coatings 2016, 6, 18. [Google Scholar] [CrossRef]

- Jaskula, P.; Ejsmont, J.; Stienss, M.; Ronowski, G.; Szydlowski, C.; Swieczko-Zurek, B.; Rys, D. Initial field validation of poroelastic pavement made with crumb rubber, mineral aggregate and highly polymer-modified bitumen. Materials 2020, 13, 1339. [Google Scholar] [CrossRef]

- Mioduszewski, P.; Ejsmont, J.; Ronowski, G.; Taryma, S. Further development of the poroelastic road surface within the new Polish project SEPOR. In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference, Madrid, Spain, 16–19 June 2019; pp. 6879–6887. [Google Scholar]

- Liang, M.; Xin, X.; Fan, W.; Wang, H.; Ren, S.; Shi, J. Effects of polymerized sulfur on rheological properties, morphology and stability of SBS modified asphalt. Constr. Build. Mater. 2017, 150, 860–871. [Google Scholar] [CrossRef]

- Pakholak, R.; Plewa, A.; Hatalski, R. Evaluation of selected technical properties of bitumen binders modified with SBS copolymer and crumb rubber. Struct. Environ. 2020, 12, 12–19. [Google Scholar] [CrossRef]

- Mazzotta, F.; Tataranni, P.; Simone, A.; Fornai, D.; Airey, G.; Sangiorgi, C. Multi-scale rheo-mechanical study of sma mixtures containing fine crumb rubber in a new dry-hybrid technology. Appl. Sci. 2020, 10, 3887. [Google Scholar] [CrossRef]

- Li, L.; Guo, Z.; Ran, L.; Zhang, J. Study on low-temperature cracking performance of asphalt under heat and light together conditions. Materials 2020, 13, 1541. [Google Scholar] [CrossRef] [PubMed]

- Pszczoła, M.; Ryś, D.; Jaskuła, P. Analysis of climatic zones in Poland with regard to asphalt performance grading. Roads Bridges-Drog. i Mosty 2017, 16, 245–264. [Google Scholar] [CrossRef]

- Mackiewicz, P.; Szydło, A. Viscoelastic parameters of asphalt mixtures identified in static and dynamic tests. Materials 2019, 12, 2084. [Google Scholar] [CrossRef]

- Wahengbam, R.D.; Rajbongshi, P. An approach for dynamic stiffness evaluation in asphalt concrete. Constr. Build. Mater. 2015, 96, 541–549. [Google Scholar] [CrossRef]

- Tiraturyan, A.N.; Uglova, E.V.; Lyapin, A.A. Studying the energy distribution of the dynamic influences of road transport on the layers of nonrigid pavements. PNRPU Mech. Bull. 2017, 2, 178–194. [Google Scholar] [CrossRef]

- Shirini, B.; Imaninasab, R. Performance evaluation of rubberized and SBS modified porous asphalt mixtures. Constr. Build. Mater. 2016, 107, 165–171. [Google Scholar] [CrossRef]

- Mazurek, G.; Iwański, M. Multidimensional analysis of the effects of waste materials on physical and mechanical properties of recycled mixtures with foamed bitumen. Appl. Sci. 2018, 8, 282. [Google Scholar] [CrossRef]

- Iwanski, M.; Chomicz-Kowalska, A.; Maciejewski, K. The influence of hydrated lime on IT-CY stiffness modulus of foam-based asphalt concrete compacted at 95 °C. Mater. Sci. Eng. 2019, 471, 032029. [Google Scholar] [CrossRef]

- European Standard: EN 12607-1:2014. Bitumen and Bituminous Binders—Determination of the Resistance to Hardening Under Influence of Heat and Air-Part 1: RTFOT Method. Available online: https://www.sis.se/api/document/preview/104363/ (accessed on 9 July 2020).

- European Standard: EN 12697-30:2019. Bituminous Mixtures—Test Methods—Part 30: Specimen Preparation by Impact Compactor. Available online: https://www.sis.se/api/document/preview/80009154/ (accessed on 9 July 2020).

- Poland Technical Requirements: TR-2 2014. Asphalt Pavements on National Roads—Asphalt Mixtures—Part 2. Available online: https://www.gddkia.gov.pl/frontend/web/userfiles/articles/d/dokumenty-techniczne_8162/Dokumenty%20techniczne/WT2%20cz1.pdf (accessed on 9 July 2020).

- ASTM D6931-17. Standard Test Method for Indirect Tensile (IDT) Strength of Asphalt Mixtures; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- European Standard: EN 12697-17:2017. Bituminous Mixtures—Test Methods—Part 17: Particle Loss of Porous Asphalt Specimens. Available online: https://www.sis.se/api/document/preview/8025276/ (accessed on 9 July 2020).

- Sangiorgi, C.; Tataranni, P.; Simone, A.; Vignali, V.; Lantieri, C.; Dondi, G. Stone mastic asphalt (SMA) with crumb rubber according to a new dry-hybrid technology: A laboratory and trial field evaluation. Constr. Build. Mater. 2018, 182, 200–209. [Google Scholar] [CrossRef]

- European Standard: EN 12697-26:2018. Bituminous Mixtures—Test Methods—Part 26: Stiffness. Available online: https://www.sis.se/api/document/preview/80004874/ (accessed on 9 July 2020).

- European Standard: EN 12697-25: 2016. Bituminous Mixtures—Test methods—Part 25: Cyclic Compression Test. Available online: https://www.sis.se/api/document/preview/8021917/ (accessed on 9 July 2020).

- Hysteresis Phenomenon. Available online: http://www.koros-plast.ru/stroenie-polimerov/yavlenie-gisterezisa.html (accessed on 25 June 2020).

| Temperature | Units of Measurement | Type of Binder | |||

|---|---|---|---|---|---|

| Reference Binder 50/70/After RTFOT | SBSM-5/After RTFOT | CRM-10/After RTFOT | SBSM-2 + CRM-10/After RTFOT | ||

| 5 °C 15 °C 25 °C | (0.1 mm) | Penetration | |||

| 11.4/8.4 | 8.7/6.1 | 8.7/6.8 | 7.7/5.6 | ||

| 32.8/20.3 | 20.6/16.2 | 19.5/14.1 | 16.2/13.1 | ||

| 58.3/44.3 | 40.2/30.1 | 40.0/27.8 | 30.6/24.8 | ||

| Softening point | (°C) | 50.8/56.3 | 78.6/77.8 | 60.6/68.2 | 70.7/77.8 |

| 90 °C 110 °C 135 °C | (Pa·s) | Dynamic viscosity | |||

| 11.3/19.3 | 224.4/258.7 | 83.6/265.4 | 292.2/574.1 | ||

| 2.2/3.6 | 25.1/27.7 | 13.4/39.3 | 43.7/74.9 | ||

| 0.5/0.7 | 2.5/3.6 | 2.1/4.8 | 5.4/8.8 | ||

| 5 °C 15 °C 25 °C | (J/cm2) | Strain energy | |||

| 5.62/6.16 | 19.40/27.31 | 5.90/7.25 | 13.60/17.24 | ||

| 0.91/2.33 | 4.38/7.52 | 2.34/3.57 | 4.95/7.32 | ||

| 0.06/0.32 | 1.39/2.16 | 0.45/0.88 | 1.22/2.89 | ||

| 5 °C 15 °C 25 °C | (N) | Maximum tensile strength | |||

| 83.1/118.8 | 113.6/128.6 | 88.4/123.3 | 129.0/147.4 | ||

| 10.9/18.9 | 23.9/43.8 | 24.2/37.0 | 39.7/45.5 | ||

| 1.1/3.4 | 4.8/9.4 | 4.78.5 | 10.0/14.2 | ||

| 15 °C 25 °C | (%) | Elastic recovery | |||

| 7.5/15.5 | 81.9/72.5 | 65.1/64.4 | 68.5/70.5 | ||

| 9.5/16.3 | 88.7/80.8 | 71.1/70.2 | 73.7/73.6 | ||

| Measured Properties | Standard | Specifications | Coarse Aggregate | Fine Aggregate | Limestone Filler |

|---|---|---|---|---|---|

| Los Angeles abrasion | EN 1097-2 | ˂25 | 17 | - | - |

| Polished stone value | EN 1097-8 | >50 | 54 | - | - |

| Frost resistance in 1% NaCl | EN 1367-6 | ˂7 | 4 | - | - |

| Dust content (%) | EN 933-1 | coarse ˂ 2 | 0.7 | - | - |

| fine ˂ 16 | - | 2.931 | - | ||

| Grain density (Mg/m3) | EN 1097-6 | - | 2.890 | 2.698 | - |

| Grain density (Mg/m3) | EN 1097-7 | - | - | - | 2.671 |

| Measured Properties | Type of Mixture | ||||

|---|---|---|---|---|---|

| PA8 | SMA8 LA | SMA8 LA (10% RG) | SMA8 LA (20% RG) | SMA8 LA (30% RG) | |

| Air void content (%) | 23.84 | 10.56 | 11.64 | 11.99 | 15.05 |

| Binder content (%) | 6.3 | 6.8 | 8.0 | 10.0 | 12.0 |

| Bulk density (Mg/m3) | 1.954 | 2.261 | 2.045 | 1.819 | 1.651 |

| Type of Binder | Type of Mixture | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| PA8 | SMA8 LA | SMA8 LA (10% RG) | SMA8 LA (20% RG) | SMA8 LA (30% RG) | ||||||

| ITSR | Cant. | ITSR | Cant. | ITSR | Cant. | ITSR | Cant. | ITSR | Cant. | |

| 50/70 | 80.77 | 13.44 | 86.12 | 20,33 | 84.26 | 28.47 | 83.08 | 17.98 | 79.75 | 10.14 |

| SBSM-5 | 91.44 | 14.84 | 95.12 | 4.40 | 95.47 | 7.79 | 91.24 | 4.64 | 89.07 | 4.91 |

| CRM-10 | 92.55 | 14,34 | 91.97 | 5.19 | 88.49 | 8.53 | 90.66 | 8.21 | 89.52 | 4.99 |

| SBSM-2+CRM-10 | 93.57 | 12.35 | 92.78 | 4.73 | 90.31 | 8.17 | 92.10 | 4.99 | 87.02 | 2.22 |

| Type of Mixture | Type of Binder | IT-CY (MPa) | Loop Area (-) | ||

|---|---|---|---|---|---|

| Temperature (°C) | Average Value | Temperature (°C) | Average Value | ||

| PA8 | 50/70 | 5 | 4840 | 15 | 1.72 |

| 15 | 2303 | 25 | 5.72 | ||

| 25 | 770 | 35 | 5.57 | ||

| SBSM-5 | 5 | 4860 | 15 | 2.10 | |

| 15 | 2575 | 25 | 3.36 | ||

| 25 | 1092 | 35 | 6.29 | ||

| CRM-10 | 5 | 4794 | 15 | 3.69 | |

| 15 | 2350 | 25 | 4.47 | ||

| 25 | 1176 | 35 | 7.16 | ||

| SBSM-2 + CRM-10 | 5 | 3901 | 15 | 3.80 | |

| 15 | 2067 | 25 | 4.58 | ||

| 25 | 1018 | 35 | 6.03 | ||

| SMA8 LA | 50/70 | 5 | 7894 | 15 | 2.22 |

| 15 | 3207 | 25 | 4.34 | ||

| 25 | 1181 | 35 | 4.44 | ||

| SBSM-5 | 5 | 6808 | 15 | 1.86 | |

| 15 | 3464 | 25 | 3.72 | ||

| 25 | 1420 | 35 | 5.32 | ||

| CRM-10 | 5 | 6633 | 15 | 2.42 | |

| 15 | 3557 | 25 | 4.54 | ||

| 25 | 1490 | 35 | 6.97 | ||

| SBSM-2 + CRM-10 | 5 | 7526 | 15 | 1.71 | |

| 15 | 4082 | 25 | 3.05 | ||

| 25 | 1754 | 35 | 4.99 | ||

| SMA8 LA (10% RG) | 50/70 | 5 | 2996 | 15 | 8.06 |

| 15 | 1126 | 25 | 9.46 | ||

| 25 | 291 | 35 | 9.20 | ||

| SBSM-5 | 5 | 3537 | 15 | 7.96 | |

| 15 | 1712 | 25 | 9.23 | ||

| 25 | 769 | 35 | 11.00 | ||

| CRM-10 | 5 | 2962 | 15 | 9.25 | |

| 15 | 1508 | 25 | 11.13 | ||

| 25 | 566 | 35 | 11.00 | ||

| SBSM-2 + CRM-10 | 5 | 2983 | 15 | 9.08 | |

| 15 | 1588 | 25 | 11.79 | ||

| 25 | 581 | 35 | 12.75 | ||

| SMA8 LA (20% RG) | 50/70 | 5 | 1196 | 15 | 26.32 |

| 15 | 563 | 25 | 24.06 | ||

| 25 | 112 | 35 | 20.39 | ||

| SBSM-5 | 5 | 1484 | 15 | 24.35 | |

| 15 | 830 | 25 | 26.41 | ||

| 25 | 119 | 35 | 43.45 | ||

| CRM-10 | 5 | 1235 | 15 | 28.75 | |

| 15 | 602 | 25 | 34.04 | ||

| 25 | 85 | 35 | 50.79 | ||

| SBSM-2 + CRM-10 | 5 | 1202 | 15 | 25.61 | |

| 15 | 699 | 25 | 33.21 | ||

| 25 | 132 | 35 | 47.03 | ||

| SMA8 LA (30% RG) | 50/70 | 5 | 608 | 15 | 47.46 |

| 15 | 140 | 25 | 59.76 | ||

| 25 | 60 | 35 | 51.02 | ||

| SBSM-5 | 5 | 691 | 15 | 50.92 | |

| 15 | 132 | 25 | 65.95 | ||

| 25 | 90 | 35 | 81.49 | ||

| CRM-10 | 5 | 485 | 15 | 55.75 | |

| 15 | 96 | 25 | 66.25 | ||

| 25 | 54 | 35 | 91.25 | ||

| SBSM-2 + CRM-10 | 5 | 655 | 15 | 43.96 | |

| 15 | 111 | 25 | 62.47 | ||

| 25 | 66 | 35 | 84.10 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gardziejczyk, W.; Plewa, A.; Pakholak, R. Effect of Addition of Rubber Granulate and Type of Modified Binder on the Viscoelastic Properties of Stone Mastic Asphalt Reducing Tire/Road Noise (SMA LA). Materials 2020, 13, 3446. https://doi.org/10.3390/ma13163446

Gardziejczyk W, Plewa A, Pakholak R. Effect of Addition of Rubber Granulate and Type of Modified Binder on the Viscoelastic Properties of Stone Mastic Asphalt Reducing Tire/Road Noise (SMA LA). Materials. 2020; 13(16):3446. https://doi.org/10.3390/ma13163446

Chicago/Turabian StyleGardziejczyk, Wladyslaw, Andrzej Plewa, and Raman Pakholak. 2020. "Effect of Addition of Rubber Granulate and Type of Modified Binder on the Viscoelastic Properties of Stone Mastic Asphalt Reducing Tire/Road Noise (SMA LA)" Materials 13, no. 16: 3446. https://doi.org/10.3390/ma13163446

APA StyleGardziejczyk, W., Plewa, A., & Pakholak, R. (2020). Effect of Addition of Rubber Granulate and Type of Modified Binder on the Viscoelastic Properties of Stone Mastic Asphalt Reducing Tire/Road Noise (SMA LA). Materials, 13(16), 3446. https://doi.org/10.3390/ma13163446